Mathematical Modelling of Ree-Eyring Nanofluid Using Koo-Kleinstreuer and Cattaneo-Christov Models on Chemically Reactive AA7072-AA7075 Alloys over a Magnetic Dipole Stretching Surface

Abstract

:1. Introduction

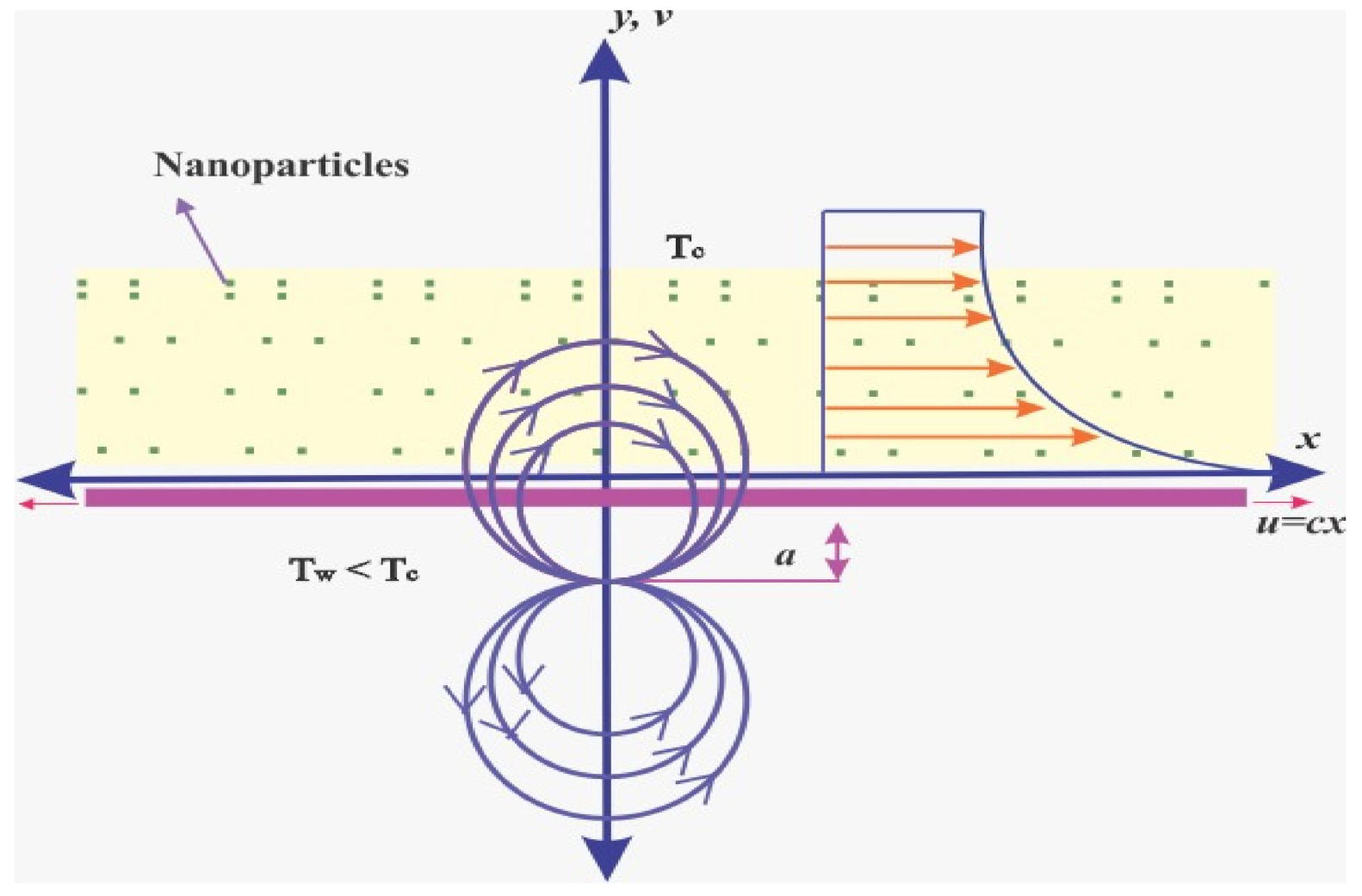

2. Mathematical Model and Formulation

3. Solution Method and Details

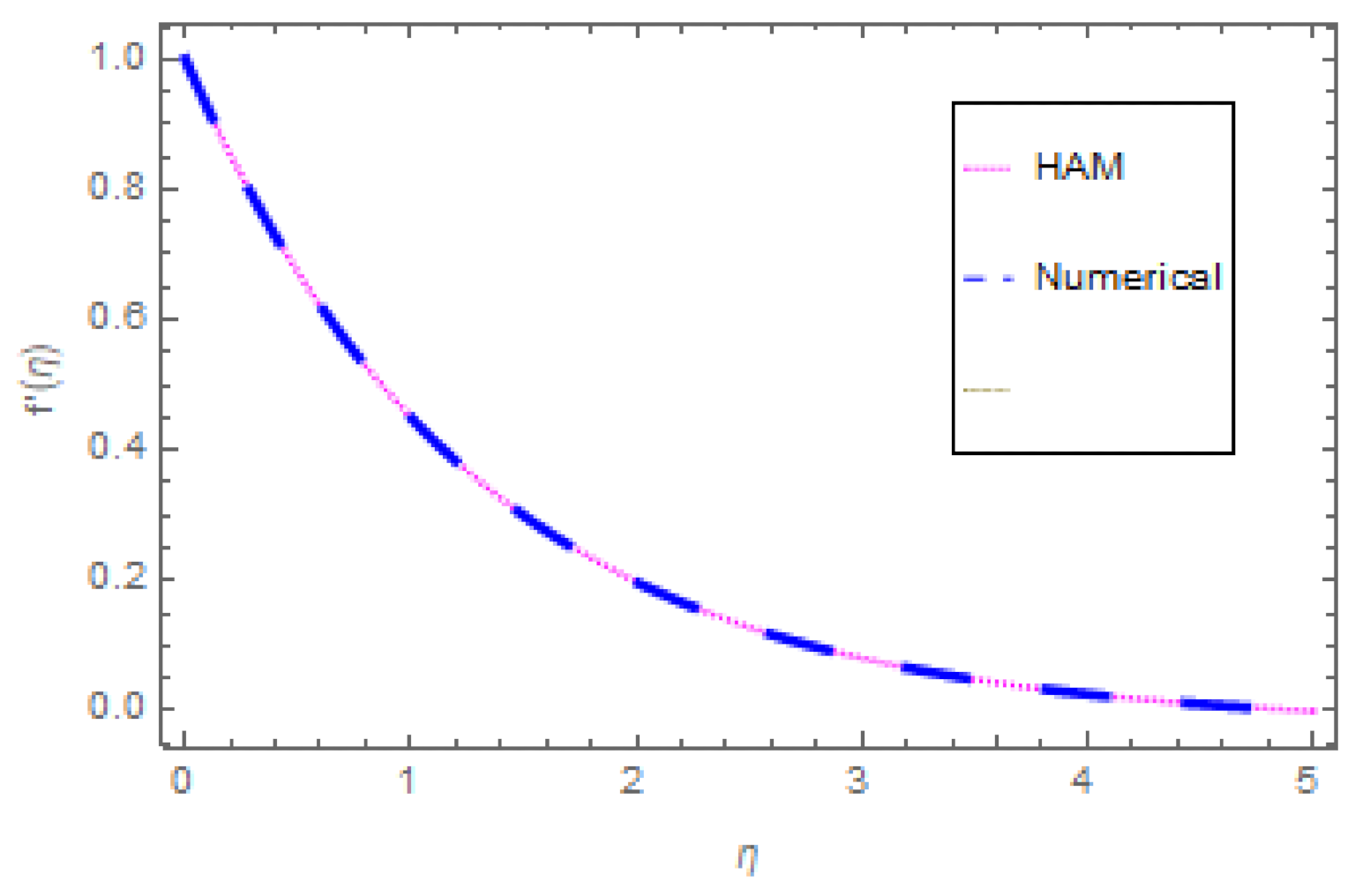

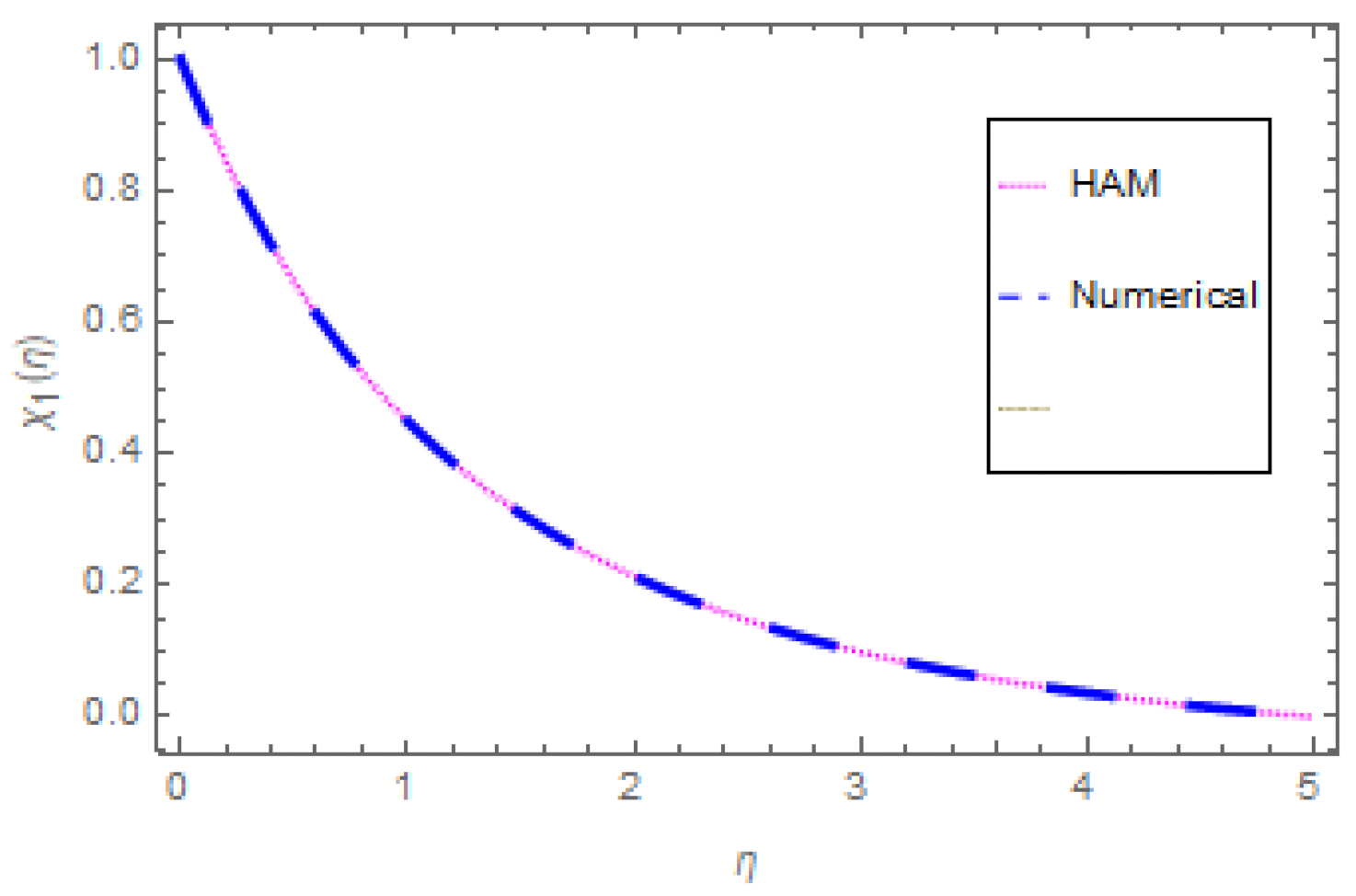

Validation and Comparison

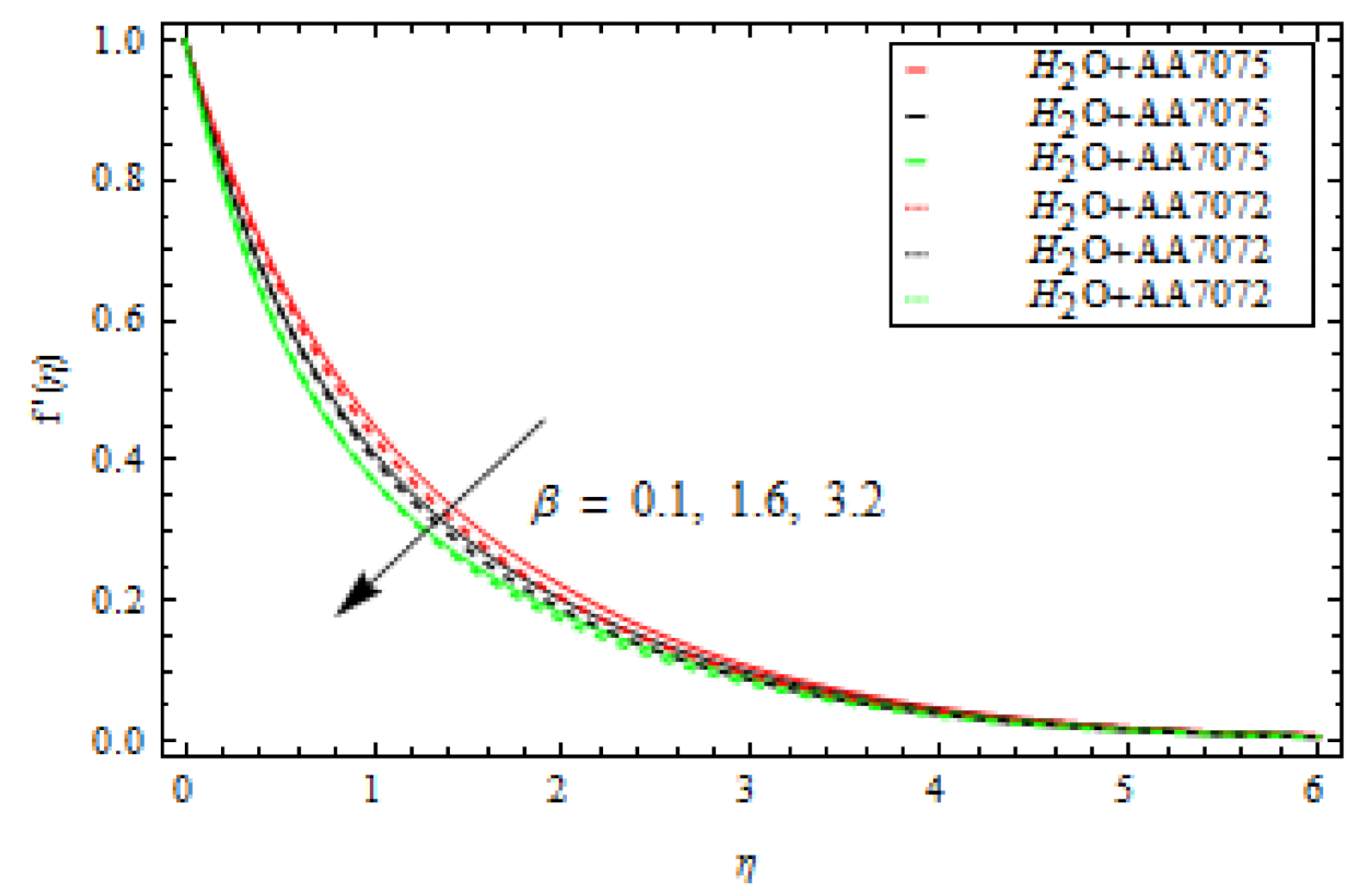

4. Results and Discussion

5. Conclusions

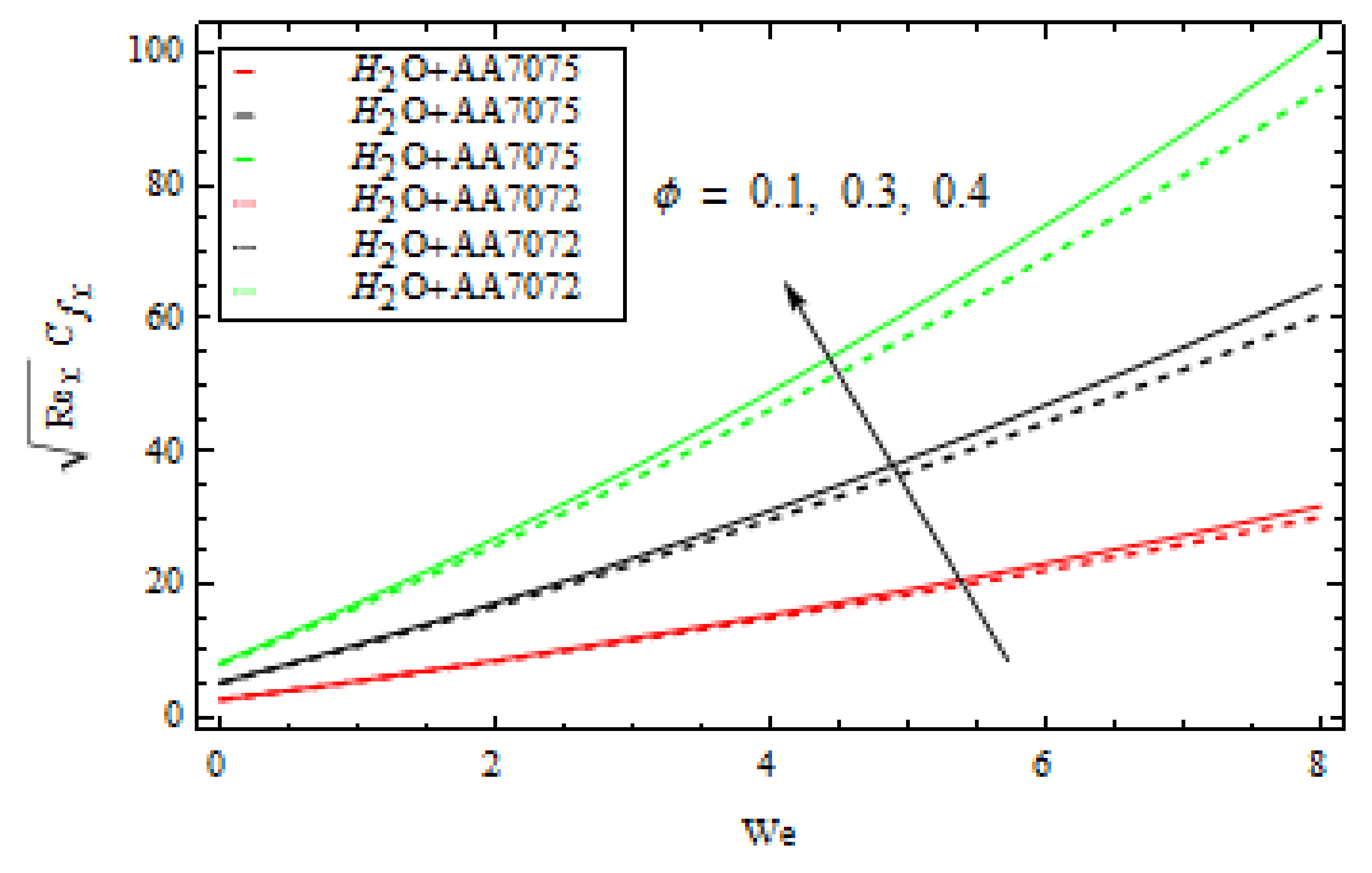

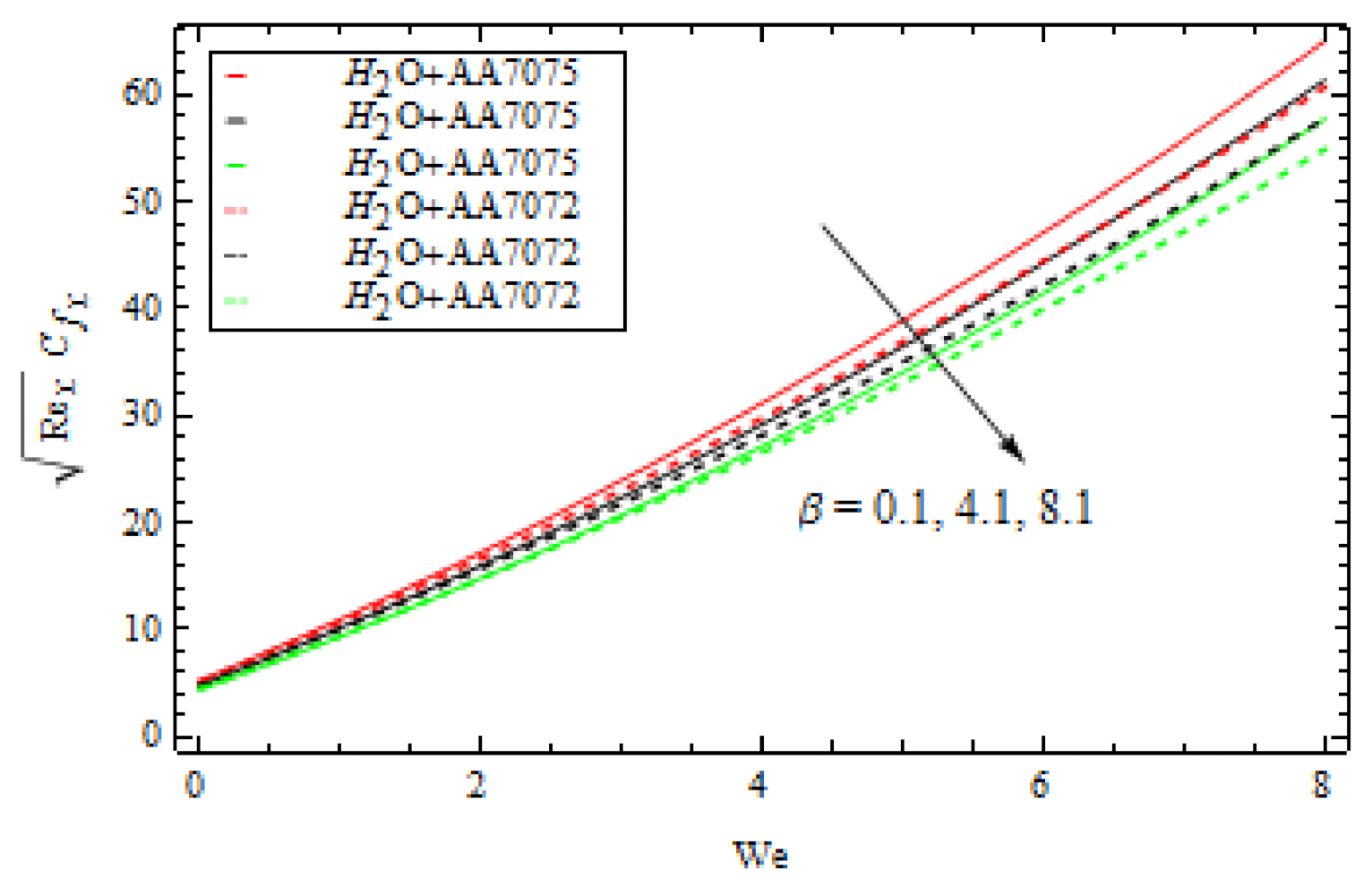

- An escalation in volume fraction, Weissenberg number, and the ferromagnetic interaction parameter affects the velocity gradient. Furthermore, all these parameters negatively influence the velocity gradient of alloy , which falls quicker than the velocity gradient of alloy .

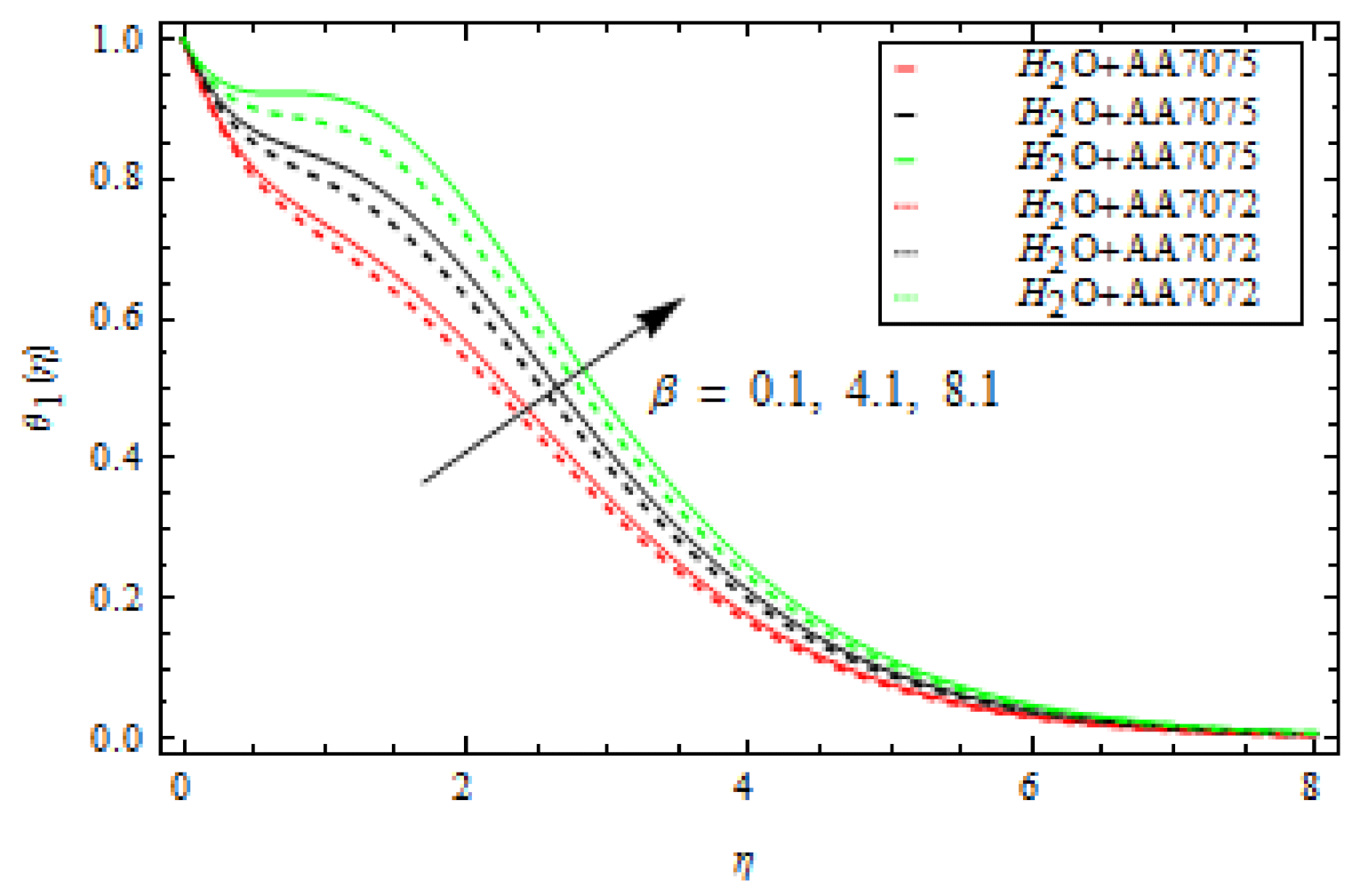

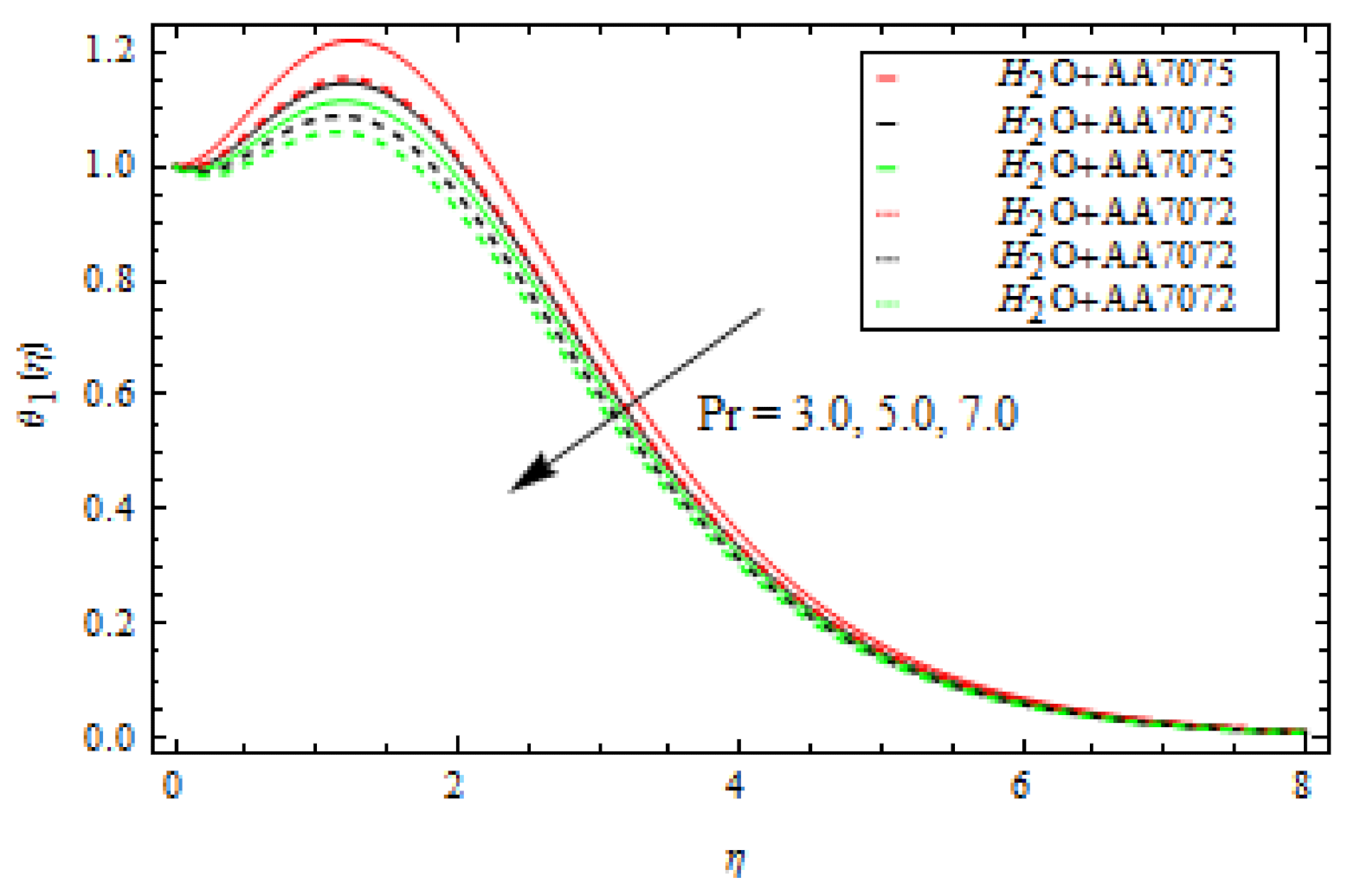

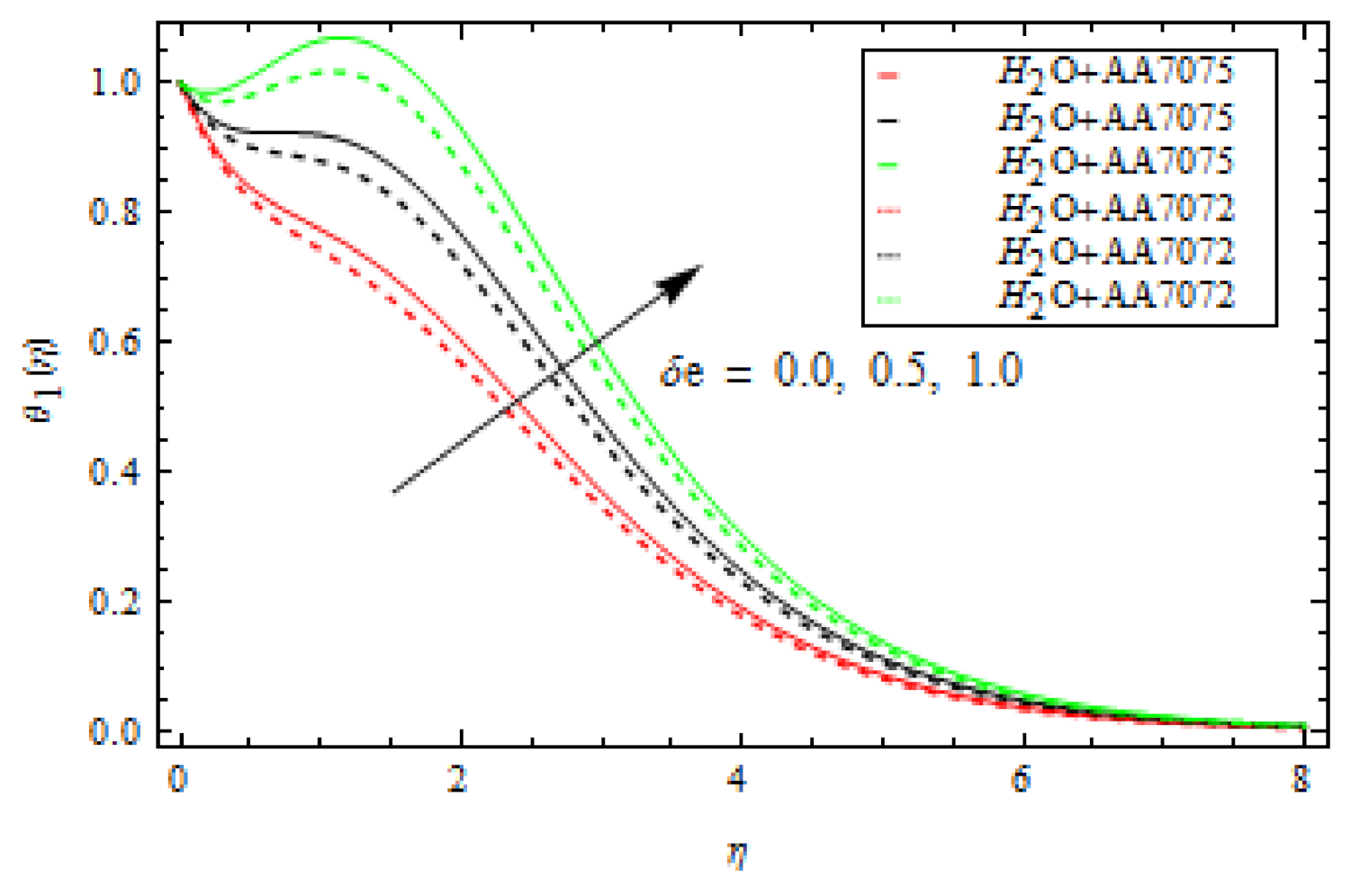

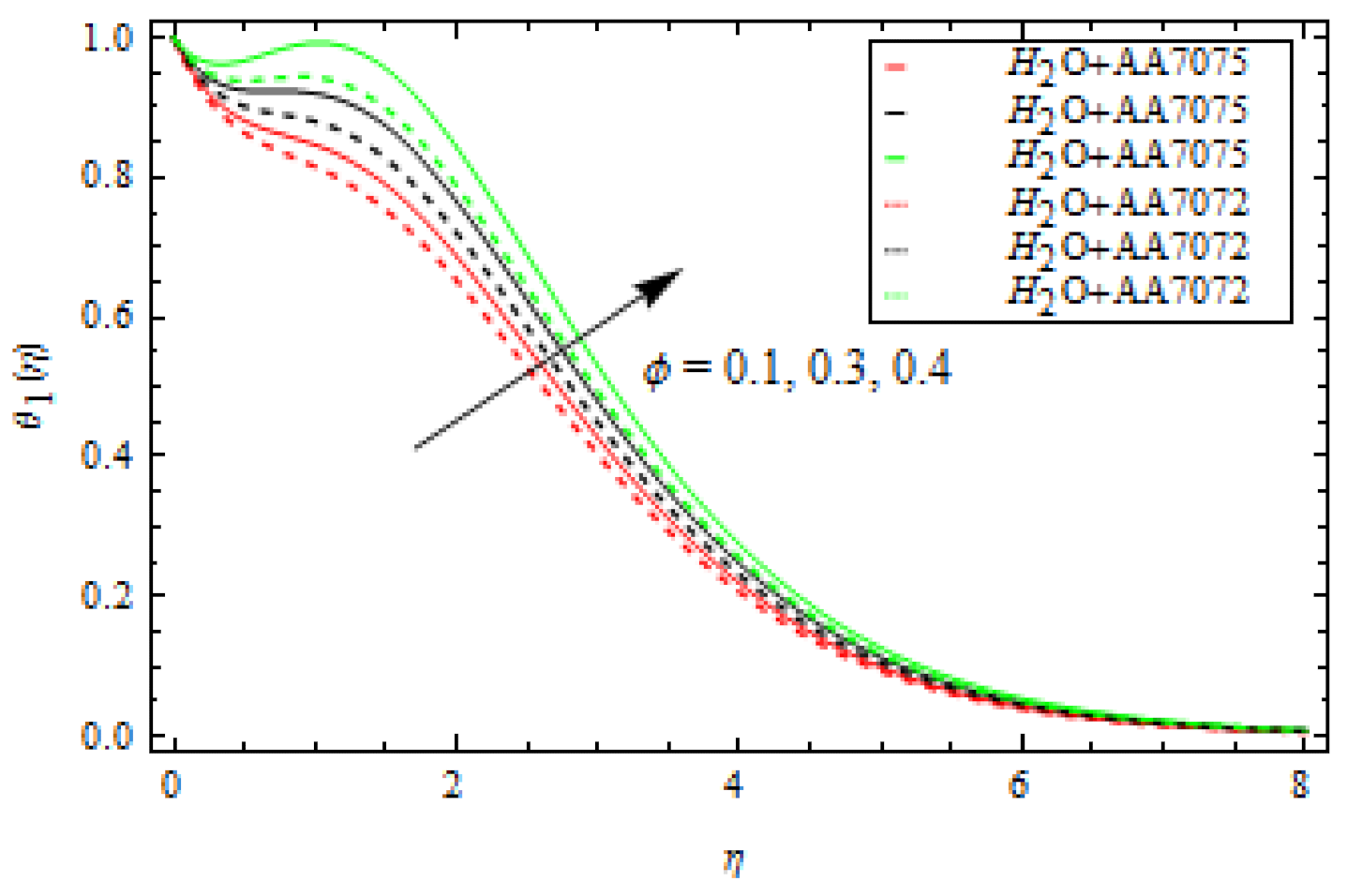

- As the ferromagnetic interaction, viscous dissipation parameter, thermal relaxation parameter, and volume fraction grow, the temperature gradient of both alloys increases, whereas contrasting behaviour is revealed for the Prandtl number. Moreover, in and when treated with alloy, the closeness of the thermal layer further improves.

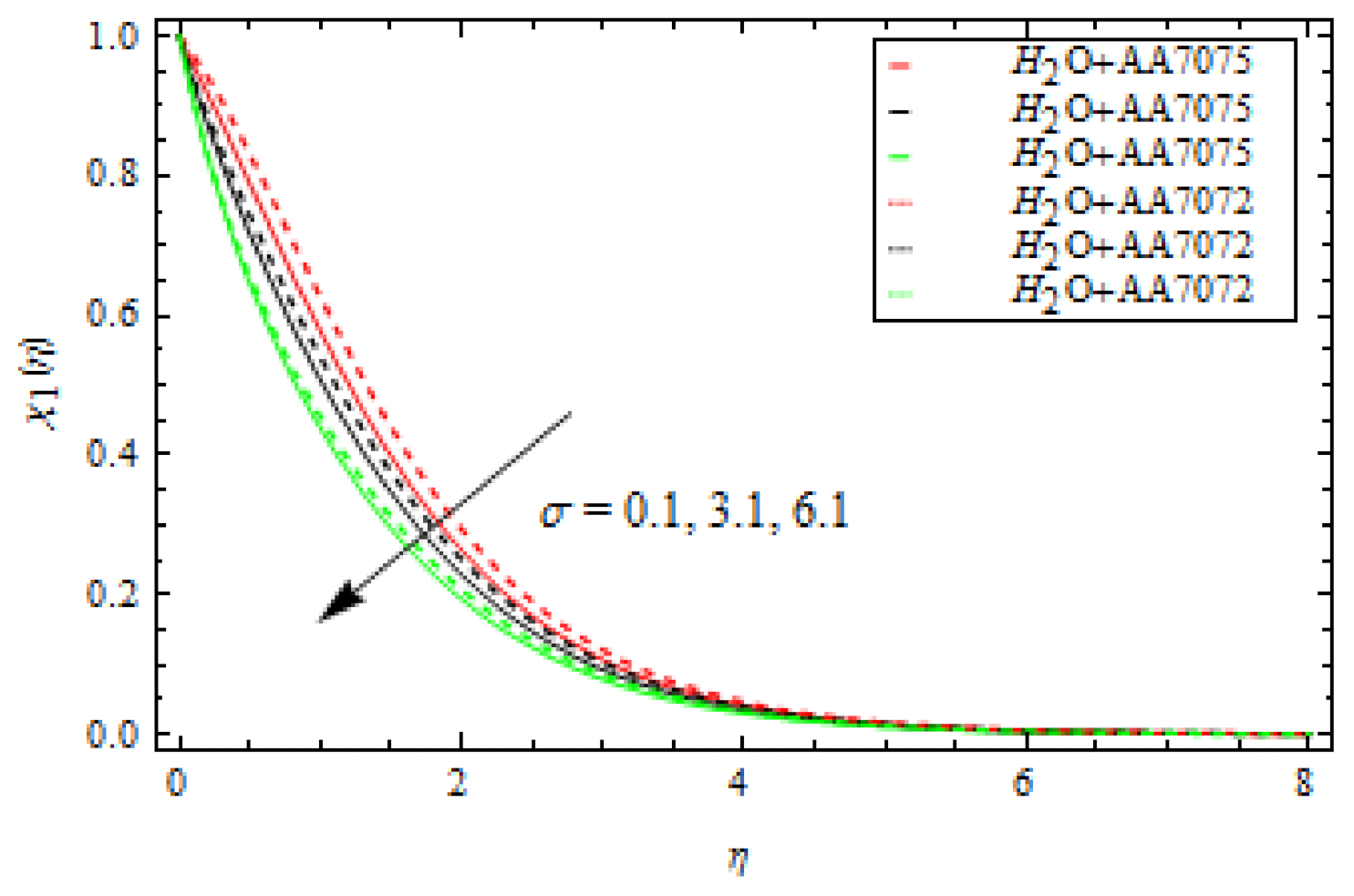

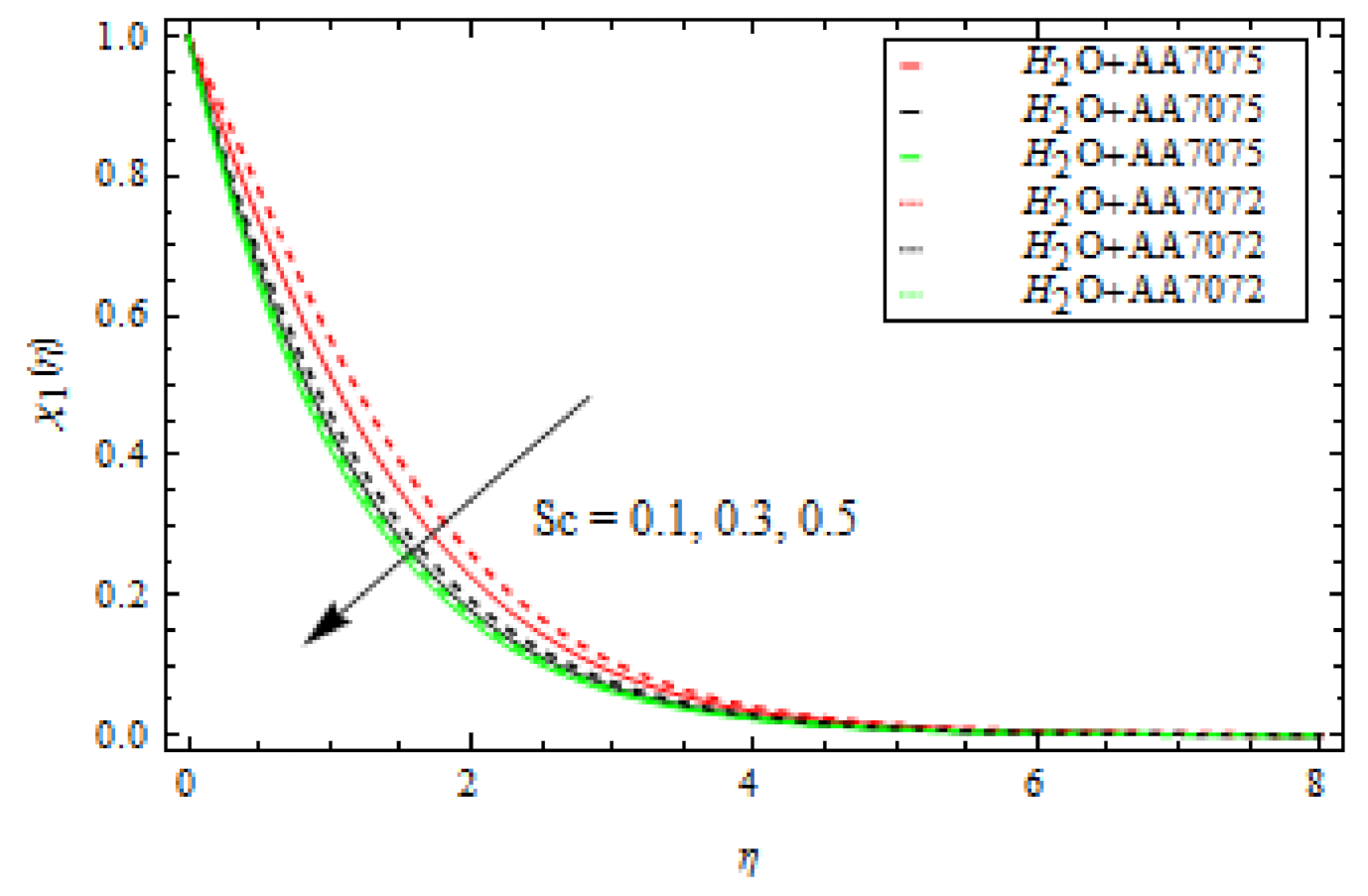

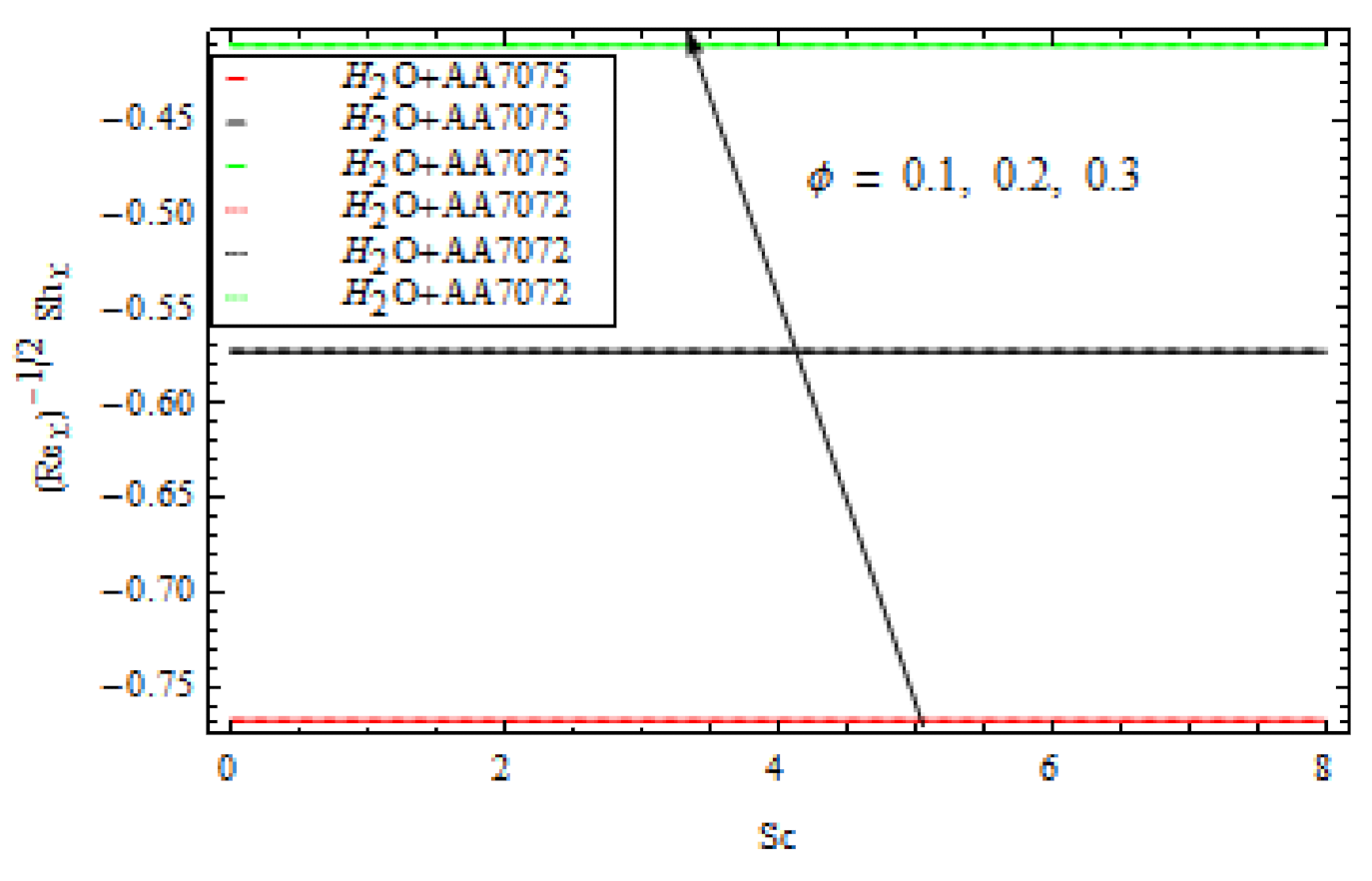

- A growth in the reaction rate parameter and the Schmidt number brings down the concentration profile. Similarly, all parameters negatively influence the concentration profile of alloy , which drops quicker than the concentration profile of alloy .

- An improvement in the volume fraction enhances the surface drag force; however, an improvement in the ferromagnetic interaction decreases the surface drag force.

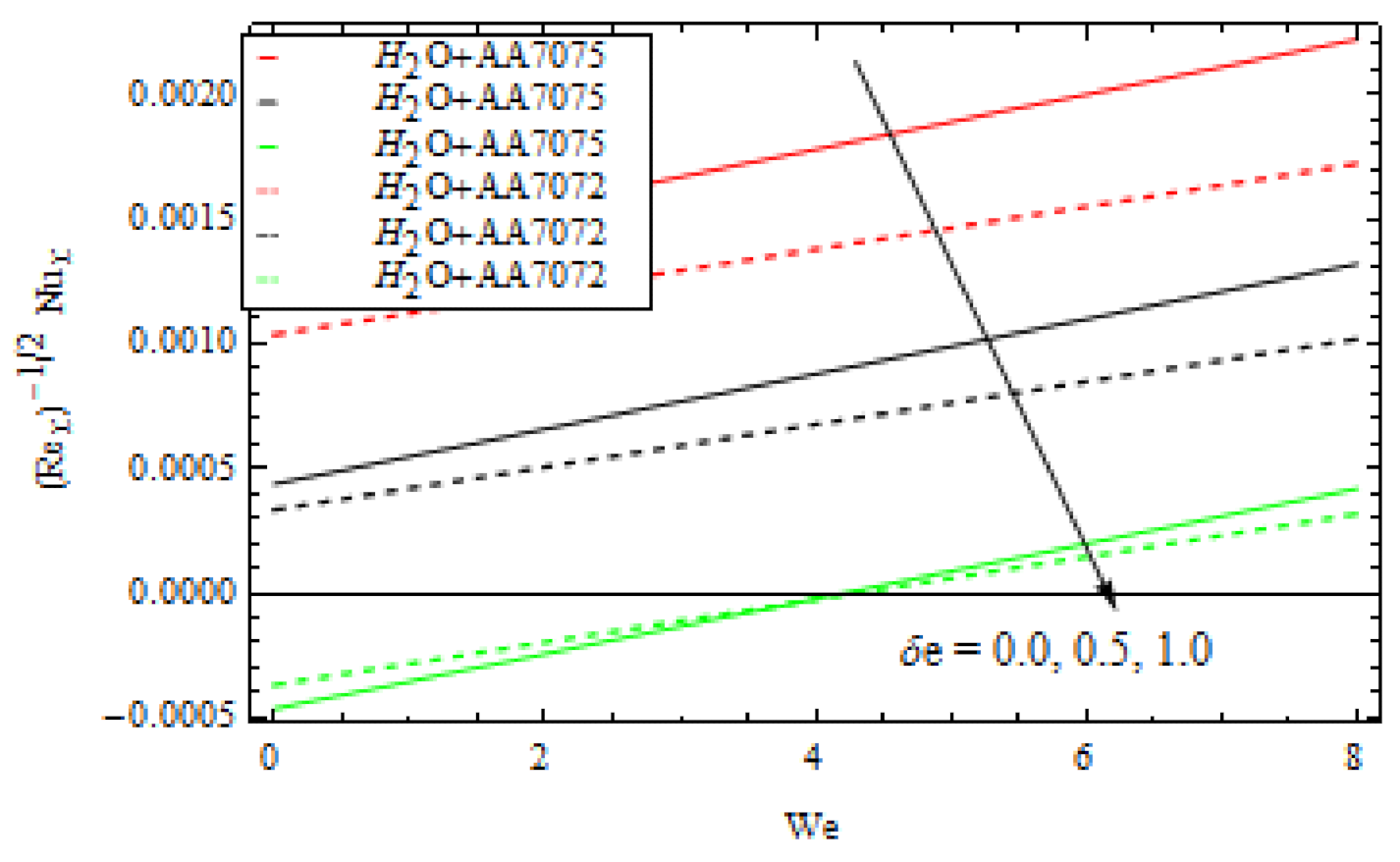

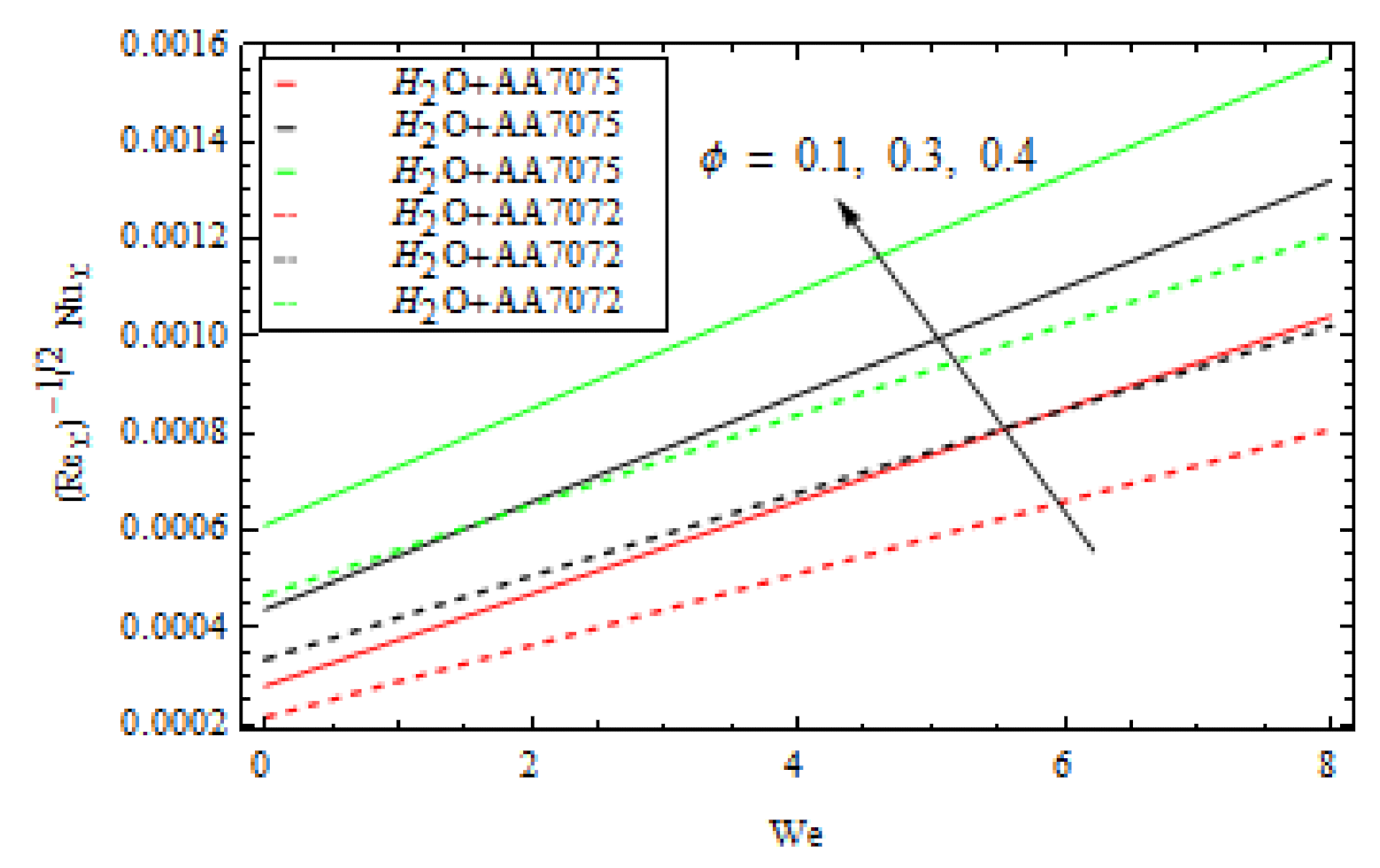

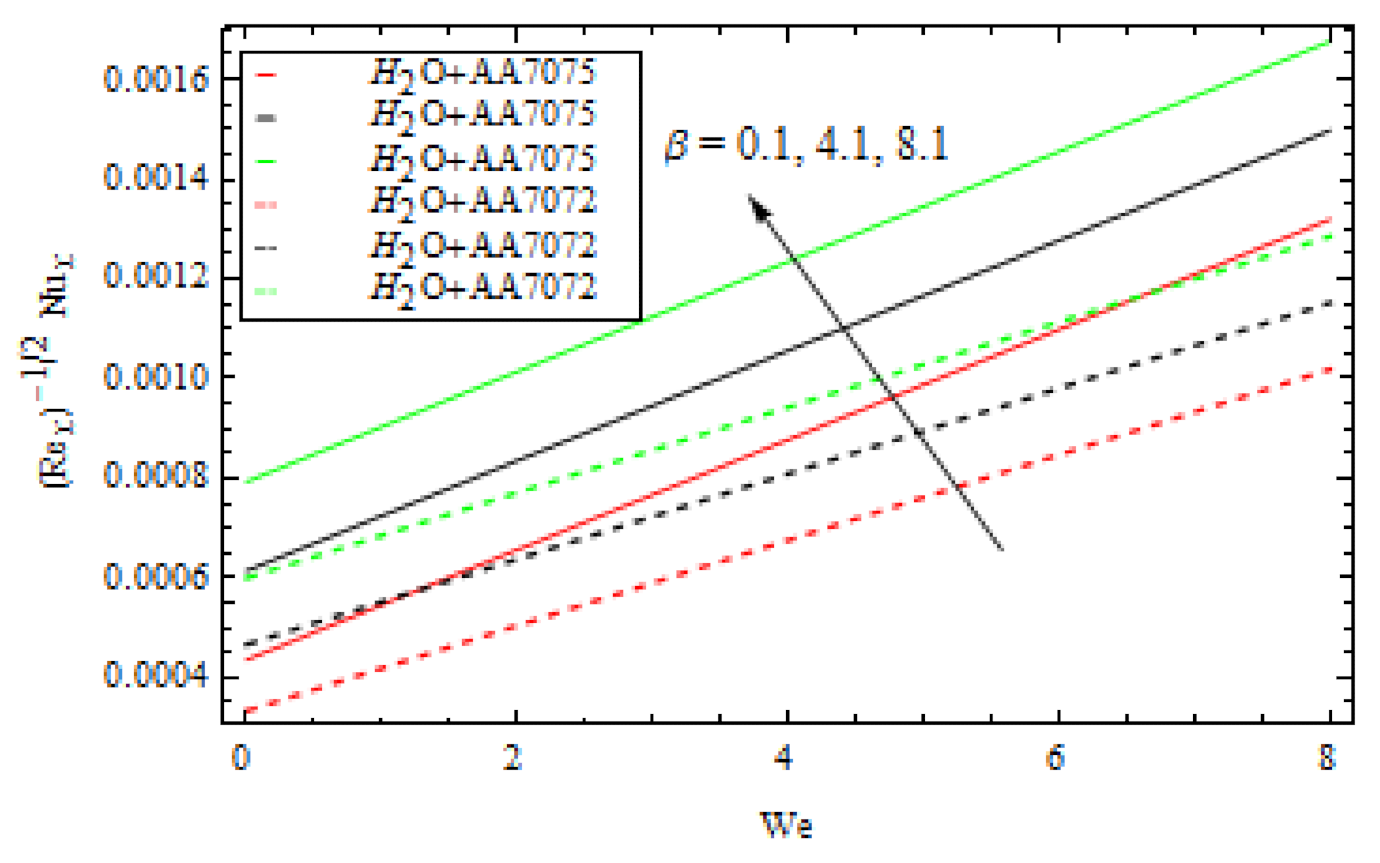

- The Nusselt number rises as the volume fraction and ferromagnetic interaction grow; however it falls as the thermal relaxation parameter rises.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Distance | |

| Constant | |

| Specific heat transfer | |

| Concentration | |

| Thermal conductivity | |

| K | Constant |

| H | Magnetic field intensity |

| M | Magnetisation |

| Pr | Prandtl number |

| Re | Local Reynolds number |

| Sc | Schmidt number |

| T | Temperature of fluid |

| u, v | Velocity components |

| We | Weissenberg number |

| x, y | Coordinates axis |

| Greek Letter | |

| α | Dimensionless distance |

| β | Ferromagnetic interaction parameter |

| Constant | |

| Material constant of the fluid | |

| Dimensionless Curie temperature | |

| Thermal relaxation parameter | |

| Independent coordinate | |

| Dimensionless temperature profile | |

| Viscous dissipation parameter | |

| Thermal relaxation time | |

| Dynamic viscosity | |

| Magnetic permeability | |

| Kinematic viscosity | |

| Density | |

| Heat capacitance | |

| Reaction rate parameter | |

| Scalar potential | |

| Volume fraction | |

| Dimensionless concentration profile | |

| Stream function | |

| Subscript | |

| Fluid | |

| Nanofluid | |

| Curie | |

| Surface | |

| Solid particle | |

References

- Choi, S.U.; Eastman, J.A. Enhancing thermal conductivity of fluids with nanoparticles. ASME Int. Mech. Eng. Congr. Expo. 1995, 10, 12–17. [Google Scholar]

- Kishan, N.; Deepa, G. Viscous Dissipation Effects on Stagnation Point Flow and Heat Transfer of a Micropolar Fluid with Uniform Suction or Blowing. Adv. Appl. Sci. Res. 2012, 3, 430–439. [Google Scholar]

- Alim, M.; Alam, M.; Mamun, A.A.; Hossain, B. Combined effect of viscous dissipation and joule heating on the coupling of conduction and free convection along a vertical flat plate. Int. Commun. Heat Mass Transf. 2008, 35, 338–346. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Hatami, M.; Ganji, D. Nanofluid flow and heat transfer in a rotating system in the presence of a magnetic field. J. Mol. Liq. 2014, 190, 112–120. [Google Scholar] [CrossRef]

- He, W.; Mashayekhi, R.; Toghraie, D.; Akbari, O.A.; Li, Z.; Tlili, I. Hydrothermal performance of nanofluid flow in a sinusoidal double layer microchannel in order to geometric optimization. Int. Commun. Heat Mass Transf. 2020, 117, 104700. [Google Scholar] [CrossRef]

- Mahdavi, M.; Sharifpur, M.; Meyer, J.P. Fluid flow and heat transfer analysis of nanofluid jet cooling on a hot surface with various roughness. Int. Commun. Heat Mass Transf. 2020, 118, 104842. [Google Scholar] [CrossRef]

- Abdelsalam, S.I.; Mekheimer, K.; Zaher, A. Alterations in blood stream by electroosmotic forces of hybrid nanofluid through diseased artery: Aneurysmal/stenosed segment. Chin. J. Phys. 2020, 67, 314–329. [Google Scholar] [CrossRef]

- Nadeem, S.; Israr-Ur-Rehman, M.; Saleem, S.; Bonyah, E. Dual solutions in MHD stagnation point flow of nanofluid induced by porous stretching/shrinking sheet with anisotropic slip. AIP Adv. 2020, 10, 065207. [Google Scholar] [CrossRef]

- Khan, U.; Waini, I.; Ishak, A.; Pop, I. Unsteady hybrid nanofluid flow over a radially permeable shrinking/stretching surface. J. Mol. Liq. 2021, 331, 115752. [Google Scholar] [CrossRef]

- Abbas, N.; Nadeem, S.; Saleem, S.; Issakhov, A. Transportation of modified nanofluid flow with time dependent viscosity over a Riga plate: Exponentially stretching. Ain Shams Eng. J. 2021, 12, 3967–3973. [Google Scholar] [CrossRef]

- Awais, M.; Awan, S.E.; Raja, M.; Nawaz, M.; Khan, W.; Malik, M.Y.; He, Y. Heat Transfer in Nanomaterial Suspension (CuO and Al2O3) Using KKL Model. Coatings 2021, 11, 417. [Google Scholar] [CrossRef]

- Sandeep, N.; Animasaun, I. Heat transfer in wall jet flow of magnetic-nanofluids with variable magnetic field. Alex. Eng. J. 2017, 56, 263–269. [Google Scholar] [CrossRef]

- Kandasamy, R.; Adnan, N.A.B.; Abbood, J.A.A.; Kamarulzaki, M.; Saifullah, M. Electric field strength on water based aluminum alloys nanofluids flow up a non-linear inclined sheet. Eng. Sci. Technol. Int. J. 2018, 22, 229–236. [Google Scholar] [CrossRef]

- Tlili, I.; Nabwey, H.A.; Ashwinkumar, G.; Sandeep, N. 3-D magnetohydrodynamic AA7072-AA7075/methanol hybrid nanofluid flow above an uneven thickness surface with slip effect. Sci. Rep. 2020, 10, 4265. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, J.; Shahzad, A.; Khan, M.; Ali, R. A note on convective heat transfer of an MHD Jeffrey fluid over a stretching sheet. AIP Adv. 2015, 5, 117117. [Google Scholar] [CrossRef] [Green Version]

- Masood, K.H.A.N.; Ramzan, A.L.I.; Shahzad, A. MHD Falkner-Skan Flow with Mixed Convection and Convective Boundary Conditions. Walailak J. Sci. Technol. 2013, 10, 517–529. [Google Scholar] [CrossRef]

- Malik, M.; Salahuddin, T.; Hussain, A.; Bilal, S. MHD flow of tangent hyperbolic fluid over a stretching cylinder: Using Keller box method. J. Magn. Magn. Mater. 2015, 395, 271–276. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Rashidi, M.; Hayat, T.; Ganji, D. Free convection of magnetic nanofluid considering MFD viscosity effect. J. Mol. Liq. 2016, 218, 393–399. [Google Scholar] [CrossRef]

- Crane, L.J. Flow past a stretching plate. Z. Für Angew. Math. Und Phys. 1970, 21, 645–647. [Google Scholar] [CrossRef]

- Brady, J.F.; Acrivos, A. Steady flow in a channel or tube with an accelerating surface velocity. An exact solution to the Navier—Stokes equations with reverse flow. J. Fluid Mech. 1981, 112, 127–150. [Google Scholar] [CrossRef]

- Wang, C.Y. Fluid flow due to a stretching cylinder. Phys. Fluids 1988, 31, 466. [Google Scholar] [CrossRef]

- Elbashbeshy, E.M.; Aldawody, D.A. Heat transfer over an unsteady stretching surface with variable heat flux in the presence of a heat source or sink. Comput. Math. Appl. 2010, 60, 2806–2811. [Google Scholar] [CrossRef] [Green Version]

- Nadeem, S.; Hussain, A.; Khan, M. HAM solutions for boundary layer flow in the region of the stagnation point towards a stretching sheet. Commun. Nonlinear Sci. Numer. Simul. 2010, 15, 475–481. [Google Scholar] [CrossRef]

- Awan, A.U.; Abid, S.; Ullah, N.; Nadeem, S. Magnetohydrodynamic oblique stagnation point flow of second grade fluid over an oscillatory stretching surface. Results Phys. 2020, 18, 103233. [Google Scholar] [CrossRef]

- Jawad, M.; Saeed, A.; Gul, T. Entropy Generation for MHD Maxwell Nanofluid Flow Past a Porous and Stretching Surface with Dufour and Soret Effects. Braz. J. Phys. 2021, 51, 469–480. [Google Scholar] [CrossRef]

- Bestman, A.R. Natural convection boundary layer with suction and mass transfer in a porous medium. Int. J. Energy Res. 1990, 14, 389–396. [Google Scholar] [CrossRef]

- Mustafaa, M.; Hayat, T.; Obaidat, S. Boundary layer flow of a nanofluid over an exponentially stretching sheet with convective boundary conditions. Int. J. Numer. Methods Heat Fluid Flow 2013, 23, 945–959. [Google Scholar] [CrossRef]

- Mohyud-Din, S.T.; Khan, U.; Ahmed, N.; Bin-Mohsin, B. Heat and mass transfer analysis for MHD flow of nanofluid inconvergent/divergent channels with stretchable walls using Buongiorno’s model. Neural Comput. Appl. 2016, 28, 4079–4092. [Google Scholar] [CrossRef]

- Aleem, M.; Asjad, M.I.; Shaheen, A.; Khan, I. MHD Influence on different water based nanofluids (TiO2, Al2O3, CuO) in porous medium with chemical reaction and Newtonian heating. Chaos Solitons Fractals 2019, 130, 109437. [Google Scholar] [CrossRef]

- Hayat, T.; Khan, S.A.; Khan, M.I.; Alsaedi, A. Theoretical investigation of Ree–Eyring nanofluid flow with entropy optimization and Arrhenius activation energy between two rotating disks. Comput. Methods Programs Biomed. 2019, 177, 57–68. [Google Scholar] [CrossRef]

- Tanveer, A.; Malik, M. Slip and porosity effects on peristalsis of MHD Ree-Eyring nanofluid in curved geometry. Ain Shams Eng. J. 2020, 12, 955–968. [Google Scholar] [CrossRef]

- Khan, M.I.; Kadry, S.; Chu, Y.-M.; Khan, W.A.; Kumar, A. Exploration of Lorentz force on a paraboloid stretched surface in flow of Ree-Eyring nanomaterial. J. Mater. Res. Technol. 2020, 9, 10265–10275. [Google Scholar] [CrossRef]

- Al-Mdallal, Q.M.; Renuka, A.; Muthtamilselvan, M.; Abdalla, B. Ree-Eyring fluid flow of Cu-water nanofluid between infinite spinning disks with an effect of thermal radiation. Ain Shams Eng. J. 2021, 12, 2947–2956. [Google Scholar] [CrossRef]

- Rao, D.P.C.; Thiagarajan, S.; Kumar, V.S. Darcy-Forchheimer flow of Ree–Eyring fluid over an inclined plate with chemical reaction: A statistical approach. Heat Transf. 2021, 50, 7120–7138. [Google Scholar] [CrossRef]

- Zeeshan, A.; Majeed, A. Effect of Magnetic Dipole on Radiative Non-Darcian Mixed Convective Flow over a Stretching Sheet in Porous Medium. J. Nanofluids 2016, 5, 617–626. [Google Scholar] [CrossRef]

- Prasannakumara, B. Numerical simulation of heat transport in Maxwell nanofluid flow over a stretching sheet considering magnetic dipole effect. Partial Differ. Equations Appl. Math. 2021, 4, 100064. [Google Scholar] [CrossRef]

- Souayeh, B.; Yasin, E.; Alam, M.W.; Hussain, S.G. Numerical Simulation of Magnetic Dipole Flow Over a Stretching Sheet in the Presence of Non-Uniform Heat Source/Sink. Front. Energy Res. 2021, 9, 824. [Google Scholar] [CrossRef]

- García-Merino, J.A.; Torres-Torres, D.; Carrillo-Delgado, C.; Trejo-Valdez, M.; Torres-Torres, C. Trejo-Valdez and C. Torres-Torres Optofluidic and strain measurements induced by polarization-resolved nanosecond pulses in gold-based nanofluids. Optik 2019, 182, 443–451. [Google Scholar] [CrossRef]

| HAM Solution | Numerical Solution | Absolute Error | |

|---|---|---|---|

| HAM Solution | Numerical Solution | Absolute Error | |

|---|---|---|---|

| HAM Solution | Numerical Solution | Absolute Error | |

|---|---|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, Z.; Vrinceanu, N.; Rooman, M.; Deebani, W.; Shutaywi, M. Mathematical Modelling of Ree-Eyring Nanofluid Using Koo-Kleinstreuer and Cattaneo-Christov Models on Chemically Reactive AA7072-AA7075 Alloys over a Magnetic Dipole Stretching Surface. Coatings 2022, 12, 391. https://doi.org/10.3390/coatings12030391

Shah Z, Vrinceanu N, Rooman M, Deebani W, Shutaywi M. Mathematical Modelling of Ree-Eyring Nanofluid Using Koo-Kleinstreuer and Cattaneo-Christov Models on Chemically Reactive AA7072-AA7075 Alloys over a Magnetic Dipole Stretching Surface. Coatings. 2022; 12(3):391. https://doi.org/10.3390/coatings12030391

Chicago/Turabian StyleShah, Zahir, Narcisa Vrinceanu, Muhammad Rooman, Wejdan Deebani, and Meshal Shutaywi. 2022. "Mathematical Modelling of Ree-Eyring Nanofluid Using Koo-Kleinstreuer and Cattaneo-Christov Models on Chemically Reactive AA7072-AA7075 Alloys over a Magnetic Dipole Stretching Surface" Coatings 12, no. 3: 391. https://doi.org/10.3390/coatings12030391

APA StyleShah, Z., Vrinceanu, N., Rooman, M., Deebani, W., & Shutaywi, M. (2022). Mathematical Modelling of Ree-Eyring Nanofluid Using Koo-Kleinstreuer and Cattaneo-Christov Models on Chemically Reactive AA7072-AA7075 Alloys over a Magnetic Dipole Stretching Surface. Coatings, 12(3), 391. https://doi.org/10.3390/coatings12030391