Laser Ablation of Copper Alloy under Varying Environmental Conditions to Achieve Purpose-Built Surface Structures

Abstract

:1. Introduction

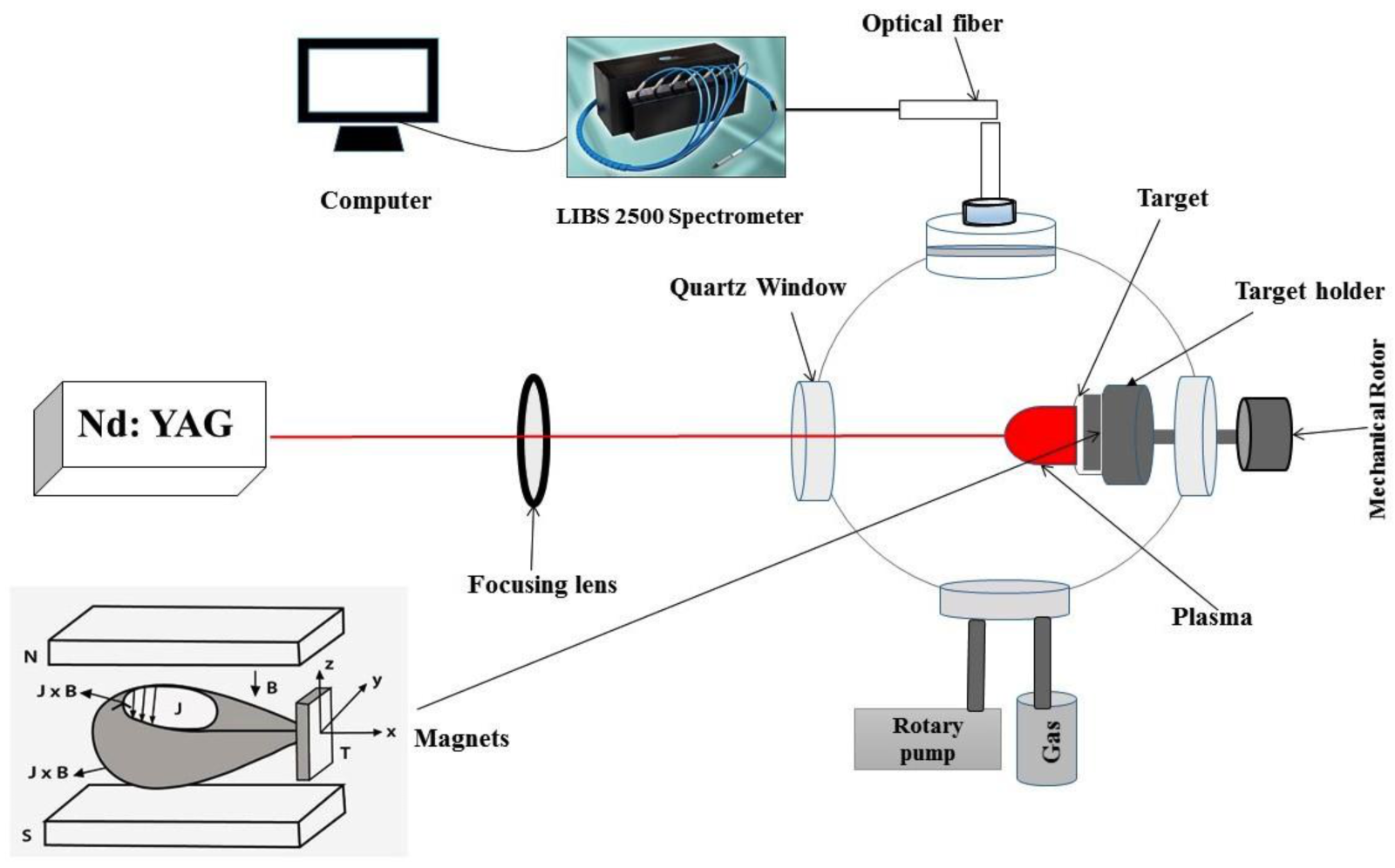

2. Experimentation

2.1. Sample Preparation

2.2. Measurements

- Ar, Ne, and He were employed as background gases in the first set of experiments. Twenty pressures (1, 2, 3, 4, 5, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, and 200 torr) of inert gases were supplied for the experiment. These data were collected by exposing a Cu-alloy target to a single 150 mJ laser pulse at an intensity of 3.8 GW/cm2 for 1.25 µs, then recording the resulting plasma emissions both without and with TMF.

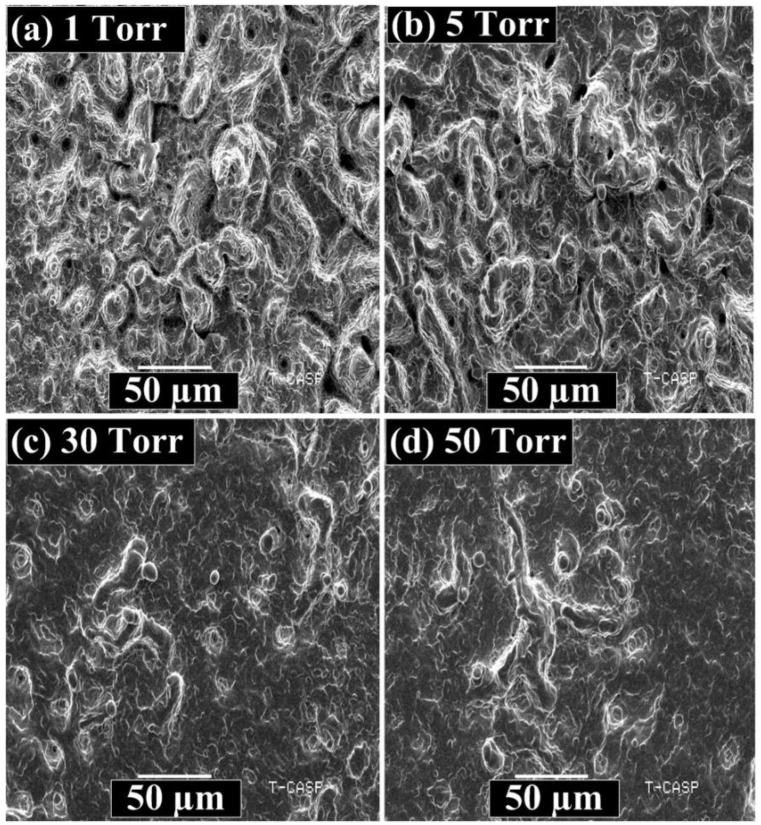

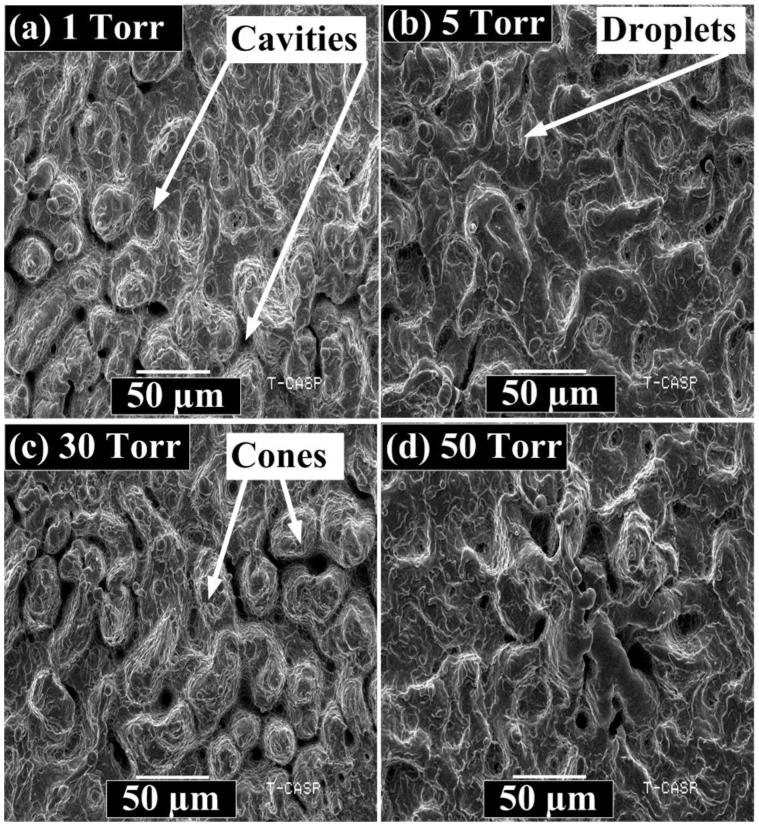

- A second series of studies were conducted to establish a relationship between the LPP parameters and the growth of surface structures. The Cu alloy target in this set was irradiated by 200 laser shots at 3.8 GW/cm2 in a variety of environments, including Ar, Ne, and He at 1, 5, 30, and 50 torr pressure. The surface structures of laser-irradiated Mg alloy have been investigated using SEM examination. A scanning electron microscope (JEOL JSM 6490-A, Tokyo, Japan) was utilized for this analysis.

3. Results

3.1. Effect of a Transverse Magnetic Field on LPP of Cu-Alloy

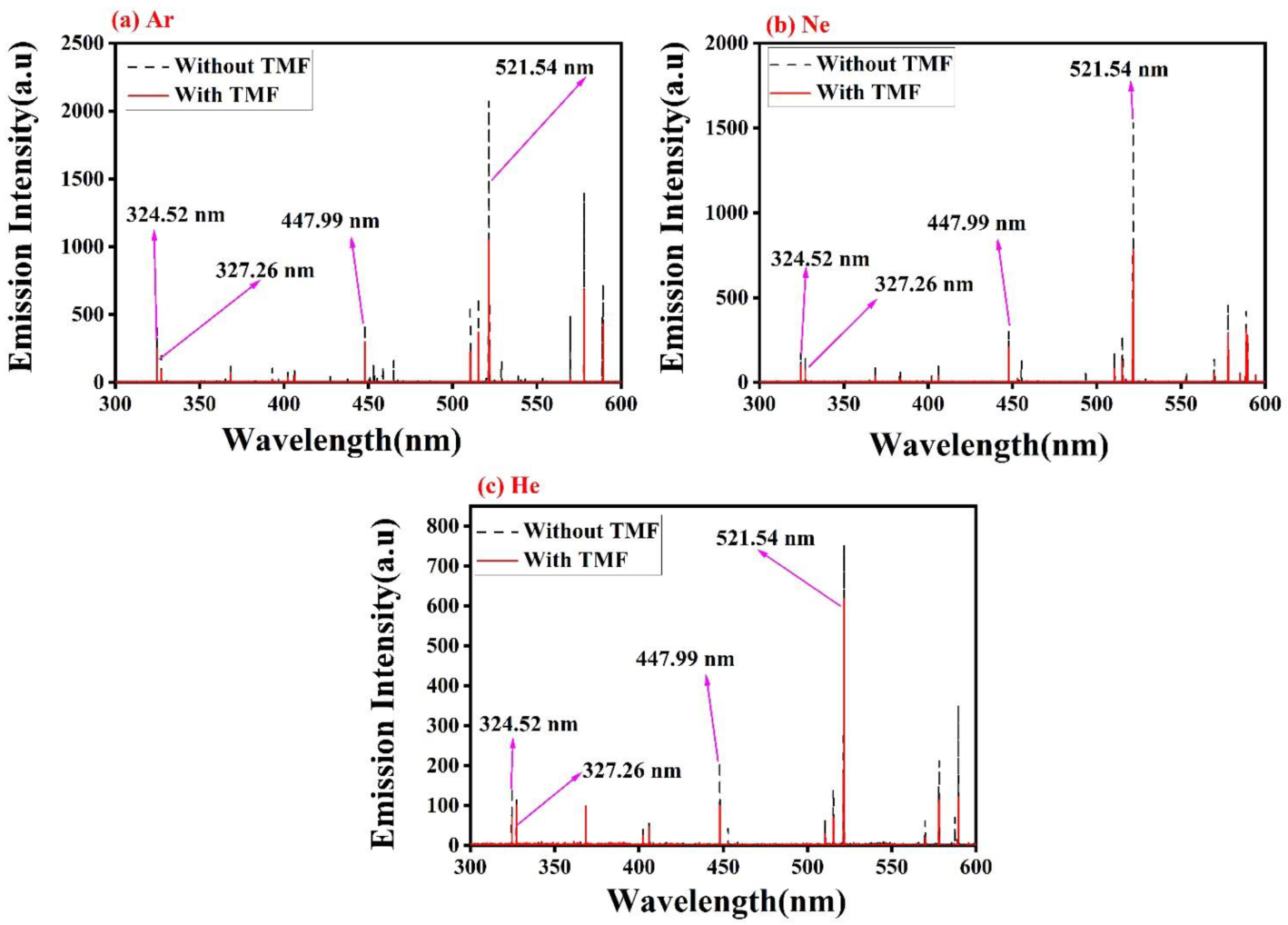

3.1.1. Investigation of Optical Emission Spectra of LPP of Cu-Alloy

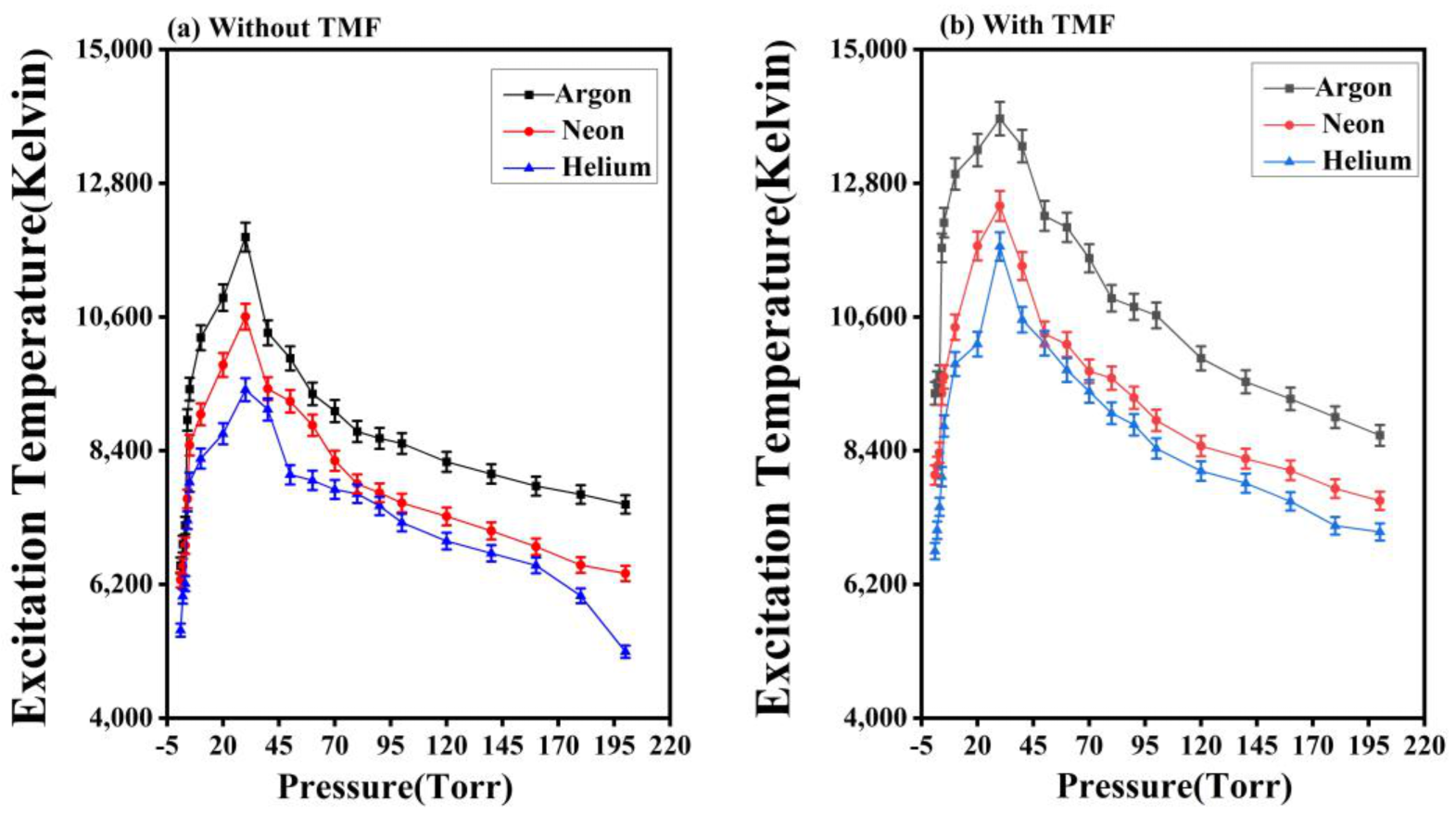

3.1.2. Investigation of Electron Temperature of Cu-Alloy Plasma

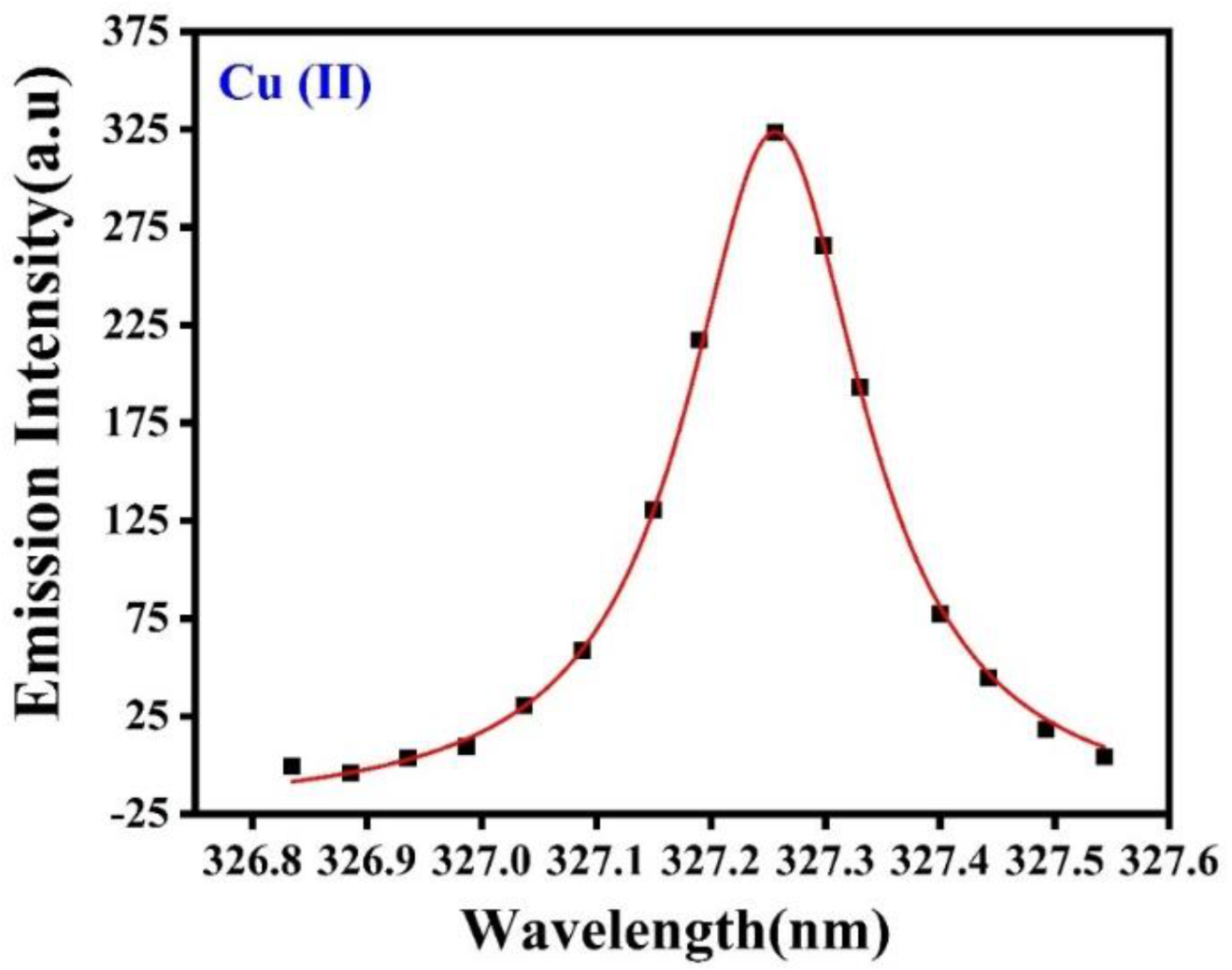

3.1.3. Investigation of Electron Number Density of Cu-Alloy Plasma

4. Discussion

4.1. Investigation of Surface Analysis of Laser-Irradiated Cu Alloy

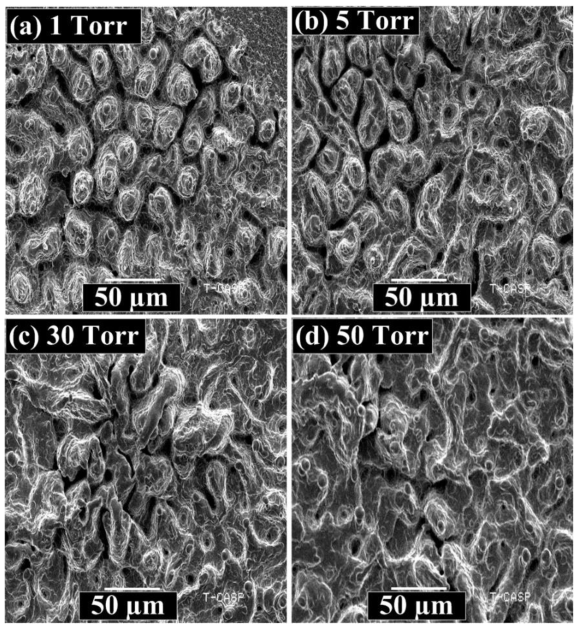

4.1.1. Surface Morphology of Cu-Alloy under Ar Environment without TMF

4.1.2. Surface Morphology of Cu-Alloy under Ar Environment with TMF

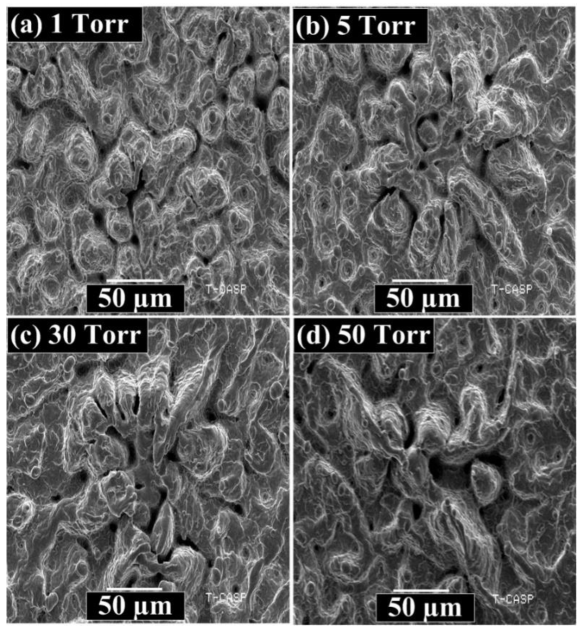

4.1.3. Surface Morphology of Cu-Alloy under Ne Environment without TMF

4.1.4. Surface Morphology of Cu-Alloy under Ne Environment with TMF

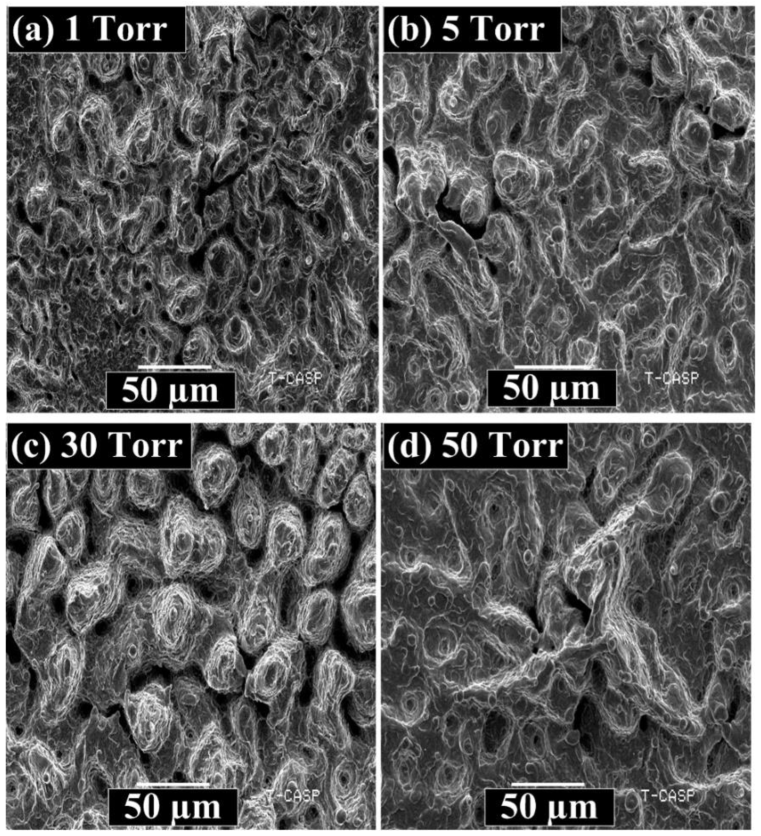

4.1.5. Surface Morphology of Cu-Alloy under He Environment without TMF

4.1.6. Surface Morphology of Cu-Alloy under He Environment with TMF

5. Conclusions

- Cu plasmas are found to be pressure-dependent in terms of emission intensity, Te, and ne initially; by increasing pressure, all of these parameters increase, and, after reaching their maximums, the electron temperature and electron number density values begin to drop or become saturated as pressure continues to rise. This holds true regardless of the surrounding conditions. Te and ne exhibit the same tendencies in the presence of TMF as they do in the absence of a field over a wide range of environmental variables.

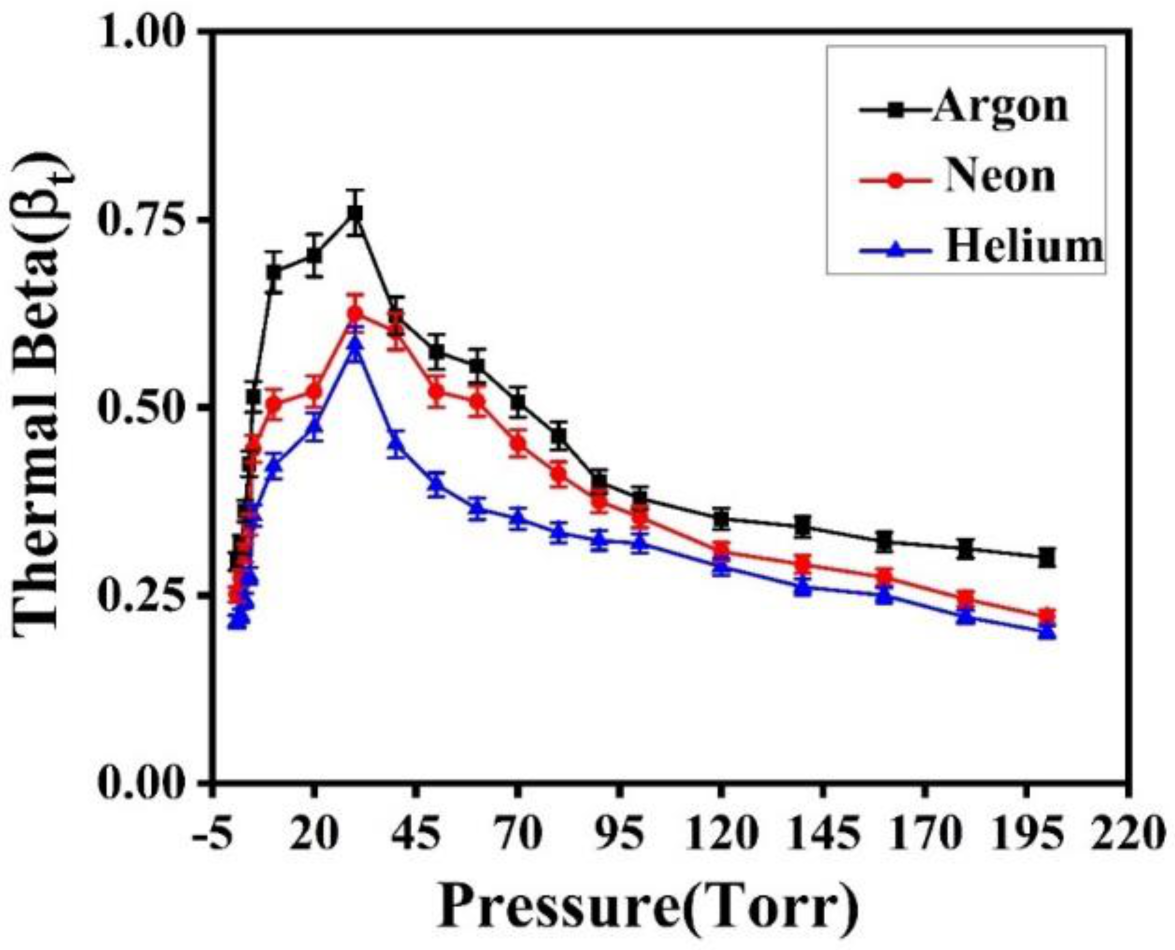

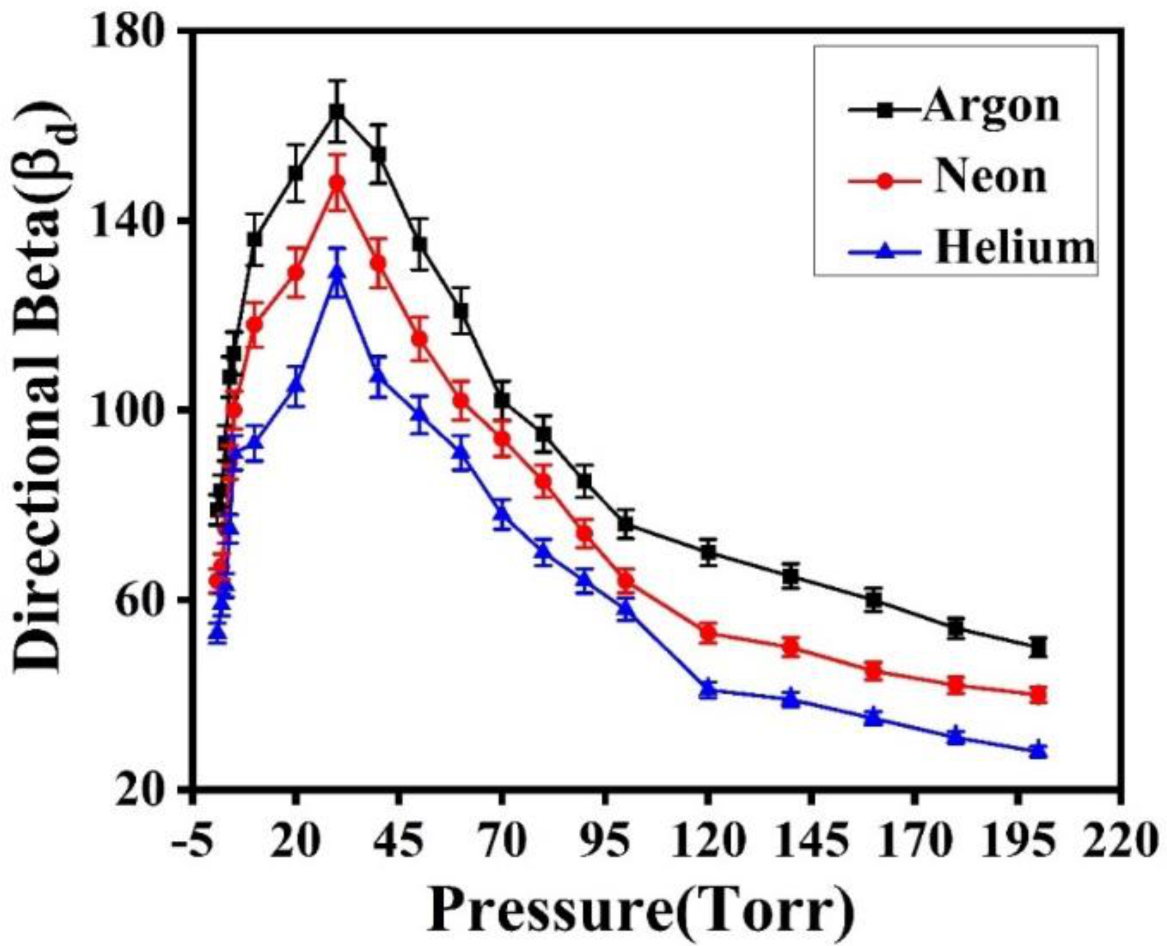

- The ambient Ar environment has higher Te and ne spectral intensities than the Ne and He environments under all conditions. Ar has a faster rate of cascade formation and lower thermal conductivity, E/M ratio, and ionization potentials than Ne and He, which explains these results. The confinement of Cu plasma under a 0.6 T TMF is confirmed by analytical assessments, including thermal beta (βt), directional beta (βd), and containment radii (Rs) for different ambient gas pressures.

- In the absence of TMF, the formation of less distinct surface structures, such as diffusive cones, cavities, droplets, and non-uniform melting and ridges, is observed on Cu-alloy, whereas, for Cu-alloy in TMF, distinct and well-defined structuring is observed, viz., the large-scale melting, micro-sized spherical cones and cavities, pores, and organized ridges.

- Improved Te and ne from a plasma that has been magnetically contained may make it a more useful ion source for ion implantation, thin-film deposition, and coating applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Inam, A.; Hegde, M.; Wu, X.; Venkatesan, T.; England, P.; Miceli, P.; Chase, E.; Chang, C.; Tarascon, J.; Wachtman, J. As-deposited high Tc and Jc superconducting thin films made at low temperatures. Appl. Phys. Lett. 1988, 53, 908–910. [Google Scholar] [CrossRef]

- Mao, X.; Russo, R.E.; Liu, H.; Ho, J. As-deposited Sb-doped Bi-Pb-Sr-Ca-Cu-O thin films prepared by pulsed laser deposition. Appl. Phys. Lett. 1990, 57, 2591–2593. [Google Scholar] [CrossRef]

- Sugioka, K.; Toyoda, K. Self-aligned microfabrication of metal-semiconductor contacts by projection-patterned excimer laser doping. Jpn. J. Appl. Phys. 1990, 29, 2255. [Google Scholar] [CrossRef]

- Sternitzke, K.D.; McCreery, R.L. Laser microfabrication and activation of graphite and glassy carbon electrodes. Anal. Chem. 1990, 62, 1339–1344. [Google Scholar] [CrossRef]

- Anderson, R.R.; Parrish, J.A. Selective photothermolysis: Precise microsurgery by selective absorption of pulsed radiation. Science 1983, 220, 524–527. [Google Scholar] [CrossRef] [Green Version]

- Khalid, A.; Bashir, S.; Akram, M.; Hayat, A. Laser-induced breakdown spectroscopy analysis of human deciduous teeth samples. Lasers Med. Sci. 2015, 30, 2233–2238. [Google Scholar] [CrossRef]

- Bulatov, V.; Xu, L.; Schechter, I. Spectroscopic imaging of laser-induced plasma. Anal. Chem. 1996, 68, 2966–2973. [Google Scholar] [CrossRef]

- Amoruso, S.; Bruzzese, R.; Spinelli, N.; Velotta, R. Characterization of laser-ablation plasmas. J. Phys. B At. Mol. Opt. Phys. 1999, 32, R131. [Google Scholar] [CrossRef]

- De Giacomo, A.; Dell’Aglio, M.; Gaudiuso, R.; Amoruso, S.; De Pascale, O. Effects of the background environment on formation, evolution and emission spectra of laser-induced plasmas. Spectrochim. Acta Part B At. Spectrosc. 2012, 78, 1–19. [Google Scholar] [CrossRef]

- Dyer, P.; Issa, A.; Key, P. Dynamics of excimer laser ablation of superconductors in an oxygen environment. Appl. Phys. Lett. 1990, 57, 186–188. [Google Scholar] [CrossRef]

- Harilal, S.S.; Bindhu, C.V.; Tillack, M.S.; Najmabadi, F.; Gaeris, A.C. Internal structure and expansion dynamics of laser ablation plumes into ambient gases. J. Appl. Phys. 2003, 93, 2380–2388. [Google Scholar] [CrossRef] [Green Version]

- Park, S.M.; Moon, J.Y. Laser ablation of graphite in an oxygen jet. J. Chem. Phys. 1998, 109, 8124–8129. [Google Scholar] [CrossRef]

- Mayo, R.; Newman, J.; Sharma, A.; Yamagata, Y.; Narayan, J. Electrostatic measurement of plasma plume characteristics in pulsed laser evaporated carbon. J. Appl. Phys. A 1999, 86, 2865–2871. [Google Scholar] [CrossRef]

- Kim, D.; Park, H.K.; Grigoropoulos, C.P. Interferometric probing of rapid vaporization at a solid–liquid interface induced by pulsed-laser irradiation. Int. J. Heat Mass Transf. 2001, 44, 3843–3853. [Google Scholar] [CrossRef]

- Masubuchi, T.; Tada, T.; Nomura, E.; Hatanaka, K.; Fukumura, H.; Masuhara, H. Laser-induced decomposition and ablation dynamics studied by nanosecond interferometry. 4. A polyimide film. J. Phys. Chem. A 2002, 106, 2180–2186. [Google Scholar] [CrossRef]

- Laube, S.; Voevodin, A. In situ time of flight laser induced florescence spectroscopy of carbon by pulsed laser deposition. Surf. Coat. Technol. 1998, 105, 125–129. [Google Scholar] [CrossRef]

- Glenzer, S.; Fournier, K.; Decker, C.; Hammel, B.; Lee, R.; Lours, L.; MacGowan, B.; Osterheld, A. Accuracy of K-shell spectra modeling in high-density plasmas. Phys. Rev. E 2000, 62, 2728. [Google Scholar] [CrossRef]

- Hayat, A.; Bashir, S.; Rafique, M.S.; Ahmed, R.; Akram, M.; Mahmood, K.; Zaheer, A.; Hussain, T.; Dawood, A. Spatial confinement effects employed by metallic blocker and Ar gas pressures on laser-induced breakdown spectroscopy and surface modifications of laser-irradiated Mg. Laser Part. Beams 2017, 35, 313–325. [Google Scholar] [CrossRef]

- Voevodin, A.; Jones, J.; Zabinski, J. Characterization of ZrO2/Y2O3 laser ablation plasma in vacuum, oxygen, and argon environments. J. Appl. Phys. 2000, 88, 1088–1096. [Google Scholar] [CrossRef]

- Harilal, S. Expansion dynamics of laser ablated carbon plasma plume in helium ambient. Appl. Surf. Sci. 2001, 172, 103–109. [Google Scholar] [CrossRef]

- Cremers, D.A.; Radziemski, L.J. Handbook of Laser-Induced Breakdown Spectroscopy; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Amin, S.; Bashir, S.; Anjum, S.; Akram, M.; Hayat, A.; Waheed, S.; Iftikhar, H.; Dawood, A.; Mahmood, K. Optical emission spectroscopy of magnetically confined laser induced vanadium pentoxide (V2O5) plasma. Phys. Plasmas 2017, 24, 083112. [Google Scholar] [CrossRef]

- Dawood, M.; Margot, J. Effect of ambient gas pressure and nature on the temporal evolution of aluminum laser-induced plasmas. AIP Adv. 2014, 4, 037111. [Google Scholar] [CrossRef]

- Russo, R.; Mao, X.; Liu, C.; Gonzalez, J. Laser assisted plasma spectrochemistry: Laser ablation. J. Anal. At. Spectrom. 2004, 19, 1084–1089. [Google Scholar] [CrossRef]

- Akram, M.; Bashir, S.; Hayat, A.; Mahmood, K.; Ahmad, R.; Rahman, M.K. Effect of laser irradiance on the surface morphology and laser Induced plasma parameters of zinc. Laser Part. Beams 2014, 32, 119–128. [Google Scholar] [CrossRef] [Green Version]

- Akram, M.; Bashir, S.; Rafique, M.S.; Hayat, A.; Mahmood, K. Laser induced surface morphology of molybdenum correlated with breakdown spectroscopy. Plasma Chem. Plasma Process. 2017, 37, 287–304. [Google Scholar] [CrossRef]

- Arshad, A.; Bashir, S.; Hayat, A.; Akram, M.; Khalid, A.; Yaseen, N.; Ahmad, Q.S. Effect of magnetic field on laser-induced breakdown spectroscopy of graphite plasma. Appl. Phys. B 2016, 122, 63. [Google Scholar] [CrossRef]

- Neogi, A.; Thareja, R. Dynamics of laser produced carbon plasma expanding in a nonuniform magnetic field. J. Appl. Phys. 1999, 85, 1131–1136. [Google Scholar] [CrossRef]

- Hussain, A.; Qi, L.; Zuoqiang, H.; Xun, G.; Jingquan, L. The Effect of an External Magnetic Field on the Plume Expansion Dynamics of Laser-Induced Aluminum Plasma. Plasma Sci. Technol. 2015, 17, 693. [Google Scholar] [CrossRef] [Green Version]

- Winske, D. Development of flute modes on expanding plasma clouds. Phys. Fluids 1989, 1, 1900–1910. [Google Scholar] [CrossRef]

- Neogi, A.; Thareja, R.K. Laser-produced carbon plasma expanding in vacuum, low pressure ambient gas and nonuniform magnetic field. Phys. Plasmas 1999, 6, 365–371. [Google Scholar] [CrossRef]

- Gekelman, W.; Van Zeeland, M.; Vincena, S.; Pribyl, P. Laboratory experiments on Alfvén waves caused by rapidly expanding plasmas and their relationship to space phenomena. J. Geophys. Res. Space Phys. 2003, 108, 1281. [Google Scholar] [CrossRef] [Green Version]

- Kawasaki, H.; Doi, K.; Hiraishi, S.; Suda, Y. Effects of cross-magnetic field on thin film preparation by pulsed Nd/YAG laser deposition. Thin Solid Film. 2000, 374, 278–281. [Google Scholar] [CrossRef]

- Harilal, S.; O’Shay, B.; Tillack, M.S. Debris mitigation in a laser-produced tin plume using a magnetic field. J. Appl. Phys. 2005, 98, 036102. [Google Scholar] [CrossRef] [Green Version]

- Cowpe, J.; Pilkington, R.; Astin, J.; Hill, A. The effect of ambient pressure on laser-induced silicon plasma temperature, density and morphology. J. Phys. D Appl. Phys 2009, 42, 165202. [Google Scholar] [CrossRef] [Green Version]

- Patel, D.; Pandey, P.K.; Thareja, R.K. Brass plasmoid in external magnetic field at different air pressures. Phys. Plasmas 2013, 20, 103503. [Google Scholar] [CrossRef]

- Raju, M.S.; Singh, R.; Gopinath, P.; Kumar, A. Influence of magnetic field on laser-produced barium plasmas: Spectral and dynamic behaviour of neutral and ionic species. J. Appl. Phys. 2014, 116, 153301. [Google Scholar] [CrossRef]

- Rai, V.; Singh, J.P. Effect of laser intensity and dynamics of plasma on laser induced breakdown spectroscopy. arXiv 2014, arXiv:1406.7703. [Google Scholar]

- Corsi, M.; Cristoforetti, G.; Hidalgo, M.; Iriarte, D.; Legnaioli, S.; Palleschi, V.; Salvetti, A.; Tognoni, E. Effect of laser-induced crater depth in laser-induced breakdown spectroscopy emission features. Appl. Spect. 2005, 59, 853–860. [Google Scholar] [CrossRef]

- Rai, V.N.; Zhang, H.; Yueh, F.Y.; Singh, J.P.; Kumar, A. Effect of steady magnetic field on laser-induced breakdown spectroscopy. Appl. Opt. 2003, 42, 3662–3669. [Google Scholar] [CrossRef]

- Hussain, A.; Asghar, H.; Iqbal, T.; Ishfaq, M.; Shahbaz, R.M.; Riaz, Q. Improving the spectral intensity of aluminum plasma by applied-magnetic field in laser-induced breakdown spectroscopy. Optik 2021, 251, 168220. [Google Scholar] [CrossRef]

- Liu, P.; Hai, R.; Wu, D.; Xiao, Q.; Sun, L.; Ding, H. The enhanced effect of optical emission from laser induced breakdown spectroscopy of an Al-Li alloy in the presence of magnetic field confinement. Plasma Sci. Technol. 2015, 17, 687. [Google Scholar] [CrossRef]

- Wang, T.; Yasuda, K.; Nishikawa, H. Fabrication of micron-sized protrusions on metal surface for metal/polymer easy-disassembly joining by selective laser melting technology. Mater. Des. 2022, 220, 110873. [Google Scholar] [CrossRef]

- Min, J.; Wan, H.; Carlson, B.E.; Lin, J.; Sun, C. Application of laser ablation in adhesive bonding of metallic materials: A review. Opt. Laser Technol. 2020, 128, 106188. [Google Scholar] [CrossRef]

- Singh, K.S.; Sharma, A.K. Time-integrated optical emission studies on laser-produced copper plasma in the presence of magnetic field in air ambient at atmospheric pressure. Appl. Phys. A 2017, 123, 325. [Google Scholar] [CrossRef]

- WikiPedia. Available online: https://en.wikipedia.org/wiki/Gilding_metal (accessed on 10 December 2022).

- Demtröder, W. Laser Spectroscopy: Basic Concepts and Instrumentation; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- List, I.A. Atomic Line List v3.00b4. Available online: http://www.pa.uky.edu/~peter/newpage/ (accessed on 18 August 2021).

- Reader, J.; Corliss, C.H.; Wiese, W.; Martin, G. Wavelengths and Transition Probabilities for Atoms and Atomic Ions: Part 1. Wavelengths, Part 2. Transition Probabilities; NSRDS-NBS.; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1980; Volume 68, p. 409. [Google Scholar]

- Singh, K.S.; Sharma, A.K. Multi-structured temporal behavior of neutral copper transitions in laser-produced plasma in the presence of variable transverse static magnetic field. Phys. Plasmas 2016, 23, 013304. [Google Scholar] [CrossRef]

- Li, Y.; Hu, C.; Zhang, H.; Jiang, Z.; Li, Z. Optical emission enhancement of laser-produced copper plasma under a steady magnetic field. App. Opt. 2009, 48, B105–B110. [Google Scholar] [CrossRef]

- Cheng, L.; Xun, G.; Qi, L.; Chao, S.; Jingquan, L. Spectral enhancement of laser-induced breakdown spectroscopy in external magnetic field. Plasma Sci. Technol. 2015, 17, 919–922. [Google Scholar]

- Harilal, S.; Tillack, M.; O’shay, B.; Bindhu, C.; Najmabadi, F. Confinement and dynamics of laser-produced plasma expanding across a transverse magnetic field. Phys. Rev. E 2004, 69, 026413. [Google Scholar] [CrossRef] [Green Version]

- Iftikhar, H.; Bashir, S.; Dawood, A.; Akram, M.; Hayat, A.; Mahmood, K.; Zaheer, A.; Amin, S.; Murtaza, F. Magnetic field effect on laser-induced breakdown spectroscopy and surface modifications of germanium at various fluences. Laser Part. Beams 2017, 35, 159–169. [Google Scholar] [CrossRef]

- Joshi, H.; Kumar, A.; Singh, R.; Prahlad, V. Effect of a transverse magnetic field on the plume emission in laser-produced plasma: An atomic analysis. Spectrochim. Acta B 2010, 65, 415–419. [Google Scholar] [CrossRef]

- Kim, T.H.; Nam, S.H.; Park, H.S.; Song, J.K.; Park, S.M. Effects of transverse magnetic field on a laser-produced Zn plasma plume and ZnO films grown by pulsed laser deposition. Appl. Surf. Sci 2007, 253, 8054–8058. [Google Scholar] [CrossRef]

- Shen, X.; Lu, Y.; Gebre, T.; Ling, H.; Han, Y. Optical emission in magnetically confined laser-induced breakdown spectroscopy. J. Appl Phys. 2006, 100, 053303. [Google Scholar] [CrossRef]

- Harilal, S.; Sizyuk, T.; Hassanein, A.; Campos, D.; Hough, P.; Sizyuk, V. The effect of excitation wavelength on dynamics of laser-produced tin plasma. J. Appl. Phys. 2011, 109, 063306. [Google Scholar] [CrossRef]

- Nakimana, A.; Tao, H.; Camino, A.; Gao, X.; Hao, Z.; Lin, J. Effect of ambient pressure on femtosecond laserinduced breakdown spectroscopy of Al in Argon. In Proceedings of the International Conference on Optoelectronics and Microelectronics (ICOM), Changchun, Jilin, 23–25 August 2012; pp. 146–150. [Google Scholar]

- Luo, W.; Zhao, X.; Sun, Q.; Gao, C.; Tang, J.; Wang, H.; Zhao, W. Characteristics of the aluminum alloy plasma produced by a 1064 nm Nd: YAG laser with different irradiances. Pramana 2010, 74, 945–959. [Google Scholar] [CrossRef]

- Radziemski, L.J.; Cremers, D.A. Laser-Induced Plasmas and Applications; CRC Press: Boca Raton, FL, USA, 1989. [Google Scholar]

- Farid, N.; Bashir, S.; Mehmood, K. Effect of ambient gas conditions on laser-induced copper plasma and surface morphology. Phys. Scr. 2012, 85, 015702. [Google Scholar] [CrossRef]

- Farid, N.; Harilal, S.S.; Ding, H.; Hassanein, A. Emission features and expansion dynamics of nanosecond laser ablation plumes at different ambient pressures. J. Appl. Phys. 2014, 115, 033107. [Google Scholar] [CrossRef]

- Harilal, S.S.; Bindhu, C.V.; Nampoori, V.P.N.; Vallabhan, C.P.G. Influence of ambient gas on the temperature and density of laser produced carbon plasma. Appl. Phys. Lett. 1998, 72, 167–169. [Google Scholar] [CrossRef] [Green Version]

- Knight, A.K.; Scherbarth, N.L.; Cremers, D.A.; Ferris, M. Characterization of laser-induced breakdown spectroscopy (LIBS) for application to space exploration. Appl. Spectrosc. 2000, 54, 331–340. [Google Scholar] [CrossRef]

- Iida, Y. Effects of atmosphere on laser vaporization and excitation processes of solid samples. Spectrochim. Acta B 1990, 45, 1353–1367. [Google Scholar] [CrossRef]

- Effenberger, A.J.; Scott, J.R. Effect of atmospheric conditions on LIBS spectra. Sensors 2010, 10, 4907–4925. [Google Scholar] [CrossRef] [Green Version]

- Boyd, T.J.M.; Sanderson, J.J. The Physics of Plasmas; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Peyser, T.; Manka, C.; Ripin, B.; Ganguli, G. Electron–ion hybrid instability in laser-produced plasma expansions across magnetic fields. Phys. Fluids B 1992, 4, 2448–2458. [Google Scholar] [CrossRef]

- Bleiner, D.; Bogaerts, A. Multiplicity and contiguity of ablation mechanisms in laser-assisted analytical micro-sampling. Spectrochim. Acta B 2006, 61, 421–432. [Google Scholar] [CrossRef]

- Zuhlke, C.A.; Anderson, T.P.; Alexander, D.R. Formation of multiscale surface structures on nickel via above surface growth and below surface growth mechanisms using femtosecond laser pulses. Opt. Express 2013, 21, 8460–8473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bashir, S.; Khurshid, S.; Akram, M.; Ali, N.; Ahmad, S.; Yousaf, D. Pulsed laser ablation of Ni in vacuum and N2 atmosphere at various fluences. Quantum Electron. 2015, 45, 640–647. [Google Scholar] [CrossRef]

- Mansour, N.; Jamshidi-Ghaleh, K.; Ashkenasi, D. Formation of conical microstructures of silicon with picosecond laser pulses in air. JLMN 2006, 1, 12–16. [Google Scholar] [CrossRef] [Green Version]

- Sarfraz, S.M.A.; Bashir, S.; Mahmood, K.; Khaliq, A.; Rizvi, R. Fluence-dependent sputtering yield measurement, surface morphology, crater depth, and hardness of laser-irradiated Zr in N2 and Ne environments. J. Opt. Soc. Am. B 2019, 36, 1945–1957. [Google Scholar] [CrossRef]

- Körner, C.; Mayerhofer, R.; Hartmann, M.; Bergmann, H.W. Physical and material aspects in using visible laser pulses of nanosecond duration for ablation. J. Appl. Phys. A 1996, 63, 123–131. [Google Scholar] [CrossRef]

- Tokarev, V. Viscous liquid expulsion in nanosecond UV laser ablation: From “clean” ablation to nanostructures. Laser Phys. 2006, 16, 1291–1307. [Google Scholar] [CrossRef]

- Lappalainen, J.; Frantti, J.; Lantto, V. Particulate formation in PZT thin films during pulsed laser ablation deposition. Korean Phys. Soc. 1998, 32, S1183–S1186. [Google Scholar]

- Aristov, Y.I.; Tokarev, M.M.; Freni, A.; Glaznev, I.S.; Restuccia, G. Kinetics of water adsorption on silica Fuji Davison RD. Microporous Mesoporous Mater. 2006, 96, 65–71. [Google Scholar] [CrossRef]

- Yousaf, D.; Bashir, S.; Akram, M.; Kalsoom, U.-I.; Ali, N. Laser irradiation effects on the surface, structural and mechanical properties of Al–Cu alloy 2024. Radiat. Eff. Defects Solids 2014, 169, 144–156. [Google Scholar] [CrossRef]

- Dauscher, A.; Feregotto, V.; Cordier, P.; Thomy, A. Laser induced periodic surface structures on iron. Appl. Surf. Sci. 1996, 96, 410–414. [Google Scholar] [CrossRef]

- Barmina, E.V.; Barberoglu, M.; Zorba, V.; Simakin, A.V.; Stratakis, E.; Fotakis, K.; Shafeev, G.A. Surface nanotexturing of tantalum by laser ablation in water. Quantum Electron. 2009, 39, 89. [Google Scholar] [CrossRef]

- Ko, S.H.; Pan, H.; Hwang, D.J.; Chung, J.; Ryu, S.; Grigoropoulos, C.P.; Poulikakos, D. High resolution selective multilayer laser processing by nanosecond laser ablation of metal nanoparticle films. J. Appl. Phys. 2007, 102, 093102. [Google Scholar] [CrossRef] [Green Version]

- Obilor, A.F.; Pacella, M.; Wilson, A.; Silberschmidt, V.V. Micro-texturing of polymer surfaces using lasers: A review. J. Adv. Manuf. Technol. 2022, 120, 103–135. [Google Scholar] [CrossRef]

- Tofil, S.; Barbucha, R.; Kocik, M.; Kozera, R.; Tański, M.; Arivazhagan, N.; Yao, J.; Zrak, A. Adhesive Joints with Laser Shaped Surface Microstructures. Materials 2021, 14, 7548. [Google Scholar] [CrossRef]

- Rudawska, A. Adhesive properties of metals and metal alloys. In Surface Energy; Aliofkhazraei, M., Ed.; InTech: Rijeka, Croatia, 2015; pp. 85–121. [Google Scholar]

| Spectroscopic Data | ||||

|---|---|---|---|---|

| Wavelength (nm) | Transitions | Energy of Upper Level Em (cm−1) | Statistical Weight gm | Transition Probabilities (108S−1) |

| 324.52 | 3d9.5p–3d9.7d | 153,821.94 | 5 | 5.95 × 10−3 |

| 327.26 | 3d8.(3F).4s.4p.(3Po)–3d9.(2D<3/2>).7s | 146,936.32 | 5 | 2.00 × 10−4 |

| 447.99 | 3d9.4d–3d9.6p | 138,401.95 | 7 | 2.16 × 10−4 |

| 521.54 | 3d10.9p⇾3d9.4s.(3D).7s | 134,742.85 | 9 | 5.41 × 10−4 |

| Argon | ||||||

|---|---|---|---|---|---|---|

| Pressure | Te (Kelvin) | ne (1018) (cm−3) | Analytical Parameters | |||

| Without TMF | With TMF | Without TMF | With TMF | Thermal Beta | Directed Beta | |

| 1 | 6513 | 9344 | 1.19 | 1.23 | 0.30 | 79 |

| 2 | 6864 | 9515 | 1.24 | 1.28 | 0.32 | 83 |

| 3 | 7171 | 9616 | 1.30 | 1.36 | 0.36 | 93 |

| 4 | 8907 | 11,737 | 1.38 | 1.48 | 0.43 | 107 |

| 5 | 9413 | 12,152 | 1.42 | 1.59 | 0.51 | 112 |

| 10 | 10,259 | 12,954 | 1.52 | 1.66 | 0.68 | 136 |

| 20 | 10,919 | 13,346 | 1.61 | 1.72 | 0.70 | 150 |

| 30 | 11,915 | 13,864 | 1.78 | 2.19 | 0.76 | 163 |

| 40 | 10,341 | 13,411 | 1.72 | 1.99 | 0.62 | 154 |

| 50 | 9922 | 12,264 | 1.71 | 1.94 | 0.58 | 135 |

| 60 | 9336 | 12,075 | 1.65 | 1.90 | 0.56 | 121 |

| 70 | 9053 | 11,567 | 1.62 | 1.79 | 0.51 | 102 |

| 80 | 8715 | 10,909 | 1.58 | 1.75 | 0.46 | 95 |

| 90 | 8603 | 10,767 | 1.46 | 1.70 | 0.40 | 85 |

| 100 | 8519 | 10,627 | 1.39 | 1.65 | 0.38 | 76 |

| 120 | 8218 | 9922 | 1.3 | 1.64 | 0.35 | 70 |

| 140 | 8019 | 9536 | 1.28 | 1.60 | 0.34 | 65 |

| 160 | 7819 | 9253 | 1.24 | 1.59 | 0.32 | 60 |

| 180 | 7681 | 8953 | 1.11 | 1.54 | 0.31 | 54 |

| 200 | 7519 | 8653 | 1.00 | 1.50 | 0.30 | 50 |

| Neon | ||||||

|---|---|---|---|---|---|---|

| Pressure | Te (Kelvin) | ne (1018) (cm−3) | Analytical Parameters | |||

| Without TMF | With TMF | Without TMF | With TMF | Thermal Beta | Directed Beta | |

| 1 | 6278 | 8000 | 0.98 | 1.12 | 0.25 | 64 |

| 2 | 6496 | 8139 | 1.11 | 1.13 | 0.27 | 67 |

| 3 | 6841 | 8368 | 1.15 | 1.19 | 0.31 | 75 |

| 4 | 7609 | 9340 | 1.19 | 1.26 | 0.34 | 89 |

| 5 | 8491 | 9616 | 1.25 | 1.32 | 0.45 | 100 |

| 10 | 9000 | 10,432 | 1.28 | 1.42 | 0.50 | 118 |

| 20 | 9810 | 11,768 | 1.42 | 1.60 | 0.52 | 129 |

| 30 | 10,605 | 12,427 | 1.58 | 1.85 | 0.63 | 148 |

| 40 | 9421 | 11,440 | 1.47 | 1.83 | 0.60 | 131 |

| 50 | 9214 | 10,322 | 1.41 | 1.78 | 0.52 | 115 |

| 60 | 8820 | 10,149 | 1.36 | 1.73 | 0.51 | 102 |

| 70 | 8236 | 9709 | 1.31 | 1.69 | 0.45 | 94 |

| 80 | 7855 | 9595 | 1.23 | 1.55 | 0.41 | 85 |

| 90 | 7708 | 9272 | 1.17 | 1.48 | 0.38 | 74 |

| 100 | 7541 | 8900 | 1.08 | 1.42 | 0.35 | 64 |

| 120 | 7320 | 8477 | 1.01 | 1.40 | 0.31 | 53 |

| 140 | 7080 | 8270 | 0.99 | 1.30 | 0.29 | 50 |

| 160 | 6820 | 8077 | 0.91 | 1.25 | 0.27 | 45 |

| 180 | 6520 | 7777 | 0.86 | 1.20 | 0.25 | 42 |

| 200 | 6380 | 7577 | 0.81 | 1.19 | 0.22 | 40 |

| Helium | ||||||

|---|---|---|---|---|---|---|

| Pressure | Te (Kelvin) | ne (1018) (cm−3) | Analytical Parameters | |||

| Without TMF | With TMF | Without TMF | With TMF | Thermal Beta | Directed Beta | |

| 1 | 5449 | 6750 | 0.75 | 0.90 | 0.22 | 53 |

| 2 | 6006 | 7093 | 0.89 | 0.95 | 0.23 | 59 |

| 3 | 6213 | 7476 | 0.99 | 1.01 | 0.24 | 63 |

| 4 | 7257 | 7974 | 1.07 | 1.24 | 0.28 | 75 |

| 5 | 7881 | 8806 | 1.12 | 1.29 | 0.36 | 91 |

| 10 | 8271 | 9827 | 1.18 | 1.36 | 0.42 | 93 |

| 20 | 8681 | 10,154 | 1.28 | 1.49 | 0.47 | 105 |

| 30 | 9404 | 11,760 | 1.41 | 1.62 | 0.58 | 129 |

| 40 | 9080 | 10,555 | 1.33 | 1.52 | 0.45 | 107 |

| 50 | 8006 | 10,170 | 1.22 | 1.44 | 0.40 | 99 |

| 60 | 7913 | 9727 | 1.12 | 1.41 | 0.37 | 91 |

| 70 | 7762 | 9378 | 1.01 | 1.23 | 0.35 | 78 |

| 80 | 7693 | 9017 | 0.99 | 1.16 | 0.33 | 70 |

| 90 | 7490 | 8827 | 0.95 | 1.06 | 0.32 | 64 |

| 100 | 7218 | 8438 | 0.92 | 1.00 | 0.31 | 58 |

| 120 | 6913 | 8066 | 0.87 | 0.99 | 0.29 | 41 |

| 140 | 6713 | 7866 | 0.81 | 0.98 | 0.26 | 39 |

| 160 | 6513 | 7566 | 0.75 | 0.91 | 0.25 | 35 |

| 180 | 6013 | 7166 | 0.71 | 0.89 | 0.22 | 31 |

| 200 | 5093 | 7066 | 0.69 | 0.82 | 0.20 | 28 |

| Argon | |||||||

|---|---|---|---|---|---|---|---|

| Without TMF | With TMF | ||||||

| Pressure | Cavities (103)/cm2 | Cones (103)/cm2 | Avg. Cone Dia. (µm) | Pressure | Cavities (103)/cm2 | Cones (103)/cm2 | Avg. Cone Dia. (µm) |

| 1 | 21.746 | 20.757 | 28.2 | 1 | 14.44 | 8.4 | 33 |

| 5 | 18.54 | 12.21 | 14.7 | 5 | 12 | 3.2 | 12.1 |

| 30 | 6.1 | 9.78 | 17 | 30 | 24 | 13.5 | 35.4 |

| 50 | 0 | 2.1 | 0.9 | 50 | 17 | 9.3 | 18.7 |

| Average | 11.5965 | 11.21175 | 15.2 | Average | 16.86 | 8.6 | 24.8 |

| Neon | |||||||

| Without TMF | With TMF | ||||||

| Pressure | Cavities (103)/cm2 | Cones (103)/cm2 | Avg. Cone Dia. (µm) | Pressure | Cavities (103)/cm2 | Cones (103)/cm2 | Avg. Cone Dia. (µm) |

| 1 | 28.65 | 15.287 | 25.7 | 1 | 37.1 | 80.3 | 24.2 |

| 5 | 19.94 | 28 | 22.7 | 5 | 64.9 | 76.35 | 24.2 |

| 30 | 10.2 | 16.56 | 22 | 30 | 31.2 | 26.87 | 18.2 |

| 50 | 19.1 | 25.47 | 27 | 50 | 28.9 | 46.93 | 28.75 |

| Average | 19.4725 | 21.32925 | 24.35 | Average | 40.525 | 57.6125 | 23.8375 |

| Helium | |||||||

| Without TMF | With TMF | ||||||

| Pressure | Cavities (103)/cm2 | Cones (103)/cm2 | Avg. Cone Dia. (µm) | Pressure | Cavities (103)/cm2 | Cones (103)/cm2 | Avg. Cone Dia. (µm) |

| 1 | 31.2 | 31.9 | 30 | 1 | 15.89 | 28.37 | 25.3 |

| 5 | 21.2 | 21.9 | 29.4 | 5 | 12.71 | 55.6 | 30.4 |

| 30 | 23.1 | 22.6 | 25.7 | 30 | 45.94 | 33.35 | 35.4 |

| 50 | 22.1 | 12.1 | 26.6 | 50 | 12.3 | 12.3 | 23.8 |

| Average | 24.4 | 22.125 | 27.925 | Average | 21.71 | 32.405 | 28.725 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dawood, A.; Ahmed, N.; Bashir, S.; Hayat, A.; Sarfraz, S.M.A.; Ayub, A. Laser Ablation of Copper Alloy under Varying Environmental Conditions to Achieve Purpose-Built Surface Structures. Coatings 2022, 12, 1972. https://doi.org/10.3390/coatings12121972

Dawood A, Ahmed N, Bashir S, Hayat A, Sarfraz SMA, Ayub A. Laser Ablation of Copper Alloy under Varying Environmental Conditions to Achieve Purpose-Built Surface Structures. Coatings. 2022; 12(12):1972. https://doi.org/10.3390/coatings12121972

Chicago/Turabian StyleDawood, Asadullah, Naveed Ahmed, Shazia Bashir, Asma Hayat, Syed Muhammad Abouzar Sarfraz, and Ambreen Ayub. 2022. "Laser Ablation of Copper Alloy under Varying Environmental Conditions to Achieve Purpose-Built Surface Structures" Coatings 12, no. 12: 1972. https://doi.org/10.3390/coatings12121972