Thermal Conductivity of Multi-Sized Porous Thermal Barrier Coatings at Micro and Nano Scales after Long-Term Service at High Temperatures

Abstract

:1. Introduction

2. Experimental Materials and Procedures

2.1. Powder and Coating Deposition

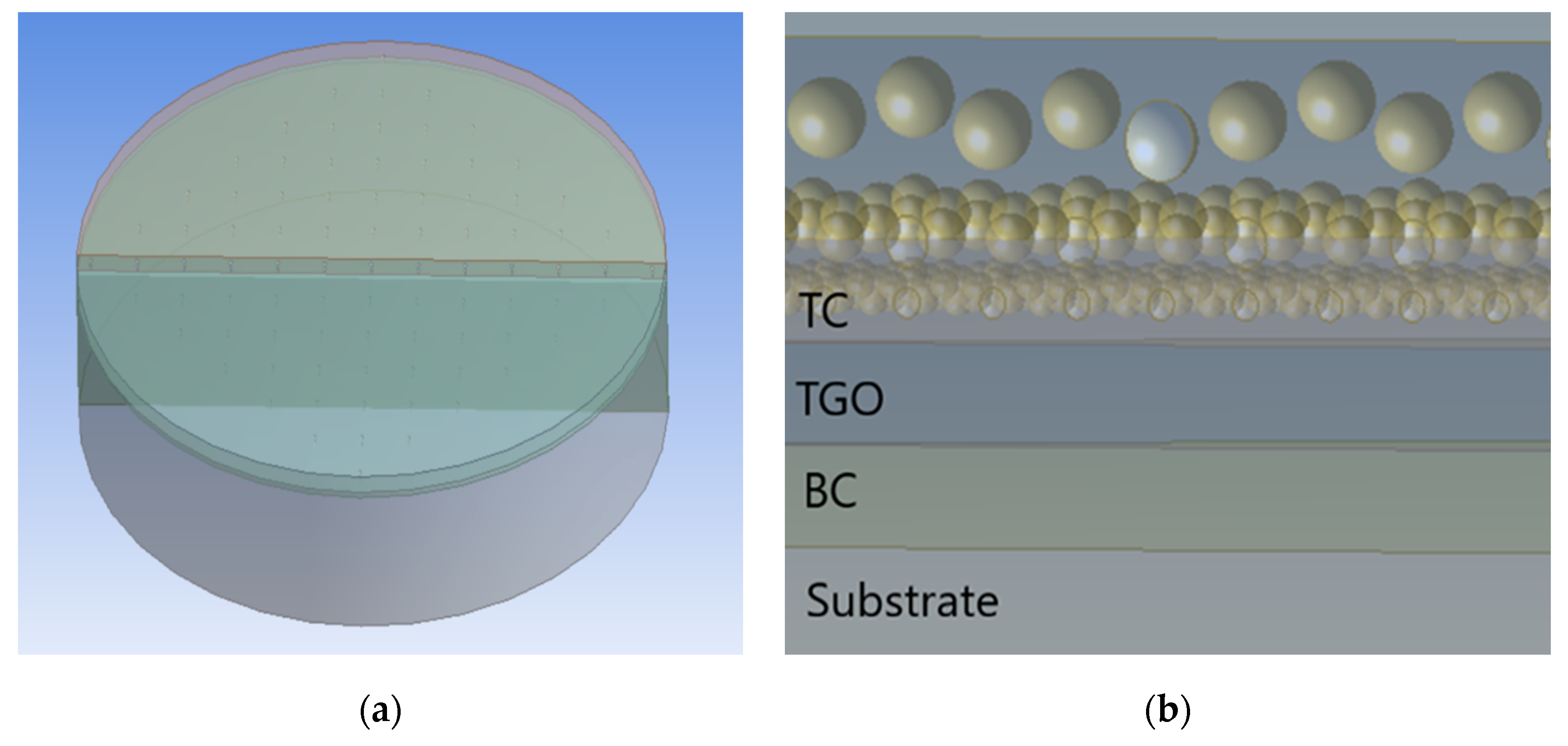

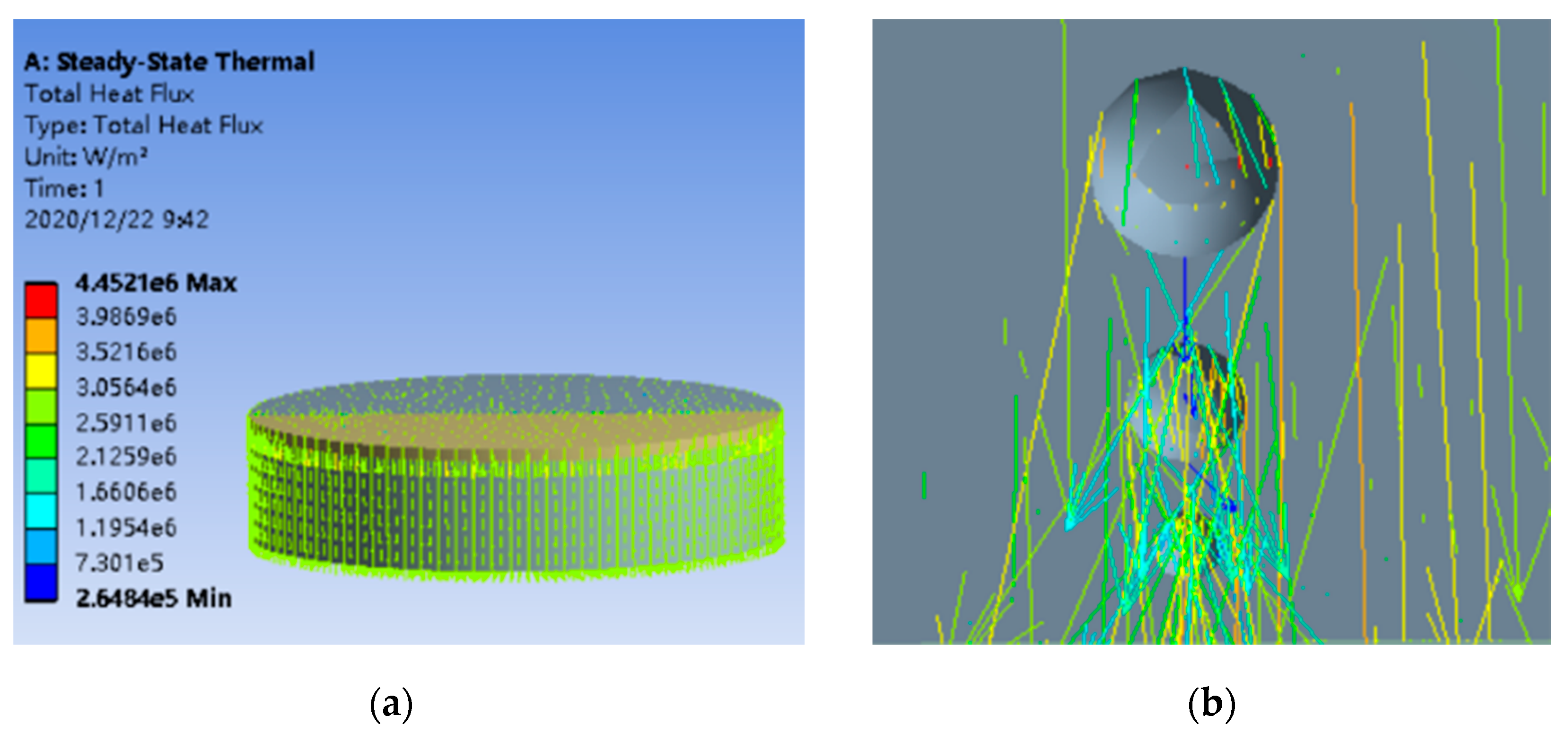

2.2. Thermal Conductivity Simulation

2.3. Characterization

3. Results

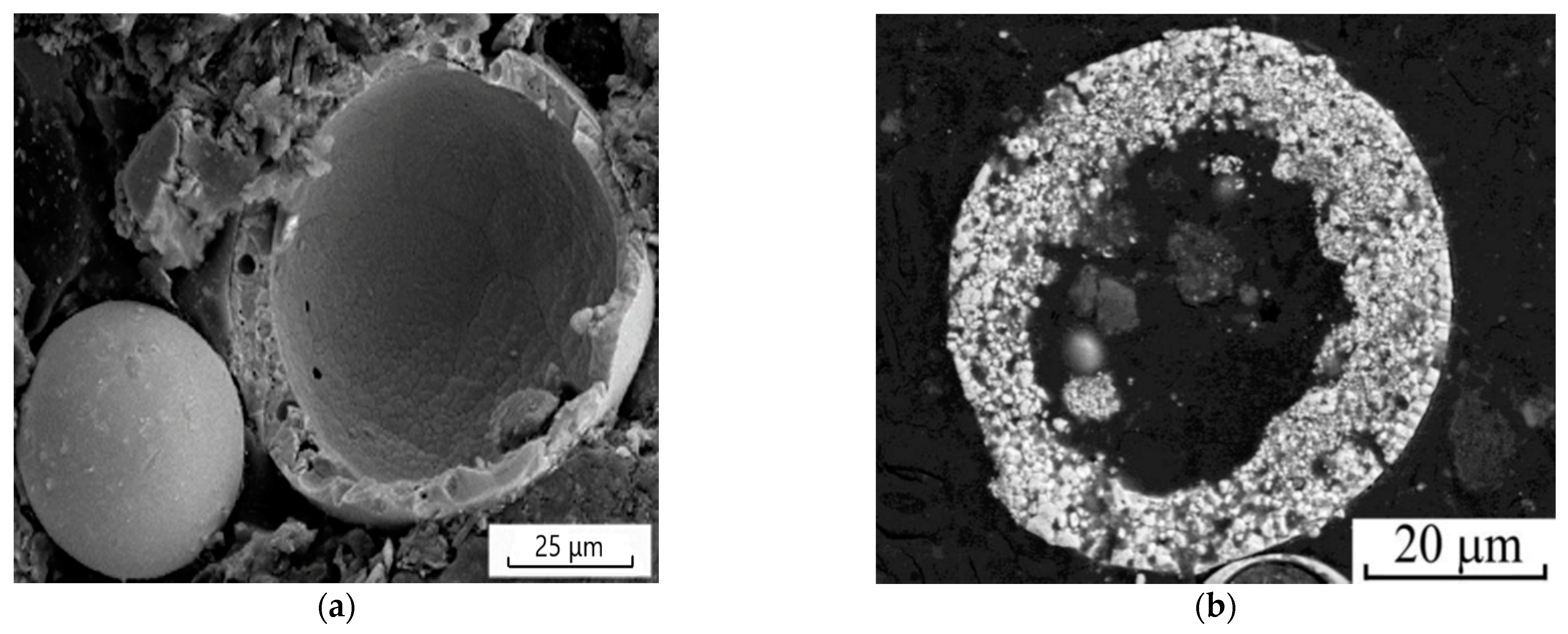

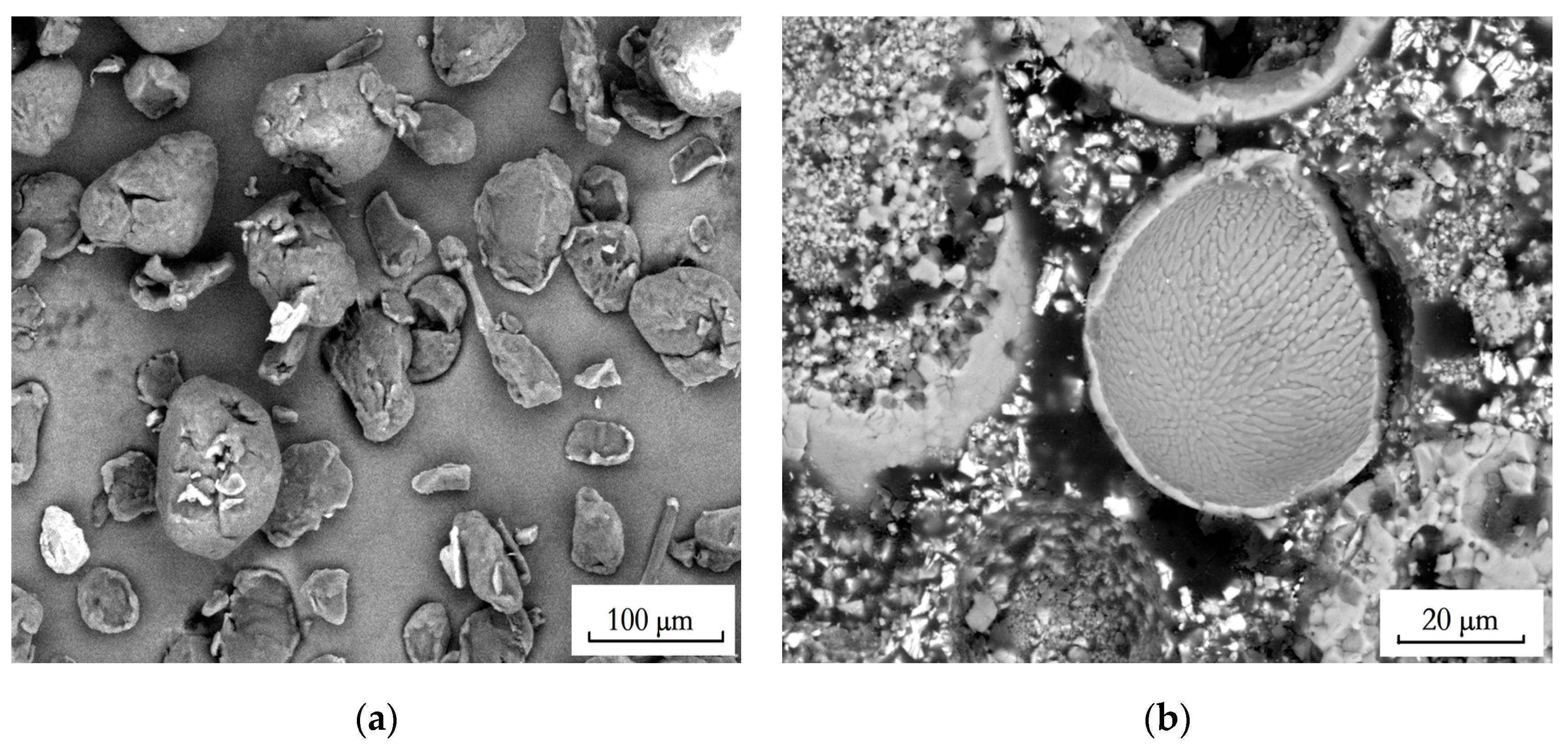

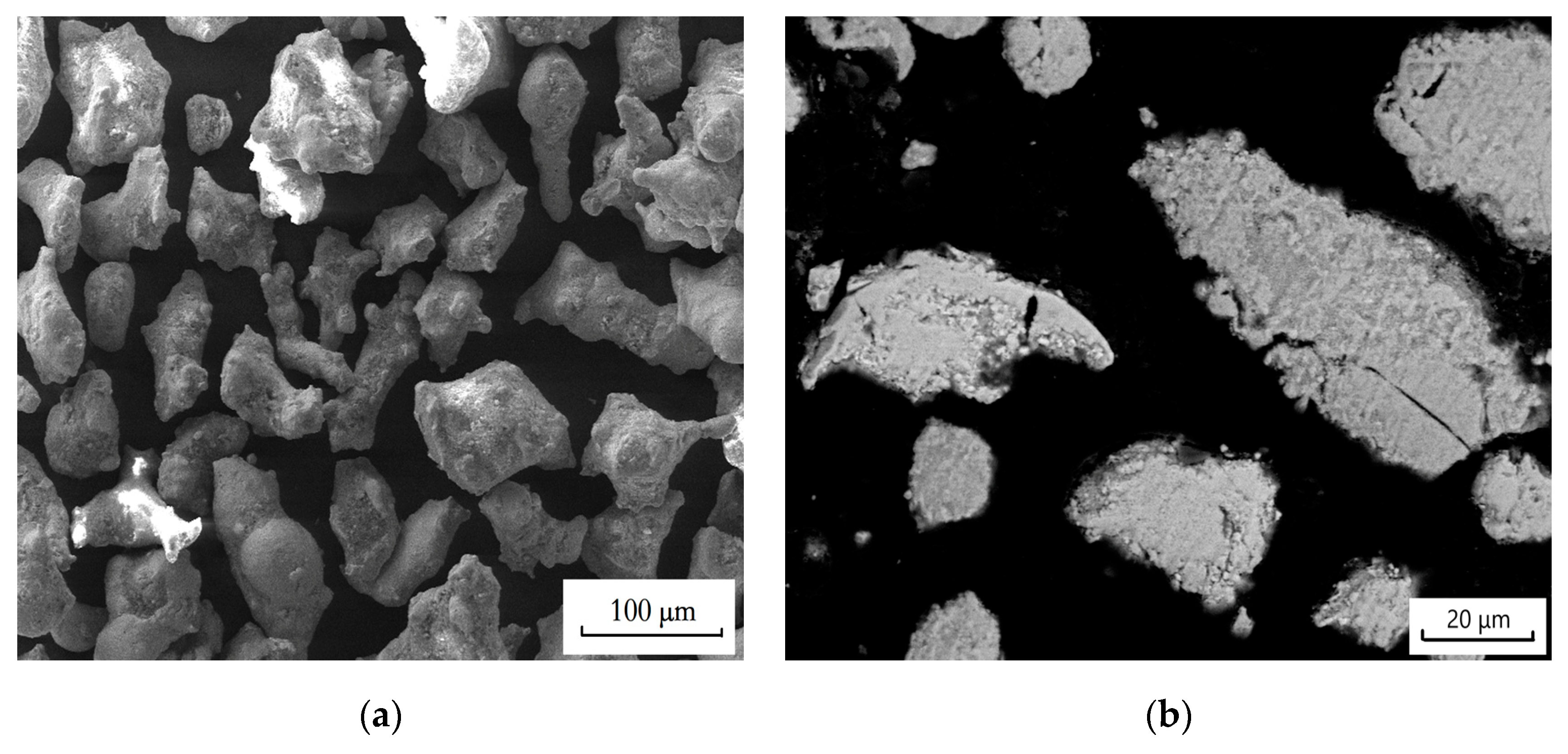

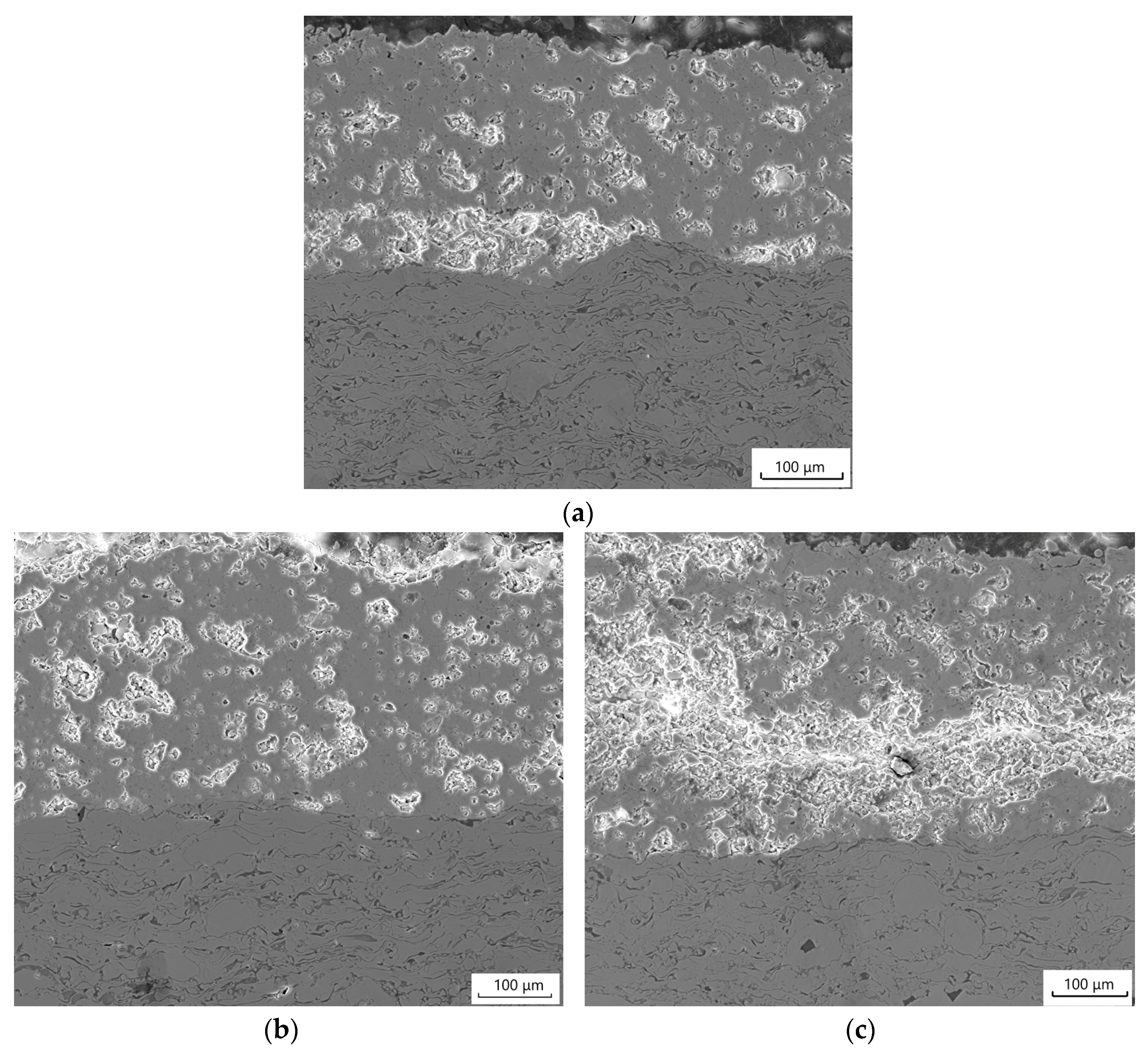

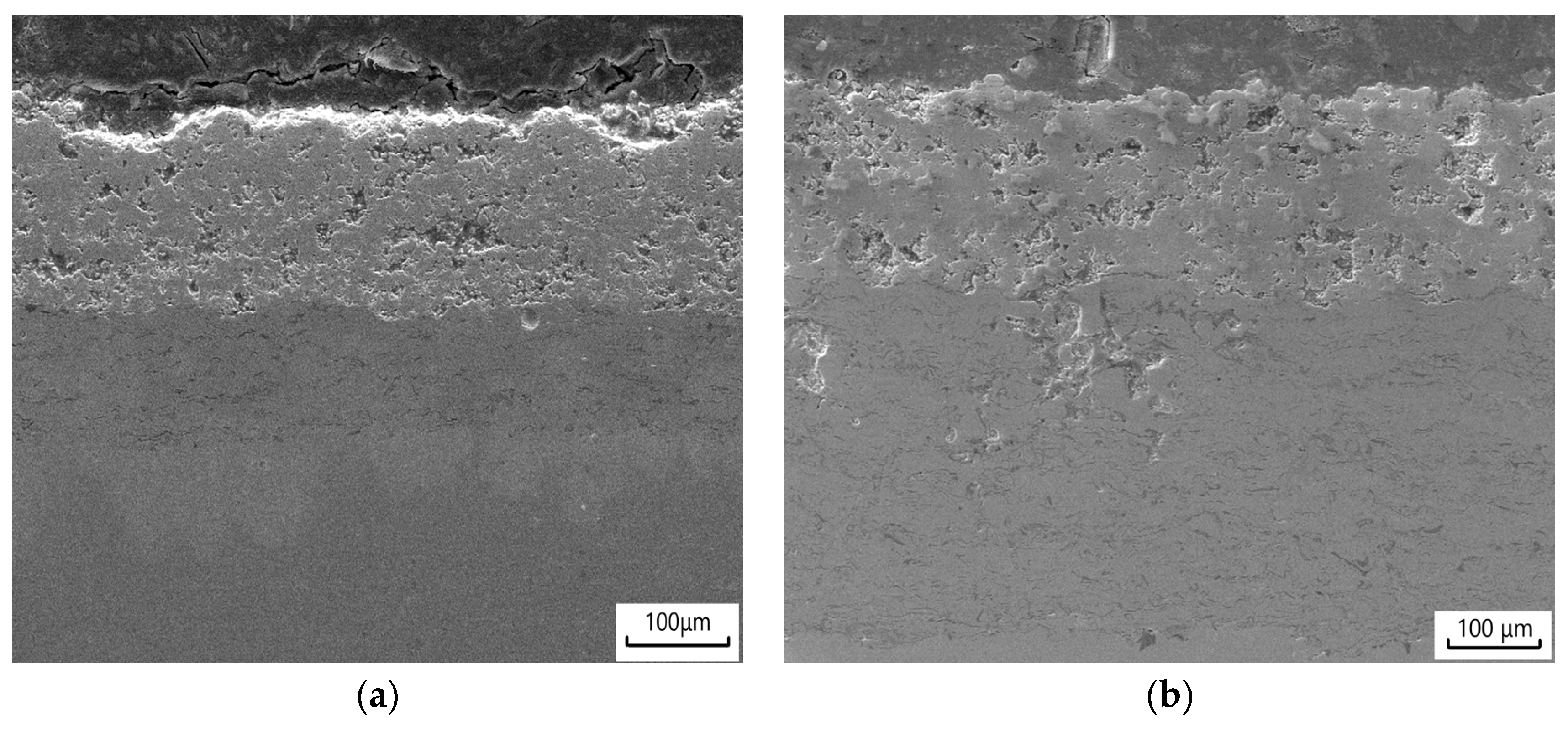

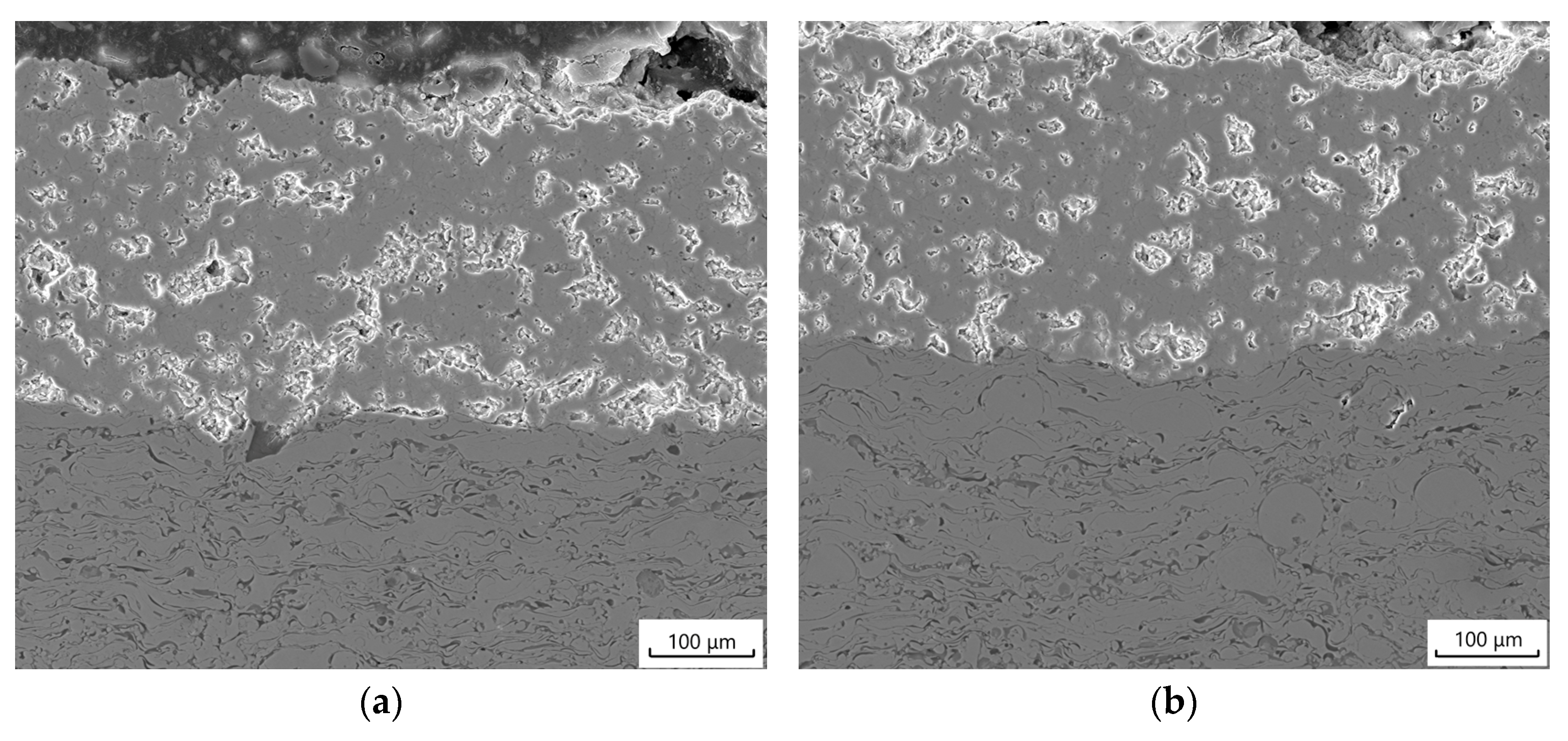

3.1. Microstructure of the Deposited Porous TBCs

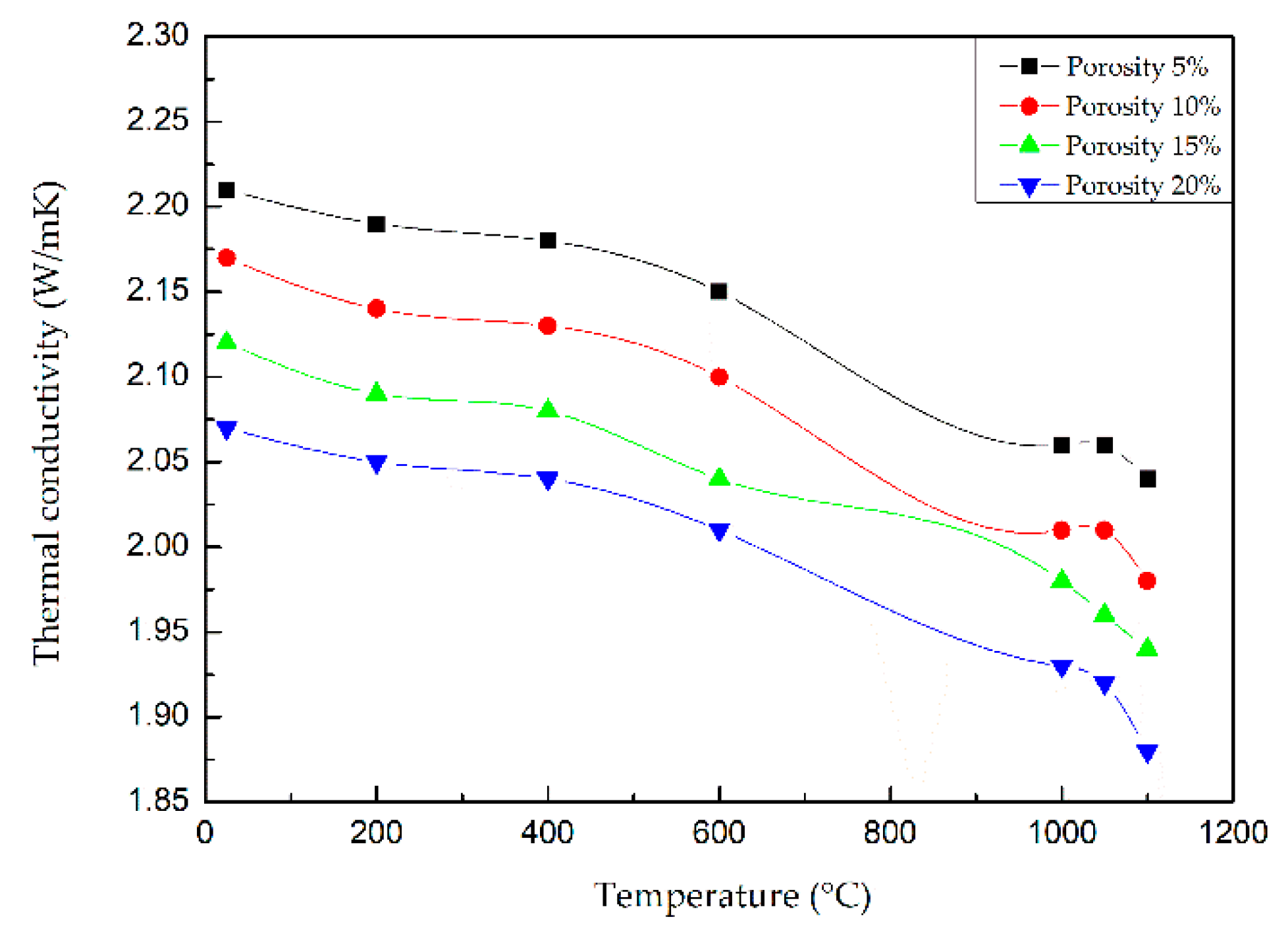

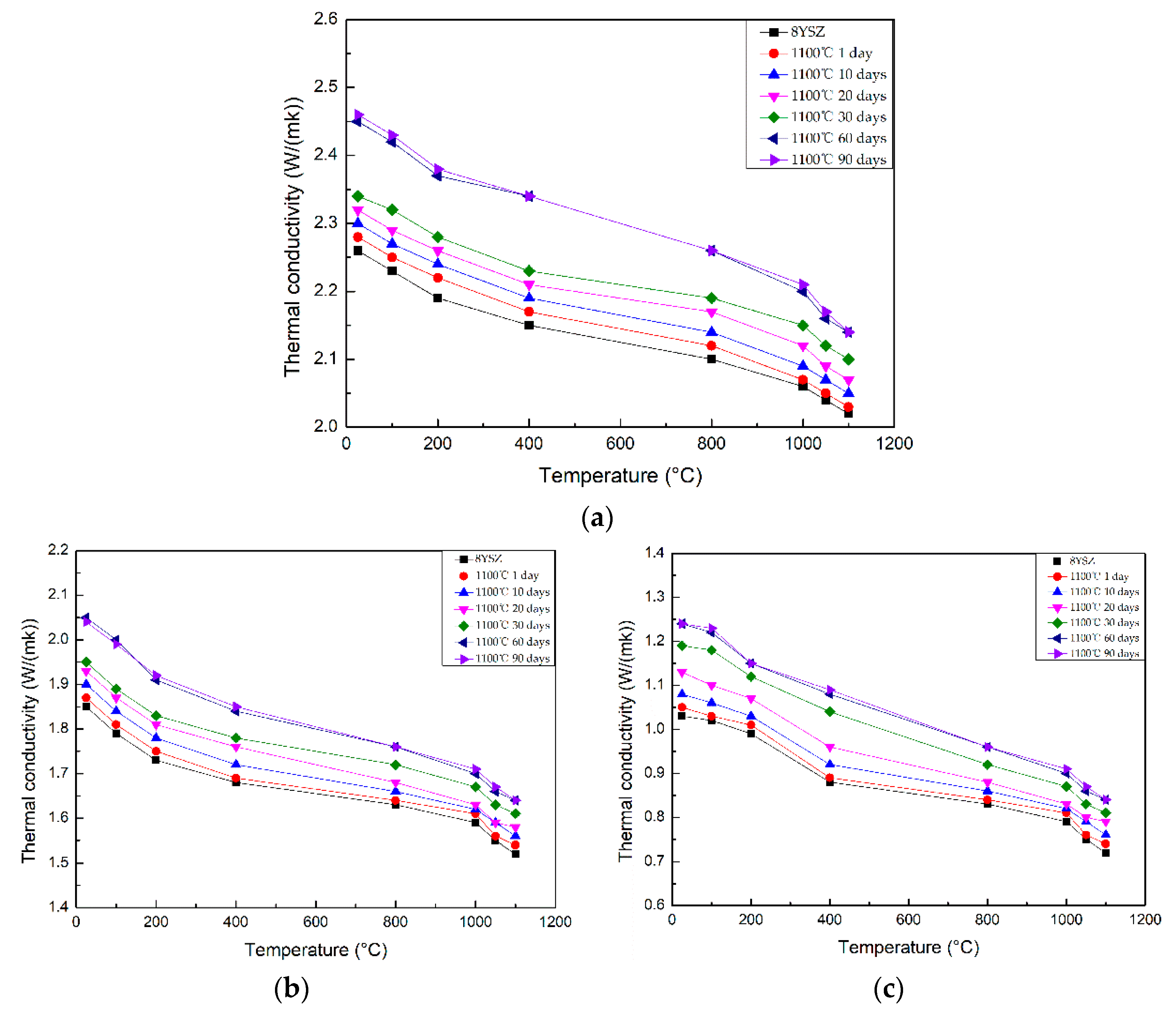

3.2. Thermal Conductivity Computation of Porous TBCs after Long Time Serving

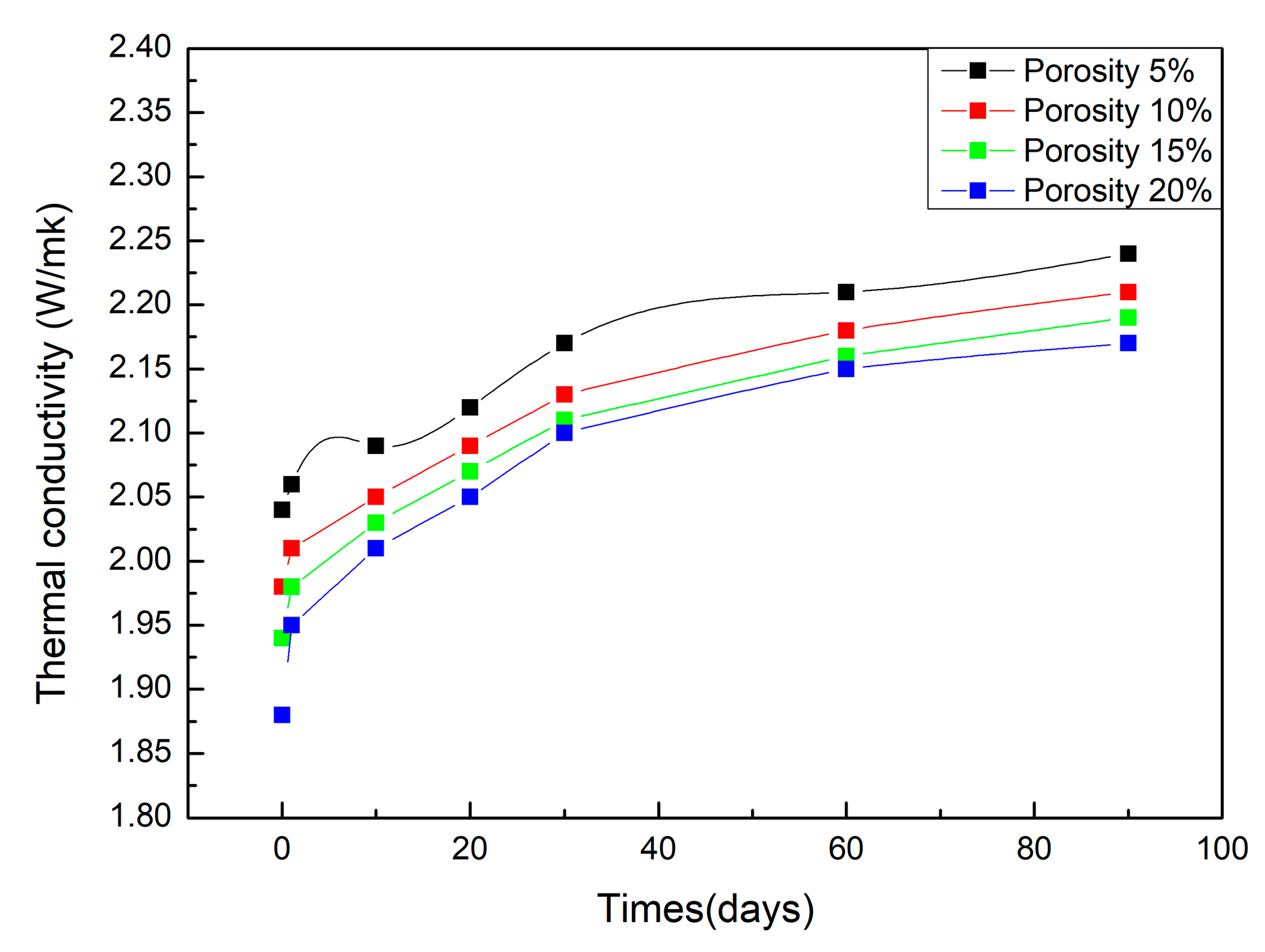

3.3. Thermal Conductivity of the Multi-Sized Porous TBCs after Long-Term Serving at High Temperature

4. Discussion

4.1. Diffusion in Multi-Sized Porous TBCs and Nano Pores Extinction Mechanism

4.2. Thermal Conductivity Evolution Mechanism in Multi-Sized Porous TBCs

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Evans, A.G.; Mumm, D.R.; Hutchinson, J.W.; Meier, G.H.; Pettit, F.S. Mechanisms controlling the durability of thermal barrier coatings. Prog. Mater. Sci. 2001, 46, 505–553. [Google Scholar] [CrossRef]

- Pia, G.; Casnedi, L.; Sanna, U. Porosity and pore size distribution influence on thermal conductivity of yttria-stabilized zirconia:Experimental findings and model predictions. Ceram. Int. 2016, 42, 5802–5809. [Google Scholar] [CrossRef]

- Schlichting, K.; Padture, N.; Jordan, E.; Gell, M. Failure modes in plasma-sprayed thermal barrier coatings. Mater. Sci. Eng. A-Struct. 2003, 342, 120–130. [Google Scholar] [CrossRef]

- Rabiei, A.; Evans, A.G. Failure mechanisms associated with the thermally grown oxide in plasma-sprayed thermal barrier coatings. Acta Mater. 2000, 48, 3963–3976. [Google Scholar] [CrossRef]

- Planques, P.; Vidal, V.; Lours, P.; Proton, V.; Crabos, F.; Huez, J.; Viguier, B. Mechanical and Thermo-physical Properties of Plasma-Sprayed Thermal Barrier Coatings: A Literature Survey. Oxid. Met. 2017, 88, 133–143. [Google Scholar] [CrossRef] [Green Version]

- Brinkiene, K.; Kezelis, R. Correlations between processing parameters and microstructure for YSZ films produced by plasma spray technique. J. Eur. Ceram. Soc. 2004, 24, 1095–1099. [Google Scholar] [CrossRef]

- Paul, S.; Cipitria, A.; Golosnoy, I.O.; Xie, L.; Dorfman, M.R.; Clyne, T.W. Effects of Impurity Content on the Sintering Characteristics of Plasma-Sprayed Zirconia. J. Therm. Spray Technol. 2007, 16, 798–803. [Google Scholar] [CrossRef] [Green Version]

- Nicholls, J.; Lawson, K.; Johnstone, A.; Rickerby, D. Methods to reduce the thermal conductivity of EB-PVD TBCs. Surf. Coat. Technol. 2002, 151–152, 383–391. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.; Witz, G.; Howell, P.C.; Hitchman, N. Interplay of the phase and the chemical composition of the powder feedstock on the properties of porous 8YSZ thermal barrier coatings. J. Eur. Ceram. Soc. 2021, 41, 3706–3716. [Google Scholar] [CrossRef]

- Carpio, P.; Borrell, A.; Salvador, M.D.; Gómez, A.; Martínez, E.; Sánchez, E. Microstructure and mechanical properties of plasma spraying coatings from YSZ feedstocks comprising nano- and submicron-sized particles. Ceram. Int. 2015, 41, 4108–4117. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Zhao, Y.; Yang, D.; Gao, J. A novel plasma-sprayed nanostructured coating with agglomerated-unsintered feedstock. J. Therm. Spray Technol. 2016, 25, 291–300. [Google Scholar] [CrossRef]

- Vardelle, A.M.; Moreau, C.; Akedo, J.; Ashrafizadeh, H.; Berndt, C.; Berghaus, J.O.; Boulos, M.; Brogan, J.; Bourtsalas, A.C.; Dolatabadi, A.; et al. The 2016 Thermal Spray Roadmap. J. Therm. Spray Technol. 2016, 25, 1376–1440. [Google Scholar] [CrossRef]

- Cao, X.Q.; Vassen, R.; Stoever, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Taylor, R.; Brandon, J.R.; Paul, M. Microstructure, composition and property relationships of plasma-sprayed thermal barrier coatings. Surf. Coat. Technol. 1992, 50, 141–149. [Google Scholar] [CrossRef]

- Yang, M.; Zhu, Y.; Wang, X.; Guo, S.; Hu, J.; Zhao, L.; Chu, Y. Effect of five kinds of pores shape on thermal stress properties of thermal barrier coatings by finite element method. Ceram. Int. 2017, 43, 9664–9678. [Google Scholar] [CrossRef]

- Gao, P.-H.; Yang, G.-J.; Cao, S.-T.; Li, J.-P.; Yang, Z.; Guo, Y.-C. Heredity and variation of hollow structure from powders to coatings through atmospheric plasma spraying. Surf. Coat. Technol. 2016, 305, 76–82. [Google Scholar] [CrossRef]

- Tatsuo, S.; Hiroya, O.; Masayuki, A. A novel low-thermal-conductivity plasma sprayed thermal barrier coating controlled by large pores. Surf. Coat. Technol. 2016, 285, 120–127. [Google Scholar]

- Lv, B.; Jin, X.; Cao, J.; Xu, B.; Wang, Y.; Fang, D. Advances in numerical modeling of environmental barrier coating systems for gas turbines. J. Eur. Ceram. Soc. 2020, 40, 3363–3379. [Google Scholar] [CrossRef]

- Pekshev, P.Y.; Tcherniakov, S.V.; Arzhakin, N.A.; Rutskin, V.V. Plasma-sprayed multilayer protective coatings for gas turbine units. Surf. Coat. Technol. 1994, 64, 5–9. [Google Scholar] [CrossRef]

- Cernuschi, F.; Golosnoy, I.; Bison, P.; Moscatelli, A.; Vassen, R.; Bossmann, H.-P.; Capelli, S. Microstructural characterization of porous thermal barrier coatings by IR gas porosimetry and sintering forecasts. Acta Mater. 2013, 61, 248–262. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, N.; Wang, Z.; Gong, S.; Xu, H. Thermal cycling life and thermal diffusivity of a plasma-sprayed nanostructured thermal barrier coating. Scr. Mater. 2004, 51, 945–948. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Zhang, W.Q.; Sun, X.G.; He, J.Q.; Pan, Z.Y.; Wang, C.H. Finite element simulation of stress distribution and development in 8YSZ and double-ceramic-layer La2Zr2O7/8YSZ thermal barrier coatings during thermal shock. Appl. Surf. Sci. 2012, 258, 3540–3551. [Google Scholar] [CrossRef]

- Gilbert, A.; Kokini, K.; Sankarasubramanian, S. Thermal fracture of zirconia–mullite composite thermal barrier coatings under thermal shock: A numerical study. Surf. Coat Technol. 2008, 203, 91–98. [Google Scholar] [CrossRef]

- Bäker, M. Finite element simulation of interface cracks in thermal barrier coatings. Comput. Mater. Sci. 2012, 64, 79–83. [Google Scholar] [CrossRef]

- Sivakumar, S.; Praveen, K.; Shanmugavelayutham, G.; Yugeswaran, S.; Mostaghimi, J. Thermo-physical behavior of atmospheric plasma sprayed high porosity Lanthanum Zirconate coatings. Surf. Coat. Technol. 2017, 326, 173–182. [Google Scholar] [CrossRef]

- Yugeswaran, S.; Kobayashi, A.; Selvan, B.; Ananthapadmanabhan, P. In-flight behavior of lanthanum zirconate (La2Zr2O7) particles in gas tunnel type plasma jet and its coating properties. Vacuum 2013, 88, 139–143. [Google Scholar] [CrossRef]

- Kadam, N.R.; Karthikeyan, G.; Kulkarni, D.M. Effect of substrate rotation on the microstructure of 8YSZ thermal barrier coatings by EB-PVD. Mater. Today Proc. 2020, 28, 678–683. [Google Scholar] [CrossRef]

- Ruiji, Z.; Xing, Z.; Chen, X.; Li, H.; Fangwei, G.; Xin, W.; Xiaofeng, Z. Preparation of long-lifetime thermal barrier coatings and toughening mechanism by using hierarchy structured zirconia-based microspheres. J. Eur. Ceram. Soc. 2021, 41, 4625–4636. [Google Scholar]

- Zhou, F.; Wang, Y.; Liu, M.; Deng, C.; Zhang, X. Thermo-physical and thermal insulation properties of multi-scale nanostructured thermal barrier coatings using as-prepared t′-8YSZ feedstocks. Ceram. Int. 2019, 45, 24096–24103. [Google Scholar] [CrossRef]

- Cao, J.; Gao, K.; Cao, X.Y.; Jiang, B. Thermal shock behavior of a 8YSZ/CoCrAlYTaSi thermal sprayed barrier coating on GH202 superalloy. Ceram. Int. 2019, 46, 7489–7498. [Google Scholar] [CrossRef]

- Łatka, L.; Cattini, A.; Pawłowski, L.; Valette, S.; Pateyron, B.; Lecompte, J.-P.; Kumar, R.; Denoirjean, A. Thermal diffusivity and conductivity of yttria stabilized zirconia coatings obtained by suspension plasma spraying. Surf. Coat. Technol. 2012, 208, 87–91. [Google Scholar] [CrossRef]

| Coating | Parameters | |

|---|---|---|

| Bond Coat | Arc voltage (V) | 67 |

| Arc current (A) | 540 | |

| H2 pressure (MPa) | 0.3 | |

| Ar flow (SLPM) | 36.7 | |

| Powder feeding rate (rad/min) | 3.5 | |

| Top Coat | Arc voltage (V) | 70 |

| Arc current (A) | 600 | |

| H2 pressure (MPa) | 0.2 | |

| Ar flow (SLPM) | 34.5 | |

| Powder feeding rate (rad/min) | 3.7 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, P.-H.; Zeng, S.-C.; Jin, C.; Zhang, B.; Chen, B.-Y.; Yang, Z.; Guo, Y.-C.; Liang, M.-X.; Li, J.-P.; Li, Q.-P.; et al. Thermal Conductivity of Multi-Sized Porous Thermal Barrier Coatings at Micro and Nano Scales after Long-Term Service at High Temperatures. Coatings 2021, 11, 1183. https://doi.org/10.3390/coatings11101183

Gao P-H, Zeng S-C, Jin C, Zhang B, Chen B-Y, Yang Z, Guo Y-C, Liang M-X, Li J-P, Li Q-P, et al. Thermal Conductivity of Multi-Sized Porous Thermal Barrier Coatings at Micro and Nano Scales after Long-Term Service at High Temperatures. Coatings. 2021; 11(10):1183. https://doi.org/10.3390/coatings11101183

Chicago/Turabian StyleGao, Pei-Hu, Sheng-Cong Zeng, Can Jin, Bo Zhang, Bai-Yang Chen, Zhong Yang, Yong-Chun Guo, Min-Xian Liang, Jian-Ping Li, Quan-Ping Li, and et al. 2021. "Thermal Conductivity of Multi-Sized Porous Thermal Barrier Coatings at Micro and Nano Scales after Long-Term Service at High Temperatures" Coatings 11, no. 10: 1183. https://doi.org/10.3390/coatings11101183

APA StyleGao, P.-H., Zeng, S.-C., Jin, C., Zhang, B., Chen, B.-Y., Yang, Z., Guo, Y.-C., Liang, M.-X., Li, J.-P., Li, Q.-P., Lu, Y.-Q., Jia, L., & Zhao, D. (2021). Thermal Conductivity of Multi-Sized Porous Thermal Barrier Coatings at Micro and Nano Scales after Long-Term Service at High Temperatures. Coatings, 11(10), 1183. https://doi.org/10.3390/coatings11101183