A Review on In Situ Mechanical Testing of Coatings

Abstract

:1. Introduction

- The first is to monitor and observe the activated deformation and damage mechanisms within and at the interface of materials under varied thermal and mechanical loading conditions; for instance, revealing the relationship between the dislocation motion and fracture of High-Entropy Alloys [4,5], distinguish between different failure and cracking modes [6,7,8] during thermomechanical loading, the role nanoparticle addition and material composition on the fracture behavior of varied coating [9,10], etc.

- The second is to extract the mechanical characteristics of the materials being tested at different length scales to quantify the size effect and identify the effect of certain parameters such as the elemental composition, phase structure, and process parameters on these characteristics [11]. For example, this includes the utilization of tensile and bending experimentation at macro/micro/nano scales to measure tensile strength, elastic modulus, fracture toughness [9,12,13,14], etc.

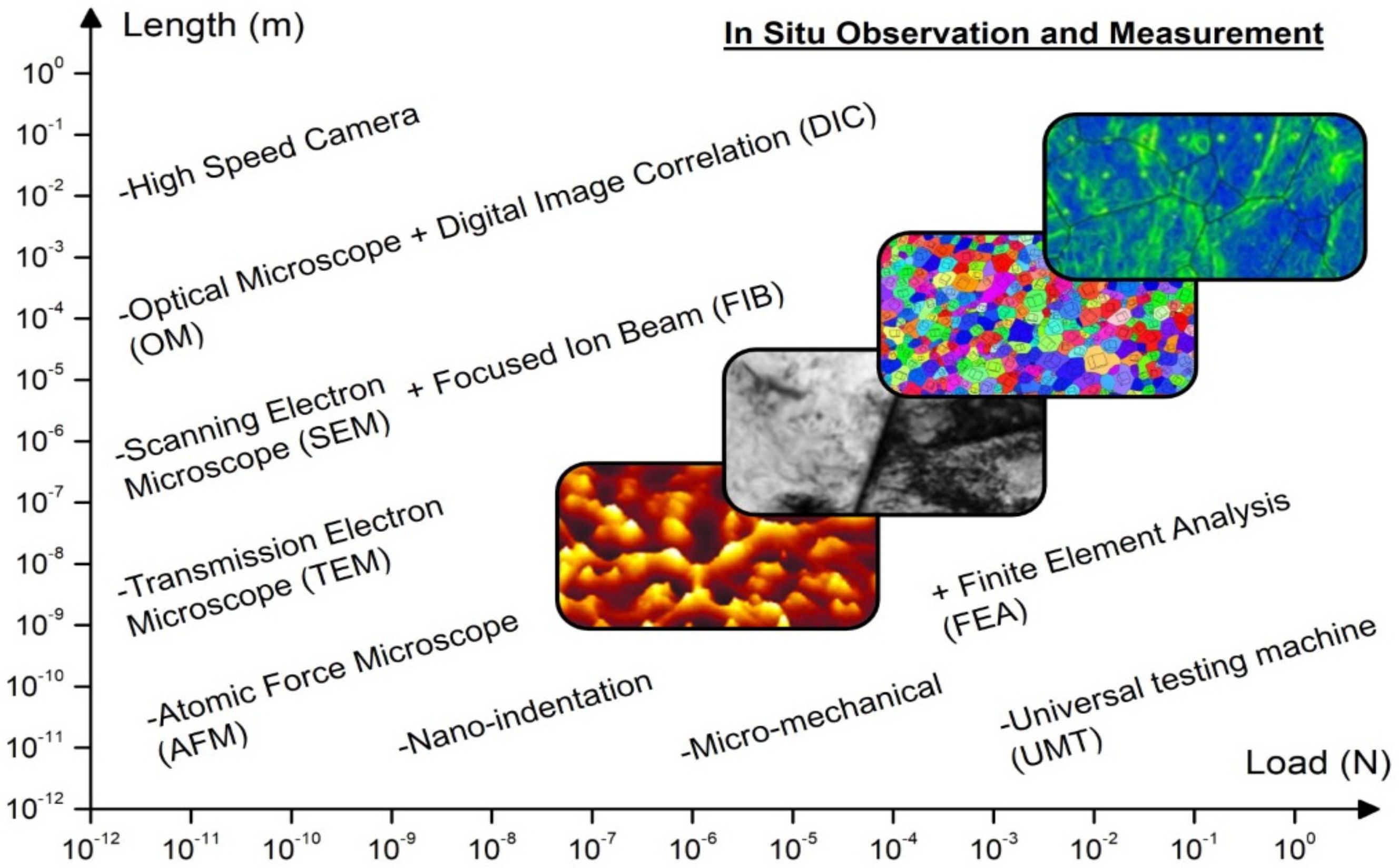

2. In Situ Assessment Techniques

3. In Situ Tensile Testing of Coatings

3.1. Macro-Tensile Testing

3.1.1. Room Temperature Experimentation

3.1.2. High-Temperature Experimentation

3.2. Micro-Tensile Testing

3.3. Nano-Tensile Testing

4. In Situ Bending Testing of Coatings

4.1. Macro-Bending Testing

4.2. Micro-Bending Testing

4.3. Fractural Toughness Measurements

5. Future Trends

- Extending the SEM testing temperature limits to examine the responses of coatings and thin films (e.g., TBCs, EBCs, etc.) under extreme conditions, which will help in maintaining the safety and reliability of the corresponding industrial applications. Furthermore, it will compensate for the low quality of images obtained when the temperature exceeds 600 °C because of thermal electrons.

- Testing the fracture behavior of coatings and thin films under different mechanical stress states that can be achieved by using notched samples of varied stress triaxialities (ranging from pure shear to plan strain conditions).

- Since high-entropy alloys introduce promising mechanical, structural, and physical properties, they are becoming a flourishing scientific research field. Hence, more in situ work should be devoted to exploiting HEAs as a coating material to reveal their unique mechanical behavior.

- The FEA can provide an efficient approach to understanding the thermomechanical behavior of coatings and thin films under complex loading conditions, saving effort and time. Therefore, there is a need for more incorporation of FEA in thermomechanical and fracture analysis of coatings and thin films.

6. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

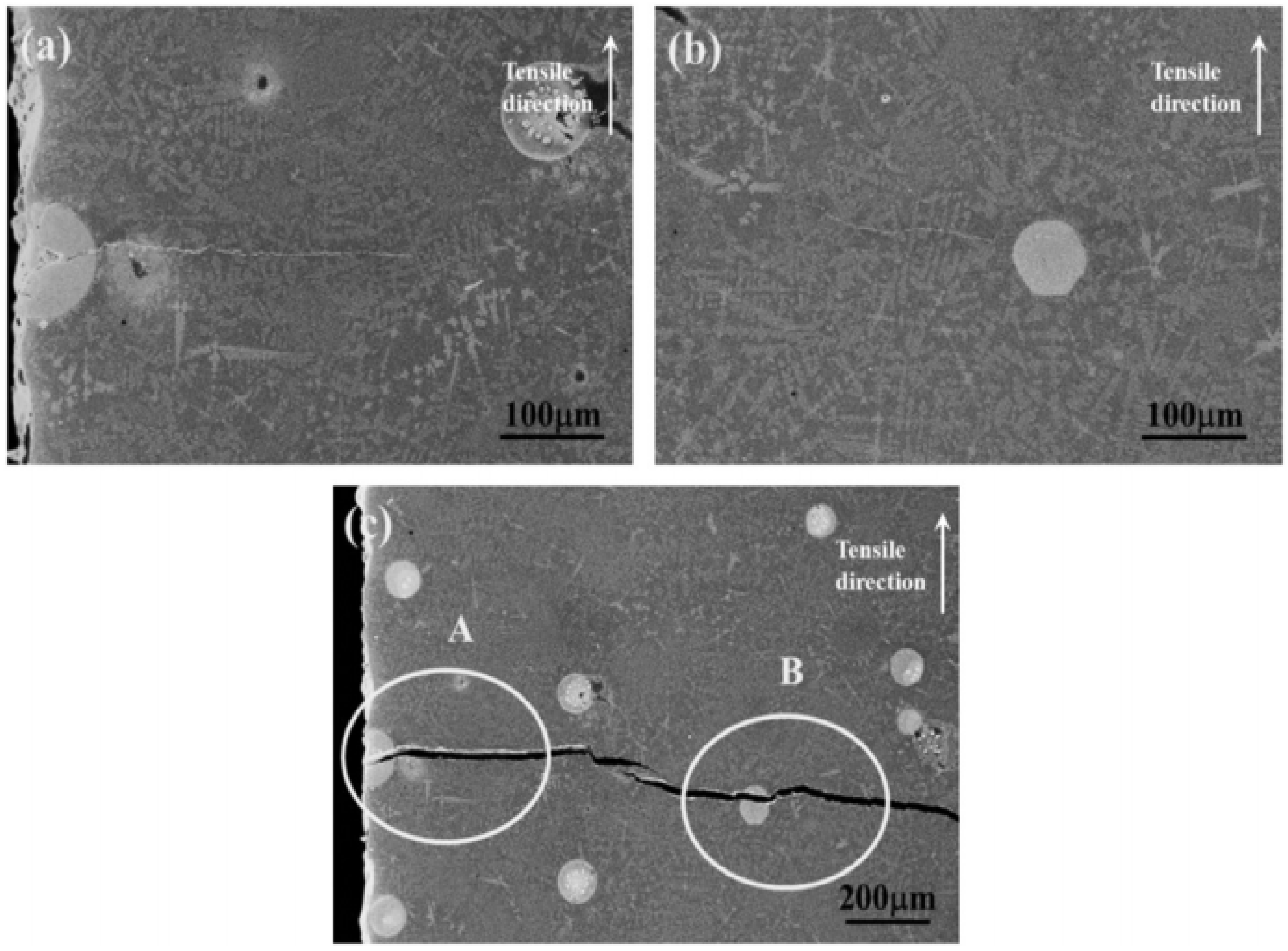

- Zou, Y.; Wang, Y.; Wei, D.; Du, Q.; Ouyang, J.; Jia, D.; Zhou, Y. In-situ SEM analysis of brittle plasma electrolytic oxidation coating bonded to plastic aluminum substrate: Microstructure and fracture behaviors. Mater. Charact. 2019, 156, 109851. [Google Scholar] [CrossRef]

- Liu, F.; Tang, D.M.; Gan, H.; Mo, X.; Chen, J.; Deng, S.; Xu, N.; Bando, Y.; Golberg, D. Individual boron nanowire has ultra-high specific young’s modulus and fracture strength as revealed by in situ transmission electron microscopy. ACS Nano 2013, 7, 10112–10120. [Google Scholar] [CrossRef] [PubMed]

- Heiroth, S.; Ghisleni, R.; Lippert, T.; Michler, J.; Wokaun, A. Optical and mechanical properties of amorphous and crystalline yttria-stabilized zirconia thin films prepared by pulsed laser deposition. Acta Mater. 2011, 59, 2330–2340. [Google Scholar] [CrossRef]

- Cai, Z.; Cui, X.; Liu, E.; Li, Y.; Dong, M.; Lu, B.; Jin, G. Fracture behavior of high-entropy alloy coating by in-situ TEM tensile testing. J. Alloys Compd. 2017, 729, 897–902. [Google Scholar] [CrossRef]

- Cai, Z.; Cui, X.; Jin, G.; Lu, B.; Zhang, D.; Zhang, Z. In situ TEM tensile testing on high-entropy alloy coating by laser surface alloying. J. Alloys Compd. 2017, 708, 380–384. [Google Scholar] [CrossRef]

- Zaman, S.B.; Hazrati, J.; de Rooij, M.; van den Boogaard, T. Cracking Behavior of Coating during Hot Tensile Tests of AlSi-Coated Press Hardening Steel. Procedia Manuf. 2020, 47, 602–607. [Google Scholar] [CrossRef]

- Jiang, J.; Zhan, D.; Lv, J.; Ma, X.; He, X.; Wang, D.; Hu, Y.; Zhai, H.; Tu, J.; Zhang, W. Comparative study on the tensile cracking behavior of CrN and Cr coatings for accident-tolerant fuel claddings. Surf. Coat. Technol. 2021, 409, 126812. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, X.; Luo, H.; Sahraei, E. Investigation of the deformation mechanisms of lithium-ion battery components using in-situ micro tests. Appl. Energy 2018, 224, 251–266. [Google Scholar] [CrossRef]

- Mukherjee, B.; Kumar, R.; Islam, A.; Rahman, O.S.A.; Keshri, A.K. Evaluation of strength-ductility combination by in-situ tensile testing of graphene nano platelets reinforced shroud plasma sprayed Nickel-Aluminium coating. J. Alloys Compd. 2018, 765, 1082–1089. [Google Scholar] [CrossRef]

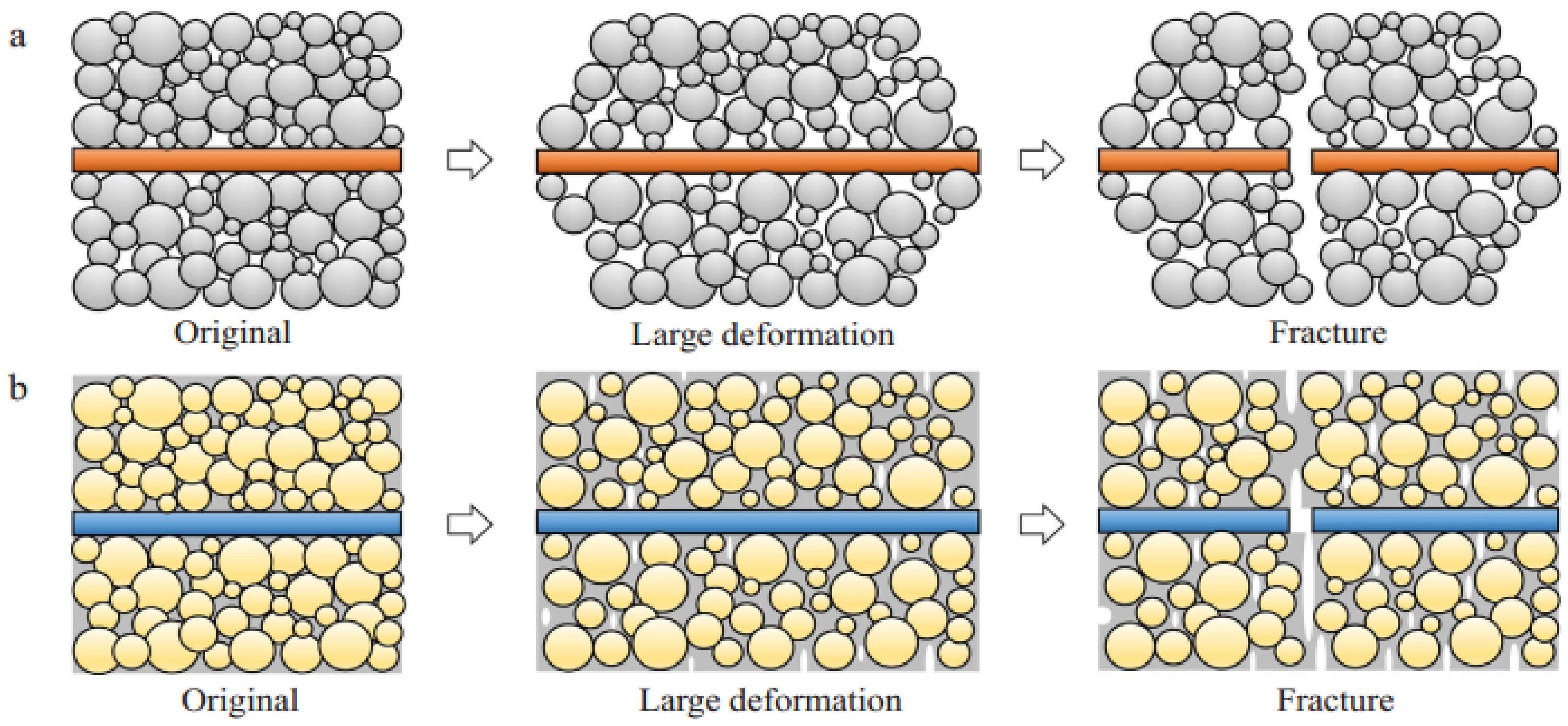

- Xu, J.-S.; Zhang, X.-C.; Xuan, F.-Z.; Tian, F.-Q.; Wang, Z.-D.; Tu, S.-T. Tensile properties and fracture behavior of laser cladded WC/Ni composite coatings with different contents of WC particle studied by in-situ tensile testing. Mater. Sci. Eng. A 2013, 560, 744–751. [Google Scholar] [CrossRef]

- Greer, J.R.; De Hosson, J.T.M. Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 2011, 56, 654–724. [Google Scholar] [CrossRef]

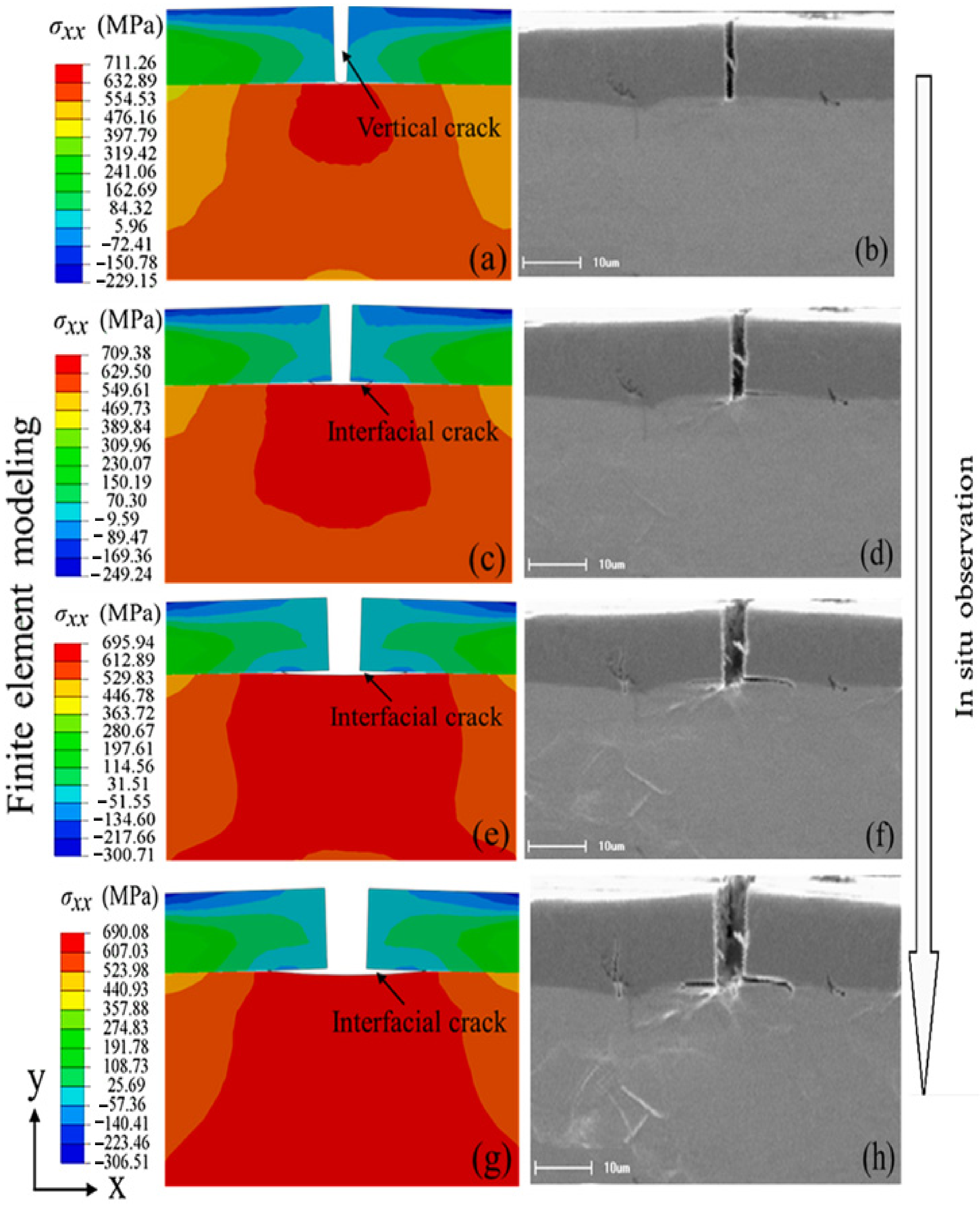

- Rehman, H.U.; Ahmed, F.; Schmid, C.; Schaufler, J.; Durst, K. Study on the deformation mechanics of hard brittle coatings on ductile substrates using in-situ tensile testing and cohesive zone FEM modeling. Surf. Coat. Technol. 2012, 207, 163–169. [Google Scholar] [CrossRef]

- Schaufler, J.; Schmid, C.; Durst, K.; Göken, M. Determination of the interfacial strength and fracture toughness of aC: H coatings by in-situ microcantilever bending. Thin Solid Films 2012, 522, 480–484. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Williams, C.J.; Brewster, G.; Xiao, P. Determination of fracture toughness of a platinum-modified nickel aluminide coating by micromechanical testing. Materialia 2021, 20, 101267. [Google Scholar] [CrossRef]

- Hirsch, P.B. Direct Observations of moving dislocations: Reflections on the thirtieth anniversary of the first recorded observations of moving dislocations by transmission electron microscopy. Mater. Sci. Eng. 1986, 84, 1–10. [Google Scholar] [CrossRef]

- Hirsch, P.B.; Horne, R.W.; Whelan, M.J. Direct observations of the arrangement and motion of dislocations in aluminium. Philos. Mag. 1956, 1, 677–684. [Google Scholar] [CrossRef]

- Chen, Z.; Li, G.; Wu, Z.; Xia, Y. The crack propagating behavior of composite coatings prepared by PEO on aluminized steel during in situ tensile processing. Mater. Sci. Eng. A 2011, 528, 1409–1414. [Google Scholar] [CrossRef] [Green Version]

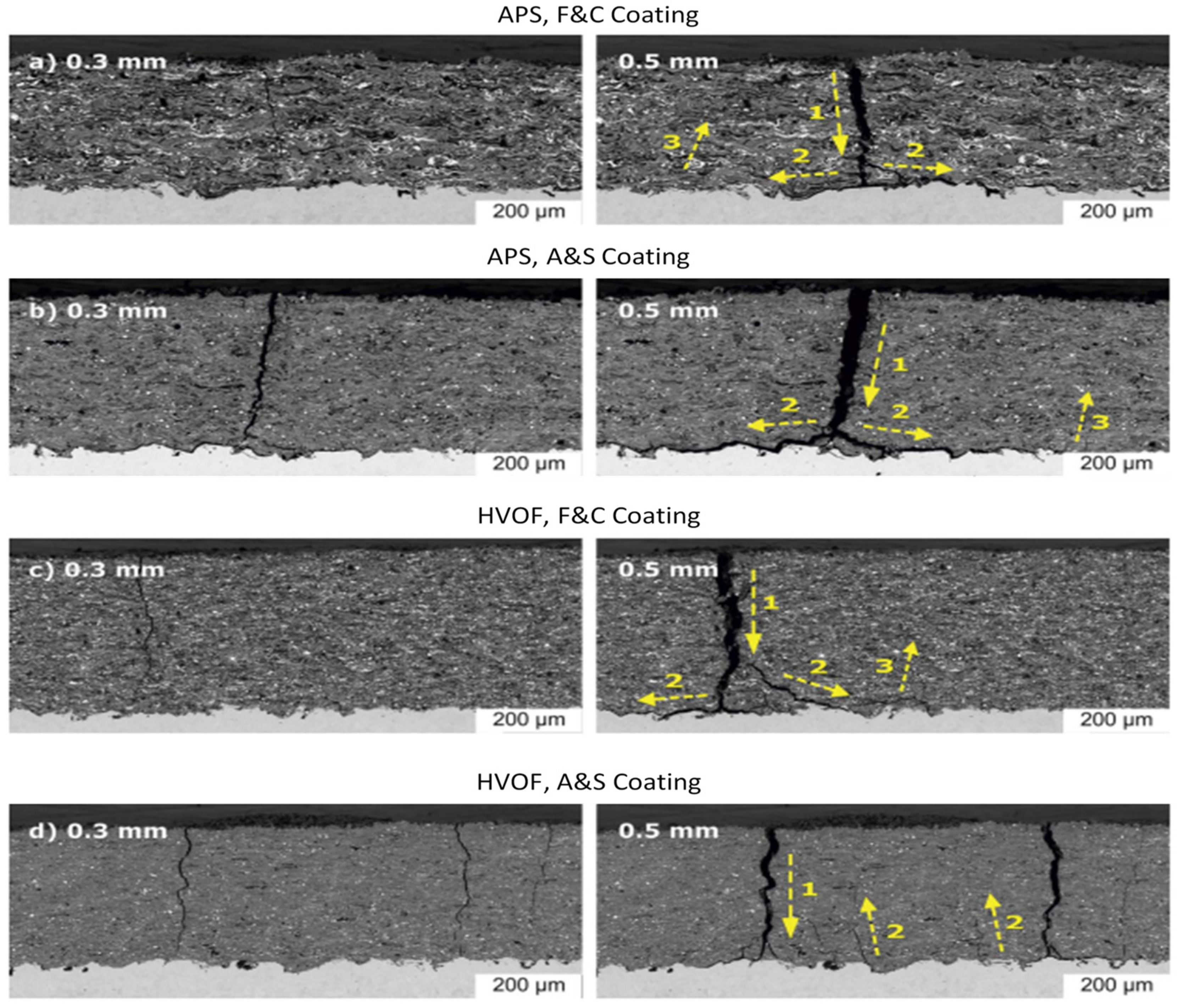

- Kiilakoski, J.; Musalek, R.; Lukac, F.; Koivuluoto, H.; Vuoristo, P. Evaluating the toughness of APS and HVOF-sprayed Al2O3-ZrO2-coatings by in-situ-and macroscopic bending. J. Eur. Ceram. Soc. 2018, 38, 1908–1918. [Google Scholar] [CrossRef]

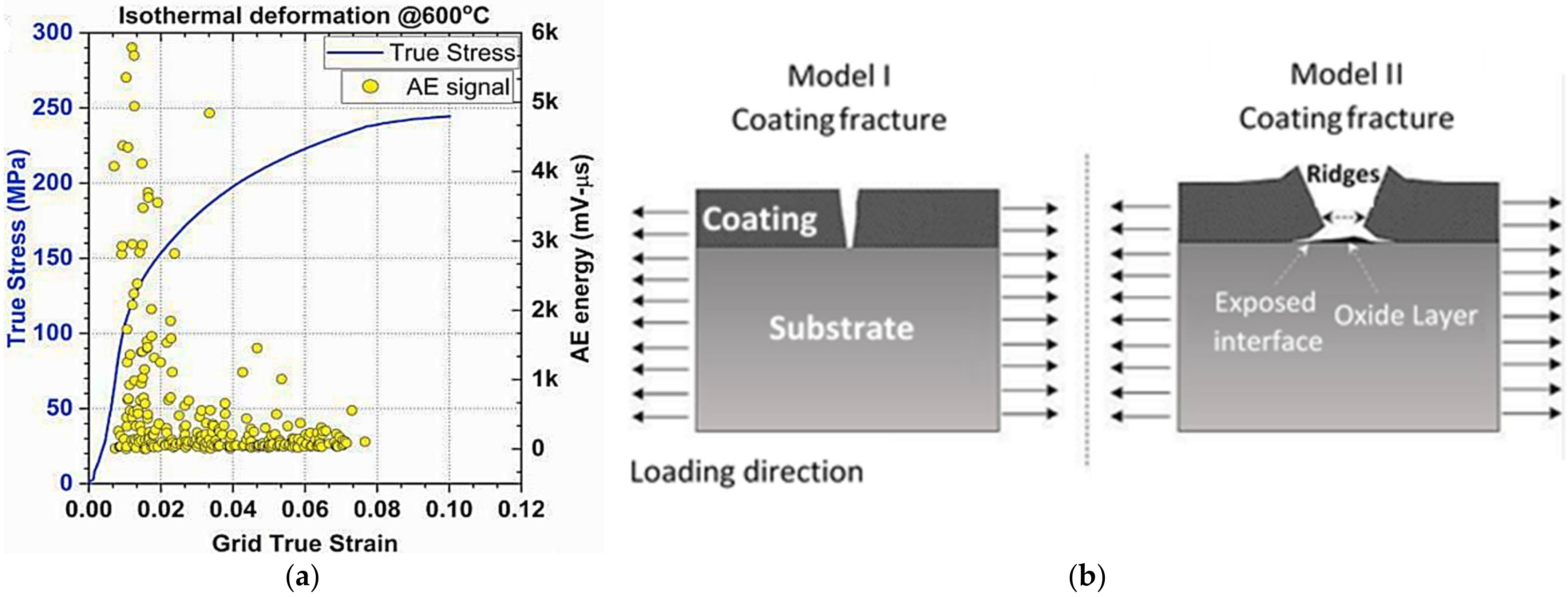

- Zhou, M.; Yao, W.B.; Yang, X.S.; Peng, Z.B.; Li, K.K.; Dai, C.Y.; Mao, W.G.; Zhou, Y.C.; Lu, C. In-situ and real-time tests on the damage evolution and fracture of thermal barrier coatings under tension: A coupled acoustic emission and digital image correlation method. Surf. Coat. Technol. 2014, 240, 40–47. [Google Scholar] [CrossRef]

- Rudolf, C.; Boesl, B.; Agarwal, A. In situ mechanical testing techniques for real-time materials deformation characterization. JOM 2016, 68, 136–142. [Google Scholar] [CrossRef]

- Singh, S.; Singh, H.; Chaudhary, S.; Buddu, R.K. Effect of substrate surface roughness on properties of cold-sprayed copper coatings on SS316L steel. Surf. Coat. Technol. 2020, 389, 125619. [Google Scholar] [CrossRef]

- Bouaziz, H.; Brinza, O.; Haddar, N.; Gasperini, M.; Feki, M. In-situ SEM study of crack initiation, propagation and interfacial debonding of Ni-P coating during tensile tests: Heat treatment effect. Mater. Charact. 2017, 123, 106–114. [Google Scholar] [CrossRef]

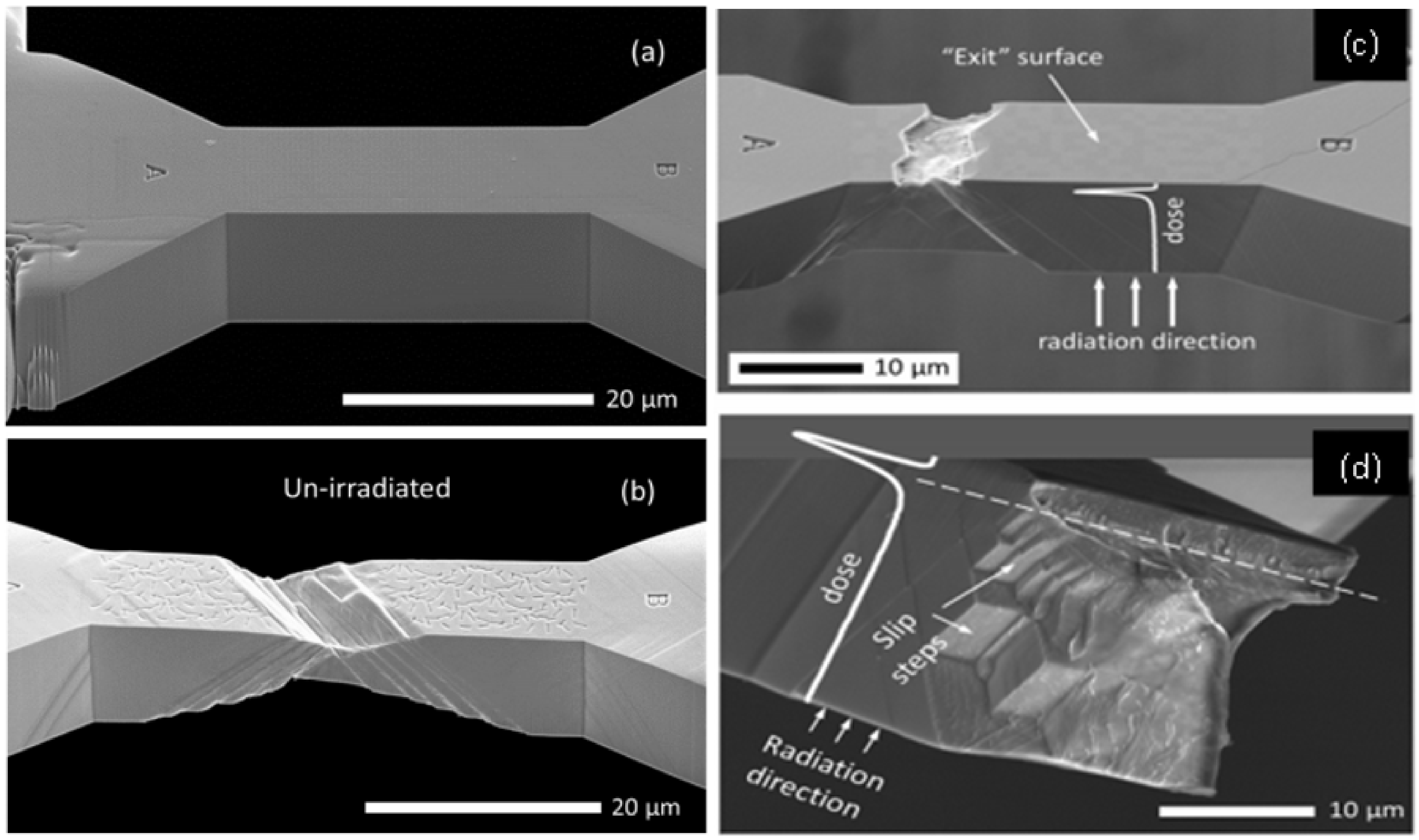

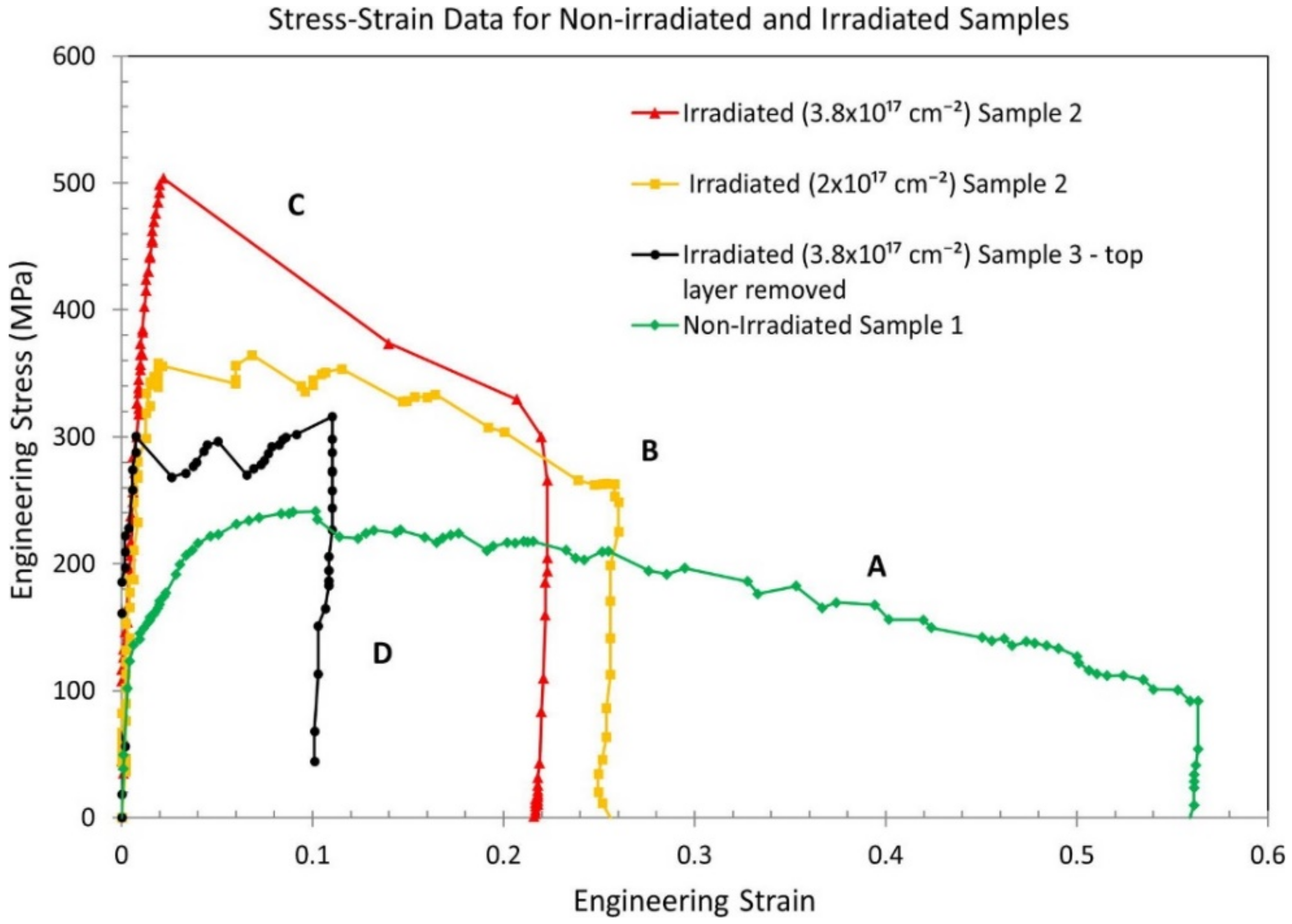

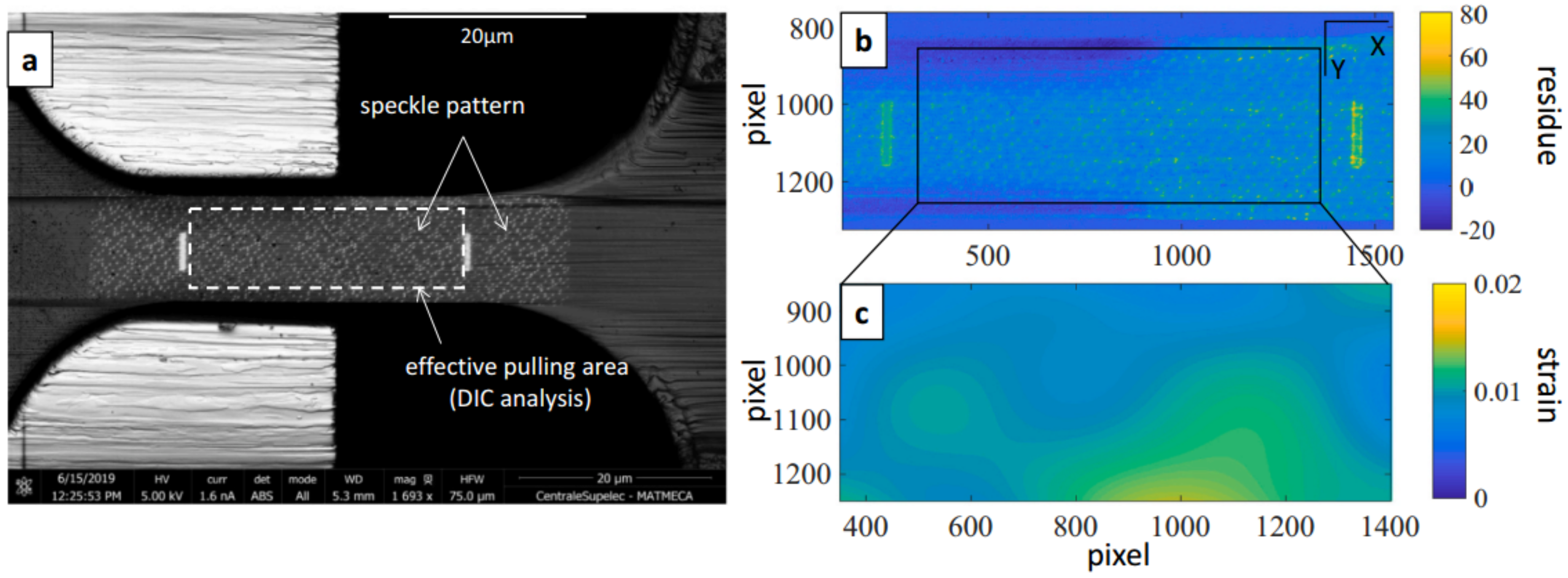

- Reichardt, A.; Ionescu, M.; Davis, J.; Edwards, L.; Harrison, R.P.; Hosemann, P.; Bhattacharyya, D. In situ micro tensile testing of He+2 ion irradiated and implanted single crystal nickel film. Acta Mater. 2015, 100, 147–154. [Google Scholar] [CrossRef] [Green Version]

- Mao, W.; Wang, Y.; Huang, H.; Zeng, L.; Wang, Y.; Lv, L.; Feng, B.; Zou, C.; Dai, C.; Tang, Q. In situ characterizations of mechanical behaviors of freestanding (Gd0.9Yb0.1)2Zr2O7 coatings by bending tests under different temperatures based on digital image correlation. J. Eur. Ceram. Soc. 2020, 40, 491–502. [Google Scholar] [CrossRef]

- Cai, X.; Xu, Y.; Zhao, N.; Zhong, L.; Zhao, Z.; Wang, J. Investigation of the adhesion strength and deformation behaviour of in situ fabricated NbC coatings by scratch testing. Surf. Coat. Technol. 2016, 299, 135–142. [Google Scholar] [CrossRef]

- Best, J.P.; Guillonneau, G.; Grop, S.; Taylor, A.A.; Frey, D.; Longchamp, Q.; Schär, T.; Morstein, M.; Breguet, J.-M.; Michler, J. High temperature impact testing of a thin hard coating using a novel high-frequency in situ micromechanical device. Surf. Coat. Technol. 2018, 333, 178–186. [Google Scholar] [CrossRef]

- Cao, H.; Bai, M.; Inkson, B.J.; Zhong, X.; De Hosson, J.T.M.; Pei, Y.; Xiao, P. Self-healing WS2 tribofilms: An in-situ appraisal of mechanisms. Scr. Mater. 2021, 204, 114124. [Google Scholar] [CrossRef]

- Rzepiejewska-Malyska, K.A.; Mook, W.M.; Parlinska-Wojtan, M.; Hejduk, J.; Michler, J. In situ scanning electron microscopy indentation studies on multilayer nitride films: Methodology and deformation mechanisms. J. Mater. Res. 2009, 24, 1208–1221. [Google Scholar] [CrossRef] [Green Version]

- Qu, Z.; Wei, K.; He, Q.; He, R.; Pei, Y.; Wang, S.; Fang, D. High temperature fracture toughness and residual stress in thermal barrier coatings evaluated by an in-situ indentation method. Ceram. Int. 2018, 44, 7926–7929. [Google Scholar] [CrossRef]

- Nautiyal, P.; Boesl, B.; Agarwal, A. In-Situ Mechanics of Materials; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Gane, N.; Bowden, F.P. Microdeformation of solids. J. Appl. Phys. 1968, 39, 1432–1435. [Google Scholar] [CrossRef]

- Bangert, H.; Wagendristel, A. Ultralow-load hardness tester for use in a scanning electron microscope. Rev. Sci. Instrum. 1985, 56, 1568–1572. [Google Scholar] [CrossRef]

- Wang, C.L.; Lai, Y.H.; Huang, J.C.; Nieh, T.G. Creep of nanocrystalline nickel: A direct comparison between uniaxial and nanoindentation creep. Scr. Mater. 2010, 62, 175–178. [Google Scholar] [CrossRef]

- Nautiyal, P.; Jain, J.; Agarwal, A. A comparative study of indentation induced creep in pure magnesium and AZ61 alloy. Mater. Sci. Eng. A 2015, 630, 131–138. [Google Scholar] [CrossRef]

- Rabe, R.; Breguet, J.M.; Schwaller, P.; Stauss, S.; Haug, F.J.; Patscheider, J.; Michler, J. Observation of fracture and plastic deformation during indentation and scratching inside the scanning electron microscope. Thin Solid Films 2004, 469–470, 206–213. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Patel, R.R.; Agarwal, A. Nanoscratch behavior of carbon nanotube reinforced aluminum coatings. Thin Solid Films 2010, 518, 1703–1711. [Google Scholar] [CrossRef]

- Takeuchi, T. Load-Elongation Curves of Pure Body-Centred Cubic Metals at Low Temperatures. J. Phys. Soc. Jpn. 1973, 35, 1149–1160. [Google Scholar] [CrossRef]

- Sumino, K.; Sato, M. In-situ HVEM Observations of Dislocation Processes during High Temperature Deformation of Silicon Crystals. Krist. Tech. 1979, 14, 1343–1350. [Google Scholar] [CrossRef]

- Louchet, F.; Kubin, L.P.; Vesely, D. In situ deformation of b.c.c. crystals at low temperatures in a high-voltage electron microscope Dislocation mechanisms and strain-rate equation. Philos. Mag. A 1979, 39, 433–454. [Google Scholar] [CrossRef]

- Ohr, S.M. An electron microscope study of crack tip deformation and its impact on the dislocation theory of fracture. Mater. Sci. Eng. 1985, 72, 1–35. [Google Scholar] [CrossRef]

- Mindess, S.; Diamond, S. A preliminary SEM study of crack propagation in mortar. Cem. Concr. Res. 1980, 10, 509–519. [Google Scholar] [CrossRef]

- Sernicola, G.; Giovannini, T.; Patel, P.; Kermode, J.; Balint, D.S.; Britton, B.; Giuliani, F. In situ stable crack growth at the micron scale. Nat. Commun. 2017, 8, 108. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Boesl, B.; Silvestroni, L.; Sciti, D.; Agarwal, A. Deformation mechanism in graphene nanoplatelet reinforced tantalum carbide using high load in situ indentation. Mater. Sci. Eng. A 2016, 674, 270–275. [Google Scholar] [CrossRef]

- Fazel, Z.A.; Elmkhah, H.; Fattah-Alhosseini, A.; Babaei, K.; Meghdari, M. Comparing electrochemical behavior of applied CrN/TiN nanoscale multilayer and TiN single-layer coatings deposited by CAE-PVD method. J. Asian Ceram. Soc. 2020, 8, 510–518. [Google Scholar] [CrossRef] [Green Version]

- Icriverzi, M.; Rusen, L.; Brajnicov, S.; Bonciu, A.; Dinescu, M.; Cimpean, A.; Evans, R.W.; Dinca, V.; Roseanu, A. Macrophage in vitro response on hybrid coatings obtained by matrix assisted pulsed laser evaporation. Coatings 2019, 9, 236. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Xu, F.; Qin, Q.; Fung, W.Y.; Lu, W. Mechanical properties of vapor–liquid–solid synthesized silicon nanowires. Nano Lett. 2009, 9, 3934–3939. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Qin, Q.; Gu, Y.; Wang, Z. Friction and shear strength at the nanowire–substrate interfaces. Nanoscale Res. Lett. 2010, 5, 291–295. [Google Scholar] [CrossRef] [Green Version]

- Joshi, M.; Bhattacharyya, A.; Ali, S.W. Characterization Techniques for Nanotechnology Applications in Textiles. 2008. Available online: http://nopr.niscair.res.in/handle/123456789/2019 (accessed on 1 December 2021).

- Suzuki, E. High-resolution scanning electron microscopy of immunogold-labelled cells by the use of thin plasma coating of osmium. J. Microsc. 2002, 208, 153–157. [Google Scholar] [CrossRef]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Scott, J.H.J.; Joy, D.C. Scanning Electron Microscopy and X-ray Microanalysis; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 1493966766. [Google Scholar]

- Legros, M. In situ mechanical TEM: Seeing and measuring under stress with electrons. C. R. Phys. 2014, 15, 224–240. [Google Scholar] [CrossRef]

- Voisin, T.; Grapes, M.D.; Zhang, Y.; Lorenzo, N.J.; Ligda, J.P.; Schuster, B.E.; Santala, M.K.; Li, T.; Campbell, G.H.; Weihs, T.P. DTEM in situ mechanical testing: Defects motion at high strain rates. In Dynamic Behavior of Materials; Springer: Berlin/Heidelberg, Germany, 2017; Volume 1, pp. 209–213. [Google Scholar]

- Erni, R.; Rossell, M.D.; Kisielowski, C.; Dahmen, U. Atomic-resolution imaging with a sub-50-pm electron probe. Phys. Rev. Lett. 2009, 102, 96101. [Google Scholar] [CrossRef] [Green Version]

- O’Keefe, M.A.; Allard, L.F. Sub-Angstrom Electron Microscopy for Sub-Angstrom Nano-Metrology; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2004. [Google Scholar]

- Nishinoiri, S.; Enoki, M.; Tomita, K. In situ monitoring of microfracture during plasma spray coating by laser AE technique. Sci. Technol. Adv. Mater. 2003, 4, 623. [Google Scholar] [CrossRef]

- Ray, A.K.; Roy, N.; Kar, A.; Ray, A.K.; Bose, S.C.; Das, G.; Sahu, J.K.; Das, D.K.; Venkataraman, B.; Joshi, S.V. Mechanical property and characterization of a NiCoCrAlY type metallic bond coat used in turbine blade. Mater. Sci. Eng. A 2009, 505, 96–104. [Google Scholar] [CrossRef]

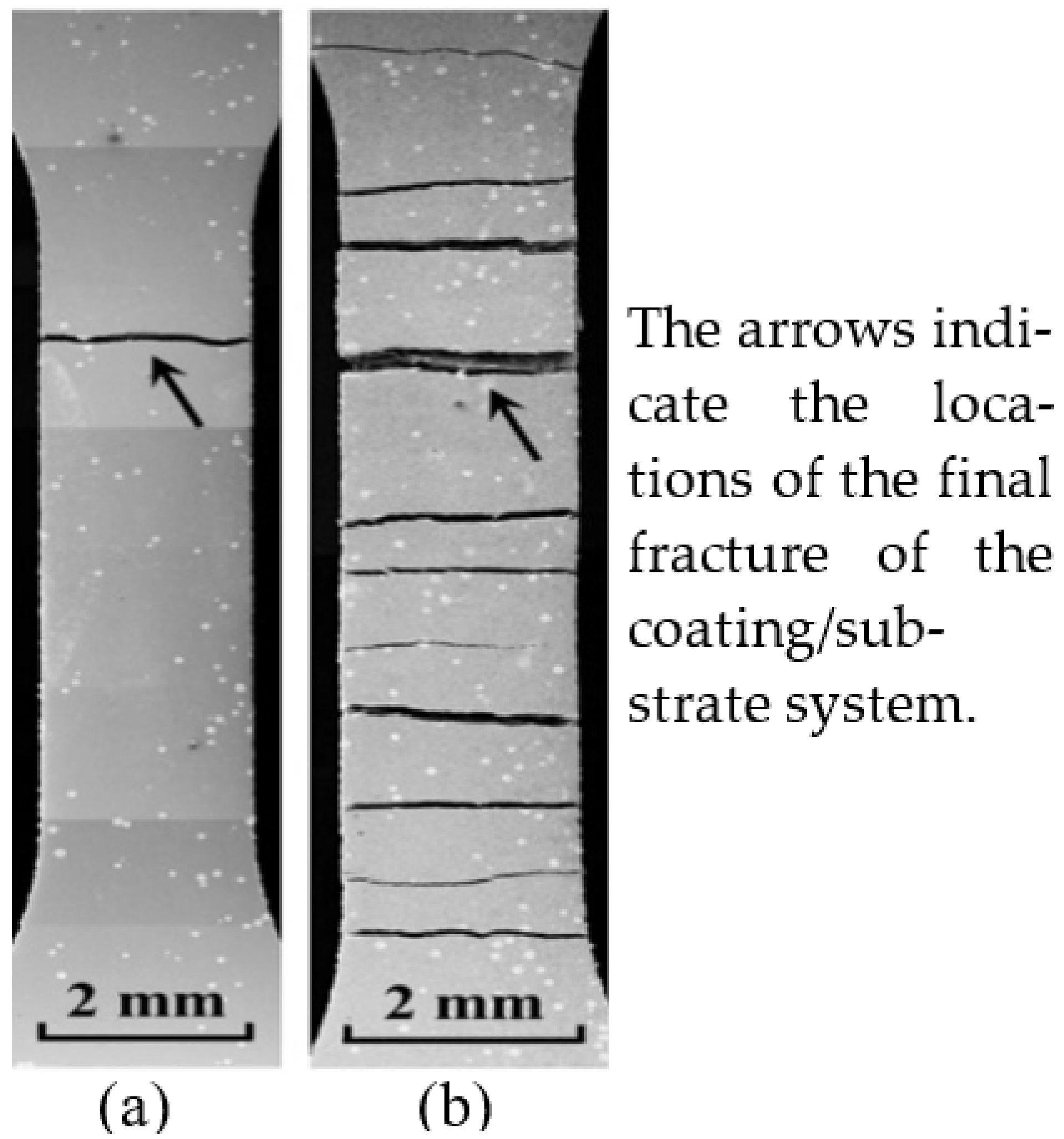

- Wu, D.J.; Mao, W.G.; Zhou, Y.C.; Lu, C. Digital image correlation approach to cracking and decohesion in a brittle coating/ductile substrate system. Appl. Surf. Sci. 2011, 257, 6040–6043. [Google Scholar] [CrossRef] [Green Version]

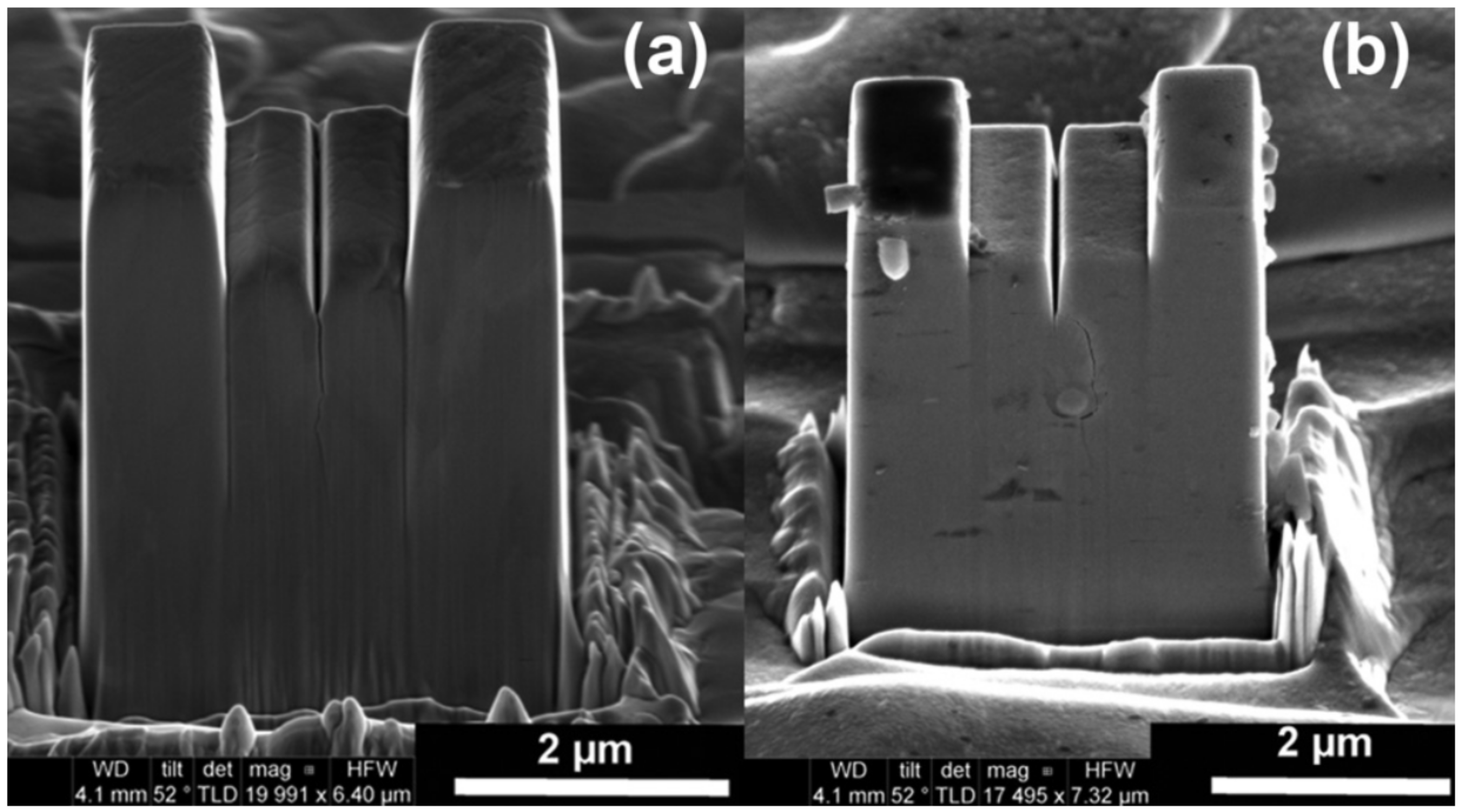

- Pfeiffer, C.; Affeldt, E.; Göken, M. Miniaturized bend tests on partially stabilized EB-PVD ZrO2 thermal barrier coatings. Surf. Coat. Technol. 2011, 205, 3245–3250. [Google Scholar] [CrossRef]

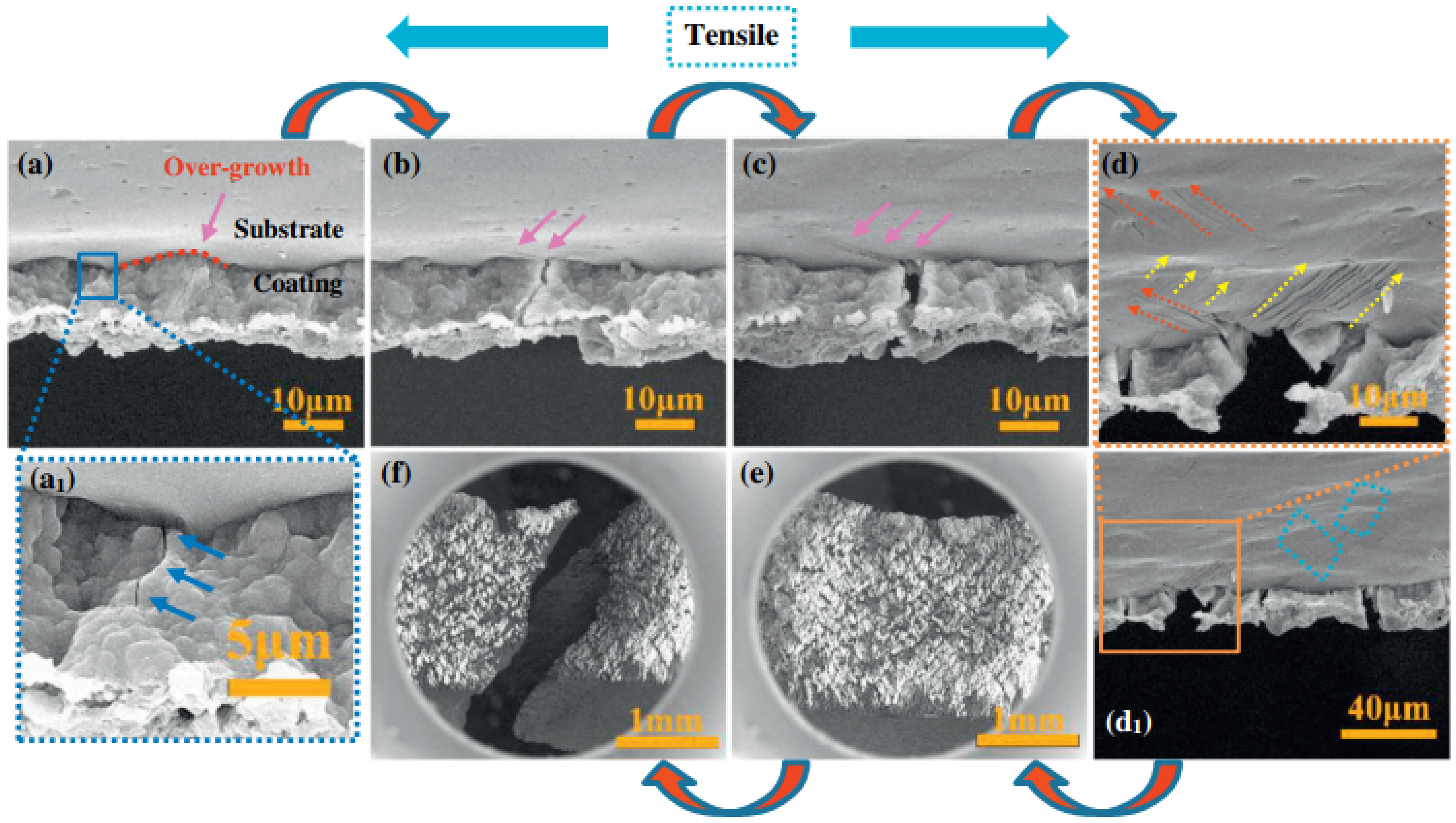

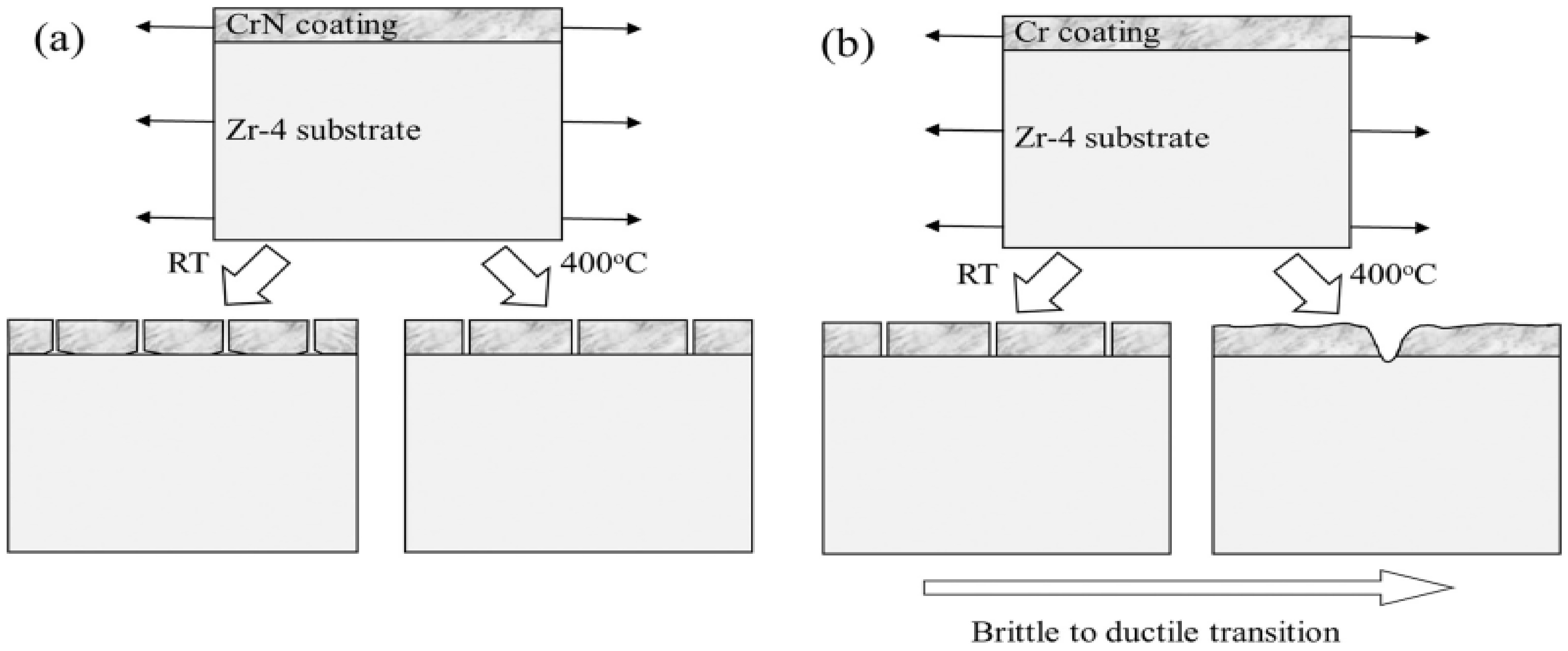

- Jiang, J.; Zhai, H.; Du, M.; Wang, D.; Pei, X.; Ma, X.; Wang, B. Temperature-dependent deformation and cracking behavior in Cr coating for accident tolerant fuel cladding: An in situ SEM study. Surf. Coat. Technol. 2021, 427, 127815. [Google Scholar] [CrossRef]

- da Costa, M.V.T.; Bolinsson, J.; Fayet, P.; Gamstedt, E.K. Transverse ridge cracking in tensile fragmentation tests of thin brittle coatings on polymer substrates. Surf. Coat. Technol. 2020, 382, 125025. [Google Scholar] [CrossRef]

- Völker, B.; Du, C.; Fager, H.; Rueß, H.; Soler, R.; Kirchlechner, C.; Dehm, G.; Schneider, J.M. How tensile tests allow a screening of the fracture toughness of hard coatings. Surf. Coat. Technol. 2020, 390, 125645. [Google Scholar] [CrossRef]

- Mao, W.G.; Chen, Y.Y.; Wang, Y.J.; Zhou, M.; Yang, H.Y.; Wang, Z.; Dai, C.Y.; Chen, X.; Fang, D.N. A multilayer structure shear lag model applied in the tensile fracture characteristics of supersonic plasma sprayed thermal barrier coating systems based on digital image correlation. Surf. Coat. Technol. 2018, 350, 211–226. [Google Scholar] [CrossRef]

- Singh, S.; Chaudhary, S.; Singh, H. Effect of electroplated interlayers on properties of cold-sprayed copper coatings on SS316L steel. Surf. Coat. Technol. 2019, 375, 54–65. [Google Scholar] [CrossRef]

- da Costa, M.V.T.; Bolinsson, J.; Neagu, R.C.; Fayet, P.; Gamstedt, E.K. Experimental assessment of micromechanical models for fragmentation analysis of thin metal oxide coatings on polymer films under uniaxial tensile deformation. Surf. Coat. Technol. 2019, 370, 374–383. [Google Scholar] [CrossRef]

- Rochat, G.; Leterrier, Y.; Fayet, P.; Månson, J.-A. Mechanical analysis of ultrathin oxide coatings on polymer substrates in situ in a scanning electron microscope. Thin Solid Films 2003, 437, 204–210. [Google Scholar] [CrossRef]

- Chen, B.F.; Hwang, J.; Yu, G.P.; Huang, J.H. In situ observation of the cracking behavior of TiN coating on 304 stainless steel subjected to tensile strain. Thin Solid Films 1999, 352, 173–178. [Google Scholar] [CrossRef]

- Ahmadi, M.; Salgın, B.; Kooi, B.J.; Pei, Y. Cracking behavior and formability of Zn-Al-Mg coatings: Understanding the influence of steel substrates. Mater. Des. 2021, 212, 110215. [Google Scholar] [CrossRef]

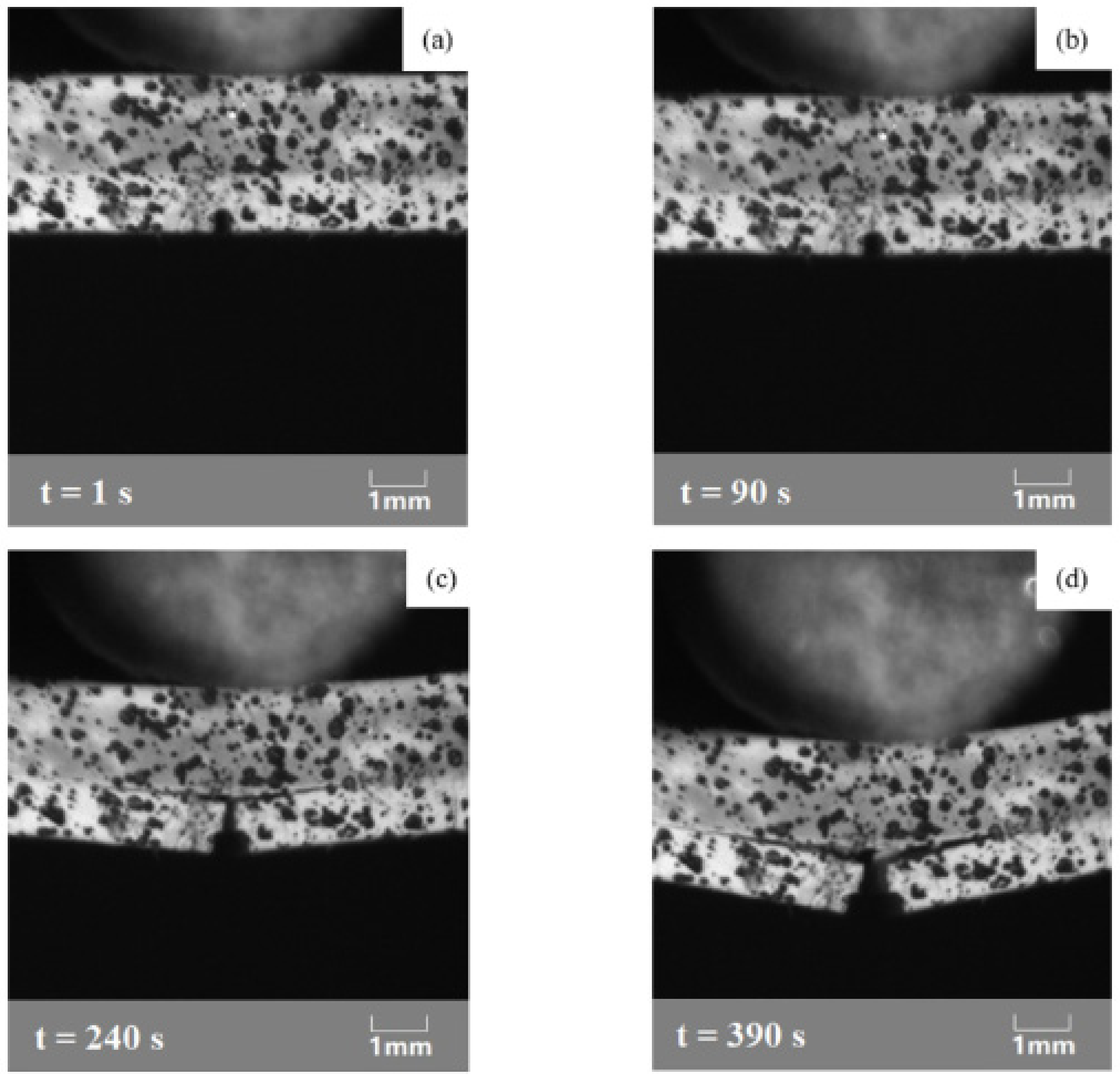

- Yang, L.; Zhou, Y.C.; Mao, W.G.; Lu, C. Real-time acoustic emission testing based on wavelet transform for the failure process of thermal barrier coatings. Appl. Phys. Lett. 2008, 93, 231906. [Google Scholar] [CrossRef]

- Patibanda, S.; Nagda, V.J.; Kalra, J.; Sivakumar, G.; Abrahams, R.; Jonnalagadda, K.N. Mechanical behavior of freestanding 8YSZ thin films under tensile and bending loads. Surf. Coat. Technol. 2020, 393, 125771. [Google Scholar] [CrossRef]

- Qian, L.; Zhu, S.; Kagawa, Y.; Kubo, T. Tensile damage evolution behavior in plasma-sprayed thermal barrier coating system. Surf. Coat. Technol. 2003, 173, 178–184. [Google Scholar] [CrossRef]

- Jiang, J.; Zhai, H.; Gong, P.; Zhang, W.; He, X.; Ma, X.; Wang, B. In-situ study on the tensile behavior of Cr-coated zircaloy for accident tolerant fuel claddings. Surf. Coat. Technol. 2020, 394, 125747. [Google Scholar] [CrossRef]

- Ma, X.; Zhai, H.; Meng, F.; Jiang, J.; He, X.; Hu, Y.; Zhang, W.; Tu, J.; Wei, D.; Wang, B. Benefit or harm of accident tolerant coatings on the low-cycle fatigue properties of Zr-4 cladding alloy: In-situ studies at 400 °C. J. Nucl. Mater. 2021, 545, 152651. [Google Scholar] [CrossRef]

- bin Zaman, S.; Hazrati, J.; de Rooij, M.; Matthews, D.; van den Boogaard, T. Investigating AlSi coating fracture at high temperatures using acoustic emission sensors. Surf. Coat. Technol. 2021, 423, 127587. [Google Scholar] [CrossRef]

- Appleby, M.P.; Zhu, D.; Morscher, G.N. Mechanical properties and real-time damage evaluations of environmental barrier coated SiC/SiC CMCs subjected to tensile loading under thermal gradients. Surf. Coat. Technol. 2015, 284, 318–326. [Google Scholar] [CrossRef] [Green Version]

- Arnaud, P.; Heripre, E.; Douit, F.; Aubin, V.; Fouvry, S.; Guiheux, R.; Branger, V.; Michel, G. Micromechanical tensile test investigation to identify elastic and toughness properties of thin nitride compound layers. Surf. Coat. Technol. 2021, 421, 127303. [Google Scholar] [CrossRef]

- Chen, Y.; Li, C.; Zhao, X.; Xiao, P. Measurements and understanding of the stiffness of an air plasma sprayed thermal barrier coating. Surf. Coat. Technol. 2020, 394, 125678. [Google Scholar] [CrossRef]

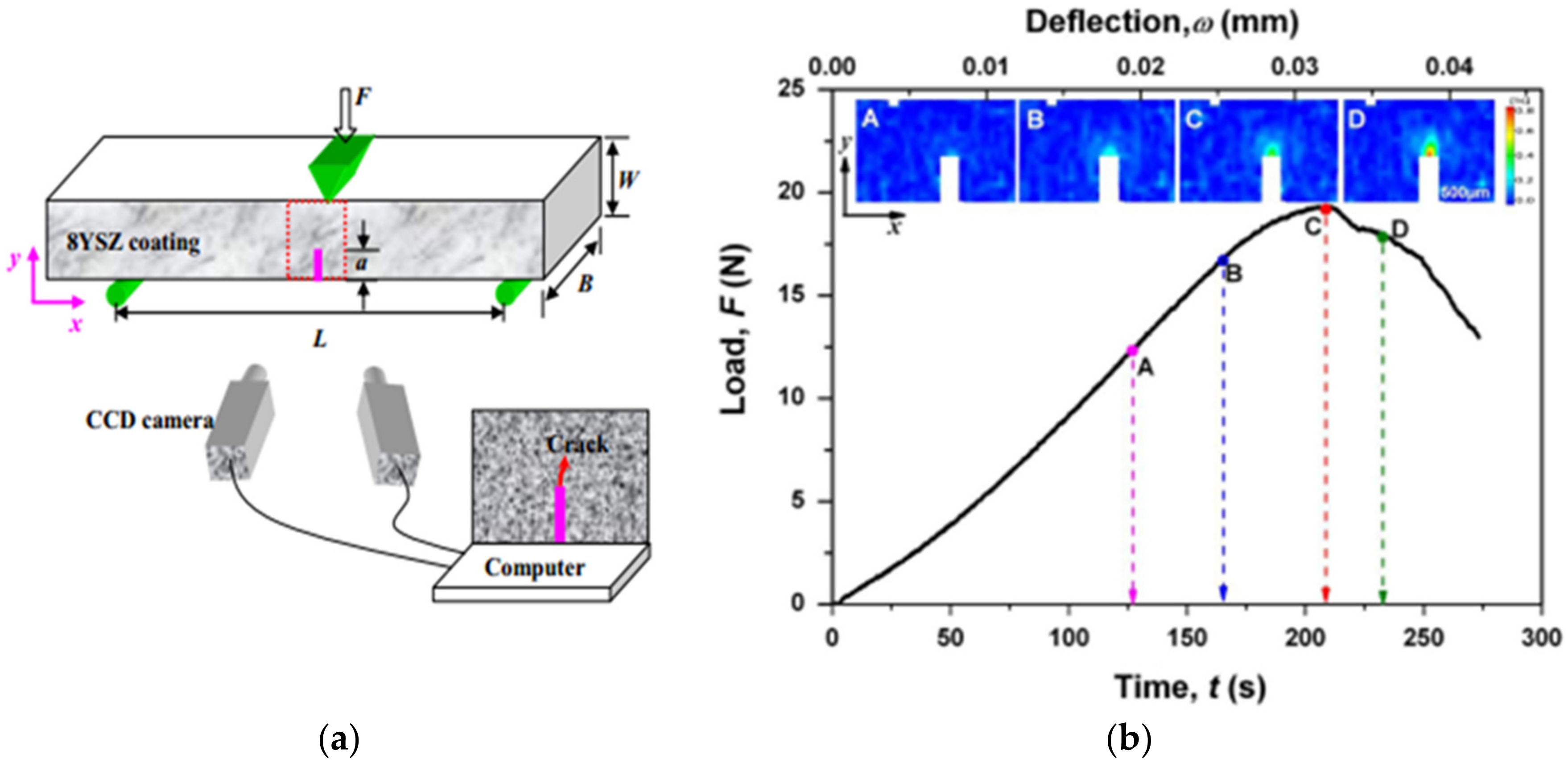

- Zhu, W.; Wu, Q.; Yang, L.; Zhou, Y.C. In situ characterization of high temperature elastic modulus and fracture toughness in air plasma sprayed thermal barrier coatings under bending by using digital image correlation. Ceram. Int. 2020, 46, 18526–18533. [Google Scholar] [CrossRef]

- Yang, L.; Zhong, Z.C.; You, J.; Zhang, Q.M.; Zhou, Y.C.; Tang, W.Z. Acoustic emission evaluation of fracture characteristics in thermal barrier coatings under bending. Surf. Coat. Technol. 2013, 232, 710–718. [Google Scholar] [CrossRef]

- Jiang, P.; Fan, X.; Sun, Y.; Li, D.; Wang, T. Bending-driven failure mechanism and modelling of double-ceramic-layer thermal barrier coating system. Int. J. Solids Struct. 2018, 130, 11–20. [Google Scholar] [CrossRef]

- Li, X.N.; Liang, L.H.; Xie, J.J.; Chen, L.; Wei, Y.G. Thickness-dependent fracture characteristics of ceramic coatings bonded on the alloy substrates. Surf. Coat. Technol. 2014, 258, 1039–1047. [Google Scholar] [CrossRef]

- Martins, J.P.; Yu, H.; Chen, Y.; Brewster, G.; McIntyre, R.; Xiao, P. Effect of bond coat topography on the fracture mechanics and lifetime of air-plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2021, 421, 127447. [Google Scholar] [CrossRef]

- Planques, P.; Vidal, V.; Lours, P.; Proton, V.; Crabos, F.; Huez, J.; Viguier, B. Characterization of the mechanical properties of thermal barrier coatings by 3 points bending tests and modified small punch tests. Surf. Coat. Technol. 2017, 332, 40–46. [Google Scholar] [CrossRef] [Green Version]

- Wan, J.; Zhou, M.; Yang, X.S.; Dai, C.Y.; Zhang, Y.; Mao, W.G.; Lu, C. Fracture characteristics of freestanding 8 wt% Y2O3–ZrO2 coatings by single edge notched beam and Vickers indentation tests. Mater. Sci. Eng. A 2013, 581, 140–144. [Google Scholar] [CrossRef] [Green Version]

- Mušálek, R.; Kovářík, O.; Matějíček, J. In-situ observation of crack propagation in thermally sprayed coatings. Surf. Coat. Technol. 2010, 205, 1807–1811. [Google Scholar] [CrossRef]

- Liu, H.T.; Yang, L.W.; Sun, X.; Cheng, H.F.; Wang, C.Y.; Mao, W.G.; Molina-Aldareguia, J.M. Enhancing the fracture resistance of carbon fiber reinforced SiC matrix composites by interface modification through a simple fiber heat-treatment process. Carbon 2016, 109, 435–443. [Google Scholar] [CrossRef]

- Jiang, J.; Yuan, M.; Du, M.; Ma, X. On the crack propagation and fracture properties of Cr-coated Zr-4 alloys for accident-tolerant fuel cladding: In situ three-point bending test and cohesive zone modeling. Surf. Coat. Technol. 2021, 427, 127810. [Google Scholar] [CrossRef]

- Jiang, J.; Du, M.; Pan, Z.; Yuan, M.; Ma, X.; Wang, B. Effects of oxidation and inter-diffusion on the fracture mechanisms of Cr-coated Zry-4 alloys: An in situ three-point bending study. Mater. Des. 2021, 212, 110168. [Google Scholar] [CrossRef]

- Liang, L.H.; Li, X.N.; Liu, H.Y.; Wang, Y.B.; Wei, Y.G. Power-law characteristics of damage and failure of ceramic coating systems under three-point bending. Surf. Coat. Technol. 2016, 285, 113–119. [Google Scholar] [CrossRef] [Green Version]

- Grigore, E.; Ruset, C.; Short, K.; Hoeft, D.; Dong, H.; Li, X.Y.; Bell, T. In situ investigation of the internal stress within the nc-Ti2N/nc-TiN nanocomposite coatings produced by a combined magnetron sputtering and ion implantation method. Surf. Coat. Technol. 2005, 200, 744–747. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, C.; Zhang, Z.-W.; Li, Y.-C.; Yasir, M.; Wang, H.-T.; Liu, L. Toughening Fe-based amorphous coatings by reinforcement of amorphous carbon. Sci. Rep. 2017, 7, 4084. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, X.; Zhao, X.; Markocsan, N.; Nylén, P.; Xiao, P. Measurements of elastic modulus and fracture toughness of an air plasma sprayed thermal barrier coating using micro-cantilever bending. Surf. Coat. Technol. 2019, 374, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Armstrong, D.E.J.; Haseeb, A.; Roberts, S.G.; Wilkinson, A.J.; Bade, K. Nanoindentation and micro-mechanical fracture toughness of electrodeposited nanocrystalline Ni–W alloy films. Thin Solid Films 2012, 520, 4369–4372. [Google Scholar] [CrossRef]

- Di Maio, D.; Roberts, S.G. Measuring fracture toughness of coatings using focused-ion-beam-machined microbeams. J. Mater. Res. 2005, 20, 299–302. [Google Scholar] [CrossRef]

- Matoy, K.; Schönherr, H.; Detzel, T.; Schöberl, T.; Pippan, R.; Motz, C.; Dehm, G. A comparative micro-cantilever study of the mechanical behavior of silicon based passivation films. Thin Solid Films 2009, 518, 247–256. [Google Scholar] [CrossRef]

- Matoy, K.; Detzel, T.; Müller, M.; Motz, C.; Dehm, G. Interface fracture properties of thin films studied by using the micro-cantilever deflection technique. Surf. Coat. Technol. 2009, 204, 878–881. [Google Scholar] [CrossRef]

- Riedl, A.; Daniel, R.; Stefenelli, M.; Schöberl, T.; Kolednik, O.; Mitterer, C.; Keckes, J. A novel approach for determining fracture toughness of hard coatings on the micrometer scale. Scr. Mater. 2012, 67, 708–711. [Google Scholar] [CrossRef]

- Chen, Y.; Xiao, P. Micromechanical testing of a thermally grown oxide on a MCrAlY coating. Surf. Coat. Technol. 2021, 419, 127300. [Google Scholar] [CrossRef]

- Liu, S.; Wheeler, J.M.; Howie, P.R.; Zeng, X.T.; Michler, J.; Clegg, W.J. Measuring the fracture resistance of hard coatings. Appl. Phys. Lett. 2013, 102, 171907. [Google Scholar] [CrossRef] [Green Version]

- Gruber, D.P.; Zalesak, J.; Todt, J.; Tkadletz, M.; Sartory, B.; Suuronen, J.-P.; Ziegelwanger, T.; Czettl, C.; Mitterer, C.; Keckes, J. Surface oxidation of nanocrystalline CVD TiB2 hard coatings revealed by cross-sectional nano-analytics and in-situ micro-cantilever testing. Surf. Coat. Technol. 2020, 399, 126181. [Google Scholar] [CrossRef]

- Mondal, K.; Nuñez, L., III; Downey, C.M.; van Rooyen, I.J. Thermal Barrier Coatings Overview: Design, Manufacturing, and Applications in High-Temperature Industries. Ind. Eng. Chem. Res. 2021, 60, 6061–6077. [Google Scholar] [CrossRef]

| A Review on In Situ Mechanical Testing of Coatings | |||||

|---|---|---|---|---|---|

| Monitoring Techniques | SEM | TEM | DIC | AE | |

| Mechanical testing | Tensile | Bending | |||

| Methods | Macro-tensile (RT and HT) | Micro/Nano-tensile (FIB samples) | Macro-bending (3-point or 4 point) | Micro-bending (FIB samples) | |

| Covered Subjects | Deformation and fracture of coatings | Mechanical characteristics evolution | Heat treatment & temperature dependance effects | Material composition & structure | Thickness variation & Deposition method |

| Coatings studied | Thermal barrier coating | Composite coatings (GNPs/NiAl) | Metal/alloy coatings (Cr on Zr) | Hard ceramic coating (CrN, TiN) | |

| Current Limits |

| ||||

| Future perspectives |

| ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amer, M.; Hayat, Q.; Janik, V.; Jennett, N.; Nottingham, J.; Bai, M. A Review on In Situ Mechanical Testing of Coatings. Coatings 2022, 12, 299. https://doi.org/10.3390/coatings12030299

Amer M, Hayat Q, Janik V, Jennett N, Nottingham J, Bai M. A Review on In Situ Mechanical Testing of Coatings. Coatings. 2022; 12(3):299. https://doi.org/10.3390/coatings12030299

Chicago/Turabian StyleAmer, Mohamed, Qamar Hayat, Vit Janik, Nigel Jennett, Jon Nottingham, and Mingwen Bai. 2022. "A Review on In Situ Mechanical Testing of Coatings" Coatings 12, no. 3: 299. https://doi.org/10.3390/coatings12030299

APA StyleAmer, M., Hayat, Q., Janik, V., Jennett, N., Nottingham, J., & Bai, M. (2022). A Review on In Situ Mechanical Testing of Coatings. Coatings, 12(3), 299. https://doi.org/10.3390/coatings12030299