Research on Coarse-Grained Discrete Element Model and Optimization for Fine Particles

Abstract

:1. Introduction

2. Numerical Modeling

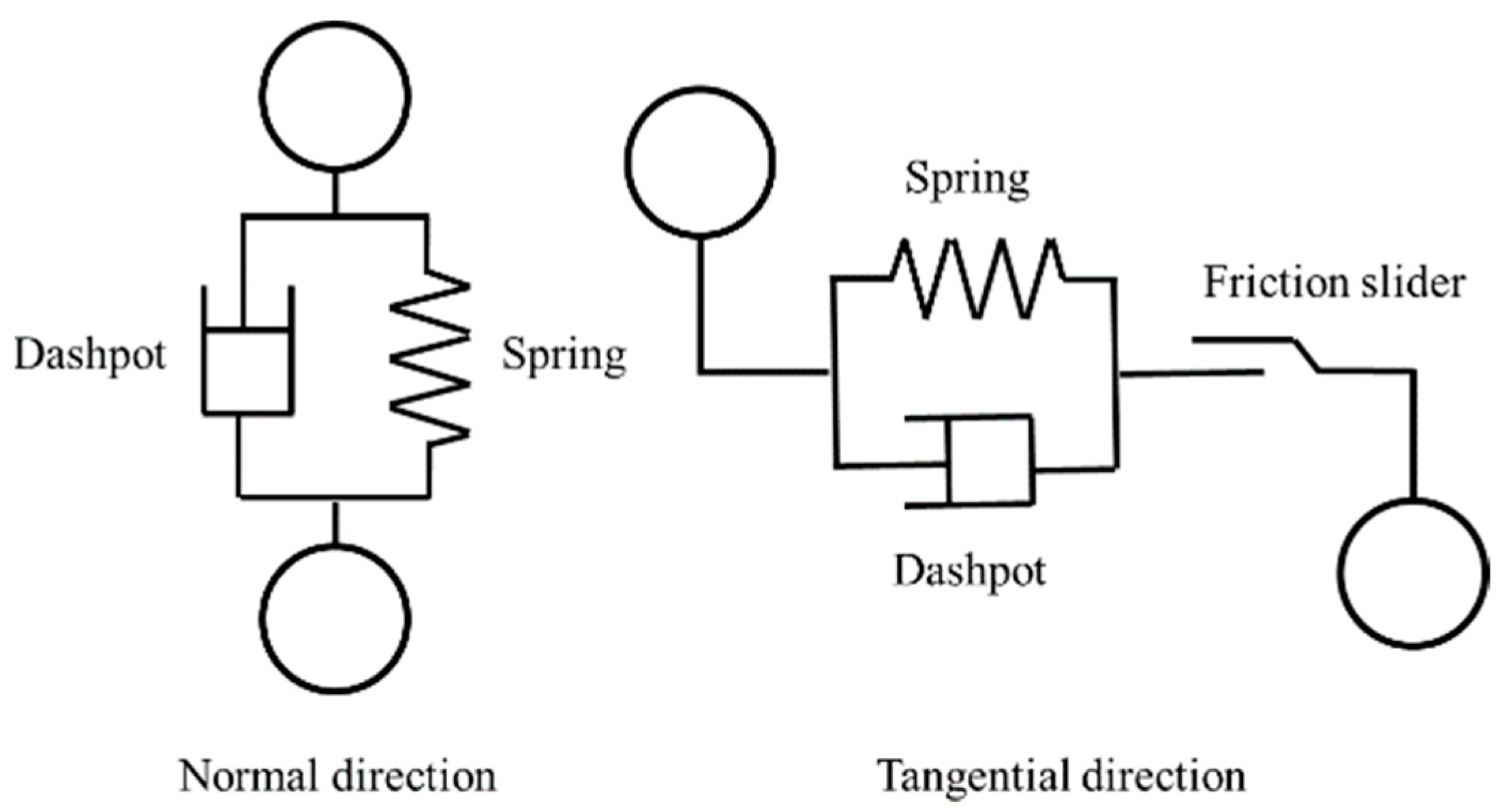

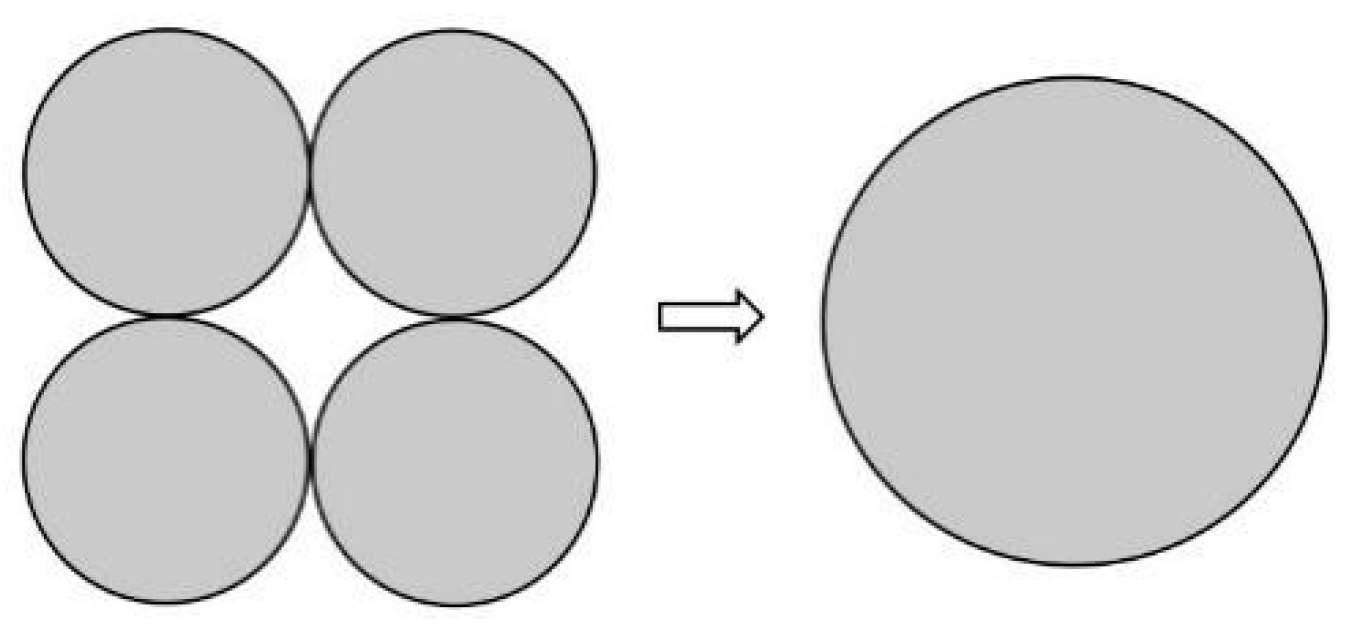

2.1. Simulation Method

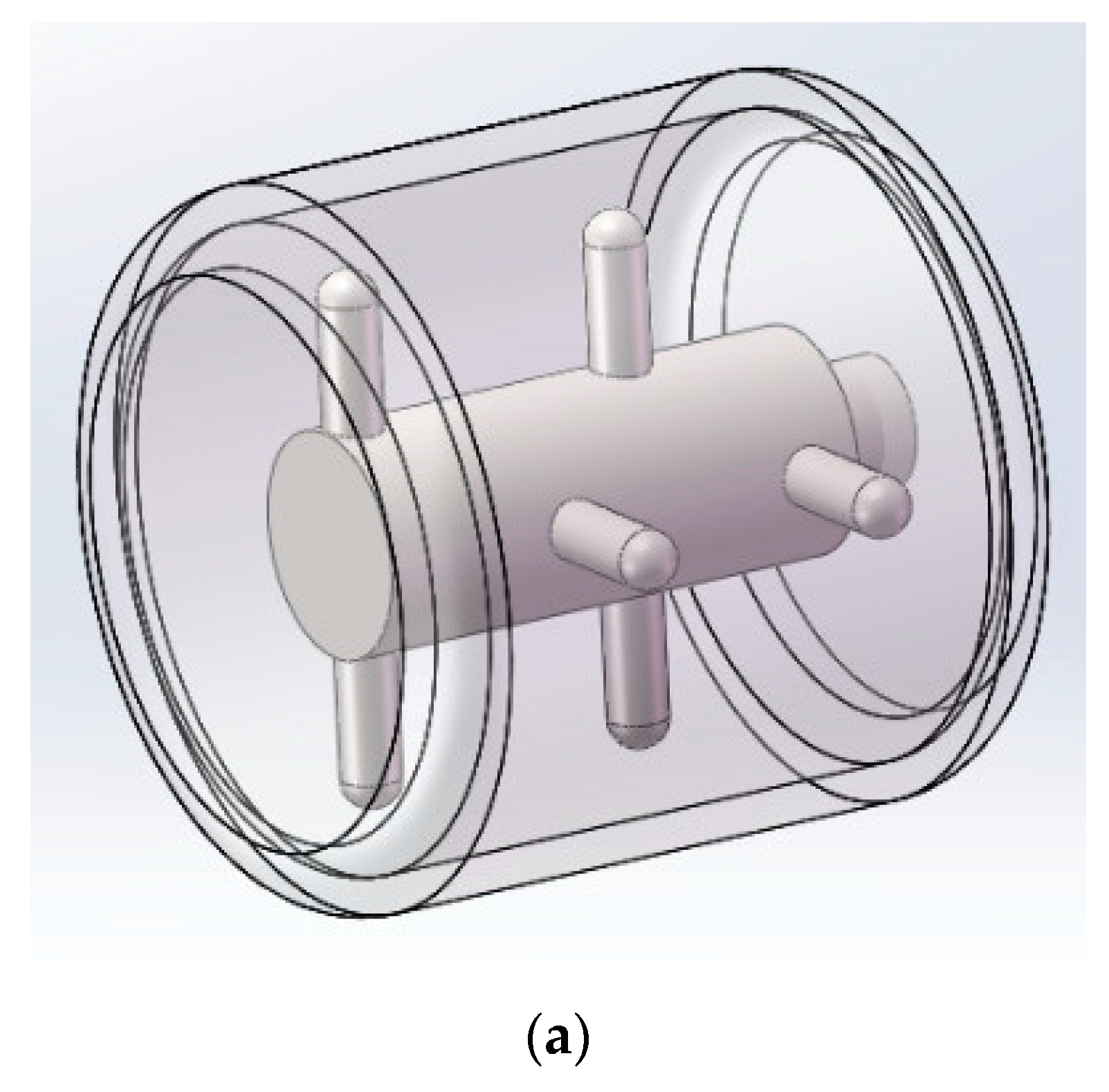

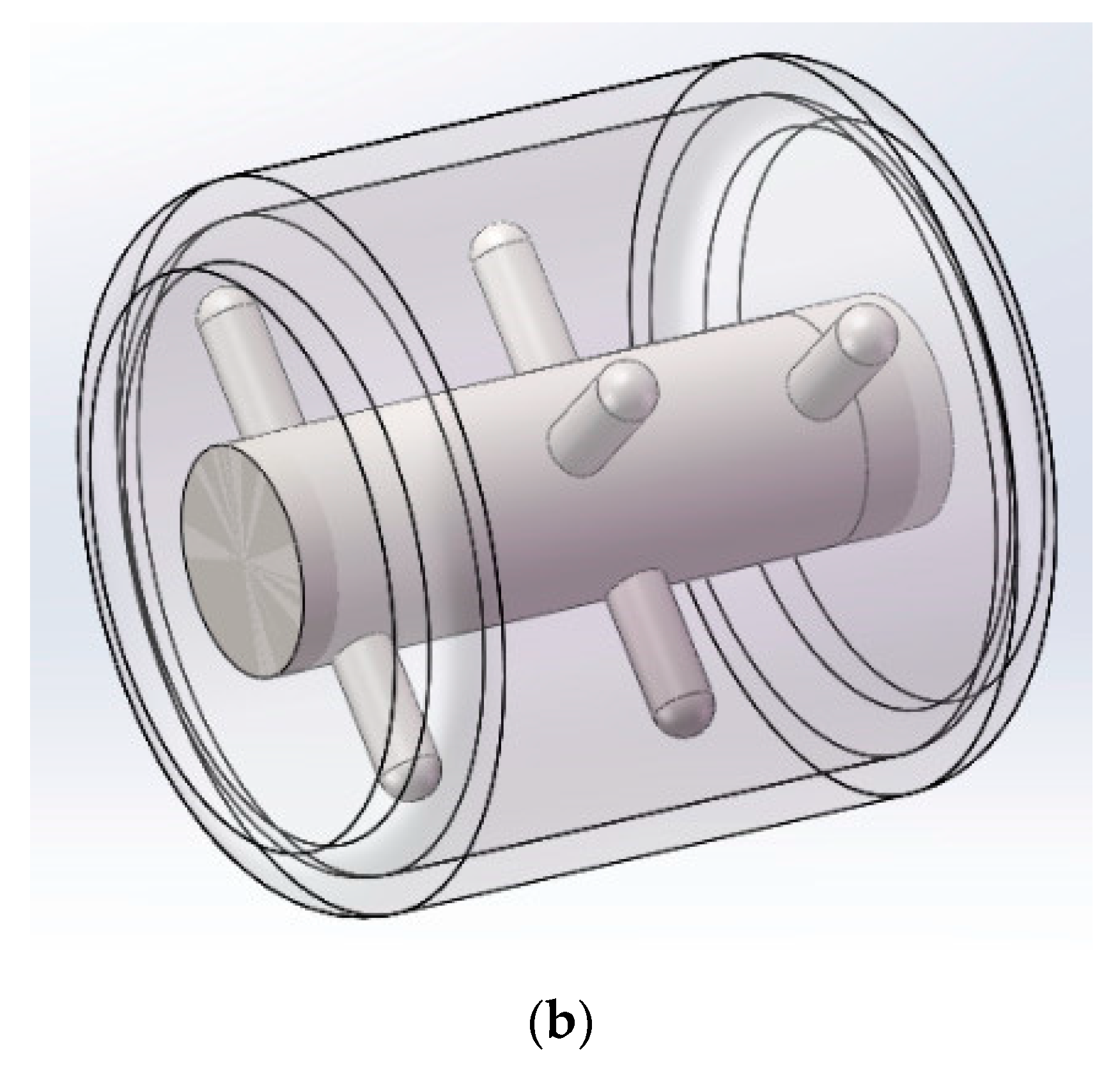

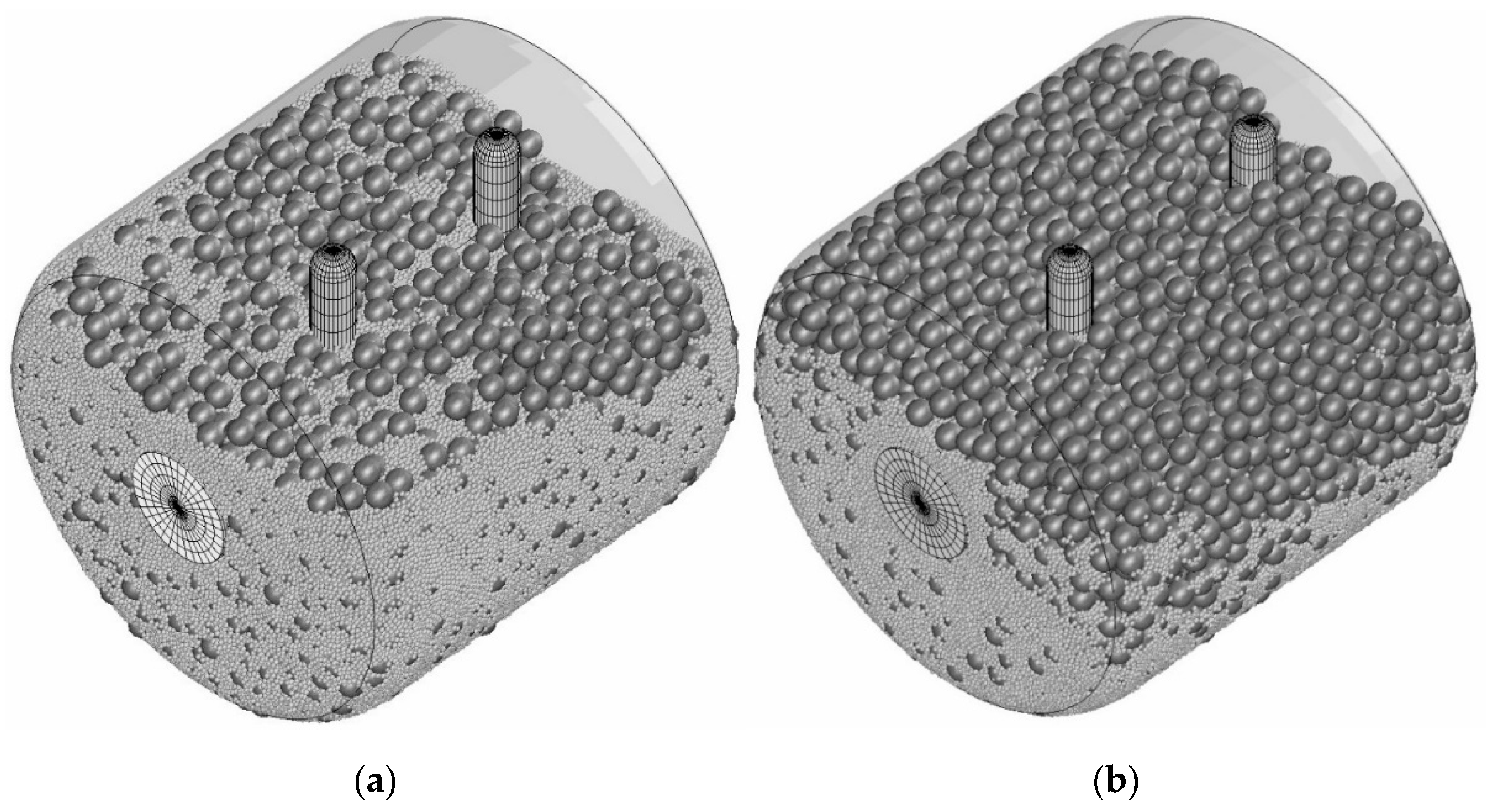

2.2. Simulation Conditions and Model

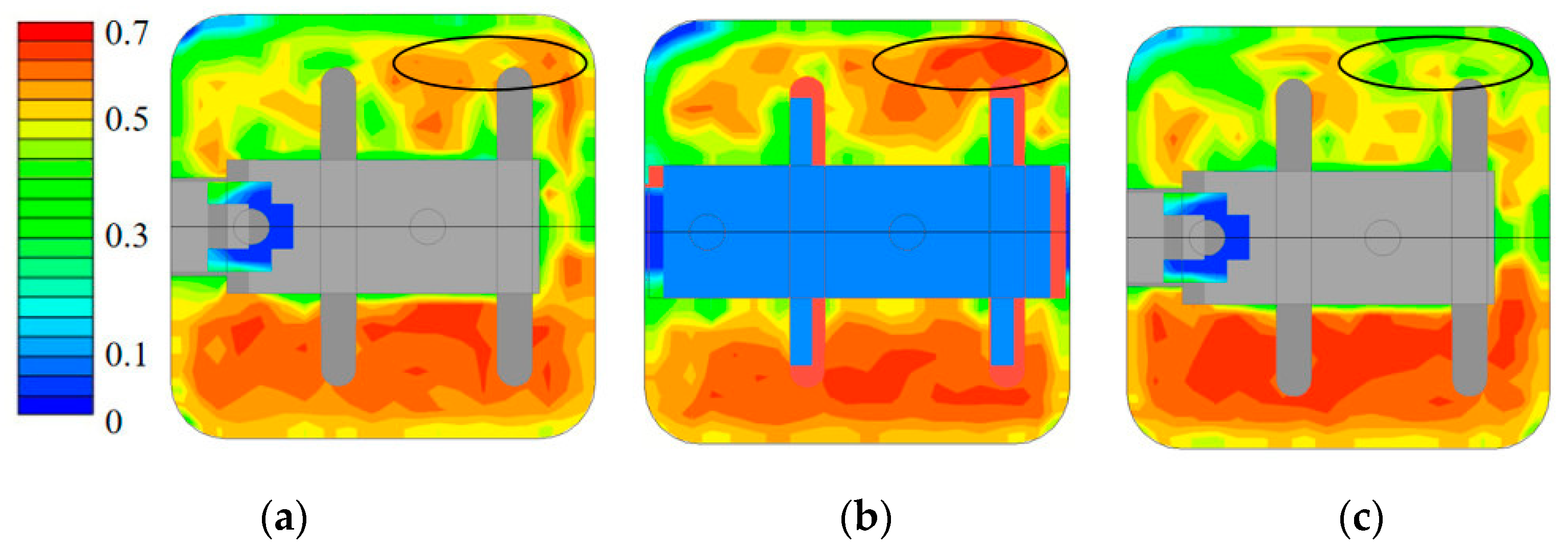

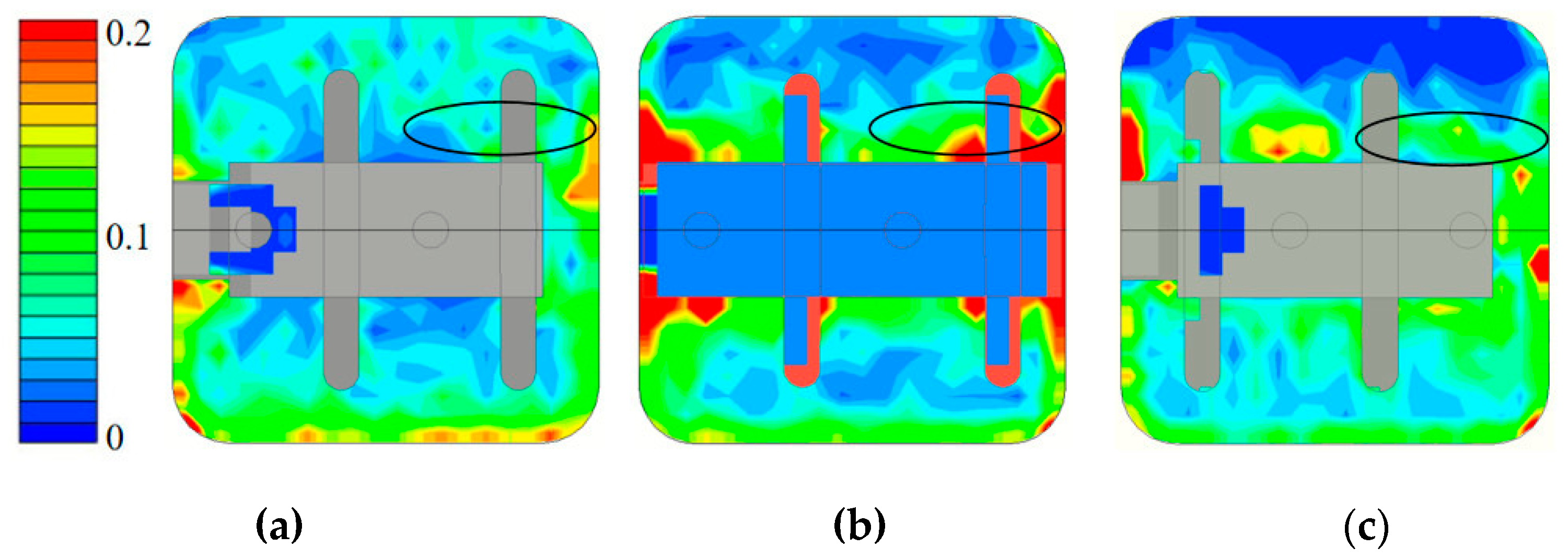

3. Comparison of Different Model Conditions

4. Results and Discussion

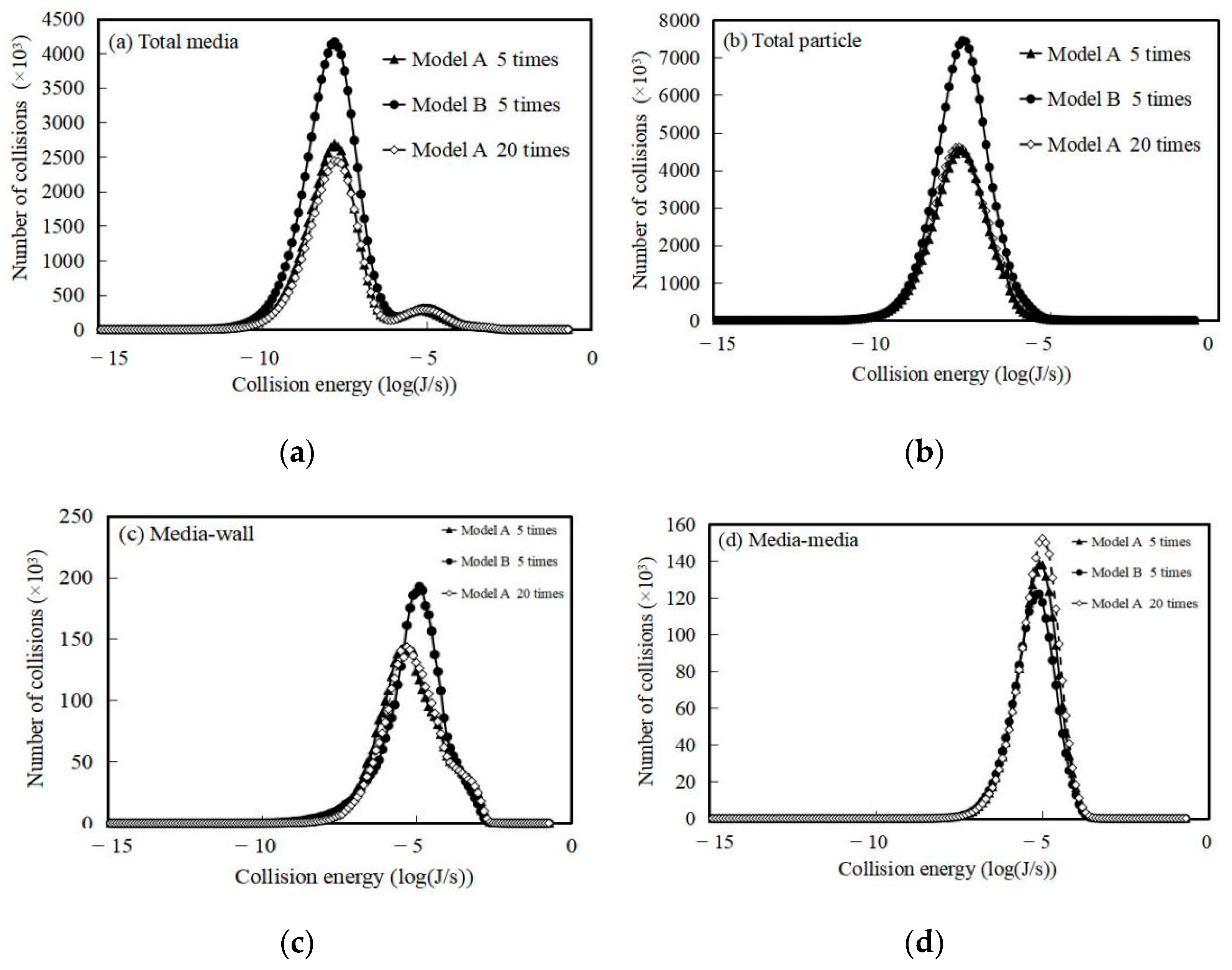

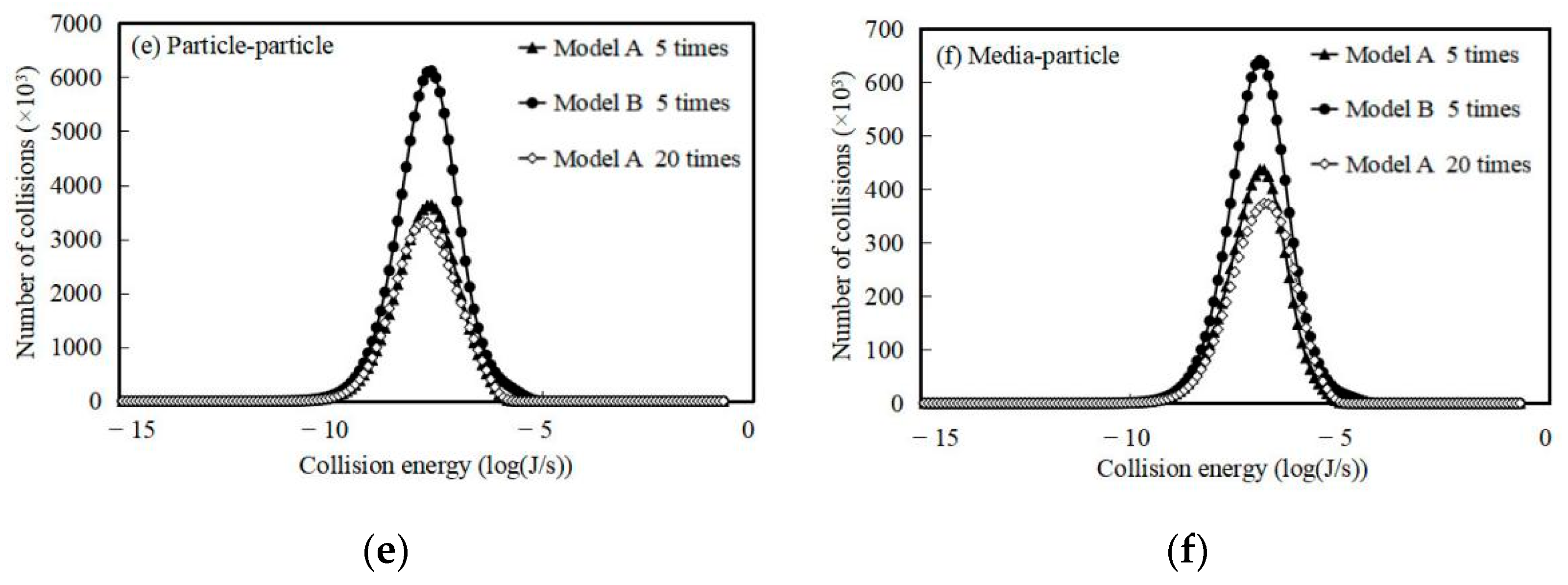

4.1. Comparison of Collision Energy

4.2. Comparison of Average Collision Energy

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schwarz, M.P. Modelling flocculation using CFD-DEM in a turbulent flow, with reference to “Particle flocculation in a stirred tank: A microscopic test by coupled CFD-DEM approach” by Wang et al. J. Environ. Chem. Eng. 2022, 10, 107646. [Google Scholar] [CrossRef]

- Hu, L.; Zhu, H.; Hua, J. DEM study on effects of particle size and grinding media properties on energy transitions in a horizontal agitator. Adv. Powder Technol. 2022, 33, 103604. [Google Scholar] [CrossRef]

- Feng, Z.-K.; Xu, W.-J.; Lubbe, R. Three-dimensional morphological characteristics of particles in nature and its application for DEM simulation. Powder Technol. 2020, 364, 635–646. [Google Scholar] [CrossRef]

- Pulatsu, B.; Erdogmus, E.; Lourenço, P.B.; Lemos, J.V.; Tuncay, K. Simulation of the in-plane structural behavior of unreinforced masonry walls and buildings using DEM. Structures 2020, 27, 2274–2287. [Google Scholar] [CrossRef]

- Beloglazov, I. Automation experimental studies of grinding process in jaw crusher using DEM simulation. J. Phys. Conf. Ser. 2018, 1118, 012007. [Google Scholar] [CrossRef]

- Adeli, H. Advances in Design Optimization; CRC Press: London, UK, 1994. [Google Scholar]

- Li, Z.; Tong, X.; Zhou, B.; Wang, X. Modeling and parameter optimization for the design of vibrating screens. Miner. Eng. 2015, 83, 149–155. [Google Scholar] [CrossRef]

- Kannan, A.S.; Jareteg, K.; Lassen, N.C.K.; Carstensen, J.M.; Hansen, M.A.E.; Dam, F.; Sasic, S. Design and performance optimization of gravity tables using a combined CFD-DEM framework. Powder Technol. 2017, 318, 423–440. [Google Scholar] [CrossRef]

- Zhu, H.P.; Zhou, Z.Y.; Yang, R.Y.; Yu, A.B. Discrete particle simulation of particulate systems: Theoretical developments. Chem. Eng. Sci. 2007, 62, 3378–3396. [Google Scholar] [CrossRef]

- Ji, S.; Wang, S.; Zhou, Z. Influence of particle shape on mixing rate in rotating drums based on super-quadric DEM simulations. Adv. Powder Technol. 2020, 31, 3540–3550. [Google Scholar] [CrossRef]

- Bibak, Z.; Banisi, S. A combined physical and DEM modelling approach to investigate particle shape effects on load movement in tumbling mills. Adv. Powder Technol. 2021, 32, 916–930. [Google Scholar] [CrossRef]

- Fukui, S.; Tsunazawa, Y.; Hisatomi, S.; Granata, G.; Tokoro, C.; Okuyama, K.; Iwamoto, M.; Sekine, Y. Effect of agitator shaft direction on grinding performance in media stirred mill: Investigation using DEM simulation. Mater. Trans. 2018, 59, 488–493. [Google Scholar] [CrossRef] [Green Version]

- Hu, L.; Zhu, H.; Hua, J. DEM simulation of energy transitions in a hammer mill: Effect of impeller configurations, agitation speed, and fill level. Powder Technol. 2021, 394, 1077–1093. [Google Scholar] [CrossRef]

- Munjiza, A. The Combined Finite-Discrete Element Method; John Wiley & Sons: Chichester, UK, 2004. [Google Scholar]

- Jajcevic, D.; Siegmann, E.; Radeke, C.; Khinast, J.G. Large-scale CFD–DEM simulations of fluidized granular systems. Chem. Eng. Sci. 2013, 98, 298–310. [Google Scholar] [CrossRef]

- Cleary, P.W.; Morrison, R.D. Comminution mechanisms, particle shape evolution and collision energy partitioning in tumbling mills. Miner. Eng. 2016, 86, 75–95. [Google Scholar] [CrossRef]

- Deng, X.; Zheng, K.; Davé, R.N. Discrete element method based analysis of mixing and collision dynamics in adhesive mixing process. Chem. Eng. Sci. 2018, 190, 220–231. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Lucay, F.A.; Botero, Y.L. Trends in modeling, design, and optimization of multiphase systems in minerals processing. Minerals 2020, 10, 22. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Kajiwara, S.; Sakai, M. Numerical investigation on the mixing mechanism in a cross-torus paddle mixer using the DEM-CFD method. Powder Technol. 2021, 377, 89–102. [Google Scholar] [CrossRef]

- Hlosta, J.; Jezerská, L.; Rozbroj, J.; Žurovec, D.; Nečas, J.; Zegzulka, J. DEM Investigation of the influence of particulate properties and operating conditions on the mixing process in rotary drums: Part 2—Process Validation and Experimental Study. Processes 2020, 8, 184. [Google Scholar] [CrossRef] [Green Version]

- Ketterhagen, W.R.; am Ende, M.T.; Hancock, B.C. Process modeling in the pharmaceutical industry using the discrete element method. J. Pharm. Sci. 2009, 98, 442–470. [Google Scholar] [CrossRef]

- Levitt, M.; Warshel, A. Computer simulation of protein folding. Nature 1975, 253, 694–698. [Google Scholar] [CrossRef]

- Warshel, A.; Levitt, M. Theoretical studies of enzymic reactions: Dielectric, electrostatic and steric stabilization of the carbonium ion in the reaction of lysozyme. J. Mol. Biol. 1976, 103, 227–249. [Google Scholar] [CrossRef]

- Levitt, M. Birth and future of multiscale modeling for macromolecular systems (Nobel Lecture). Angew. Chem. Int. Ed. 2014, 53, 10006–10018. [Google Scholar] [CrossRef] [PubMed]

- Badaczewska-Dawid, A.E.; Kolinski, A.; Kmiecik, S. Computational reconstruction of atomistic protein structures from coarse-grained models. Comput. Struct. Biotechnol. J. 2020, 18, 162–176. [Google Scholar] [CrossRef] [PubMed]

- Queteschiner, D.; Lichtenegger, T.; Pirker, S.; Schneiderbauer, S. Multi-level coarse-grain model of the DEM. Powder Technol. 2018, 338, 614–624. [Google Scholar] [CrossRef]

- Queteschiner, D.; Lichtenegger, T.; Schneiderbauer, S.; Pirker, S. Coupling resolved and coarse-grain DEM models. Part. Sci. Technol. 2018, 36, 517–522. [Google Scholar] [CrossRef]

- Chan, E.L.; Washino, K. Coarse grain model for DEM simulation of dense and dynamic particle flow with liquid bridge forces. Chem. Eng. Res. Des. 2018, 132, 1060–1069. [Google Scholar] [CrossRef]

- Sakai, M.; Takahashi, H.; Pain, C.C.; Latham, J.-P.; Xiang, J. Study on a large-scale discrete element model for fine particles in a fluidized bed. Adv. Powder Technol. 2012, 23, 673–681. [Google Scholar] [CrossRef]

- Warheit, D.B. Hazard and risk assessment strategies for nanoparticle exposures: How far have we come in the past 10 years? F1000Research 2018, 7, 376. [Google Scholar] [CrossRef] [Green Version]

- Morgeneyer, M.; Aguerre-Chariol, O.; Bressot, C. STEM imaging to characterize nanoparticle emissions and help to design nanosafer paints. Chem. Eng. Res. Des. 2018, 136, 663–674. [Google Scholar] [CrossRef]

- Bressot, C.; Aubry, A.; Pagnoux, C.; Aguerre-Chariol, O.; Morgeneyer, M. Assessment of functional nanomaterials in medical applications: Can time mend public and occupational health risks related to the products’ fate? J. Toxicol. Environ. Health Part A 2018, 81, 957–973. [Google Scholar] [CrossRef] [PubMed]

- Bressot, C.; Shandilya, N.; Jayabalan, T.; Fayet, G.; Voetz, M.; Meunier, L.; Le Bihan, O.; Aguerre-Chariol, O.; Morgeneyer, M. Exposure assessment of Nanomaterials at production sites by a Short Time Sampling (STS) approach: Strategy and first results of measurement campaigns. Process Saf. Environ. Prot. 2018, 116, 324–332. [Google Scholar] [CrossRef]

- Bressot, C.; Shandilya, N.; Nogueira, E.; Cavaco-Paulo, A.; Morgeneyer, M.; Le Bihan, O.; Aguerre-Chariol, O. Exposure Assessment Based Recommendations to Improve Nanosafety at Nanoliposome Production Sites. J. Nanomater. 2015, 16, 342. [Google Scholar] [CrossRef] [Green Version]

- Morgeneyer, M.; Ramírez-Gómez, A.; Poletto, M.; Ward-Smith, S.; Tweedie, R.J.; Heng, J.Y.; Maass, S.; Bressot, C. Particle technology as a uniform discipline? Towards a holistic approach to particles, their creation, characterisation, handling and processing! Chem. Eng. Res. Des. 2018, 146, 162–165. [Google Scholar] [CrossRef]

- Morgeneyer, M.; Shandilya, N.; Chen, Y.-M.; Le Bihan, O. Use of a modified Taber abrasion apparatus for investigating the complete stress state during abrasion and in-process wear particle aerosol generation. Chem. Eng. Res. Des. 2015, 93, 251–256. [Google Scholar] [CrossRef]

- Göhler, D.; Stintz, M.; Hillemann, L.; Vorbau, M. Characterization of Nanoparticle Release from Surface Coatings by the Simulation of a Sanding Process. Ann. Occup. Hyg. 2010, 54, 615–624. [Google Scholar] [CrossRef] [PubMed]

- Shandilya, N.; Morgeneyer, M.; Le Bihan, O. First development to model aerosol emission from solid surfaces subjected to mechanical stresses: I. Development and results. J. Aerosol Sci. 2015, 89, 43–57. [Google Scholar] [CrossRef]

- Shandilya, N.; Morgeneyer, M.; Le Bihan, O. First development to model aerosol emission from solid surfaces subjected to mechanical stresses: II. Experiment-theory comparison, simulation and sensibility analysis. J. Aerosol Sci. 2015, 89, 1–17. [Google Scholar] [CrossRef]

- Bui, T.Q.; Hu, X. A review of phase-field models, fundamentals and their applications to composite laminates. Eng. Fract. Mech. 2021, 248, 107705. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, X.; Bui, T.Q.; Yao, W. Phase field modeling of fracture in fiber reinforced composite laminate. Int. J. Mech. Sci. 2019, 161–162, 105008. [Google Scholar] [CrossRef]

- Kruggel-Emden, H.; Wirtz, S.; Scherer, V. A study on tangential force laws applicable to the discrete element method (DEM) for materials with viscoelastic or plastic behavior. Chem. Eng. Sci. 2008, 63, 1523–1541. [Google Scholar] [CrossRef]

- Ellyin, F. Fatigue Damage, Crack Growth and Life Prediction; Springer Science & Business Media: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Luding, S. Introduction to discrete element methods: Basic of contact force models and how to perform the micro-macro transition to continuum theory. Eur. J. Environ. Civ. Eng. 2008, 12, 785–826. [Google Scholar] [CrossRef]

- Mishra, B.K.; Rajamani, R.K. The discrete element method for the simulation of ball mills. Appl. Math. Model. 1992, 16, 598–604. [Google Scholar] [CrossRef]

- Weerasekara, N.S.; Liu, L.X.; Powell, M.S. Estimating energy in grinding using DEM modelling. Miner. Eng. 2016, 85, 23–33. [Google Scholar] [CrossRef] [Green Version]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

| Number of Calculations [–] | 500,000 |

|---|---|

| Time increment [s] | 1.0 × 10−5 |

| Media diameter [m] | 0.002 |

| Media density [kg/m3] | 7770 |

| Particle density [kg/m3] | 2260 |

| Coefficient of restitution [–] | 0.36 |

| Coefficient of friction [–] | 0.52 |

| Rotaion speed [rpm] | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X. Research on Coarse-Grained Discrete Element Model and Optimization for Fine Particles. Coatings 2022, 12, 1483. https://doi.org/10.3390/coatings12101483

Jiang X. Research on Coarse-Grained Discrete Element Model and Optimization for Fine Particles. Coatings. 2022; 12(10):1483. https://doi.org/10.3390/coatings12101483

Chicago/Turabian StyleJiang, Xin. 2022. "Research on Coarse-Grained Discrete Element Model and Optimization for Fine Particles" Coatings 12, no. 10: 1483. https://doi.org/10.3390/coatings12101483