Spheroidization Behavior of Nano-Primary Silicon Induced by Neodymium under High-Current Pulsed Electron Beam Irradiation

Abstract

:1. Introduction

2. Research Equipment

3. Results and Discussion

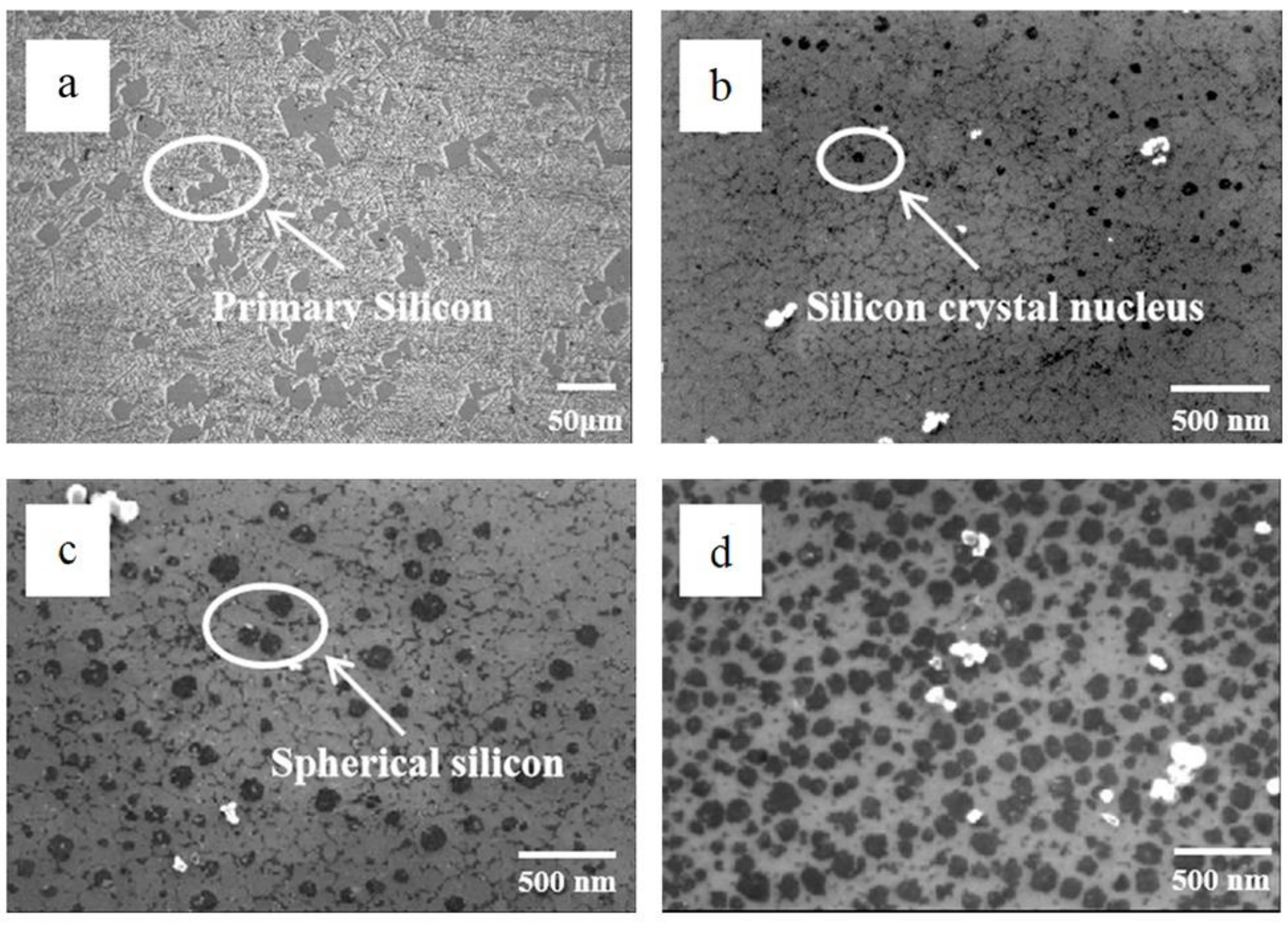

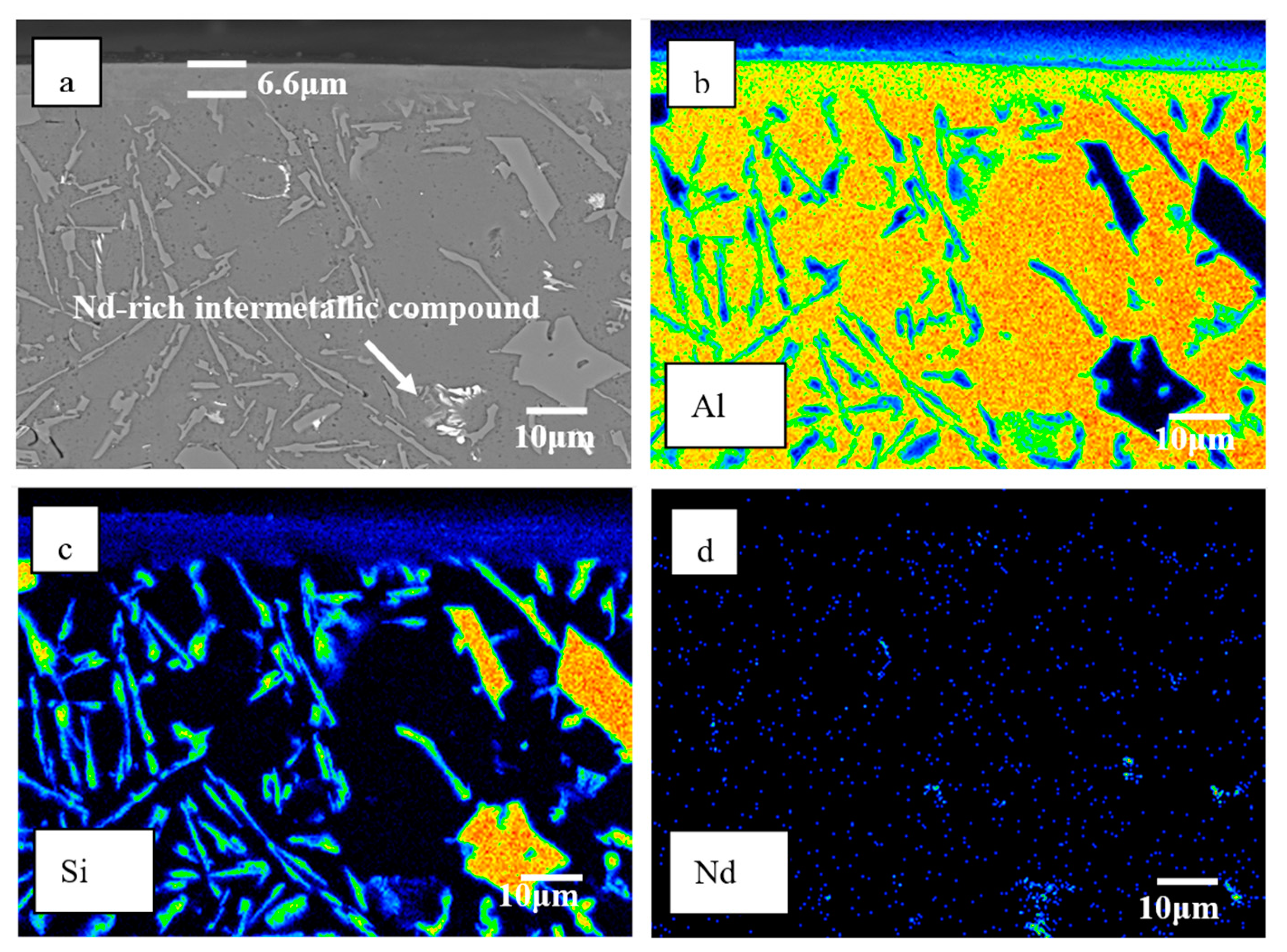

3.1. Morphology Analysis

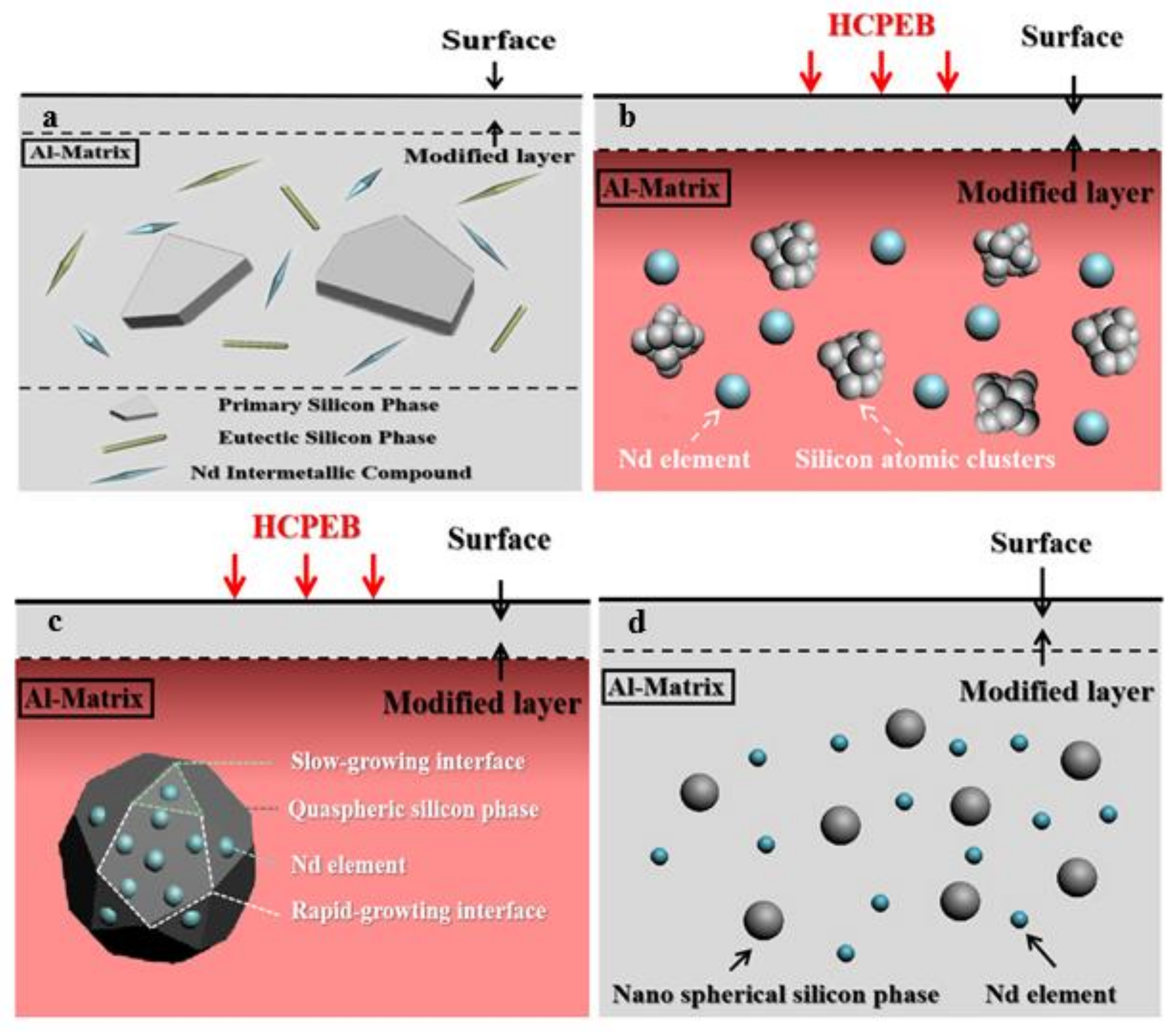

3.2. Spheroidization Mechanism of Nano-Primary Silicon Phase

3.3. Microhardness Analysis

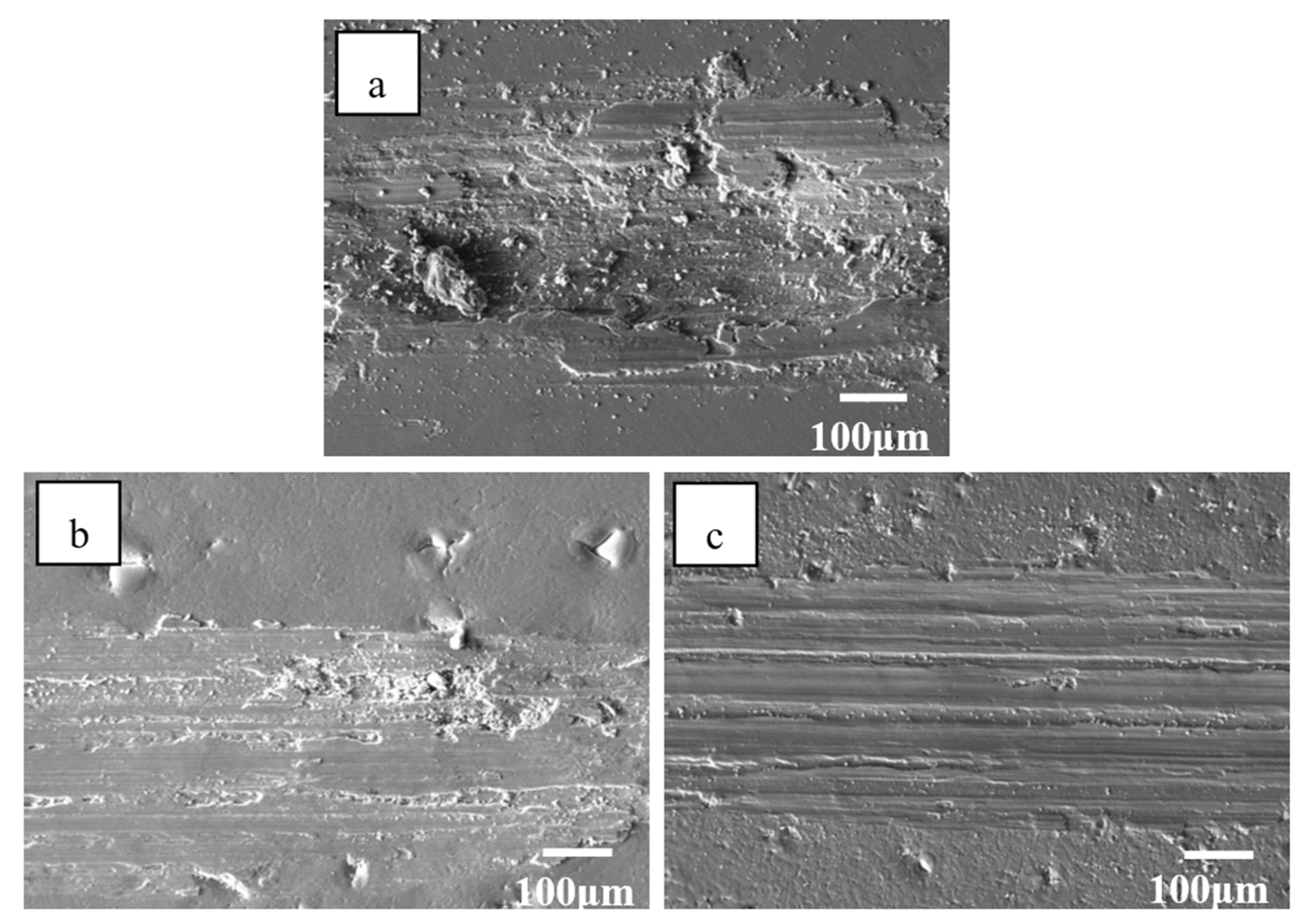

3.4. Tribological Properties

- The HCPEB treatment creates a large number of metastable structures on the alloy surface, which improves the microhardness and tribological property of the alloy surface.

- The addition of Nd removes the craters that degrade friction performance [19]. Rare earths can purify a material, reduce the number of casting defects and lower the surface roughness of the material. Based on the formation mechanism of craters, the crater structure forms preferentially at sites such as impurity phases and casting defects. The rare earths could reduce the occurrence of these sites, causing a significant improvement in the uniformity of the original microstructure, thereby eliminating the crater structure. In addition, the polishing effect produced by the electron beam results in a substantial reduction of the crater structure on the alloy surface. This reduction leads to a decrease in the surface roughness of the alloy, and hence an increase in the contact area between the material and the friction pairs. Consequently, the material can withstand higher loads (than those withstood by the original material) and the tribological property of the alloy surface is improved.

- The spheroidized primary silicon has no corner angle and is more closely combined with the matrix, making peeling off difficult and causing spalling abrasion. In addition, spherical primary silicon is evenly distributed as hard spots on the aluminum matrix to form an ideal anti-abrasion structure with good toughness and high strength.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ganiger, B.; Chandrashekharaiah, T.; Prasad, T.; Kabadi, V. Studies on Relationship between Wear Behaviour and Microstructure of a Hypereutectic Al-Si Alloy. Mater. Today Proc. 2018, 5, 25165–25173. [Google Scholar] [CrossRef]

- Jiang, Q.C.; Xu, C.L.; Lu, M.; Wang, H.Y. Effect of new Al–P–Ti–TiC–Y Modifier on Primary Silicon in Hypereutectic Al–Si Alloys. Mater. Lett. 2005, 59, 624–628. [Google Scholar] [CrossRef]

- Li, Q.; Xia, T.; Lan, Y.; Zhao, W.; Fan, L.; Li, P. Effect of Rare Earth Cerium Addition on the Microstructure and Tensile Properties of Hypereutectic Al–20% Si alloy. J. Alloys Compd. 2013, 562, 25–32. [Google Scholar] [CrossRef]

- Damavandi, E.; Nourouzi, S.; Rabiee, S.M.; Jamaati, R. Effect of ECAP on Microstructure and Tensile Properties of A390 Aluminum Alloy. Trans. Nonferr. Met. Soc. China 2019, 29, 931–940. [Google Scholar] [CrossRef]

- Li, P.; Li, Y.; Wu, Y.; Ma, G.; Liu, X. Distribution of TiB2 Particles and Its Effect on the Mechanical Properties of A390 Alloy. Mater. Sci. Eng. A 2012, 546, 146–152. [Google Scholar] [CrossRef]

- Jeon, J.; Shin, J.; Bae, D. Si Phase Modification on the Elevated Temperature Mechanical Properties of Al-Si Hypereutectic Alloys. Mater. Sci. Eng. A 2019, 748, 367–370. [Google Scholar] [CrossRef]

- Feng, H.K.; Yu, S.R.; Li, Y.L.; Gong, L.Y. Effect of Ultrasonic Treatment on Microstructures of Hypereutectic Al–Si Al-Loy. J. Mater. Process. Technol. 2008, 208, 330–335. [Google Scholar] [CrossRef]

- He, Y.F.; Yang, X.; Bao, Y.; Li, S.Y.; Chen, Z.J.; Ma, W.H.; Lv, G.Q. Effects of Silicon Content on the Separation and Pu-Rification of Primary Silicon from Hypereutectic Aluminum–Silicon Alloy by Alternating Electromagnetic Directional So-Lidification. Sep. Purif. Technol. 2019, 219, 25–32. [Google Scholar] [CrossRef]

- Jiao, X.; Wang, J.; Liu, C.; Guo, Z.; Tong, G.; Ma, S.; Bi, Y.; Zhang, Y.; Xiong, S. Characterization of HIGH-Pressure Die-Cast Hypereutectic Al-Si Alloys Based on Microstructural Distribution and fracture morphology. J. Mater. Sci. Technol. 2019, 35, 1099–1107. [Google Scholar] [CrossRef]

- Hao, Y.; Gao, B.; Tu, G.F.; Wang, Z.; Hao, S.Z. Influence of High Current Pulsed Electron Beam (HCPEB) Treatment on Wear Resistance of Hypereutectic Al-17.5Si and Al-20Si Alloys. Mater. Sci. Forum 2011, 675–677, 693–696. [Google Scholar] [CrossRef]

- Hao, Y.; Gao, B.; Tu, G.; Li, S.; Hao, S.; Dong, C. Surface Modification of Al–20Si Alloy by High Current Pulsed Electron Beam. Appl. Surf. Sci. 2011, 257, 3913–3919. [Google Scholar] [CrossRef]

- Fatahalla, N.; Hafiz, M.; Abdulkhalek, M. Effect of Microstructure on the Mechanical Properties and Fracture of Com-Mercial Hypoeutectic Al-Si Alloy Modified with Na, Sb and Sr. J. Mater. Sci. 1999, 34, 3555–3564. [Google Scholar] [CrossRef]

- Li, J.H.; Barrirero, J.; Engstler, M.; Aboulfadl, H.; Mücklich, F.; Schumacher, P. Nucleation and Growth of Eutectic Si in Al-Si Alloys with Na Addition. Met. Mater. Trans. A 2014, 46, 1300–1311. [Google Scholar] [CrossRef]

- Choi, J.; Kim, J.; Choi, C.; Rohatgi, P. Effect of Rare Earth Element on Microstructure Formation and Mechanical Properties of Thin Wall Ductile Iron Castings. Mater. Sci. Eng. A 2004, 383, 323–333. [Google Scholar] [CrossRef]

- Wang, L.; Guo, E.; Chen, H.; Wang, J.; Li, D. Effects of Light and Heavy Rare Earths on Anti-Degradation of Nodular Cast Iron. J. Rare Earths 2006, 24, 103–107. [Google Scholar] [CrossRef]

- Hu, L.; Gao, B.; Lv, J.K.; Hao, Y.; Tu, G.F.; Hao, S.Z.; Dong, C. The Metastable Structure of Hypereutectic Al–17·5Si Alloy Surface Induced by High Current Pulsed Electron Beam. Mater. Res. Innov. 2015, 19, S320–S324. [Google Scholar] [CrossRef]

- Hu, L.; Gao, B.; Lv, J.K.; Sun, S.C.; Hao, Y.; Tu, G.F. Halo Evolution of Hypereutectic Al-17.5Si Alloy Treated with High-Current Pulsed Electron Beam. J. Nanomater. 2015, 16, 247. [Google Scholar] [CrossRef] [Green Version]

- Hu, L.; Gao, B.; Zhu, G.L.; Hao, Y.; Sun, S.C.; Tu, G.F. The Effect of Neodymium on the Microcracks Generated on the Al-17.5Si Alloy Surface by High Current Pulsed Electron Beam. Appl. Surf. Sci. 2016, 364, 490–497. [Google Scholar] [CrossRef]

- Li, K.; Gao, B.; Xu, N.; Sun, Y.; Denisov, V.V.; Hu, L. The Influence of Neodymium Element on the Crater Structure Formed on Al-17.5Si Alloy Surface Processed by High-Current Pulsed Electron Beam. Coatings 2020, 10, 922. [Google Scholar] [CrossRef]

| Alloys | Al | Si | Nd |

|---|---|---|---|

| Al–17.5Si alloy | Bal. | 17.5 | - |

| Al–17.5Si–0.3 Nd alloy | Bal. | 17.5 | 0.3 |

| Ball Material Type | Working Time | Distance Traveled | Ball Pressure Force |

|---|---|---|---|

| Si3N4 | 10 min | 5 mm | 1 N |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, L.; Li, K.; Gao, B.; Xu, N.; Liu, Z.; Sun, Y.; Zhang, Y.; Xing, P. Spheroidization Behavior of Nano-Primary Silicon Induced by Neodymium under High-Current Pulsed Electron Beam Irradiation. Coatings 2021, 11, 1408. https://doi.org/10.3390/coatings11111408

Hu L, Li K, Gao B, Xu N, Liu Z, Sun Y, Zhang Y, Xing P. Spheroidization Behavior of Nano-Primary Silicon Induced by Neodymium under High-Current Pulsed Electron Beam Irradiation. Coatings. 2021; 11(11):1408. https://doi.org/10.3390/coatings11111408

Chicago/Turabian StyleHu, Liang, Kui Li, Bo Gao, Ning Xu, Zhuang Liu, Yue Sun, Ying Zhang, and Pengfei Xing. 2021. "Spheroidization Behavior of Nano-Primary Silicon Induced by Neodymium under High-Current Pulsed Electron Beam Irradiation" Coatings 11, no. 11: 1408. https://doi.org/10.3390/coatings11111408

APA StyleHu, L., Li, K., Gao, B., Xu, N., Liu, Z., Sun, Y., Zhang, Y., & Xing, P. (2021). Spheroidization Behavior of Nano-Primary Silicon Induced by Neodymium under High-Current Pulsed Electron Beam Irradiation. Coatings, 11(11), 1408. https://doi.org/10.3390/coatings11111408