Effect of Lime Stabilization and Partial Clinoptilolite Zeolite Replacement on the Behavior of a Silt-Sized Low-Plasticity Soil Subjected to Freezing–Thawing Cycles

Abstract

:1. Introduction

2. Materials and Methods

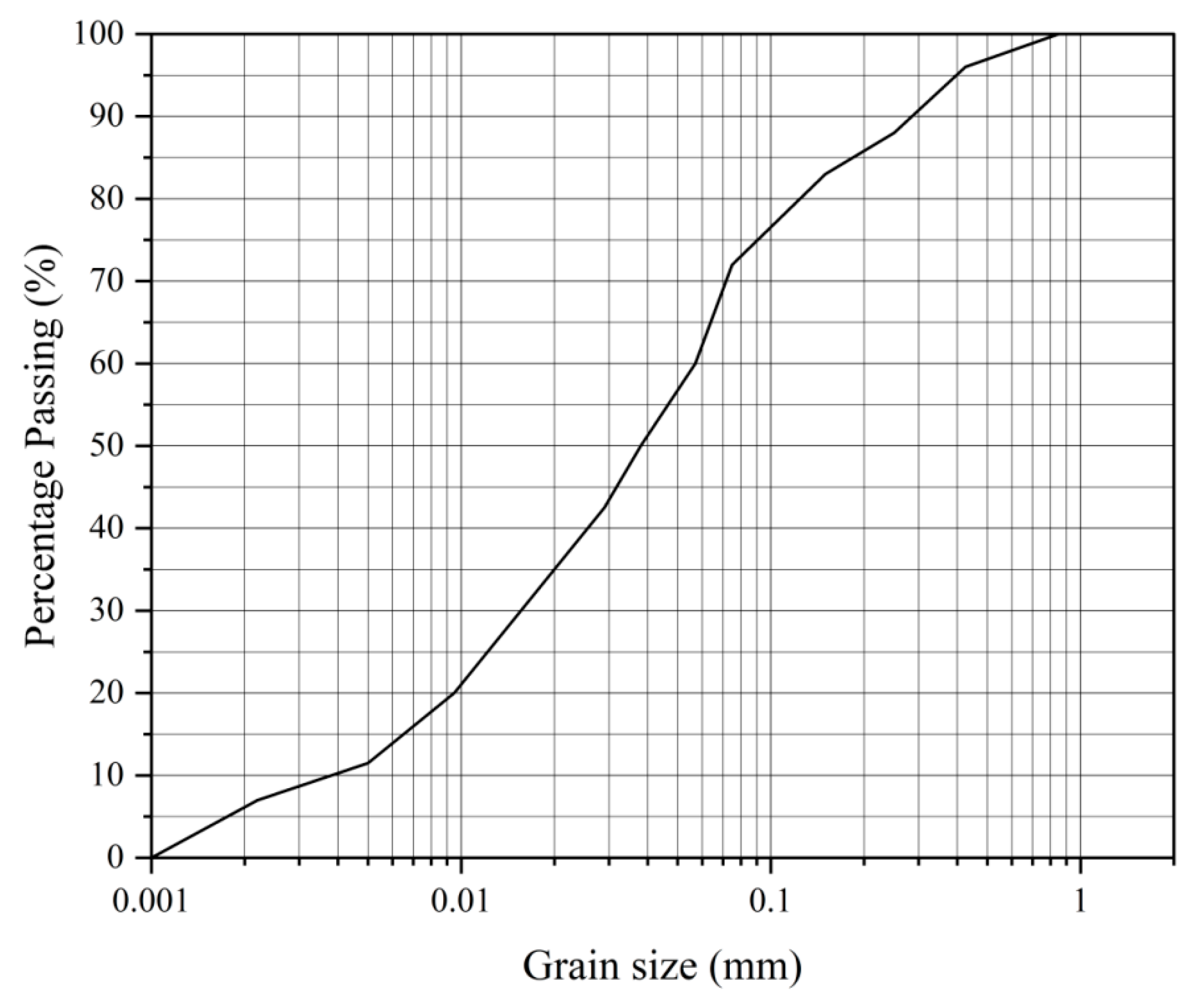

2.1. Materials Used

2.2. Mixing Proportions and Sample Preparation

2.3. Testing Program and Methodology

3. Results and Discussion

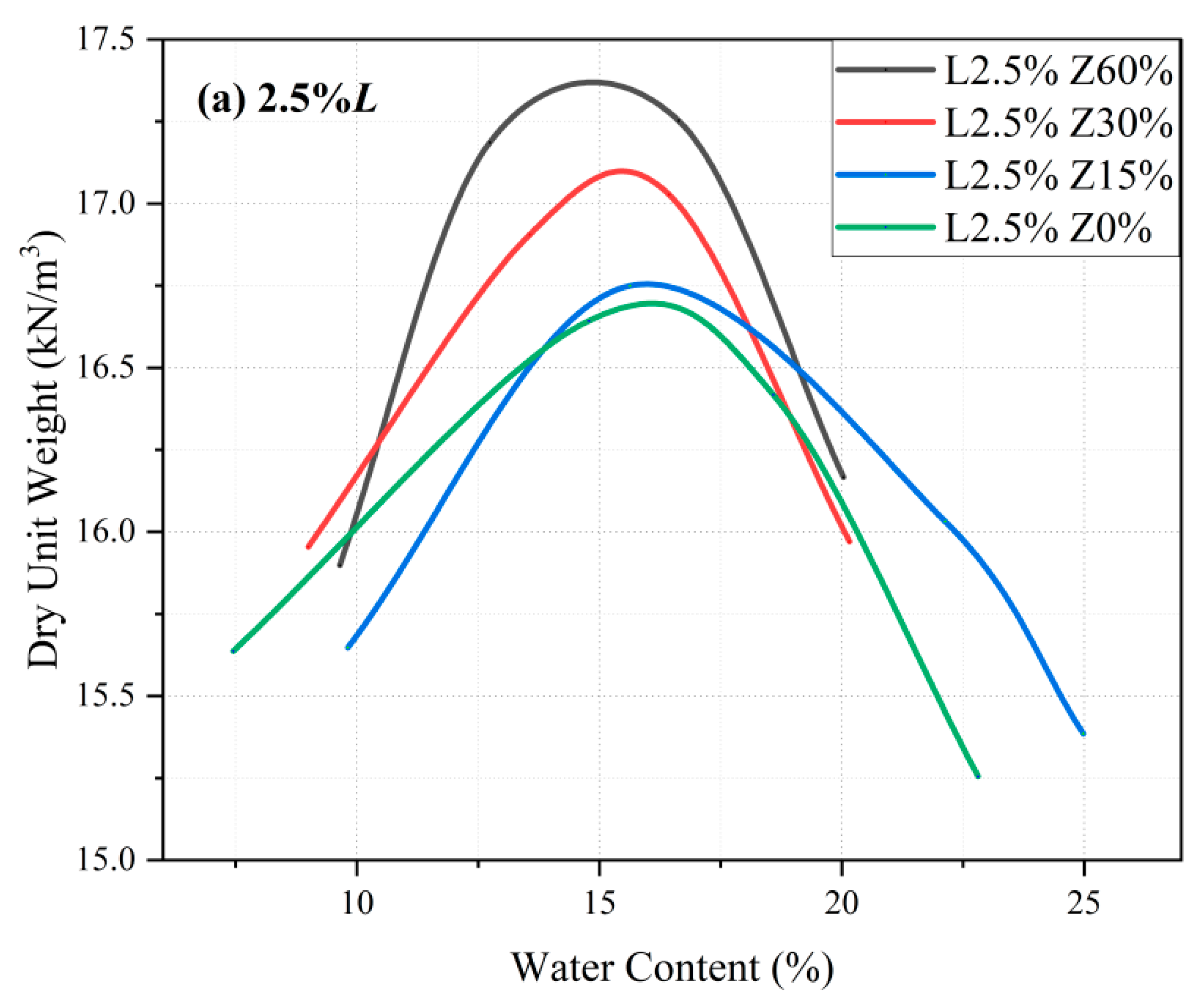

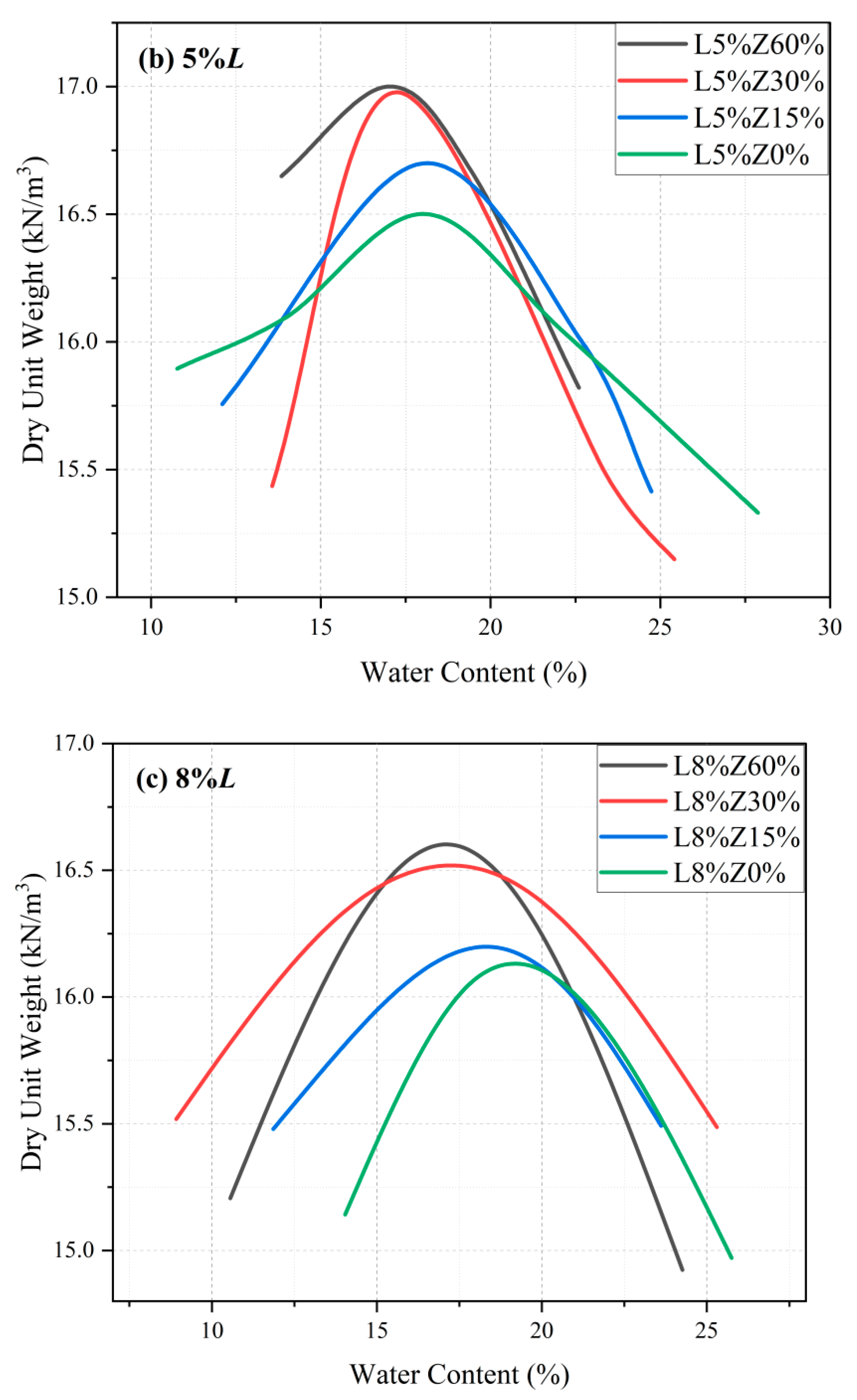

3.1. Influence of Lime–Zeolite Stabilization on the Compaction Characteristics of the Composite Soil

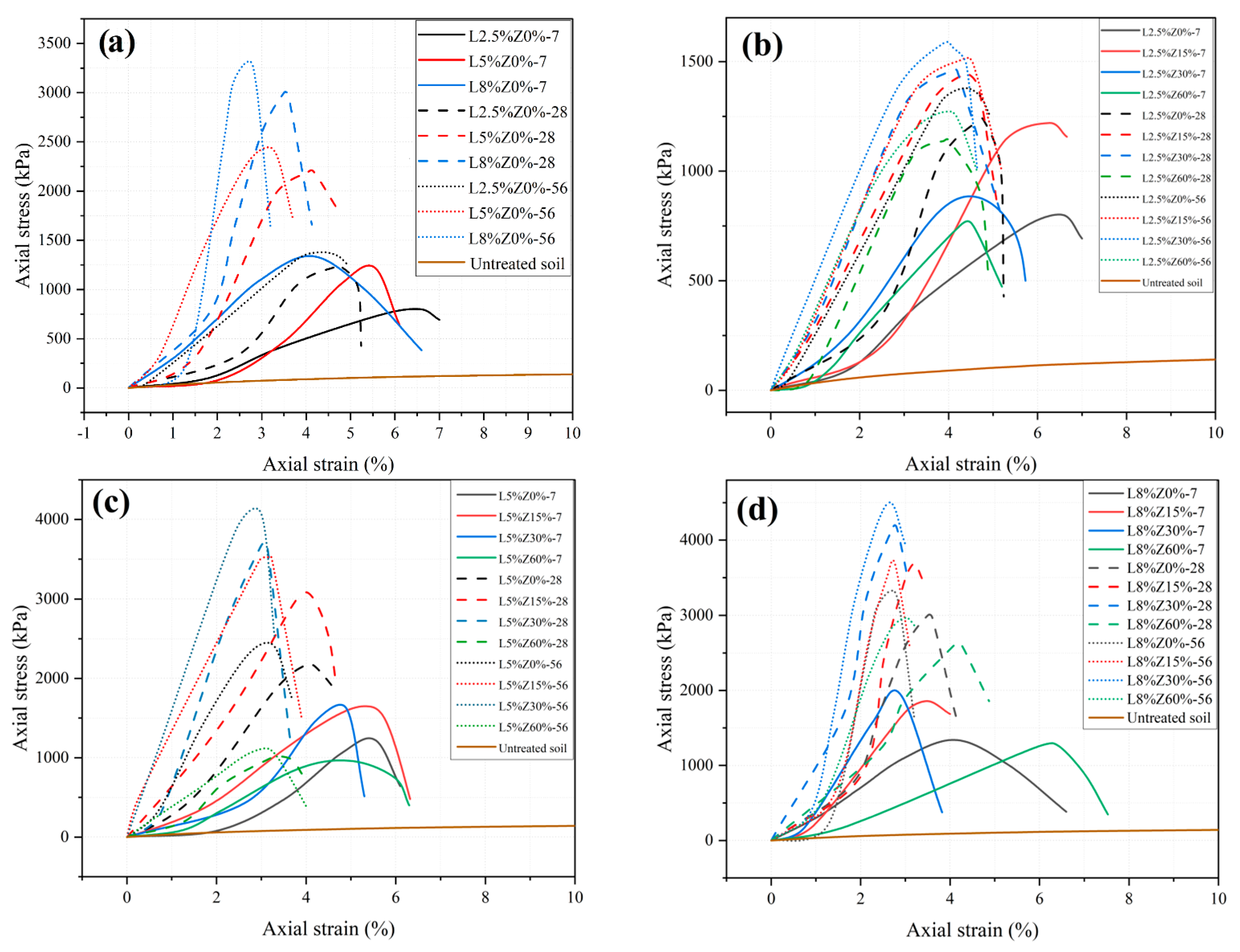

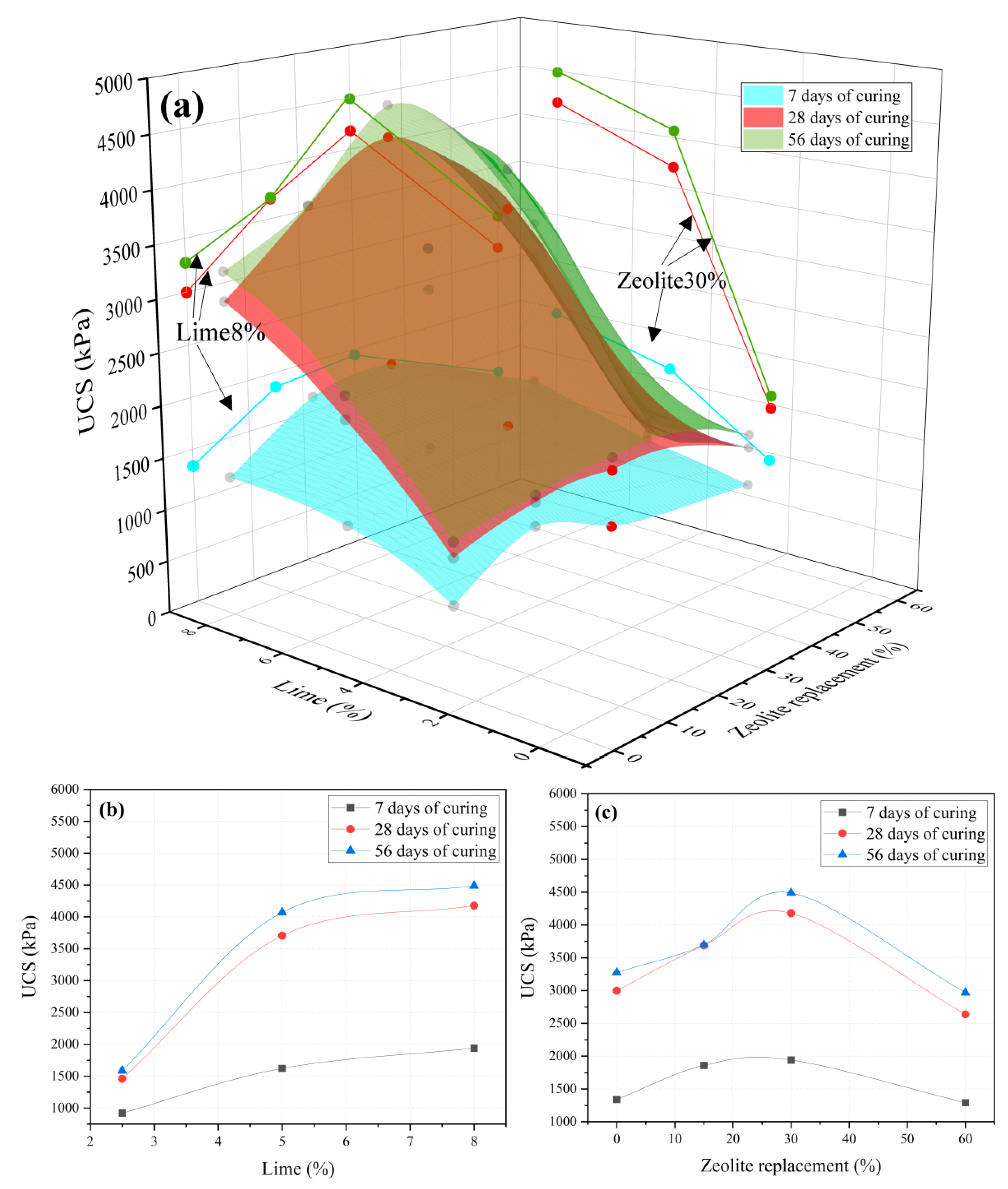

3.2. Influence of Lime–Zeolite Stabilization on UCS of the Composite Soil

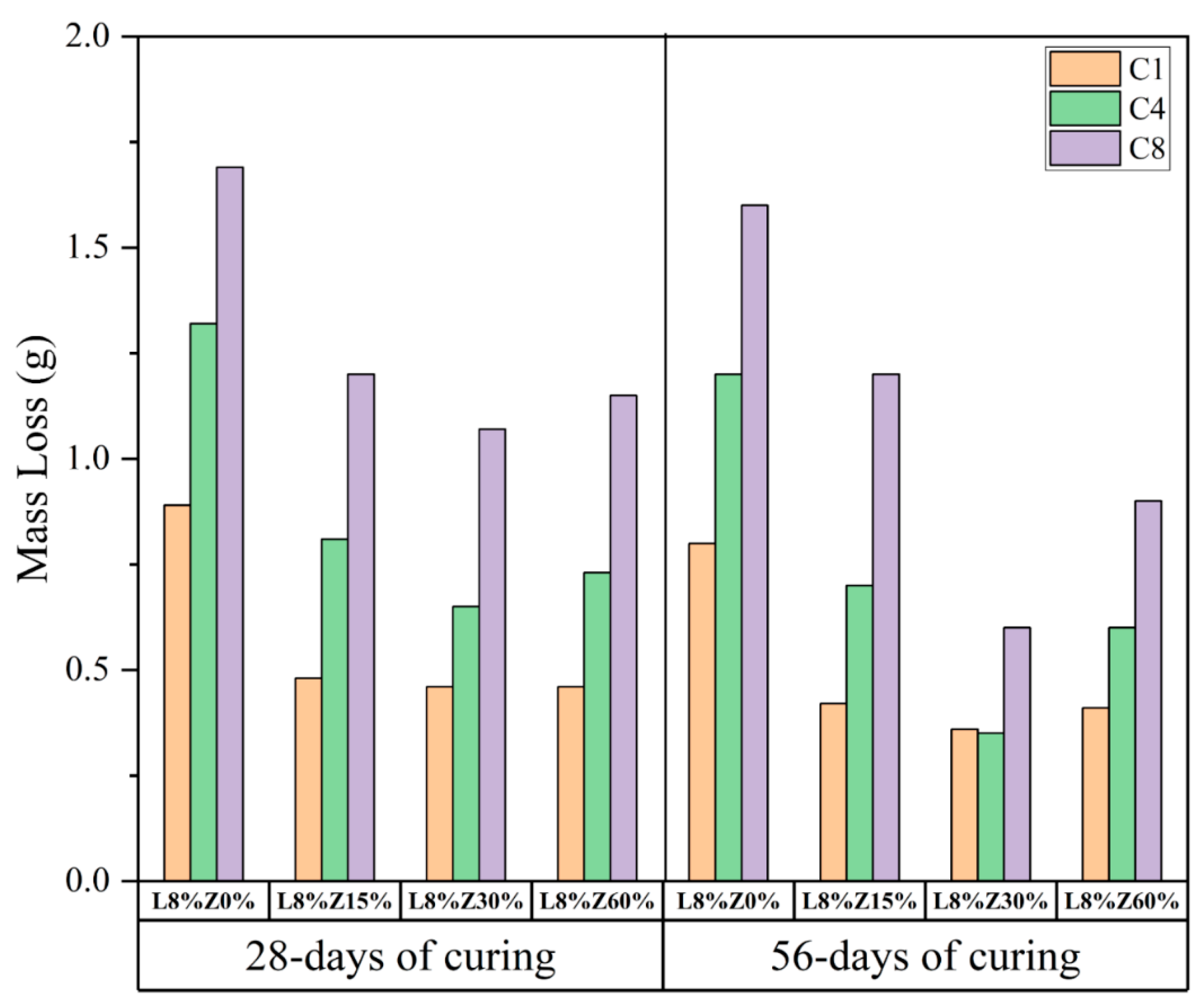

3.3. Influence of Freeze–Thaw Cycles on the Durability of Lime–Zeolite Composite Soil

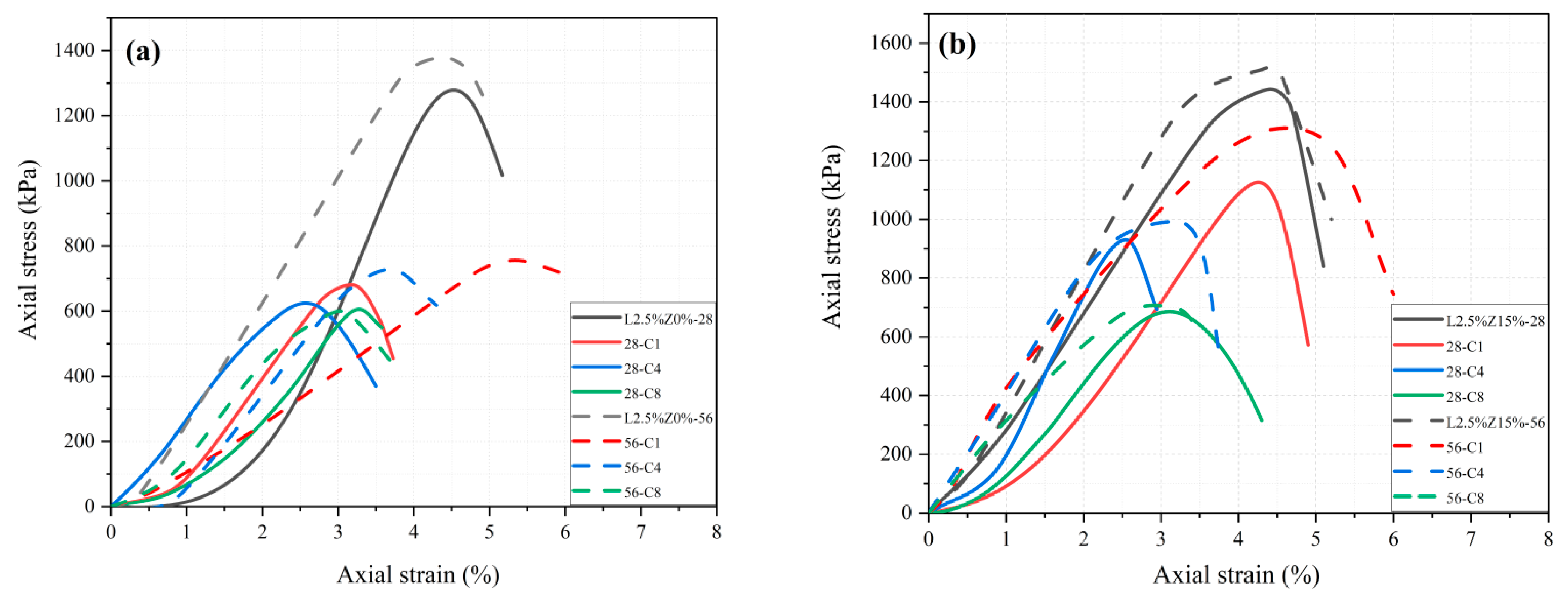

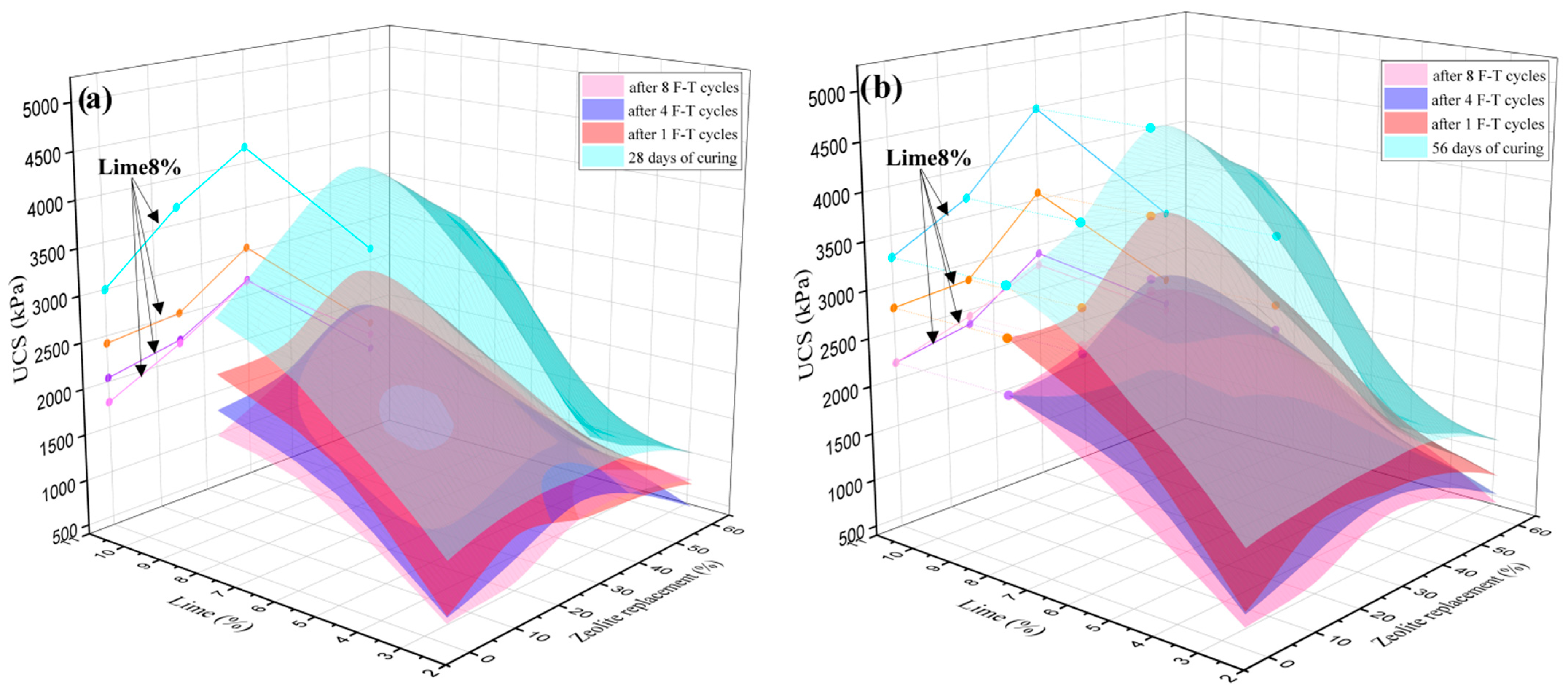

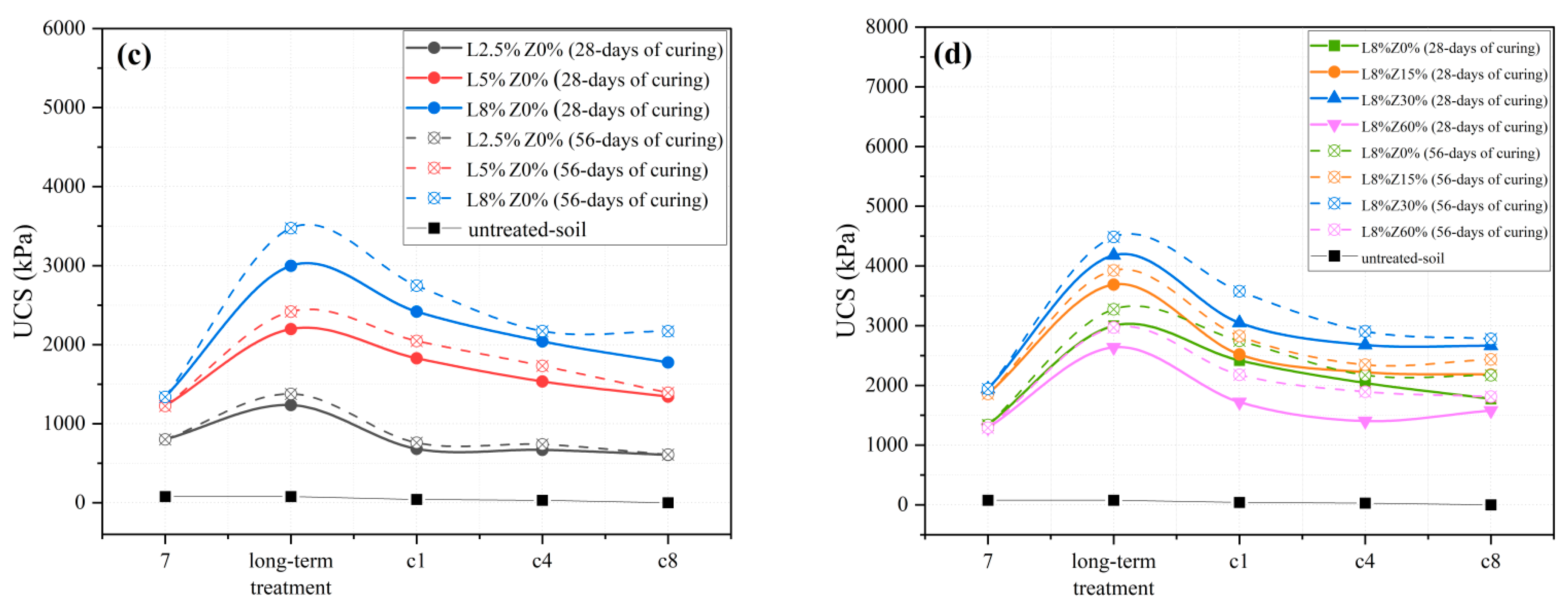

3.4. Effect of Freeze–Thaw Cycles on the UCS of Lime–Zeolite Composite Soil

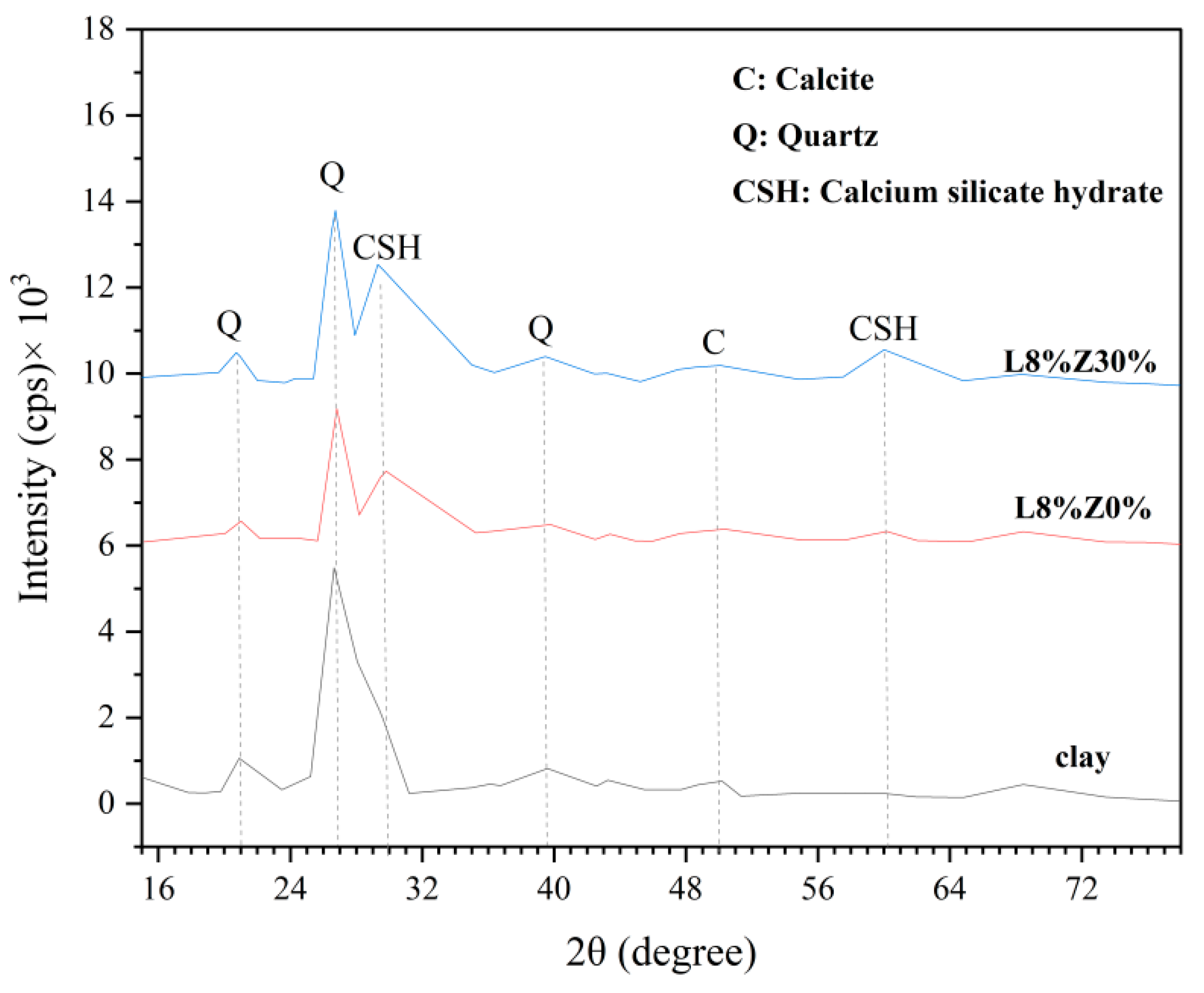

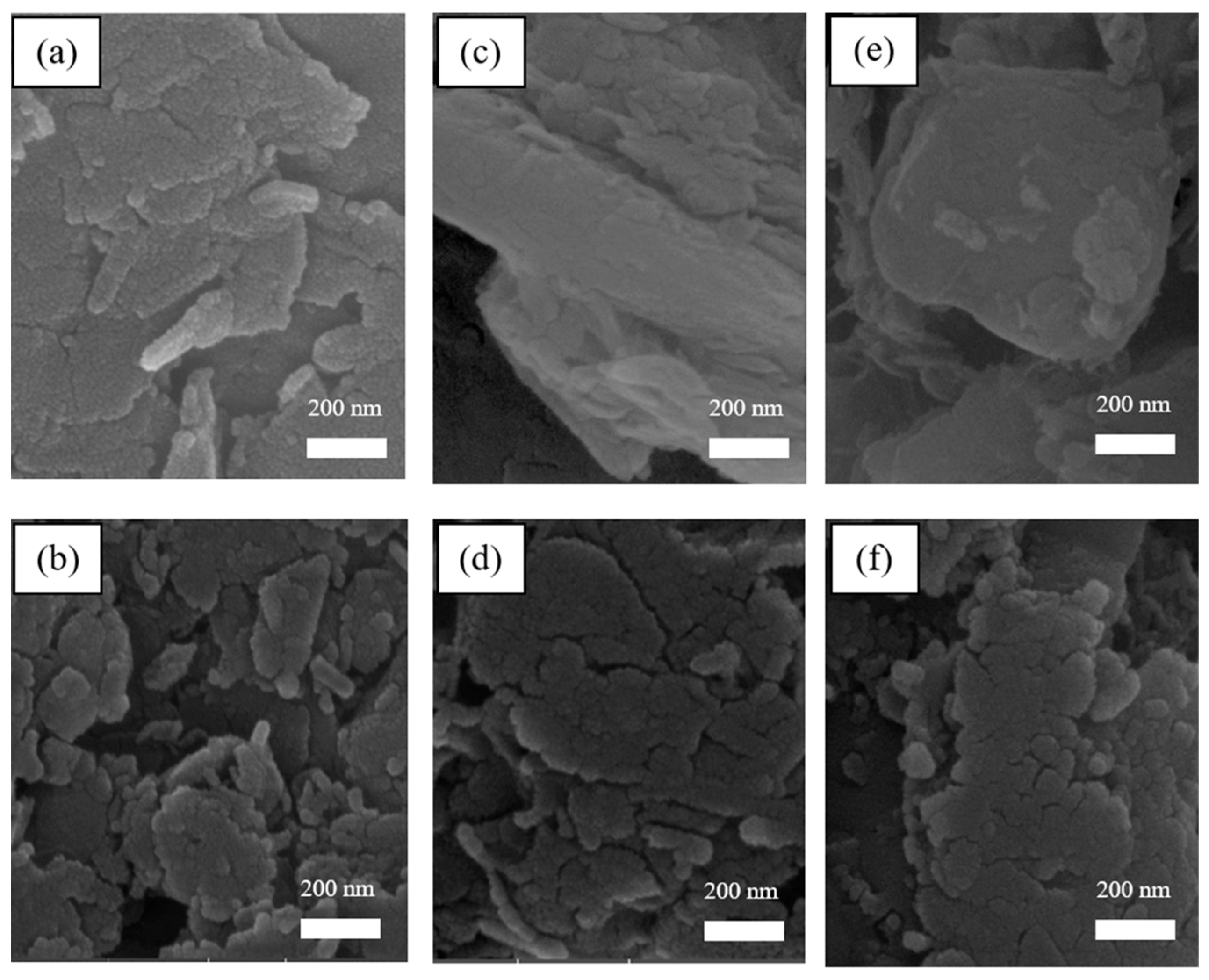

3.5. Microstructural Analysis

4. Concluding Remarks

- For the lime-stabilized specimens (Z = 0%), the increase in the lime content made the specimens lighter (i.e., their maximum dry unit weight, MDUW, values decreased by 0.6 kN/m3) and their optimum water content (OWC) increased by 2.8%). The addition of zeolite to the composite soil, as a means of partial replacement of the lime, was observed to cause a reduction in OWC and the increase in MDUW, but zeolite also increased the capacity of the specimens to absorb water.

- The addition of lime led to the increase in the UCS values of the composite samples. Moreover, the partial replacement of lime with zeolite caused a further increase in the strength of the mixtures up to 30% (which was considered as the optimum zeolite replacement), beyond which it decreased.

- The incorporation of lime and zeolite, up to the optimum content, into the tested soils was concluded to result in higher durability of the mixture, which was translated in smaller amount of mass loss occurred for the specimens with L = 8% and Z = 30%.

- The UCS values of the composite samples (treated with lime–zeolite) decreased with increasing number of freeze–thaw cycles. The lime–zeolite composite material had better durability to the freezing–thawing process compared to the untreated natural soil. The samples with L = 8% and Z = 30% rendered the greatest amount of strength against temperature changes. These observations were exacerbated in the 56-days of curing due to the continuation of pozzolanic reactions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Phanikumar, B.R.; Nagaraju, T.V. Effect of fly ash and rice husk ash on index and engineering properties of expansive clays. Geotech. Geol. Eng. 2018, 36, 3425–3436. [Google Scholar] [CrossRef]

- Vakili, A.H.; Ghasemi, J.; bin Selamat, M.R.; Salimi, M.; Farhadi, M.S. Internal erosional behaviour of dispersive clay stabilized with lignosulfonate and reinforced with polypropylene fiber. Constr. Build. Mater. 2018, 193, 405–415. [Google Scholar] [CrossRef]

- Vakili, A.H.; Selamat, M.R.; Salimi, M.; Gararei, S.G. Evaluation of pozzolanic portland cement as geotechnical stabilizer of a dispersive clay. Int. J. Geotech. Eng. 2021, 15, 504–511. [Google Scholar] [CrossRef]

- Jayapal, J.; Rajagopal, K. A short review of geosynthetic granular column treatment of soft clay soils. Ground Improv. Tech. Geosynth. 2019, 373–380. [Google Scholar] [CrossRef]

- Onyelowe, K.C. Review on the role of solid waste materials in soft soils reengineering. Mater. Sci. Energy Technol. 2019, 2, 46–51. [Google Scholar] [CrossRef]

- Kherad, M.K.; Vakili, A.H.; bin Selamat, M.R.; Salimi, M.; Farhadi, M.S.; Dezh, M. An experimental evaluation of electroosmosis treatment effect on the mechanical and chemical behavior of expansive soils. Arab. J. Geosci. 2020, 13, 1–2. [Google Scholar] [CrossRef]

- Afrasiabian, A.; Salimi, M.; Movahedrad, M.; Vakili, A.H. Assessing the impact of GBFS on mechanical behaviour and microstructure of soft clay. Int. J. Geotech. Eng. 2021, 15, 327–337. [Google Scholar] [CrossRef]

- Khadka, S.D.; Jayawickrama, P.W.; Senadheera, S.; Segvic, B. Stabilization of highly expansive soils containing sulfate using metakaolin and fly ash based geopolymer modified with lime and gypsum. Transp. Geotech. 2020, 23, 100327. [Google Scholar] [CrossRef]

- Chenarboni, H.A.; Lajevardi, S.H.; MolaAbasi, H.; Zeighami, E. The effect of zeolite and cement stabilization on the mechanical behavior of expansive soils. Constr. Build. Mater. 2021, 272, 121630. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Puppala, A.J. Strength and durability assessment of expansive soil stabilized with recycled ash and natural fibers. Transp. Geotech. 2021, 29, 100556. [Google Scholar] [CrossRef]

- Khajeh, A.; Chenari, R.J.; Payan, M. A simple review of cemented non-conventional materials: Soil composites. Geotech. Geol. Eng. 2020, 38, 1019–1040. [Google Scholar] [CrossRef]

- Fernández, M.T.; Orlandi, S.; Codevilla, M.; Piqué, T.M.; Manzanal, D. Performance of calcium lignosulfonate as a stabiliser of highly expansive clay. Transp. Geotech. 2021, 27, 100469. [Google Scholar] [CrossRef]

- Paige-Green, P. The durability of stabilized materials. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics (IACMAG), Goa, India, 1–6 October 2008; pp. 1–6. [Google Scholar]

- Liu, J.; Wang, T.; Tian, Y. Experimental study of the dynamic properties of cement-and lime-modified clay soils subjected to freeze–thaw cycles. Cold Reg. Sci. Technol. 2010, 61, 29–33. [Google Scholar] [CrossRef]

- Güllü, H.; Khudir, A. Effect of freeze–thaw cycles on unconfined compressive strength of fine-grained soil treated with jute fiber, steel fiber and lime. Cold Reg. Sci. Technol. 2014, 106, 55–65. [Google Scholar] [CrossRef]

- Ahmadi, S.; Ghasemzadeh, H.; Changizi, F. Effects of A Low-Carbon Emission Additive on Mechanical Properties of Fine-grained Soil under Freeze-Thaw Cycles. J. Cleaner Prod. 2021, 304, 127157. [Google Scholar] [CrossRef]

- Hong, X.; Wang, H.; Shi, F. Influence of NaCl freeze thaw cycles and cyclic loading on the mechanical performance and permeability of sulphoaluminate cement reactive powder concrete. Coatings 2020, 10, 1227. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.; Li, Y.; Dai, W. laboratory investigation on physical, rheological thermal and microscopic characteristics of water-foamed asphalt under three environmental conditions. Coatings 2020, 10, 239. [Google Scholar] [CrossRef] [Green Version]

- Grotzinger, J.P.; Jordan, T.H. Understanding Earth, 7th ed.; W.H. Freeman and Company: New York, NY, USA, 2014. [Google Scholar]

- Saada, A.S.; Bianchini, G.F.; Liang, L. Cracks, bifurcation and shear bands propagation in saturated clays. Geotechnique 1994, 44, 35–64. [Google Scholar] [CrossRef]

- Gao, Y.; Song, W.; Zhang, F.; Qin, H. Limit analysis of slopeswith cracks: Comparisons of results. Eng. Geol. 2015, 188, 97–100. [Google Scholar] [CrossRef]

- Lozada, C.; Caicedo, B.; Thorel, L. Effects of cracks and desiccation on the bearing capacity of soil deposits. Géotech. Lett. 2015, 5, 112–117. [Google Scholar] [CrossRef]

- Spencer, E. Effect of tension on stability of embankments. J. Soil Mech. Found. Div. 1968, 94, 1159–1176. [Google Scholar] [CrossRef]

- Dyer, M.; Utili, S.; Zielinski, M. Field survey of desiccation fissuring of flood embankments. Proc. ICE Water Manag. 2009, 162, 221–232. [Google Scholar] [CrossRef]

- Yesiller NMiller, C.J.; Inci, G.; Yaldo, K. Desiccation and cracking behavior of three compacted landfill liner soils. Eng. Geol. 2000, 57, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.; Shi, B.; Liu, C.; Zhao, L.; Wang, B. Influencing factors of geometrical structure of surface shrinkage cracks in clayey soils. Eng. Geol. 2008, 101, 204–217. [Google Scholar] [CrossRef]

- Chamberlain, E.J.; Gow, A.J. Effect of freezing and thawing on the permeability and structure of soils. Eng. Geol. 1979, 13, 73–92. [Google Scholar] [CrossRef]

- Zhang, Z.; Wei, M.A.; Feng, W.; Xiao, D.; Hou, X. Reconstruction of soil particle composition during freeze-thaw cycling: A review. Pedosphere 2016, 26, 167–179. [Google Scholar] [CrossRef]

- Zhang, Y.; Johnson, A.E.; White, D.J. Freeze-thaw performance of cement and fly ash stabilized loess. Transp. Geotech. 2019, 21, 100279. [Google Scholar] [CrossRef]

- Wang, S.; Yang, Z.J.; Yang, P. Structural change and volumetric shrinkage of clay due to freeze-thaw by 3D X-ray computed tomography. Cold Reg. Sci. Technol. 2017, 138, 108–116. [Google Scholar] [CrossRef]

- Roghani, A. Quantifying the effect of freeze-thaw cycles on track surface deformation and degradation of railway track geometry; Case study. Transp. Geotech. 2021, 30, 100601. [Google Scholar] [CrossRef]

- Akagawa, S.; Nishisato, K. Tensile strength of frozen soil in the temperature range of the frozen fringe. Cold Reg. Sci. Technol. 2009, 57, 13–22. [Google Scholar] [CrossRef] [Green Version]

- Yıldız, M.; Soğancı, A.S. Effect of freezing and thawing on strength and permeability of lime-stabilized clays. Sci. Iran. 2012, 19, 1013–1017. [Google Scholar] [CrossRef] [Green Version]

- Altun, S.; Sezer, A.; Erol, A. The effects of additives and curing conditions on the mechanical behavior of a silty soil. Cold Reg. Sci. Technol. 2009, 56, 135–140. [Google Scholar] [CrossRef]

- Jong, E.D.; Kachanoski, R.G. Drying of frozen soils. Can. J. Soil Sci. 1988, 68, 807–811. [Google Scholar] [CrossRef]

- Morgenstern, N.R.; Anderson, D.M. Physics, chemistry, and mechanics of frozen ground: A review. In Permafrost: North American Contribution [to The] Second International Conference; National Academies: Washington, DC, USA, 1973; Volume 2, p. 257. [Google Scholar]

- Ozawa, H. Thermodynamics of frost heaving: A thermodynamic proposition for dynamic phenomena. Phys. Rev. E 1997, 56, 2811. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, S.; Weng, L.; Wang, L.; Li, Z.; Xu, L. Fractal analysis of cracking in a clayey soil under freeze–thaw cycles. Eng. Geol. 2016, 208, 93–99. [Google Scholar] [CrossRef]

- Wang, D.Y.; Ma, W.; Niu, Y.H.; Chang, X.X.; Wen, Z. Effects of cyclic freezing and thawing on mechanical properties of Qinghai–Tibet clay. Cold Reg. Sci. Technol. 2007, 48, 34–43. [Google Scholar] [CrossRef]

- Roustaei, M.; Eslami, A.; Ghazavi, M. Effects of freeze–thaw cycles on a fiber reinforced fine grained soil in relation to geotechnical parameters. Cold Reg. Sci. Technol. 2015, 120, 127–137. [Google Scholar] [CrossRef]

- Ingles, O.G.; Metcalf, J.B. Soil Stabilization Principles and Practice; Butterworth and Company Publishers Limited: London, UK; Transport and Road Research Laboratory: Crowthorne, UK; Transportation Research Board: Washington, DC, USA, 1972; Volume 11. [Google Scholar]

- Sharma, N.K.; Swain, S.K.; Sahoo, U.C. Stabilization of a clayey soil with fly ash and lime: A micro level investigation. Geotech. Geol. Eng. 2012, 30, 1197–1205. [Google Scholar] [CrossRef]

- Koohpeyma, H.R.; Vakili, A.H.; Moayedi, H.; Panjsetooni, A.; Nazir, R. Investigating the effect of lignosulfonate on erosion rate of the embankments constructed with clayey sand. Sci. World J. 2013, 2013, 587462. [Google Scholar] [CrossRef] [PubMed]

- Yi, Y.; Zheng, X.; Liu, S.; Al-Tabbaa, A. Comparison of reactive magnesia-and carbide slag-activated ground granulated blastfurnace slag and Portland cement for stabilisation of a natural soil. Appl. Clay Sci. 2015, 111, 21–26. [Google Scholar] [CrossRef]

- Phetchuay, C.; Horpibulsuk, S.; Arulrajah, A.; Suksiripattanapong, C.; Udomchai, A. Strength development in soft marine clay stabilized by fly ash and calcium carbide residue based geopolymer. Appl. Clay Sci. 2016, 127, 134–142. [Google Scholar] [CrossRef]

- Yaghoubi, M.; Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Bo, M.W.; Darmawan, S. Effects of industrial by-product based geopolymers on the strength development of a soft soil. Soils Found. 2018, 58, 716–728. [Google Scholar] [CrossRef]

- Yao, K.; Wang, W.; Li, N.; Zhang, C.; Wang, L. Investigation on strength and microstructure characteristics of nano-MgO admixed with cemented soft soil. Constr. Build. Mater. 2019, 206, 160–168. [Google Scholar] [CrossRef]

- MolaAbasi, H.; Khajeh, A.; Semsani, S.N.; Kordnaeij, A. Prediction of zeolite-cemented sand tensile strength by GMDH type neural network. J. Adhes. Sci. Technol. 2019, 33, 1611–1625. [Google Scholar] [CrossRef]

- Dempsey, B.J.; Thompson, M.R. Vacuum Saturation Method for Predicting Freeze-Thaw Durability of Stabilized Materials; Transportation Research Board: Washington, DC, USA, 1973. [Google Scholar]

- ASTM C593-19. Standard Specification for Fly Ash and Other Pozzolans for Use with Lime for Soil Stabilization; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Sauer, E.K.; Weimer, N.F. Deformation of lime modified clay after freeze-thaw. Transp. Eng. J. ASCE 1978, 104, 201–212. [Google Scholar] [CrossRef]

- Tebaldi, G.; Orazi, M.; Orazi, U.S. Effect of freeze—Thaw cycles on mechanical behavior of lime-stabilized soil. J. Mater. Civ. Eng. 2016, 28, 06016002. [Google Scholar] [CrossRef]

- Saygili, A.; Dayan, M. Freeze-thaw behavior of lime stabilized clay reinforced with silica fume and synthetic fibers. Cold Reg. Sci. Technol. 2019, 161, 107–114. [Google Scholar] [CrossRef]

- Boz, A.; Sezer, A. Influence of fiber type and content on freeze-thaw resistance of fiber reinforced lime stabilized clay. Cold Reg. Sci. Technol. 2018, 151, 359–366. [Google Scholar] [CrossRef]

- Yusuf, M.O.; Johari, M.A.M.; Ahmad, Z.A.; Maslehuddin, M. Strength and microstructure of alkali-activated binary blended binder containing palm oil fuel ash and ground blast-furnace slag. Constr. Build. Mater. 2014, 52, 504–510. [Google Scholar] [CrossRef]

- Goodarzi, A.R.; Akbari, H.R.; Salimi, M. Enhanced stabilization of highly expansive clays by mixing cement and silica fume. Appl. Clay Sci. 2016, 132, 675–684. [Google Scholar] [CrossRef]

- Salimi, M.; Ilkhani, M.; Vakili, A.H. Stabilization treatment of Na-montmorillonite with binary mixtures of lime and steelmaking slag. Int. J. Geotech. Eng. 2020, 14, 295–301. [Google Scholar] [CrossRef]

- Salimi, M.; Ghorbani, A. Mechanical and compressibility characteristics of a soft clay stabilized by slag-based mixtures and geopolymers. Appl. Clay Sci. 2020, 184, 105390. [Google Scholar] [CrossRef]

- Samarakoon, M.H.; Ranjith, P.G.; Rathnaweera, T.D.; Perera, M.S.A. Recent advances in alkaline cement binders: A review. J. Clean. Prod. 2019, 227, 70–87. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Chen, J.J.; Li, L.G.; Ng, P.L.; Kwan, A.K.H. Effects of superfine zeolite on strength, flowability and cohesiveness of cementitious paste. Cem. Concr. Compos. 2017, 83, 101–110. [Google Scholar] [CrossRef]

- Burris, L.; Juenger, M.C.G. Effect of calcination on the reactivity of natural clinoptilolite zeolites used as supplementary cementitious materials. Constr. Build. Mater. 2020, 258, 119988. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, J.; Ho, J.C.M. Zeolite to improve strength-shrinkage performance of high-strength engineered cementitious composite. Constr. Build. Mater. 2020, 234, 117335. [Google Scholar] [CrossRef]

- Faheem, A.; Ali Rizwan, S.; Bier, T.A. Properties of self-compacting mortars using blends of limestone powder, fly ash, and zeolite powder. Constr. Build. Mater. 2021, 286, 122788. [Google Scholar] [CrossRef]

- Kushnir, A.R.L.; Heap, M.J.; Griffiths, L.; Wadsworth, F.B.; Langella, A.; Baud, P.; Reuschlé, T.; Kendrick, J.E.; Utley, J.E.P. The fire resistance of high-strength concrete containing natural zeolites. Cem. Concr. Compos. 2021, 116, 103897. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, J.; Ding, X.; Chu, H.; Zhang, J. Frost resistance of internal curing concrete with calcined natural zeolite particles. Constr. Build. Mater. 2021, 288, 123062. [Google Scholar] [CrossRef]

- Ravazi, S.M.; Nazarpour, H.; Beygi, M.H. Investigation of the efficacy of nano-silica on mechanical properties of Green-Engineered Cementitious Composite (GECC) containing high volume natural zeolite. Constr. Build. Mater. 2021, 291, 123246. [Google Scholar]

- Han, X.; Cao, Z.; Wang, R.; He, P.; Zhang, Y.; Yu, J.; Ge, Y. Effect of silane coupling agent modified zeolite warm mix additives on properties of asphalt. Constr. Build. Mater. 2020, 259, 119713. [Google Scholar] [CrossRef]

- Hamzani; Munirwansyh; Hasan, M.; Sugiarto, S. Determining the properties of semi-flexible pavement using waste tire rubber powder and natural zeolite. Constr. Build. Mater. 2021, 266, 121199. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, Y.; Long, Y.; Chen, Z.; Cui, P.; Wu, R.; Chang, X. VOCs reduction in bitumen binder with optimally designed Ca(OH)2-incorporated zeolite. Constr. Build. Mater. 2021, 279, 122485. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Saberian, M.; Moradi, M.; Vali, R.; Li, J. Stabilized marine and desert sands with deep mixing of cement and sodium bentonite. Geomech. Eng. 2018, 14, 553–562. [Google Scholar]

- Perraki, T.; Kakali, G.; Kontoleon, F. The effect of natural zeolites on the early hydration of Portland cement. Microporous Mesoporous Mater. 2003, 61, 205–212. [Google Scholar] [CrossRef]

- Feng, N.Q.; Li, G.Z.; Zang, X.W. High-strength and flowing concrete with a zeolitic mineral admixture. Cem. Concr. Aggreg. 1990, 12, 61–69. [Google Scholar]

- Mola-Abasi, H.; Khajeh, A.; Naderi Semsani, S. Variables controlling tensile strength of stabilized sand with cement and zeolite. J. Adhes. Sci. Technol. 2018, 32, 947–962. [Google Scholar] [CrossRef]

- Mola-Abasi, H.; Kordtabar, B.; Kordnaeij, A. Effect of natural zeolite and cement additive on the strength of sand. Geotech. Geol. Eng. 2016, 34, 1539–1551. [Google Scholar] [CrossRef]

- Mola-Abasi, H.; Shooshpasha, I. Influence of zeolite and cement additions on mechanical behavior of sandy soil. J. Rock Mech. Geotech. Eng. 2016, 8, 746–752. [Google Scholar] [CrossRef] [Green Version]

- MolaAbasi, H. Evaluation of zeolite effect on strength of babolsar sand stabilized with cement using unconfined compression test. Modares Civ. Eng. J. 2017, 16, 203–213. [Google Scholar]

- Khajeh, A.; MolaAbasi, H.; Naderi Semsani, S. Tensile strength parameters controlling of zeolite-cemented sands. Sci. Iran. 2019, 26, 213–223. [Google Scholar] [CrossRef] [Green Version]

- Goodarzian, A.; Ghasemipanah, A.; Moayed, R.Z.; Niroumand, H. Influence of nanozeolite particles on improvement of clayey soil. Int. J. Geotech. Geol. Eng. 2020, 14, 40–48. [Google Scholar]

- Akbari, H.R.; Sharafi, H.; Goodarzi, A.R. Effect of polypropylene fiber inclusion in kaolin clay stabilized with lime and nano-zeolite considering temperatures of 20 and 40 °C. Bull. Eng. Geol. Environ. 2021, 80, 1841–1855. [Google Scholar] [CrossRef]

- Cai, R.; Yan, Y. Corrosion-resistant zeolite coatings. Corrosion 2008, 64, 271–278. [Google Scholar] [CrossRef]

- Calabrese, L. Anticorrosion behavior of zeolite coatings obtained by in situ crystallization: A critical review. Materials 2018, 12, 59. [Google Scholar] [CrossRef] [Green Version]

- Javierre, E. Modeling self-healing mechanisms in coatings: Approaches and perspectives. Coatings 2019, 9, 122. [Google Scholar] [CrossRef] [Green Version]

- Calabrese, L.; Proverbio, E. A Brief Overview on the Anticorrosion Performances of Sol-Gel Zeolite Coatings. Coatings 2019, 9, 409. [Google Scholar] [CrossRef] [Green Version]

- ASTM D854-14. Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM D4318-17e1. Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D698-12e2. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft3 (600 kN-m/m3)); ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D2487-17e1. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Parriaux, A. Geology: Basics for Engineers; CRC Press, Taylor and Francis Group: Oxon, UK, 2009. [Google Scholar]

- Williams, P.J.; Smith, M.W. The Frozen Earth: Fundamentals of Geocryology; Cambridge University Press: Cambridge, UK, 1989; Volume 306. [Google Scholar]

- Hohmann, M. Soil freezing—The concept of soil water potential. State of the art. Cold Reg. Sci. Technol. 1997, 25, 101–110. [Google Scholar] [CrossRef]

- ASTM D560/D560M-16. Standard Test Methods for Freezing and Thawing Compacted Soil-Cement Mixtures; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Hotineanu, A.; Bouasker, M.; Aldaood, A.; Al-Mukhtar, M. Effect of freeze–thaw cycling on the mechanical properties of lime-stabilized expansive clays. Cold Reg. Sci. Technol. 2015, 119, 151–157. [Google Scholar] [CrossRef]

- ASTM D559/D559M-15. Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D2166/D2166M-16. Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Ramlakhan, B.; Kumar, S.A.; Arora, T.R. Effect of lime and fly ash on engineering properties of black cotton soil. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 535–541. [Google Scholar]

- Harichane, K.; Ghrici, M.; Kenai, S.; Grine, K. Use of natural pozzolana and lime for stabilization of cohesive soils. Geotech. Geol. Eng. 2011, 29, 759–769. [Google Scholar] [CrossRef]

- Al-Swaidani, A.; Hammoud, I.; Meziab, A. Effect of adding natural pozzolana on geotechnical properties of lime-stabilized clayey soil. J. Rock Mech. Geotech. Eng. 2016, 8, 714–725. [Google Scholar] [CrossRef] [Green Version]

- Ikeagwuani, C.C.; Obeta, I.N.; Agunwamba, J.C. Stabilization of black cotton soil subgrade using sawdust ash and lime. Soils Found. 2019, 59, 162–175. [Google Scholar] [CrossRef]

- Islam, S.; Hoque, N.R.; Haque, M.A.; Mishra, P.N.; Mamun, M.M.H.; Dey, S. Strength development in fine-grained paddy field soil by lime addition. J. Build. Eng. 2019, 26, 100857. [Google Scholar] [CrossRef]

- González de Vallejo, L.I.; Ferrer, M. Geological Engineering; CRC Press, Taylor & Francis Group: London, UK, 2011. [Google Scholar]

- Terrel, R.L.; Epps, J.A.; Barenberg, E.J.; Mitchell, J.K.; Thompson, M.R. Soil Stabilization in Pavement Structures: A User’s Manual; Federal Highway Administration (FHWA), US Department of Transportation: Washington, DC, USA, 1979; Volume 1.

- Mallela, J.; Quintus, H.V.; Smith, K. Consideration of lime-stabilized layers in mechanistic-empirical pavement design. Nat. Lime Assoc. 2004, 200, 1–40. [Google Scholar]

- Aldaood, A.; Bouasker, M.; Al-Mukhtar, M. Impact of freeze–thaw cycles on mechanical behaviour of lime stabilized gypseous soils. Cold Reg. Sci. Technol. 2014, 99, 38–45. [Google Scholar] [CrossRef]

| Soil Properties | Value | Specification |

|---|---|---|

| Specific gravity () | 2.71 | ASTM D854 [86] |

| Liquid Limit (LL), % | 29.1 | ASTM D4318 [87] |

| Plasticity index (PI), % | 7.9 | ASTM D4318 [87] |

| Maximum dry unit weight (), g/m3 | 1.7 | ASTM D698 [88] |

| Optimum water content (), % | 15.1 | ASTM D698 [88] |

| Soil classification (USCS) | CL | ASTM D2487 [89] |

| Percentage of fines, % | 72% | ASTM D2487 [89] |

| SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | K2O | MgO | TiO2 | MnO | P2O5 | L.O.I * | Sr (ppm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clay | 49.06 | 11.80 | 5.38 | 12.37 | 1.80 | 2.57 | 3.8 | 0.66 | 0.11 | 0.24 | 12.11 | 459 |

| Zeolite | 72.98 | 11.63 | 1.29 | 1.53 | 1.89 | 2.68 | 0.56 | 0.188 | 0.015 | 0.052 | 6.89 | 2514 |

| Lime | 4.99 | 1.32 | 0.12 | 54.92 | 0.65 | 0.11 | 0.44 | 0.04 | 0.003 | 0.43 | 33.97 | 1383 |

| Curing Time | 7, 28, 56 Days |

|---|---|

| Lime (%) | 2.5%, 5%, 8% |

| Zeolite Replacement (%) | 0%, 15%, 30%, 60% |

| Freeze–thaw cycle | 0, 1, 4, 8 |

| Mixing ID | Total Additions (%) | Lime Percentage in Total (L) (%) | Zeolite Percentage in Total (%) | Lime Replacement with Zeolite (%) | Moisture Content for Compaction Test |

|---|---|---|---|---|---|

| Untreated Clay | 0 | 0 | 0 | 0 | 6.81, 9.61, 13.54, 15.1(OWC), 20.72, 23.18 |

| L2.5%Z0% | 2.5 | 2.5 | 0 | 0 | 7.45, 14.79, 16.20(OWC), 18.59, 22.81 |

| L2.5%Z15% | 2.5 | 2.125 | 0.375 | 15 | 9.81, 15.63, 15.97(OWC), 22.13, 24.98 |

| L2.5%Z30% | 2.5 | 1.75 | 0.75 | 30 | 9.00, 13.57, 15.58(OWC), 16.44, 20.16 |

| L2.5%Z60% | 2.5 | 1 | 1.5 | 60 | 9.65, 12.74, 14.86(OWC), 16.63, 20.03 |

| L5%Z0% | 5 | 5 | 0 | 0 | 10.77, 14.00, 18.08, 18.18(OWC), 22.19, 27.87 |

| L5%Z15% | 5 | 4.25 | 0.75 | 15 | 12.10, 17.93, 17.50(OWC), 22.68, 24.74 |

| L5%Z30% | 5 | 3.5 | 1.5 | 30 | 13.57, 17.10(OWC), 17.23, 23.50, 25.41 |

| L5%Z60% | 5 | 2 | 3 | 60 | 13.84, 16.50(OWC), 17.01, 19.46, 22.60 |

| L8%Z0% | 8 | 8 | 0 | 0 | 14.04, 17.83, 19.00(OWC), 24.10, 25.75 |

| L8%Z15% | 8 | 6.8 | 1.2 | 15 | 11.86, 13.64, 18.20(OWC), 18.53, 21.12, 23.61 |

| L8%Z30% | 8 | 5.6 | 2.4 | 30 | 8.92, 14.48, 17.30(OWC), 19.36, 25.30 |

| L8%Z60% | 8 | 3.2 | 4.8 | 60 | 10.56, 17.10(OWC), 17.14, 24.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shirmohammadi, S.; Ghaffarpour Jahromi, S.; Payan, M.; Senetakis, K. Effect of Lime Stabilization and Partial Clinoptilolite Zeolite Replacement on the Behavior of a Silt-Sized Low-Plasticity Soil Subjected to Freezing–Thawing Cycles. Coatings 2021, 11, 994. https://doi.org/10.3390/coatings11080994

Shirmohammadi S, Ghaffarpour Jahromi S, Payan M, Senetakis K. Effect of Lime Stabilization and Partial Clinoptilolite Zeolite Replacement on the Behavior of a Silt-Sized Low-Plasticity Soil Subjected to Freezing–Thawing Cycles. Coatings. 2021; 11(8):994. https://doi.org/10.3390/coatings11080994

Chicago/Turabian StyleShirmohammadi, Sarah, Saeed Ghaffarpour Jahromi, Meghdad Payan, and Kostas Senetakis. 2021. "Effect of Lime Stabilization and Partial Clinoptilolite Zeolite Replacement on the Behavior of a Silt-Sized Low-Plasticity Soil Subjected to Freezing–Thawing Cycles" Coatings 11, no. 8: 994. https://doi.org/10.3390/coatings11080994

APA StyleShirmohammadi, S., Ghaffarpour Jahromi, S., Payan, M., & Senetakis, K. (2021). Effect of Lime Stabilization and Partial Clinoptilolite Zeolite Replacement on the Behavior of a Silt-Sized Low-Plasticity Soil Subjected to Freezing–Thawing Cycles. Coatings, 11(8), 994. https://doi.org/10.3390/coatings11080994