A Review of In-Service Coating Health Monitoring Technologies: Towards “Smart” Neural-Like Networks for Condition-Based Preventive Maintenance

Abstract

:1. Introduction

2. Organic Coating Generalities

3. Organic Coating-Embedded Health Monitoring Technologies

3.1. Evolution of the Electrochemical Properties of Coatings

3.1.1. Electrochemical Impedance Spectroscopy (EIS)

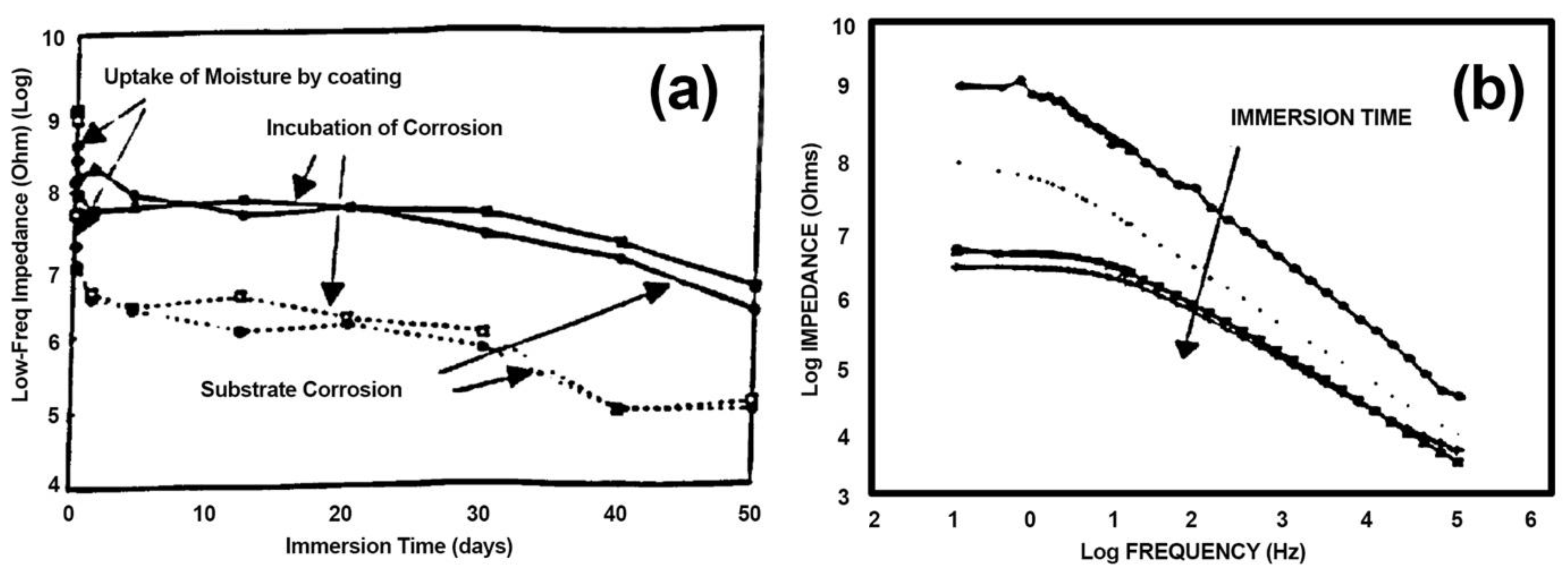

- The uptake of moisture by the coating,

- Corrosion incubation time,

- The corrosion of the substrate.

3.1.2. Electrochemical Noise Measurements (ENM)

3.1.3. Potentiodynamic Polarisation Measurement (PDP)

3.2. Evolution of the Internal Stress–Strain State of Coatings

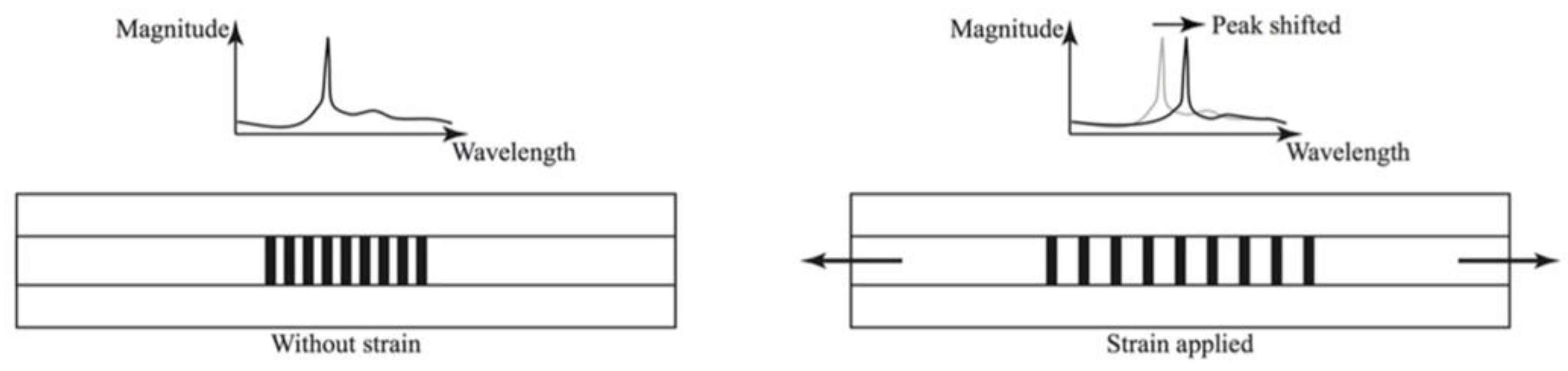

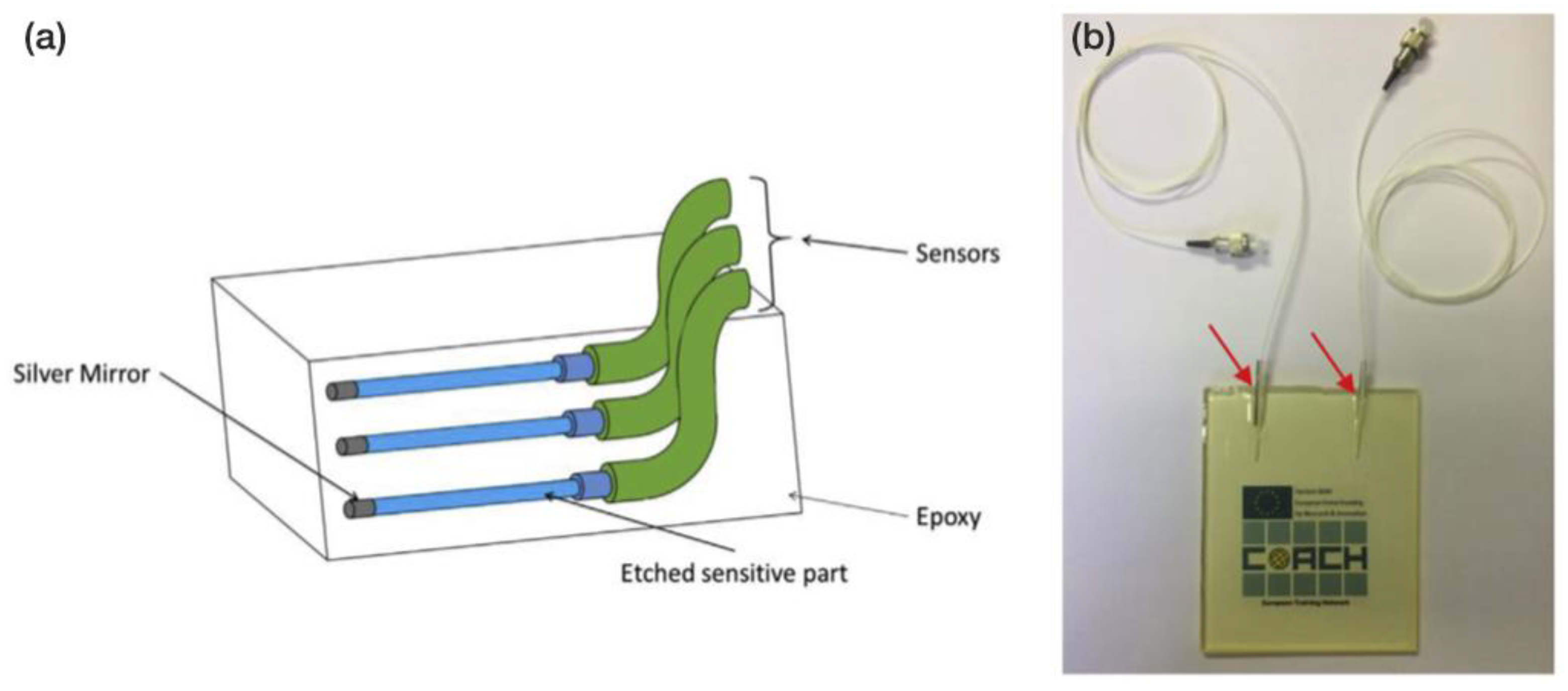

3.2.1. Optical Fibres–Fibre Bragg Gratings

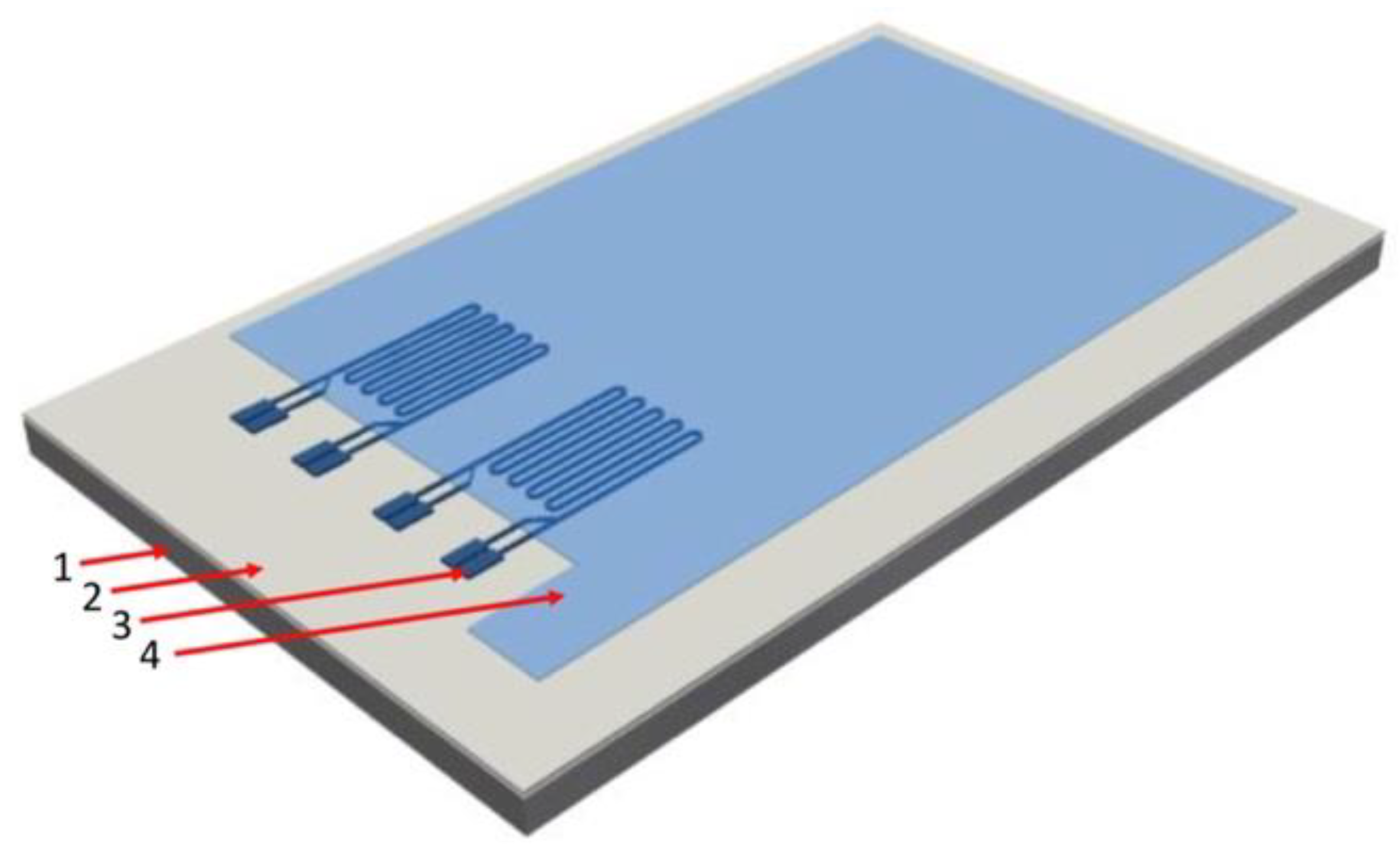

3.2.2. Embedded Piezoresistive-Based Strain Gauges

3.3. Other Technologies

4. Connectivity and Sensor Networks: Towards Neural Systems and Industry 4.0

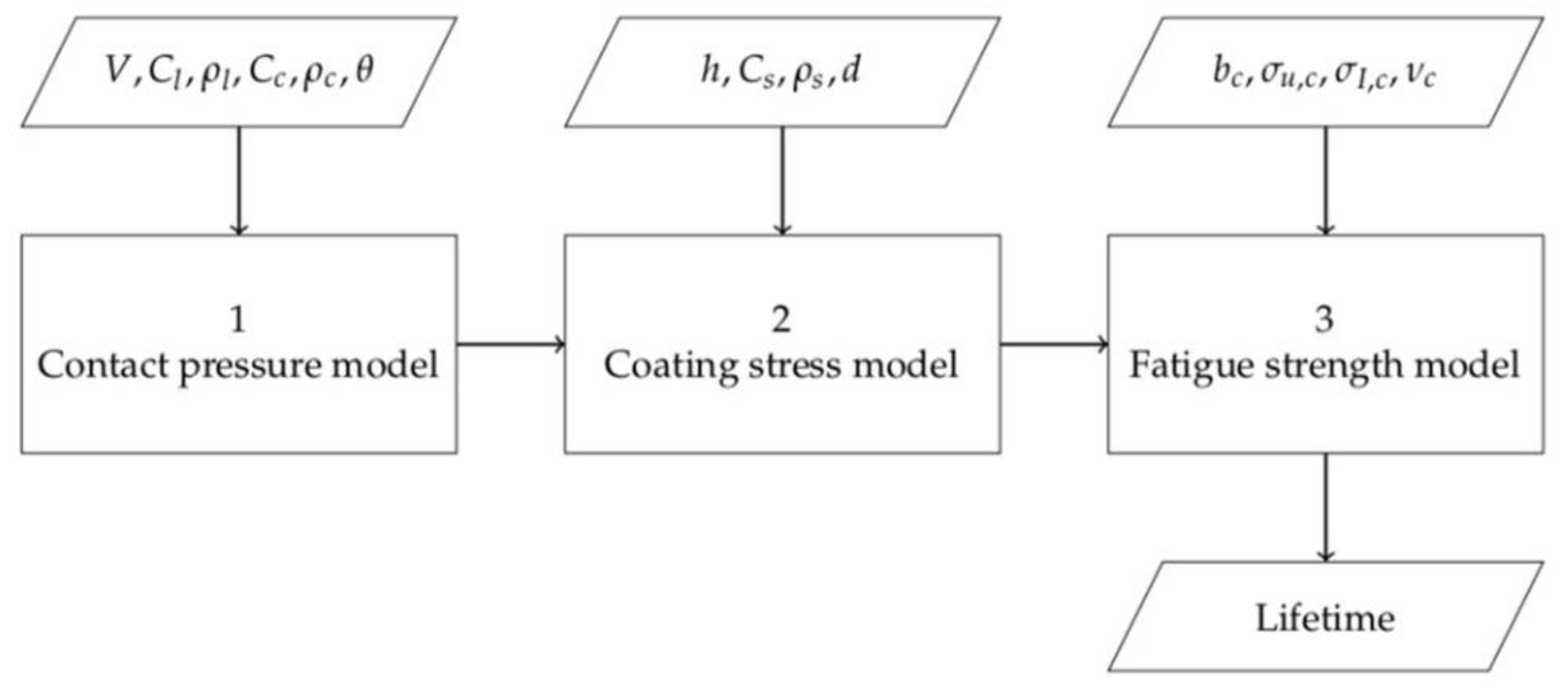

5. Modelling of Coating Behaviour

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kendig, M.; Mills, D.J. An historical perspective on the corrosion protection by paints. Prog. Org. Coat. 2017, 102, 53–59. [Google Scholar] [CrossRef] [Green Version]

- Fayomi, O.S.I.; Akande, I.G.; Odigie, S. Economic impact of corrosion in oil sectors and prevention: An overview. J. Phys. Conf. Ser. 2019, 1378, 022037. [Google Scholar] [CrossRef]

- Soliman, M.; Frangopol, D.M. Life-Cycle Cost Evaluation of Conventional and Corrosion-Resistant Steel for Bridges. J. Bridge Eng. 2015, 20, 06014005. [Google Scholar] [CrossRef] [Green Version]

- Shekari, E.; Khan, F.; Ahmed, S. Economic risk analysis of pitting corrosion in process facilities. Int. J. Press. Vessels Pip. 2017, 157, 51–62. [Google Scholar] [CrossRef]

- Ulaeto, S.B.; Rajan, R.; Pancrecious, J.K.; Rajan, T.P.D.; Pai, B.C. Developments in smart anticorrosive coatings with multifunctional characteristics. Prog. Org. Coat. 2017, 111, 294–314. [Google Scholar] [CrossRef]

- Feng, W.; Patel, S.H.; Young, M.-Y.; Zunino, J.L.; Xanthos, M. Smart Polymeric Coatings—Recent Advances. Adv. Polym. Technol. 2012, 32, 474–485. [Google Scholar] [CrossRef]

- Li, W.; Hintze, P.; Calle, L.M.; Buhrow, J.; Curran, J.; Muehlberg, A.J.; Gelling, V.J.; Webster, D.C.; Croll, S.G.; Contu, F.; et al. Smart coating for corrosion indication and prevention: Recent progress. In Proceedings of the CORROSION 2009, Atlanta, Georgia, 22–26 March 2009. [Google Scholar]

- Al-Saffar, Y.; Aldraihem, O.; Baz, A. Smart paint sensor for monitoring structural vibrations. Smart Mater. Struct. 2012, 21, 045004. [Google Scholar] [CrossRef]

- Egusa, S.; Iwasawa, N. Piezoelectric paints as one approach to smart structural materials with health-monitoring capabilities. Smart Mater. Struct. 1998, 7, 438–445. [Google Scholar] [CrossRef]

- Gray, H.N.; Jorgensen, B.; McClaugherty, D.L.; Kippenberger, A. Smart polymeric coatings for surface decontamination. Ind. Eng. Chem. Res. 2001, 40, 3540–3546. [Google Scholar] [CrossRef]

- Zheludkevich, M.L.; Tedim, J.; Ferreira, M.G.S. “Smart” coatings for active corrosion protection based on multi-functional micro and nanocontainers. Electrochim. Acta 2012, 82, 314–323. [Google Scholar] [CrossRef]

- Nazeer, A.A.; Madkour, M. Potential use of smart coatings for corrosion protection of metals and alloys: A review. J. Mol. Liq. 2018, 253, 11–22. [Google Scholar] [CrossRef]

- Lemartinel, A.; Castro, M.; Fouché, O.; De Luca, J.C.; Feller, J.F. A review of nanocarbon-based solutions for the structural health monitoring of composite parts used in renewable energies. J. Compos. Sci. 2022, 6, 32. [Google Scholar] [CrossRef]

- Zhao, X.; Gao, H.; Zhang, G.; Ayhan, B.; Yan, F.; Kwan, C.; Rose, J.L. Active health monitoring of an aircraft wing with embedded piezoelectric sensor/actuator network: I. Defect detection, localization and growth monitoring. Smart Mater. Struct. 2007, 16, 1208–1217. [Google Scholar] [CrossRef]

- Qing, X.; Li, W.; Wang, Y.; Sun, H. Piezoelectric transducer-based structural health monitoring for aircraft applications. Sensors 2019, 19, 545. [Google Scholar] [CrossRef] [PubMed]

- Webb, G.T.; Vardanega, P.J.; Middleton, C.R. Categories of SHM Deployments: Technologies and Capabilities. J. Bridge Eng. 2014, 20, 04014118. [Google Scholar] [CrossRef] [Green Version]

- Muralidharan, S.; Saraswathy, V.; Madhavamayandi, A.; Thangavel, K.; Palaniswamy, N. Evaluation of embeddable potential sensor for corrosion monitoring in concrete structures. Electrochim. Acta 2008, 53, 7248–7254. [Google Scholar] [CrossRef]

- Angst, U.M. Challenges and opportunities in corrosion of steel in concrete. Mater. Struct. Constr. 2018, 51, 4. [Google Scholar] [CrossRef] [Green Version]

- Martínez, I.; Andrade, C. Examples of reinforcement corrosion monitoring by embedded sensors in concrete structures. Cem. Concr. Compos. 2009, 31, 545–554. [Google Scholar] [CrossRef]

- Muralidharan, S.; Saraswathy, V.; Berchmans, L.J.; Thangavel, K.; Ann, K.Y. Nickel ferrite (NiFe2O4): A possible candidate material as reference electrode for corrosion monitoring of steel in concrete environments. Sens. Actuators B Chem. 2010, 145, 225–231. [Google Scholar] [CrossRef]

- Khadra, M.; Marie-Victoire, E.; Bouichou, M.; Crémona, C.; Vildaer, S. New warning sensors to detect corrosion risk in reinforced concrete. MATEC Web Conf. 2019, 289, 06002. [Google Scholar] [CrossRef]

- Song, F.M.; Brossia, S.; Dunn, D.; Sridhar, N. New permanent reference electrode for protection of underground pipelines and storage tanks. Corros. Eng. Sci. Technol. 2005, 40, 262–269. [Google Scholar] [CrossRef]

- Yu, L.; Giurgiutiu, V.; Pollock, P. A Multi-Mode Sensing System for Corrosion Detection Using Piezoelectric Wafer Active Sensors; Tomizuka, M., Ed.; International Society for Optics and Photonics: San Diego, CA, USA, 2008; Volume 6932, p. 69322H. [Google Scholar]

- Lemartinel, A. Development of Self-Sensing Structural Composites Parts for Wind Mill Blades Monitoring; University of South Brittany (UBS): Lorient, France, 2017. [Google Scholar]

- De Luca, J.C.; Feller, J.F.; Castro, M.; Fouche, O.; Lascoup, B.; Raujol, J.; Lemartinel, A. Structural strain monitoring of a composite scaled turbine blade using embedded QRS sensoring. In Structural Health Monitoring 2019: Enabling Intelligent Life-Cycle Health Management for Industry Internet of Things (IIOT), Proceedings of the 12th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 10–12 September 2019; DEStech Publications, Inc.: Lancaster, PA, USA, 2019; Volume 2. [Google Scholar]

- Diler, E.; Lédan, F.; LeBozec, N.; Thierry, D. Real-time monitoring of the degradation of metallic and organic coatings using electrical resistance sensors. Mater. Corros. 2017, 68, 1365–1376. [Google Scholar] [CrossRef]

- LeBozec, N.; Thierry, D.; Le Calvé, P.; Favennec, C.; Pautasso, J.P.; Hubert, C. Performance of marine and offshore paint systems: Correlation of accelerated corrosion tests and field exposure on operating ships. Mater. Corros. 2015, 66, 215–225. [Google Scholar] [CrossRef]

- Trinchi, A.; Muster, T.H.; Cole, I.S.; Dunlop, J.B.; Collocott, S.J. Embedded magnetic nanoparticle sensors for monitoring primer failure beneath paint. Sens. Actuators B Chem. 2015, 210, 446–452. [Google Scholar] [CrossRef]

- Marro Bellot, C.; Olivero, M.; Sangermano, M.; Salvo, M. Towards self-diagnosis composites: Detection of moisture diffusion through epoxy by embedded evanescent wave optical fibre sensors. Polym. Test. 2018, 71, 248–254. [Google Scholar] [CrossRef]

- Wilson, A.R.; Muscat, R.F. Novel thin wire paint and sealant degradation sensor. Sens. Actuators A Phys. 2011, 169, 301–307. [Google Scholar] [CrossRef]

- Li, Y.; Feng, W.; Meng, L.; Tse, K.M.; Li, Z.; Huang, L.; Su, Z.; Guo, S. Investigation on in-situ sprayed, annealed and corona poled PVDF-TrFE coatings for guided wave-based structural health monitoring: From crystallization to piezoelectricity. Mater. Des. 2021, 199, 109415. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Structural health monitoring with piezoelectric wafer active sensors. In Proceedings of the 16th International Conference on Adaptive Structures and Technologies, Paris, France, 9–12 October 2005; pp. 94–100. [Google Scholar]

- Gu, X.; Stanley, D.; Byrd, W.E.; Dickens, B.; Vaca-Trigo, I.; Meeker, W.Q.; Nguyen, T.; Chin, J.W.; Martin, J.W. Linking Accelerated Laboratory Test with Outdoor Performance Results for a Model Epoxy Coating System. In Service Life Prediction of Polymeric Materials; Springer: Boston, MA, USA, 2009. [Google Scholar]

- White, J.R. Polymer ageing: Physics, chemistry or engineering? Time to reflect. Comptes Rendus Chim. 2006, 9, 1396–1408. [Google Scholar] [CrossRef]

- Jacques, L.F.E. Accelerated and outdoor/natural exposure testing of coatings. Prog. Polym. Sci. 2000, 25, 1337–1362. [Google Scholar] [CrossRef]

- Deflorian, F.; Rossi, S.; Fedrizzi, L.; Zanella, C. Comparison of organic coating accelerated tests and natural weathering considering meteorological data. Prog. Org. Coat. 2007, 59, 244–250. [Google Scholar] [CrossRef]

- Perrin, F.X.; Merlatti, C.; Aragon, E.; Margaillan, A. Degradation study of polymer coating: Improvement in coating weatherability testing and coating failure prediction. Prog. Org. Coat. 2009, 64, 466–473. [Google Scholar] [CrossRef]

- Perrin, F.X.; Irigoyen, M.; Aragon, E.; Vernet, J.L. Evaluation of accelerated weathering tests for three paint systems: A comparative study of their aging behaviour. Polym. Degrad. Stab. 2001, 72, 115–124. [Google Scholar] [CrossRef]

- Lyon, S.B.; Bingham, R.; Mills, D.J. Advances in corrosion protection by organic coatings: What we know and what we would like to know. Prog. Org. Coat. 2017, 102, 2–7. [Google Scholar] [CrossRef] [Green Version]

- Skerry, B.S.; Simpson, C.H. Corrosion and Weathering of Paints for Atmospheric Corrosion Control. Corrosion 2010, 49, 663–674. [Google Scholar] [CrossRef]

- Kenny, E.D.; Paredes, R.S.C.; de Lacerda, L.A.; Sica, Y.C.; de Souza, G.P.; Lázaris, J. Artificial neural network corrosion modeling for metals in an equatorial climate. Corros. Sci. 2009, 51, 2266–2278. [Google Scholar] [CrossRef]

- Ma, T.N.G.; Abu, A.J. A field study of outdoor atmospheric corrosion rates of mild steel around Kaduna metropolis. Int. J. Mech. Eng. 2018, 5, 7–21. [Google Scholar] [CrossRef]

- Guerguer, M.; Naamane, S.; Raccurt, O.; Bouaouine, H. Neural network modeling of Moroccan weather conditions effect on solar reflectors degradation. AIP Conf. Proc. 2020, 2303, 150008. [Google Scholar]

- Popova, K.; Prošek, T. Corrosion Monitoring in Atmospheric Conditions: A Review. Metals 2022, 12, 171. [Google Scholar] [CrossRef]

- Nordhorn, C.; Mücke, R.; Mack, D.E.; Vaßen, R. Probabilistic lifetime model for atmospherically plasma sprayed thermal barrier coating systems. Mech. Mater. 2016, 93, 199–208. [Google Scholar] [CrossRef]

- Tian, W.; Meng, F.; Liu, L.; Li, Y.; Wang, F. Lifetime prediction for organic coating under alternating hydrostatic pressure by artificial neural network. Sci. Rep. 2017, 7, 40827. [Google Scholar] [CrossRef] [Green Version]

- Olivier, M.G.; Fedel, M.; Sciamanna, V.; Vandermiers, C.; Motte, C.; Poelman, M.; Deflorian, F. Study of the effect of nanoclay incorporation on the rheological properties and corrosion protection by a silane layer. Prog. Org. Coat. 2011, 72, 15–20. [Google Scholar] [CrossRef]

- Upadhyay, V.; Allahar, K.N.; Bierwagen, G.P. Environmental humidity influence on a topcoat/Mg-rich primer system with embedded electrodes. Sens. Actuators B Chem. 2014, 193, 522–529. [Google Scholar] [CrossRef]

- Su, Y.; Kravets, V.G.; Wong, S.L.; Waters, J.; Geim, A.K.; Nair, R.R. Impermeable barrier films and protective coatings based on reduced graphene oxide. Nat. Commun. 2014, 5, 4843. [Google Scholar] [CrossRef] [PubMed]

- Sørensen, P.A.; Kiil, S.; Dam-Johansen, K.; Weinell, C.E. Anticorrosive coatings: A review. J. Coat. Technol. Res. 2009, 6, 135–176. [Google Scholar] [CrossRef]

- Linossier, I.; Gaillard, F.; Romand, M.; Nguyen, T. A Spectroscopic Technique for Studies of Water Transport along the Interface and Hydrolytic Stability of Polymer/Substrate Systems. J. Adhes. 1999, 70, 221–239. [Google Scholar] [CrossRef]

- Tator, K.B.; Lanterman, R. Coating deterioration: A mechanistic overview. In Proceedings of the CORROSION 2016, Vancouver, BC, Canada, 6–10 March 2016; pp. 1–12. [Google Scholar]

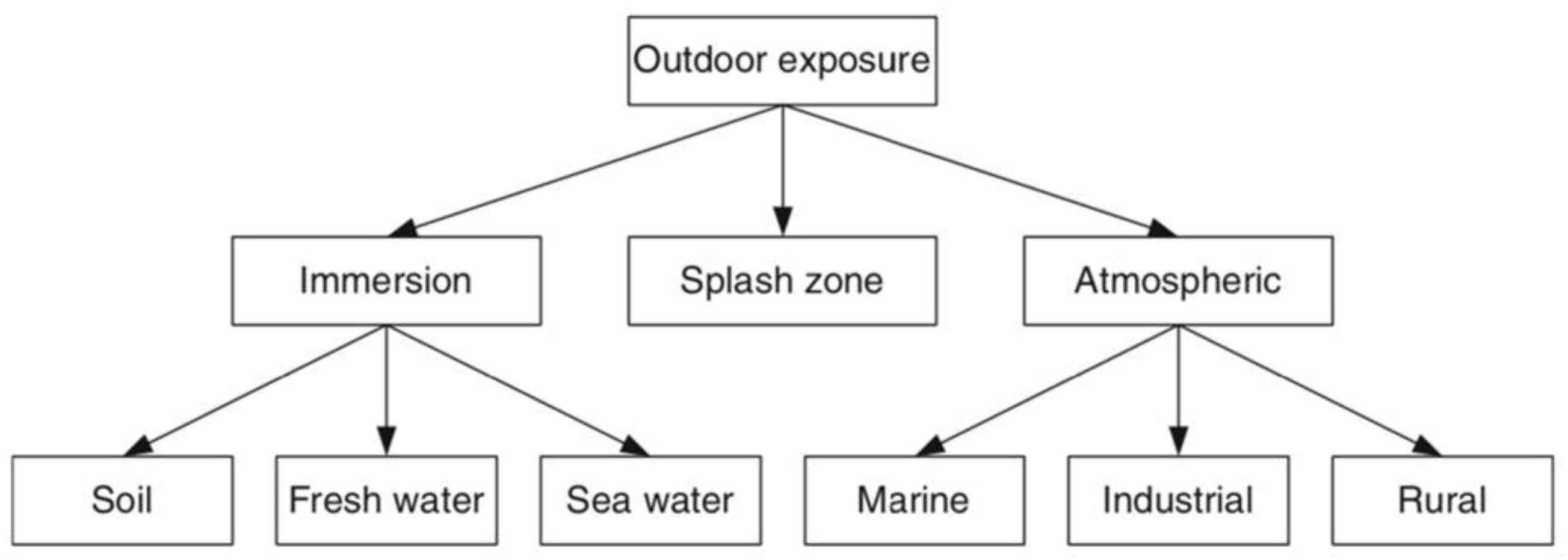

- ISO 12944; Corrosion Protection of Steel Structures by Protective Paint Systems. International Standards Organization: Geneve, Switzerland, 1998.

- Han, Y.; Wang, J.; Zhang, H.; Zhao, S.; Ma, Q.; Wang, Z. Electrochemical impedance spectroscopy (EIS): An efficiency method to monitor resin curing processes. Sens. Actuators A Phys. 2016, 250, 78–86. [Google Scholar] [CrossRef]

- Miszczyk, A.; Miszczyk, A.; Schauer, T. Electrochemical approach to evaluate the interlayer adhesion of organic coatings Article in Progress in Organic Coatings · April 2005 Tworzywa konstrukcyjne odporne na gorące kwasy mineralne 1990 View project Chemometrics methods in corrosion View project. Prog. Org. Coat. 2005, 52, 298–305. [Google Scholar] [CrossRef]

- Moreno, C.; Hernández, S.; Santana, J.J.; González-Guzmán, J.; Souto, R.M.; González, S. Characterization of water uptake by organic coatings used for the corrosion protection of steel as determined from capacitance measurements. Int. J. Electrochem. Sci. 2012, 7, 7390–7403. [Google Scholar]

- Hu, J.M.; Zhang, J.Q.; Cao, C.N. Determination of water uptake and diffusion of Cl-ion in epoxy primer on aluminum alloys in NaCl solution by electrochemical impedance spectroscopy. Prog. Org. Coat. 2003, 46, 273–279. [Google Scholar] [CrossRef]

- Duarte, R.G.; Castela, A.S.; Ferreira, M.G.S. A new model for estimation of water uptake of an organic coating by EIS: The tortuosity pore model. Prog. Org. Coat. 2009, 65, 197–205. [Google Scholar] [CrossRef]

- Nguyen, A.S.; Causse, N.; Musiani, M.; Orazem, M.E.; Pébère, N.; Tribollet, B.; Vivier, V. Determination of water uptake in organic coatings deposited on 2024 aluminium alloy: Comparison between impedance measurements and gravimetry. Prog. Org. Coat. 2017, 112, 93–100. [Google Scholar] [CrossRef] [Green Version]

- Deflorian, F.; Fedrizzi, L. Adhesion characterization of protective organic coatings by electrochemical impedance spectroscopy. J. Adhes. Sci. Technol. 1999, 13, 629–645. [Google Scholar] [CrossRef]

- Hinton, A.J. Determination of coating adhesion using electrochemical impedance spectroscopy. Solartron Anal. 2010, 2, 18–23. [Google Scholar]

- Hu, J.; Li, X.; Gao, J.; Zhao, Q. UV aging characterization of epoxy varnish coated steel upon exposure to artificial weathering environment. Mater. Des. 2009, 30, 1542–1547. [Google Scholar] [CrossRef]

- Kittel, J.; Celati, N.; Keddam, M.; Takenouti, H. New methods for the study of organic coatings by EIS: New insights into attached and free films. Prog. Org. Coat. 2001, 41, 93–98. [Google Scholar] [CrossRef]

- Armas, R.A.; Gervasi, C.A.; Di Sarli, A.; Real, S.G.; Vilche, J.R. Zinc-rich paints on steels in artificial seawater by electrochemical impedance spectroscopy. Corrosion 1992, 48, 379–383. [Google Scholar] [CrossRef]

- Beiro, M.; Collazo, A.; Izquierdo, M.; Nóvoa, X.R.; Pérez, C. Characterisation of barrier properties of organic paints: The zinc phosphate effectiveness. Prog. Org. Coat. 2003, 46, 97–106. [Google Scholar] [CrossRef]

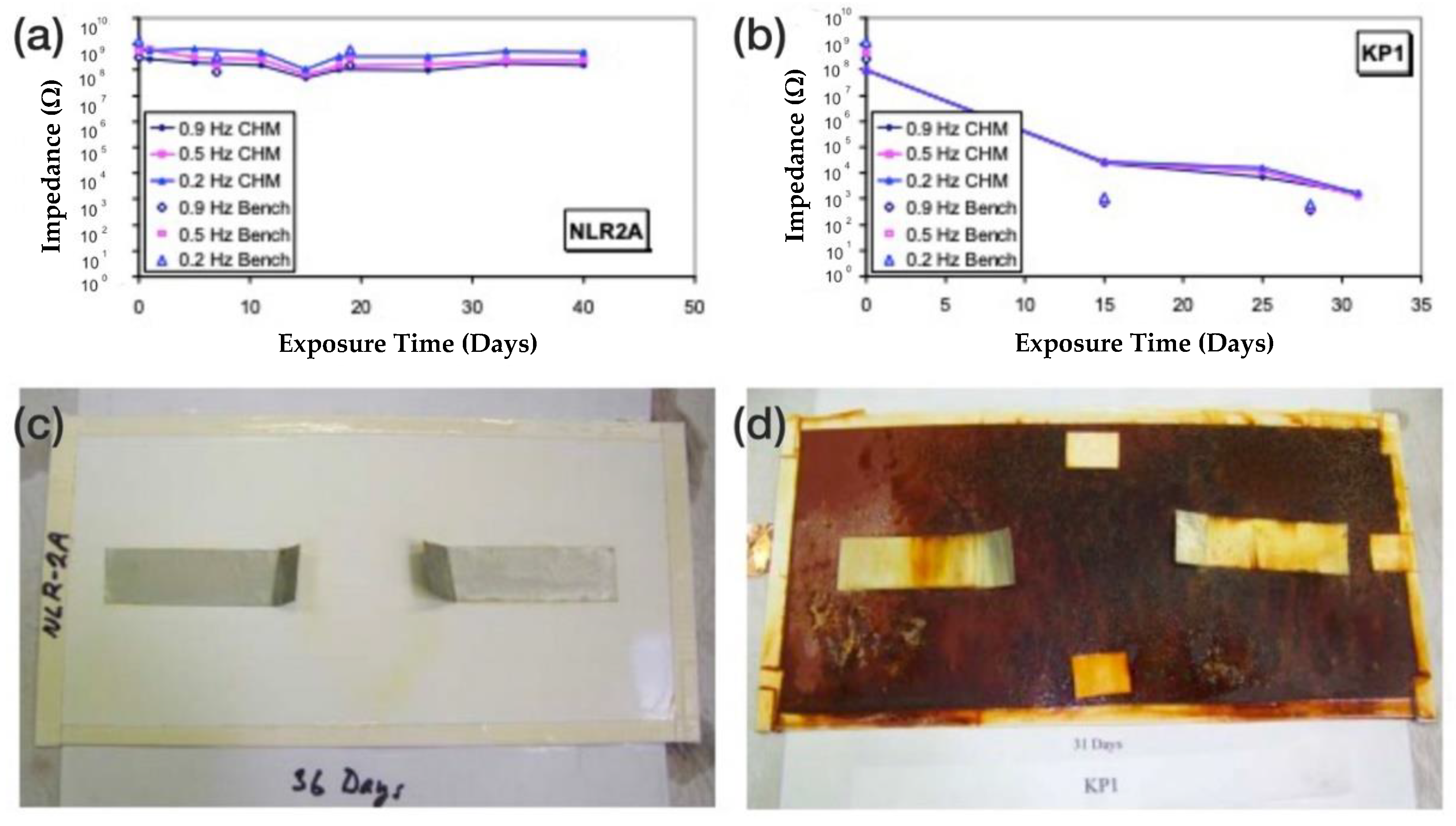

- Bierwagen, G.; Tallman, D.; Li, J.; He, L.; Jeffcoate, C. EIS studies of coated metals in accelerated exposure. Prog. Org. Coat. 2003, 46, 149–158. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Souza, C.A.C.; Abrantes, J.C.C. Use of Electrochemical Impedance Spectroscopy (EIS) to monitoring the corrosion of reinforced concrete. Rev. IBRACON Estrut. Mater. 2015, 8, 529–546. [Google Scholar] [CrossRef]

- Gamry, I. Basics of Electrochemical Impedance Spectroscopy. Available online: https://www.gamry.com/assets/Application-Notes/Basics-of-EIS.pdf (accessed on 1 April 2022).

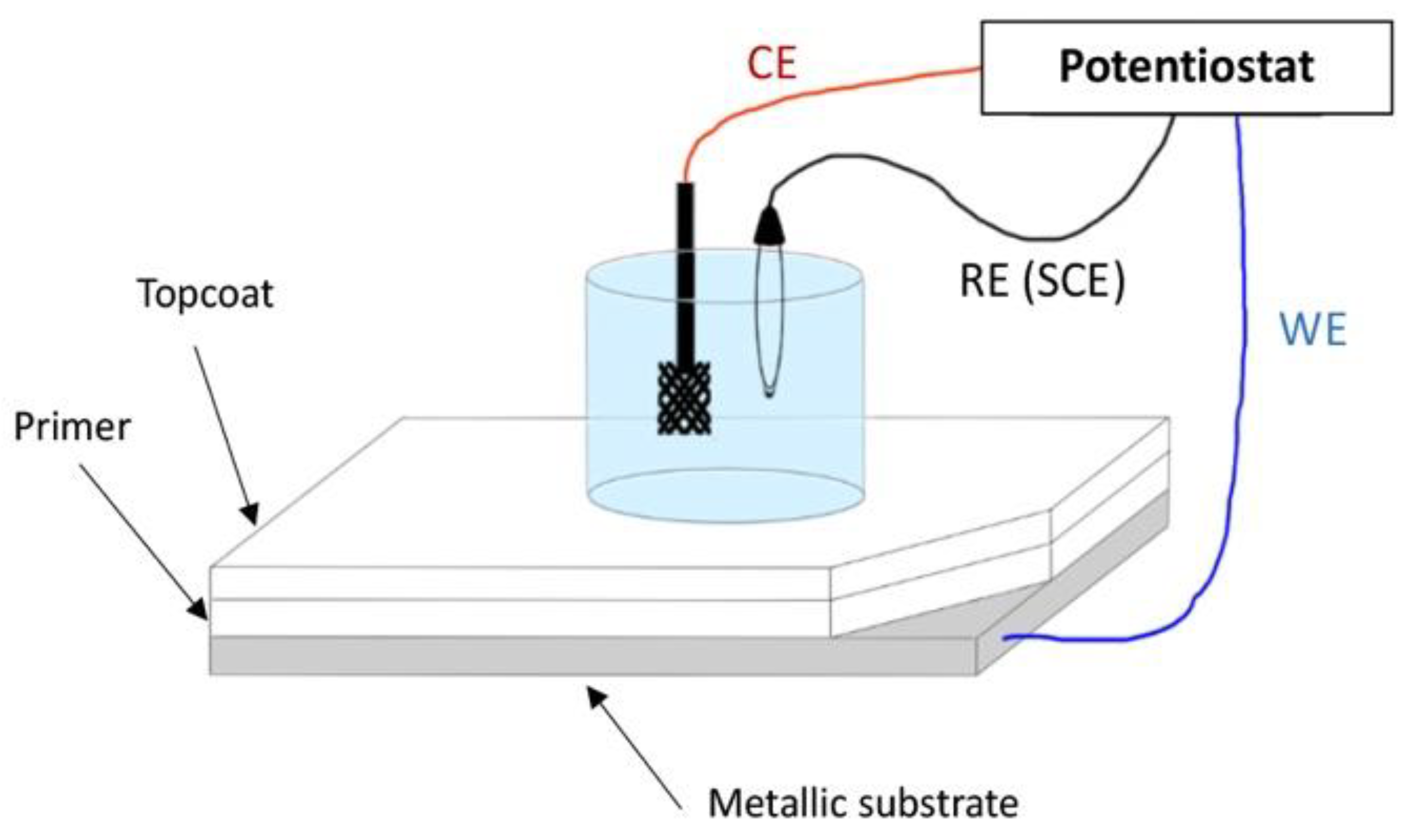

- Allahar, K.N.; Bierwagen, G.; Battocchi, D.; Gelling, V.J. Examination of the feasibility of the use of in-situ corrosion sensors in army vehicules. In Proceedings of the Tri-Service Corrosion Conference, Houston, TX, USA, 14–18 November 2005. [Google Scholar]

- Brasher, D.M.; Kingsbury, A.H. Electrical measurements in the study of immersed paint coatings on metal. I. Comparison between capacitance and gravimetric methods of estimating water-uptake. J. Appl. Chem. 1954, 4, 62–72. [Google Scholar] [CrossRef]

- Le Thu, Q.; Takenouti, H.; Touzain, S. EIS characterization of thick flawed organic coatings aged under cathodic protection in seawater. Electrochim. Acta 2006, 51, 2491–2502. [Google Scholar] [CrossRef]

- Amirudin, A.; Thieny, D. Application of electrochemical impedance spectroscopy to study the degradation of polymer-coated metals. Prog. Org. Coat. 1995, 26, 1–28. [Google Scholar] [CrossRef]

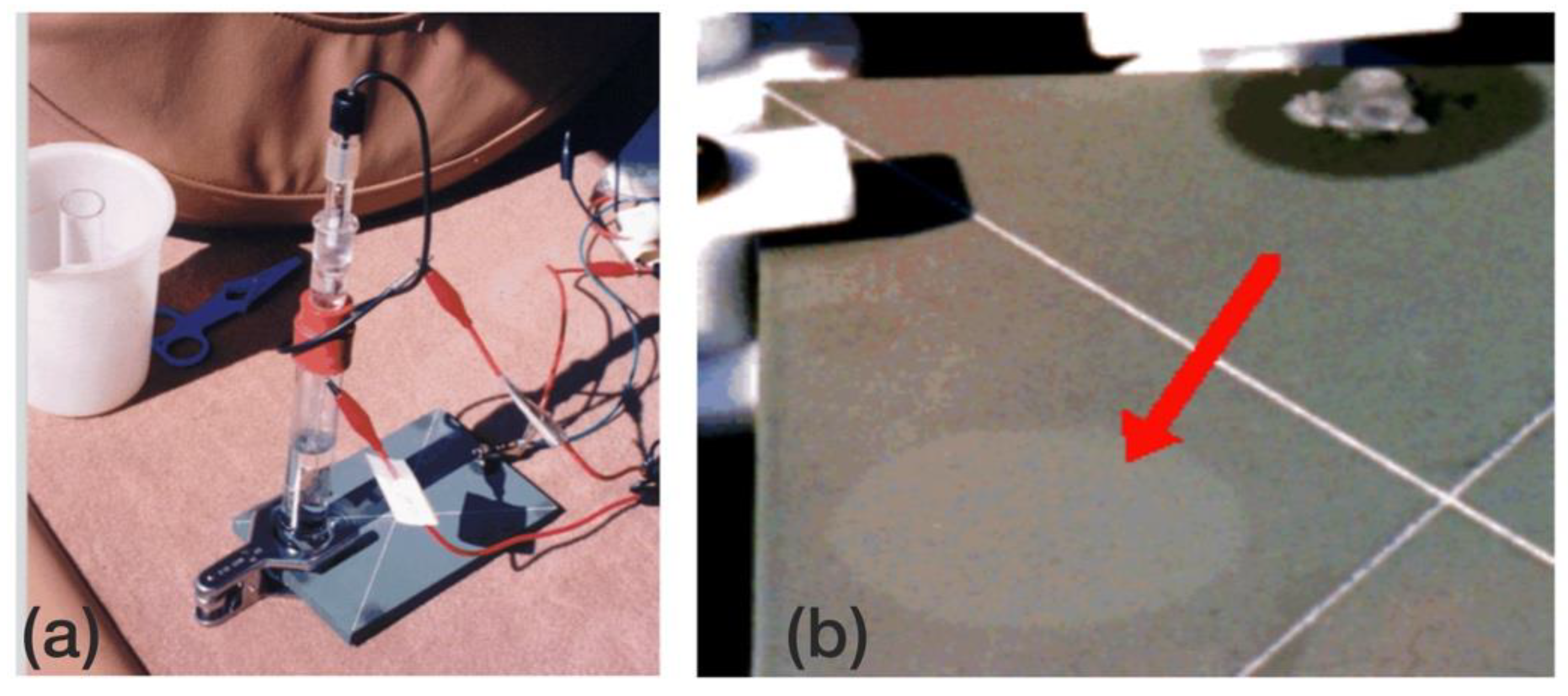

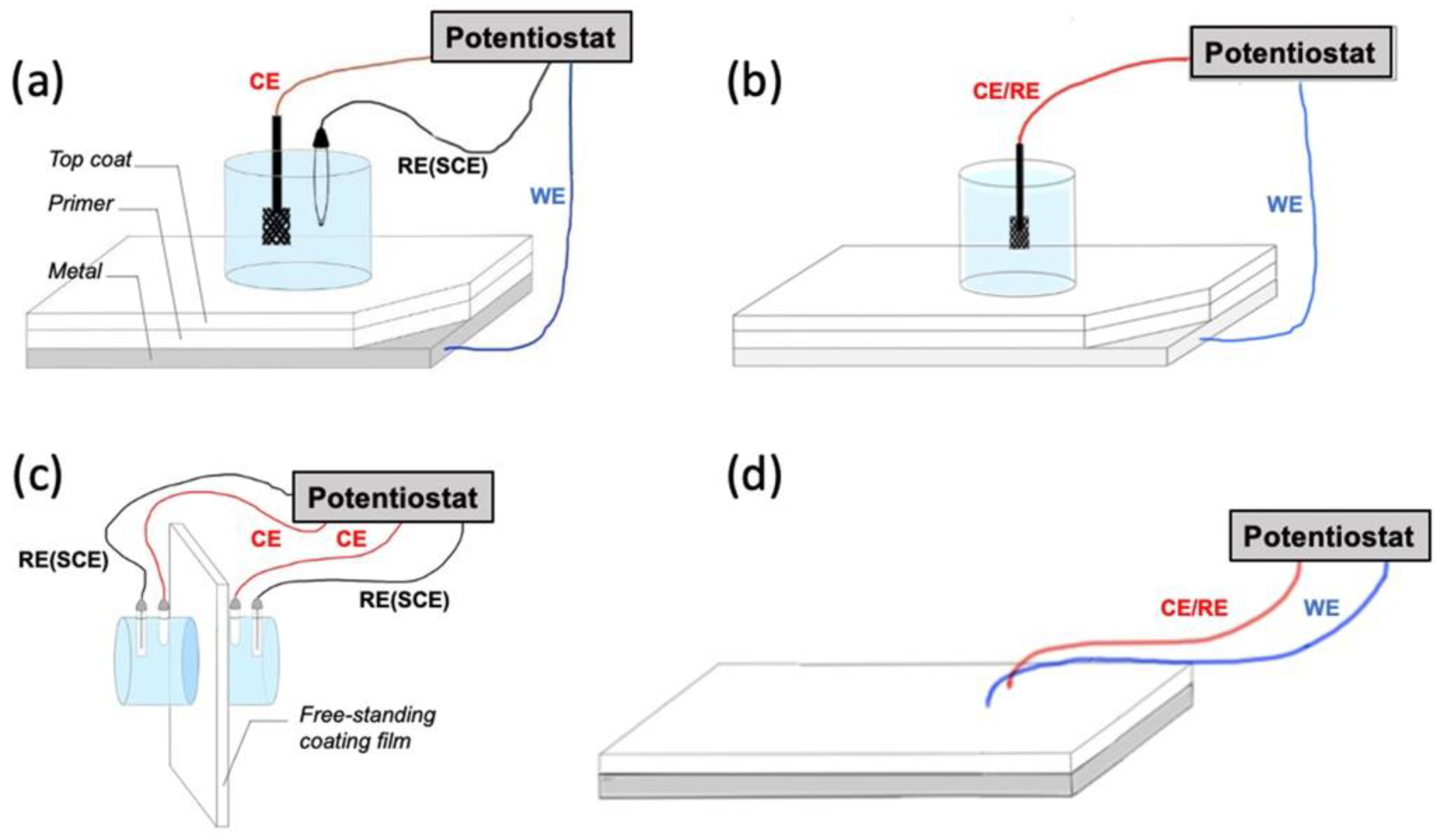

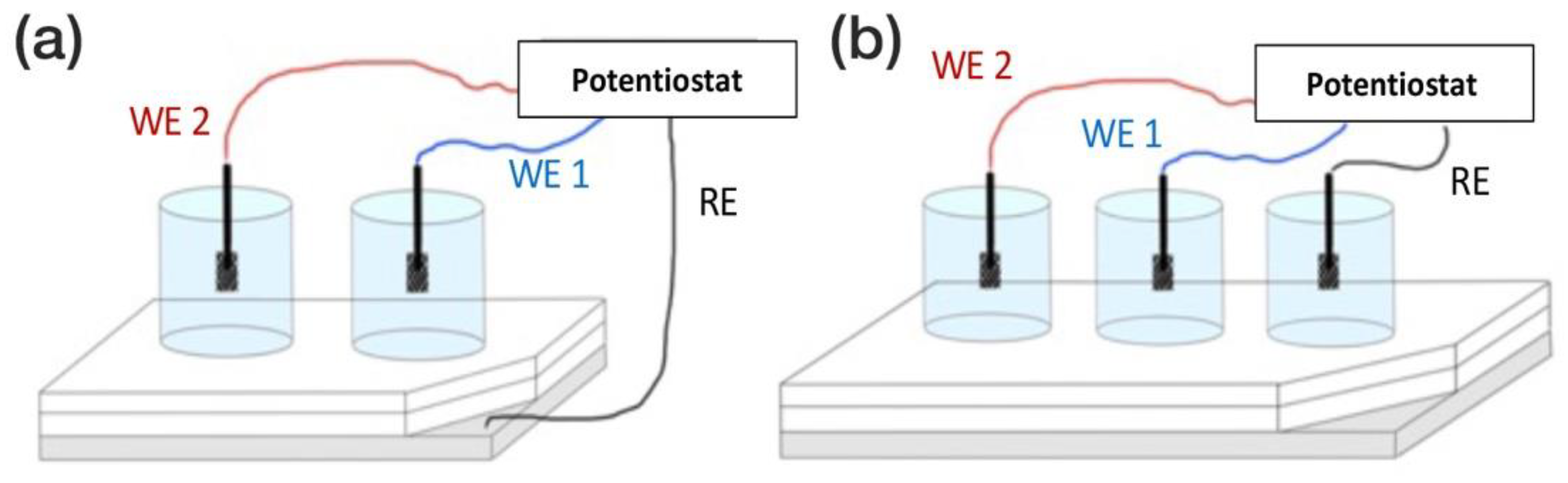

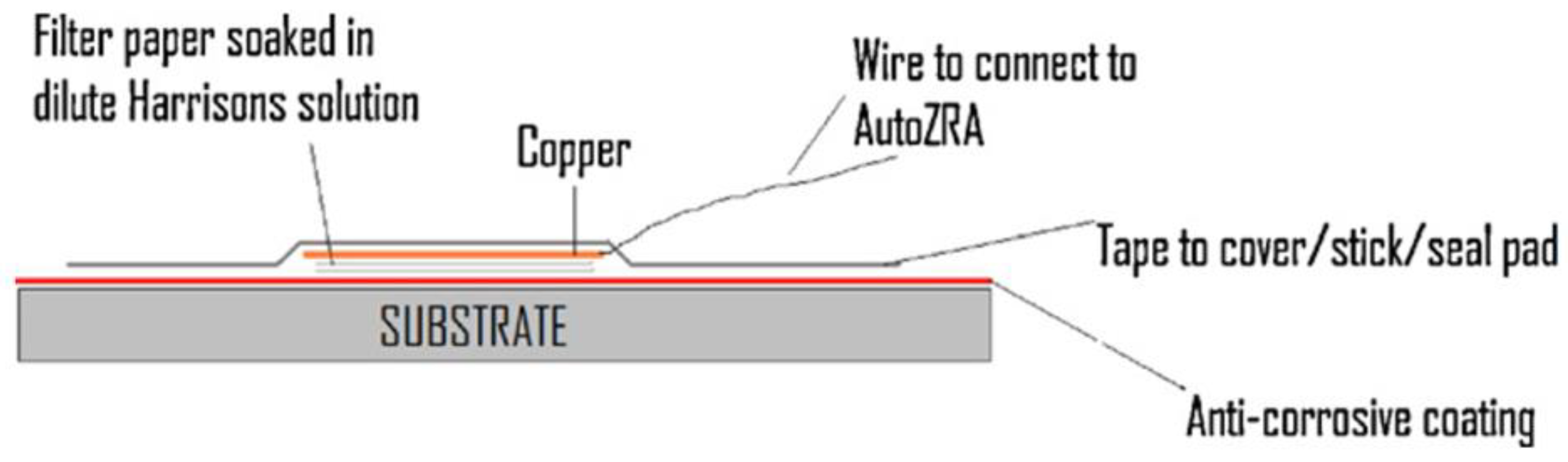

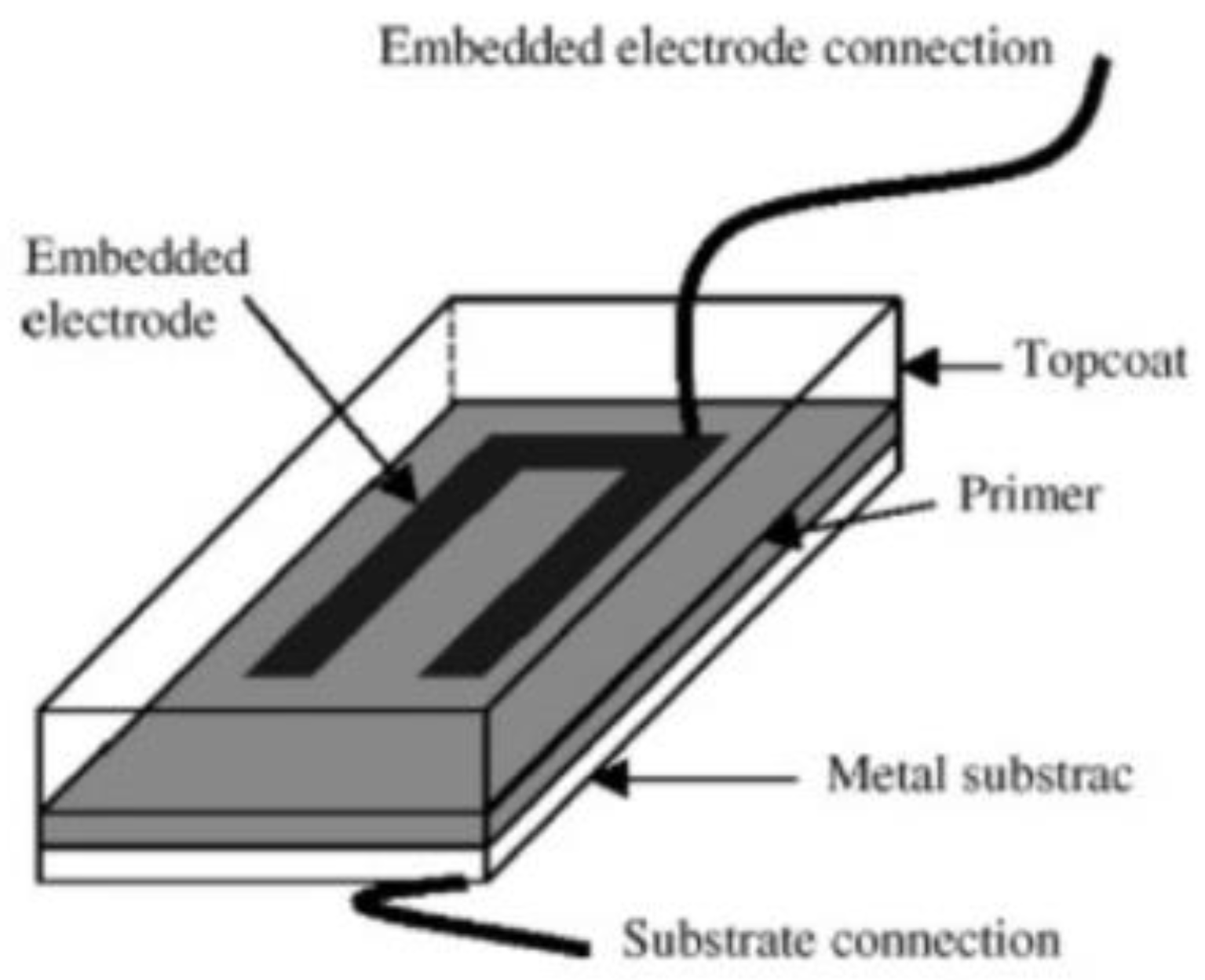

- Bierwagen, G.; Wang, X.; Tallman, D. In situ study of coatings using embedded electrodes for ENM measurements. Prog. Org. Coat. 2003, 46, 163–175. [Google Scholar] [CrossRef]

- Merten, B.E.; Battocchi, D.; Tallman, D.E.; Bierwagen, G.P. Embedded Reference Electrode for Potential-Monitoring of Cathodic Protective Systems. J. Electrochem. Soc. 2010, 157, C244. [Google Scholar] [CrossRef]

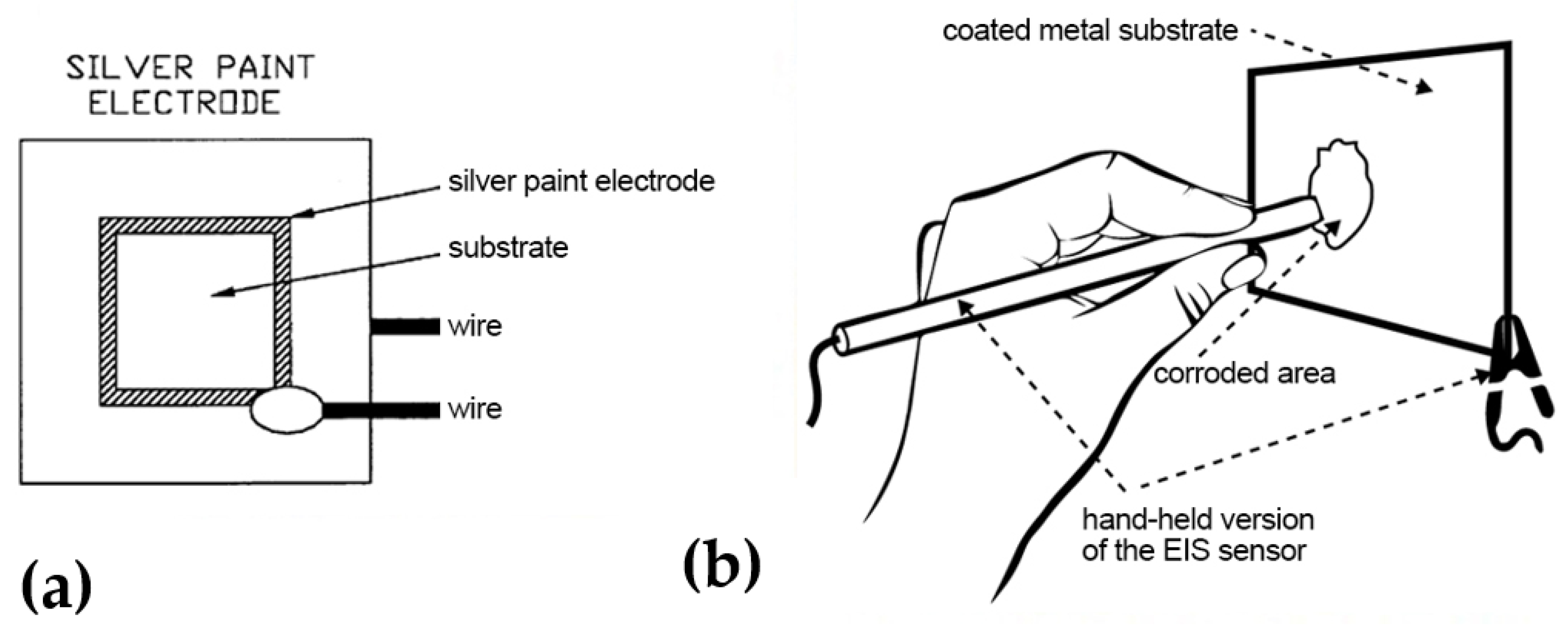

- Davis, G. EIS-based in-situ sensor for the early detection of coating degradation and substrate corrosion. In Proceedings of the CORROSION 2000, Orlando, FL, USA, 26–31 March 2000. [Google Scholar]

- Davis, G.D.; Dacres, C.M. Electrochemical Sensors for Evaluating Corrosion and Adhesion on Painted Metal Structures. U.S. Patent 5,859,537, 12 January 1999. [Google Scholar]

- Davis, G.D.; Dacres, C.M.; Krebs, L.A. In-situ corrosion sensor for coating testing and screening. Mater. Perform. 2000, 39, 46–50. [Google Scholar]

- Davis, G.D.; Ross, R.A.; Raghu, S.D. Coating health monitoring system for army ground vehicles. In Proceedings of the CORROSION 2007, Nashville, TN, USA, 11–15 March 2007. [Google Scholar]

- Kittel, J.; Celati, N.; Keddam, M.; Takenouti, H. Influence of the coating-substrate interactions on the corrosion protection: Characterisation by impedance spectroscopy of the inner and outer parts of a coating. Prog. Org. Coat. 2003, 46, 135–147. [Google Scholar] [CrossRef]

- Duarte, R.G.; Castela, A.S.; Ferreira, M.G.S. Influence of the solution cation mobility on the water uptake estimation of PVC Plastisol freestanding films by EIS. Prog. Org. Coat. 2006, 57, 408–415. [Google Scholar] [CrossRef]

- Bierwagen, G.P.; Allahar, K.N.; Su, Q.; Gelling, V.J. Electrochemically characterizing the ac–dc–ac accelerated test method using embedded electrodes. Corros. Sci. 2009, 51, 95–101. [Google Scholar] [CrossRef]

- Allahar, K.; Su, Q.; Bierwagen, G. Non-substrate EIS monitoring of organic coatings with embedded electrodes. Prog. Org. Coat. 2010, 67, 180–187. [Google Scholar] [CrossRef]

- Brossia, C.S. Apparatus and Method for Detecting the Degradation of a Coating Using Embedded Sensors. U.S. Patent 6,911,828B1, 23 May 2005. [Google Scholar]

- De Rosa, R.L.; Earl, D.A.; Bierwagen, G.P. Statistical evaluation of EIS and ENM data collected for monitoring corrosion barrier properties of organic coatings on Al-2024-T3. Corros. Sci. 2002, 44, 1607–1620. [Google Scholar] [CrossRef]

- Iverson, W.P. Transient Voltage Changes Produced in Corroding Metals and Alloys. J. Electrochem. Soc. 1968, 115, 617. [Google Scholar] [CrossRef]

- Skerry, B.S.; Eden, D.A. Characterisation of coatings performance using electrochemical noise analysis. Prog. Org. Coat. 1991, 19, 379–396. [Google Scholar] [CrossRef]

- Bierwagen, G.P. Calculation of Noise Resistance from Simultaneous Electrochemical Voltage and Current Noise Data. J. Electrochem. Soc. 1994, 141, L155. [Google Scholar] [CrossRef]

- Cottis, R.A. Electrochemical noise for corrosion monitoring. In Techniques for Corrosion Monitoring; Woodhead Publishing Series in Metals and Surface Engineering; Elsevier: Cambridge, UK, 2021; pp. 99–122. [Google Scholar]

- Bertocci, U. Noise Resistance Applied to Corrosion Measurements. J. Electrochem. Soc. 1997, 144, 37. [Google Scholar] [CrossRef]

- Jamali, S.; Mills, D.J.; Woodcock, C. Ways of increasing the effectiveness of the electrochemical noise method for assessment of organic coatings on metal. ECS Trans. 2010, 24, 115–125. [Google Scholar] [CrossRef]

- Rodriguez-Pardo, L.; Cao-Paz, A.; Fariña, J.; Covelo, A.; Nóvoa, X.R.; Pérez, C. Water uptake kinetics in anti-corrosion organic films with a high resolution microbalance oscillator sensor. Sens. Actuators B Chem. 2010, 144, 443–449. [Google Scholar] [CrossRef]

- Mabbutt, S.J.; Mills, D.J. Technical note Novel configurations for electrochemical noise measurements. Br. Corros. J. 1998, 33, 158–160. [Google Scholar] [CrossRef]

- Mabbutt, S.; Mills, D.J.; Woodcock, C.P. Developments of the electrochemical noise method (ENM) for more practical assessment of anti-corrosion coatings. Prog. Org. Coat. 2007, 59, 192–196. [Google Scholar] [CrossRef] [Green Version]

- Mills, D.J.; Broster, M.; Razaq, I. Continuing work to enable electrochemical methods to be used to monitor the performance of organic coatings in the field. Prog. Org. Coat. 2008, 63, 267–271. [Google Scholar] [CrossRef]

- Su, Q.; Allahar, K.; Bierwagen, G. Embedded electrode electrochemical noise monitoring of the corrosion beneath organic coatings induced by ac–dc–ac conditions. Electrochim. Acta 2008, 53, 2825–2830. [Google Scholar] [CrossRef]

- Allahar, K.N.; Upadhyay, V.; Bierwagen, G.P.; Gelling, V.J. Monitoring of a military vehicle coating under prohesion exposure by embedded sensors. Prog. Org. Coat. 2009, 65, 142–151. [Google Scholar] [CrossRef]

- Telegdi, J.; Shaban, A.; Vastag, G. Biocorrosion—Steel. In Encyclopedia of Interfacial Chemistry; Elsevier: New York, NY, USA, 2018; pp. 28–42. [Google Scholar]

- Rahman, S.U.; Atta Ogwu, A. Corrosion and Mott-Schottky probe of chromium nitride coatings exposed to saline solution for engineering and biomedical applications. In Advances in Medical and Surgical Engineering; Elsevier: London, UK, 2020; pp. 239–265. [Google Scholar]

- Shin, C.-S.; Liaw, S.-K.; Yang, S.-W. Post-Impact Fatigue Damage Monitoring Using Fiber Bragg Grating Sensors. Sensors 2014, 14, 4144–4153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, F.; Huang, Y.; Azarmi, F.; Wang, Y. Pitted Corrosion Detection of Thermal Sprayed Metallic Coatings Using Fiber Bragg Grating Sensors. Coatings 2017, 7, 35. [Google Scholar] [CrossRef] [Green Version]

- Ramezani-Dana, H.; Casari, P.; Perronnet, A.; Fréour, S.; Jacquemin, F.; Lupi, C. Hygroscopic strain measurement by fibre Bragg gratings sensors in organic matrix composites - Application to monitoring of a composite structure. Compos. Part B Eng. 2014, 58, 76–82. [Google Scholar] [CrossRef]

- Enser, H.; Sell, J.K.; Hilber, W.; Jakoby, B. Printed strain sensors in organic coatings: In depth analysis of sensor signal effects. Sens. Actuators A Phys. 2018, 281, 258–263. [Google Scholar] [CrossRef]

- Enser, H.; Kulha, P.; Sell, J.K.; Schatzl-Linder, M.; Strauß, B.; Hilber, W.; Jakoby, B. Printed strain gauges embedded in organic coatings—Analysis of gauge factor and temperature dependence. Sens. Actuators A Phys. 2018, 276, 137–143. [Google Scholar] [CrossRef]

- Enser, H.; Kulha, P.; Sell, J.K.; Jakoby, B.; Hilber, W.; Strauß, B.; Schatzl-Linder, M. Printed Strain Gauges Embedded in Organic Coatings. Procedia Eng. 2016, 168, 822–825. [Google Scholar] [CrossRef]

- Kulha, P.; Enser, H.; Sell, J.K.; Strauß, B.; Schatzl-Linder, M.; Jakoby, B.; Hilber, W. Temperature dependence of gauge factor of printed piezoresistive layers embedded in organic coatings. Proceedings 2017, 1, 618. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Anderson, N.; Bland, S.; Nutt, S.; Jursich, G.; Joshi, S. All-printed strain sensors: Building blocks of the aircraft structural health monitoring system. Sens. Actuators A Phys. 2017, 253, 165–172. [Google Scholar] [CrossRef] [Green Version]

- Zymelka, D.; Togashi, K.; Ohigashi, R.; Yamashita, T.; Takamatsu, S.; Itoh, T.; Kobayashi, T. Printed strain sensor array for application to structural health monitoring. Smart Mater. Struct. 2017, 26, 105040. [Google Scholar] [CrossRef]

- Sell, J.K.; Enser, H.; Jakoby, B.; Schatzl-Linder, M.; Strauss, B.; Hilber, W. Printed Embedded Transducers: Capacitive Touch Sensors Integrated into the Organic Coating of Metalic Substrates. IEEE Sens. J. 2016, 16, 7101–7108. [Google Scholar] [CrossRef]

- Zarifi, M.H.; Deif, S.; Daneshmand, M. Wireless passive RFID sensor for pipeline integrity monitoring. Sens. Actuators A Phys. 2017, 261, 24–29. [Google Scholar] [CrossRef]

- Khalifeh, R.; Yasri, M.S.; Lescop, B.; Gallee, F.; Diler, E.; Thierry, D.; Rioual, S. Development of wireless and passive corrosion sensors for material degradation monitoring in coastal zones and immersed environment. IEEE J. Ocean. Eng. 2016, 41, 776–782. [Google Scholar] [CrossRef]

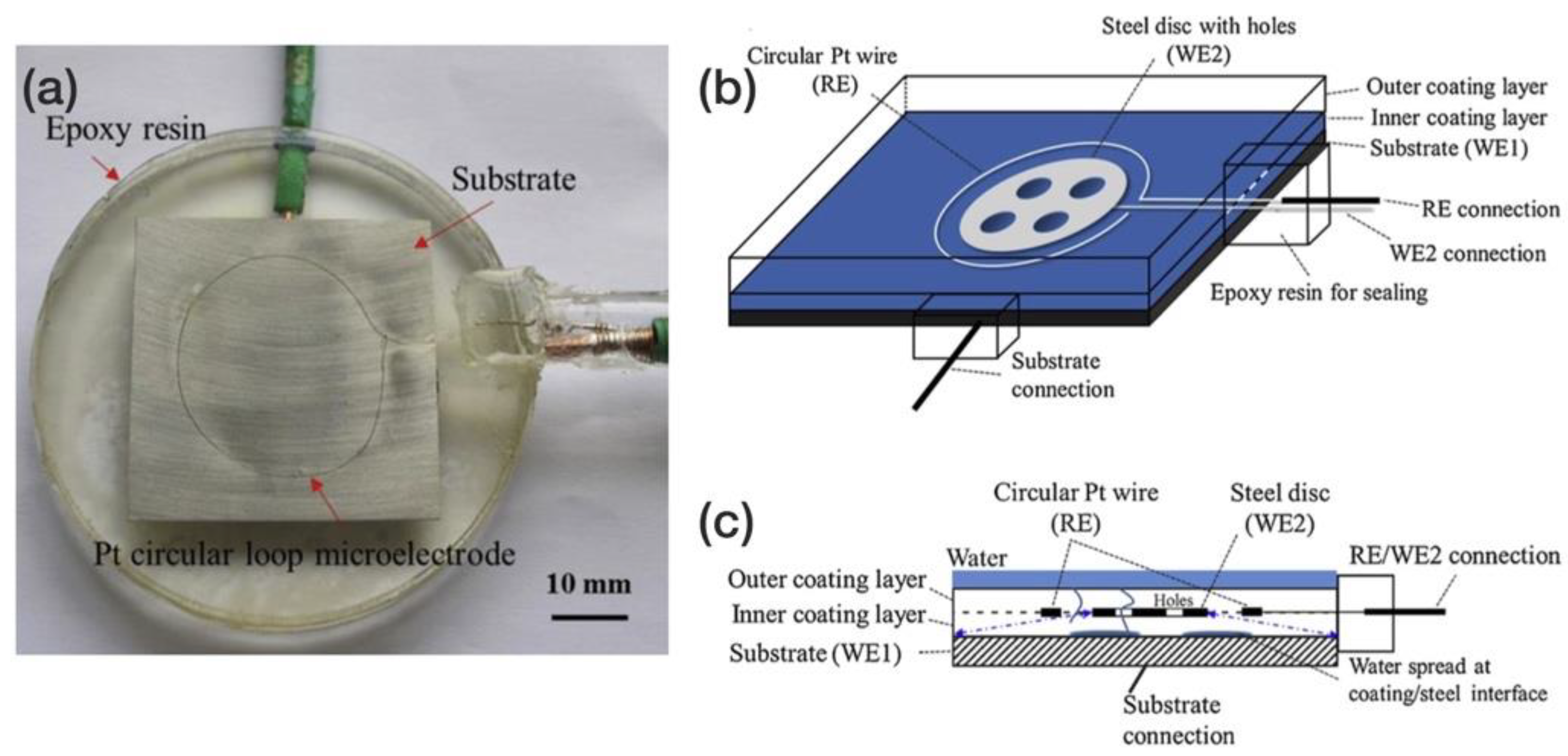

- Muscat, R.F.; Wilson, A.R. Corrosion onset detection sensor. IEEE Sens. J. 2017, 17, 8424–8430. [Google Scholar] [CrossRef]

- Akpakwu, G.A.; Silva, B.J.; Hancke, G.P.; Abu-Mahfouz, A.M. A Survey on 5G Networks for the Internet of Things: Communication Technologies and Challenges. IEEE Access 2017, 6, 3619–3647. [Google Scholar] [CrossRef]

- Rao, S.K.; Prasad, R. Impact of 5G Technologies on Industry 4.0. Wirel. Pers. Commun. 2018, 100, 145–159. [Google Scholar] [CrossRef]

- Al-Falahy, N.; Alani, O.Y. Technologies for 5G Networks: Challenges and Opportunities. IT Prof. 2017, 19, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Popov, V.V.; Kudryavtseva, E.V.; Kumar Katiyar, N.; Shishkin, A.; Stepanov, S.I.; Goel, S. Industry 4.0 and Digitalisation in Healthcare. Materials 2022, 15, 2140. [Google Scholar] [CrossRef]

- Parthiban, T.; Ravi, R.; Parthiban, G.T.; Srinivasan, S.; Ramakrishnan, K.R.; Raghavan, M. Neural network analysis for corrosion of steel in concrete. Corros. Sci. 2005, 47, 1625–1642. [Google Scholar] [CrossRef]

- Ding, L.; Rangaraju, P.; Poursaee, A. Application of generalized regression neural network method for corrosion modeling of steel embedded in soil. Soils Found. 2019, 59, 474–483. [Google Scholar] [CrossRef]

- Wilson, A.R.; Vincent, P.S. Networked low-power sensing: Network interface and main operating system. IEEE Sens. J. 2010, 10, 1495–1507. [Google Scholar] [CrossRef]

- Vincent, P.S.; McMahon, P.J.; Muscat, R.F.; Zeve, L.; Wilson, A.R. A small low-power networked and versatile sensor interface. In Smart Structures, Devices & Systems III; Al-Sarawi, S.F., Ed.; International Society for Optics and Photonics: Bellingham, WA, USA, 2006; Volume 6414, p. 64140Z. [Google Scholar]

- Demo, J.; Steiner, A.; Friedersdorf, F.; Putic, M.; Street, F.; Suite, A. Development of a Wireless Miniaturized Smart Sensor Network for Aircraft Corrosion Monitoring. In Proceedings of the 2010 IEEE Aerospace Conference, Big Sky, MT, USA, 6–13 March 2010. [Google Scholar]

- Li, Z.; Zheng, Q.; Wang, Z.L.; Li, Z. Nanogenerator-Based Self-Powered Sensors for Wearable and Implantable Electronics. Research 2020, 2020, 1–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karabetoglu, S.; Sisman, A.; Fatih Ozturk, Z.; Sahin, T. Characterization of a thermoelectric generator at low temperatures. Energy Convers. Manag. 2012, 62, 47–50. [Google Scholar] [CrossRef]

- Zhang, Y.; Cleary, M.; Wang, X.; Kempf, N.; Schoensee, L.; Yang, J.; Joshi, G.; Meda, L. High-temperature and high-power-density nanostructured thermoelectric generator for automotive waste heat recovery. Energy Convers. Manag. 2015, 105, 946–950. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Liang, L.; Lv, H.; Zhang, Y.; Chen, G. Elastic aerogel thermoelectric generator with vertical temperature-difference architecture and compression-induced power enhancement. Nano Energy 2021, 90, 106577. [Google Scholar] [CrossRef]

- Kim, D.K.; Duan, C.; Chen, Y.F.; Majumdar, A. Power generation from concentration gradient by reverse electrodialysis in ion-selective nanochannels. Microfluid. Nanofluid. 2010, 9, 1215–1224. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors–Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef]

- El-hami, M.; Glynne-Jones, P.; White, N.M.; Hill, M.; Beeby, S.; James, E.; Brown, A.D.; Ross, J.N. Design and fabrication of a new vibration-based electromechanical power generator. Sens. Actuators A Phys. 2001, 92, 335–342. [Google Scholar] [CrossRef]

- Wu, C.; Liu, R.; Wang, J.; Zi, Y.; Lin, L.; Wang, Z.L. A spring-based resonance coupling for hugely enhancing the performance of triboelectric nanogenerators for harvesting low-frequency vibration energy. Nano Energy 2017, 32, 287–293. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Van Heyst, B. A comprehensive review on vibration based micro power generators using electromagnetic and piezoelectric transducer mechanisms. Energy Convers. Manag. 2015, 106, 728–747. [Google Scholar] [CrossRef]

- Pommersheim, J.M.; Nguyen, T.; Zhang, Z.; Hubbard, J.B. Degradation of organic coatings on steel: Mathematical models and predictions. Prog. Org. Coat. 1994, 25, 23–41. [Google Scholar] [CrossRef]

- Nicolai, R.P.; Budai, G.; Dekker, R.; Vreijling, M. Modeling the deterioration of the coating on steel structures: A comparison of methods. Conf. Proc.-IEEE Int. Conf. Syst. Man Cybern. 2004, 5, 4177–4182. [Google Scholar] [CrossRef]

- Loveday, D.; Peterson, P.; Rodgers, B. Evaluation of organic coatings with electrochemical impedance spectroscopy: Part 1: Fundamentals of electrochemical impedance spectroscopy. CoatingsTech 2004, 1, 46–52. [Google Scholar]

- Hinderliter, B.R.; Croll, S.G.; Tallman, D.E.; Su, Q.; Bierwagen, G.P. Interpretation of EIS data from accelerated exposure of coated metals based on modeling of coating physical properties. Electrochim. Acta 2006, 51, 4505–4515. [Google Scholar] [CrossRef]

- Hoksbergen, N.; Akkerman, R.; Baran, I. The Springer model for lifetime prediction of wind turbine blade leading edge protection systems: A review and sensitivity study. Materials 2022, 15, 1170. [Google Scholar] [CrossRef]

- Domenech, L.; Renau, J.; Šakalyte, A.; Sánchez, F. Top coating anti-erosion performance analysis in wind turbine blades depending on relative acoustic impedance. Part 1: Modelling approach. Coatings 2020, 10, 685. [Google Scholar] [CrossRef]

- Herring, R.; Domenech, L.; Renau, J.; Šakalytė, A.; Ward, C.; Dyer, K.; Sánchez, F. Assessment of a wind turbine blade erosion lifetime prediction model with industrial protection materials and testing methods. Coatings 2021, 11, 767. [Google Scholar] [CrossRef]

| Targeted Coating Properties | Technology | Advantages/Drawbacks | Tele-Operated Yet |

|---|---|---|---|

| Electrochemical properties | EIS | Versatile; very well-known/Prone to noise; affected by electromagnetic fields; very complex data analysis | Yes |

| ENM | Quicker data gathering; less intrusive/Very complex theoretical background; affected by electromagnetic fields | Yes | |

| Internal stress–strain state | Optical fibres (FBGs) | Well-known technology; high sensitivity/Difficult to embed; fragile; affected by temperature | Yes/No |

| Piezoresistive-based gauges | Simple yet versatile; easy to fabricate; easy data handling and interpretation; high sensitivity/Affected by temperature | No | |

| Others | Magnetic nanoparticles | Simplest deployment/Need for a nearby device to interrogate the system through the application of a strong magnetic field; very niche | No |

| RFID | Low-cost; unpowered; wireless/Difficult to embed; niche; only tested on buried pipes | No | |

| Conductive wires | Simple; easy to operate/May be invasive when embedded | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frias-Cacho, X.; Castro, M.; Nguyen, D.-D.; Grolleau, A.-M.; Feller, J.-F. A Review of In-Service Coating Health Monitoring Technologies: Towards “Smart” Neural-Like Networks for Condition-Based Preventive Maintenance. Coatings 2022, 12, 565. https://doi.org/10.3390/coatings12050565

Frias-Cacho X, Castro M, Nguyen D-D, Grolleau A-M, Feller J-F. A Review of In-Service Coating Health Monitoring Technologies: Towards “Smart” Neural-Like Networks for Condition-Based Preventive Maintenance. Coatings. 2022; 12(5):565. https://doi.org/10.3390/coatings12050565

Chicago/Turabian StyleFrias-Cacho, Xavier, Mickaël Castro, Dang-Dan Nguyen, Anne-Marie Grolleau, and Jean-Francois Feller. 2022. "A Review of In-Service Coating Health Monitoring Technologies: Towards “Smart” Neural-Like Networks for Condition-Based Preventive Maintenance" Coatings 12, no. 5: 565. https://doi.org/10.3390/coatings12050565

APA StyleFrias-Cacho, X., Castro, M., Nguyen, D.-D., Grolleau, A.-M., & Feller, J.-F. (2022). A Review of In-Service Coating Health Monitoring Technologies: Towards “Smart” Neural-Like Networks for Condition-Based Preventive Maintenance. Coatings, 12(5), 565. https://doi.org/10.3390/coatings12050565