1. Introduction

Dispersing nanoceramic particles into a metal matrix can enhance many performance aspects of the substrate, including strength, temperature stability, wear, fatigue resistance, and toughness [

1,

2,

3,

4,

5]. These characteristics have led to the expanded use of nanoceramic particles in various structural, aerospace, automotive, and railway applications [

6,

7,

8].

Titanium alloys are of special interest to the aerospace industry because of their outstanding mechanical properties, such as high strength-to-weight ratios, superior strength [

9], and high fracture toughness and corrosion resistance [

10,

11]. Different types of coatings have been proposed in the literature to improve the performance of titanium alloys. For example, Guo et al. [

12] synthesized three kinds of laser-boronizing composite coatings on titanium substrates by using powders of B, BN, and B

4C as starting materials. The three composite coatings had higher microhardness and better wear resistance than pure titanium substrate. Further, Savalani et al. [

13] fabricated TiC-reinforced titanium matrix composite layers by laser cladding with 5, 10, 15, and 20 weight percentages of carbon-nanotubes. In particular, Ti/SiC composites have recently received attention because of their great potential in improving mechanical behaviors. For example, Machethe et al. [

14] deposited titanium with SiC-based cermet for improved surface properties. Further, Singh et al. [

15] synthesized composite coatings using a mixture of Ti/SiC/C powders on a titanium substrate, which showed significant potential for wear-resistant surfaces. In an earlier study, a Ti/SiC metal matrix nanocomposite (MMNC) coating with 5% weight of SiC, was deposited on a Ti-6Al-4V substrate. This coating exhibited a higher surface hardness, lower coefficient of friction, and superior wear rate, compared with the substrate [

16]. Additionally, it also improved the hypervelocity impact resistance of the titanium substrates [

17].

Different technologies exist for metal additive manufacturing, such as powder bed fusion. During the powder bed fusion process, powder layers are repeatedly melted by an energy source until a fully dense part is obtained [

18]. The selective laser melting (SLM) technique, which falls into this category, has been used by some researchers. For instance, a titanium diboride powder mixture was incorporated into a titanium substrate by an SLM process [

19]. In another study, micron-sized TiC particles were added to 316L austenitic stainless steel using SLM [

20]. In another research, tubes with a wall thickness of 500 μm were made of 316L stainless steel using the SLM technique [

21]. This technique was also used by Zhang et al. [

16] to create a Ti/SiC MMNC coating.

While the coatings have been shown to enhance the performance of various components, the mechanisms of these enhancements are not well understood, due to the limited ability to conduct material characterization tests, similar to what can be carried out with bulk materials. A common technique for testing thin film coating is micro-indentation, where an indenter made of a hard material, typically diamond, is applied to the coating under controlled displacement or force conditions [

22]. The resulting deformation is then recorded. While micro-indentation is mainly a hardness test [

23], several researchers have explored combining it with finite element techniques to predict the mechanical properties of structures based on micro-indentation experiments. For instance, a finite element model to simulate the micro-indentation process of an Al6061-T6 aluminum alloy was developed by Amiri et al. [

24]. In this work, the indentation load-depth curves from experimental tests and numerical analyses were compared, to calibrate the plastic behavior of the numerical model. Similarly, Iankov et al. [

25] carried out finite element simulations of micro-indentation to investigate the material properties of a thin copper film deposited over a brass alloy (CuZn36) substrate, using a trial-and-error approach. Additionally, a finite element analysis was performed by Iio et al. [

26] to obtain the modulus of elasticity and yield stress of a hollow-strut cellular material based on micro-indentation experiments.

For modeling composites made of materials with significantly different characteristics and crystal sizes, researchers have developed various techniques, such as meso-scale and micro-scale modeling. In micro-scale modeling, the composite is typically considered as a single transverse isotropic or orthotropic material [

27]. In meso-scale modeling, the reinforcement and the matrix are modeled as separated entities. For example, Ghasemi et al. [

28] developed a computational model of an aluminum/silica nanocomposite. They employed an elastoplastic material model and a ductile damage model, for an aluminum matrix, and a linear elastic model for nanosilica particles. Further, Teng et al. [

29] performed a multi-scale simulation study on the cutting mechanism of magnesium-based metal matrix composites reinforced with SiC nanoparticles. Lepore et al. [

30] developed a meso-scale model to study non-linear fatigue propagation of multiple cracks in an aluminum metal matrix composite with silicon–carbide fiber reinforcement. The material behavior of the aluminum was modeled by means of the Ramberg–Osgood equation, while linear material properties were used for the reinforcing fibers.

As the literature failed to provide a general approach for identifying the material models of composites, this work proposes a methodology for identifying the material model parameters of composite coatings using a combination of micro-indentation experiments and meso/micro-scale simulations.

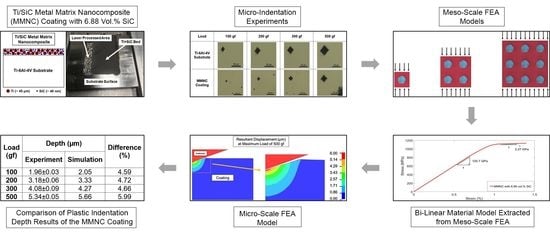

Figure 1 summarizes the approach. The proposed methodology starts with micro-indentation testing on the composite coatings. The testing can be either load controlled or displacement controlled; however, the former was preferred. The residual indentation depth values should be measured.

In the next stage, a unit cell of the composite coating was modeled including the metal matrix and the reinforcement particle sphere suspended in the middle. As this approach assumes that the reinforcement particles are distributed uniformly within the metal matrix, the size of the unit cell was selected such that the volume fraction of the composite coating would be maintained. The appropriate material models were selected for both the reinforcement particles and the metal matrix. A quasi-static uniaxial compression simulation was performed by applying a vertical displacement to the top face of the matrix, and fully constraining the bottom face. The overall stress was then computed by dividing the measured load by the cross-sectional area of the bottom surface. The overall strain was calculated by dividing the displacement at the cube’s top surface by its initial height. The resulting stress–strain curve of the composite coating was extracted from the meso-scale model. Multiple cube sizes were tested, and the results were almost stable.

The last stage includes developing an axisymmetric micro-scale finite element model to simulate the micro-indentation experiments of the composite coating. The stress–strain curve parameters obtained from the meso-scale model were incorporated into this micro-scale model. The plastic indentation depth results of the experiments and micro-scale study were compared, to validate the material model parameters of the composite coating.

As an example, the application of this methodology in identifying the material model parameters of a Ti/SiC metal matrix nanocomposite coating fabricated on a titanium substrate using the selective laser melting technique is presented in the rest of this paper.

The following is a brief overview of the paper:

Section 2 presents the micro-indentation testing, performed on both the Ti-6Al-4V substrate and Ti/SiC MMNC coating. The meso-scale model of the Ti/SiC MMNC coating, and the micro-scale finite element model of the micro-indentation testing under various loads are presented in

Section 3 and

Section 4, respectively. Discussions are presented in

Section 5, and finally, conclusions are drawn in

Section 6.

3. Meso-Scale Modeling of the Ti/SiC MMNC Coating

As discussed in

Section 1, a meso-scale finite element model of uniaxial compression was developed in LS-DYNA code [

32]. The unit cell of the Ti/SiC MMNC coating was modeled as a Ti matrix with a 40 nm SiC sphere suspended in the middle [

16]. This unit cell was a 157 nm cube, which was selected to maintain the SiC volume fraction of 6.88%, or a 5% weight ratio.

A bi-linear plasticity model (MAT_024—piecewise linear plasticity) was used for the Ti matrix [

33], while a linear elastic material model (MAT_001—elastic) was used for the SiC. The parameters of these material models are summarized in

Table 4, where

ρ is density,

ν is Poisson’s ratio,

E is the modulus of elasticity,

is yield strength, and

Etan is the tangent modulus. For Poisson’s ratio and modulus of elasticity of the SiC, the values reported in [

34] were used in the simulations. The compressive failure strain of SiC was also monitored using the range reported in [

35] to assess its structural integrity. Tied surface-to-surface contact was applied between the sphere and the matrix, which means that there was no surface separation under tensile load. A quasi-static uniaxial compression simulation was performed by applying a vertical displacement of 10 nm to the top face of the matrix, while completely fixing the bottom face. The lateral sides of the unit cell were not restrained, similar to [

36]. The meso-scale finite element model of the MMNC coating is shown in

Figure 3.

A mesh convergence analysis was performed, considering two cases with average element sizes of 10 and 5 nm, respectively. The actual number of elements in each case is summarized in

Table 5. The maximum principal stress contours of the matrix and the reinforcement parts of the models, with 10 and 5 nm element sizes, are shown in

Figure 4. In both cases, the maximum strain in the SiC particle was about 0.35%, which is below the failure strain of SiC [

35]. The resulting overall stress–strain curves were extremely close for both the 10 and 5 nm element size cases. However, since the model with the 5 nm average element size was able to produce a more defined stress gradient distribution for both materials, this element size was selected for the rest of the meso-scale studies.

To verify the results, the single cube model was used to build meso-scale models with 8 and 27 SiC spheres. In both models, the spheres were uniformly spaced within the Ti matrix while maintaining the same SiC volume fraction. These three models are shown in

Figure 5. The number of elements in these models is also summarized in

Table 6. The loading and boundary conditions were maintained similarly to the single sphere model. The resulting stress-strain curves were obtained in each case, as explained in

Section 1. The overall stress–strain curves of the three models are shown in

Figure 6. These curves were almost identical, which showed that expanding the number of cells did not change the resulting stress–strain curve. The resulting modulus of elasticity, yield strength, and tangent moduli were 120.7 GPa, 1122 MPa, and 2.27 GPa, respectively.

To verify the elastic behavior, the resulting modulus of elasticity was compared with the result of the Halpin–Tsai (HT) model, which is a well-accepted formulation for a composite’s modulus of elasticity,

Ec [

37], expressed as follows:

where

Em is the modulus of elasticity of the matrix;

s is the aspect ratio of the reinforcement;

Vp is its volume fraction;

q is a parameter, which can be written as

where

Ep is the modulus of elasticity of the reinforcement. The parameters used in the Halpin–Tsai model are shown in

Table 7. These results show that the Halpin–Tsai modulus of elasticity is almost identical to the result from the meso-scale study, 120.7 GPa.

It may be of interest to compare the resulting bi-linear elastic–plastic parameters with the corresponding parameters of the MMNC, with 35% SiC by volume [

31]. As

Table 8 shows, the difference in their densities is justified by the lower percentage of SiC in the material under consideration. Similarly, the lower percentage of SiC nanoparticles with high stiffness and rigidity results in lower

E and

Etan. On the other hand, the yield strength of both materials is very close.