The Damage Threshold of Multilayer Film Induced by Femtosecond and Picosecond Laser Pulses

Abstract

:1. Introduction

2. Experimental Details

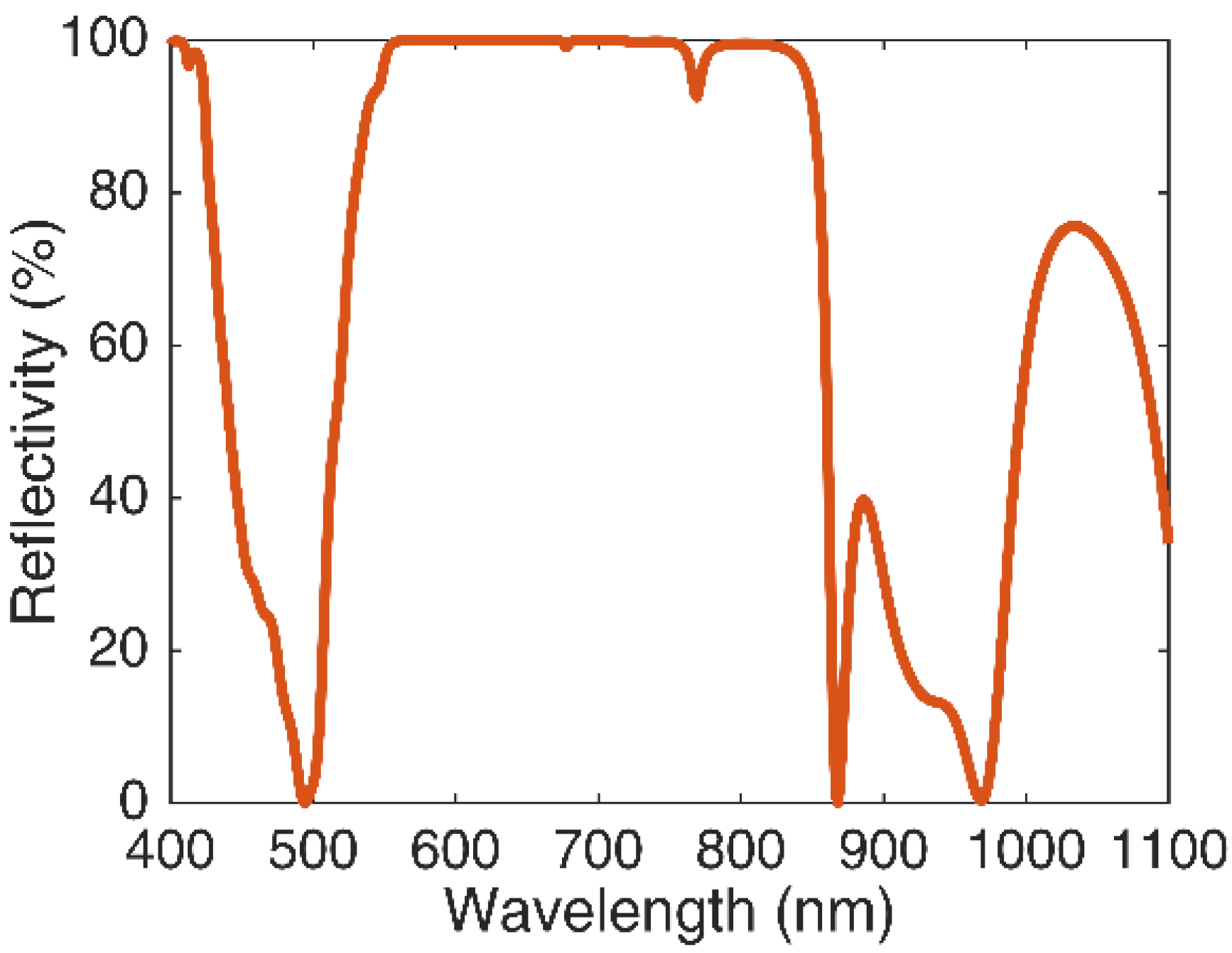

2.1. Sample Customization

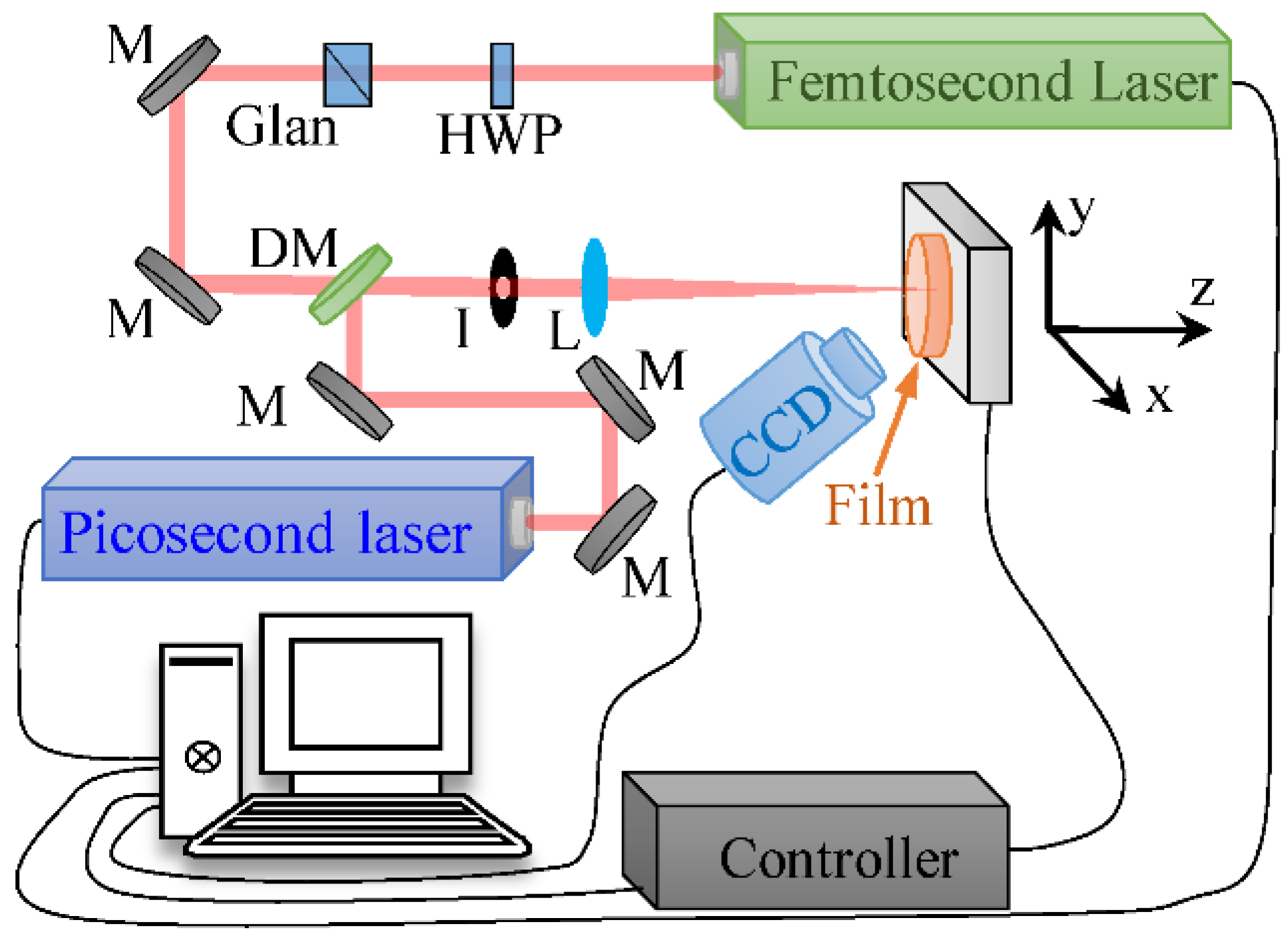

2.2. Experimental Device

2.3. Laser Damage Threshold Test

- A.

- The mean distance of essential defects is small compared to the spot size.

- B.

- Most of the defects trigger damage at an identical laser fluence.

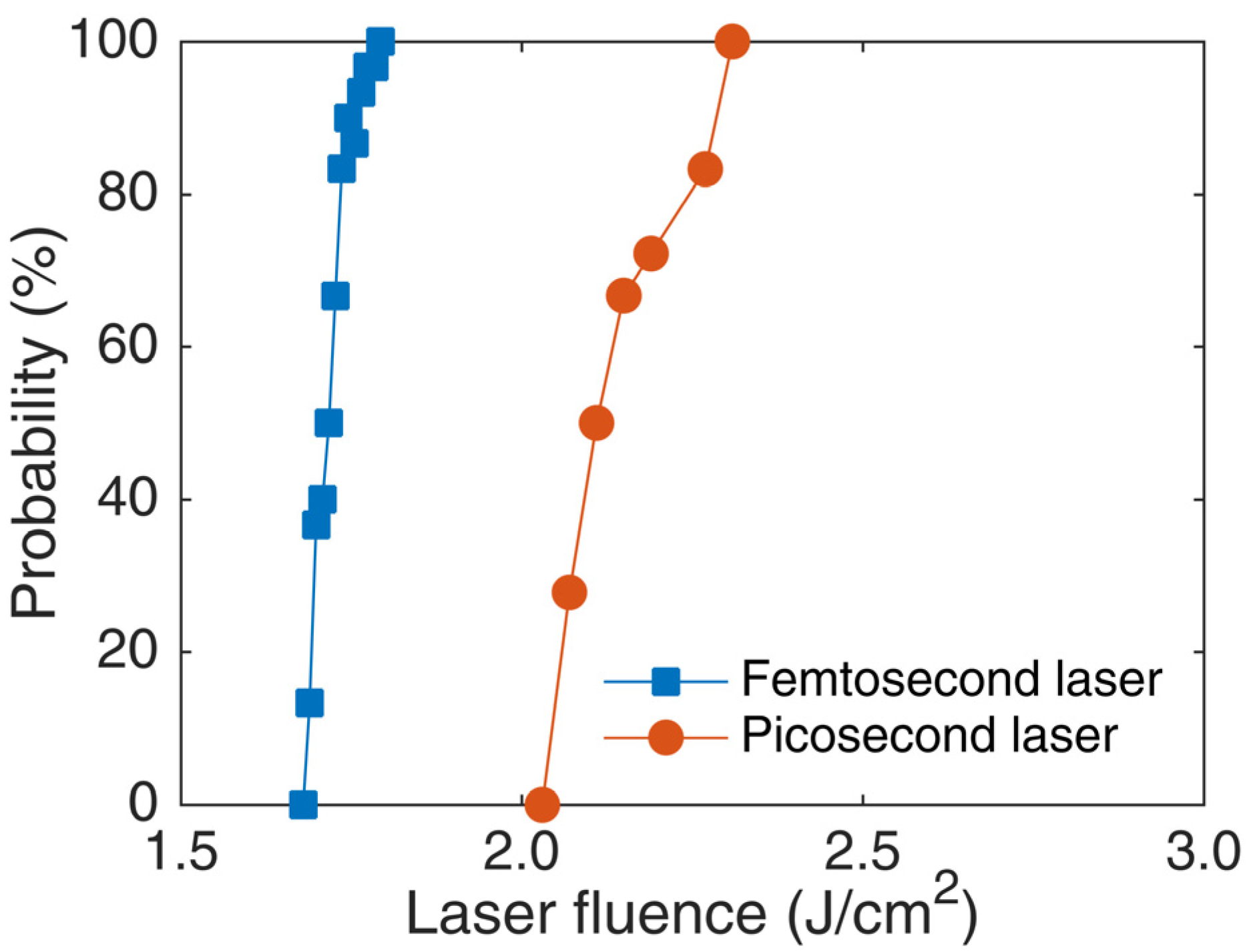

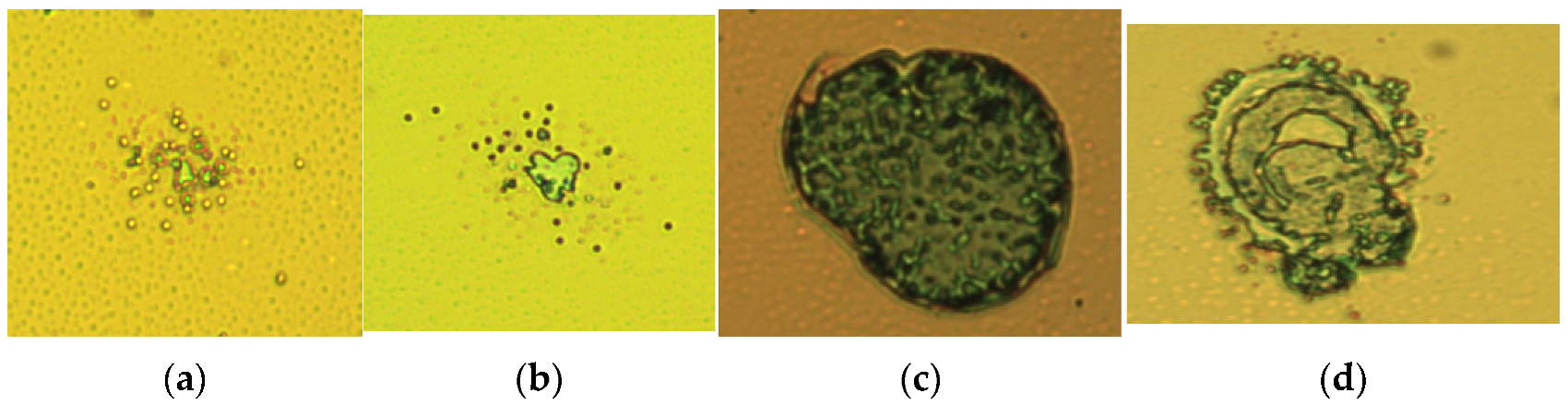

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghang, Y.; Jin, C.; Li, C.; Deng, W.; Jin, J. ArF excimer laser induced damage on high reflective fluoride film. Laser Technol. 2014, 38, 302–306. [Google Scholar]

- Zhu, M.; Yi, K.; Li, D.; Liu, X.; Qi, H.; Shao, J. Influence of SiO2 overcoat layer and electric field distribution on laser damage threshold and damage morphology of transport mirror coatings. Opt. Commun. 2014, 319, 75–79. [Google Scholar] [CrossRef]

- Velpula, P.K.; Kramer, D.; Rus, B. Femtosecond laser-induced damage characterization of multilayer dielectric coatings. Coatings 2020, 10, 603. [Google Scholar] [CrossRef]

- Yu, H.; Tang, F.; Chen, J.; Yi, Z.; Ye, X.; Wang, Y. Reflective meta-films with anti-damage property via field distribution manipulation. Coatings 2021, 11, 640. [Google Scholar] [CrossRef]

- Schaffer, C.B.; Brodeur, A.; Mazur, E. Laser-induced breakdown and damage in bulk transparent materials induced by tightly focused femtosecond laser pulses. Meas. Sci. Technol. 2001, 12, 1784–1794. [Google Scholar] [CrossRef]

- Bonod, N.; Néauport, J. Optical performance and laser induced damage threshold improvement of diffraction gratings used as compressors in ultra high intensity lasers. Opt. Commun. 2006, 260, 649–655. [Google Scholar] [CrossRef] [Green Version]

- Uteza, O.; Bussière, B.; Canova, F.; Chambaret, J.P.; Delaporte, P.; Itina, T.; Sentis, M. Laser-induced damage threshold of sapphire in nanosecond, picosecond and femtosecond regimes. Appl. Surf. Sci. 2007, 254, 799–803. [Google Scholar] [CrossRef]

- Bonse, J.; Solis, J.; Urech, L.; Lippert, T.; Wokaun, A. Femtosecond and nanosecond laser damage thresholds of doped and undoped triazenepolymer thin films. Appl. Surf. Sci. 2007, 253, 7787–7791. [Google Scholar] [CrossRef]

- Laurence, T.A.; Negres, R.A.; Ly, S.; Shen, N.; Carr, C.W.; Alessi, D.A.; Rigatti, A.; Bude, J.D. The role of defects in laser-induced modifications of silica coatings and fused silica using picosecond pulses at 1053 nm: II. Scaling laws and the density of precursors. Opt. Express 2017, 25, 15381–15401. [Google Scholar] [CrossRef]

- Kozlov, A.A.; Lambropoulos, J.C.; Oliver, J.B.; Hoffman, B.N.; Demos, S.G. Mechanisms of picosecond laser-induced damage in common multilayer dielectric coatings. Sci. Rep. 2019, 9, 607. [Google Scholar] [CrossRef] [Green Version]

- Yao, J.; Fan, Z.; Jin, Y.; Zhao, Y.; He, H.; Shao, J. Investigation of damage threshold to TiO2 coatings at different laser wavelength and pulse duration. Thin Solid Film. 2008, 516, 1237–1241. [Google Scholar] [CrossRef]

- Wang, X.; Shen, Z.H.; Lu, J.; Ni, X.W. Laser-induced damage threshold of silicon in millisecond, nanosecond, and picosecond regimes. J. Appl. Phys. 2010, 108, 033103. [Google Scholar]

- Zhou, X.; Ba, R.; Zheng, Y.; Yuan, J.; Li, W.; Chen, B. The effect of laser pulse width on laser-induced damage at K9 and UBK7 components surface. In Proceedings of the Pacific Rim Laser Damage, Shanghai, China, 17–20 May 2015; Volume 9532. [Google Scholar]

- Matsukawa, T.; Nawata, K.; Notake, T.; Qi, F.; Kawamata, H.; Minamide, H. Pump-beam-induced optical damage depended on repetition frequency and pulse width in 4-dimethylamino-n′-methyl-4′-stilbazolium tosylate crystal. Appl. Phys. Lett. 2013, 103, 023302. [Google Scholar] [CrossRef]

- Jin-Young, K.; Garg, A.; Rymaszewski, E.J.; Toh-Ming, L. High frequency response of amorphous tantalum oxide thin films. IEEE Trans. Compon. Packag. Technol. 2001, 24, 526–533. [Google Scholar] [CrossRef]

- Pecovska-Gjorgjevich, M.; Novkovski, N.; Atanassova, E. Electrical properties of thin rf sputtered Ta2O5 films after constant current stress. Microelectron. Reliab. 2003, 43, 235–241. [Google Scholar] [CrossRef]

- Dimitrova, T.; Arshak, K.; Atanassova, E. Crystallization effects in oxygen annealed Ta2O5 thin films on Si. Thin Solid Film. 2001, 381, 31–38. [Google Scholar] [CrossRef]

- Shibata, S. Dielectric constants of Ta2O5 thin films deposited by r.F. Sputtering. Thin Solid Film. 1996, 277, 1–4. [Google Scholar] [CrossRef]

- Neaton, J.B.; Muller, D.A.; Ashcroft, N.W. Electronic properties of the Si/SiO2 interface from first principles. Phys. Rev. Lett. 2000, 85, 1298–1301. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, M.; Zhang, S.; Deng, S.; Gong, F.; Wang, F.; Pan, Y.; Li, G.; Jin, Y. Effects of annealing on residual stress in Ta2O5 films deposited by dual ion beam sputtering. Coatings 2018, 8, 150. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Shankar, A.; Kishore, N.; Mukherjee, C.; Kamparath, R.; Thakur, S. Laser induced damage threshold of Ta2O5 and Ta2O5/SiO2 films at 532 and 1064 nm. Optik 2019, 176, 438–447. [Google Scholar] [CrossRef]

- Aydogdu, G.H.; Batman, H.; Cosar, M.B.; Ozhan, A.E.S. Enhancement of laser damage resistance at 1064 nm of high and anti-reflective optical multilayers by tailoring the electric field distribution and post-annealing. In Proceedings of the Society of Vacuum Coaters 59th Annual Technical Conference Proceedings, Indianapolis, IN, USA, 9–13 May 2016; pp. 247–251. [Google Scholar]

- Becker, J.; Bernhardt, A. ISO 11254: An international standard for the determination of the laser-induced damage threshold. In Proceedings of the SPIE–The International Society for Optical Engineering, Boulder, CO, USA, 27–29 October 1993; Volume 2114, p. 703. [Google Scholar]

- Wu, S.J.; Shi, W.; Su, J.H. Using an external electric field to reduce laser damage of dlc films. Int. J. Mater. Prod. Technol. 2013, 45, 74–82. [Google Scholar] [CrossRef]

- Du, D.; Liu, X.; Korn, G.; Squier, J.; Mourou, G. Laser-induced breakdown by impact ionization in SiO2 with pulse widths from 7 ns to 150 fs. Appl. Phys. Lett. 1994, 64, 3071. [Google Scholar] [CrossRef] [Green Version]

- Jasapara, J.; Nampoothiri, A.V.V.; Rudolph, W.; Ristau, D.; Starke, K. Femtosecond laser pulse induced breakdown in dielectric thin films. Phys. Rev. B 2001, 63, 045117. [Google Scholar] [CrossRef]

- Mero, M.; Liu, J.; Rudolph, W.; Ristau, D.; Starke, K. Scaling laws of femtosecond laser pulse induced breakdown in oxide films. Phys. Rev. B 2005, 71, 115109. [Google Scholar] [CrossRef]

- Chimier, B.; Utéza, O.; Sanner, N.; Sentis, M.; Itina, T.; Lassonde, P.; Légaré, F.; Vidal, F.; Kieffer, J.C. Damage and ablation thresholds of fused-silica in femtosecond regime. Phys. Rev. B 2011, 84, 094104. [Google Scholar] [CrossRef] [Green Version]

- Dijon, J.; Poulingue, M.; Hue, J. Thermomechanical model of mirror laser damage at 1.06 μm: I. Nodule ejection. In Proceedings of the Laser-Induced Damage in Optical Materials: 1998, Boulder, CO, USA, 28 September–1 October 1998; Volume 3578. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Cheng, X.; Shao, J.; Zheng, C.; Chen, A.; Zhang, L. The Damage Threshold of Multilayer Film Induced by Femtosecond and Picosecond Laser Pulses. Coatings 2022, 12, 251. https://doi.org/10.3390/coatings12020251

Wang Y, Cheng X, Shao J, Zheng C, Chen A, Zhang L. The Damage Threshold of Multilayer Film Induced by Femtosecond and Picosecond Laser Pulses. Coatings. 2022; 12(2):251. https://doi.org/10.3390/coatings12020251

Chicago/Turabian StyleWang, Yunzhe, Xiangzheng Cheng, Junfeng Shao, Changbin Zheng, Anmin Chen, and Luwei Zhang. 2022. "The Damage Threshold of Multilayer Film Induced by Femtosecond and Picosecond Laser Pulses" Coatings 12, no. 2: 251. https://doi.org/10.3390/coatings12020251

APA StyleWang, Y., Cheng, X., Shao, J., Zheng, C., Chen, A., & Zhang, L. (2022). The Damage Threshold of Multilayer Film Induced by Femtosecond and Picosecond Laser Pulses. Coatings, 12(2), 251. https://doi.org/10.3390/coatings12020251