Continuous Numerical Analysis of Slug Rivet Installation Process Using Parameterized Modeling Method

Abstract

:1. Introduction

2. Materials and Methods

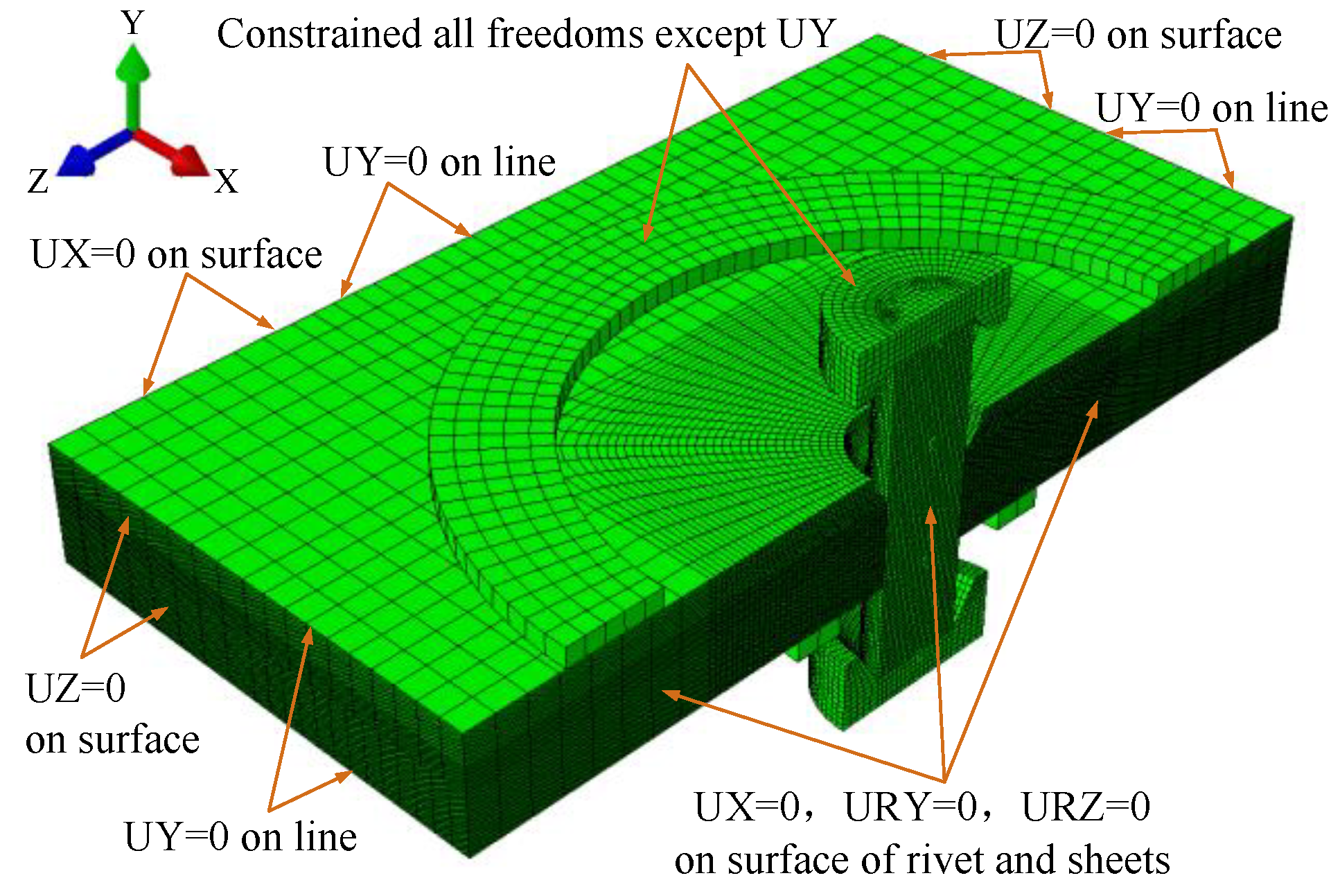

2.1. Baseline Model Establishment

2.2. Parameterized Model Establishment

3. Results

3.1. Parameter Analysis

3.2. Optimal Parameter Analysis

3.3. Verification Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, C. Survey report of aircraft automatic assembly technology and equipment application. Aeronaut. Manuf. Technol. 2011, 19, 54–55. [Google Scholar]

- Rooks, B. Automatic wing box assembly developments. Ind. Robot. Int. J. 2001, 28, 297–302. [Google Scholar] [CrossRef] [Green Version]

- Holden, R.; Haworth, P.; Kendrick, I.; Smith, A. Automated riveting cell for a320 wing sheets with improved throughput and reliability (sa2). SAE Tech. Paper 2007, 3915, 2688–3627. [Google Scholar]

- Sarh, B.; Buttrick, J.; Munk, C.; Bossi, R. Aircraft Manufacturing and Assembly; Springer Nature: Berlin/Heidelberg, Germany, 2009; pp. 893–910. [Google Scholar]

- Liu, L.X.; Li, X.N.; Wang, Z.Q.; Li, W.P. Semi-empirical research on automatic drilling and riveting process of headless rivet. J. Northwestern Polytech. Univ. 2013, 31, 77–82. [Google Scholar]

- Cheraghi, S.H. Effect of variations in the riveting process on the quality of riveted joints. Int. J. Adv. Manuf. Technol. 2007, 39, 1144–1155. [Google Scholar] [CrossRef]

- Li, Y.J. An Analysis of Riveting Process by Theoretical, Nonlinear Finite Element and Experimental Methods; Wichita State University: Wichita, KS, USA, 1998. [Google Scholar]

- Song, D.L.; Li, Y.; Luo, B.; Li, X.G. An effective mathematical modeling for and simulation analysis of flush rivet pressing force of CFRP/AI components. J. Northwestern Polytech. Univ. 2012, 30, 558–564. [Google Scholar]

- Mu, W.; Li, Y.; Zhang, K.; Cheng, H. Notice of Retraction: An effective method of studying interference-fit riveting for 2117-T4 aluminum slug rivet. In Proceedings of the 2010 International Conference on Computer and Communication Technologies in Agriculture Engineering, Chengdu, China, 12–13 June 2010; IEEE: Chengdu, China, 2010; Volume 2, pp. 303–307. [Google Scholar]

- Mu, W.Q.; Li, Y.; Zhang, K.F.; Cheng, H. Mathematical modeling for and simulation analysis of flush rivet pressing force. J. Northwestern Polytech. Univ. 2010, 28, 742–747. [Google Scholar]

- Lei, C.; Bi, Y.; Li, J.; Ke, Y. Experiment and numerical simulations of a slug rivet installation process based on different modeling methods. Int. J. Adv. Manuf. Technol. 2018, 97, 1481–1496. [Google Scholar] [CrossRef]

- Lei, C.; Bi, Y.; Li, J.; Ke, Y. Effect of riveting parameters on the quality of riveted aircraft structures with slug rivet. Adv. Mech. Eng. 2017, 9, 1–12. [Google Scholar] [CrossRef]

- Reinhall, P.G.; Ghassaei, S.; Choo, V. An analysis of rivet die design in electromagnetic riveting. J. Vib. Acoust. 1988, 110, 65–69. [Google Scholar] [CrossRef]

- Chang, Z.; Wang, Z.; Zhang, J.; Yang, Y.; Kang, Y. Investigation of riveting parameters influence on the riveted joints deformation during slug rivet installation. Syst. Des. Complex. 2016, 11. [Google Scholar] [CrossRef]

- Lei, C.; Li, J. Effect of rivet die structure on the quality of riveted aircraft structures using slug rivet. Int. J. Adv. Manuf. Technol. 2020, 107, 229–245. [Google Scholar] [CrossRef]

- Wang, Z.; Chang, Z.; Luo, Q.; Hua, S.; Zhao, H.; Kang, Y. Optimization of riveting parameters using Kriging and particle swarm optimization to improve deformation homogeneity in aircraft assembly. Adv. Mech. Eng. 2017, 9, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Shanghai Aircraft Manufacturing Company. Rivet Criterion ZPS-XXX 2010; Shanghai Aircraft Manufacturing Company: Shanghai, China, 2010. [Google Scholar]

- Yang, Y. Research on Riveting Process of Uniform and Reasonable Interference for Aircraft Thin-Walled Structure. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2013. [Google Scholar]

- Liang, K.; Jiang, L.P.; Wei, H.Y.; Chen, W.L.; Jiang, H.Y.; Xu, R.W.; Wang, Y.B.; Yu, L. Interference uniformity analysis based on the clearance between the hole and rivet. Appl. Mech. Mater. 2012, 246, 28–32. [Google Scholar] [CrossRef]

| Structure Parameter | Structure Parameter |

|---|---|

| Countersunk hole diameter, E | Countersunk hole depth, C |

| Rivet hole diameter | Fillet radius, R1 |

| Total thickness, T | Fillet radius, R2 |

| Sheet thickness | Slug rivet diameter |

| Protrusion height, PU (protrusion height out of the upper sheet) and PL (protrusion height out of the lower sheet) | Slug rivet length |

| Procedure Parameter | Procedure Parameter |

|---|---|

| Squeezing force | Symmetry of squeezing force |

| Clamping force | Symmetry of clamping force |

| Synchronism of the riveting dies | Countersunk hole structure |

| Rivet Die Type | Parameter Value Range |

|---|---|

| Type 1 | |

| Type 2 | |

| Type 3 |

| Weight Coefficient | 0.0001 | 0.001 | 0.01 | 0.1 | 1 | 10 | 100 | 1000 | 10,000 |

|---|---|---|---|---|---|---|---|---|---|

| Optimum value | 5.74 | 5.74 | 5.74 | 5.74 | 5.79 | 5.89 | 5.89 | 5.89 | 5.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, C.; Bi, Y.; Li, J. Continuous Numerical Analysis of Slug Rivet Installation Process Using Parameterized Modeling Method. Coatings 2021, 11, 189. https://doi.org/10.3390/coatings11020189

Lei C, Bi Y, Li J. Continuous Numerical Analysis of Slug Rivet Installation Process Using Parameterized Modeling Method. Coatings. 2021; 11(2):189. https://doi.org/10.3390/coatings11020189

Chicago/Turabian StyleLei, Changyi, Yunbo Bi, and Jiangxiong Li. 2021. "Continuous Numerical Analysis of Slug Rivet Installation Process Using Parameterized Modeling Method" Coatings 11, no. 2: 189. https://doi.org/10.3390/coatings11020189