Preliminary Investigation of Sequential Application of Different Calcium Oxalate Solutions for Carbonate Rock Conservation

Abstract

:1. Introduction

2. Materials and Methods

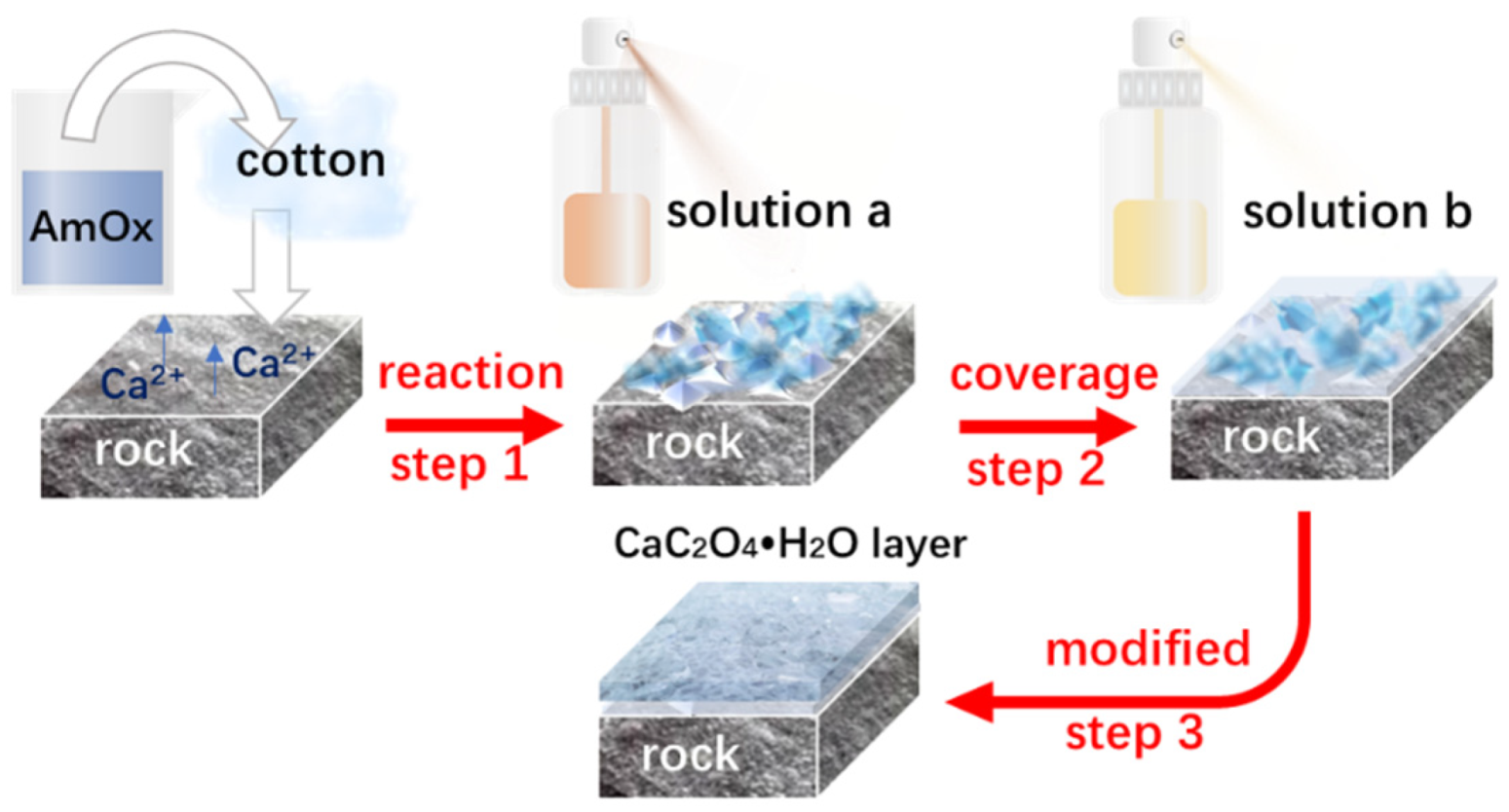

2.1. Coating Formulation

2.2. Stone Substrate

2.3. Characterization Techniques

3. Results and Discussion

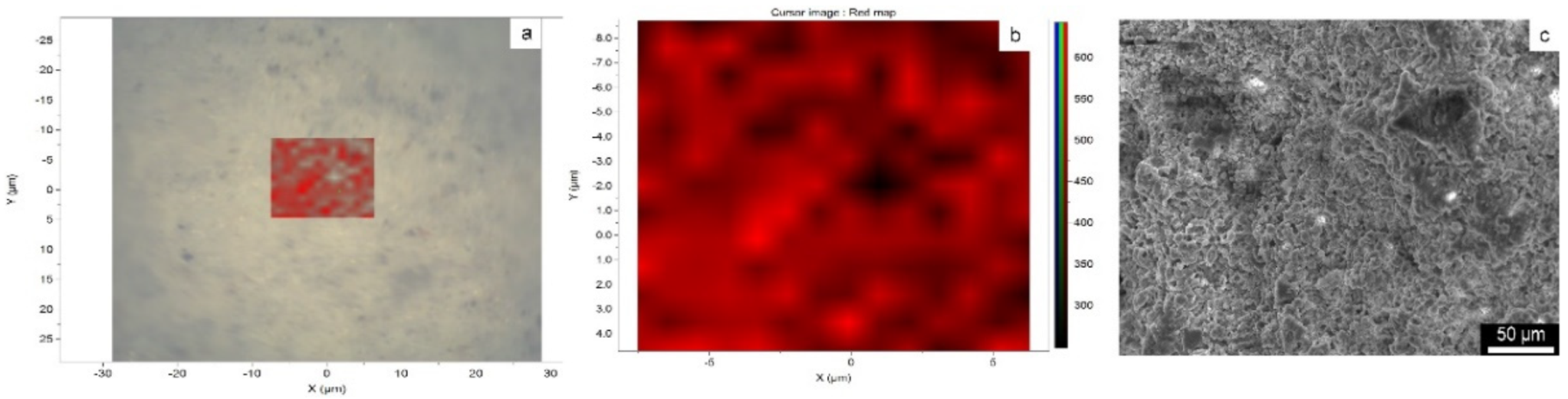

3.1. Characterization of the Film

3.2. Protective Properties of the Film

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Dong, T.L.; Zhang, K.; Yang, F.W.; Wang, L.Q. Preliminary Study of the Targeted Cleaning of an Artificial Gypsum Layer on White Marble. Coatings 2021, 11, 37. [Google Scholar] [CrossRef]

- Gherardi, F. Current and Future Trends in Protective Treatments for Stone Heritage. In Conserving Stone Heritage: Traditional and Innovative Materials and Techniques; Gherardi, F., Maravelaki, P.N., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 137–176. [Google Scholar]

- Zucchelli, M.; Mazzon, G.; Bertolacci, L.; Carzino, R.; Zendri, E.; Athanassiou, A. Stone sustainable protection and preservation using a zein-based hydrophobic coating. Prog. Org. Coat. 2021, 159, 11. [Google Scholar] [CrossRef]

- Ion, R.M.; Iancu, L.; Vasilievici, G.; Grigore, M.E.; Andrei, R.E.; Radu, G.I.; Grigorescu, R.M.; Teodorescu, S.; Bucurica, I.A.; Ion, M.L.; et al. Ion-Substituted Carbonated Hydroxyapatite Coatings for Model Stone Samples. Coatings 2019, 9, 231. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, F.W.; Zuo, G.F.; Zhang, R.X.; Wei, G.F.; Ma, Q. Protection of the surface weathering stone artworks by a chemical conversion method. Constr. Build. Mater. 2018, 182, 210–214. [Google Scholar] [CrossRef]

- Dei, L.; Salvadori, B. Nanotechnology in cultural heritage conservation: Nanometric slaked lime saves architectonic and artistic surfaces from decay. J. Cult. Herit. 2006, 7, 110–115. [Google Scholar] [CrossRef]

- Price, C.A. The consolidation of limestone using a lime poultice and limewater. Stud. Conserv. 1984, 29, 160–162. [Google Scholar] [CrossRef]

- Drdacky, M.; Slizkova, Z.; Ziegenbalg, G. A Nano Approach to Consolidation of Degraded Historic Lime Mortars. J. Nano Res. 2009, 8, 13–22. [Google Scholar] [CrossRef]

- Ziegenbalg, G.; Bra, K.; Pianski, J. Nano-lime-A new material for the consolidation and conservation of historic mortars. In Proceedings of the 2nd Historic Mortars Conference, Prague, Czech Republic, 22–24 September 2010; pp. 1301–1309. [Google Scholar]

- Ziegenbalg, G. Colloidal calcium hydroxide-a new material for consolidation and conservation of carbonatic stones. In Proceedings of the 11th International Congress on Deterioration and Conservation of Stone III, Torun, Poland, 15–20 September 2008; pp. 1109–1115. [Google Scholar]

- Rampazzi, L. Calcium oxalate films on works of art: A review. J. Cult. Herit. 2019, 40, 195–214. [Google Scholar] [CrossRef]

- Sassoni, E. Hydroxyapatite and Other Calcium Phosphates for the Conservation of Cultural Heritage: A Review. Materials 2018, 11, 557. [Google Scholar] [CrossRef]

- Lu, R.C.; Wang, L.; Liu, Y.; Yang, F.W.; Yang, L.; Wang, L.Q.; Gao, X. Conservation of surface gypsification stone relics using methanol solution of barium hydroxide as a novel treating agent. Appl. Phys. A Mater. Sci. Process. 2022, 128, 8. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Corcione, C.E. Historically Accurate Reconstruction of the Materials and Conservation Technologies Used on the Facades of the Artistic Buildings in Lecce (Apulia, Italy). Materials 2022, 15, 3658. [Google Scholar] [CrossRef] [PubMed]

- Aragoni, M.C.; Giacopetti, L.; Arca, M.; Carcangiu, G.; Columbu, S.; Gimeno, D.; Isaia, F.; Lippolis, V.; Meloni, P.; Ezquerra, A.N.; et al. Ammonium monoethyloxalate (AmEtOx): A new agent for the conservation of carbonate stone substrates. New J. Chem. 2021, 45, 14. [Google Scholar] [CrossRef]

- Dreyfuss, T. Artificially induced calcium oxalate on limestone in urban environments-New findings. J. Cult. Herit. 2020, 42, 56–63. [Google Scholar] [CrossRef]

- Gomez-Villalba, L.S.; Feijoo, J.; Rabanal, M.E.; Fort, R. In-situ electrochemical synthesis of inorganic compounds for materials conservation: Assessment of their effects on the porous structure. Ceram. Int. 2021, 47, 30406–30424. [Google Scholar] [CrossRef]

- Calore, N.; Botteon, A.; Colombo, C.; Comunian, A.; Possenti, E.; Realini, M.; Sali, D.; Conti, C. High Resolution ATR μ-FTIR to map the diffusion of conservation treatments applied to painted plasters. Vib. Spectrosc. 2018, 98, 105–110. [Google Scholar] [CrossRef]

- Suyamud, B.; Ferrier, J.; Csetenyi, L.; Inthorn, D.; Gadd, G.M. Biotransformation of struvite by Aspergillus niger: Phosphate release and magnesium biomineralization as glushinskite. Environ. Microbiol. 2020, 22, 1588–1602. [Google Scholar] [CrossRef]

- Maiore, L.; Aragoni, M.C.; Carcangiu, G.; Cocco, O.; Isaia, F.; Lippolis, V.; Meloni, P.; Murru, A.; Tuveri, E.; Arca, M. Synthesis, characterization and DFT-modeling of novel agents for the protection and restoration of historical calcareous stone substrates. J. Colloid Interface Sci. 2015, 448, 320–330. [Google Scholar] [CrossRef]

- Ruiz-Agudo, E.; Alvarez-Lloret, P.; Putnis, C.V.; Rodriguez-Navarro, A.B.; Putnis, A. Influence of chemical and structural factors on the calcite-calcium oxalate transformation. Crystengcomm 2013, 15, 9968–9979. [Google Scholar] [CrossRef]

- Burgos-Cara, A.; Putnis, C.V.; Ortega-Huertas, M.; Ruiz-Agudo, E. Influence of pH and citrate on the formation of oxalate layers on calcite revealed by in situ nanoscale imaging. Crystengcomm 2017, 19, 3420–3429. [Google Scholar] [CrossRef]

- Conti, C.; Aliatis, I.; Casati, M.; Colombo, C.; Matteini, M.; Negrotti, R.; Realini, M.; Zerbi, G. Diethyl oxalate as a new potential conservation product for decayed carbonatic substrates. J. Cult. Herit. 2014, 15, 336–338. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, Q.; Zhao, Y.J.; Lv, J.; Li, Z.H.; Ma, X.B. Autocatalytic Kinetic Study of Dimethyl Oxalate Consecutive Hydrolysis. Ind. Eng. Chem. Res. 2014, 53, 4207–4214. [Google Scholar] [CrossRef]

- Graziani, G.; Sassoni, E.; Franzoni, E.; Scherer, G.W. Hydroxyapatite coatings for marble protection: Optimization of calcite covering and acid resistance. Appl. Surf. Sci. 2016, 368, 241–257. [Google Scholar] [CrossRef]

- Graziani, G.; Sassoni, E.; Scherer, G.W.; Franzoni, E. Resistance to simulated rain of hydroxyapatite- and calcium oxalate-based coatings for protection of marble against corrosion. Corrosion Sci. 2017, 127, 168–174. [Google Scholar] [CrossRef]

- Maravelaki, P.N.; Kapetanaki, K.; Stefanakis, D. TEOS-PDMS-Calcium Oxalate Hydrophobic Nanocomposite for Protection and Stone Consolidation. Heritage 2021, 4, 4068–4075. [Google Scholar] [CrossRef]

- He, L.; Wang, L.; Liu, Y.; Yang, F.W.; Gao, X. Preparation of calcium oxalate film on the surface of historic carbonate stone in a humid environment. New J. Chem. 2022, 46, 1099–1104. [Google Scholar] [CrossRef]

- Mendes, G.D.; Bahri-Esfahani, J.; Csetenyi, L.; Hillier, S.; George, T.S.; Gadd, G.M. Chemical and Physical Mechanisms of Fungal Bioweathering of Rock Phosphate. Geomicrobiol. J. 2021, 38, 384–394. [Google Scholar] [CrossRef]

- Aggelakopoulou, E.; Bakolas, A. What were the colors of the Parthenon? Investigation of the entablature’s cornice blocks. J. Archaeol. Sci. 2022, 140, 18. [Google Scholar] [CrossRef]

- Akbar, N.A.; Aziz, H.A.; Adlan, M.N. Characteristic Study of Physical and Chemical Properties of Limestone Subjected to Adsorption of Fe and Mn in Groundwater. In Proceedings of the AWAM International Conference on Civil Engineering (AICCE), Nibong Tebal, Malaysia, 21–22 August 2019; pp. 621–627. [Google Scholar]

- Ibis, F.; Dhand, P.; Suleymanli, S.; van der Heijden, A.; Kramer, H.J.M.; Eral, H.B. A Combined Experimental and Modelling Study on Solubility of Calcium Oxalate Monohydrate at Physiologically Relevant pH and Temperatures. Crystals 2020, 10, 924. [Google Scholar] [CrossRef]

| Sample | Type | Test Description | Analysis Description |

|---|---|---|---|

| 1 | coated stone | according to analysis requirement | XRD, Raman, FTIR, AFM, SEM (surface and cross section) |

| 2 | stone-1 | simulate acid rain dissolution experiment at pH 1 | XRD, Raman, SEM (surface) |

| 3 | stone-2 | simulate acid rain dissolution experiment at pH 2 | XRD, Raman, SEM (surface) |

| 4 | stone-3 | simulate acid rain dissolution experiment at pH 3 | XRD, Raman, SEM (surface) |

| 5 | stone-4 | simulate acid rain dissolution experiment at pH 4 | XRD, Raman, SEM (surface) |

| 6 | coated stone-1 | simulate acid rain dissolution experiment at pH 1 | XRD, Raman, SEM (surface) |

| 7 | coated stone-2 | simulate acid rain dissolution experiment at pH 2 | XRD, Raman, SEM (surface) |

| 8 | coated stone-3 | simulate acid rain dissolution experiment at pH 3 | XRD, Raman, SEM (surface) |

| 9 | coated stone-4 | simulate acid rain dissolution experiment at pH 4 | XRD, Raman, SEM (surface) |

| 10 | coated green-white stone | exposure to outside environment (Beijing huairou district) | Digital image, Raman mapping, SEM (surface section) |

| Samples | 2θ (°) | hkl |

|---|---|---|

| Dolomite (36–0426) | 30.938 | 104 |

| Coated Stone-1 | 30.937 | 104 |

| Coated Stone-2 | 30.960 | 104 |

| Coated Stone-3 | 30.982 | 104 |

| Coated Stone-4 | 30.978 | 104 |

| Stone-1 | 30.880 | 104 |

| Stone-2 | 30.940 | 104 |

| Stone-3 | 31.000 | 104 |

| Stone-4 | 30.940 | 104 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zha, J.; Gu, Y.; Wei, S.; Han, H.; Wang, A.; Ma, Q. Preliminary Investigation of Sequential Application of Different Calcium Oxalate Solutions for Carbonate Rock Conservation. Coatings 2022, 12, 1412. https://doi.org/10.3390/coatings12101412

Zha J, Gu Y, Wei S, Han H, Wang A, Ma Q. Preliminary Investigation of Sequential Application of Different Calcium Oxalate Solutions for Carbonate Rock Conservation. Coatings. 2022; 12(10):1412. https://doi.org/10.3390/coatings12101412

Chicago/Turabian StyleZha, Jianrui, Yaoqi Gu, Shuya Wei, Huarui Han, Ankun Wang, and Qinglin Ma. 2022. "Preliminary Investigation of Sequential Application of Different Calcium Oxalate Solutions for Carbonate Rock Conservation" Coatings 12, no. 10: 1412. https://doi.org/10.3390/coatings12101412

APA StyleZha, J., Gu, Y., Wei, S., Han, H., Wang, A., & Ma, Q. (2022). Preliminary Investigation of Sequential Application of Different Calcium Oxalate Solutions for Carbonate Rock Conservation. Coatings, 12(10), 1412. https://doi.org/10.3390/coatings12101412