Improvement of Ferroelectricity in Ce-Doped Hf0.5Zr0.5O2 Thin Films

Abstract

:1. Introduction

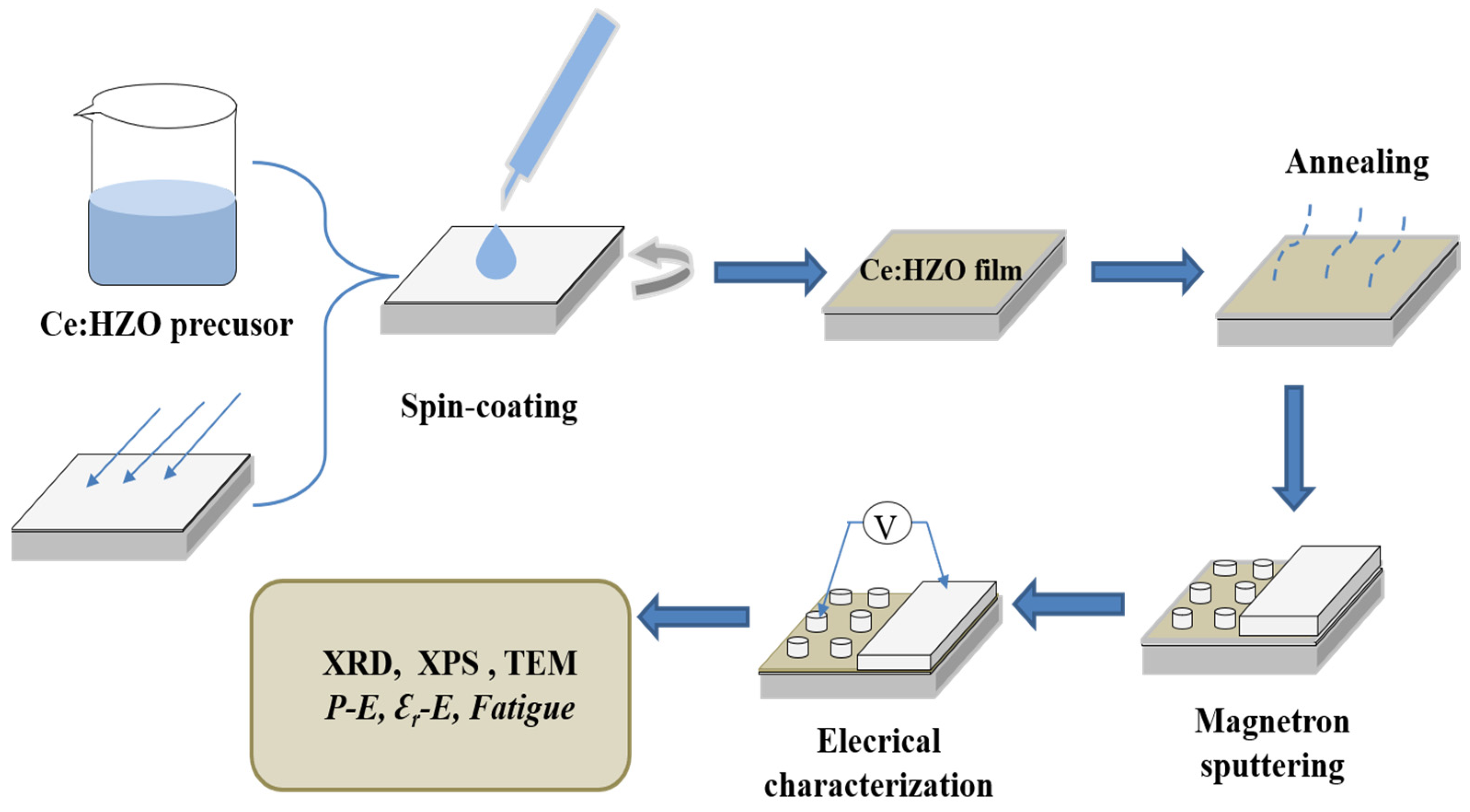

2. Experimental Procedure

3. Results

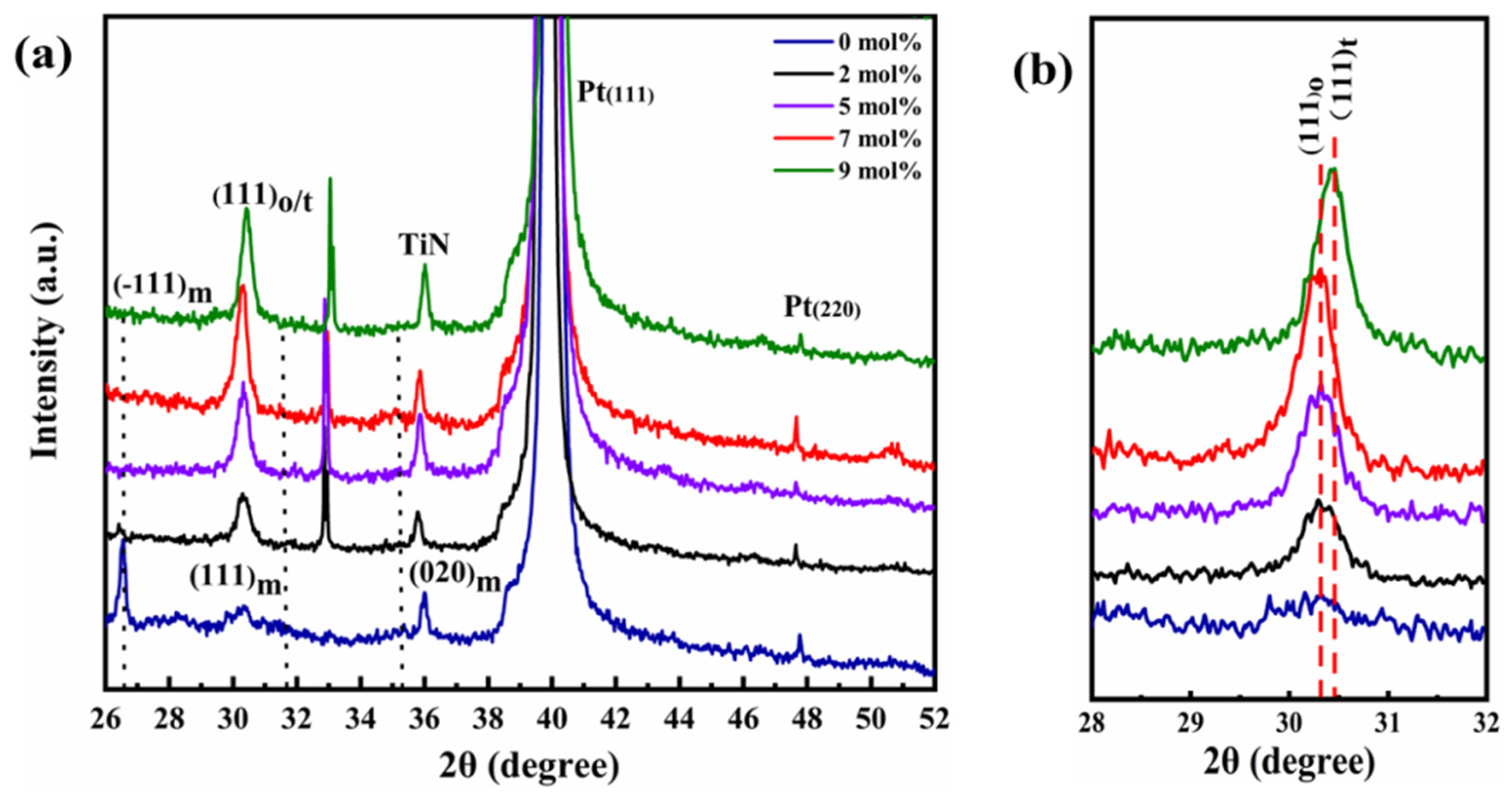

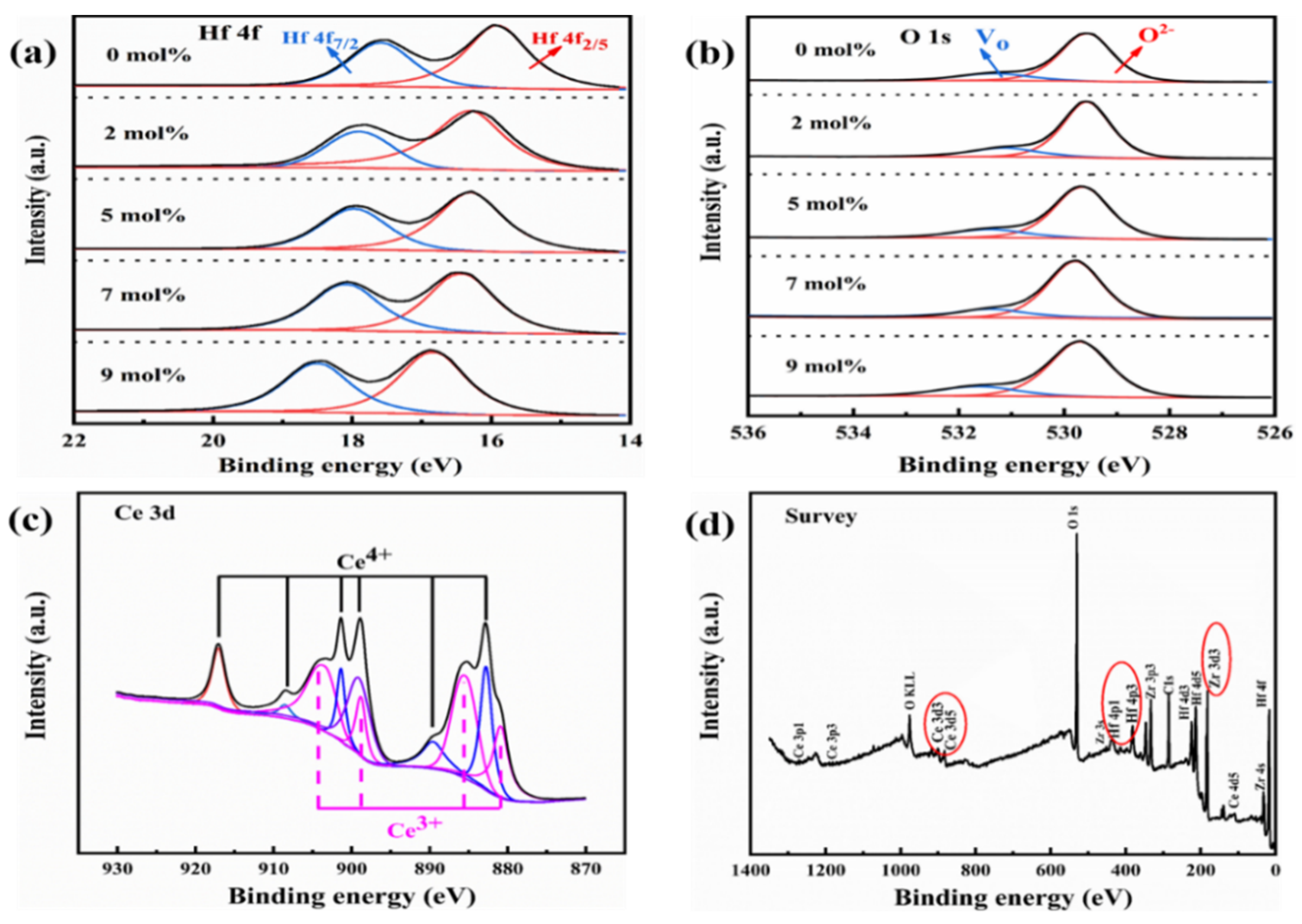

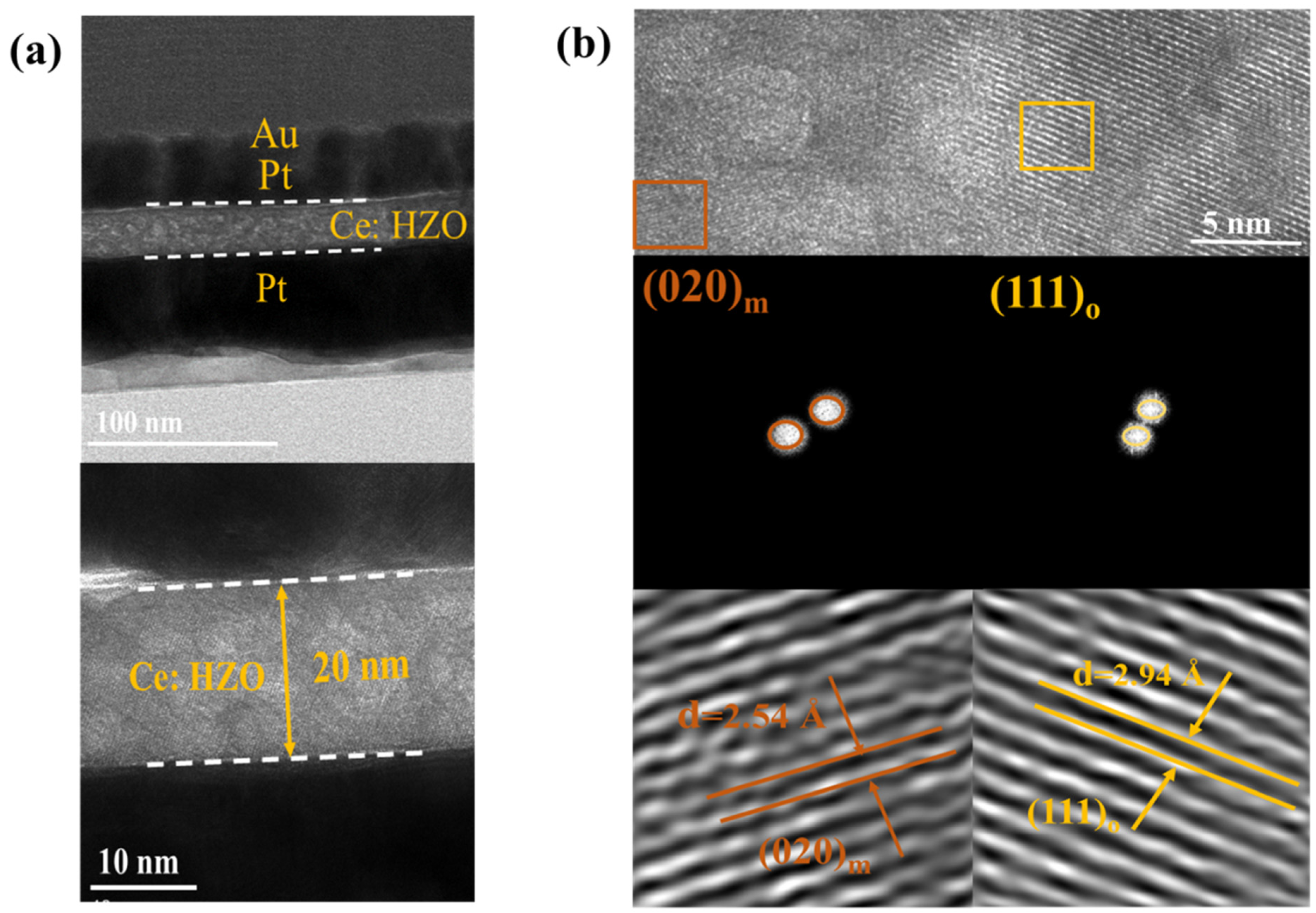

3.1. Microstructure Characterization of Ce: HZO Films

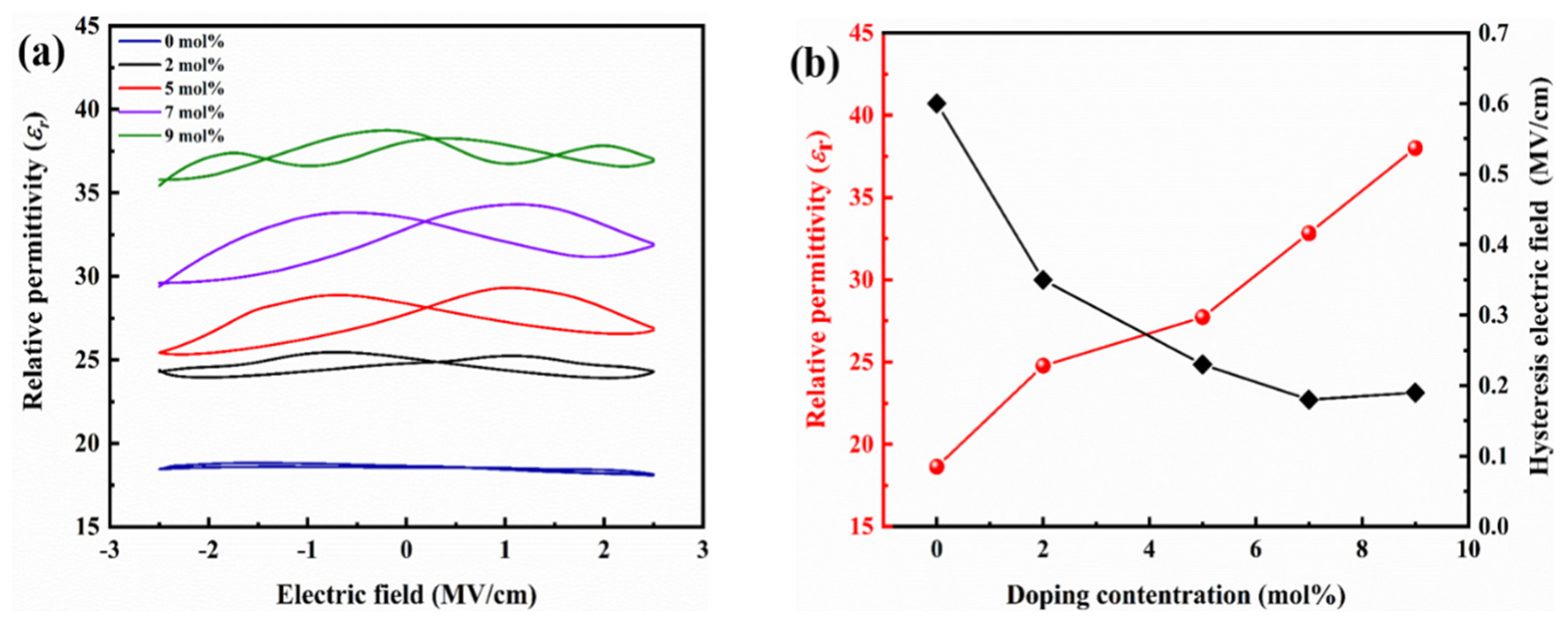

3.2. Electrical Properties of Ce: HZO Thin Films

| Dopant | Remanent Polarization (μC/cm2) | Coercive Field (MV/cm) | Dopant Concentration (mol%) | Substrate (Bottom Electrode) | Film |

|---|---|---|---|---|---|

| Sm | 12 | (−1.1, +1.6) | 5.2 | Pt | [11] |

| (Zr, Y) | 15 | (−1.4, +1.4) | 5 | Pt/Ti/SiO2/Si | [23] |

| (Zr, Sr) | 14.6 | (−1.1, +1.1) | 0.5 | Pt/Ti/SiO2/Si | [24] |

| Zr | 8 | (−0.8, +0.8) | 50 | Pt/TiO2/(100) Si | [25] |

| Pr | 6.9 | (−1.2, +1.2) | 5 | Pt/TiO2/(100) Si | [28] |

| Y | 14.2 | (+1.4, −1.8) | 2 | Si (100) | [33] |

| La | 12.5 | (−1.1, +1.6) | 5.2 | Pt | [34] |

| Y | 10 | (−1.6, +1.0) | 5 | Pt | [39] |

| Ba | 12 | (−1.7, +1.5) | 7.5 | Pt/TiO2/SiO2 | [44] |

| Ca | 5 | (−0.9, +0.7) | 5.2 | Si (100) | [44] |

| Mg | 3 | (−0.8, +0.8) | 7.5 | Pt/TiO2/SiO2 | [44] |

| (Zr, Ce) | 17 | (−1.2, +1.1) | 7 | Pt/Ti/SiO2/Si | This work |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Y.Q.; Wang, C.H.; Dong, H.; Wallace, R.M.; Cho, K.; Wang, W.H.; Wang, W.C. Origin of indium diffusion in high-k oxide HfO2. ACS Appl. Mater. Interfaces 2016, 8, 7595–7600. [Google Scholar] [CrossRef] [PubMed]

- Tirmali, P.M.; Khairnar, A.G.; Joshi, B.N.; Mahajanl, A.M. Structural and electrical characteristics of RF-sputtered HfO2 high-k based MOS capacitors. Solid-State Electron. 2011, 62, 44–47. [Google Scholar] [CrossRef]

- Böscke, T.S.; Müller, J.; Bräuhaus, D.; Schröder, U.; Böttger, U. Ferroelectricity in hafnium oxide thin films. Appl. Phys. Lett. 2011, 99, 102903. [Google Scholar] [CrossRef]

- Khan, A.I.; Keshavarzi, A.; Datta, S. The future of ferroelectric field-effect transistor technology. Nat. Electron. 2020, 3, 588–597. [Google Scholar] [CrossRef]

- Park, M.H.; Lee, Y.H.; Mikolajick, T.; Schroeder, U. Review and perspective on ferroelectric HfO2-based thin films for memory applications. MRS Commun. 2018, 8, 795–808. [Google Scholar] [CrossRef] [Green Version]

- Olsen, T.; Schröder, U.; Müller, S.; Krause, A.; Martin, D.; Singh, A.; Müller, J. Co-sputtering yttrium into hafnium oxide thin films to produce ferroelectric properties. Appl. Phys. Lett. 2012, 101, 082905. [Google Scholar] [CrossRef]

- Mueller, S.; Mueller, J.; Singh, A.; Riedel, S.; Sundqvist, J.; Schroeder, U.; Mikolajick, T. Incipient ferroelectricity in Al-doped HfO2 thin films. Adv. Funct. Mater. 2012, 22, 2412–2417. [Google Scholar] [CrossRef]

- Chouprik, A.; Chernikova, A.; Markeev, A.; Mikheev, V.; Negrov, D.; Spiridonov, M.; Zarubin, S.; Zenkevich, A. Electron transport across ultrathin ferroelectric Hf0.5Zr0.5O2 films on Si. Microelectron. Eng. 2017, 178, 250–253. [Google Scholar] [CrossRef]

- Wei, A.Q.; Chen, C.; Tang, L.; Zhou, K.C.; Zhang, D. Chemical solution deposition of ferroelectric Sr: HfO2 film from inorganic salt precursors. J. Alloys Compd. 2018, 731, 546–553. [Google Scholar] [CrossRef]

- Sourav, D.; Han, Q.B.; Bu, W.X.; Baig, M.A.; Sung, P.J.; Su, C.J.; Lee, Y.J.; Lu, D.D. Uniform crystal formation and electrical variability reduction in hafnium-oxide-based ferroelectric memory by thermal engineering. ACS Appl. Electron. Mater. 2021, 3, 619–628. [Google Scholar]

- Starschich, S.; Griesche, D.; Schneller, T.; Böttger, U. Chemical solution deposition of ferroelectric hafnium oxide for future lead free ferroelectric devices. ECS J. Solid State Sci. Technol. 2015, 4, P419. [Google Scholar] [CrossRef]

- Tromm, T.C.U.; Zhang, J.; Schubert, J.; Luysberg, M.; Zander, W.; Han, Q.; Meuffels, P.; Meertens, D.; Glass, S.; Bernardy, P.; et al. Ferroelectricity in Lu doped HfO2 layers. Appl. Phys. Lett. 2017, 111, 142904. [Google Scholar] [CrossRef] [Green Version]

- Mehmood, F.; Mikolajick, T.; Schroeder, U. Lanthanum doping induced structural changes and their implications on ferroelectric properties of Hf1-xZrxO2 thin film. Appl. Phys. Lett. 2020, 117, 092902. [Google Scholar] [CrossRef]

- Schroeder, U.; Yurchuk, E.; Müller, J.; Martin, D.; Schenk, T.; Polakowski, P. Impact of different dopants on the switching properties of ferroelectric hafniumoxide. Jpn. J. Appl. Phys. 2014, 53, 08LE02. [Google Scholar] [CrossRef]

- Shimizu, T.; Yokouchi, T.; Shiraishi, T.; Oikawa, T. Study on the effect of heat treatment conditions on metalorganic-chemical-vapor-deposited ferroelectric Hf0.5Zr0.5O2 thin film on Ir electrode. Jpn. J. Appl. Phys. 2014, 53, 09PA04. [Google Scholar] [CrossRef]

- Liu, B.W.; Zhang, Y.R.; Zhang, L.J.; Yuan, Q.T.; Zhang, W.; Li, Y.B. Excellent HZO ferroelectric thin films on flexible PET substrate. J. Alloys Compd. 2022, 919, 165872. [Google Scholar] [CrossRef]

- Lederer, M.; Bagul, P.; Lehninger, D.; Mertens, K.; Reck, A.; Olivo, R. Influence of annealing temperature on the structural and electrical properties of Si-doped ferroelectric hafnium oxide. ACS Appl. Electron. Mater. 2021, 3, 4115–4120. [Google Scholar] [CrossRef]

- Ali, T.; Olivo, R.; Kerdilès, S.; Lehninger, D.; Lederer, M.; Sourav, D.; Royet, A.-S.; Sünbül, A.; Prabhu, A.; Kühnel, K.; et al. Study of nanosecond laser annealing on silicon doped hafnium oxide film crystallization and capacitor reliability. In Proceedings of the 2022 IEEE International Memory Workshop (IMW), Dresden, Germany, 15–18 May 2022; pp. 1–4. [Google Scholar]

- Wang, D.; Zhang, Y.; Wang, J.L.; Luo, C.L.; Li, M.; Shuai, W.T.; Tao, R.Q.; Fan, Z.; Chen, D.Y.; Zeng, M. Enhanced ferroelectric polarization with less wake-up effect and improved endurance of Hf0.5Zr0.5O2 thin films by implementing W electrode. J. Mater. Sci. Technol. 2022, 104, 1–7. [Google Scholar] [CrossRef]

- Payne, A.; Hsain, H.A.; Lee, Y.; Strnad, A.N.; Jones, L.J.; Hanrahan, B. Thermal stability of antiferroelectric-like Al: HfO2 thin films with TiN or Pt electrodes. Appl. Phys. Lett. 2022, 120, 232901. [Google Scholar] [CrossRef]

- Katayama, K.; Shimizu, T.; Sakata, O.; Shiraishi, T.; Nakamura, S.; Kiguchi, T.; Akama, A.; Konno, J.T.; Uchida, H.; Funakubo, H. Orientation control and domain structure analysis of {100}-oriented epitaxial ferroelectric orthorhombic HfO2-based thin films. J. Appl. Phys. 2016, 119, 134101. [Google Scholar] [CrossRef]

- Kozodaev, M.G.; Chernikova, A.G.; Korostylev, E.V.; Park, M.H.; Khakimov, R.R.; Hwang, C.S.; Markeev, A.M. Mitigating wakeup effect and improving endurance of ferroelectric HfO2-ZrO2 thin films by careful La-doping. J. Appl. Phys. 2019, 125, 034101. [Google Scholar] [CrossRef]

- Mohit, T.M.; Haga, K.I.; Eisuke, T. Impact of annealing environment on electrical properties of yttrium-doped hafnium zirconium dioxide thin films prepared by the solution process. Jpn. J. Appl. Phys. 2020, 59, SPPB03. [Google Scholar] [CrossRef]

- Yin, L.; Gong, S.Q.; Li, X.Y.; Lu, B.B.; Peng, Q.X.; Zheng, S.Z.; Liao, M.; Zhou, Y.C. Improvement of ferroelectricity and endurance in Sr doped Hf0.5Zr0.5O2 films. J. Alloys Compd. 2022, 914, 165301. [Google Scholar] [CrossRef]

- Shuhei, N.; Hiroshi, F.; Hiroshi, U. Crystallization behavior and ferroelectric property of HfO2-ZrO2 films fabricated by chemical solution deposition. Jpn. J. Appl. Phys. 2018, 57, 11UF06. [Google Scholar]

- Künneth, C.; Materlik, R.; Falkowski, M.; Kersch, A. Impact of Four-Valent Doping on the Crystallographic Phase Formation for Ferroelectric HfO2 from First-Principles: Implications for Ferroelectric Memory and Energy-Related Applications. ACS Appl. Nano Mater. 2018, 1, 254–264. [Google Scholar] [CrossRef] [Green Version]

- Zheng, S.Z.; Zhao, Z.D.; Liu, Z.T.; Zeng, B.J.; Yin, L.; Peng, Q.X.; Liao, M.; Zhou, Y.C. Improvement of remanent polarization of CeO2-HfO2 solid solution thin films on Si substrates by chemical solution deposition. Appl. Phys. Lett. 2020, 117, 212904. [Google Scholar] [CrossRef]

- Liu, H.; Zheng, S.Z.; Chen, Q.; Zeng, B.J.; Jiang, J.; Peng, Q.X.; Liao, M.; Zhou, Y.C. Structural and ferroelectric properties of Pr doped HfO2 thin films fabricated by chemical solution method. J. Mater. Sci. Mater. Electron. 2019, 30, 5771–5779. [Google Scholar] [CrossRef]

- Shibayama, S.; Nagano, J.; Asaka, K.; Sakashita, M.; Nakatsuka, O. Impact of Wet Annealing on Ferroelectric Phase Formation and Phase Transition of HfO2-ZrO2 System. ACS Appl. Electron. Mater. 2021, 3, 2203–2211. [Google Scholar] [CrossRef]

- Falkowski, M.; Kersch, A. Optimizing the piezoelectric strain in ZrO2 and HfO2-Based incipient ferroelectrics for thin-film applications: An ab initio dopant screening study. ACS Appl. Mater. Interfaces 2020, 12, 32915–32924. [Google Scholar] [CrossRef]

- Avis, C.; Kim, Y.G.; Jang, J. Solution processed hafnium oxide as a gate insulator for low-voltage oxide thin-film transistors. J. Mater. Chem. 2012, 22, 17415–17420. [Google Scholar] [CrossRef]

- Pan, T.M.; Lu, C.H. Switching behavior in rare-earth films fabricated in full room temperature. IEEE Trans. Electron Devices 2012, 59, 956–961. [Google Scholar] [CrossRef]

- Wang, X.X.; Zhou, D.Y.; Li, S.D.; Liu, X.H.; Zhao, P.; Sun, N.; Ali, F.; Wang, J.J. Ferroelectric yttrium doped hafnium oxide films from all-inorganic aqueous precursor solution. Ceram. Int. 2018, 44, 13867–13872. [Google Scholar] [CrossRef]

- Islamov, D.R.; Zalyalov, T.M.; Orlov, O.M.; Gritsenko, V.A.; Krasnikov, G.Y. Impact of oxygen vacancy on the ferroelectric properties of lanthanum-doped hafnium oxide. Appl. Phys. Lett. 2020, 117, 162901. [Google Scholar] [CrossRef]

- Hsain, H.A.; Lee, Y.H.; Parsons, G. Compositional dependence of crystallization temperatures and phase evolution in hafnia-zirconia (Hf1-XZrX) O2 thin films. Appl. Phys. Lett. 2020, 116, 192901. [Google Scholar] [CrossRef]

- Xiao, W.W.; Liu, C.; Peng, Y.; Zheng, S.Z.; Zhang, C.F.; Liao, M.; Zhou, Y.C. Performance improvement of Hf0.5 Zr0.5O2-based ferroelectric-field-effect transistors with ZrO2 seed layers. IEEE Electron Device Lett. 2019, 40, 714–717. [Google Scholar] [CrossRef]

- Hoffmann, M.; Schroeder, U.; Schenk, T.; Shimizu, T.; Funakubo, H.; Sakata, O.; Pohl, D.; Drescher, M.; Adelmann, C.; Materlik, R.; et al. Stabilizing the ferroelectric phase in doped hafnium oxide. J. Appl. Phys. 2015, 118, 072006. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Wang, G.C.; Lu, T.M.; Palasantzas, G.; De Hosson, J.T.M. Surface-roughness effect on capacitance and leakage current of an insulating film. Phys. Rev. B 1999, 60, 9157. [Google Scholar] [CrossRef] [Green Version]

- Fields, S.S.; Smith, S.W.; Ryan, P.J.; Jaszewski, I.A.; Alejandro, S.B.; Esteves, G.; Steve, L. Phase-exchange-driven wake-up and fatigue in ferroelectric hafnium zirconium oxide films. ACS Appl. Mater. Interfaces 2020, 12, 26577–26585. [Google Scholar] [CrossRef]

- Starschich, S.S.; Menzel, S.; Böttger, U. Evidence for oxygen vacancies movement during wake-up in ferroelectric hafnium oxide. Appl. Phys. Lett. 2016, 108, 032903. [Google Scholar] [CrossRef] [Green Version]

- Song, T.F.; Tan, H.; Estandía, S.; Gàzquez, J.; Gich, M. Improved polarization and endurance in ferroelectric Hf0.5Zr0.5O2 films on SrTiO3 (110). Nanoscale 2022, 14, 2337–2343. [Google Scholar] [CrossRef]

- Kim, S.J.; Mohan, J.; Summerfelt, S.R.; Kim, J. Ferroelectric Hf0.5Zr0.5O2 thin films: A review of recent advances. JOM 2019, 71, 246–255. [Google Scholar] [CrossRef]

- Lyu, J.; Song, T.F.; Fina, I.; Sánchez, F. High polarization, endurance and retention in sub-5 nm Hf0.5Zr0.5 O2 films. Nanoscale 2020, 12, 11280–11287. [Google Scholar] [CrossRef] [PubMed]

- Starschich, S.; Boettger, U. An extensive study of the influence of dopants on the ferroelectric properties of HfO2. J. Mater. Chem. C 2017, 5, 333–338. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.-G.; Liu, S.-W.; Yang, L.-S.; Jiang, Y.; Xiong, K.; Li, G.; Ouyang, J.; Tang, M.-H. Improvement of Ferroelectricity in Ce-Doped Hf0.5Zr0.5O2 Thin Films. Coatings 2022, 12, 1766. https://doi.org/10.3390/coatings12111766

Xiao Y-G, Liu S-W, Yang L-S, Jiang Y, Xiong K, Li G, Ouyang J, Tang M-H. Improvement of Ferroelectricity in Ce-Doped Hf0.5Zr0.5O2 Thin Films. Coatings. 2022; 12(11):1766. https://doi.org/10.3390/coatings12111766

Chicago/Turabian StyleXiao, Yong-Guang, Si-Wei Liu, Li-Sha Yang, Yong Jiang, Ke Xiong, Gang Li, Jun Ouyang, and Ming-Hua Tang. 2022. "Improvement of Ferroelectricity in Ce-Doped Hf0.5Zr0.5O2 Thin Films" Coatings 12, no. 11: 1766. https://doi.org/10.3390/coatings12111766