A Review on the Processing Technologies for Corrosion Resistant Thermoelectric Oxide Coatings

Abstract

:1. Introduction

2. Thermoelectric Oxide Coating Processing Technologies

2.1. Vapor Phase Deposition

2.2. Liquid Phase Deposition

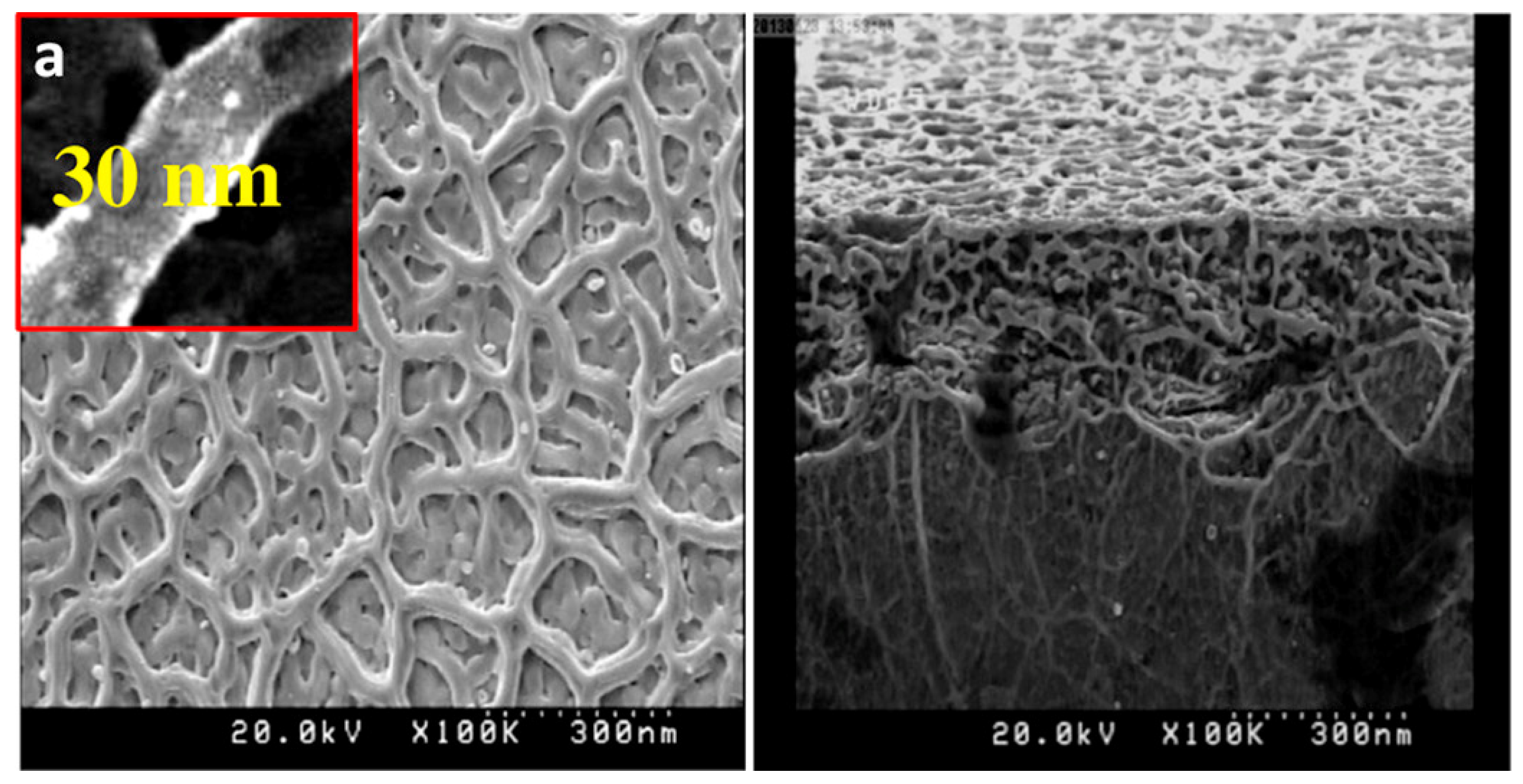

2.3. Nanocasting

2.4. Solid-State Processing

2.5. Energy Beam Techniques

3. Perspectives and Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Klochko, N.P.; Klepikova, K.S.; Khrypunova, I.V.; Zhadan, D.O.; Petrushenko, S.I.; Kopach, V.R.; Dukarov, S.V.; Sukhov, V.M.; Kirichenko, M.V.; Khrypunova, A.L. Flexible thermoelectric module based on zinc oxide thin film grown via SILAR. Curr. Appl. Phys. 2021, 21, 121–133. [Google Scholar] [CrossRef]

- Kumar, A.; Sivaprahasam, D.; Thakur, A.D. Colossal Seebeck coefficient in Aurivillius phase-perovskite oxide composite. J. Alloys Compd. 2021, 853, 157001. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, L.X.; Li, H.Q.; Li, D.; Yang, N.; Jiang, X.B.; Qiu, S.Z. Performance analysis of alkali metal thermoelectric converter and segmented thermoelectric generator hybrid system based on a comprehensive model. Appl. Thermal. Eng. 2021, 183, 116206. [Google Scholar] [CrossRef]

- Tian, X.X.; Asaadi, S.; Moria, H.; Kaood, A.; Pourhedayat, S.; Jermsittiparsert, K. Proposing tube-bundle arrangement of tubular thermoelectric module as a novel air cooler. Energy 2020, 208, 118428. [Google Scholar] [CrossRef]

- Gan, Y.X. Nanomaterials for Thermoelectric Devices, 1st ed.; Jenny Stanford Publishing: Singapore, 2018; pp. 6–8. [Google Scholar]

- Boulat, L.; Viennois, R.; Oliviero, E.; Dadras, M.; Fréty, N. Study of TaN and TaN-Ta-TaN thin films as diffusion barriers in CeFe4Sb12 skutterudite. J. Appl. Phys. 2019, 126, 125306. [Google Scholar] [CrossRef]

- Appel, O.; Zaharoni, T.; Breuer, G.; Beeri, O.; Gelbstein, Y. Thermoelectric properties of Ti0.3Zr0.35Hf0.35Ni1.005Sn Half-Heusler alloy. J. Appl. Phys. 2019, 126, 085110. [Google Scholar] [CrossRef]

- Zeier, W.G.; Schmitt, J.; Hautier, G.; Aydemir, U.; Gibbs, Z.M.; Felser, C.; Snyder, G.J. Engineering Half-Heusler thermoelectric materials using Zintl chemistry. Nat. Rev. Mater. 2016, 1, 16032. [Google Scholar] [CrossRef]

- Landmann, D.; Tang, Y.; Kunz, B.; Huber, R.; Widner, D.; Rickhaus, P.; Widmer, R.N.; Elsener, H.R.; Battaglia, C. Fabrication, characterization, and application-matched design of thermoelectric modules based on Half-Heusler FeNbSb and TiNiSn. J. Appl. Phys. 2019, 126, 085113. [Google Scholar] [CrossRef]

- Rogl, G.; Ghosh, S.; Wang, L.; Bursik, J.; Grytsiv, A.; Kerber, M.; Bauer, E.; Mallik, R.C.; Chen, X.Q.; Zehetbauer, M.; et al. Half-Heusler alloys: Enhancement of ZT after severe plastic deformation (ultra-low thermal conductivity). Acta Mater. 2020, 183, 285–300. [Google Scholar] [CrossRef]

- Gürth, M.; Rogl, G.; Romaka, V.V.; Grytsiv, A.; Bauer, E.; Rogl, P. Thermoelectric high ZT Half-Heusler alloys Ti1−x−yZrxHfyNiSn. Acta Mater. 2016, 104, 210–222. [Google Scholar] [CrossRef]

- Tavassoli, A.; Failamani, F.; Grytsiv, A.; Rogl, G.; Heinrich, P.; Müller, H.; Bauer, E.; Zehetbauer, M.; Rogl, P. On the Half-Heusler compounds Nb1−x{Ti,Zr,Hf}xFeSb: Phase relations, thermoelectric properties at low and high temperature, and mechanical properties. Acta Mater. 2017, 135, 263–276. [Google Scholar] [CrossRef]

- Shi, Y.; Sturm, C.; Kleinke, H. Chalcogenides as thermoelectric materials. J. Solid State Chem. 2019, 270, 273–279. [Google Scholar] [CrossRef]

- Gelbstein, Y.; Dashevsky, Z.; Dariel, M.P. High performance n-type PbTe-based materials for thermoelectric applications. Phys. B 2005, 363, 196–205. [Google Scholar] [CrossRef]

- Guo, Q.; Assoud, A.; Kleinke, H. Improved bulk materials with thermoelectric figure-of-merit>1: Tl10−xSnxTe6 and Tl10−xPbxTe6. Adv. Energy Mater. 2014, 4, 1400348. [Google Scholar] [CrossRef]

- Zhao, L.D.; Chang, C.; Tan, G.; Kanatzidis, M.G. SnSe: A remarkable new thermoelectric material. Energy Environ. Sci. 2016, 9, 3044–3060. [Google Scholar] [CrossRef]

- Zhao, L.D.; Lo, S.H.; Zhang, Y.S.; Sun, H.; Tan, G.H.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 2014, 508, 373–377. [Google Scholar] [CrossRef]

- Liu, H.; Shi, X.; Xu, F.; Zhang, L.; Zhang, W.; Chen, L.; Li, Q.; Uher, C.; Day, T.; Snyder, G.J. Copper ion liquid-like thermoelectrics. Nat. Mater. 2021, 11, 422–425. [Google Scholar] [CrossRef] [PubMed]

- Assoud, A.; Thomas, S.; Sutherland, B.; Zhang, H.; Tritt, T.M.; Kleinke, H. Thermoelectric properties of the new polytelluride Ba3Cu14−δTe12. Chem. Mater. 2006, 18, 3866–3872. [Google Scholar] [CrossRef]

- Shi, Y.X.; Assoud, A.; Sankar, C.R.; Kleinke, H. TlAg12Se7: A new pnp conduction switching material with extraordinarily low thermal conductivity. Chem. Mater. 2017, 29, 9565–9571. [Google Scholar] [CrossRef]

- Snedaker, M.L.; Zhang, Y.; Birkel, C.S.; Wang, H.; Day, T.; Shi, Y.; Ji, X.; Kraemer, S.; Mills, C.E.; Moosazadeh, A.; et al. Silicon-based thermoelectrics made from a boron-doped silicon dioxide nanocomposite. Chem. Mater. 2013, 25, 4867–4873. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Hu, M. Record low thermal conductivity of polycrystalline Si nanowire: Breaking the Casimir limit by severe suppression of propagons. Nano Lett. 2016, 16, 6178–6187. [Google Scholar] [CrossRef] [PubMed]

- Ferrer-Argemi, L.; Yu, Z.; Lee, J. Effects of metal silicide inclusion interface and shape on thermal transport in silicon nanocomposites. J. Appl. Phys. 2019, 126, 035106. [Google Scholar] [CrossRef]

- Nakasawa, H.; Hayashi, K.; Takamatsu, T.; Miyazaki, Y. Lattice dynamics and lattice thermal conductivity of CrSi2 calculated from first principles and the phonon Boltzmann transport equation. J. Appl. Phys. 2019, 126, 025105. [Google Scholar] [CrossRef]

- Murphy-Armando, F. Enhancement of the electronic thermoelectric properties of bulk strained silicon-germanium alloys using the scattering relaxation times from first principles calculations. J. Appl. Phys. 2019, 126, 215103. [Google Scholar] [CrossRef] [Green Version]

- Antonov, A.; Ivanov, Y.; Konstantinov, P.; Kuznetsova, V.; Novikov, S.; Ovchinnikov, A.; Pshenay-Severin, D.; Burkov, A. Thermoelectric and galvanomagnetic properties of topologically non-trivial (Co-M)Si semimetals (M = Fe, Ni) at high temperatures. J. Appl. Phys. 2019, 126, 245103. [Google Scholar] [CrossRef]

- Khalil, M.; Moll, A.; Godfroy, M.; Letrouit-Lebranchu, A.; Villeroy, B.; Alleno, E.; Viennois, R.; Beaudhuin, M. Thermoelectric properties and stability of nanostructured chromium disilicide CrSi2. J. Appl. Phys. 2019, 126, 135103. [Google Scholar] [CrossRef]

- Nonoguchi, Y.; Tani, A.; Kitano, T.; Kawai, T. Enhanced thermoelectric properties of semiconducting carbon nanotube films by UV/ozone treatment. J. Appl. Phys. 2019, 126, 135108. [Google Scholar] [CrossRef]

- Kim, G.; Kim, S.W.; Rim, H.J.; Lee, H.; Kim, J.; Roh, J.W.; Kim, B.W.; Lee, K.H.; Lee, W. Improved trade-off between thermoelectric performance and mechanical reliability of Mg2Si by hybridization of few-layered reduced graphene oxides. Script. Mater. 2019, 162, 402–407. [Google Scholar] [CrossRef]

- Tan, X.; Liu, Y.C.; Liu, R.; Zhou, Z.F.; Liu, C.; Lan, J.L.; Zhang, Q.H.; Lin, Y.H.; Nan, C.W. Synergistical enhancement of thermoelectric properties in n-type Bi2O2Se by carrier engineering and hierarchical microstructure. Adv. Energy Mater. 2019, 9, 1900354. [Google Scholar] [CrossRef]

- Kenfaui, D.; Lenoir, B.; Chateigner, D.; Ouladdiaf, B.; Gomina, M.; Noudem, J.G. Development of multilayer textured Ca3Co4O9 materials for thermoelectric generators: Influence of the anisotropy on the transport properties. J. Eur. Ceram. Soc. 2012, 32, 2405–2414. [Google Scholar] [CrossRef]

- Yin, Y.; Tudu, B.; Tiwari, A. Recent advances in oxide thermoelectric materials and modules. Vacuum 2017, 146, 356–374. [Google Scholar] [CrossRef]

- Baranovskiy, A.; Amouyal, Y. Structural stability of calcium-manganate based CaO(CaMnO3)m (m = 1, 2, 3, ∞) compounds for thermoelectric applications. J. Alloys Compd. 2016, 687, 562–569. [Google Scholar] [CrossRef]

- Tauc, J. The thermal photo-electric phenomenon in semi-conductors. Cechoslov. Fiz. Zurnal (Czechoslov. J. Phys.) 1955, 5, 528–535. [Google Scholar] [CrossRef]

- Kwok, H.B.; Bube, R.H. Thermoelectric and photothermoelectric effects in semiconductors: CdS single crystals. J. Appl. Phys. 1973, 44, 138. [Google Scholar] [CrossRef]

- Harper, J.G.; Matthews, H.E.; Bube, R.H. Photothermoelectric Effects in semiconductors: N- and p-type silicon. J. Appl. Phys. 1970, 41, 765. [Google Scholar] [CrossRef]

- Shiraishi, Y.; Tanabe, K.; Taniguchi, H.; Okazaki, R.; Terasaki, I. Interplay between quantum paraelectricity and thermoelectricity in the photo-Seebeck effect in a single crystal. J. Appl. Phys. 2019, 126, 045111. [Google Scholar] [CrossRef]

- Okazaki, R.; Horikawa, A.; Yasui, Y.; Terasaki, I. Photo-Seebeck effect in ZnO. J. Phys. Soc. Jpn. 2012, 81, 114722. [Google Scholar] [CrossRef] [Green Version]

- Horikawa, A.; Igarashi, T.; Terasaki, I.; Okazaki, R. Photo-Seebeck effect in polycrystalline ZnO. J. Appl. Phys. 2015, 118, 095101. [Google Scholar] [CrossRef]

- Tanabe, K. Influence of carrier diffusion on photo-Seebeck effect in zinc oxide. J. Appl. Phys. 2018, 124, 035108. [Google Scholar] [CrossRef]

- Suzuki, K.; Watanabe, T.; Kakemoto, H.; Irie, H. Photo- and gas-tuned, reversible thermoelectric properties and anomalous photo-thermoelectric effects of platinum-loaded tungsten trioxide. J. Appl. Phys. 2016, 119, 245109. [Google Scholar] [CrossRef]

- Azuma, C.; Kawano, T.; Kakemoto, H.; Irie, H. Photo-controllable thermoelectric properties with reversibility and photo-thermoelectric effects of tungsten trioxide accompanied by its photochromic phenomenon. J. Appl. Phys. 2014, 116, 173502. [Google Scholar] [CrossRef]

- Mondal, P.S.; Okazaki, R.; Taniguchi, H.; Terasaki, I. Photo-Seebeck effect in tetragonal PbO single crystals. J. Appl. Phys. 2013, 114, 173710. [Google Scholar] [CrossRef] [Green Version]

- Diez, J.C.; Torres, M.A.; Rasekh, S.; Constantinescu, G.; Madre, M.A.; Sotelo, A. Enhancement of Ca3Co4O9 thermoelectric properties by Cr for Co substitution. Ceram. Int. 2013, 39, 6051–6056. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Wang, J.; Wang, C.; Xia, S. Ce1−xSrxZnSbO: New thermoelectric materials formed between intermetallics and oxides. J. Alloys Compd. 2016, 688, 849–853. [Google Scholar] [CrossRef]

- Zhang, Y.; Sugo, K.; Cho, H.J.; Ohta, H. Thermoelectric phase diagram of the SrTiO3-LaTiO3 solid-solution system through a metal to Mott insulator transition. J. Appl. Phys. 2019, 126, 075104. [Google Scholar] [CrossRef]

- Bresch, S.; Mieller, B.; Schoenauer-Kamin, D.; Moos, R.; Giovanelli, F.; Rabe, T. Influence of pressure assisted sintering and reaction sintering on microstructure and thermoelectric properties of bi-doped and undoped calcium cobaltite. J. Appl. Phys. 2019, 126, 075102. [Google Scholar] [CrossRef]

- Jerič, M.; de Boor, J.; Jančar, B.; Ceh, M. An enhanced thermoelectric figure of merit for Sr(Ti0.8Nb0.2)O3 based on a Ruddlesden–Popper-polytype-induced microstructure. J. Eur. Ceram. Soc. 2016, 36, 1177–1182. [Google Scholar] [CrossRef]

- Han, J.; Sun, Q.; Li, W.; Song, Y. Microstructure and thermoelectric properties of La0.1Dy0.1SrxTiO3 ceramics. Ceram. Int. 2017, 43, 5557–5563. [Google Scholar] [CrossRef]

- Tiginyanu, I.M.; Lupan, O.; Ursaki, V.V.; Chow, L.; Enachi, M. Nanostructures of metal oxides. In Comprehensive Semiconductor Science and Technology; Bhattacharya, P., Fornari, R., Kamimura, H., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2011; Volume 3, pp. 396–479. [Google Scholar]

- Matsuo, J.; Katsumata, H.; Minami, E.; Yamada, I. O2 cluster ion-assisted deposition for tin-doped indium oxide films. Nucl. Instrum. Methods Phys. Res. Sec. B Beam Interact. Mater. At. 2000, 161–163, 952–957. [Google Scholar] [CrossRef]

- Therese, G.H.A.; Kamath, P.V. Electrochemical synthesis of metal oxides and hydroxides. Chem. Mater. 2000, 12, 1195–1204. [Google Scholar] [CrossRef]

- Esposito, S. “Traditional” sol-gel chemistry as a powerful tool for the preparation of supported metal and metal oxide catalysts. Materials 2019, 12, 668. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, H.; Ning, H.; Busbee, J.; Shen, Z.; Kiggins, C.; Hua, Y.; Eaves, J.; Davis III, J.; Shi, T.; Shao, Y.T.; et al. Electroplating lithium transition metal oxides. Sci. Adv. 2017, 3, e1602427. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.; Guo, R.; Meng, J.; Liu, X.; Wang, X.; Li, Q.; Mai, L. Facile electrospinning formation of carbon-confined metal oxide cube-in-tube nanostructures for stable lithium storage. Chem. Commun. 2017, 53, 8284–8287. [Google Scholar] [CrossRef] [PubMed]

- Tsukuma, K.; Akiyama, T.; Imai, H. Liquid phase deposition film of tin oxide. J. Non Cryst. Solids 1997, 210, 48–54. [Google Scholar] [CrossRef]

- Deng, X.; Chen, K.; Tüysüz, H. Protocol for the nanocasting method: Preparation of ordered mesoporous metal oxides. Chem. Mater. 2017, 29, 40–52. [Google Scholar] [CrossRef]

- Ozegowski, M.; Meteva, K.; Metev, S.; Sepold, G. Pulsed laser deposition of multicomponent metal and oxide films. Appl. Surf. Sci. 1999, 138–139, 68–74. [Google Scholar] [CrossRef]

- Kathalingam, A.; Shanmugam, K.; Park, H.C.; Kim, H.S. Fabrication of arrayed metal oxide structures by electrochemical local oxidation using metallic tip with electric field and humidity. J. Mater. Proc. Technol. 2018, 252, 304–312. [Google Scholar] [CrossRef]

- Hsu, M.C.; Leu, I.C.; Sun, Y.M.; Hon, M.H. Fabrication of CdS@TiO2 coaxial composite nanocables arrays by liquid-phase deposition. J. Cryst. Growth 2005, 285, 642–648. [Google Scholar] [CrossRef]

- Wu, J.M.; Wu, W.T.; Shih, H.C. Characterization of single-crystalline TiO2 nanowires grown by thermal evaporation. J. Electrochem. Soc. 2005, 152, G613. [Google Scholar] [CrossRef]

- Wang, Z.L. Functional oxide nanobelts: Materials, properties and potential applications in nanosystems and biotechnology. Annu. Rev. Phys. Chem. 2004, 55, 159–196. [Google Scholar] [CrossRef] [Green Version]

- Zhao, S.; Wang, L.; Yang, L.; Chen, Y. Synthesis and ultraviolet luminescence properties of half-wall Al2O3 nanotube arrays. J. Phys. D Appl. Phys. 2009, 42, 225106. [Google Scholar] [CrossRef]

- Li, P.G.; Lei, M.; Tang, W.H.; Guo, X.; Wang, X. Facile route to straight SnO2 nanowires and their optical properties. J. Alloys Compd. 2009, 477, 515–518. [Google Scholar] [CrossRef]

- Jiang, X.; Herricks, T.; Xia, Y. CuO nanowires can be synthesized by heating copper substrates in air. Nano Lett. 2002, 2, 1333–1338. [Google Scholar] [CrossRef]

- Xiang, X.; Cao, C.B.; Guo, Y.; Zhu, H.S. A simple method to synthesize gallium oxide nanosheets and nanobelts. Chem. Phys. Lett. 2003, 378, 660. [Google Scholar] [CrossRef]

- Cha, H.G.; Kim, C.W.; Kim, Y.H.; Jung, M.H.; Ji, E.S.; Das, B.K.; Kim, J.C.; Kang, Y.S. Preparation and characterization of α-Fe2O3 nanorod-thin film by metal-organic chemical vapor deposition. Thin Solid Film. 2009, 517, 1853–1856. [Google Scholar] [CrossRef]

- Basharat, S.; Carmalt, C.J.; Barnett, S.A.; Tocher, D.A.; Davies, H.O. Aerosol assisted chemical vapor deposition of In2O3 films from Me3In and donor functionalized alcohols. Inorg. Chem. 2007, 46, 9473–9480. [Google Scholar] [CrossRef]

- Terasako, T.; Ohmae, K.; Yamane, M.; Shirakata, S. Carrier transport in undoped CdO films grown by atmospheric-pressure chemical vapor deposition. Thin Solid Film. 2014, 572, 20–27. [Google Scholar] [CrossRef]

- Stetsovych, V.; Pagliuca, F.; Dvořák, F.; Duchoň, T.; Vorokhta, M.; Aulická, M.; Lachnitt, J.; Schernich, S.; Matolínová, I.; Veltruská, K.; et al. Epitaxial cubic Ce2O3 films via Ce-CeO2 interfacial reaction. J. Phys. Chem. Lett. 2013, 4, 866–871. [Google Scholar] [CrossRef]

- Ahmoum, H.; Li, G.J.; Belakry, S.; Boughrara, M.; Suait, M.S.; Kerouad, M.; Wang, Q. Structural, morphological and transport properties of Ni doped ZnO thin films deposited by thermal co-evaporation method. Mater. Sci. Semicond. Proc. 2021, 123, 105530. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.; Porteiro, J.; Míguez, J.; Pinto, G. Sputtering physical vapour deposition (PVD) coatings: A critical review on process improvement and market trend demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef] [Green Version]

- Perednis, D.; Gauckler, L.J. Thin film deposition using spray pyrolysis. J. Electroceram. 2005, 14, 103–111. [Google Scholar] [CrossRef]

- Arca, E.; Fleischer, K.; Shvets, I.V. Influence of the precursors and chemical composition of the solution on the properties of ZnO thin films grown by spray pyrolysis. J. Phys. Chem. C 2009, 113, 21074–21081. [Google Scholar] [CrossRef]

- Hateef, A.A. Effect of the thickness on electrical properties of TiO2 thin films, prepared by thermal chemical spray pyrolysis deposition. Int. J. Innov. Res. Sci. Eng. Technol. (Irjesti) 2012, 1, 175–179. [Google Scholar]

- Andronic, L.; Manolache, S.; Duta, A. TiO2 thin films prepared by spray pyrolysis deposition (SPD) and their photocatalytic activities. J. Optoelectron. Adv. Mater. 2007, 9, 1403–1406. [Google Scholar]

- Boyadzhiev, S.; Georgieva, V.; Rassovska, M. Characterization of reactive sputtered TiO2 thin films for gas sensor applications. J. Phys. Conf. Ser. 2010, 253, 012040. [Google Scholar] [CrossRef]

- Hussian, H.A.R.A.; Hassan, M.A.M.; Agool, I.R. Synthesis of titanium dioxide (TiO2) nanofiber and nanotube using different chemical method. Optik 2016, 127, 2996–2999. [Google Scholar] [CrossRef]

- Ennaceri, H.; Boujnah, M.; Taleb, A.; Khaldoun, A.; Sáez-Araoz, R.; Ennaoui, A.; Kenz, A.E.; Benyoussef, A. Thickness effect on the optical properties of TiO2-anatase thin films prepared by ultrasonic spray pyrolysis: Experimental and ab initio study. Int. J. Hydrog. Energy 2017, 42, 19467–19480. [Google Scholar] [CrossRef]

- Oja, I.; Mere, A.; Krunks, M.; Solterbeck, C.H.; Es-Souni, M. Properties of TiO2 films prepared by the spray pyrolysis method. In Functional Nanomaterials for Optoelectronics and Other Applications; Lojkowski, W., Blizzard, J.R., Eds.; Solid State Phenom; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2004; Volume 99–100, pp. 259–264. [Google Scholar] [CrossRef]

- Castaneda, L.; Alonso, J.C.; Ortiz, A.; Andrade, E.; Saniger, J.M.; Banuelos, J.G. Spray pyrolysis deposition and characterization of titanium oxide thin films. Mater. Chem. Phys. 2003, 77, 938–944. [Google Scholar] [CrossRef]

- Vautey, C.; Burgos, M.; Langlet, M. Aerosol-gel deposition and low temperature heat-treatment of SiO2 layers. Thin Solid Film. 1999, 347, 184–194. [Google Scholar] [CrossRef]

- Djaoued, Y.; Taj, R.; Brüning, R.; Badilescu, S.; Ashrit, P.V.; Bader, G.; Vo-Van, T. Study of the phase transition and the thermal nitridation of nanocrystalline sol–gel titania films. J. Non Cryst. Solids 2002, 297, 55–66. [Google Scholar] [CrossRef]

- Burgos, M.; Langlet, M. The sol-gel transformation of TIPT coatings: A FTIR study. Thin Solid Film. 1999, 349, 19–23. [Google Scholar] [CrossRef]

- Alam, M.J.; Cameron, D.C. Preparation and characterization of TiO2 thin films by sol-gel method. J. Sol Gel Sci. Technol. 2002, 25, 137–145. [Google Scholar] [CrossRef]

- Yao, T.; Uchimoto, Y.; Sugiyama, T.; Nagai, Y. Synthesis of (La, Sr)MeO3 (Me = Cr, Mn, Fe, Co) solid solutions from aqueous solutions. Solid State Ion. 2000, 135, 359–364. [Google Scholar] [CrossRef]

- Deki, S.; Iizuka, S.; Akamatsu, K.; Mizuhata, M.; Kajinami, A. Novel fabrication method for Si1−xTixO2 thin films with graded composition profiles by liquid phase deposition. J. Mater. Chem. 2001, 11, 984–986. [Google Scholar] [CrossRef]

- Koumoto, K.; Seo, S.; Sugiyama, T.; Seo, W.S.; Dressick, W.J. Micropatterning of titanium dioxide on self-assembled monolayers using a liquid-phase deposition process. Chem. Mater. 1999, 11, 2305–2309. [Google Scholar] [CrossRef]

- Deki, S.; Aoi, Y.; Asaoka, Y.; Kajinami, A.; Mizuhata, M. Preparation and characterization of Au-dispersed TiO2 thin films by a liquid-phase deposition method. J. Mater. Chem. 1996, 7, 733–736. [Google Scholar] [CrossRef]

- Gao, Y.; Masuda, Y.; Yonezawa, T.; Koumoto, K. Preparation of SrTiO3 thin films by the liquid phase deposition method. Mater. Sci. Eng. B 2003, 99, 290–293. [Google Scholar] [CrossRef]

- Su, L.; Gan, Y.X.; Zhang, L. Thermoelectricity of nanocomposites containing TiO2-CoO coaxial nanocables. Script. Mater. 2011, 64, 745–748. [Google Scholar] [CrossRef]

- Chen, L.L.; Zhang, Z.Y.; Qi, N.; Zhou, B.; Deng, S.P.; Chen, Z.Q.; Wu, Y.C.; Tang, X.F. Giant reduction in thermal conductivity of Co3O4 with ordered mesopore structures. Microporous Mesoporous Mater. 2020, 296, 109969. [Google Scholar] [CrossRef]

- Zhou, B.; Li, C.Y.; Qi, N.; Jiang, M.; Wang, B.; Chen, Z.Q. Pore structure of mesoporous silica (KIT-6) synthesized at different temperatures using positron as a nondestructive probe. Appl. Surf. Sci. 2018, 450, 31–37. [Google Scholar] [CrossRef]

- Sun, S.; Gao, Q.; Wang, H.; Zhu, J.; Guo, H. Influence of textural parameters on the catalytic behavior for CO oxidation over ordered mesoporous Co3O4. Appl. Catal. B Environ. 2010, 97, 284–291. [Google Scholar] [CrossRef]

- Jiang, D.; Ekren, D.; Azough, F.; Day, S.J.; Chen, K.; Mahajan, A.; Kepaptsoglou, D.M.; Ramasse, Q.M.; Reece, M.J.; Freer, R. The structure and thermoelectric properties of tungsten bronze Ba6Ti2Nb8O30. J. Appl. Phys. 2019, 126, 125115. [Google Scholar] [CrossRef] [Green Version]

- Presečnik, M.; Bernik, S. Microstructural and thermoelectric properties of WO3-doped Ca3Co4O9 ceramics. Ceram. Int. 2016, 42, 16103–16108. [Google Scholar] [CrossRef]

- Kahraman, F.; Madre, M.A.; Rasekh, S.; Salvador, C.; Bosque, P.; Torres, M.A.; Diez, J.C.; Sotelo, A. Enhancement of mechanical and thermoelectric properties of Ca3Co4O9 by Ag addition. J. Eur. Ceram. Soc. 2015, 35, 3835–3841. [Google Scholar] [CrossRef] [Green Version]

- Demirel, S.; Altin, E.; Oz, E.; Altin, S.; Bayri, A. An enhancement ZT and spin state transition of Ca3Co4O9 with Pb doping. J. Alloys Compd. 2015, 627, 430–437. [Google Scholar] [CrossRef]

- Yu, J.; Li, T.; Sun, Q. Single-layer BiOBr: An effective p-type 2D thermoelectric material. J. Appl. Phys. 2019, 125, 205111. [Google Scholar] [CrossRef]

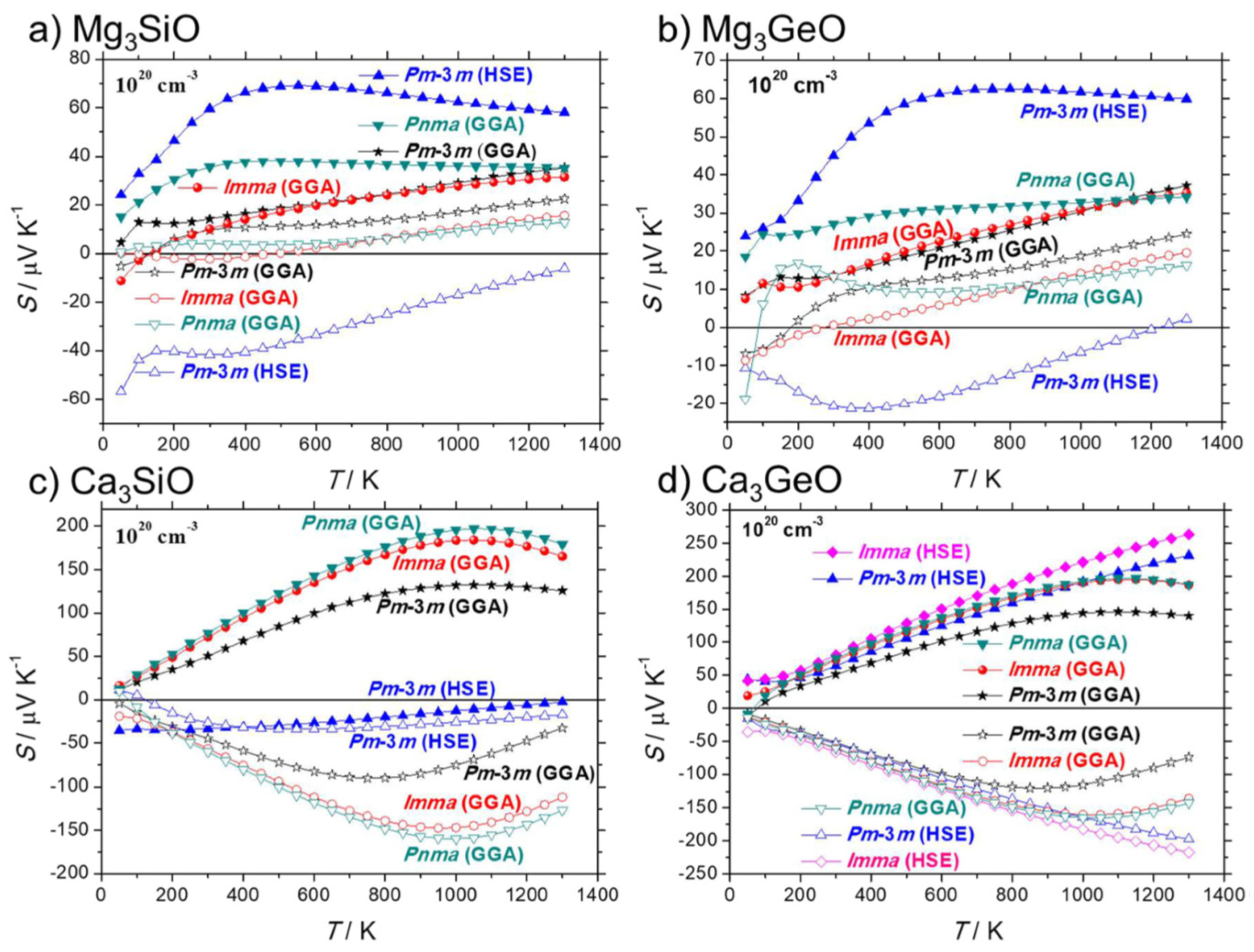

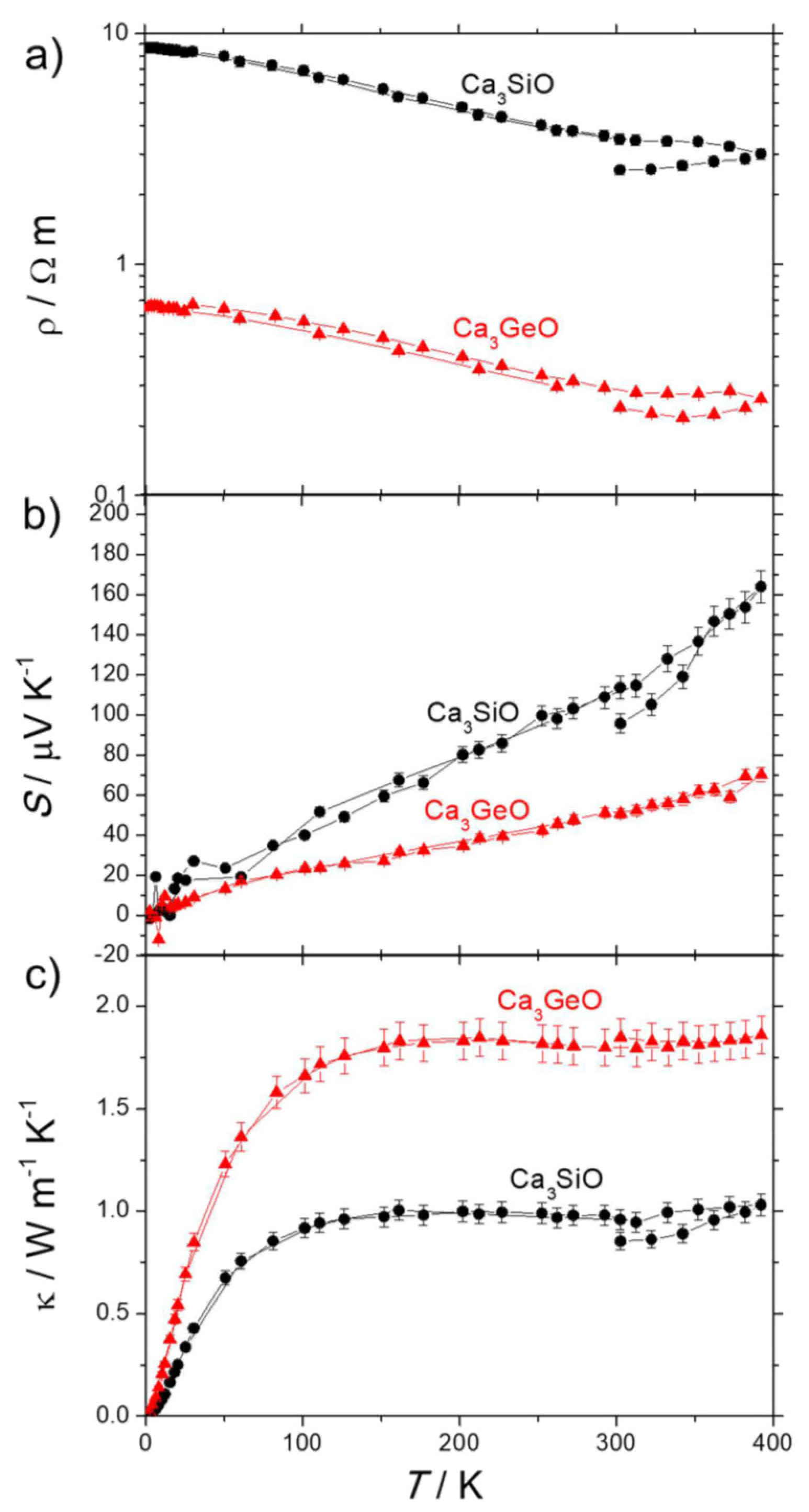

- Pöhls, J.H.; Mar, A. Thermoelectric properties of inverse perovskites A3TtO (A = Mg, Ca; Tt = Si, Ge): Computational and experimental investigations. J. Appl. Phys. 2019, 126, 025110. [Google Scholar] [CrossRef]

- Madre, M.A.; Rasekh, S.; Diez, J.C.; Sotelo, A. New solution method to produce high performance thermoelectric ceramics: A case study of Bi-Sr-Co-O. Mater. Lett. 2010, 64, 2566–2568. [Google Scholar] [CrossRef] [Green Version]

- Sotelo, A.; Rasekh, S.; Madre, M.A.; Guilmeau, E.; Marinel, S.; Diez, J.C. Solution-based synthesis routes to thermoelectric Bi2Ca2Co1.7Ox. J. Eur. Ceram. Soc. 2011, 31, 1763–1769. [Google Scholar] [CrossRef] [Green Version]

- Griesser, A.; Kraus, T.; Klein, O.; Karl, H. Low-resistance electrical contact between epitaxially grown thermoelectric oxide material (Ca2CoO3)(0.62)CoO2 and iridium. Thin Solid Film. 2021, 717, 138420. [Google Scholar] [CrossRef]

- Jones, J.G.; Boeckl, J.J.; Smith, S.R.; Landis, G.R.; Murphy, N.R.; Hu, Z.Q.; Bowers, C.T.; Stutz, C.E. Al2O3-BaTiO3 nanolaminates fabricated by multistationary target pulsed laser deposition with in situ ellipsometry. J. Nanophotonics 2017, 11, 043506. [Google Scholar] [CrossRef]

- Gutierrez-Llorente, A.; Iglesias, L.; Rodriguez-Gonzalez, B.; Rivadulla, F. Epitaxial stabilization of pulsed laser deposited Srn+1IrnO3n+1 thin films: Entangled effect of growth dynamics and strain. APL Mater. 2018, 6, 091101. [Google Scholar] [CrossRef] [Green Version]

- Kulik, P.; Yu, C.J.; Sokolov, A.; Liang, W.T.; Harris, V.G. BaFe12O19 magnetoplumbite films grown on SiO2/Si substrates for widescale magnetic film semiconductor systems integration. Scr. Mater. 2020, 188, 190–194. [Google Scholar] [CrossRef]

- Xiao, T.T.; Yang, Q.; Yu, J.; Xiong, Z.W.; Wu, W.D. Annealing condition effects on the structural properties of FePt nanoparticles embedded in MgO via pulsed laser deposition. Nanomaterials 2021, 11, 131. [Google Scholar] [CrossRef] [PubMed]

- Cesaria, M.; Lorusso, A.; Caricato, A.P.; Finocchiaro, P.; Amaducci, S.; Martino, M.; Aziz, M.R.; Calcagnile, L.; Perrone, A.; Quarta, G. B-10-based films grown by pulsed laser deposition for neutron conversion applications. Appl. Phys. A Mater. Sci. Proc. 2020, 126, 404. [Google Scholar] [CrossRef]

- Bhogra, A.; Masarrat, A.; Meena, R.; Hasina, D.; Bala, M.; Dong, C.L.; Chen, C.L.; Kumar, T.A.; Kandasami, A. Tuning the electrical and thermoelectric properties of N ion implanted SrTiO3 thin films and their conduction mechanisms. Sci. Rep. 2019, 9, 14486. [Google Scholar] [CrossRef] [PubMed]

- Bhogra, A.; Masarrat, A.; Hasina, D.; Meena, R.; Umapathy, G.R.; Kumar, A.; Som, T.; Dong, C.L.; Chen, C.L.; Kandasami, A. Significant role of substrate temperature on the morphology, electronic structure and thermoelectric properties of SrTiO3 films deposited by pulsed laser deposition. Surf. Coat. Technol. 2021, 407, 126740. [Google Scholar] [CrossRef]

- Christopher, B.; Rao, A.; Deka, U.; Prasad, K.S.; Okram, G.S.; Sanjeev, G.; Petwal, V.C.; Verma, V.P.; Dwivedi, J. Electrical, thermal and magnetic studies on 7.5 MeV electron beam irradiated PrCoO3 polycrystalline samples. Phys. B Condens. Matter 2018, 540, 26–32. [Google Scholar] [CrossRef]

- Kennedy, J.; Murmu, P.P.; Leveneur, J.; Williams, G.V.W.; Moody, R.L.; Maity, T.; Chong, S.V. Enhanced power factor and increased conductivity of aluminum doped zinc oxide thin films for thermoelectric applications. J. Nanosci. Nanotechnol. 2018, 18, 1384–1387. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, P.; Yu, K.Q.; Zhao, X.L.; Ding, G.F. ITO film prepared by ion beam sputtering and its application in high-temperature thermocouple. Vacuum 2017, 146, 31–34. [Google Scholar] [CrossRef]

- Zhu, C.H.; Li, Z.Z.; An, H.P.; Tang, G.D.; Hou, D.L. Enhancing the thermoelectric properties of Ca3Co4O9 thin films by the addition of a nanoscale NbNx second phase. J. Electron. Mater. 2014, 43, 3666–3671. [Google Scholar] [CrossRef]

- Panomsuwan, G.; Takai, O.; Saito, N. Fabrication and characterization of epitaxial SrTiO3/Nb-doped SrTiO3 superlattices by double ECR ion beam sputter deposition. Vacuum 2013, 89, 35–39. [Google Scholar] [CrossRef]

- Waller, G.; Stein, A.; Abiade, J.T. Nanofabrication of doped, complex oxides. J. Vac. Sci. Technol. B 2012, 30, 011804. [Google Scholar] [CrossRef]

- Beke, S. A review of the growth of V2O5 films from 1885 to 2010. Thin Solid Film 2011, 519, 1761–1771. [Google Scholar] [CrossRef]

- Ramana, C.V.; Hussain, O.M.; Naidu, B.S.; Reddy, P.J. Influence of substrate temperature on the composition and structural properties of electron beam evaporated V2O5 thin films. Vacuum 1997, 48, 431–434. [Google Scholar] [CrossRef]

- Ramana, C.V.; Hussain, O.M.; Uthanna, S.; Naidu, B.S. Influence of oxygen partial pressure on the optical properties of electron beam evaporated vanadium pentoxide thin films. Opt. Mater. 1998, 10, 101–107. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, P.; Kulkarni, N.; Kaur, D. Structural and optical studies of nanocrystalline V2O5 thin films. Thin Solid Film 2008, 516, 912–918. [Google Scholar] [CrossRef]

- Gan, Y.X.; Gan, J.B. Measuring the electrical and photonic properties of cobalt oxide-containing composite carbon fibers. J. Compos. Sci. 2020, 4, 156. [Google Scholar] [CrossRef]

| Temperature | TiO2 (µV/K) | CoO | TiO2 + Ag | TiO2 + Ag + CoO |

|---|---|---|---|---|

| ΔV/ΔT@40 °C | −220 | −93.33 | −393.33 | −300 |

| ΔV/ΔT@45 °C | −210 | −90 | −320 | −255 |

| ΔV/ΔT@50 °C | −172 | −68 | −296 | −208 |

| ΔV/ΔT@55 °C | −153.33 | −80 | −316.67 | −200 |

| ΔV/ΔT@60 °C | −125.71 | −71.43 | −274.29 | −162.86 |

| ΔV/ΔT@70 °C | −106.67 | −66.67 | −266.67 | −166.67 |

| ΔV/ΔT@80 °C | −98.18 | −60 | −245.45 | −129.09 |

| ΔV/ΔT@90 °C | −101.54 | −60 | −27.69 | −113.85 |

| ΔV/ΔT@110 °C | −78.82 | −56.47 | −207.06 | −108.24 |

| ΔV/ΔT@130 °C | −90.48 | −34.29 | −153.33 | −107.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, Y.X. A Review on the Processing Technologies for Corrosion Resistant Thermoelectric Oxide Coatings. Coatings 2021, 11, 284. https://doi.org/10.3390/coatings11030284

Gan YX. A Review on the Processing Technologies for Corrosion Resistant Thermoelectric Oxide Coatings. Coatings. 2021; 11(3):284. https://doi.org/10.3390/coatings11030284

Chicago/Turabian StyleGan, Yong X. 2021. "A Review on the Processing Technologies for Corrosion Resistant Thermoelectric Oxide Coatings" Coatings 11, no. 3: 284. https://doi.org/10.3390/coatings11030284

APA StyleGan, Y. X. (2021). A Review on the Processing Technologies for Corrosion Resistant Thermoelectric Oxide Coatings. Coatings, 11(3), 284. https://doi.org/10.3390/coatings11030284