Author Contributions

Conceptualization, methodology, validation, resources, data management, supervision, N.H.; formal analysis, investigation, X.Y.; writing—review and editing, W.Z. All authors have read and agreed to the published version of the manuscript.

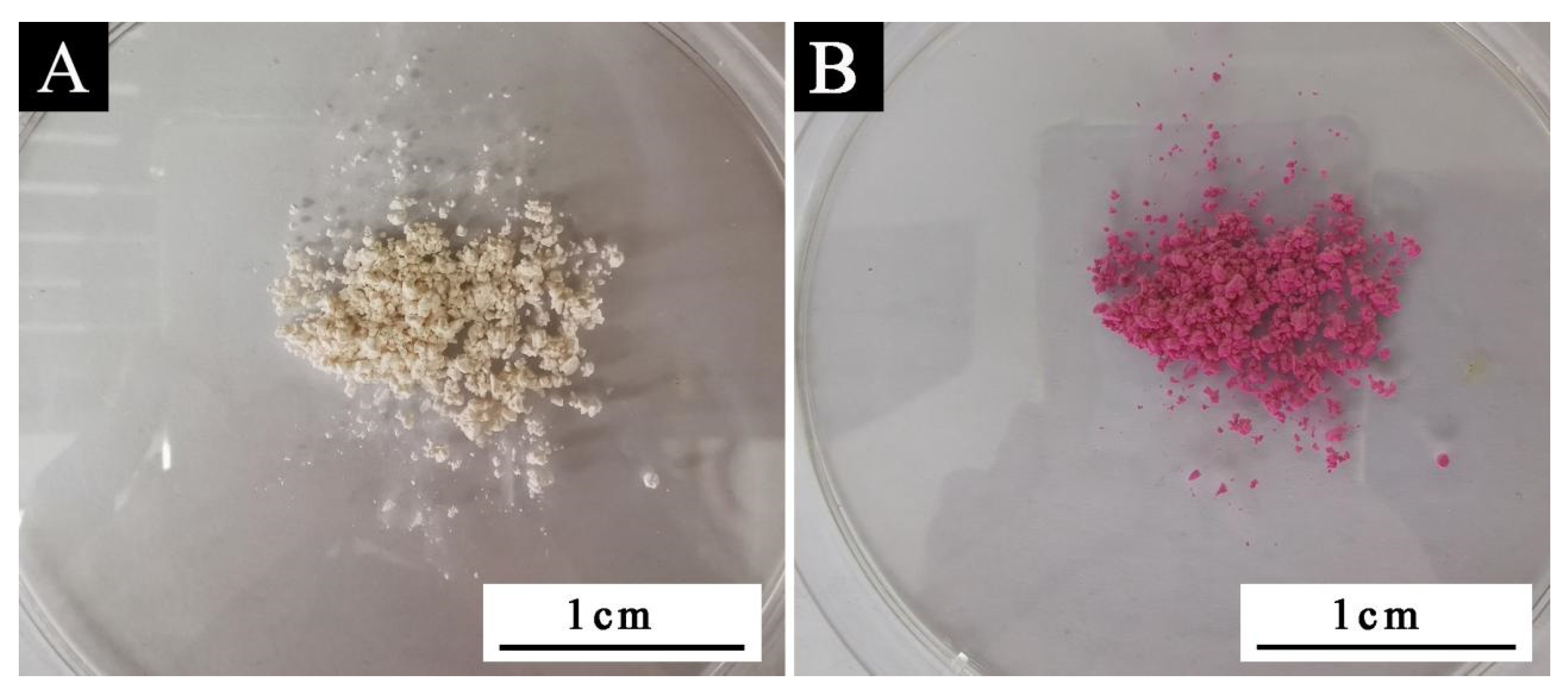

Figure 1.

Macroscopic morphology of the photochromic microcapsules: (A) before photochromism, (B) after photochromism.

Figure 1.

Macroscopic morphology of the photochromic microcapsules: (A) before photochromism, (B) after photochromism.

Figure 2.

The research methods and process.

Figure 2.

The research methods and process.

Figure 3.

Morphology of the photochromic microcapsules: (A) high-magnification SEM image, (B) low-magnification SEM image.

Figure 3.

Morphology of the photochromic microcapsules: (A) high-magnification SEM image, (B) low-magnification SEM image.

Figure 4.

Particle size distribution diagram.

Figure 4.

Particle size distribution diagram.

Figure 5.

FTIR image of the photochromic microcapsules.

Figure 5.

FTIR image of the photochromic microcapsules.

Figure 6.

FTIR image of the coatings: (A) wave number at 500–4000 cm−1, (B) wave number at 600–1800 cm−1.

Figure 6.

FTIR image of the coatings: (A) wave number at 500–4000 cm−1, (B) wave number at 600–1800 cm−1.

Figure 7.

Color difference of the coatings.

Figure 7.

Color difference of the coatings.

Figure 8.

Discoloration process of the coating on the wood substrate with 15.0% microcapsules. Visible light exposure time: (A) 0 s, (B) 5 s, (C) 10 s, (D) 15 s, (E) 20 s.

Figure 8.

Discoloration process of the coating on the wood substrate with 15.0% microcapsules. Visible light exposure time: (A) 0 s, (B) 5 s, (C) 10 s, (D) 15 s, (E) 20 s.

Figure 9.

Discoloration process of the coating on the metal substrate with 10.0% microcapsules. Visible light exposure time: (A) 0 s, (B) 5 s, (C) 10 s, (D) 15 s, (E) 20 s.

Figure 9.

Discoloration process of the coating on the metal substrate with 10.0% microcapsules. Visible light exposure time: (A) 0 s, (B) 5 s, (C) 10 s, (D) 15 s, (E) 20 s.

Figure 10.

Morphology of the coatings with the addition of different microcapsule loadings on wood surface: (A) 0%, (B) 15.0%, (C) 20.0%.

Figure 10.

Morphology of the coatings with the addition of different microcapsule loadings on wood surface: (A) 0%, (B) 15.0%, (C) 20.0%.

Figure 11.

Morphology of the coatings with the addition of different microcapsule loadings on metal surface: (A) 0%, (B) 10.0%, (C) 15.0%.

Figure 11.

Morphology of the coatings with the addition of different microcapsule loadings on metal surface: (A) 0%, (B) 10.0%, (C) 15.0%.

Figure 12.

The discoloration mechanism of the photochromic microcapsules.

Figure 12.

The discoloration mechanism of the photochromic microcapsules.

Figure 13.

Gloss of coatings with different microcapsule contents: (A) on wood substrate, (B) on metal substrate.

Figure 13.

Gloss of coatings with different microcapsule contents: (A) on wood substrate, (B) on metal substrate.

Table 1.

Comparison of two coatings.

Table 1.

Comparison of two coatings.

| Type of Coating | Performance and Characteristics | Application Fields |

|---|

| traditional waterborne coating | green and environmental protection, save resources, insufficient hardness | furniture, ships, containers, steel frames, etc. |

| waterborne coating with photochromic microcapsules | green and environmental protection, save resources, reversible color change, hardness enhancement | intelligent color-changing furniture, architecture, textiles, metal products, etc. |

Table 2.

List of experimental materials.

Table 2.

List of experimental materials.

| Material | Molecular Formula | MW (g/mol) | CAS No. | Concentration | Producer |

|---|

| photochromic microcapsule | - | - | - | - | Shenzhen Oriental Colour Changing Technology Co., Ltd., Shenzhen, China |

| waterborne acrylic coating | - | - | 9003-01-4 | - | Dulux Paint Co., Ltd., Shanghai, China |

| aluminum alloy | - | - | - | - | Shanghai Yixuan Aluminum Co., Ltd., Shanghai, China |

| Tilia europaea | - | - | - | - | Guangzhou Yihua Life Technology Co., Ltd., Guangzhou, China |

| sodium chloride | NaCl | 58.4428 | 7647-14-5 | 0.85% | Sichuan Kelun Pharmaceutical Co., Ltd., Chengdu, China |

| acetic acid | CH3COOH | 60.05 | 64-19-7 | 99.9% | Dingrui Biology Co., Ltd., Zhengzhou, China |

| ethanol | C2H6O | 46.07 | 64-17-5 | 99.9% | Dingrui Biology Co., Ltd., Zhengzhou, China |

| coffee | - | - | - | - | Luckin Coffee Group Co., Ltd., Beijing, China |

Table 3.

Components of the photochromic microcapsules.

Table 3.

Components of the photochromic microcapsules.

| Chemical Composition | CAS No. | Mass Fraction (%) |

|---|

| polyformaldehyde melamine | 9003-08-1 | 32.0–36.0 |

| styrene maleic anhydride copolymer | 31959-78-1 | 6.5–8.0 |

| 1,2-dimethyl-4-(1-phenyl-ethyl)-benzene | 6196-95-8 | 50.0–60.0 |

| photochromic purple dye (1,3,3-Trimethylindolino-6′-(1-piperidinyl)spironaphthoxazine) | 114747-45-4 | 2.6–4.0 |

Table 4.

Experimental material list.

Table 4.

Experimental material list.

| Substrate | Content of Microcapsules (%) | Weight of Microcapsules (g) | Weight of Waterborne Coating (g) |

|---|

| wood | 0 | 0 | 4.0 |

| 5.0 | 0.2 | 3.8 |

| 10.0 | 0.4 | 3.6 |

| 15.0 | 0.6 | 3.4 |

| 20.0 | 0.8 | 3.2 |

| 25.0 | 1.0 | 3.0 |

| metal | 0 | 0 | 2.0 |

| 5.0 | 0.1 | 1.9 |

| 10.0 | 0.2 | 1.8 |

| 15.0 | 0.3 | 1.7 |

| 20.0 | 0.4 | 1.6 |

| 25.0 | 0.5 | 1.5 |

Table 5.

Experimental instrument list.

Table 5.

Experimental instrument list.

| Instrument | Model | Producer |

|---|

| sandpaper | 600 mesh, 800 mesh | Foshan Jingshen abrasive tools Co., Ltd., Foshan, China |

| scanning electron microscope (SEM) | Quanta-200 | FEI Company Hillsboro, OR, USA |

| Fourier transform infrared spectrometer | VERTEX 80V | Germany Bruker Co., Ltd., Karlsruhe, Germany |

| portable colorimeter | SEGT-J | Guoti Precision Testing Instrument Co., Ltd., Shenyang, China |

| gloss meter | X-rite ci60 | Shenzhen 3nh Technology Co., Ltd., Shenzhen, China |

| portable paint film hardness tester | QHQ-A | Wenzhou Shengce Instrument Co., Ltd., Wenzhou, China |

| paint film gridding instrument | QFH-HG600 | Wenzhou Shengce Instrument Co., Ltd., Wenzhou, China |

| paint film impactor tester | BEVS1601 | Shanghai Meiyu Instrument Co., Ltd., Shanghai, China |

| paint film roughness tester | SJ-210 | Shenzhen Fengteng Precision Instrument Co., Ltd., Shenzhen, China |

| ultraviolet aging machine | BLD-Z-850 | Kunshan Bailida Experimental Equipment Co., Ltd., Kunshan, China |

Table 6.

Characteristic peaks in the FTIR image.

Table 6.

Characteristic peaks in the FTIR image.

| Wavenumber (cm−1) | Bond | Substance | Cause of Formation |

|---|

| 3027 | C-H | styrene maleic anhydride copolymer | stretching vibration |

| 2967 | -CH2 | styrene maleic anhydride copolymer | stretching vibration |

| 697 | C-H | styrene maleic anhydride copolymer | in-plane bending vibration |

| 1120 | C-H | styrene maleic anhydride copolymer | out-of-plane bending vibration |

| 3346 | -NH | polyformaldehyde melamine | stretching vibration |

| 816 | thiotriazinone | polyformaldehyde melamine | stretching vibration |

| 1343 | thiotriazinone | polyformaldehyde melamine | stretching vibration |

| 2924 | -CH2 | indole | stretching vibration |

Table 7.

Color difference data of the coatings before and after photochromism.

Table 7.

Color difference data of the coatings before and after photochromism.

| Substrate | Microcapsule Content (%) | Before Photochromism | After Photochromism | ΔE* |

|---|

| L1* | a1* | b1* | L2* | a2* | b2* |

|---|

| wood | 0 | 72.5 ± 2.9 | 14.6 ±0.4 | 30.0 ± 1.1 | 75.0 ±1.9 | 10.7 ± 0.4 | 33.8 ± 0.8 | 6.0 ± 0.2 |

| 5.0 | 75.0 ± 1.4 | 14.0 ± 0.5 | 26.6 ± 0.8 | 62.4 ± 1.9 | 31.4 ± 1.0 | 10.1 ± 0.4 | 27.1 ± 1.0 |

| 10.0 | 77.3 ± 2.9 | 12.3 ± 0.4 | 18.5 ± 0.4 | 59.5 ± 2.0 | 37.5 ± 1.3 | −1.7 | 36.9 ± 1.4 |

| 15.0 | 81.2 ± 3.6 | 10.7 ± 0.3 | 13.4 ± 0.5 | 55.7 ± 1.5 | 35.1 ± 1.4 | −3.6 ± 0.1 | 39.2 ± 0.9 |

| 20.0 | 81.0 ± 3.0 | 10.0 ± 0.3 | 10.8 ± 0.4 | 59.9 ± 1.8 | 36.1 ± 1.8 | −8.2 ± 0.3 | 38.6 ± 0.8 |

| 25.0 | 82.1 ± 3.5 | 10.6 ± 0.3 | 9.3 ± 0.2 | 63.3 ± 1.7 | 33.4 ± 1.4 | −8.2 ± 0.3 | 34.4 ± 1.6 |

| metal | 0 | 35.1 ± 1.2 | 8.7 ± 0.2 | −12.5 ± 0.4 | 36.8 ± 1.6 | 8.2 ± 0.3 | −18.3 ± 0.6 | 5.9 ± 0.1 |

| 5.0 | 81.8 ± 2.9 | 2.2 ± 0.0 | 4.7 ± 0.1 | 46.5 ± 1.2 | 45.9 ± 2.2 | −13.6 ± 0.5 | 59.1 ± 2.1 |

| 10.0 | 82.3 ± 3.1 | 2.9 ± 0.0 | 5.7 ±0.1 | 44.3 ± 2.1 | 47.9 ± 1.8 | −13.5 ± 0.5 | 62.0 ± 2.7 |

| 15.0 | 84.5 ± 3.6 | 3.7 ± 0.1 | 5.5 ± 0.1 | 45.5 ± 1.4 | 47.7 ± 1.9 | −13.1 ± 0.5 | 61.7 ± 1.6 |

| 20.0 | 85.0 ± 2.7 | 4.3 ± 0.1 | 5.3 ± 0.1 | 47.6 ± 1.0 | 47.3 ± 1.4 | −12.5 ± 0.4 | 59.7 ± 1.9 |

| 25.0 | 87.3 ± 3.2 | 4.5 ± 0.1 | 11.1 ± 0.4 | 64.4 ± 1.9 | 45.8 ± 1.6 | −8.2 ± 0.3 | 51.1 ± 1.3 |

Table 8.

Gloss of coatings with different microcapsule contents.

Table 8.

Gloss of coatings with different microcapsule contents.

| Substrate | Microcapsule Content (%) | | Gloss (%) | | Light Loss Rate (%) |

|---|

| 20° | 60° | 85° |

|---|

| wood | 0 | 11.2 | 30.6 | 35.2 | - |

| 5.0 | 5.7 | 19.1 | 23.7 | 37.5 |

| 10.0 | 3.7 | 11.6 | 16.2 | 62.1 |

| 15.0 | 2.4 | 7.1 | 10.6 | 76.8 |

| 20.0 | 2.2 | 4.7 | 7.4 | 84.6 |

| 25.0 | 1.9 | 3.5 | 6.9 | 88.6 |

| metal | 0 | 26.6 | 70.8 | 90.0 | - |

| 5.0 | 10.2 | 29.6 | 45.0 | 58.2 |

| 10.0 | 4.6 | 15.9 | 28.1 | 77.5 |

| 15.0 | 3.0 | 9.5 | 16.4 | 86.6 |

| 20.0 | 2.3 | 6.3 | 10.7 | 91.1 |

| 25.0 | 1.7 | 4.0 | 7.8 | 94.3 |

Table 9.

Mechanical properties and roughness of coatings with different microcapsule contents.

Table 9.

Mechanical properties and roughness of coatings with different microcapsule contents.

| Substrate | Microcapsule Content (%) | Hardness | Adhesion (Grade) | Impact Strength (kg·cm) | Roughness (μm) |

|---|

| wood | 0 | H | 0 | 3 | 0.2 |

| 5.0 | H | 1 | 3 | 0.4 |

| 10.0 | 2H | 1 | 3 | 0.5 |

| 15.0 | 3H | 1 | 4 | 1.2 |

| 20.0 | 3H | 2 | 4 | 2.2 |

| 25.0 | 4H | 2 | 3 | 1.5 |

| metal | 0 | 2H | 0 | 4 | 0.5 |

| 5.0 | 3H | 1 | 4 | 0.7 |

| 10.0 | 3H | 1 | 4 | 0.9 |

| 15.0 | 4H | 1 | 5 | 1.0 |

| 20.0 | 4H | 1 | 5 | 1.9 |

| 25.0 | 5H | 2 | 4 | 3.0 |

Table 10.

Color difference of the coatings before and after cold liquid resistance test.

Table 10.

Color difference of the coatings before and after cold liquid resistance test.

| Substrate | Microcapsule Content (%) | Color Difference |

|---|

| Acetic Acid | Coffee | NaCl | Ethanol |

|---|

| wood | 0 | 1.9 | 3.8 | 1.2 | 2.9 |

| 5.0 | 1.8 | 1.1 | 1.5 | 0.7 |

| 10.0 | 2.5 | 2.5 | 0.7 | 3.0 |

| 15.0 | 1.6 | 4.2 | 2.6 | 1.1 |

| 20.0 | 2.7 | 8.3 | 1.5 | 1.6 |

| 25.0 | 1.6 | 10.7 | 1.9 | 1.9 |

| metal | 0 | 1.5 | 4.4 | 2.0 | 2.9 |

| 5.0 | 1.8 | 2.4 | 2.3 | 2.2 |

| 10.0 | 2.1 | 2.0 | 3.7 | 2.4 |

| 15.0 | 4.3 | 2.0 | 3.3 | 2.0 |

| 20.0 | 2.5 | 5.2 | 5.1 | 2.6 |

| 25.0 | 4.0 | 8.7 | 6.1 | 5.1 |

Table 11.

Gloss of the coatings before and after cold liquid resistance test.

Table 11.

Gloss of the coatings before and after cold liquid resistance test.

| Substrate | Microcapsule Content (%) | Gloss before Cold Liquid Resistance Test (%) | Gloss after Cold Liquid Resistance Test (%) |

|---|

| Acetic Acid | Coffee | NaCl | Ethanol |

|---|

| wood | 0 | 30.6 | 28.6 | 29.3 | 30.9 | 28.7 |

| 5.0 | 19.1 | 17.6 | 18.7 | 19.0 | 20.5 |

| 10.0 | 11.6 | 11.1 | 12.1 | 10.4 | 11.8 |

| 15.0 | 7.1 | 7.2 | 7.1 | 7.9 | 7.4 |

| 20.0 | 4.7 | 4.7 | 4.1 | 4.2 | 4.4 |

| 25.0 | 3.5 | 3.2 | 3.6 | 3.3 | 3.6 |

| metal | 0 | 70.8 | 68.9 | 70.9 | 69.5 | 70.0 |

| 5.0 | 29.6 | 28.8 | 27.5 | 28.7 | 27.3 |

| 10.0 | 15.9 | 15.4 | 16.7 | 15.4 | 15.9 |

| 15.0 | 9.5 | 8.9 | 9.7 | 9.1 | 9.6 |

| 20.0 | 6.3 | 6.1 | 6.6 | 6.0 | 6.0 |

| 25.0 | 4.0 | 3.8 | 4.5 | 4.1 | 4.0 |

Table 12.

Cold liquid resistance grade of the coatings with different loadings of microcapsules.

Table 12.

Cold liquid resistance grade of the coatings with different loadings of microcapsules.

| Substrate | Microcapsule Content (%) | Cold Liquid Resistance (Grade) |

|---|

| Acetic Acid | Coffee | NaCl | Ethanol |

|---|

| wood | 0 | 1 | 1 | 1 | 1 |

| 5.0 | 1 | 1 | 1 | 1 |

| 10.0 | 1 | 1 | 1 | 1 |

| 15.0 | 1 | 1 | 1 | 1 |

| 20.0 | 2 | 2 | 2 | 2 |

| 25.0 | 2 | 2 | 2 | 2 |

| metal | 0 | 1 | 1 | 1 | 1 |

| 5.0 | 1 | 1 | 1 | 1 |

| 10.0 | 1 | 1 | 1 | 1 |

| 15.0 | 1 | 1 | 1 | 1 |

| 20.0 | 1 | 2 | 1 | 1 |

| 25.0 | 1 | 3 | 1 | 1 |

Table 13.

Color difference data of the coatings before and after aging.

Table 13.

Color difference data of the coatings before and after aging.

| Substrate | Microcapsule Content (%) | State | L* | a* | b* | ΔL* | Δa* | Δb* | ΔE* |

|---|

| wood | 0 | before aging | 75.0 ± 2.1 | 10.7 ± 0.3 | 33.8 ± 1.0 | 4.2 ± 0.2 | −1.4 | 5.4 ± 0.1 | 6.9 ± 0.3 |

| after aging | 70.8 ± 1.9 | 12.1 ± 0.4 | 28.4 ± 1.0 |

| 15.0 | before aging | 35.7 ± 1.8 | −5.1 ± 0.1 | −3.6 ± 0.1 | −34.3 ± 1.4 | −17.9 ± 0.3 | −22.5 ± 0.8 | 44.7 ± 1.9 |

| after aging | 70.0 ± 2.8 | 12.8 ± 0.3 | 18.9 ± 0.4 |

| metal | 0 | before aging | 36.8 ± 1.4 | 8.2 ± 0.3 | −18.3 ± 0.4 | 1.6 | 0.2 | −5.1 ± 0.1 | 5.3 ± 0.1 |

| after aging | 35.2 ± 1.3 | 8.0 ± 0.3 | −13.2 ± 0.3 |

| 10.0 | before aging | 44.3 ± 1.0 | 47.9 ± 1.2 | −13.5 ± 0.4 | −35.0 ± 1.7 | 44.9 ± 1.9 | −3.3 ± 0.1 | 57.0 ± 1.5 |

| after aging | 79.3 ± 2.9 | 3.0 ± 0.1 | −10.2 ± 0.3 |