Sputter Deposited Metal Layers Embedded in Composites—From Fundamentals to Applications

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

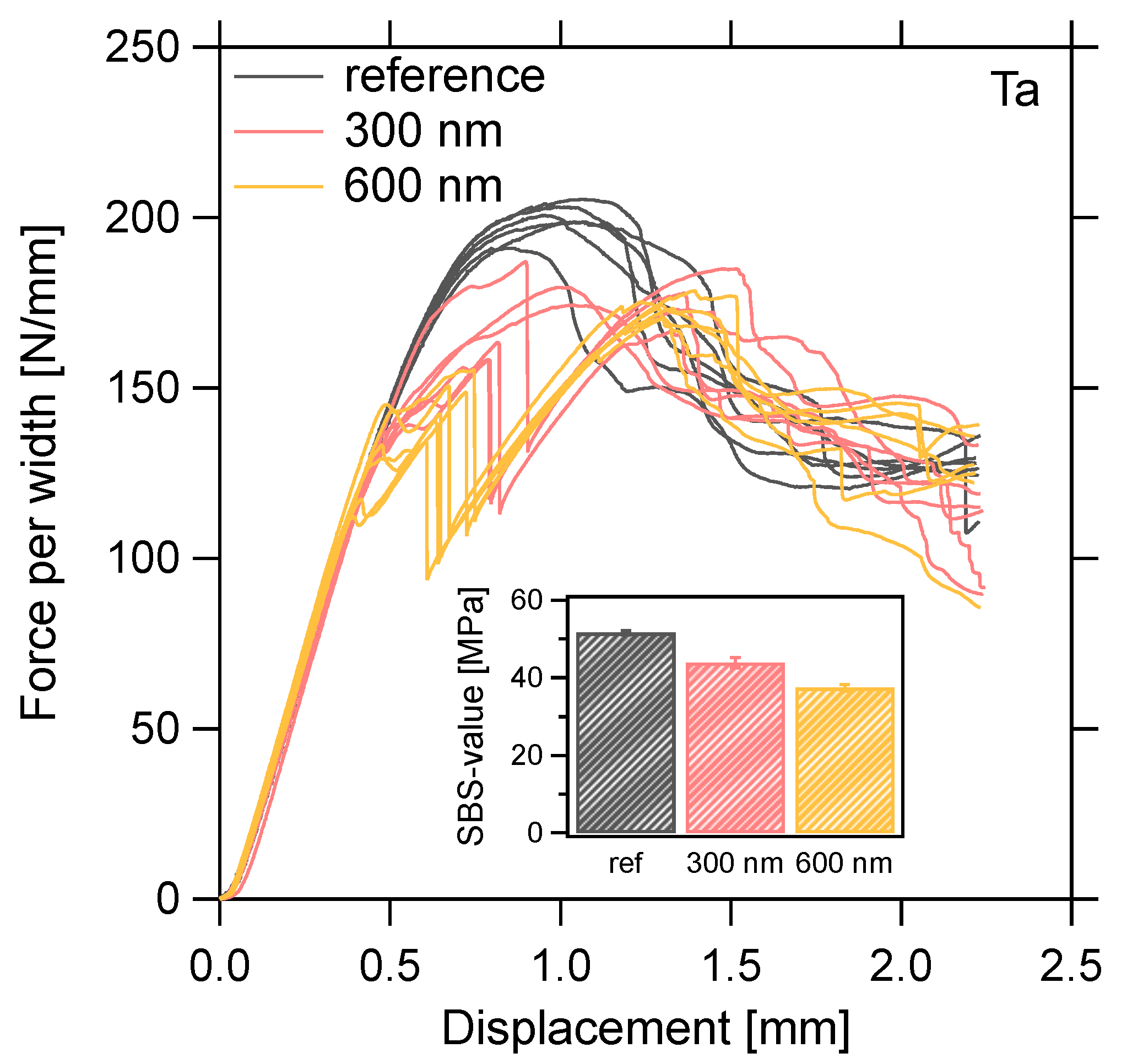

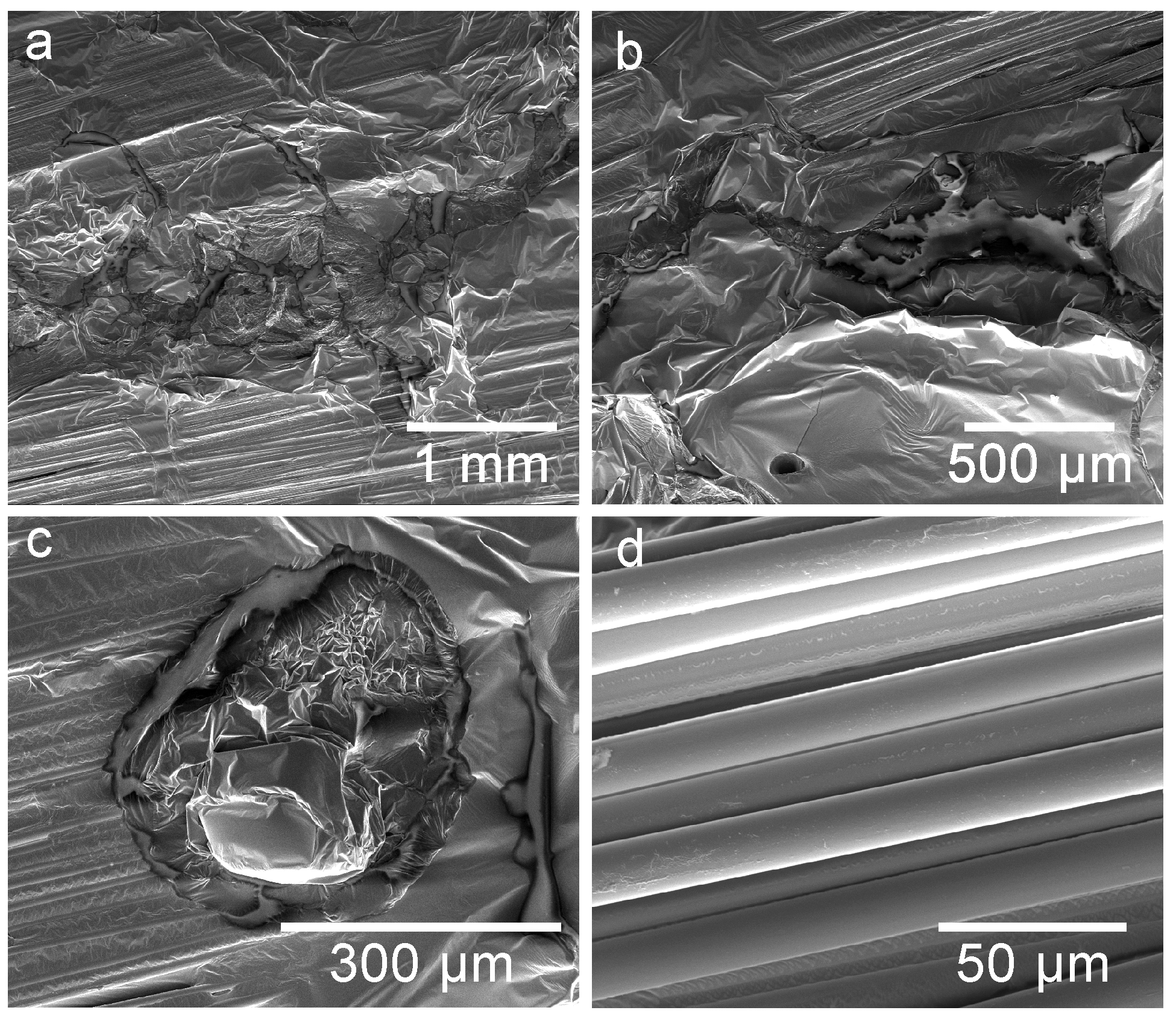

3.1. Mechanical Strength

3.2. Heat Capacity and Heat Flux Measurements

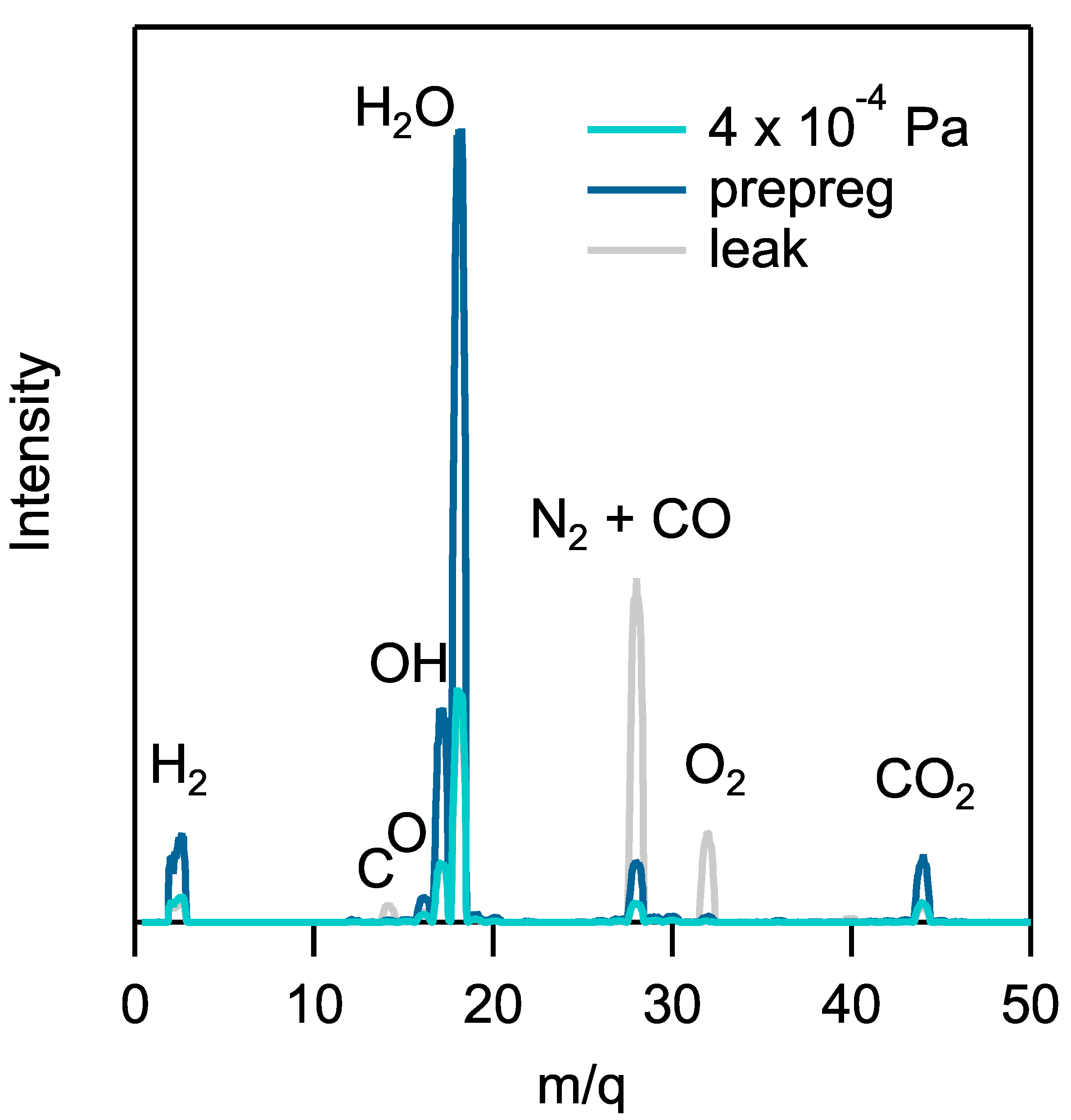

3.3. Impurities

3.4. Examples of Some Possible Applications

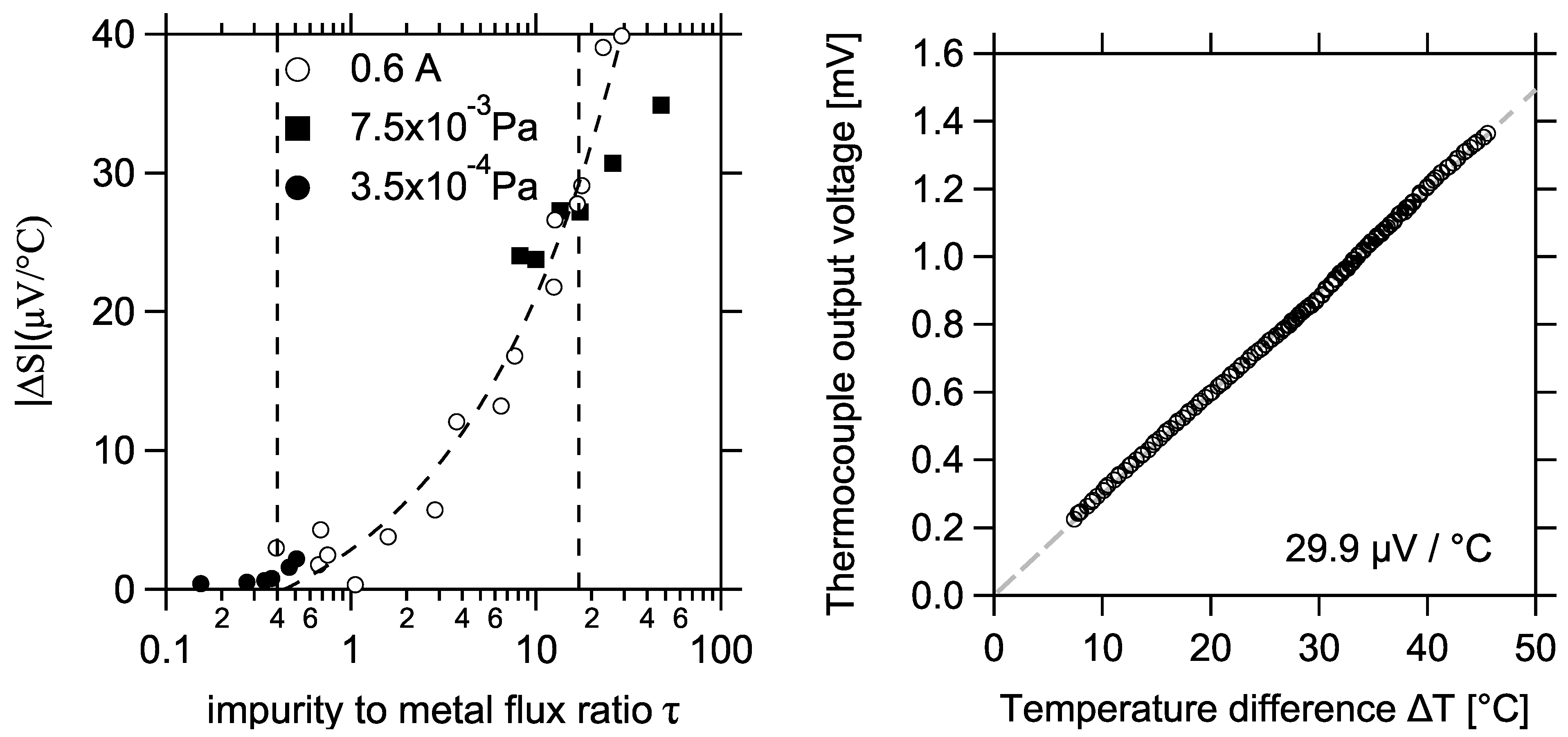

3.4.1. Single Alloy Embedded Thermocouple

3.4.2. Deicing

3.4.3. Digital Volume Correlation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gaynor, G. Boeing and the 787 Dreamliner. In Decisions; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; pp. 187–218. [Google Scholar] [CrossRef]

- Jens, B.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector: A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef] [Green Version]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-Reinforced Polymer Composites for Construction: State-of-the-Art Review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Brøndsted, P.; Lilholt, H.; Lystrup, A. Composite materials for wind power turbine blades. Annu. Rev. Mater. Res. 2005, 35, 505–538. [Google Scholar] [CrossRef]

- Griffin, D.; Zuteck, M. Scaling of composite wind turbine blades for rotors of 80 to 120 meter diameter. J. Sol. Energy Eng. 2001, 123, 310–318. [Google Scholar] [CrossRef]

- Veers, P.; Ashwill, T.; Sutherland, H.; Laird, D.; Lobitz, D.; Griffin, D.; Mandell, J.; Musial, W.; Jackson, K.; Zuteck, M. Trends in the design, manufacture and evaluation of wind turbine blades. Wind Energy 2003, 6, 245–259. [Google Scholar] [CrossRef]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain measurements of composite laminates with embedded fibre Bragg gratings: Criticism and opportunities for research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef] [Green Version]

- Zhou, G.; Sim, L.M. Damage detection and assessment in fibre reinforced composite structures with embedded fibre optic sensors: Review. Smart Mater. Struct. 2002, 11, 925. [Google Scholar] [CrossRef]

- Rumsey, M. An evaluation of sensing technologies in a wind turbine blade: Some issues, challenges and lessons learned. In Proceedings of the Industrial and Commercial Applications of Smart Structures Technologies 2011, San Diego, CA, USA, 7–8 March 2011; International Society for Optics and Photonics: Washington, DC, USA, 2011; Volume 7979. [Google Scholar] [CrossRef]

- Lammens, N.; Luyckx, G.; Paepegem, W.V.; Degrieck, J. Finite element prediction of resin pocket geometries around arbitrary inclusions in composites: Case study for an embedded optical fiber interrogator. Compos. Struct. 2016, 146, 95–107. [Google Scholar] [CrossRef]

- Missinne, J.; Teigell, B.; Lamberti, A.; Chiesura, G.; Luyckx, G.; Mattelin, M.; Van Paepegem, W.; Van Steenberge, G. Thin and flexible polymer photonic sensor foils for monitoring composite structures. Adv. Eng. Mater. 2018, 20, 1701127. [Google Scholar] [CrossRef]

- Qing, X.P.; Beard, S.J.; Kumar, A.; Li, I.; Lin, M.; Chang, F.K. Stanford Multiactuator-Receiver Transduction (SMART) Layer Technology and Its Applications. In Encyclopedia of Structural Health Monitoring; American Cancer Society: Atlanta, GA, USA, 2009; Chapter 78; pp. 1–25. [Google Scholar] [CrossRef]

- Bekas, D.; Sharif-Khodaei, Z.; Aliabadi, M. An Innovative Diagnostic Film for Structural Health Monitoring of Metallic and Composite Structures. Sensors 2018, 18, 2084. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Chiesura, G.; Vervust, T.; Bossuyt, F.; Luyckx, G.; Degrieck, J.; Vanfleteren, J. Design and fabrication of a flexible dielectric sensor system for in situ and real-time production monitoring of glass fibre reinforced composites. Sens. Actuators A Phys. 2016, 243, 103–110. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates; ASTM D2344/D2344M-16; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Cougnon, F.; Depla, D. The Seebeck Coefficient of Sputter Deposited Metallic Thin Films: The Role of Process Conditions. Coatings 2019, 9, 299. [Google Scholar] [CrossRef] [Green Version]

- Thornton, J. Substrate heating in cylindrical magnetron sputtering sources. Thin Solid Film. 1978, 54, 23–31. [Google Scholar] [CrossRef]

- Sioen, L. Assessment of Embedded Metallic Substances for the Enhancement of Micro-Computed Tomography Images of Fibre Reinforced Composites. Master’s Thesis, Ghent University, Gent, Belgium, 2019. [Google Scholar]

- Mahieu, S.; Depla, D. An in-situ monitor to measure the momentum flux during physical vapour deposition. Surf. Coatings Technol. 2010, 204, 2085–2088. [Google Scholar] [CrossRef]

- Matsunami, N.; Yamamura, Y.; Itikawa, Y.; Itoh, N.; Kazumata, Y.; Miyagawa, S.; Morita, K.; Shimizu, R.; Tawara, H. Energy dependence of the ion-induced sputtering yields of monatomic solids. At. Data Nucl. Data Tables 1984, 31, 1–80. [Google Scholar] [CrossRef]

- Yamamura, Y.; Tawara, H. Energy dependence of ion induced sputtering yields from monoatomic solids at normal incidence. At. Data Nucl. Data Tables 1996, 62, 149–253. [Google Scholar] [CrossRef]

- Möller, M.; Eckstein, W. Tridyn—A TRIM simulation code including dynamic composition changes. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1984, 2, 814–818. [Google Scholar] [CrossRef]

- Kalogiannakis, G.; Van Hemelrijck, D.; Van Assche, G. Measurements of Thermal Properties of Carbon/Epoxy and Glass/Epoxy using Modulated Temperature Differential Scanning Calorimetry. J. Compos. Mater. 2004, 38, 163–175. [Google Scholar] [CrossRef]

- Lu, N.; Suo, Z.; Vlassak, J.J. The effect of film thickness on the failure strain of polymer-supported metal films. Acta Mater. 2010, 58, 1679–1687. [Google Scholar] [CrossRef]

- Brown, R. Outgassing of epoxy resins in vacuum. Vacuum 1967, 17, 168. [Google Scholar] [CrossRef]

- Schneider, J.; Anders, A.; Hjörvarsson, B.; Petrov, I.; Macák, K.; Helmersson, U.; Sundgren, J. Hydrogen uptake in alumina thin films synthesized from an aluminum plasma stream in an oxygen ambient. Appl. Phys. Lett. 1999, 74, 200–202. [Google Scholar] [CrossRef]

- Schneider, J.; Larsson, K.; Lu, J.; Olsson, E.; Hjörvarsson, B. Role of hydrogen for the elastic properties of alumina thin films. Appl. Phys. Lett. 2002, 80, 1144–1146. [Google Scholar] [CrossRef]

- Dutta, P.; Wilman, H. Crystal growth and orientations in vacuum-condensed silver films and their systematic dependance on the residual air pressure, film thickness, rate of deposition and substrate temperature. J. Phys. D Appl. Phys. 1970, 3, 839. [Google Scholar] [CrossRef]

- Shojik, F.; Sumitomo, K.; Kinoshita, T.; Tanaka, Y.; Oura, K.; Katayama, I. Hydrogen Adsorption Effects on Thin Film Growth Mode Studied by Ion Scattering. MRS Proc. 1991, 237. [Google Scholar] [CrossRef]

- Wang, F.; Yang, C.; Liou, J.; Chen, I. Effects of Hydrogen on the Optical and Electrical Characteristics of the Sputter-Deposited Al2O3-Doped ZnO Thin Films. J. Nanomater. 2014, 2014, 857614. [Google Scholar] [CrossRef]

- Zhang, K.; Zhu, F.; Huan, C.; Wee, A. Effect of hydrogen partial pressure on optoelectronic properties of indium tin oxide thin films deposited by radio frequency magnetron sputtering method. J. Appl. Phys. 1999, 86, 974–980. [Google Scholar] [CrossRef]

- Schneider, J.; Hjörvarsson, B.; Wang, X.; Hultman, L. On the effect of hydrogen incorporation in strontium titanate layers grown by high vacuum magnetron sputtering. Appl. Phys. Lett. 1999, 75, 3476–3478. [Google Scholar] [CrossRef]

- Kakati, K.; Wilman, H. The development of oriented crystal growth during condensation of gold, silver and copper films in vacuum, and its systematic dependence on the residual gas pressure and adsorption, and the film thickness, atomic mobility and chemical reactivity. J. Phys. D Appl. Phys. 1973, 6, 1307. [Google Scholar] [CrossRef]

- Cougnon, F.; Dulmaa, A.; Dedoncker, R.; Galbadrakh, R.; Depla, D. Impurity dominated thin film growth. Appl. Phys. Lett. 2018, 112, 221903. [Google Scholar] [CrossRef] [Green Version]

- Cougnon, F.; Schramm, I.; Depla, D. On the electrical properties of sputter deposited thin films: The role of energy and impurity flux. Thin Solid Films 2019, 690, 137540. [Google Scholar] [CrossRef]

- Liu, H.; Sun, W.; Xu, S. An extremely simple thermocouple made of a single layer of metal. Adv. Mater. 2012, 24, 3275–3279. [Google Scholar] [CrossRef]

- Zhang, X.; Choi, H.; Datta, A.; Li, X. Design, fabrication and characterization of metal embedded thin film thermocouples with various film thicknesses and junction sizes. J. Micromech. Microeng. 2006, 16, 900. [Google Scholar] [CrossRef]

- Haynes, W. CRC Handbook of Chemistry and Physics, 93rd ed.; Taylor & Francis: Abingdon, UK, 2012. [Google Scholar]

- Politovich, M. Aviation meteorology and Aircraft Icing. In Encyclopedia of Atmospheric Sciences; Elsevier: Amsterdam, The Netherlands, 2015; pp. 160–165. [Google Scholar] [CrossRef]

- SAE Committee AC-9C. Air Craft Icing Technology. In SAE Aerospace Applied Thermodynamics Manual, Ice, Rain, Fog, and Frost Protection; Technical Report; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Ong, K.; Grimes, C. A resonant printed-circuit sensor for remote query monitoring of environmental parameters. Smart Mater. Struct. 2000, 9, 421. [Google Scholar] [CrossRef]

- Su, Z.; Wang, X.; Chen, Z.; Ye, L.; Wang, D. A built-in active sensor network for health monitoring of composite structures. Smart Mater. Struct. 2006, 15, 1939. [Google Scholar] [CrossRef]

- Das, N.; Khorrami, F.; Nourbakhsh, S. New integrated piezoelectric-dielectric microstrip antenna for dual wireless actuation and sensing functions. In Proceedings of the Smart Structures and Materials: Smart Electronics and MEMS, San Diego, CA, USA, 1–5 March 1998; International Society for Optics and Photonics: Washington, DC, USA, 1998; Volume 3328, pp. 133–147. [Google Scholar] [CrossRef]

- Abot, J.L.; Song, Y.; Vatsavaya, M.S.; Medikonda, S.; Kier, Z.; Jayasinghe, C.; Rooy, N.; Shanov, V.N.; Schulz, M.J. Delamination detection with carbon nanotube thread in self-sensing composite materials. Compos. Sci. Technol. 2010, 70, 1113–1119. [Google Scholar] [CrossRef]

- Sebastian, J.; Schehl, N.; Bouchard, M.; Boehle, M.; Li, L.; Lagounov, A.; Lafdi, K. Health monitoring of structural composites with embedded carbon nanotube coated glass fiber sensors. Carbon 2014, 66, 191–200. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- Schroyen, D. Application of Digital Image Correlation on the Micro-Scale of Composites. Master’s Thesis, TU Delft, Delft, The Netherlands, 2018. [Google Scholar]

- Bay, B.K.; Smith, T.S.; Fyhrie, D.P.; Saad, M. Digital volume correlation: Three-dimensional strain mapping using X-ray tomography. Exp. Mech. 1999, 39, 217–226. [Google Scholar] [CrossRef]

- Bay, B.K. Methods and applications of digital volume correlation. J. Strain Anal. Eng. Des. 2008, 43, 745–760. [Google Scholar] [CrossRef]

- Sause, M. In Situ Monitoring of Fiber-Reinforced Composites: Theory, Basic Concepts, Methods, and Applications; Springer: Berlin/Heidelberg, Germany, 2016; Volume 242. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cougnon, F.; Kersemans, M.; Van Paepegem, W.; Depla, D. Sputter Deposited Metal Layers Embedded in Composites—From Fundamentals to Applications. Coatings 2021, 11, 190. https://doi.org/10.3390/coatings11020190

Cougnon F, Kersemans M, Van Paepegem W, Depla D. Sputter Deposited Metal Layers Embedded in Composites—From Fundamentals to Applications. Coatings. 2021; 11(2):190. https://doi.org/10.3390/coatings11020190

Chicago/Turabian StyleCougnon, Florian, Mathias Kersemans, Wim Van Paepegem, and Diederik Depla. 2021. "Sputter Deposited Metal Layers Embedded in Composites—From Fundamentals to Applications" Coatings 11, no. 2: 190. https://doi.org/10.3390/coatings11020190

APA StyleCougnon, F., Kersemans, M., Van Paepegem, W., & Depla, D. (2021). Sputter Deposited Metal Layers Embedded in Composites—From Fundamentals to Applications. Coatings, 11(2), 190. https://doi.org/10.3390/coatings11020190