Aluminide Thermal Barrier Coating for High Temperature Performance of MAR 247 Nickel Based Superalloy

Abstract

:1. Introduction

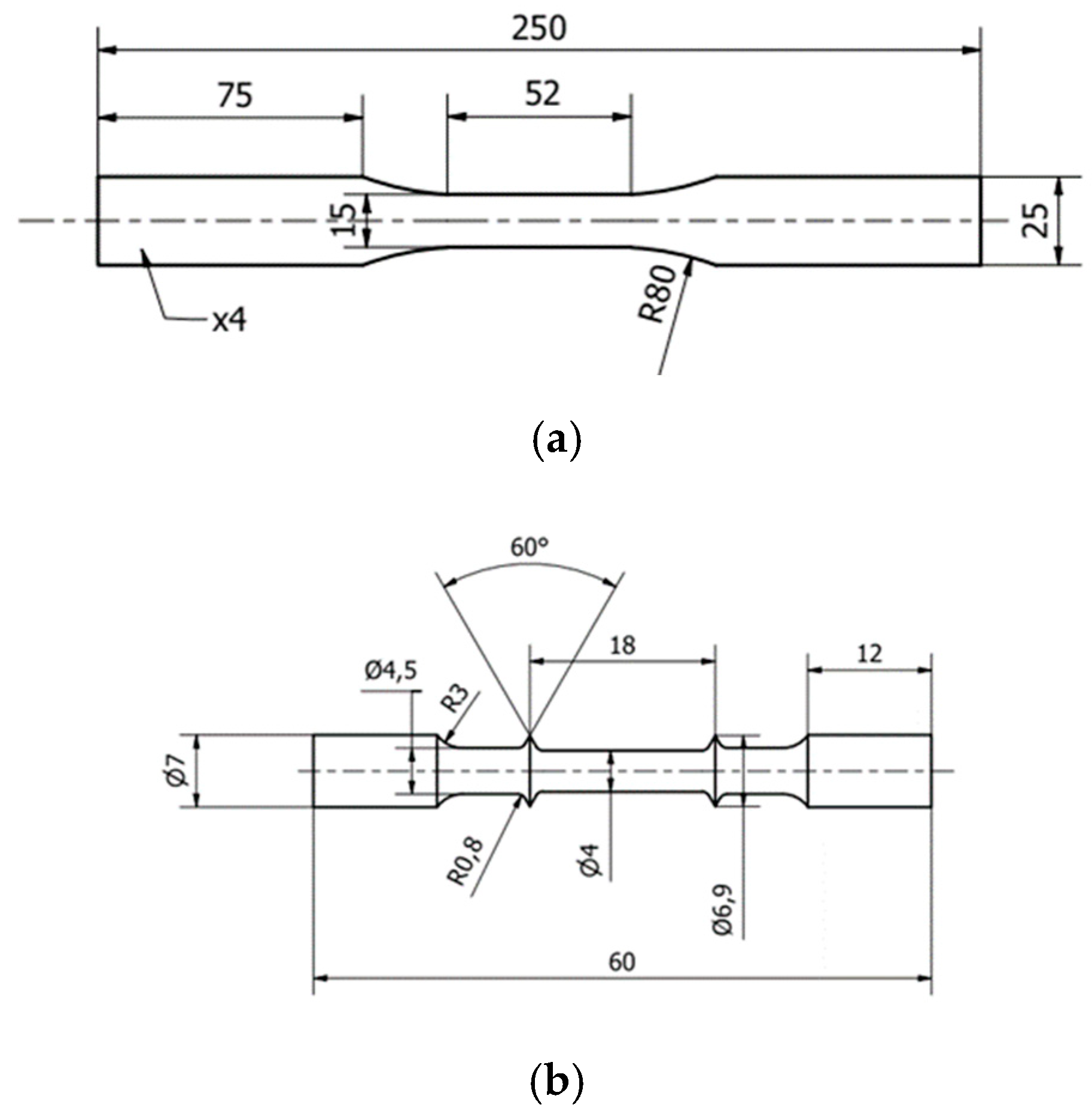

2. Materials and Methods

3. Results and Discussion

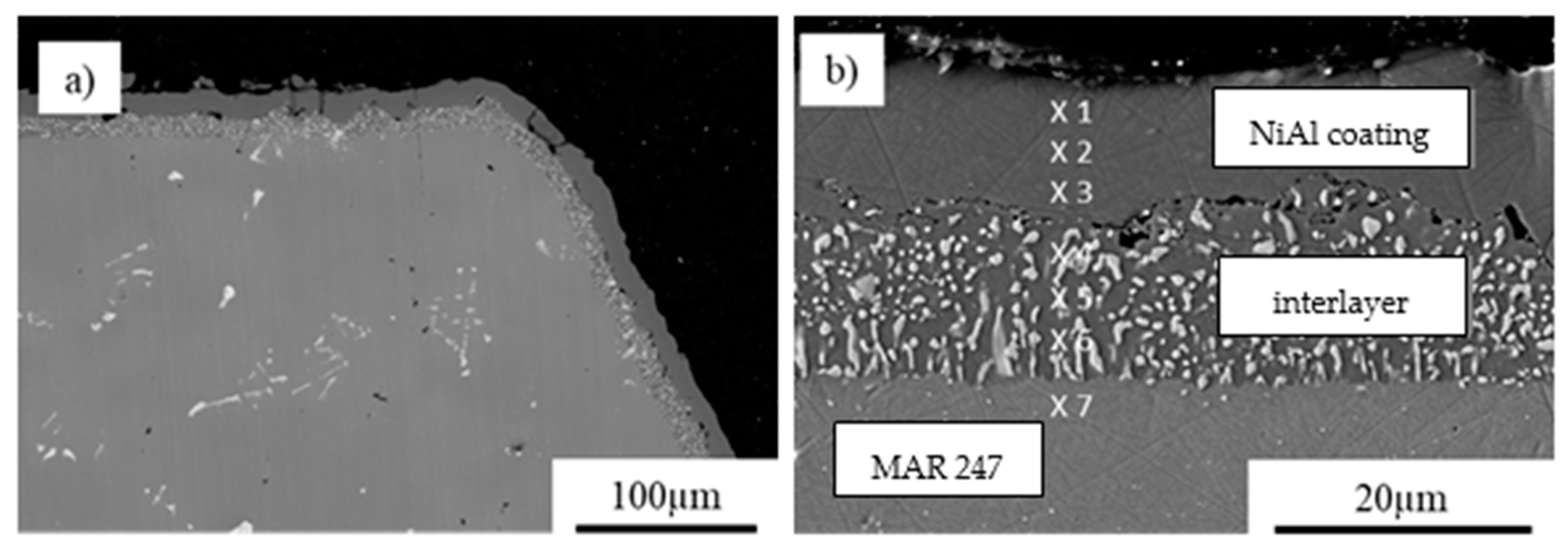

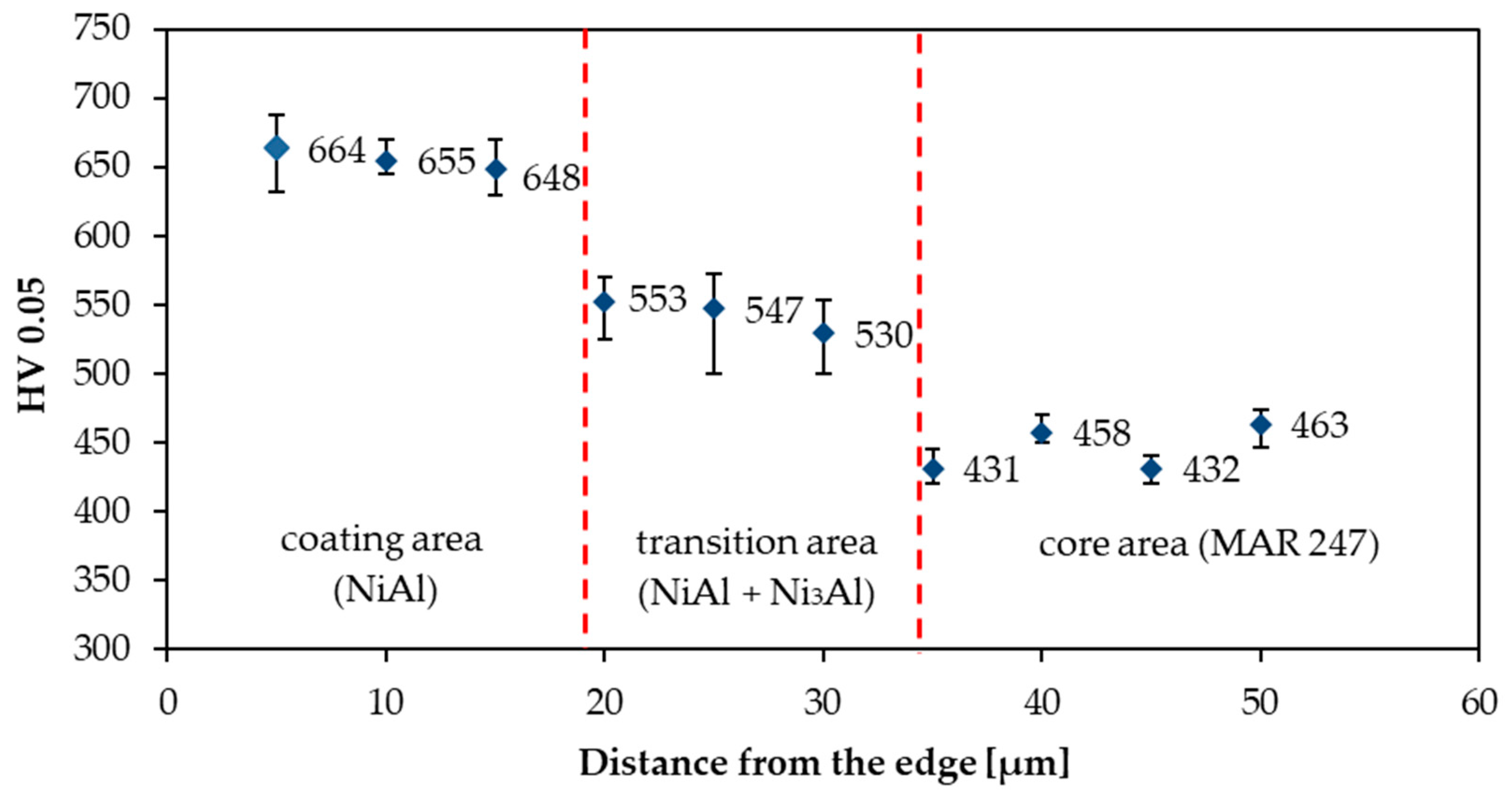

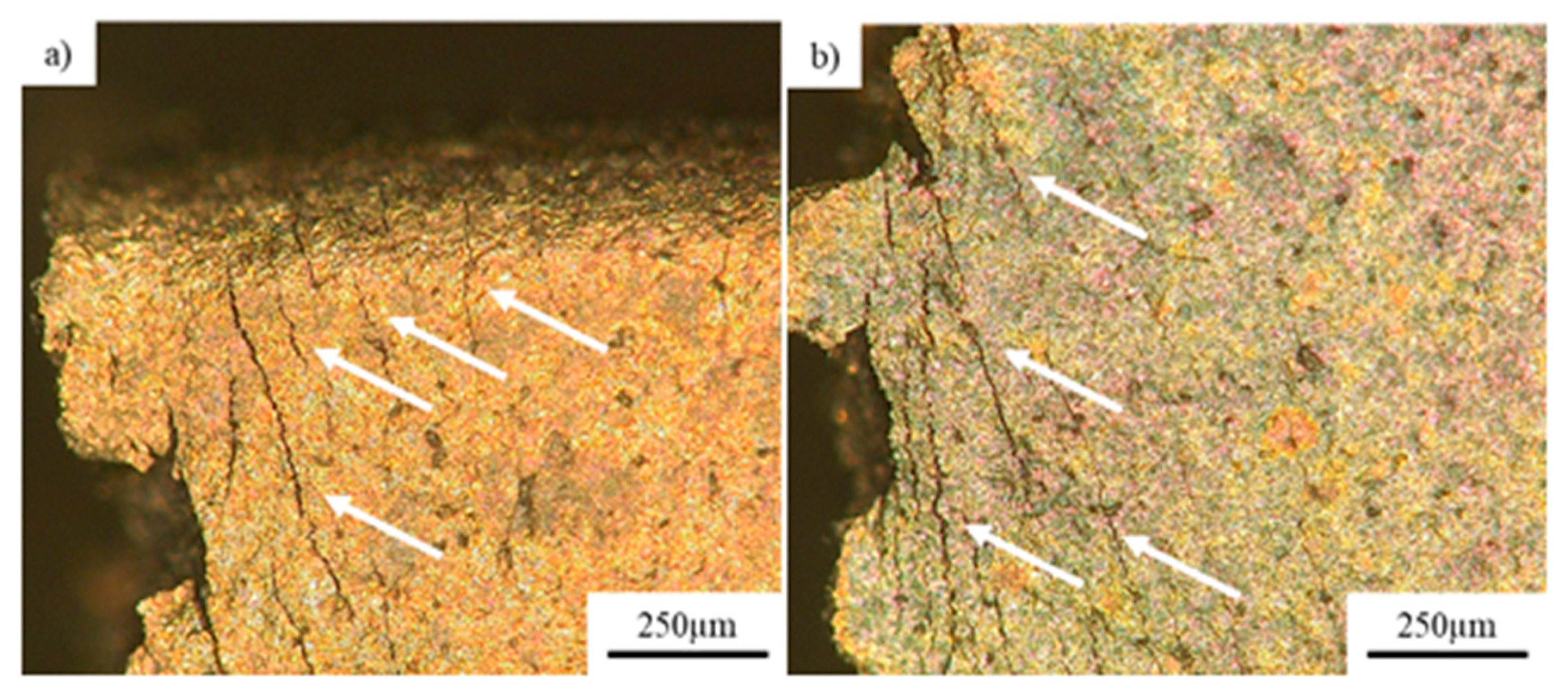

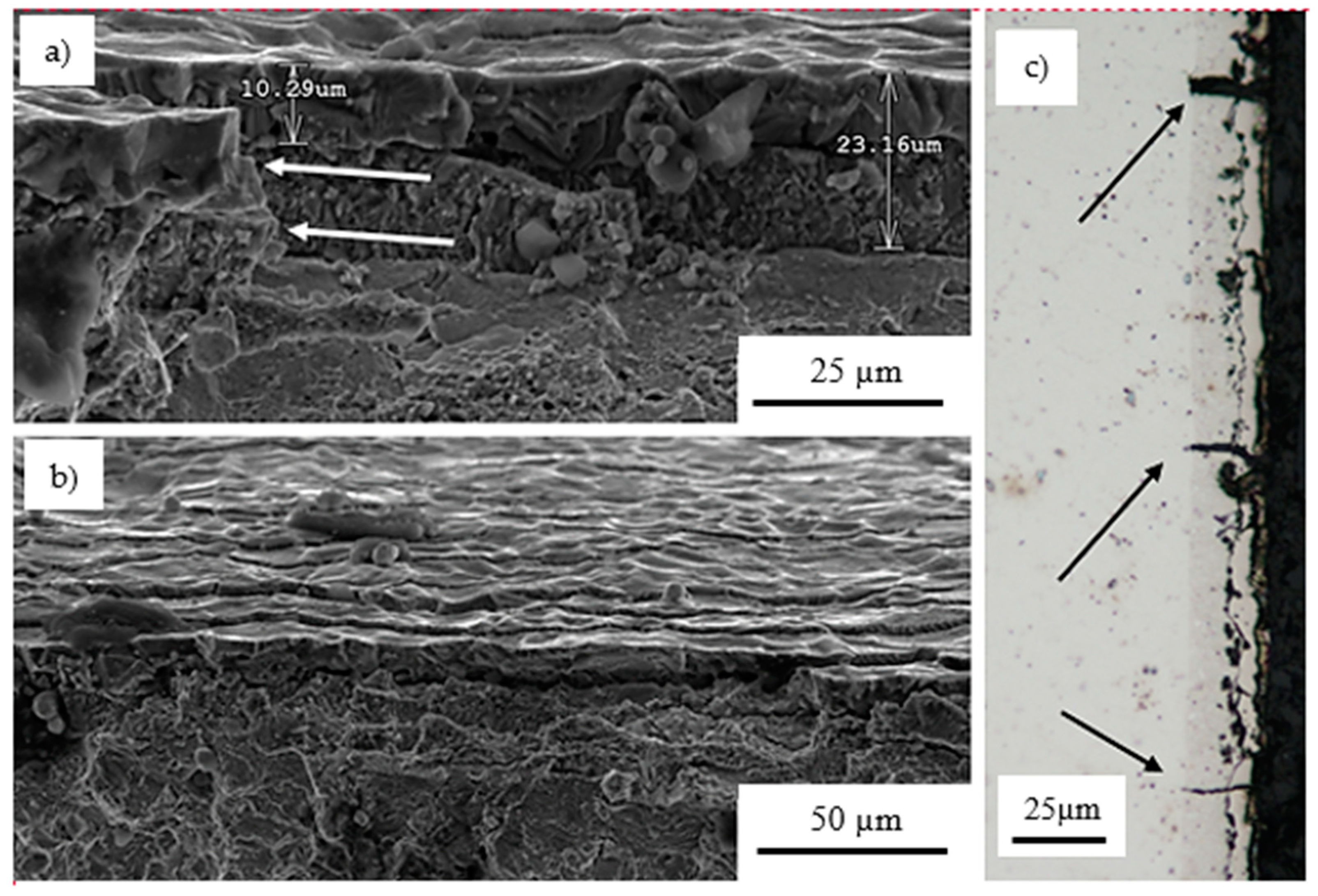

3.1. Microstructural Characterization of Coating during CVD Process

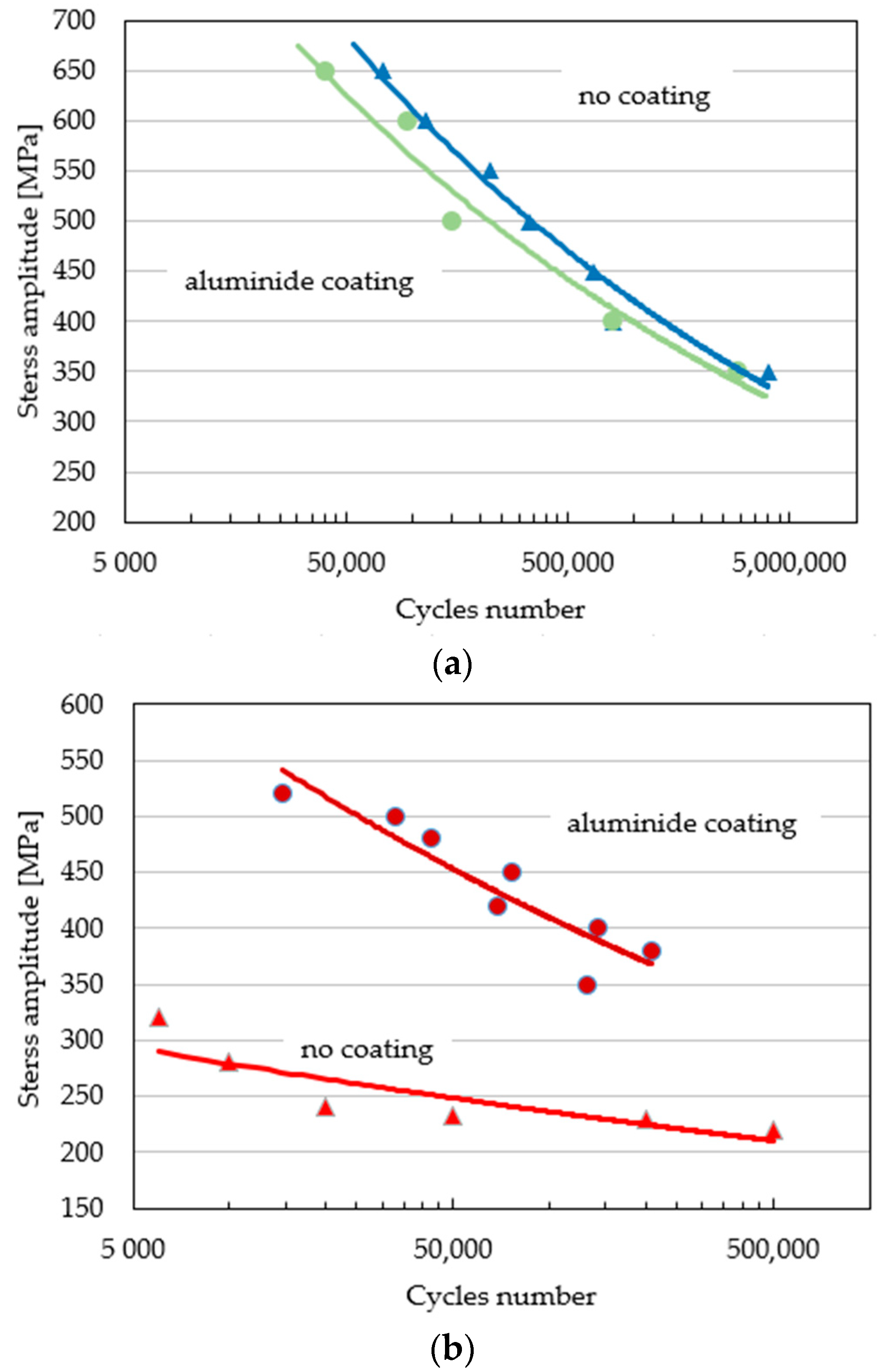

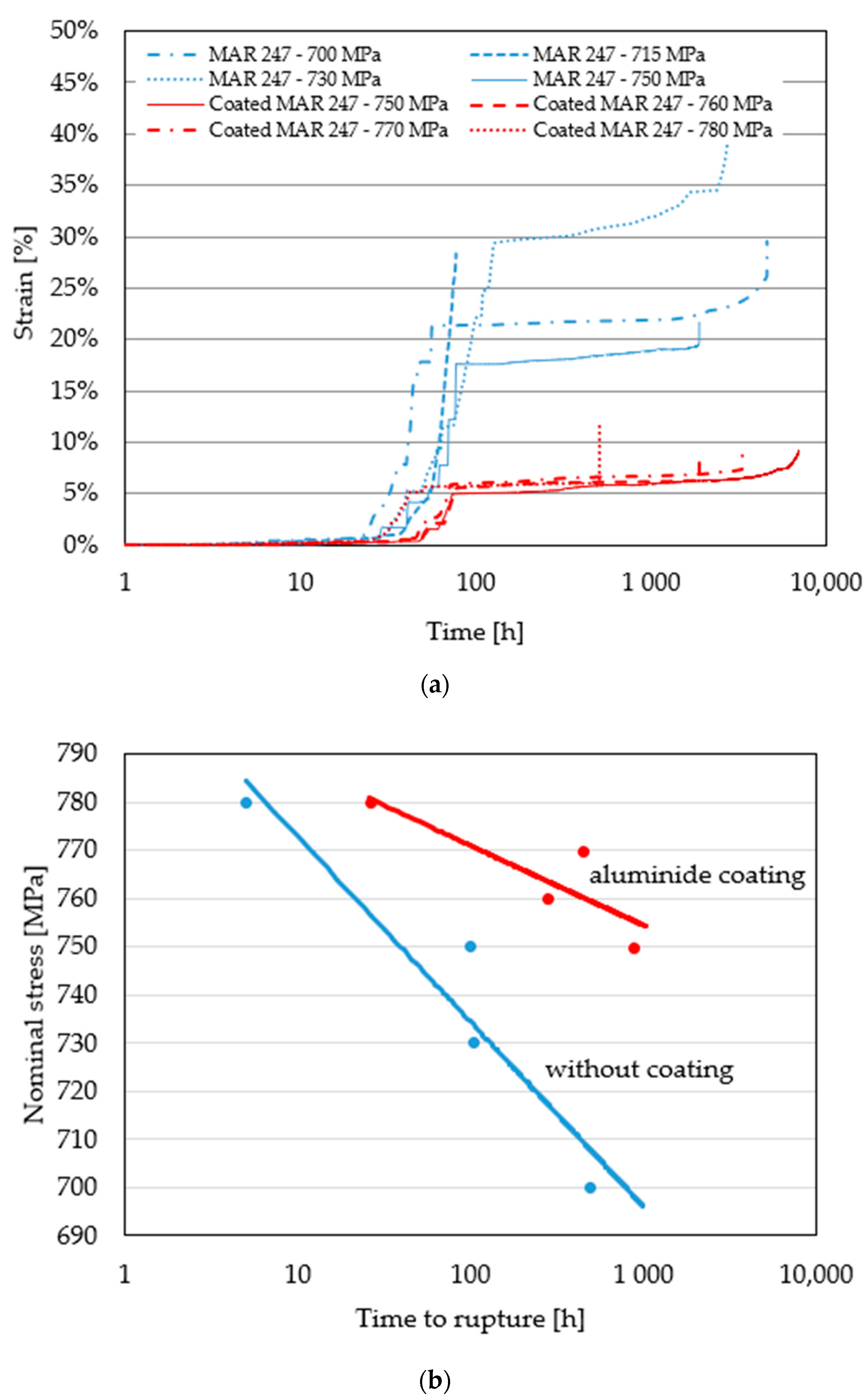

3.2. Effect of Coating on Tensile, Fatigue and Creep Performance of MAR 247 Nickel Based Superalloy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agarwal, D.C.; Brill, U. High-temperature-strength nickel alloy. Adv. Mater. Process. 2000, 158, 31–34. [Google Scholar]

- Wanhill, R.J.H. Fatigue of air supply manifold support rod in military jet engines. JFAP 2004, 4, 53–61. [Google Scholar] [CrossRef]

- Goward, G.W. Progress in coatings for gas turbine airfoils. Surf. Coat. Technol. 1998, 1, 73–79. [Google Scholar] [CrossRef]

- Reed, C.R. The Superalloys-Fundamentals and Applications; C.U.P.: Cambridge, UK, 2006; ISBN 0511-24546-7. [Google Scholar]

- Barbosa, C.; Nascimento, J.L.; Caminha, I.M.V.; Abud, I.C. Microstructural aspects of the failure analysis of nickel base superalloys components. Eng. Fail. Anal. 2005, 12, 348–361. [Google Scholar] [CrossRef]

- Kaufman, M. Properties of cast Mar-M-247 for turbine blisk applications. Superalloys 1984, 43–52. [Google Scholar] [CrossRef]

- Fritz, L.J.; Koster, W.P. Tensile and Creep Rupture Properties of (1) Uncoated and (2) Coated Engineering Alloys at Elevated Temperatures; NASA Technical Report; NAS CR-135138; NASA: Washington, DC, USA, 1977. [Google Scholar]

- NCO. Alloy IN-738 Technical Data; The International Nickel Company, Inc.: New York, NY, USA; Available online: https://www.nickelinstitute.org/media/1709/in_738alloy_preliminarydata_497_.pdf (accessed on 1 December 2020).

- Wee, S.; Do, J.; Kim, K.; Lee, C.; Seok, C.; Choi, B.-G.; Choi, Y.; Kim, W. Review on mechanical thermal properties of superalloys and thermal barrier coating used in gas turbines. Appl. Sci. 2020, 10, 5476. [Google Scholar] [CrossRef]

- Kawahara, Y. Application of high temperature corrosion-resistant materials and coatings under severe corrosive environment in waste-to-energy boilers. J. Therm. Spray Tech. 2007, 16, 202–213. [Google Scholar] [CrossRef]

- Sadeghi, E.; Markocsan, N.; Joshi, S. Advances in corrosion-resistant thermal spray coatings for renewable energy power plants: Part II—Effect of environment and outlook. J. Therm. Spray Tech. 2019, 28, 1789–1850. [Google Scholar] [CrossRef] [Green Version]

- Jozwik, P.; Polkowski, W.; Bojar, Z. Applications of Ni3Al based intermetallic alloys—Current stage and potential perceptivities. Materials 2015, 8, 2537–2568. [Google Scholar] [CrossRef]

- Cinca, N.; Lima, C.R.C.; Guilemany, J.M. An overview of intermetallics research and application: Status of thermal spray coatings. JMRTAL 2013, 2, 75–86. [Google Scholar] [CrossRef] [Green Version]

- Bochenek, K.; Basista, M. Advances in processing of NiAl intermetallic alloys and composites for high temperature aerospace applications. Prog. Aerosp. Sci. 2015, 79, 136–146. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; Li, X.H.; Tricoire, A.; Dorfman, M. Next generation thermal barrier coatings for the gas turbine industry. J. Therm. Spray Tech. 2011, 20, 108–115. [Google Scholar] [CrossRef]

- Zagula-Yavorska, M.; Sieniawski, J.; Filip, R.; Drajewicz, M. The effect of the aluminide coating on the thermal properties and oxidation resistance of Inconel 625 Ni-base superalloy. Solid State Phenom. 2015, 227, 313–316. [Google Scholar] [CrossRef]

- Stekovic, S. Low cycle fatigue and fracture of a coated superalloy CMSX-4. In Fracture of Nano and Engineering Materials and Structures; Gdoutos, E.E., Ed.; Springer: Dordrecht, The Netherland, 2006. [Google Scholar] [CrossRef]

- Okazaki, M. High-temperature strength of Ni-base superalloy coatings. Sci. Technol. Adv. Mat. 2001, 2, 357–366. [Google Scholar] [CrossRef]

- Rodriguez, P.; Mannan, S.L. High temperature low cycle fatigue. Sadhana 1995, 20, 123–164. [Google Scholar] [CrossRef]

- Castillo, R.; Willett, K.P. The effect of protective coatings on the high temperature properties of a gamma prime-strengthened Ni-base superalloy. Metall. Mater. Trans. A 1984, 15, 229–236. [Google Scholar] [CrossRef]

- Veys, J.M.; Mevrel, R. Influence of protective coatings on the mechanical properties of CMSX-2 and Cotac 784. Mater. Sci. Eng. A 1987, 88, 253–260. [Google Scholar] [CrossRef]

- Kalivodova, J.; Baxter, D.; Schutze, M.; Rohr, V. Corrosion behaviour of boiler steels, coatings and welds in flue gas environments. Mater. Corros. 2008, 59, 367–373. [Google Scholar] [CrossRef]

- Kochmańska, A.; Garbiak, M. High-temperature diffusion barrier for Ni–Cr Cast Steel. Defect Diffus. Forum. 2011, 595–600. [Google Scholar] [CrossRef]

- Zhan, Z.; He, Y.; Li, L.; Liu, H.; Dai, Y. Low-temperature formation and oxidation resistance of ultrafine aluminide coatings on Ni-base superalloy. Surf. Coat. Technol. 2009, 203, 2337–2342. [Google Scholar] [CrossRef]

- Xu, Z.H.; Dai, J.W.; Niu, J.; He, L.M.; Mu, R.D.; Wang, Z.K. Isothermal oxidation and hot corrosion behaviors of diffusion aluminide coatings deposited by chemical vapor deposition. J. Alloys Compd. 2015, 637, 343–349. [Google Scholar] [CrossRef]

- Wang, K.L.; Chen, F.S.; Leu, G.S. The aluminizing and Al–Si codeposition on AISI HP alloy and the evaluation of their carburizing resistance. Mater. Sci. Eng. A 2003, 357, 27–38. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, W. Microstructures, properties and high-temperature car-burization resistances of HVOF thermal sprayed NiAl intermetallic-based alloy coatings. Surf. Coat. Technol. 2004, 183, 18–28. [Google Scholar] [CrossRef]

- Yavorska, M.; Sieniawski, J.; Zielińska, M. Functional properties of aluminide layer deposited on inconel 713 lc ni-based superalloy in the CVD process. Arch. Metall. Mater. 2011, 56, 187–192. [Google Scholar] [CrossRef]

- Bojar, Z.; Jóźwik, P.; Bystrzycki, J. Tensile properties and fracture behavior of nanocrystalline Ni3Al intermetallic foil. Scr. Mat. 2006, 55, 399–402. [Google Scholar] [CrossRef]

- Polkowski, W.; Józwik, P.; Karczewski, K.; Bojar, Z. Evolution of crystallographic texture and strain in a fine-grained Ni3Al (Zr, B) intermetallic alloy during cold rolling. Arch. Civ. Mech. Eng. 2014, 14, 550–560. [Google Scholar] [CrossRef]

- Adamiak, S.; Bochnowski, W.; Dziedzic, A.; Filip, R.; Szeregij, E. Structure and properties of the aluminide coatings on the Inconel 625 superalloy. High. Temp. Mat. Pr. Isr. 2016, 35, 103–112. [Google Scholar] [CrossRef]

- Ning, B.; Stevenson, M.E.; Weaver, M.L.; Bradt, R.C. Apparent indentation size effect in a CVD aluminide coated Ni-base superalloy. Surf. Coat. Technol. 2003, 163, 112–117. [Google Scholar] [CrossRef]

- Zagula-Yavorska, M.; Kocurek, P.; Pytel, M. Oxidation resistance of turbine blades made of ŻS6K superalloy after aluminizing by Low-Activity CVD and VPA Methods. J. Mater. Eng. Perform. 2016, 25, 1964–1973. [Google Scholar] [CrossRef] [Green Version]

- Kukla, D.; Kopec, M.; Kowalewski, Z.L.; Politis, D.J.; Jozwiak, S.; Senderowski, C. Thermal barrier stability and wear behavior of CVD deposited aluminide coatings for MAR 247 nickel superalloy. Materials 2020, 12, 3863. [Google Scholar] [CrossRef] [PubMed]

- Maxwell, A.S.; Owen-Jones, S.; Jennett, N.M. Measurement of Young’s modulus and Poisson’s ratio of thin coatings using impact excitation and depth-sensing indentation. Rev. Sci. Instrum. 2004, 75, 970–975. [Google Scholar] [CrossRef]

- ASTM E1876-99. Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Sulak, I.; Obrtlik, K.; Celko, L. High-temperature low-cycle fatigue behaviour of HIP treated and untreated superalloy MAR-M247. Kovove Mater. 2016, 54, 471–481. [Google Scholar] [CrossRef] [Green Version]

- Corrigan, J.; Launsbach, M.G.; Mihalisin, J.R. Nickel Base Superalloy and Single Crystal Castings. U.S. Patent 8,241,560, 14 August 2012. [Google Scholar]

- Antolovich, S.D. Microstructural aspects of fatigue in Ni-base superalloys. Phil. Trans. R. Soc. A 2015, 373, 20140128. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Šmíd, M.; Kunz, L.; Hutař, P.; Hrbáček, K. High cycle fatigue of nickel-based superalloy MAR-M 247 at high temperatures. Proc. Eng. 2014, 74, 329–332. [Google Scholar] [CrossRef] [Green Version]

- Rahmani, K.; Nategh, S. Mechanical properties of uncoated and aluminide-coated René 80. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 125–137. [Google Scholar] [CrossRef]

- Samal, S.; Tyc, O.; Heller, L.; Šittner, P.; Malik, M.; Poddar, P.; Catauro, M.; Blanco, I. Study of interfacial adhesion between nickel-titanium shape memory alloy and a polymer matrix by laser surface pattern. Appl. Sci. 2020, 10, 2172. [Google Scholar] [CrossRef] [Green Version]

- Yuan, K.; Peng, R.; Li, X.-H.; Johansson, L.; Johansson, S.; Wang, Y. Creep fracture mechanism of polycrystalline Ni-based superalloy with diffusion coatings. In Proceedings of the 13th International Conference on Fracture ICF13, Beijing, China, 16–21 June 2013; Available online: http://urn.kb.se/resolve?urn=urn:nbn:se:liu:diva-8949 (accessed on 1 December 2020).

| C | Cr | Mn | Si | W | Co | Al | Ni |

|---|---|---|---|---|---|---|---|

| 0.09 | 8.80 | 0.10 | 0.25 | 9.70 | 9.50 | 5.70 | bal. |

| Point | Al | Si | Ti | Cr | Co | Ni |

|---|---|---|---|---|---|---|

| x1 | 22.99 | - | - | 2.91 | 8.37 | 65.33 |

| x2 | 21.92 | - | 0.40 | 4.30 | 9.13 | 64.25 |

| x3 | 20.63 | - | 0.69 | 5.35 | 9.69 | 63.65 |

| x4 | 19.59 | 0.45 | 0.86 | 5.78 | 10.05 | 63.28 |

| x5 | 18.49 | 0.66 | 1.02 | 6.34 | 10.50 | 63.00 |

| x6 | 18.25 | 0.69 | 1.04 | 6.68 | 9.87 | 63.48 |

| x7 | 7.24 | 1.98 | 0.94 | 6.33 | 9.11 | 66.13 |

| Material | Room Temperature | 1000 °C | ||||||

|---|---|---|---|---|---|---|---|---|

| Rm (MPa) | Re (MPa) | E (GPa) | A (%) | Rm (MPa) | Re (MPa) | E (GPa) | A (%) | |

| Uncoated MAR 247 nickel based superalloy | 980 | 800 | 185 | 6 | 380 | 330 | 85 | 5 |

| Coated MAR 247 nickel based superalloy | 1100 | 830 | 197 | 6 | 460 | 415 | 98 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopec, M.; Kukla, D.; Yuan, X.; Rejmer, W.; Kowalewski, Z.L.; Senderowski, C. Aluminide Thermal Barrier Coating for High Temperature Performance of MAR 247 Nickel Based Superalloy. Coatings 2021, 11, 48. https://doi.org/10.3390/coatings11010048

Kopec M, Kukla D, Yuan X, Rejmer W, Kowalewski ZL, Senderowski C. Aluminide Thermal Barrier Coating for High Temperature Performance of MAR 247 Nickel Based Superalloy. Coatings. 2021; 11(1):48. https://doi.org/10.3390/coatings11010048

Chicago/Turabian StyleKopec, Mateusz, Dominik Kukla, Xin Yuan, Wojciech Rejmer, Zbigniew L. Kowalewski, and Cezary Senderowski. 2021. "Aluminide Thermal Barrier Coating for High Temperature Performance of MAR 247 Nickel Based Superalloy" Coatings 11, no. 1: 48. https://doi.org/10.3390/coatings11010048