Preparation and Properties of Epoxy Resin and Polyurethane Blend Resin-Based Low-Infrared-Emissivity Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

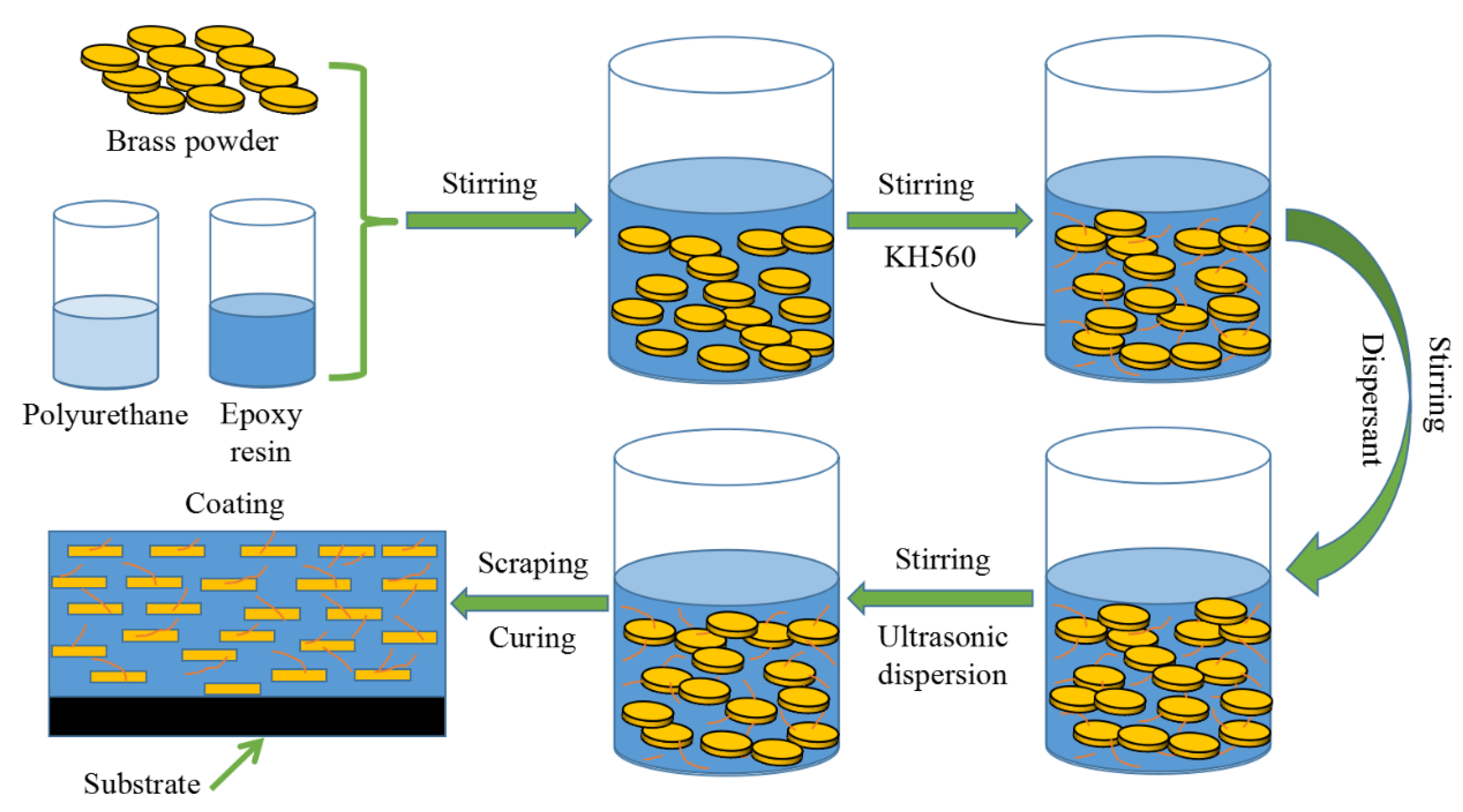

2.2. Coating Preparation

2.3. Characterization

3. Results and Discussion

3.1. Effect of Mass Ratios of Epoxy Resin to Polyurethane on Coating Properties

3.2. Effect of Brass Powder Content on Coating Properties

3.3. Effect of KH560 Content on Coating Properties

3.4. Effect of Dispersant Content on Coating Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lyu, J.; Liu, Z.W.; Wu, X.H.; Li, G.Y.; Fang, D. Nanofibrous kevlar aerogel films and their phase-change composites for highly efficient infrared stealth. ACS Nano 2019, 13, 2236–2245. [Google Scholar] [CrossRef] [PubMed]

- Phan, L.; Walkup IV, W.G.; Ordinario, D.D.; Karshalev, E.; Jocson, J.M.; Burke, A.M.; Gorodetsky, A.A. Reconfigurable infrared camouflage coatings from a cephalopod protein. Adv. Mater. 2013, 25, 5621–5625. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.T.; Zhou, M.; Zhao, Y.; Gu, W.H.; Wu, Y.; Tang, S.L.; Ji, G.B. Morphology control of eco-friendly chitosan-derived carbon aerogels for efficient microwave absorption at thin thickness and thermal stealth. Green Chem. 2022, 24, 5280–5290. [Google Scholar] [CrossRef]

- Solovyev, A.A.; Rabotkin, S.V.; Kovsharov, N.F. Polymer films with multilayer low-E coatings. Mater. Sci. Semicon. Proc. 2015, 38, 373–380. [Google Scholar] [CrossRef]

- Wang, L.; Xu, G.; Liu, C.; Hou, H.; Tan, S. Surface-modified CeO2 coating with excellent thermal shock resistance performance and low infrared emissivity at high-temperature. Surf. Coat. Technol. 2019, 357, 559–566. [Google Scholar] [CrossRef]

- Yan, X.X.; Xu, G.Y. Influence of silane coupling agent on corrosion-resistant property in low infrared emissivity Cu/polyurethane coating. Prog. Org. Coat. 2012, 73, 232–238. [Google Scholar] [CrossRef]

- Liu, Z.; Ban, G.; Ye, S.; Liu, W.; Liu, N.; Tao, R. Infrared emissivity properties of infrared stealth coatings prepared by water-based technologies. Opt. Mater. Express 2016, 6, 3716–3724. [Google Scholar] [CrossRef]

- Zhang, W.G.; Ma, Z.W.; Lv, D.D.; Luo, J.W.; Li, J. An ultra-low infrared emissivity composite coating with outstanding mechanical properties and salt water resistance. Infrared Phys. Technol. 2022, 126, 104351. [Google Scholar] [CrossRef]

- Ma, L.L.; Liu, H.; Wen, X.; Szymanska, K.; Mijowska, E.; Hao, C.C.; Tang, T.; Lei, Q.Q. Polyhydric SiO2 coating assistant to graft organophosphorus onto glass fabric for simultaneously improving flame retardancy and mechanical properties of epoxy resin composites. Compos. Part B Eng. 2022, 243, 110176. [Google Scholar] [CrossRef]

- Conradi, M.; Kocijan, A.; Kek-merl, D.; Zorko, M.; Verpoest, I. Mechanical and anticorrosion properties of nanosilica-filled epoxy-resin composite coatings. Appl. Surf. Sci. 2014, 292, 432–437. [Google Scholar] [CrossRef]

- Zhang, W.G.; Xiong, S.; Lv, D.D. Preparation and characterization of hydrogen-containing silicone oil-modified polyurethane/Al composite coating with low-infrared emissivity. J. Coat. Technol. Res. 2022, 19, 897–905. [Google Scholar] [CrossRef]

- Chang, X.T.; Chen, X.Q.; Zhang, Q.Y.; Lei, Q.H.; Wang, D.S.; Li, J.Y.; Sun, S.B. Alumina nanoparticles-reinforced graphene-containing waterborne polyurethane coating for enhancing corrosion and wear resistance. Corros. Commun. 2021, 4, 1–11. [Google Scholar] [CrossRef]

- Zhou, S.F.; Zhang, Y.; Chen, J.L.; Yan, J.; Huang, J.; Zhang, Q.X.; Zhao, G.Z.; Liu, Y.Q. Wear and corrosion resistance of fluorocarbon/epoxy blended coatings nanofilled by mechanically peeled few-layer fluorinated graphene. J. Mater. Res. Technol. 2022, 20, 2369–2384. [Google Scholar] [CrossRef]

- Yao, H.D.; Zhang, X.Y.; Shen, L.M.; Bao, N.Z. Tribological and anticorrosion properties of polyvinyl butyral (PVB) coating reinforced with phenol formaldehyde resin (PF). Prog. Org. Coat. 2021, 158, 106382. [Google Scholar] [CrossRef]

- Bahramnia, H.; Semnani, H.M.; Habibolahzadeh, A.; Abdoos, A. Epoxy/polyurethane hybrid nanocomposite coatings reinforced with MWCNTs and SiO2 nanoparticles: Processing, mechanical properties and wear behavior. Surf. Coat. Technol. 2021, 415, 127121. [Google Scholar] [CrossRef]

- Fazeli, M.; Liu, X.L.; Rudd, C. The effect of waterborne polyurethane coating on the mechanical properties of epoxy-based composite containing recycled carbon fibres. Surf. Interfaces 2022, 29, 101684. [Google Scholar] [CrossRef]

- Sivakumar, P.; Du, S.M.; Selter, M.; Daye, J.; Cho, J. Improved adhesion of polyurethane-based nanocomposite coatings to tin surface through silane coupling agents. Int. J. Adhes. Adhes. 2021, 110, 102948. [Google Scholar] [CrossRef]

- Varghese, J.T.; Cho, K.; Raju; Farrar, P.; Prentice, L.; Prusty, B.G. Influence of silane coupling agent on the mechanical performance of flowable fibre-reinforced dental composites. Dent. Mater. 2022, 38, 1173–1183. [Google Scholar] [CrossRef]

- Gou, J.F.; Wang, G.; Ning, Y.L.; Guan, L.; Zhang, Y.K.; Liao, J.W.; Wang, Y. Preparation and corrosion resistance of chromium-free Zn-Al coatings with two different silane coupling agents. Surf. Coat. Technol. 2019, 366, 1–6. [Google Scholar] [CrossRef]

- Lof, D.; Hamieau, G.; Zalich, M.; Ducher, P.; Kynde, S.; Midtgaard, S.R.; Parasida, C.F.; Arleth, L.; Jensen, G. Dispersion state of TiO2 pigment particles studied by ultra-small-angle X-ray scattering revealing dependence on dispersant but limited change during drying of paint coating. Prog. Org. Coat. 2020, 142, 105590. [Google Scholar] [CrossRef]

- Song, Z.Y.; Zhang, C.; Fu, X.Q.; Zhang, H.W.; Xian, J.Y.; Lin, J.R. Graphene nanosheet as a new particle dispersant for the jet-electrodeposition of high-performance Ni-P-WC composite coatings. Surf. Coat. Technol. 2021, 425, 127740. [Google Scholar] [CrossRef]

- Zhang, W.G.; Xu, G.Y.; Ding, R.Y.; Duan, K.G.; Qiao, J.L. Nacre biomimetic design—A possible approach to prepare low infrared emissivity composite coatings. Mater. Sci. Eng. C 2013, 33, 99–102. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.W.; Yu, D.M. Preparation and characterization of a new low infrared-emissivity coating based on modified aluminum. Prog. Org. Coat. 2013, 76, 107–112. [Google Scholar] [CrossRef]

| Mass Ratios | 2:8 | 4:6 | 6:4 | 8:2 |

|---|---|---|---|---|

| Emissivity | 0.482 | 0.519 | 0.486 | 0.475 |

| Glossiness | 49.9 | 55.0 | 45.8 | 56.0 |

| Adhesion strength/grade | 1 | 1 | 1 | 1 |

| Flexibility/mm | 4 | 4 | 5 | 7 |

| Impact strength/kg·cm | 40 | 40 | 40 | 40 |

| Brass Powder Content/wt% | 20 | 30 | 40 | 50 |

|---|---|---|---|---|

| Emissivity | 0.588 | 0.561 | 0.486 | 0.424 |

| Glossiness | 73.5 | 59.3 | 45.8 | 28.8 |

| Adhesion strength/grade | 1 | 1 | 1 | 1 |

| Flexibility/mm | 5 | 5 | 5 | 4 |

| Impact strength/kg·cm | 45 | 45 | 45 | 45 |

| KH560 Content/wt% | 0 | 1 | 3 | 5 | 7 | 9 |

|---|---|---|---|---|---|---|

| Emissivity | 0.424 | 0.484 | 0.489 | 0.502 | 0.486 | 0.518 |

| Glossiness | 28.8 | 6.1 | 7.7 | 8.7 | 8.3 | 6.0 |

| Adhesion strength/grade | 1 | 1 | 1 | 1 | 1 | 1 |

| Flexibility/mm | 4 | 3 | 2 | 1 | 1 | 1 |

| Impact strength/kg·cm | 45 | 50 | 50 | 50 | 50 | 50 |

| Dispersant Content/wt% | 0 | 1 | 5 | 9 | 13 |

|---|---|---|---|---|---|

| Emissivity | 0.486 | 0.488 | 0.434 | 0.332 | 0.329 |

| Glossiness | 8.3 | 6.6 | 7.2 | 9.0 | 10.5 |

| Adhesion strength/grade | 1 | 1 | 1 | 1 | 1 |

| Flexibility/mm | 1 | 1 | 1 | 1 | 1 |

| Impact strength/kg·cm | 50 | 50 | 50 | 50 | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Zhang, W.; Guan, Q.; Li, X.; Lv, D. Preparation and Properties of Epoxy Resin and Polyurethane Blend Resin-Based Low-Infrared-Emissivity Coatings. Coatings 2022, 12, 1708. https://doi.org/10.3390/coatings12111708

Zhang J, Zhang W, Guan Q, Li X, Lv D. Preparation and Properties of Epoxy Resin and Polyurethane Blend Resin-Based Low-Infrared-Emissivity Coatings. Coatings. 2022; 12(11):1708. https://doi.org/10.3390/coatings12111708

Chicago/Turabian StyleZhang, Jiaming, Weigang Zhang, Qishuai Guan, Xiang Li, and Dandan Lv. 2022. "Preparation and Properties of Epoxy Resin and Polyurethane Blend Resin-Based Low-Infrared-Emissivity Coatings" Coatings 12, no. 11: 1708. https://doi.org/10.3390/coatings12111708

APA StyleZhang, J., Zhang, W., Guan, Q., Li, X., & Lv, D. (2022). Preparation and Properties of Epoxy Resin and Polyurethane Blend Resin-Based Low-Infrared-Emissivity Coatings. Coatings, 12(11), 1708. https://doi.org/10.3390/coatings12111708