Tribological and Mechanical Properties of Multicomponent CrVTiNbZr(N) Coatings

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure Characterization

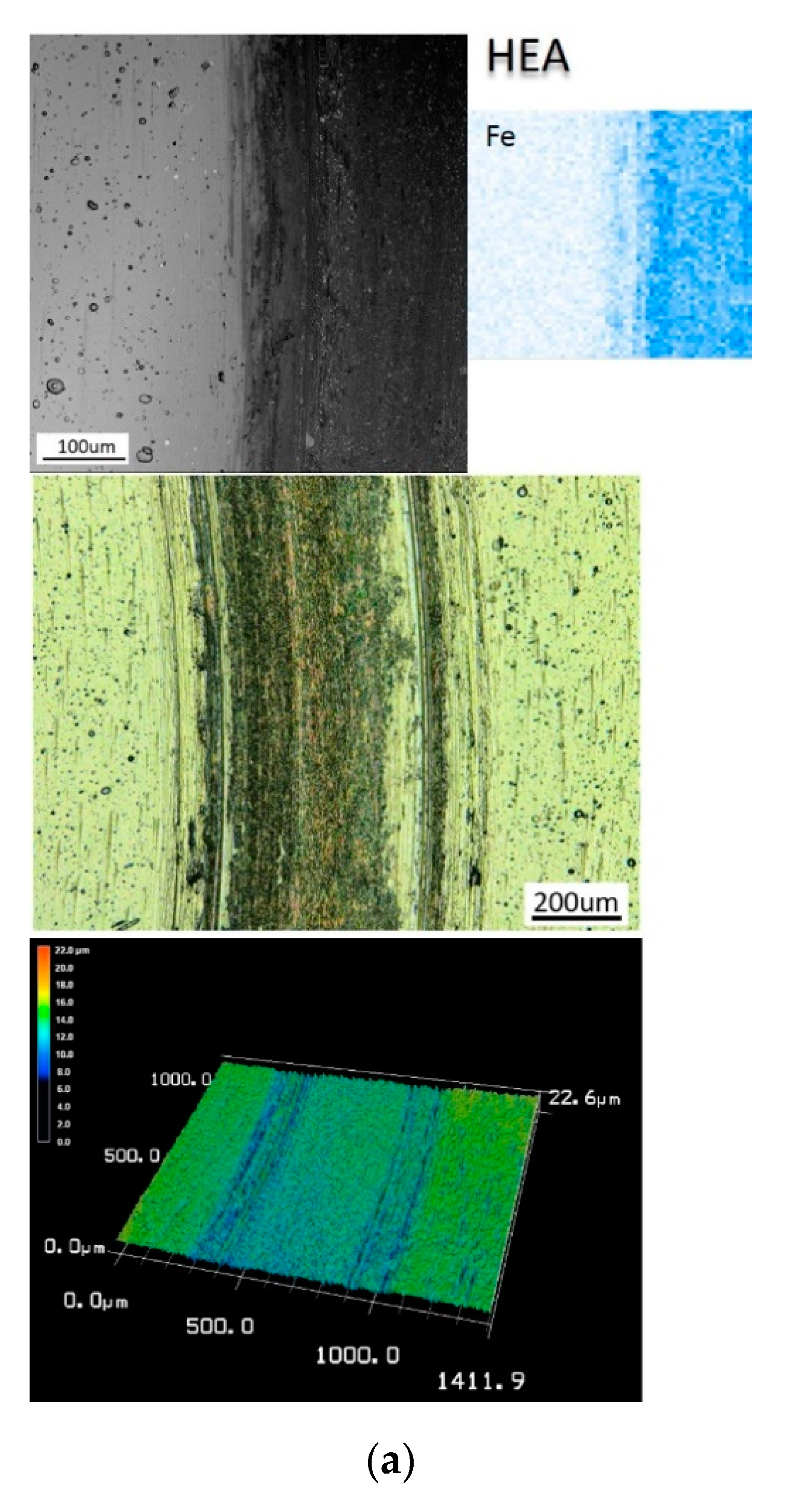

3.2. Mechanical and Tribological Properties

4. Conclusions

- In this study, the characteristics of CrVTiNbZr(N) coatings fabricated using cathodic arc deposition by changing nitrogen flow rates was addressed. When no nitrogen was introduced, the contents of five metal elements in the CrVTiNbZr HEA coating were between 14.13–26.8 at.%, and the HEA coating conforms to the high entropy alloy definition. Increase in the nitrogen content led to the transformation from single-phase bcc to fcc structure. When the nitrogen flow rate increased to 165 sccm, the HEAN-N165 coating exhibited reflections corresponding to fcc NaCl-type phases of TiNbN, CrVN and ZrN while bcc diffraction peak disappeared.

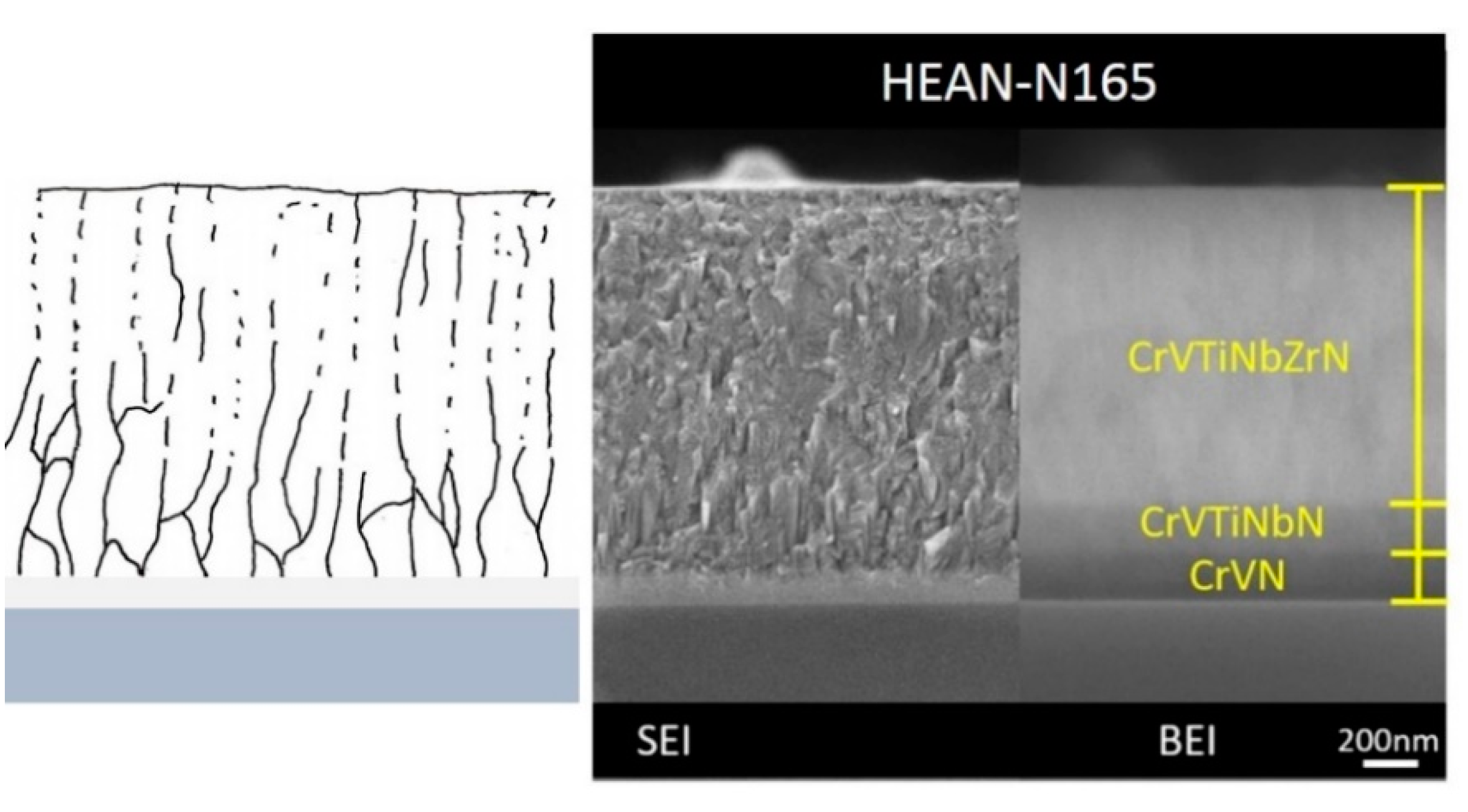

- The CrVTiNbZrN coating (HEAN-N165) had columnar structure growth from the CrV and CrVN bottom layers to the top CrVTiNbZrN layer without interruption. The top layer exhibited multilayered structures containing CrVN, TiNbN and ZrN. The design of multilayered CrVTiNbZrN coatings showed good adhesion strength. Improvement of adhesion strength was obtained with composition-gradient interlayers.

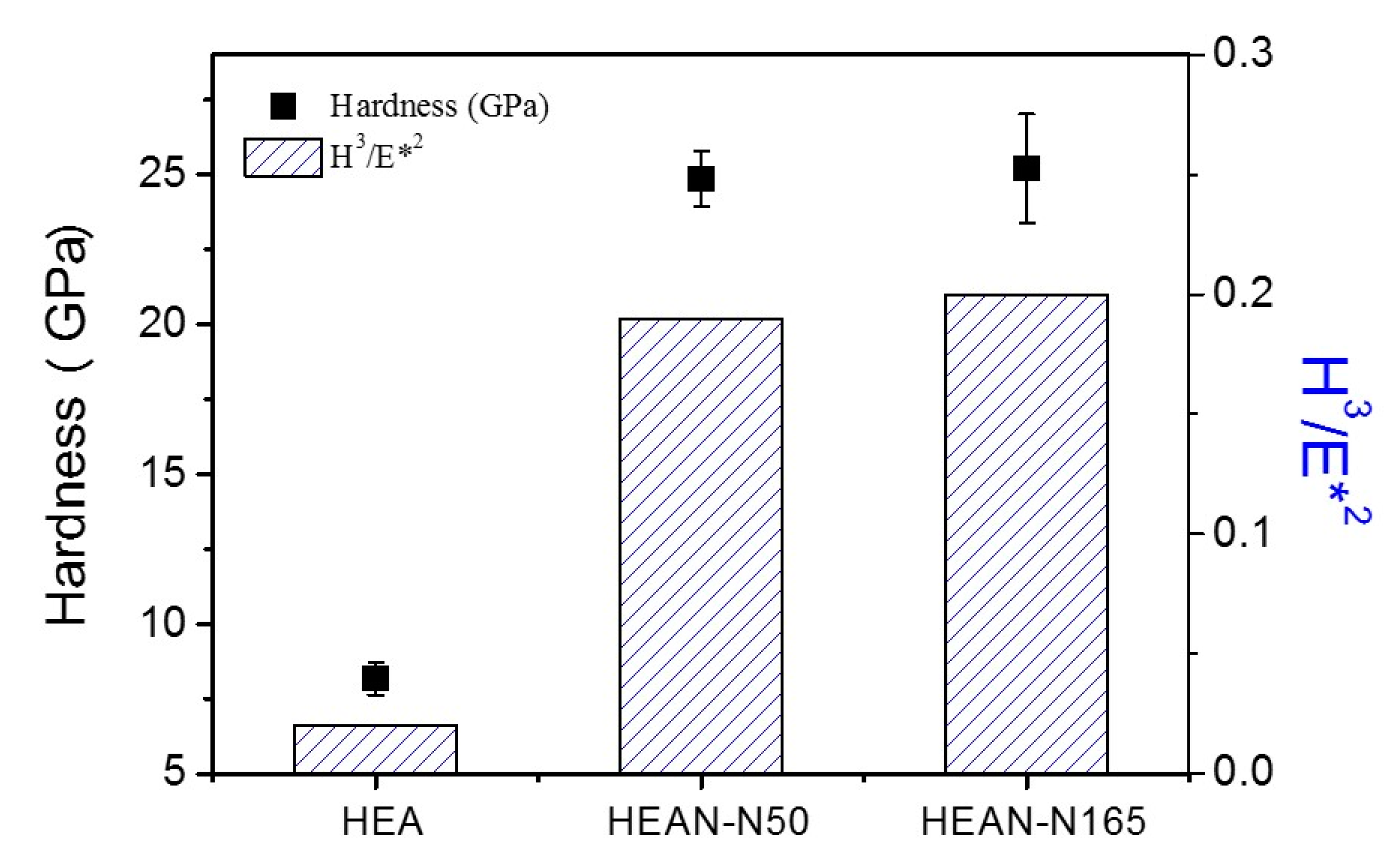

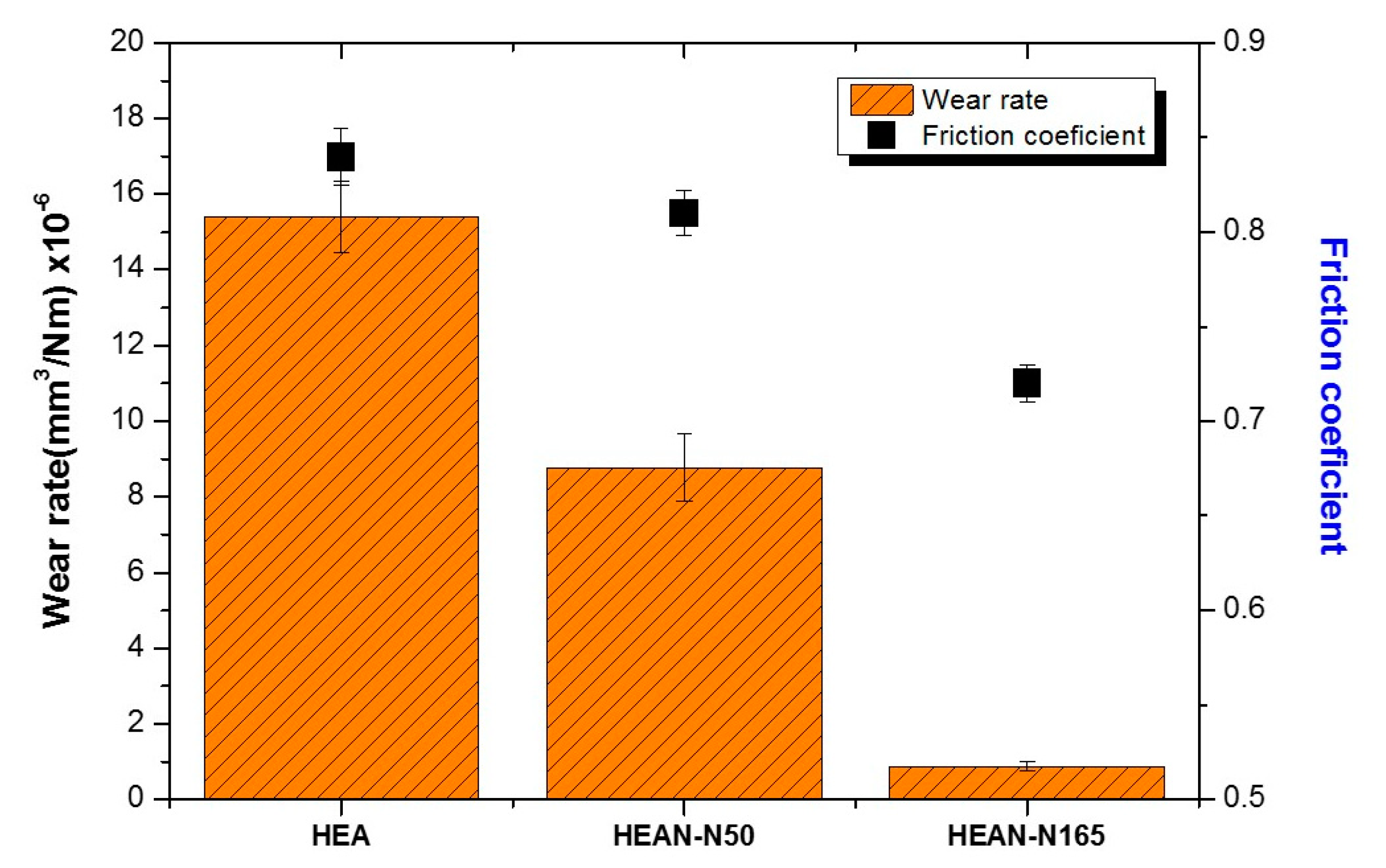

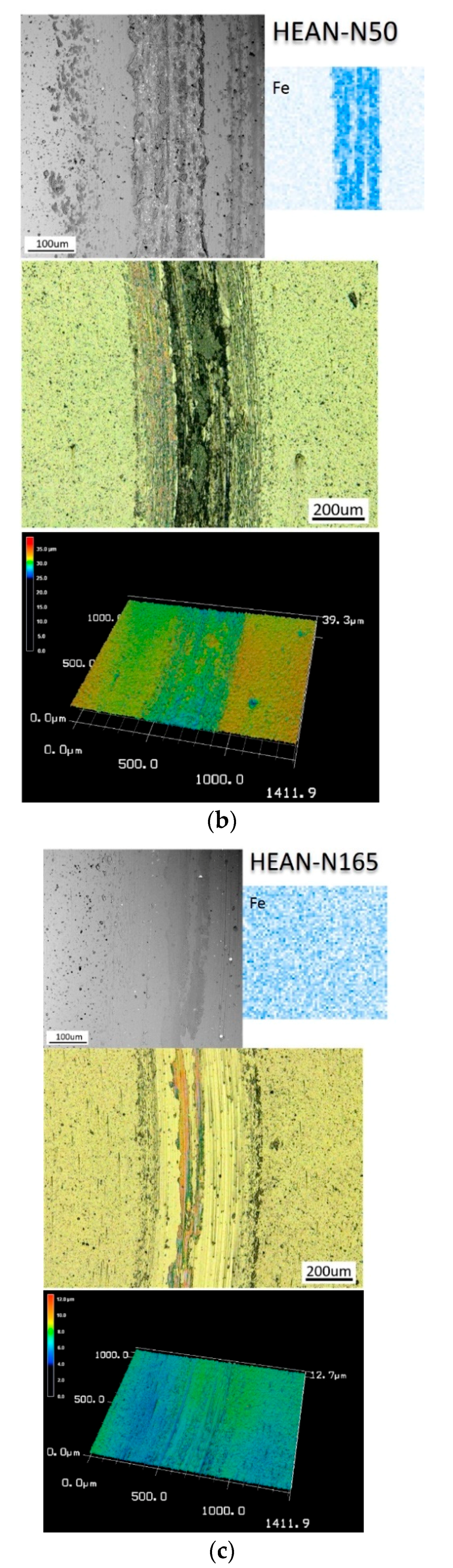

- The CrVTiNbZr(N) HEAN-N165 coating with nitrogen content higher than 50 at.% possessed the highest hardness and H3/E*2, and therefore the lowest wear rate was obtained because of high abrasion wear resistance. The strengthening effect was mainly attributed to the formation of multilayered metal nitride structure and the solid solution strengthening of multicomponent elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bull, S.; Rickerby, D.; Robertson, T.; Hendry, A.J.S.; Technology, C. The abrasive wear resistance of sputter ion plated titanium nitride coatings. Surf. Coat. Technol. 1988, 36, 743–754. [Google Scholar] [CrossRef]

- Krella, A. Cavitation erosion of TiN and CrN coatings deposited on different substrates. Wear 2013, 297, 992–997. [Google Scholar] [CrossRef]

- Deng, J.; Wu, F.; Lian, Y.; Xing, Y.; Li, S. Erosion wear of CrN, TiN, CrAlN, and TiAlN PVD nitride coatings. Int. J. Refract. Met. Hard Mater. 2012, 35, 10–16. [Google Scholar] [CrossRef]

- Drnovšek, A.; Rebelo de Figueiredo, M.; Vo, H.; Xia, A.; Vachhani, S.J.; Kolozsvári, S.; Hosemann, P.; Franz, R. Correlating high temperature mechanical and tribological properties of CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2019, 372, 361–368. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Lai, H.-M. Wear behavior and cutting performance of CrAlSiN and TiAlSiN hard coatings on cemented carbide cutting tools for Ti alloys. Surf. Coat. Technol. 2014, 259, 152–158. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Cheng, C.-M.; Liou, Y.-Y.; Tillmann, W.; Hoffmann, F.; Sprute, T. High temperature wettability of multicomponent CrAlSiN and TiAlSiN coatings by molten glass. Surf. Coat. Technol. 2013, 231, 24–28. [Google Scholar] [CrossRef]

- Sun, S.Q.; Ye, Y.W.; Wang, Y.X.; Liu, M.Q.; Liu, X.; Li, J.L.; Wang, L.P. Structure and tribological performances of CrAlSiN coatings with different Si percentages in seawater. Tribol. Int. 2017, 115, 591–599. [Google Scholar] [CrossRef]

- Li, P.; Chen, L.; Wang, S.Q.; Yang, B.; Du, Y.; Li, J.; Wu, M.J. Microstructure, mechanical and thermal properties of TiAlN/CrAlN multilayer coatings. Int. J. Refract. Met. Hard Mater. 2013, 40, 51–57. [Google Scholar] [CrossRef]

- Miletić, A.; Panjan, P.; Čekada, M.; Kovačević, L.; Terek, P.; Kovač, J.; Dražič, G.; Škorić, B. Nanolayer CrAlN/TiSiN coating designed for tribological applications. Ceram. Int. 2020, 47, 2022–2033. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf. Coat. Technol. 2020, 401, 126258. [Google Scholar] [CrossRef]

- Boxman, R.L.; Zhitomirsky, V.N.; Grimberg, I.; Rapoport, L.; Goldsmith, S.; Weiss, B.Z. Structure and hardness of vacuum arc deposited multi-component nitride coatings of Ti, Zr and Nb. Surf. Coat. Technol. 2000, 125, 257–262. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Bagdasaryan, A.A.; Beresnev, V.M.; Nyemchenko, U.S.; Ivashchenko, V.I.; Kravchenko, Y.O.; Shaimardanov, Z.K.; Plotnikov, S.V.; Maksakova, O. The effects of Cr and Si additions and deposition conditions on the structure and properties of the (Zr-Ti-Nb)N coatings. Ceram. Int. 2017, 43, 771–782. [Google Scholar] [CrossRef] [Green Version]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- McCormack, S.J.; Navrotsky, A. Thermodynamics of high entropy oxides. Acta Mater. 2021, 202, 1–21. [Google Scholar] [CrossRef]

- Kirnbauer, A.; Kretschmer, A.; Koller, C.M.; Wojcik, T.; Paneta, V.; Hans, M.; Schneider, J.M.; Polcik, P.; Mayrhofer, P.H. Mechanical properties and thermal stability of reactively sputtered multi-principal-metal Hf-Ta-Ti-V-Zr nitrides. Surf. Coat. Technol. 2020, 389, 125674. [Google Scholar] [CrossRef]

- Hsueh, H.-T.; Shen, W.-J.; Tsai, M.-H.; Yeh, J.-W. Effect of nitrogen content and substrate bias on mechanical and corrosion properties of high-entropy films (AlCrSiTiZr)100−xNx. Surf. Coat. Technol. 2012, 206, 4106–4112. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Hsu, S.-Y.; Song, R.-W.; Lo, W.-L.; Lai, Y.-T.; Tsai, S.-Y.; Duh, J.-G. Improving the hardness of high entropy nitride (Cr0.35Al0.25Nb0.12Si0.08V0.20)N coatings via tuning substrate temperature and bias for anti-wear applications. Surf. Coat. Technol. 2020, 403, 126417. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, A.; Jia, J.; Zhang, J.; Meng, J. Reaction synthesis and characterization of a new class high entropy carbide (NbTaMoW)C. Mater. Sci. Eng. A 2020, 140520. [Google Scholar] [CrossRef]

- Chicardi, E.; García-Garrido, C.; Hernández-Saz, J.; Gotor, F.J. Synthesis of all equiatomic five-transition metals High Entropy Carbides of the IVB (Ti, Zr, Hf) and VB (V, Nb, Ta) groups by a low temperature route. Ceram. Int. 2020, 46, 21421–21430. [Google Scholar] [CrossRef]

- Kirnbauer, A.; Spadt, C.; Koller, C.M.; Kolozsvári, S.; Mayrhofer, P.H. High-entropy oxide thin films based on Al–Cr–Nb–Ta–Ti. Vacuum 2019, 168, 108850. [Google Scholar] [CrossRef]

- Lo, W.-L.; Hsu, S.-Y.; Lin, Y.-C.; Tsai, S.-Y.; Lai, Y.-T.; Duh, J.-G. Improvement of high entropy alloy nitride coatings (AlCrNbSiTiMo)N on mechanical and high temperature tribological properties by tuning substrate bias. Surf. Coat. Technol. 2020, 401, 126247. [Google Scholar] [CrossRef]

- Lai, C.-H.; Lin, S.-J.; Yeh, J.-W.; Chang, S.-Y. Preparation and characterization of AlCrTaTiZr multi-element nitride coatings. Surf. Coat. Technol. 2006, 201, 3275–3280. [Google Scholar] [CrossRef]

- Johansson, K.; Riekehr, L.; Fritze, S.; Lewin, E. Multicomponent Hf-Nb-Ti-V-Zr nitride coatings by reactive magnetron sputter deposition. Surf. Coat. Technol. 2018, 349, 529–539. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, R.; Yang, Z.B.; Liu, C.H.; Chang, H.; Yang, J.J.; Liao, J.L.; Yang, Y.Y.; Liu, N. Preparation, structure, and properties of high-entropy alloy multilayer coatings for nuclear fuel cladding: A case study of AlCrMoNbZr/(AlCrMoNbZr)N. J. Nucl. Mater. 2018, 512, 15–24. [Google Scholar] [CrossRef]

- Cui, P.; Li, W.; Liu, P.; Zhang, K.; Ma, F.; Chen, X.; Feng, R.; Liaw, P.K. Effects of nitrogen content on microstructures and mechanical properties of (AlCrTiZrHf)N high-entropy alloy nitride films. J. Alloys Compd. 2020, 834, 155063. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Yang, Y.-J.; Weng, S.-Y. Effect of interlayer design on the mechanical properties of AlTiCrN and multilayered AlTiCrN/TiSiN hard coatings. Surf. Coat. Technol. 2020, 389, 125637. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chuang, C.-C.J.C. Deposition of multicomponent AlTiCrMoN protective coatings for metal cutting applications. Coatings 2020, 10, 605. [Google Scholar] [CrossRef]

- Chen, R.; Cai, Z.; Pu, J.; Lu, Z.; Chen, S.; Zheng, S.; Zeng, C. Effects of nitriding on the microstructure and properties of VAlTiCrMo high-entropy alloy coatings by sputtering technique. J. Alloys Compd. 2020, 827, 153836. [Google Scholar] [CrossRef]

- Kesaev, I.G. Cathode Processes in Electric Arcs; Nauka Publishing: Moscow, Russia, 1978. [Google Scholar]

- Avtaeva, S.; Gorokhovsky, V.; Robertson, S.; Shun’ko, E. Characterization of low-pressure high-current cascaded arc plasma in large volumes. Spectrochim. Acta Part B At. Spectrosc. 2020, 165, 105785. [Google Scholar] [CrossRef]

- Liang, S.-C.; Tsai, D.-C.; Chang, Z.-C.; Sung, H.-S.; Lin, Y.-C.; Yeh, Y.-J.; Deng, M.-J.; Shieu, F.-S. Structural and mechanical properties of multi-element (TiVCrZrHf)N coatings by reactive magnetron sputtering. Appl. Surf. Sci. 2011, 258, 399–403. [Google Scholar] [CrossRef]

- Shu, R.; Paschalidou, E.-M.; Rao, S.G.; Bakhit, B.; Boyd, R.; Moro, M.V.; Primetzhofer, D.; Greczynski, G.; Nyholm, L.; le Febvrier, A.; et al. Effect of nitrogen content on microstructure and corrosion resistance of sputter-deposited multicomponent (TiNbZrTa)Nx films. Surf. Coat. Technol. 2020, 404, 126485. [Google Scholar] [CrossRef]

- Tolde, Z.; Starý, V.; Cvrček, L.; Vandrovcová, M.; Remsa, J.; Daniš, S.; Krčil, J.; Bačáková, L.; Špatenka, P. Growth of a TiNb adhesion interlayer for bioactive coatings. Mater. Sci. Eng. C 2017, 80, 652–658. [Google Scholar] [CrossRef] [PubMed]

- Thompson, G.B.; Banerjee, R.; Dregia, S.A.; Fraser, H.L. Phase stability of bcc Zr in Nb/Zr thin film multilayers. Acta Mater. 2003, 51, 5285–5294. [Google Scholar] [CrossRef]

- Normand, J.; Moriche, R.; García-Garrido, C.; Sepúlveda Ferrer, R.E.; Chicardi, E.J.M. Development of a TiNbTaMoZr-Based High Entropy Alloy with Low Young´ s Modulus by Mechanical Alloying Route. Metals 2020, 10, 1463. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Beresnev, V.M.; Smyrnova, K.V.; Kravchenko, Y.O.; Zukowski, P.V.; Bondarenko, G.G. The influence of nitrogen pressure on the fabrication of the two-phase superhard nanocomposite (TiZrNbAlYCr)N coatings. Mater. Lett. 2018, 211, 316–318. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Avasthi, S. Diffusion barrier with 30-fold improved performance using AlCrTaTiZrN high-entropy alloy. J. Alloys Compd. 2020, 814, 151755. [Google Scholar] [CrossRef]

- Lin, C.H.; Duh, J.G.; Yeh, J.W. Multi-component nitride coatings derived from Ti–Al–Cr–Si–V target in RF magnetron sputter. Surf. Coat. Technol. 2007, 201, 6304–6308. [Google Scholar] [CrossRef]

- Huang, P.-K.; Yeh, J.-W. Effects of nitrogen content on structure and mechanical properties of multi-element (AlCrNbSiTiV)N coating. Surf. Coat. Technol. 2009, 203, 1891–1896. [Google Scholar] [CrossRef]

- Kameneva, A.; Kichigin, V. Corrosion, wear, and friction behavior of a number of multilayer two-, three- and multicomponent nitride coatings on different substrates, depending on the phase and elemental composition gradient. Appl. Surf. Sci. 2019, 489, 165–174. [Google Scholar] [CrossRef]

- International Organization for Standardization Home Page. ISO 26443:2008 Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)-Rockwell Indentation Test for Evaluation of Adhesion of Ceramic Coatings. Available online: https://www.iso.org/standard/43584.html (accessed on 15 November 2020).

- Abedi, M.; Abdollah-zadeh, A.; Vicenzo, A.; Bestetti, M.; Movassagh-Alanagh, F.; Damerchi, E. A comparative study of the mechanical and tribological properties of PECVD single layer and compositionally graded TiSiCN coatings. Ceram. Int. 2019, 45, 21200–21207. [Google Scholar] [CrossRef] [Green Version]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Chen, W.; Yan, A.; Wang, C.; Deng, Y.; Chen, D.C.; Xiao, H.; Zhang, D.; Meng, X. Microstructures and mechanical properties of AlCrN/TiSiN nanomultilayer coatings consisting of fcc single-phase solid solution. Appl. Surf. Sci. 2020, 509, 145303. [Google Scholar] [CrossRef]

- Bagdasaryan, A.A.; Pshyk, A.V.; Coy, L.E.; Konarski, P.; Misnik, M.; Ivashchenko, V.I.; Kempiński, M.; Mediukh, N.R.; Pogrebnjak, A.D.; Beresnev, V.M.; et al. A new type of (TiZrNbTaHf)N/MoN nanocomposite coating: Microstructure and properties depending on energy of incident ions. Compos. Part B Eng. 2018, 146, 132–144. [Google Scholar] [CrossRef]

- Cai, Q.; Li, S.; Pu, J.; Cai, Z.; Lu, X.; Cui, Q.; Wang, L. Effect of multicomponent doping on the structure and tribological properties of VN-based coatings. J. Alloys Compd. 2019, 806, 566–574. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Oganyan, G.; Andreev, N.; Milovich, F. Investigation of wear dynamics for cutting tools with multilayer composite nanostructured coatings in turning constructional steel. Wear 2019, 420–421, 17–37. [Google Scholar] [CrossRef]

- Jehn, H.A. Multicomponent and multiphase hard coatings for tribological applications. Surf. Coat. Technol. 2000, 131, 433–440. [Google Scholar] [CrossRef]

- Fildes, J.M.; Meyers, S.J.; Mulligan, C.P.; Kilaparti, R. Evaluation of the wear and abrasion resistance of hard coatings by ball-on-three-disk test methods—A case study. Wear 2013, 302, 1040–1049. [Google Scholar] [CrossRef]

- Yu, Y.; He, F.; Qiao, Z.; Wang, Z.; Liu, W.; Yang, J. Effects of temperature and microstructure on the triblogical properties of CoCrFeNiNbx eutectic high entropy alloys. J. Alloys Compd. 2019, 775, 1376–1385. [Google Scholar] [CrossRef]

- Henry, P.; Pac, M.J.; Rousselot, C.; Tuilier, M.H. Wear mechanisms of titanium and aluminium nitride coatings: A microtribological approach. Surf. Coat. Technol. 2013, 223, 79–86. [Google Scholar] [CrossRef]

- Jianxin, D.; Jianhua, L.; Jinlong, Z.; Wenlong, S.; Ming, N. Friction and wear behaviors of the PVD ZrN coated carbide in sliding wear tests and in machining processes. Wear 2008, 264, 298–307. [Google Scholar] [CrossRef]

- Cao, J.; Yin, Z.; Li, H.; Gao, G. Tribological studies of soft and hard alternated composite coatings with different layer thicknesses. Tribol. Int. 2017, 110, 326–332. [Google Scholar] [CrossRef]

- Contreras Romero, E.; Cortínez Osorio, J.; Talamantes Soto, R.; Hurtado Macías, A.; Gómez Botero, M. Microstructure, mechanical and tribological performance of nanostructured TiAlTaN-(TiAlN/TaN)n coatings: Understanding the effect of quaternary/multilayer volume fraction. Surf. Coat. Technol. 2019, 377, 124875. [Google Scholar] [CrossRef]

- Perfilyev, V.; Moshkovich, A.; Lapsker, I.; Laikhtman, A.; Rapoport, L. The effect of vanadium content and temperature on stick–slip phenomena under friction of CrV(x)N coatings. Wear 2013, 307, 44–51. [Google Scholar] [CrossRef]

- Biswas, B.; Purandare, Y.; Khan, I.; Hovsepian, P.E. Effect of substrate bias voltage on defect generation and their influence on corrosion and tribological properties of HIPIMS deposited CrN/NbN coatings. Surf. Coat. Technol. 2018, 344, 383–393. [Google Scholar] [CrossRef]

| Element | Chemical Content (at.%) | ||

|---|---|---|---|

| HEA | HEAN-N50 | HEAN-N165 | |

| Cr | 14.13 | 9.71 | 8.5 |

| V | 20.45 | 14.81 | 12.62 |

| Ti | 22.55 | 11.55 | 7.74 |

| Nb | 16.07 | 7.67 | 4.77 |

| Zr | 26.80 | 14.98 | 12.08 |

| N | - | 41.27 | 54.29 |

| Element | Chemical Content (at.%) | ||

|---|---|---|---|

| Dark Layer (#1) | Gray Layer (#2) | Bright Layer (#3) | |

| N | 31.12 | 32 | 27.46 |

| Zr | 36.37 | 14.42 | 16.40 |

| Ti | 7.36 | 16.68 | 7.73 |

| Nb | 4.93 | 14.43 | 4.19 |

| Cr | 9.03 | 10.98 | 19.01 |

| V | 11.19 | 11.49 | 25.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.-Y.; Chung, C.-H. Tribological and Mechanical Properties of Multicomponent CrVTiNbZr(N) Coatings. Coatings 2021, 11, 41. https://doi.org/10.3390/coatings11010041

Chang Y-Y, Chung C-H. Tribological and Mechanical Properties of Multicomponent CrVTiNbZr(N) Coatings. Coatings. 2021; 11(1):41. https://doi.org/10.3390/coatings11010041

Chicago/Turabian StyleChang, Yin-Yu, and Cheng-Hsi Chung. 2021. "Tribological and Mechanical Properties of Multicomponent CrVTiNbZr(N) Coatings" Coatings 11, no. 1: 41. https://doi.org/10.3390/coatings11010041

APA StyleChang, Y.-Y., & Chung, C.-H. (2021). Tribological and Mechanical Properties of Multicomponent CrVTiNbZr(N) Coatings. Coatings, 11(1), 41. https://doi.org/10.3390/coatings11010041