Evolution of High-Quality Homoepitaxial CVD Diamond Films Induced by Methane Concentration

Abstract

:1. Introduction

2. Materials and Methods

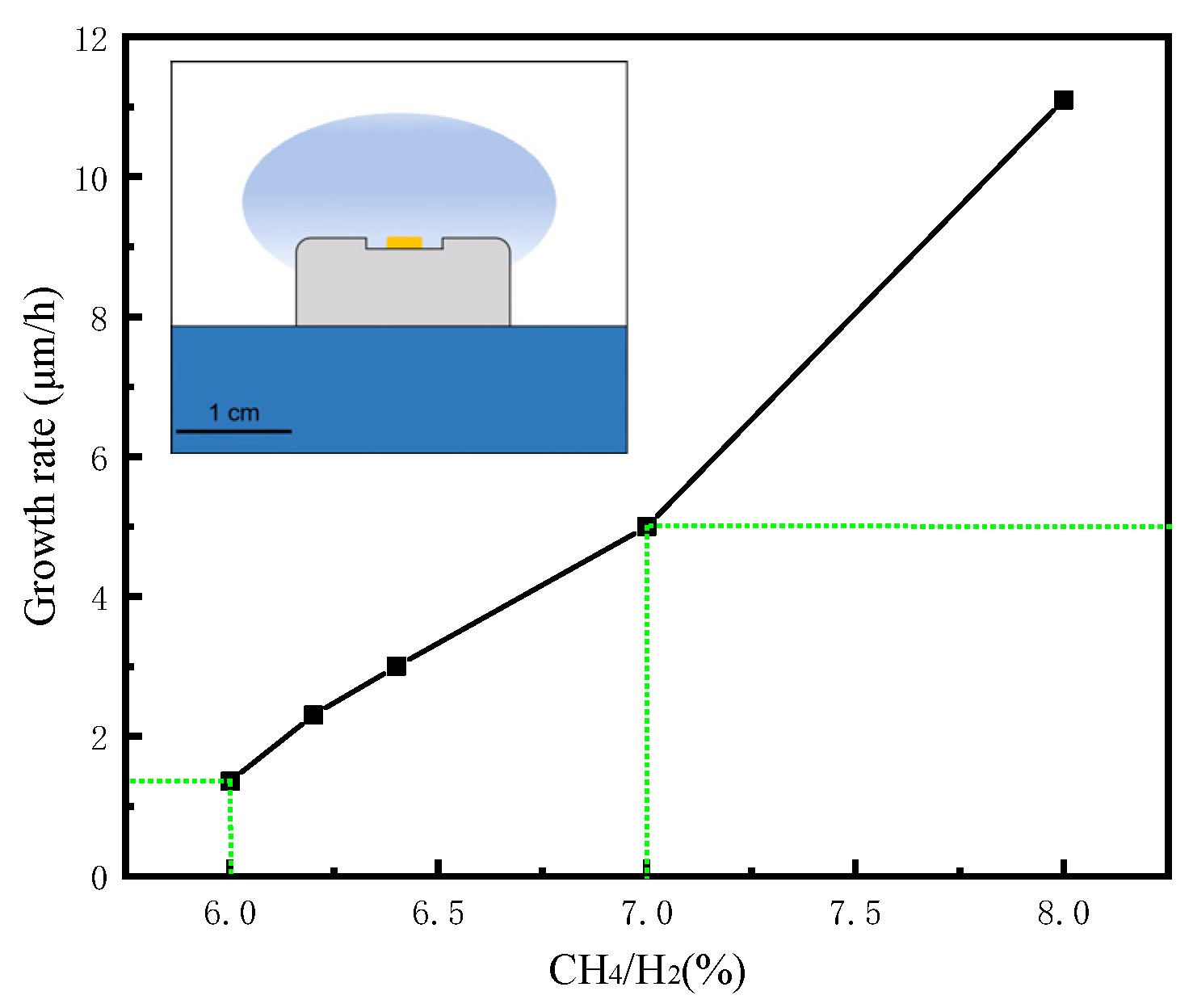

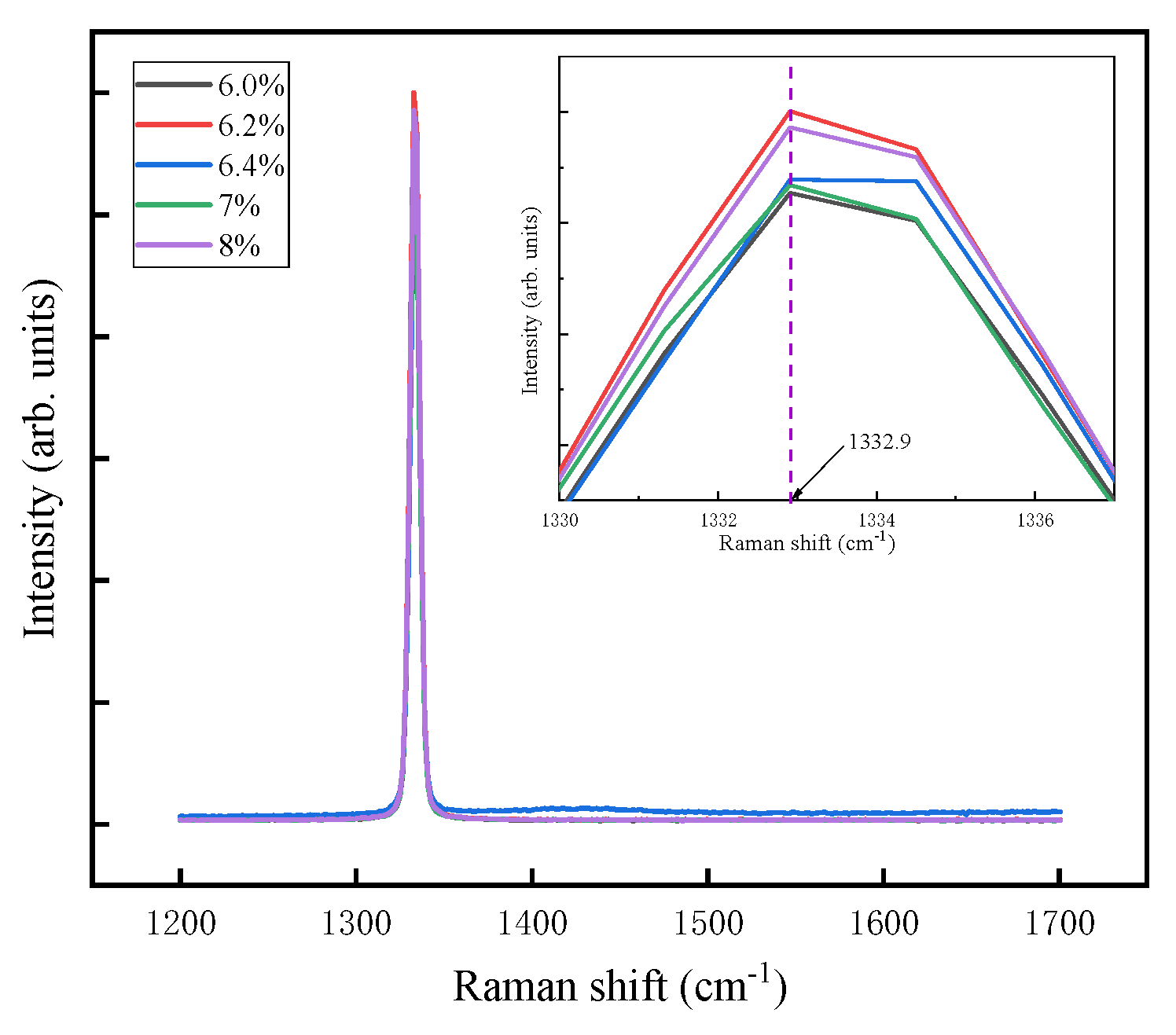

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gajewski, W.; Achatz, P.; Williams, O.A.; Haenen, K.; Bustarret, E.; Stutzmann, M.; Garrido, J. Electronic and optical properties of boron-doped nanocrystalline diamond films. Phys. Rev. B 2009, 79, 045206. [Google Scholar] [CrossRef] [Green Version]

- Angus, J.C.; Hayman, C.C. Low-Pressure, metastable growth of diamond and diamondlike phases. Science 1988, 241, 913–921. [Google Scholar] [CrossRef] [PubMed]

- Kawarada, H.; Yamada, T.; Xu, D. Diamond MOSFETs using 2D hole gas with 1700V breakdown voltage. In Proceedings of the 2016 28th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Prague, Czech Republic, 12–16 June 2016. [Google Scholar]

- Koizumi, S.; Watanabe, K.; Hasegawa, M.; Kanda, H. Ultraviolet emission from a diamond pn junction. Science 2001, 292, 1899–1901. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.W.; Liao, M.Y.; Imura, M.; Matsumoto, T.; Shibata, N.; Ikuhara, Y.; Koide, Y. Control of normally on/off characteristics in hydrogenated diamond metal-insulator-semiconductor field-effect transistors. J. Appl. Phys. 2015, 118, 115704. [Google Scholar] [CrossRef]

- Liu, X.; Lu, P.; Wang, H.; Ren, Y.; Tan, X.; Sun, S.; Jia, H. Morphology and structure of Ti-doped diamond films prepared by microwave plasma chemical vapor deposition. Appl. Surf. Sci. 2018, 442, 529–536. [Google Scholar] [CrossRef]

- Zhang, T.; Zou, Y. The effect of deposition parameters on the growth rate of microcrystalline diamond powders synthesized by HFCVD method. Coatings 2017, 7, 95. [Google Scholar] [CrossRef] [Green Version]

- Takeuchi, D.; Watanabe, H.; Yamanaka, S.; Okushi, H.; Kajimura, K. Defects in device grade homoepitaxial diamond thin films grown with ultra-low CH4/H2 conditions by microwave-plasma chemical vapor deposition. Phys. Status Solidi (a) 1999, 174, 101–115. [Google Scholar] [CrossRef]

- Kumar, A.; Topkar, A.; Das, D. Prototyping and performance study of a single crystal diamond detector for operation at high temperatures. Nucl. Instrum. Meth. A 2017, 858, 12–17. [Google Scholar] [CrossRef]

- Su, K.; He, Q.; Zhang, J.; Ren, Z.; Liu, L.; Zhang, J.; Ouyang, X.; Hao, Y. Device performance of chemical vapor deposition monocrystal diamond radiation detectors correlated with the bulk diamond properties. J. Phys. D Appl. Phys. 2021, 54, 145105. [Google Scholar] [CrossRef]

- Mildren, R.P.; Sabella, A.; Kitzler, O.; Spence, D.J.; McKay, A.M. Diamond raman laser design and performance. Opt. Eng. Diam. 2013, 239–276. [Google Scholar] [CrossRef]

- Wang, Y.-F.; Wang, W.; Wei, J.; Jiao, B.; Xu, D.; Chang, X.; Abbasi, H.N.; Song, W.; Chen, G.; Wang, H.-X. Electrochemical route to bio-compatible fluorine-terminated diamond surface. Carbon 2021, 176, 83–87. [Google Scholar] [CrossRef]

- Shimaoka, T.; Kaneko, J.H.; Tsubota, M.; Shimmyo, H.; Watanabe, H.; Chayahara, A.; Umezawa, H.; Shikata, S.-I. High-performance diamond radiation detectors produced by lift-off method. EPL Europhys. Lett. 2016, 113, 62001. [Google Scholar] [CrossRef]

- Sedov, V.; Martyanov, A.; Khomich, A.; Savin, S.; Zavedeev, E.; Ralchenko, V. Deposition of diamond films on Si by microwave plasma CVD in varied CH4-H2 mixtures: Reverse nanocrystalline-to-microcrystalline structure transition at very high methane concentrations. Diam. Relat. Mater. 2020, 109, 108072. [Google Scholar] [CrossRef]

- Ding, X.F.; Sun, X.; Wang, W.J.; Zhang, H.M.; Na Gao, H. Effect of methane concentration on the performance of diamond films prepared by MPCVD. Adv. Mater. Res. 2014, 1053, 402–406. [Google Scholar] [CrossRef]

- Li, W.-N.; Ding, Y.-S.; Suib, S.L.; DiCarlo, J.F.; Galasso, F.S. Controlling the growth of CVD carbon from methane on transition metal substrates. Surf. Coat. Technol. 2005, 190, 366–371. [Google Scholar] [CrossRef]

- Bushuev, E.; Yurov, V.; Bolshakov, A.; Ralchenko, V.; Khomich, A.; Antonova, I.; Ashkinazi, E.; Shershulin, V.; Pashinin, V.; Konov, V. Express in situ measurement of epitaxial CVD diamond film growth kinetics. Diam. Relat. Mater. 2017, 72, 61–70. [Google Scholar] [CrossRef]

- Cuenca, J.A.; Sankaran, K.J.; Pobedinskas, P.; Panda, K.; Lin, I.-N.; Porch, A.; Haenen, K.; Williams, O.A. Microwave cavity perturbation of nitrogen doped nanocrystalline diamond films. Carbon 2019, 145, 740–750. [Google Scholar] [CrossRef]

- Sutcu, L.F.; Chu, C.J.; Thompson, M.S.; Hauge, R.H.; Margrave, J.L.; D’Evelyn, M.P. Atomic force microscopy of (100), (110), and (111) homoepitaxial diamond films. J. Appl. Phys. 1992, 71, 5930. [Google Scholar] [CrossRef] [Green Version]

- Findeling-Dufour, C.; Vignes, A.; Gicquel, A. MWPACVD diamond homoepitaxial growth: Role of the plasma and the substrate parameters. Diam. Relat. Mater. 1995, 4, 429–434. [Google Scholar] [CrossRef]

- Nad, S.; Asmussen, J. Analyses of single crystal diamond substrates grown in a pocket substrate holder via MPACVD. Diam. Relat. Mater. 2016, 66, 36–46. [Google Scholar] [CrossRef]

- Wu, G.; Chen, M.-H.; Liao, J. The influence of recess depth and crystallographic orientation of seed sides on homoepitaxial growth of CVD single crystal diamonds. Diam. Relat. Mater. 2016, 65, 144–151. [Google Scholar] [CrossRef]

- Tang, C.J.; Fernandes, A.J.S.; Jiang, X.F.; Pinto, J.L.; Ye, H. Impact of high microwave power on hydrogen impurity trapping in nanocrystalline diamond films grown with simultaneous nitrogen and oxygen addition into methane/hydrogen plasma. J. Cryst. Growth 2016, 434, 36–41. [Google Scholar] [CrossRef]

- Teraji, T.; Mitani, S.; Ito, T. High rate growth and luminescence properties of high-quality homoepitaxial diamond (100) films. Phys. Status Solidi (a) 2003, 198, 395–406. [Google Scholar] [CrossRef]

- Ajeel, M.A.; Mahdi, R.I.; Aroua, M.K.T.; Majid, W.A. Preparation and characterization of electrode from annealed nano-diamond particles with boric acid for anodic oxidation process. Electrochim. Acta 2020, 362, 137221. [Google Scholar] [CrossRef]

- Azevedo, A.F.; Matsushima, J.; Vicentin, F.; Baldan, M.; Ferreira, N.G. Surface characterization of NCD films as a function of sp2/sp3 carbon and oxygen content. Appl. Surf. Sci. 2009, 255, 6565–6570. [Google Scholar] [CrossRef]

- Hu, L.; Guo, Y.; Du, S.; Tian, S.; Li, J.; Gu, C. Probing trans-polyacetylene segments in a diamond film by tip-enhanced Raman spectroscopy. Diam. Relat. Mater. 2021, 116, 108415. [Google Scholar] [CrossRef]

- Macrander, A.T.; Krasnicki, S.; Zhong, Y.; Maj, J.; Chu, Y.S. Strain mapping with parts-per-million resolution in synthetic type-Ib diamond plates. Appl. Phys. Lett. 2005, 87, 194113. [Google Scholar] [CrossRef]

- Xie, X.; Wang, X.; Peng, Y.; Cui, Y.; Chen, X.; Hu, X.; Xu, X.; Yu, P.; Wang, R. Synthesis and characterization of high quality {100} diamond single crystal. J. Mater. Sci. Mater. Electron. 2017, 28, 9813–9819. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Chen, W.; Zhang, L.; He, S.; Wang, H.; Yan, S.; Ma, W.; Guo, C.; Wang, Y. Evolution of High-Quality Homoepitaxial CVD Diamond Films Induced by Methane Concentration. Coatings 2021, 11, 888. https://doi.org/10.3390/coatings11080888

Zhang P, Chen W, Zhang L, He S, Wang H, Yan S, Ma W, Guo C, Wang Y. Evolution of High-Quality Homoepitaxial CVD Diamond Films Induced by Methane Concentration. Coatings. 2021; 11(8):888. https://doi.org/10.3390/coatings11080888

Chicago/Turabian StyleZhang, Pengfei, Weidong Chen, Longhui Zhang, Shi He, Hongxing Wang, Shufang Yan, Wen Ma, Chunxia Guo, and Yanfeng Wang. 2021. "Evolution of High-Quality Homoepitaxial CVD Diamond Films Induced by Methane Concentration" Coatings 11, no. 8: 888. https://doi.org/10.3390/coatings11080888

APA StyleZhang, P., Chen, W., Zhang, L., He, S., Wang, H., Yan, S., Ma, W., Guo, C., & Wang, Y. (2021). Evolution of High-Quality Homoepitaxial CVD Diamond Films Induced by Methane Concentration. Coatings, 11(8), 888. https://doi.org/10.3390/coatings11080888