Preparation and Study on Fretting Tribological Behavior of Composite Lubrication Structure on the Titanium Alloy Surface

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

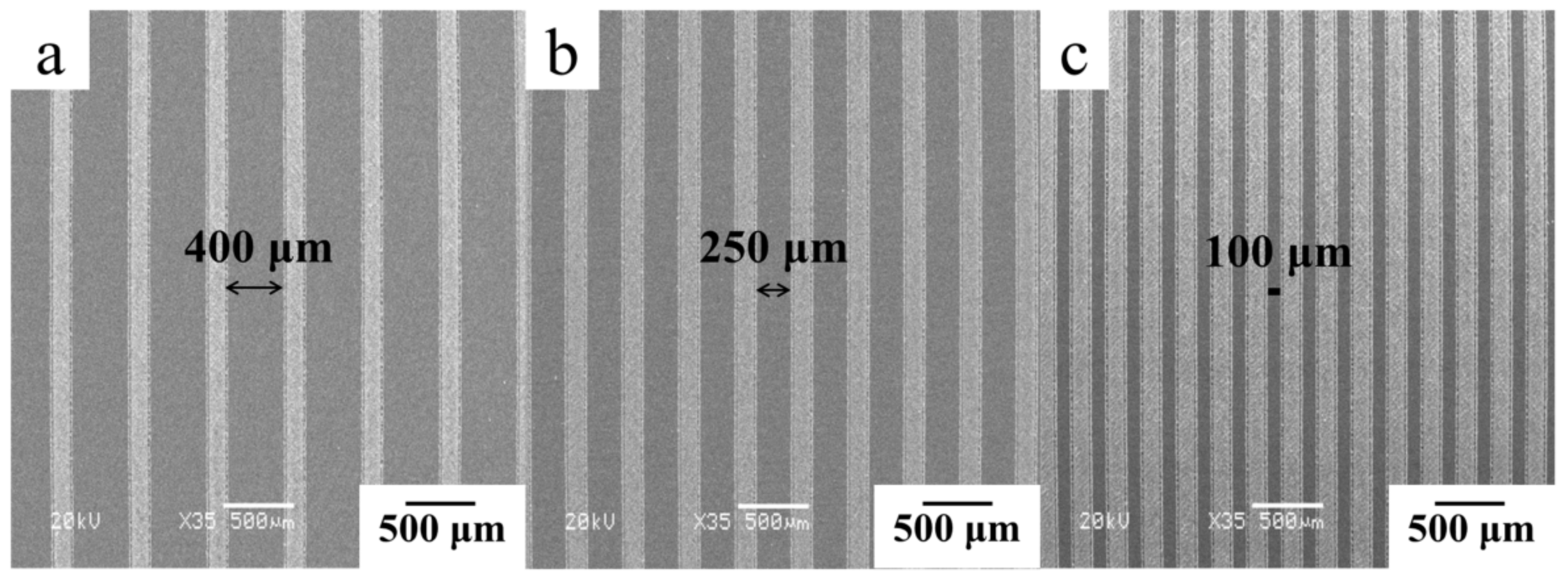

3.1. The Morphologies of Textured Surfaces

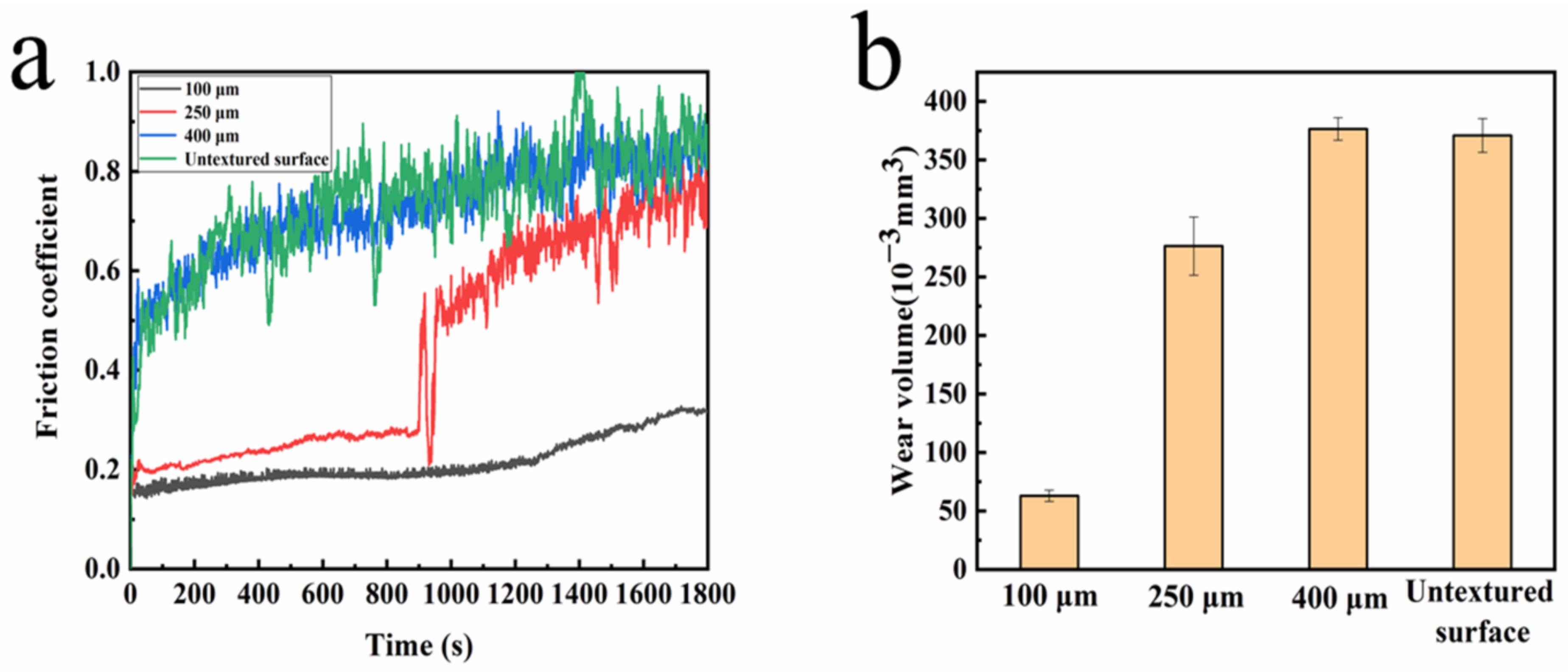

3.2. The Influence of Texture Parameters on the Fretting Wear Behaviors of the TC4 Alloy Surface

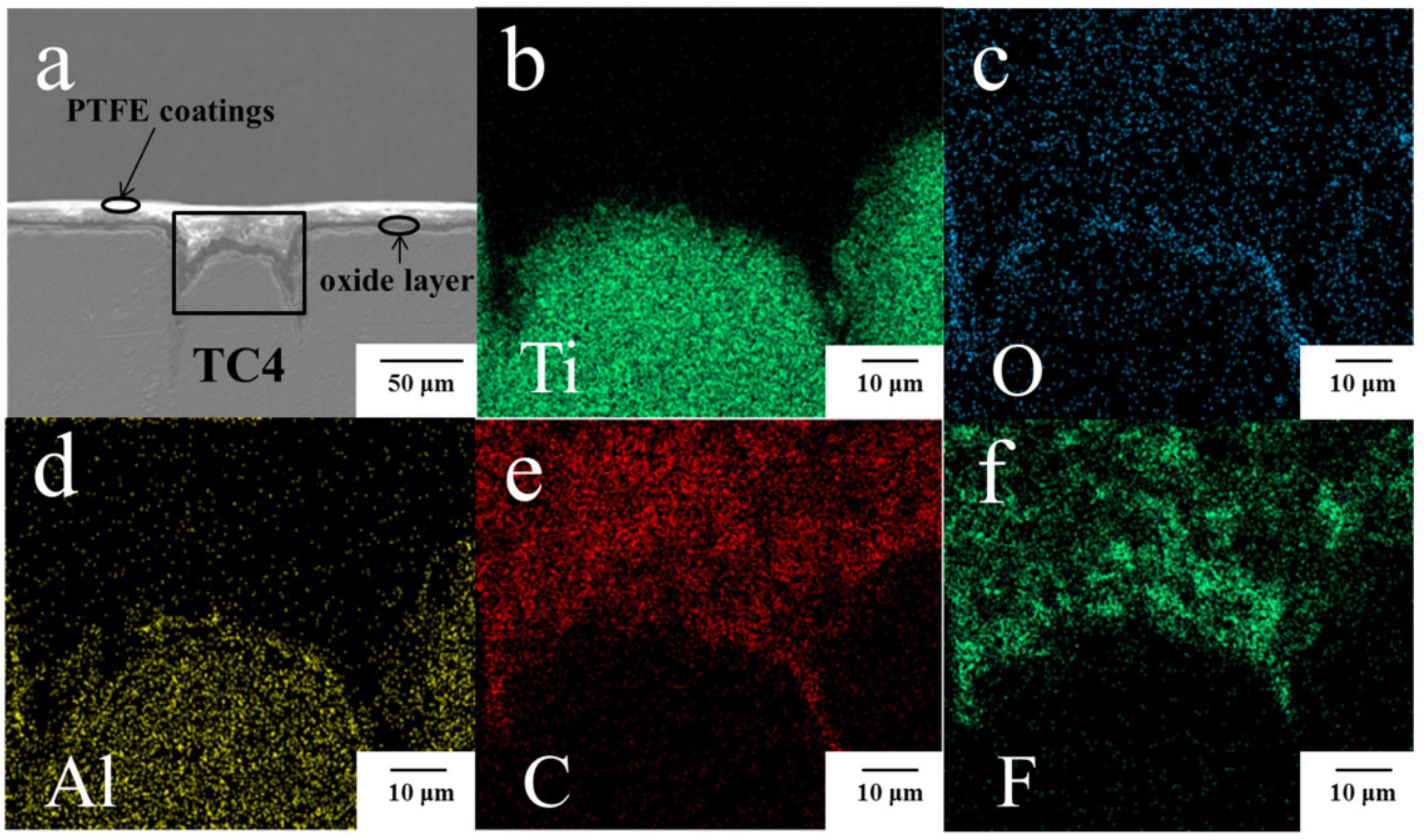

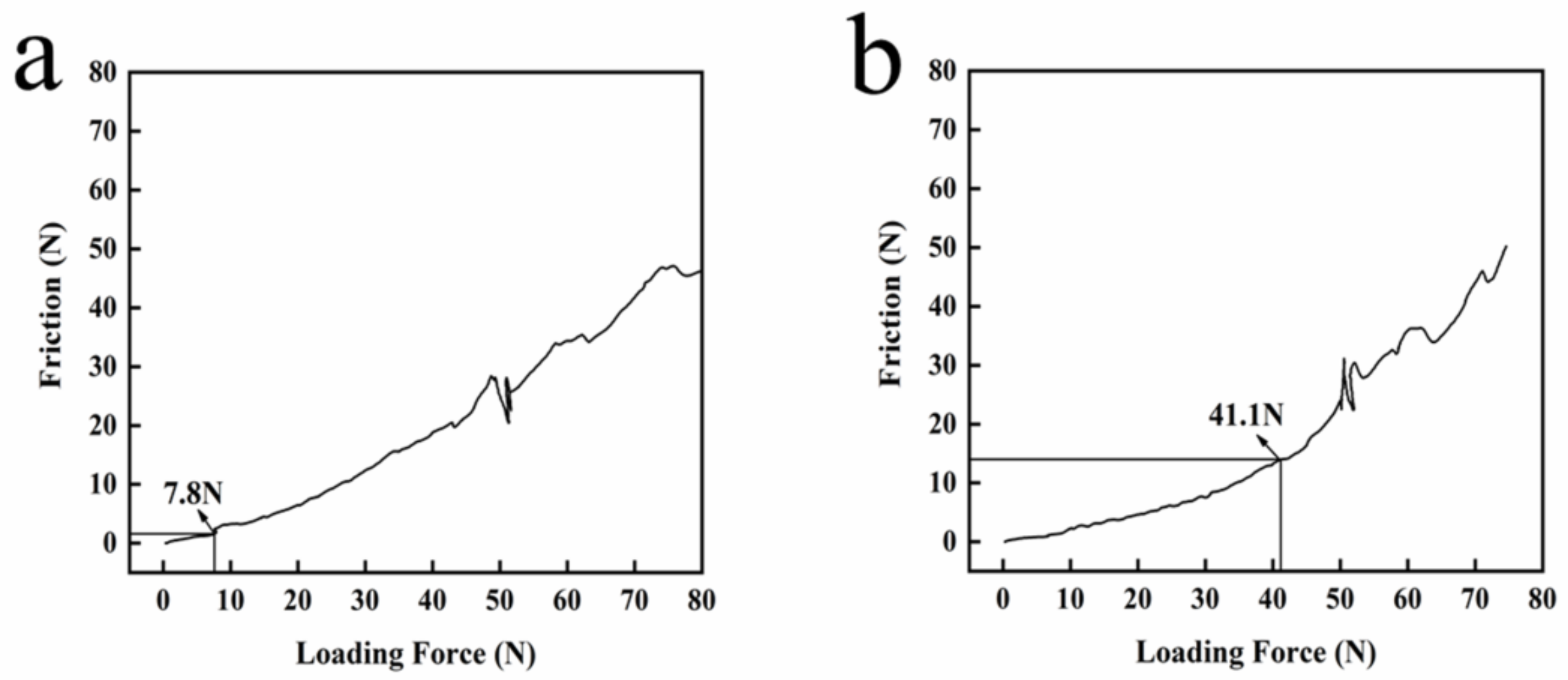

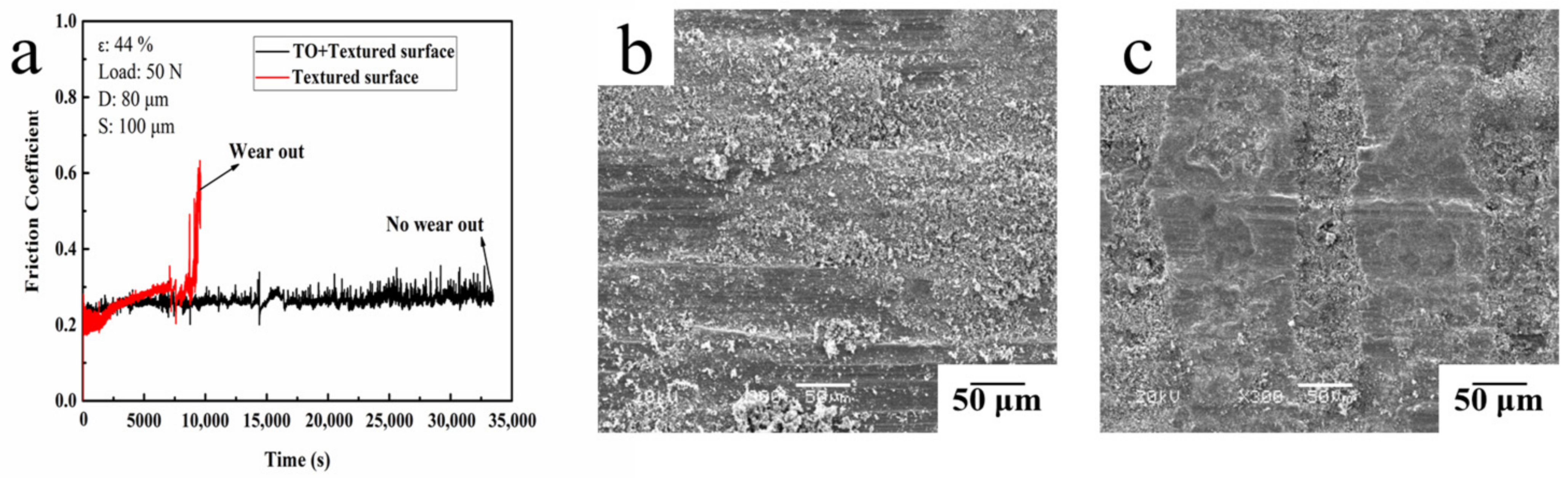

3.3. The Influence of the Combination of Thermal Oxide Layer and PTFE-Based Coating on Fretting Wear Behaviors of Textured Surface

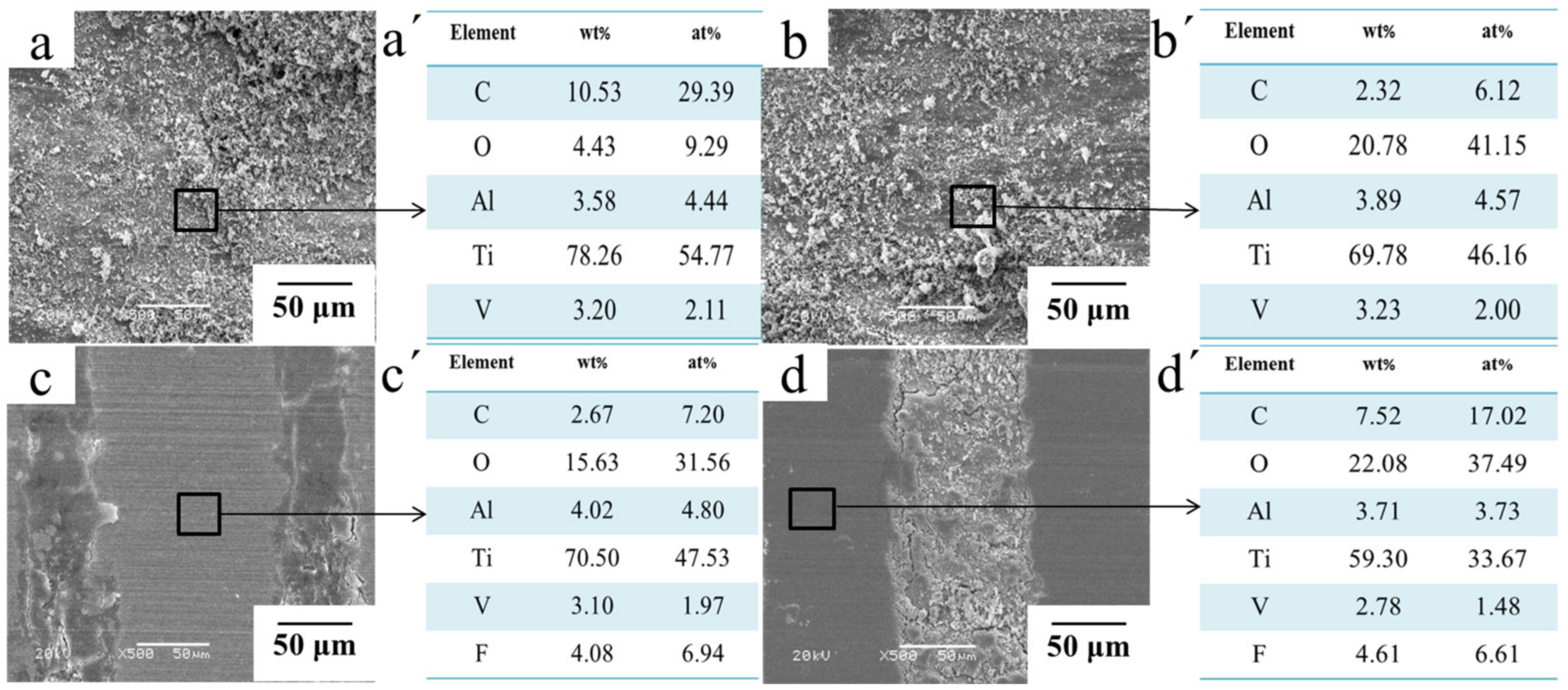

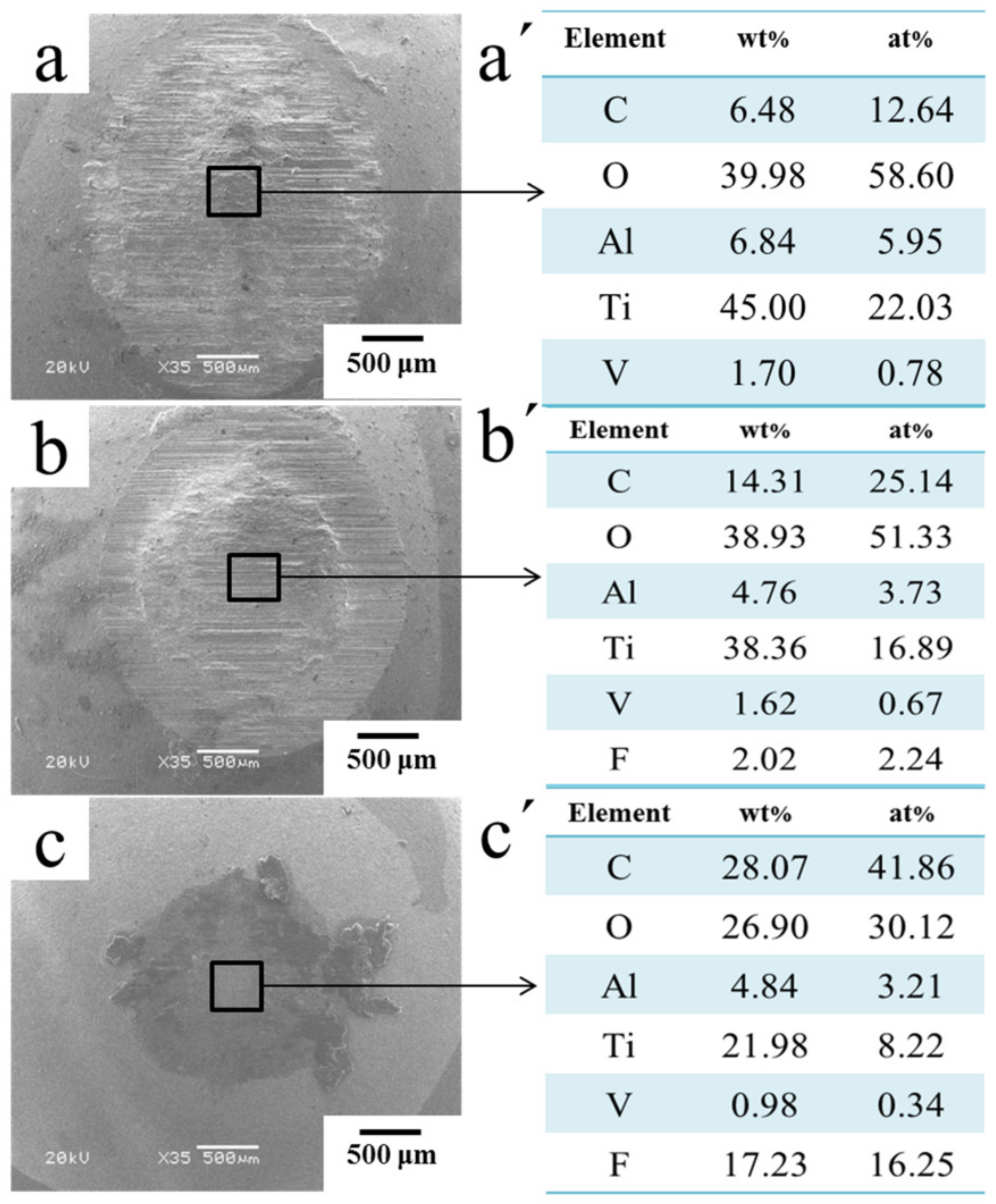

3.4. Wear Mechanism of the Composite Lubrication Structure

4. Conclusions

- (1)

- The composite lubricating structure was prepared on the surface of the titanium alloy by combining surface texture, a thermal oxidation layer, and a PTFE lubricating coating. This structure can greatly prolong the wear life under fretting conditions, and the friction coefficient is as low as 0.242, the wear rate is less than 2.3 × 10−5 mm3·N−1m−1.

- (2)

- The texture parameters have an important effect on the friction coefficient and wear rate of the composite lubrication structure, the smaller texture spacing and width are more favorable to friction-reducing and anti-wear.

- (3)

- Depending on the role of adhesion enhancement of the surface texture and rough oxide layer to coating, the wear resistance of thermal oxidation layer with high hardness, and the effect of the surface texture on storage and transfer of lubricant, the synergistic influence of the three effects makes the composite structure play the role of self-lubrication and wear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Kumar, V.A.; Gupta, R.K.; Prasad, M.J.N.V.; Murty, S.V.S.N. Recent advances in processing of titanium alloys and titanium aluminides for space applications: A review. J. Mater. Res. 2021, 36, 689–716. [Google Scholar] [CrossRef]

- Chamgordani, S.A.; Miresmaeili, R.; Aliofkhazraei, M. Improvement in tribological behavior of commercial pure titanium (CP-Ti) by surface mechanical attrition treatment (SMAT). Tribol. Int. 2018, 119, 744–752. [Google Scholar] [CrossRef]

- Sarraf, M.; Ghomi, E.R.; Alipour, S.; Ramakrishna, S.; Sukiman, N.L. A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications. Bio-Design Manuf. 2021, 42, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Bai, H.; Zhong, L.; Kang, L.; Liu, J.; Zhuang, W.; Lv, Z.; Xu, Y. A review on wear-resistant coating with high hardness and high toughness on the surface of titanium alloy. J. Alloys Compd. 2021, 882, 160645. [Google Scholar] [CrossRef]

- Du, D.; Liu, D.; Ye, Z.; Zhang, X.; Li, F.; Zhou, Z.; Yu, L. Fretting wear and fretting fatigue behaviors of diamond-like carbon and graphite-like carbon films deposited on Ti-6Al-4V alloy. Appl. Surf. Sci. 2014, 313, 462–469. [Google Scholar] [CrossRef]

- Li, Z.Y.; Liu, X.L.; Wu, G.Q.; Huang, Z. Fretting Fatigue Behavior of Ti–6Al–4V and Ti–10V–2Fe–3Al Alloys. Met. Mater. Int. 2018, 25, 64–70. [Google Scholar] [CrossRef]

- Ye, Z.; Li, J.; Liu, L.; Ma, F.; Zhao, B.; Wang, X. Microstructure and wear performance enhancement of carbon nanotubes reinforced composite coatings fabricated by laser cladding on titanium alloy. Opt. Laser Technol. 2021, 139, 106957. [Google Scholar] [CrossRef]

- Rautray, T.R.; Narayanan, R.; Kwon, T.-Y.; Kim, K.-H. Surface modification of titanium and titanium alloys by ion implantation. J. Biomed. Mater. Res. Part B Appl. Biomater. 2010, 93, 581–591. [Google Scholar] [CrossRef]

- Chen, X.; Liao, D.; Zhang, D.; Jiang, X.; Zhao, P.; Xu, R. Friction and Wear Behavior of Graphene-Modified Titanium Alloy Micro-arc Oxidation Coatings. Trans. Indian Inst. Met. 2019, 73, 73–80. [Google Scholar] [CrossRef]

- Zhang, H.; Dai, Z.; Shi, Y.; Xu, C. Technical note. Effects of Laser Hardening on Fretting Wear Behaviour of Ti Alloy. Surf. Eng. 2001, 17, 518–520. [Google Scholar] [CrossRef]

- Kang, J.; Wang, M.; Yue, W.; Fu, Z.; Zhu, L.; She, D.; Wang, C. Tribological Behavior of Titanium Alloy Treated by Nitriding and Surface Texturing Composite Technology. Materials 2019, 12, 301. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arslan, A.; Masjuki, H.H.; Kalam, A.; Varman, M.; Mufti, R.A.; Mosarof, M.H.; Khuong, L.S.; Quazi, M. Surface Texture Manufacturing Techniques and Tribological Effect of Surface Texturing on Cutting Tool Performance: A Review. Crit. Rev. Solid State Mater. Sci. 2016, 41, 447–481. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Li, X.; Yue, W.; Huang, F.; Kang, J.; Zhu, L.; Tian, B. Tribological behaviour of textured titanium under abrasive wear. Surf. Eng. 2018, 35, 378–386. [Google Scholar] [CrossRef]

- Conradi, M.; Kocijan, A.; Klobčar, D.; Podgornik, B. Tribological response of laser-textured Ti6Al4V alloy under dry conditions and lubricated with Hank’s solution. Tribol. Int. 2021, 160, 107049. [Google Scholar] [CrossRef]

- Dong, H.; Bell, T. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment. Wear 2000, 238, 131–137. [Google Scholar] [CrossRef]

- Bailey, R.; Sun, Y. Unlubricated sliding friction and wear characteristics of thermally oxidized commercially pure titanium. Wear 2013, 308, 61–70. [Google Scholar] [CrossRef]

- Dalili, N.; Edrisy, A.; Farokhzadeh, K.; Li, J.; Lo, J.; Riahi, A. Improving the wear resistance of Ti–6Al–4V/TiC composites through thermal oxidation (TO). Wear 2010, 269, 590–601. [Google Scholar] [CrossRef]

- Jia, Y.; Wan, H.; Chen, L.; Zhou, H.; Chen, J. Effects of nano-LaF 3 on the friction and wear behaviors of PTFE-based bonded solid lubricating coatings under different lubrication conditions. Appl. Surf. Sci. 2016, 382, 73–79. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Ren, J.; Gao, G.; Zhao, G.; Chen, S.; Wang, N.; Wang, J. Multi-environment adaptability of self-lubricating core/shell PTFE@PR composite: Tribological characteristics and transfer mechanism. Tribol. Int. 2020, 154, 106718. [Google Scholar] [CrossRef]

- Hu, T.; Hu, L.; Ding, Q. The effect of laser surface texturing on the tribological behavior of Ti-6Al-4V. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 2012, 226, 854–863. [Google Scholar] [CrossRef]

- Sun, Q.; Hu, T.; Fan, H.; Zhang, Y.; Hu, L. Thermal oxidation behavior and tribological properties of textured TC4 surface: Influence of thermal oxidation temperature and time. Tribol. Int. 2016, 94, 479–489. [Google Scholar] [CrossRef]

- Zhang, P.; Zou, X.; Zhang, S.; Xia, C.; Liang, C.; Liu, N.; Wang, H. Improve the binding force of PEEK coating with Mg surface by femtosecond lasers induced micro/nanostructures. J. Mater. Sci. 2021, 56, 13313–13322. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Baykara, M.Z.; Martini, A. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear–A review. Tribol. Int. 2020, 155, 106792. [Google Scholar] [CrossRef]

- Sun, Q.; Hu, T.; Fan, H.; Zhang, Y.; Hu, L. Dry sliding wear behavior of TC11 alloy at 500°C: Influence of laser surface texturing. Tribol. Int. 2015, 92, 136–145. [Google Scholar] [CrossRef]

- Mao, Y.; Wang, L.; Chen, K.; Wang, S.; Cui, X. Tribo-layer and its role in dry sliding wear of Ti–6Al–4V alloy. Wear 2013, 297, 1032–1039. [Google Scholar] [CrossRef]

- He, D.; Zheng, S.; Pu, J.; Zhang, G.; Hu, L. Improving tribological properties of titanium alloys by combining laser surface texturing and diamond-like carbon film. Tribol. Int. 2015, 82, 20–27. [Google Scholar] [CrossRef]

| Elements | Al | V | Fe | C | N | H | O | Ti | Other Elements |

|---|---|---|---|---|---|---|---|---|---|

| TC4 | 5.5–6.8 | 3.5–4.5 | 0.30 | 0.10 | 0.05 | 0.015 | 0.2 | Balance | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Song, J.; Fan, H.; Hu, T.; Hu, L. Preparation and Study on Fretting Tribological Behavior of Composite Lubrication Structure on the Titanium Alloy Surface. Coatings 2022, 12, 332. https://doi.org/10.3390/coatings12030332

Ma Z, Song J, Fan H, Hu T, Hu L. Preparation and Study on Fretting Tribological Behavior of Composite Lubrication Structure on the Titanium Alloy Surface. Coatings. 2022; 12(3):332. https://doi.org/10.3390/coatings12030332

Chicago/Turabian StyleMa, Zhen, Junjie Song, Hengzhong Fan, Tianchang Hu, and Litian Hu. 2022. "Preparation and Study on Fretting Tribological Behavior of Composite Lubrication Structure on the Titanium Alloy Surface" Coatings 12, no. 3: 332. https://doi.org/10.3390/coatings12030332

APA StyleMa, Z., Song, J., Fan, H., Hu, T., & Hu, L. (2022). Preparation and Study on Fretting Tribological Behavior of Composite Lubrication Structure on the Titanium Alloy Surface. Coatings, 12(3), 332. https://doi.org/10.3390/coatings12030332