ZIF-67 Derived Co-Ni/C Composites for High-Efficiency Broadband Microwave Absorption

Abstract

:1. Introduction

2. Experiment and Characterization

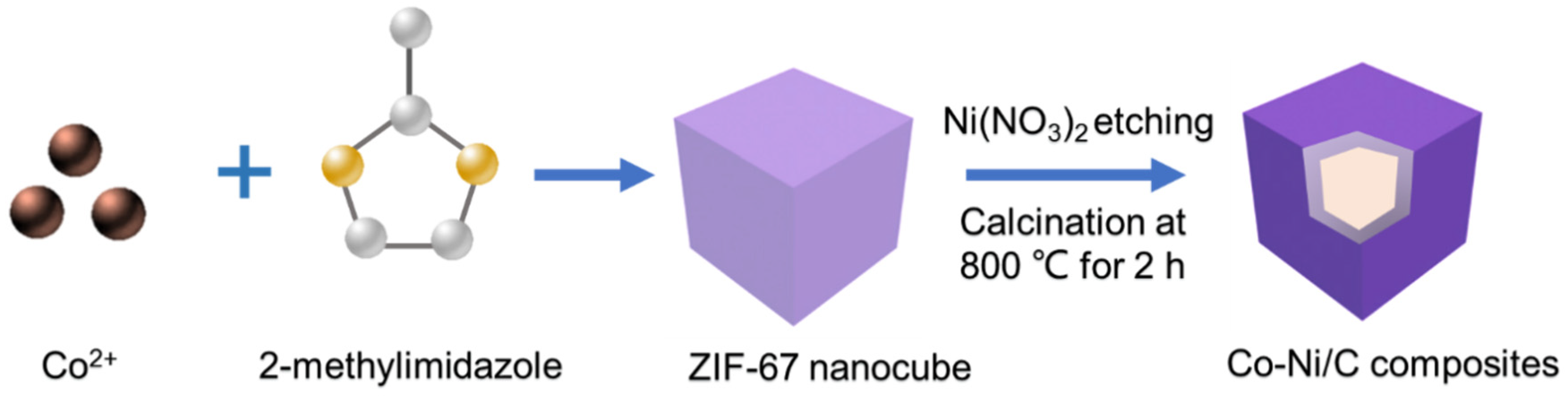

2.1. Synthesis of ZIF-67

2.2. Synthesis of Ni-Doped ZIF-67

2.3. Synthesis of Co-Ni/C

2.4. Characterization

3. Results and Discussion

3.1. Microstructure of Ni-Doped ZIF-67

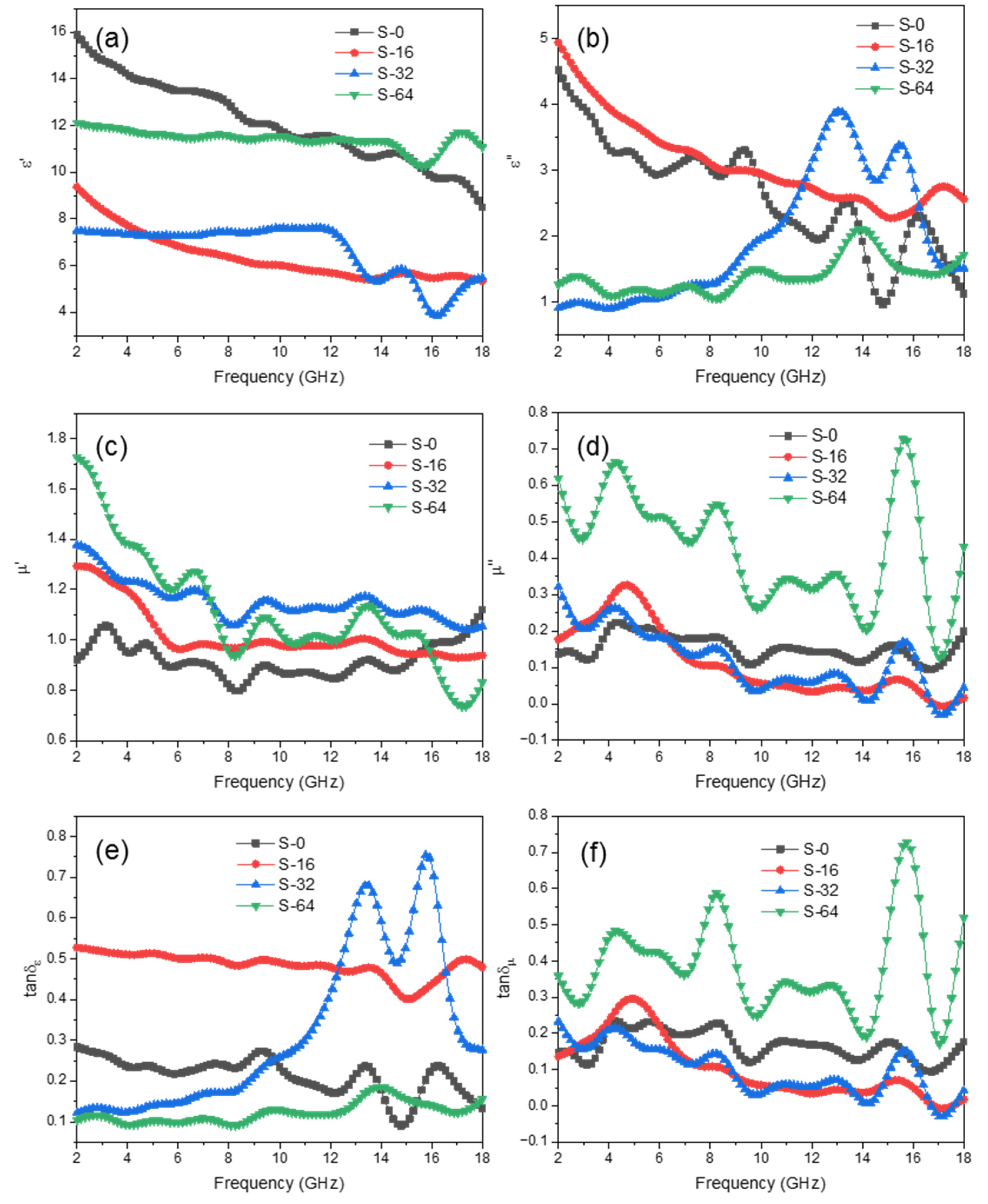

3.2. Microstructure and Microwave Absorption Properties of Co-Ni/C

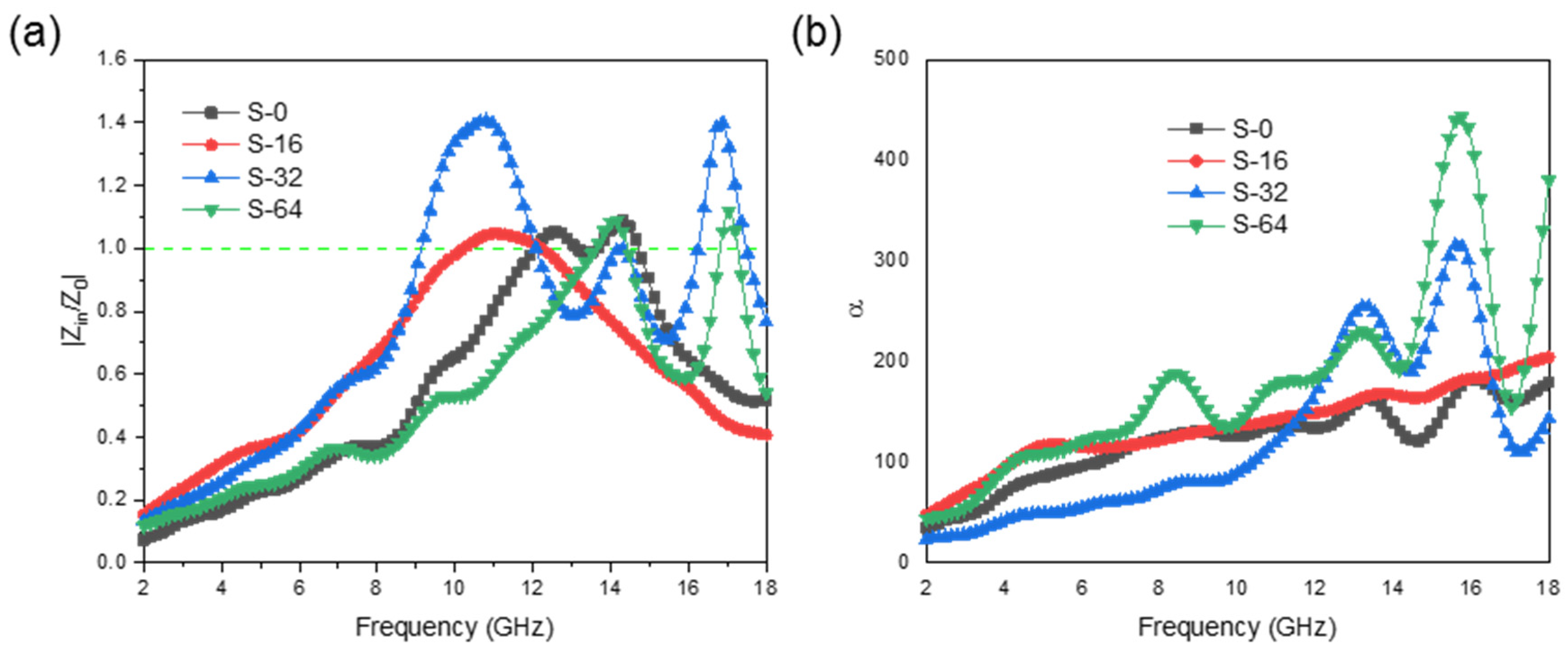

3.3. Microwave Absorption Mechanism of Co-Ni/C

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.; Zeng, M.; Liu, J.; Guo, B.; Hao, X.; Cao, Q.; Shang, Y.; Sun, X.; Liu, J.; Gao, X.; et al. Fe-based Material@N-doped Carbon Composites as Environment-friendly Microwave Absorbers. Carbon 2021, 171, 646–657. [Google Scholar] [CrossRef]

- Meng, F.; Wang, H.; Huang, F.; Guo, Y.; Wang, Z.; Hui, D.; Zhou, Z. Graphene-Based Microwave Absorbing Composites: A Review and Prospective. Compos. Part B Eng. 2018, 137, 260–277. [Google Scholar] [CrossRef]

- Cai, G.; Yan, P.; Zhang, L.; Zhou, H.; Jiang, H. Metal-Organic Framework-Based Hierarchically Porous Materials: Synthesis and Applications. Chem. Rev. 2021, 121, 12278–12326. [Google Scholar] [CrossRef]

- Ren, S.; Yu, H.; Wang, L.; Huang, Z.; Lin, T.; Huang, Y.; Yang, J.; Hong, Y.; Liu, J. State of the Art and Prospects in Metal-Organic Frameworks-Derived Microwave Absorption Materials. Nano Micro Lett. 2022, 14, 68. [Google Scholar] [CrossRef]

- Shu, J.; Yang, X.; Zhang, X.; Huang, X.; Cao, M.; Li, L.; Yang, H.; Cao, W. Tailoring MOF-Based Materials to Tune Electromagnetic Property for Great Microwave Absorbers and Devices. Carbon 2020, 162, 157–171. [Google Scholar] [CrossRef]

- Zhong, G.; Liu, D.; Zhang, J. The Application of ZIF-67 and Its Derivatives: Adsorption, Separation, Electrochemistry and Catalysts. J. Mater. Chem. A 2018, 6, 1887–1899. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Y.; Li, H.; Lin, Y.; Jiang, Z.; Xie, Z.; Kuang, Q.; Zheng, L. MOF-Derived Porous Co/C Nanocomposites with Excellent Electromagnetic Wave Absorption Properties. ACS Appl. Mater. Interfaces 2015, 7, 13604–13611. [Google Scholar] [CrossRef]

- Huang, M.; Wang, L.; Pei, K.; You, W.; Yu, X.; Wu, Z.; Che, R. Multidimension-Controllable Synthesis of MOF-Derived Co@N-Doped Carbon Composite with Magnetic-Dielectric Synergy toward Strong Microwave Absorption. Small 2020, 16, 2000158. [Google Scholar] [CrossRef]

- Ruan, W.; Mu, C.; Wang, B.; Nie, A.; Zhang, C.; Du, X.; Xiang, J.; Wen, F.; Liu, Z. Metal-Organic Framework Derived Cobalt Phosphosulfide with Ultrahigh Microwave Absorption Properties. Nanotechnology 2018, 29, 405703. [Google Scholar] [CrossRef]

- Liu, P.; Gao, S.; Wang, Y.; Huang, Y.; Wang, Y.; Luo, J. Core-Shell CoNi@Graphitic Carbon Decorated on B,N-Codoped Hollow Carbon Polyhedrons toward Lightweight and High-Efficiency Microwave Attenuation. ACS Appl. Mater. Interfaces 2019, 11, 25624–25635. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Gao, S.; Zhang, G.; Huang, Y.; You, W.; Che, R. Hollow Engineering to Co@N-Doped Carbon Nanocages via Synergistic Protecting-Etching Strategy for Ultrahigh Microwave Absorption. Adv. Funct. Mater. 2021, 31, 2102812. [Google Scholar] [CrossRef]

- Yan, J.; Huang, Y.; Han, X.; Gao, X.; Liu, P. Metal Organic Framework (ZIF-67)-Derived Hollow CoS2/N-doped Carbon Nanotube Composites for Extraordinary Electromagnetic Wave Absorption. Compos. Part B Eng. 2019, 163, 67–76. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, F.; Zhang, S.; Yuan, H.; Zhu, C.; Zhang, X.; Chen, Y. Hollow N-Doped Carbon Polyhedron Containing CoNi Alloy Nanoparticles Embedded within Few-Layer N-Doped Graphene as High-Performance Electromagnetic Wave Absorbing Material. ACS Appl. Mater. Interfaces 2018, 10, 24920–24929. [Google Scholar] [CrossRef] [PubMed]

- He, P.; Yu, X.; Lou, X. Carbon-Incorporated Nickel–Cobalt Mixed Metal Phosphide Nanoboxes with Enhanced Electrocatalytic Activity for Oxygen Evolution. Angew. Chem. Int. Ed. 2017, 56, 3897–3900. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Liu, X.; Wei, X.; Yu, R.; Shui, J. Porous CNTs/Co Composite Derived from Zeolitic Imidazolate Framework: A Lightweight, Ultrathin, and Highly Efficient Electromagnetic Wave Absorber. ACS Appl. Mater. Interfaces 2016, 8, 34686–34698. [Google Scholar] [CrossRef]

- Liu, J.; Meng, C.; Liu, Q.; Li, N.; Yu, R.; Zeng, M. Fire-resistant Iron-Based Phosphates/Phosphorus-Doped Carbon Composites Derived from Phytic Acid-Treated Metal Organic Frameworks as High-Efficiency Microwave Absorbers. Carbon 2022, 200, 472–482. [Google Scholar] [CrossRef]

- Wang, L.; Wen, B.; Bai, X.; Liu, C.; Yang, H. Facile and Green Approach to the Synthesis of Zeolitic Imidazolate Framework Nanosheet-derived 2D Co/C Composites for a Lightweight and Highly Efficient Microwave Absorber. J. Colloid Interface Sci. 2019, 540, 30–38. [Google Scholar] [CrossRef]

- Wang, L.; Bai, X.; Wen, B.; Du, Z.; Lin, Y. Honeycomb-Like Co/C Composites Derived from Hierarchically Nanoporous ZIF-67 as a Lightweight and Highly Efficient Microwave Absorber. Compos. Part B: Eng. 2019, 166, 464–471. [Google Scholar] [CrossRef]

- Song, Z.; Liu, X.; Sun, X.; Li, Y.; Nie, X.; Tang, W.; Yu, R.; Shui, J. Alginate-Templated Synthesis of CoFe/carbon Fiber Composite and the Effect of Hierarchically Porous structure on Electromagnetic Wave Absorption Performance. Carbon 2019, 151, 36–45. [Google Scholar] [CrossRef]

- Liu, G.; Liu, X.; Song, Z.; Sun, X.; Li, Y.; Shui, J.; Yu, R. Hollow Double-Shell Structured Void@SiO2@Co-C Composite for Broadband Electromagnetic Wave Absorption. Chem. Eng. J. 2021, 417, 128093. [Google Scholar] [CrossRef]

- Wang, H.; Xiang, L.; Wei, W.; An, J.; He, J.; Gong, C.; Hou, Y. Efficient and Lightweight Electromagnetic Wave Absorber Derived from Metal Organic Framework-Encapsulated Cobalt Nanoparticles. ACS Appl. Mater. Interfaces 2017, 9, 42102–42110. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Wu, Q.; Fu, Y.; Liu, T. A Review on Carbon/Magnetic Metal Composites for Microwave Absorption. J. Mater. Sci. Technol. 2021, 86, 91–109. [Google Scholar] [CrossRef]

- Zhi, D.; Li, T.; Qi, Z.; Li, J.; Tian, Y.; Deng, W.; Meng, F. Core-Shell Heterogeneous Graphene-Based Aerogel Microspheres for High-Performance Broadband Microwave Absorption via Resonance Loss and Sequential Attenuation. Chem. Eng. J. 2022, 433, 134496. [Google Scholar] [CrossRef]

- Qiang, R.; Du, Y.; Chen, D.; Ma, W.; Wang, Y.; Xu, P.; Ma, J.; Zhao, H.; Han, X. Electromagnetic Functionalized Co/C Composites by in Situ Pyrolysis of Metal-Organic Frameworks (ZIF-67). J. Alloys Compd. 2016, 681, 384–393. [Google Scholar] [CrossRef]

- Quan, B.; Liang, X.; Ji, G.; Ma, J.; Ouyang, P.; Gong, H.; Xu, G.; Du, Y. Strong Electromagnetic Wave Response Derived from the Construction of Dielectric/Magnetic Media Heterostructure and Multiple Interfaces. ACS Appl. Mater. Interfaces 2017, 9, 9964–9974. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Han, X.; Ma, Y.; Liu, D.; Wang, Y.; Xu, P.; Li, C.; Du, Y. MOFs-Derived Hollow Co/C Microspheres with Enhanced Microwave Absorption Performance. ACS Sustain. Chem. Eng. 2018, 6, 8904–8913. [Google Scholar] [CrossRef]

| Sample | Absorber Thickness (mm) | RLmax (dB) | Effective Bandwidth (GHz) | Ref |

|---|---|---|---|---|

| Co/C-800 | 2 | −32.4 | 3.8 (10.7–14.5) | [24] |

| Co/NPC@Void@CI | 2.2 | −49.2 | 6.72 (10.56–17.28) | [25] |

| CoS2/NCNTs | 2.5 | −55 | 4.5 (5.5–10) | [12] |

| Co/C-HS-600 | 2 | −31.3 | 4.4 (11.0–15.4) | [26] |

| Fe2P4O12/phosphorus-doped carbon | 2.1 | −67.6 | 5.76 (12.24–18) | [16] |

| CoNi@NG-NCP | 2.5 | −24.03 | 4.32 | [13] |

| S-16 | 2.7 | −72.88 | 6.08 (11.92–18) | This work |

| S-32 | 2.21 | −68.12 | 7.04 (9.76–16.8) | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Zhao, Y.; Fan, Z.; Yu, J.; Zeng, M. ZIF-67 Derived Co-Ni/C Composites for High-Efficiency Broadband Microwave Absorption. Coatings 2022, 12, 1667. https://doi.org/10.3390/coatings12111667

Liu Q, Zhao Y, Fan Z, Yu J, Zeng M. ZIF-67 Derived Co-Ni/C Composites for High-Efficiency Broadband Microwave Absorption. Coatings. 2022; 12(11):1667. https://doi.org/10.3390/coatings12111667

Chicago/Turabian StyleLiu, Qingwei, Yiming Zhao, Zhao Fan, Jiali Yu, and Min Zeng. 2022. "ZIF-67 Derived Co-Ni/C Composites for High-Efficiency Broadband Microwave Absorption" Coatings 12, no. 11: 1667. https://doi.org/10.3390/coatings12111667