Research on Failure Mechanism of Abrasive Belt and Effect on Sanding of Medium-Density Fiberboard (MDF)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

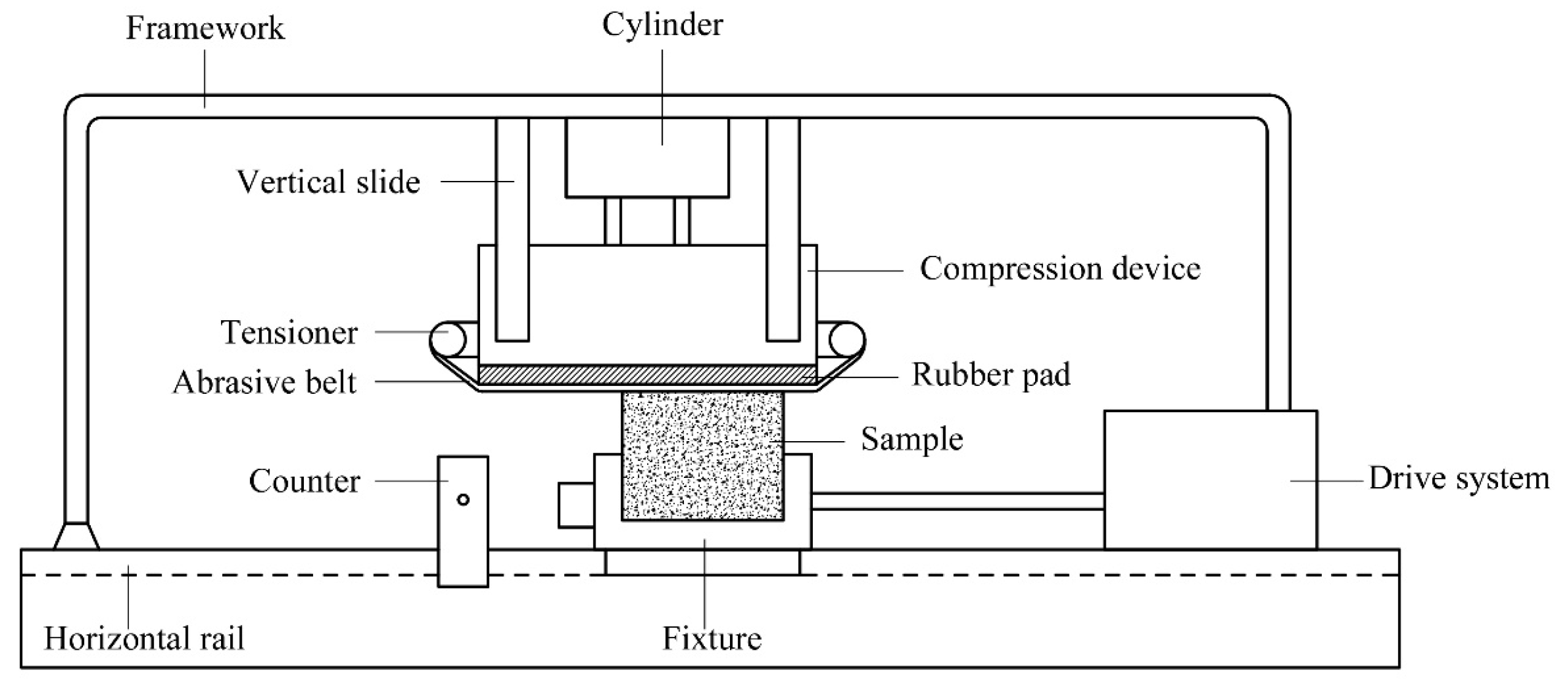

2.2. Equipment

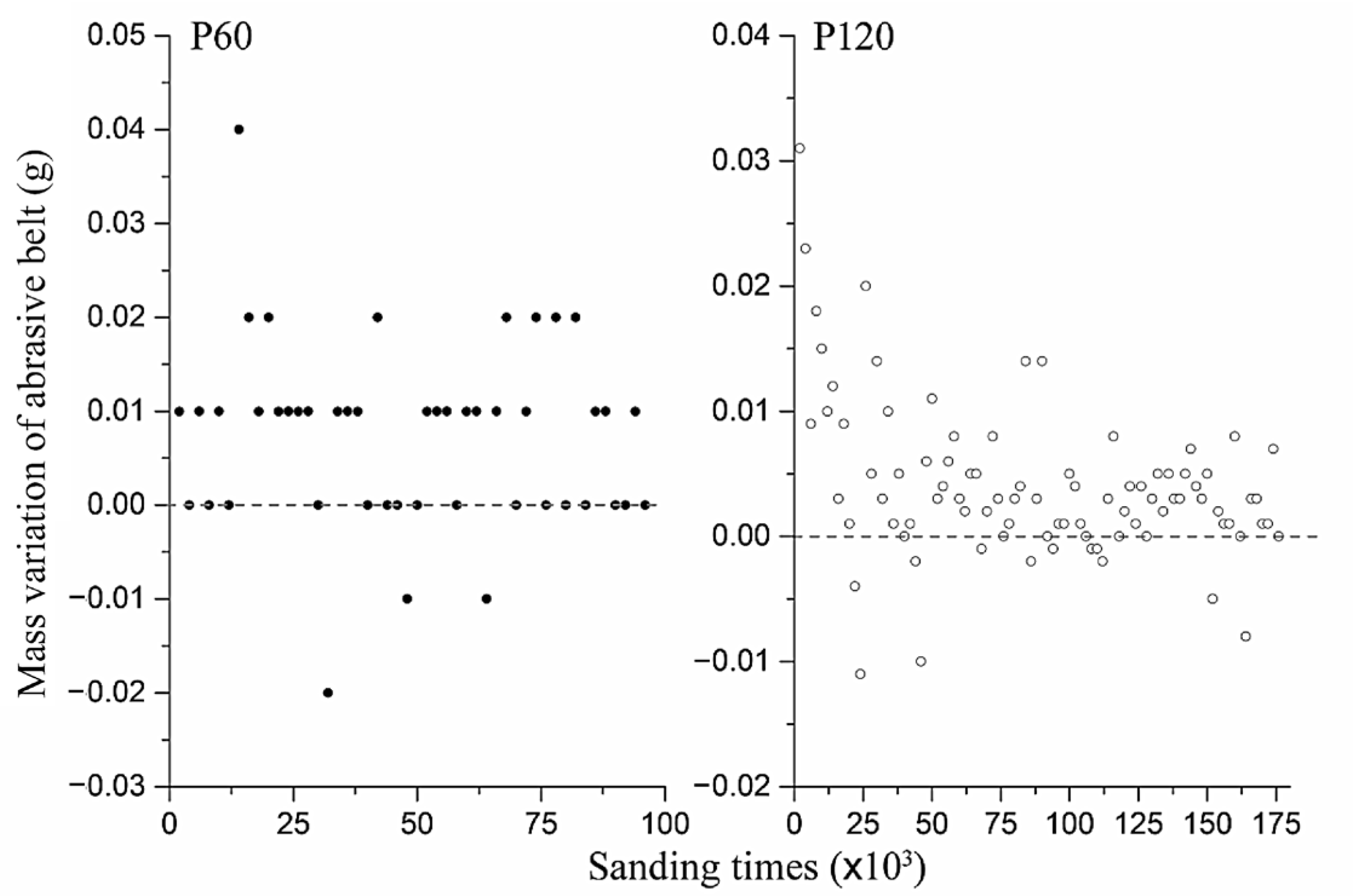

2.3. Mass Variation of Abrasive Belt

2.4. Surface Morphology of Abrasive Belt

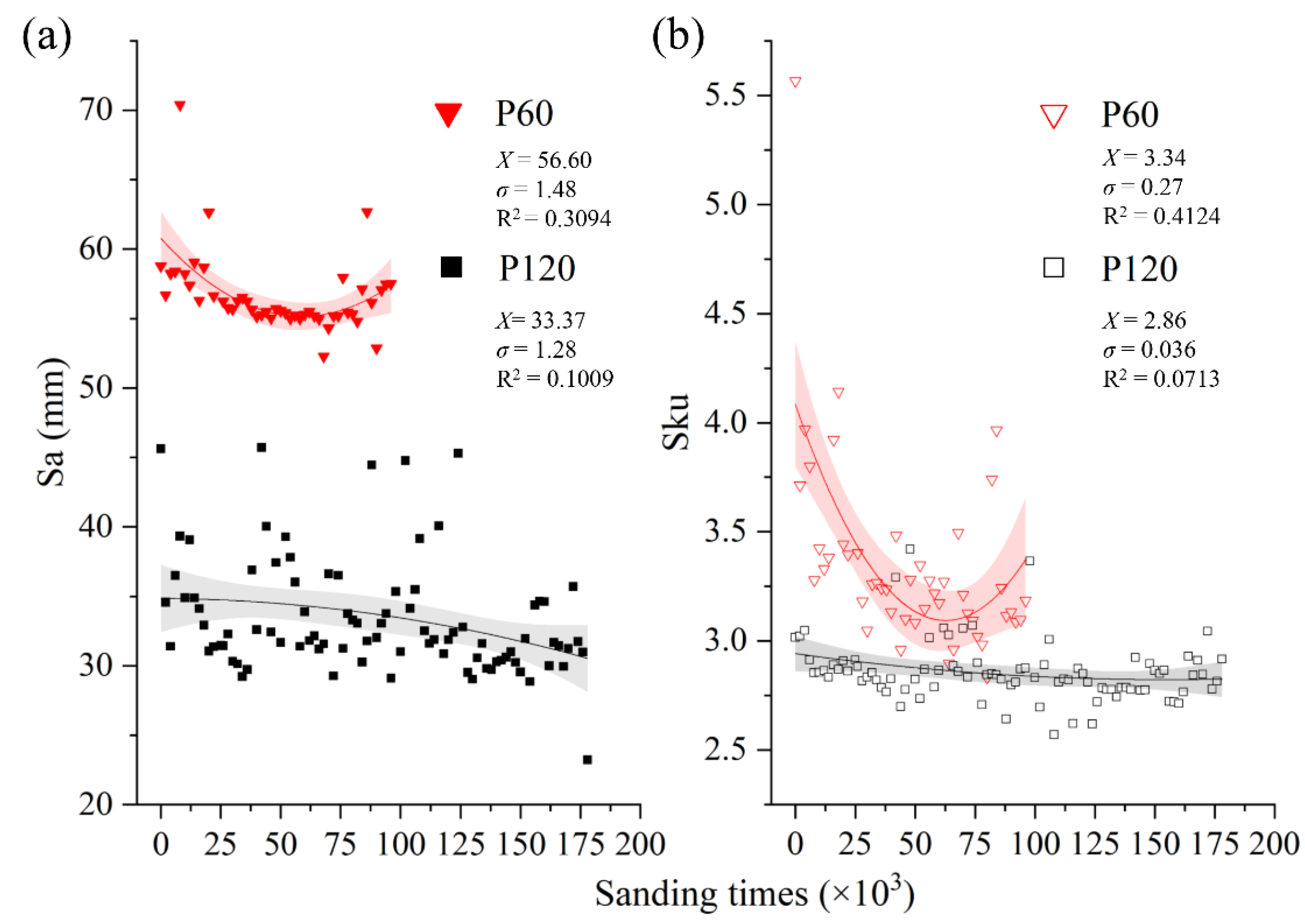

- Sa: arithmetical mean height of the scale-limited surface, which means the arithmetic mean or geometric mean of the distance between the point within the outline and the center plane. When the height distribution and frequency tend to be consistent, the Sa is lower, and when the height distribution and frequency consistency is weaker, the Sa is higher. In other words, a low Sa means a good surface flatness.

- Sku: kurtosis of the scale-limited surface. Its figure can judge the sharpness of the grits. The higher the Sku, the sharper the distribution of girts; the lower the Sku, the flatter the distribution. In general, when Sku < 3, the height distribution is higher to the mean surface; Sku = 3, the height distribution is regular (sharp and slow parts coexist); Sku > 3, the height distribution is extremely sharp [28].

3. Results and Discussion

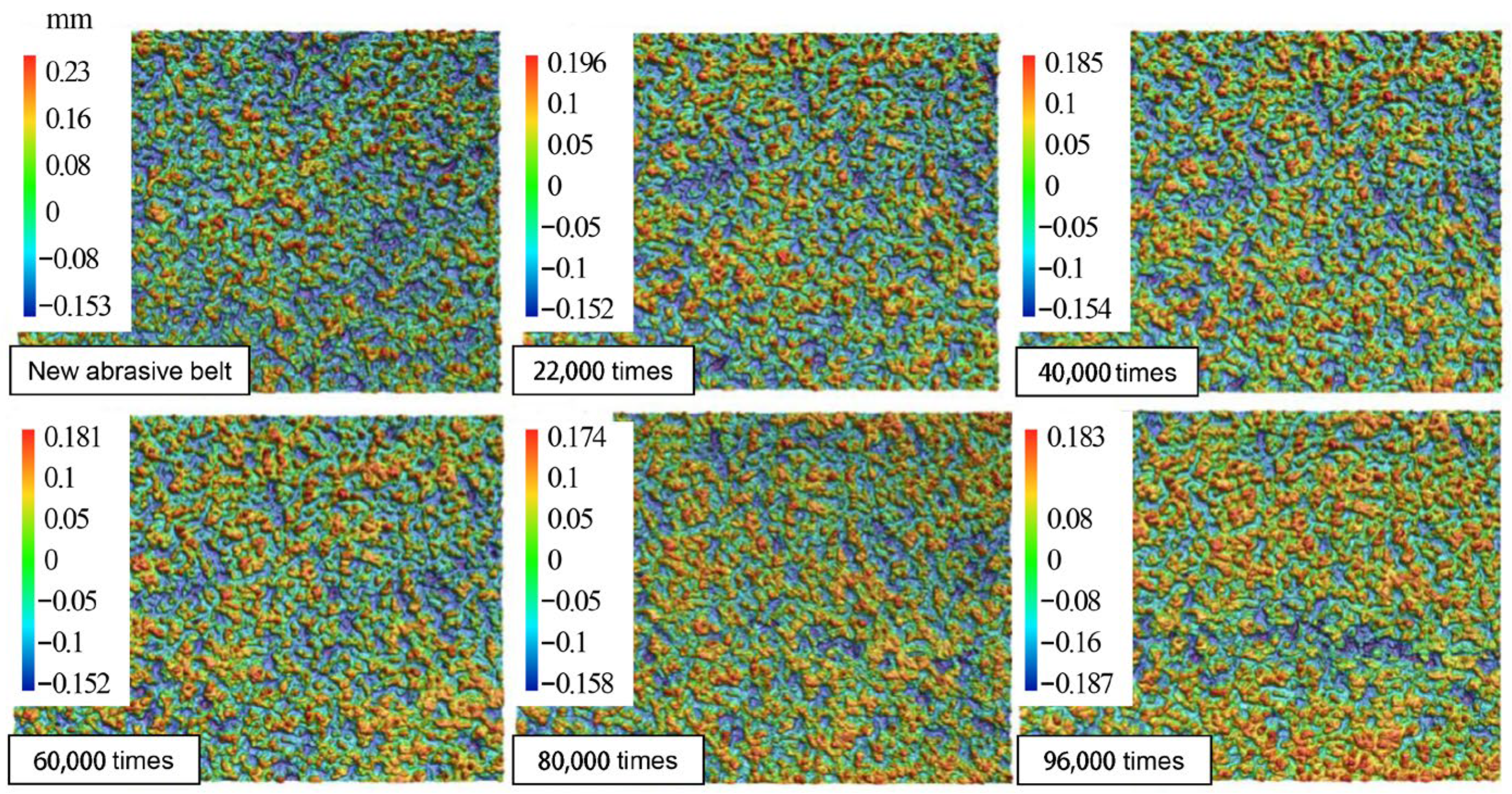

3.1. Mass Variation and 3D Morphology of Abrasive Belt

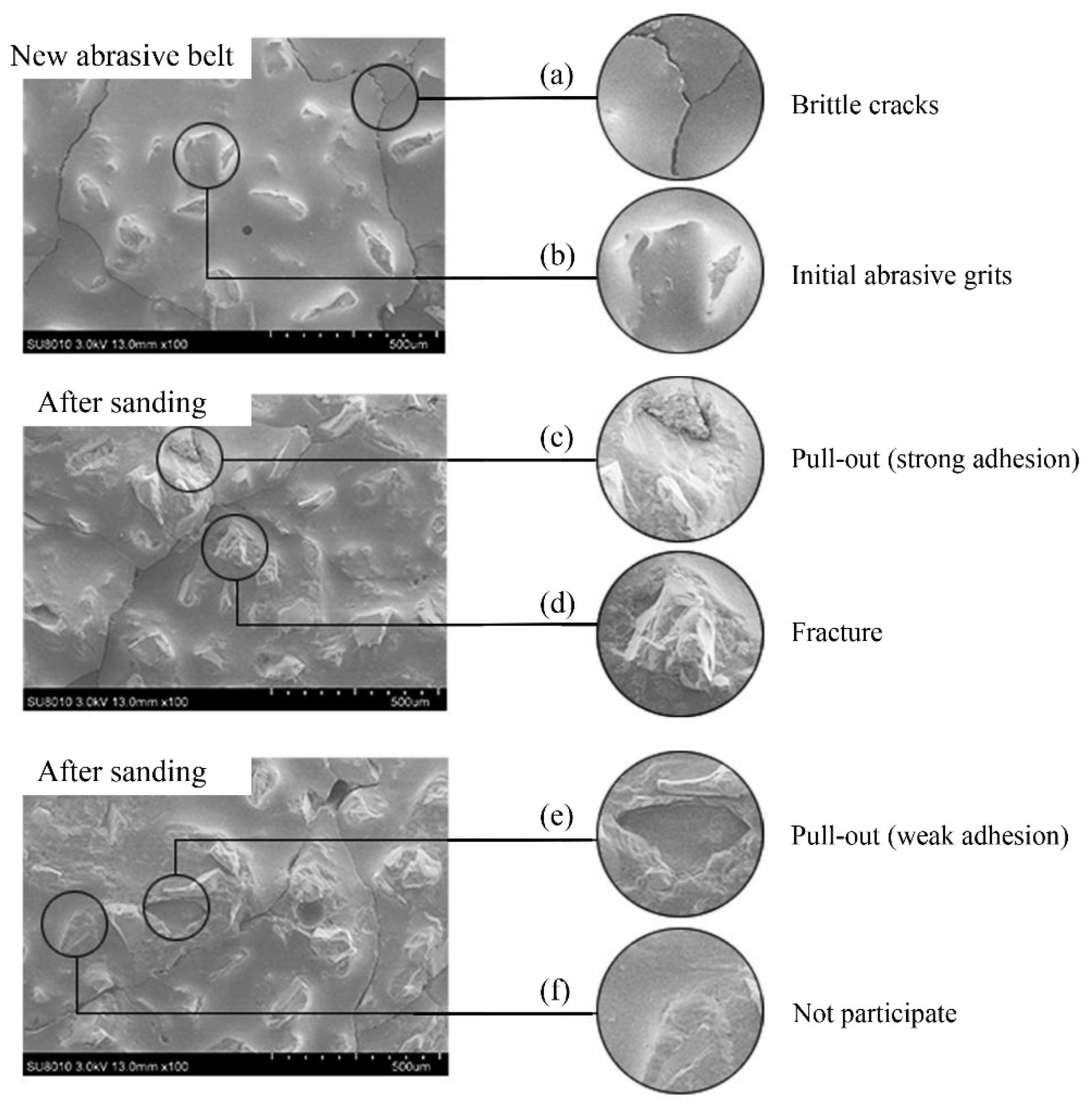

3.2. The SEM Morphology and the Surface Roughness of Abrasive Belt

4. Conclusions

- With the sanding times increasing, the abrasive-belt mass mainly increased and the mass variation trend is not significant.

- The initial maximum grit-protrusion height of abrasive grits for P60 is about 0.23 mm, and about 0.15 mm for P120. The maximum grit-protrusion height of abrasive grits dropped significantly in the early and mid stage of sanding, and remained basically constant in the late stage. As the sanding times increased, the “grits gathering” phenomenon appeared on abrasive grits adjacent to the high point, and this phenomenon is more obvious for P120.

- The Sa and Sku of P60 are larger than those of P120. When the sanding times increase, the Sa of P60 first decreases and then increases, but the Sa of P120 does not change significantly. Most of Sku (P60) were greater than 3, while lower than 3 for P120. P60 had a significant self-sharpening effect.

- With the increase in sanding times, the scope of “grits gathering” becomes larger, eventually leading to the severe “blocking” phenomenon. “Blocking” and grit wear are the predominant patterns in the failure mechanism of the abrasive belt. The height consistency of abrasive grits and the density of coating grit both have an important influence on abrasive-belt wear, failure, material removal, and surface-processing quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chung, K.Y.K.; Revell, G.S.; Summers, N.J. Measurements of dust emission, particle size distribution and formaldehyde concentration of medium density fibreboard during sawing and sanding. J. Aerosol Sci. 2000, 31, 244–245. [Google Scholar] [CrossRef]

- Davim, J.P.; Clemente, V.C.; Silva, S. Surface roughness aspects in milling MDF (medium density fibreboard). Int. J. Adv. Manuf. Technol. 2009, 40, 49–55. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Davim, J.P. Taguchi multiple-performance characteristics optimization in drilling of medium density fibreboard (MDF) to minimize delamination using utility concept. J. Mater. Process. Technol. 2008, 196, 73–78. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M.; Kminiak, R.; Banski, A. Sustainable manufacturing process in the context of wood processing by sanding. Coatings 2021, 11, 1463. [Google Scholar] [CrossRef]

- Sulaiman, O.; Hashim, R.; Subari, K.; Liang, C.K. Effect of sanding on surface roughness of rubberwood. J. Mater. Process. Technol. 2009, 209, 3949–3955. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, S.; Yiming, Z.; Jian, Z.; Bin, L. Wear mechanism and life of brown corundum abrasive belt in wood sanding process. J. For. Eng. 2020, 5, 121–127. [Google Scholar] [CrossRef]

- Tian, M.; Li, L. Study on influencing factors of sanding efficiency of abrasive belts in wood materials sanding. Wood Res. 2014, 59, 835–842. [Google Scholar]

- Zhang, J.; Yang, Y.; Luo, B.; Liu, H.; Li, L. Research on wear characteristics of abrasive belt and the effect on material removal during sanding of medium density fiberboard (MDF). Eur. J. Wood Wood Prod. 2021, 79, 1563–1576. [Google Scholar] [CrossRef]

- Setti, D.; Kirsch, B.; Aurich, J.C. Experimental investigations and kinematic simulation of single grit scratched surfaces considering pile-up behaviour: Grinding perspective. Int. J. Adv. Manuf. Technol. 2019, 103, 471–485. [Google Scholar] [CrossRef]

- Dai, C.; Ding, W.; Xu, J.; Fu, Y.; Yu, T. Influence of grain wear on material removal behavior during grinding nickel-based superalloy with a single diamond grain. Int. J. Mach. Tools Manuf. 2017, 113, 49–58. [Google Scholar] [CrossRef]

- Cheng, C.; Li, J.; Liu, Y.; Nie, M.; Wang, W. Deep convolutional neural network-based in-process tool condition monitoring in abrasive belt grinding. Comput. Ind. 2019, 106, 1–13. [Google Scholar] [CrossRef]

- He, Z.; Li, J.; Liu, Y.; Yan, J. Single-grain cutting based modeling of abrasive belt wear in cylindrical grinding. Friction 2019, 8, 208–220. [Google Scholar] [CrossRef] [Green Version]

- Huo, W.; Xu, J.; Fu, Y.; Qi, H. Research status and development of green grinding technology. Tool Eng. 2011, 9, 3–6. [Google Scholar] [CrossRef]

- Anderson, D.; Warkentin, A.; Bauer, R. Comparison of spherical and truncated cone geometries for single abrasive-grain cutting. J. Mater. Process. Tech. 2012, 212, 1946–1953. [Google Scholar] [CrossRef]

- Rasim, M.; Mattfeld, P.; Klocke, F. Analysis of the grain shape influence on the chip formation in grinding. J. Mater. Process. Technol. 2015, 226, 60–68. [Google Scholar] [CrossRef]

- Torrance, A.A. The effect of grit size and asperity blunting on abrasive wear. Wear 2002, 253, 813–819. [Google Scholar] [CrossRef]

- Zhang, J.; Ying, J.; Cheng, F.; Liu, H.; Luo, B.; Li, L. Investigating the sanding process of medium-density fiberboard and korean pine for material removal and surface creation. Coatings 2018, 8, 416. [Google Scholar] [CrossRef] [Green Version]

- Evans, P.; Cullis, I.; Kim, J.; Leung, L.; Hazneza, S.; Heady, R. Microstructure and mechanism of grain raising in wood. Coatings 2017, 7, 135. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, B.; Li, L.; Liu, H. Effect of wood porosity on surface creation process by single-grit scratching method. Wood Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Kamperidou, V.; Aidinidis, E.; Barboutis, I. Impact of structural defects on the surface quality of hardwood species sliced veneers. Appl. Sci. 2020, 10, 6265. [Google Scholar] [CrossRef]

- Demİrkir, C.; Aydin, İ.; ÇOlak, S.; ÇOlakoĞLu, G. Effects of plasma treatment and sanding process on surface roughness of wood veneers. Turk. J. Agric. For. 2014, 38, 663–667. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, B.; Li, L.; Liu, H. Cutting characteristics for sugar maple using single grit with spherical cone and triangular pyramid geometries. Materials 2019, 12, 3621. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luo, B. Study on Sanding Force and Optimal Sanding Parameters in the Belt Sanding Process of Wood Materials; Beijing Forestry University: Beijing, China, 2015. [Google Scholar]

- Ding, T.; Zhao, J.; Zhu, N.; Wang, C. A comparative study of morphological characteristics of medium-density fiberboard dust by sieve and image analyses. J. Wood Sci. 2020, 66, 1–9. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, Y. Principle and application of belt grinding. MW Met. Cut. 2008, 24, 28–30. [Google Scholar]

- Sydor, M.; Mirski, R.; Stuper-Szablewska, K.; Rogoziński, T. Efficiency of machine sanding of wood. Appl. Sci. 2021, 11, 2860. [Google Scholar] [CrossRef]

- Du, Y.; Tian, B.; Zhang, J.; Liu, H.; Luo, B. Research on abrasive belt wear and working life evaluation during sanding medium density fiberboard. J. Beijing For. Univ. 2021, 43, 126–134. [Google Scholar] [CrossRef]

- Keyence China Official Website. Available online: https://www.keyence.com.cn/ss/products/microscope/roughness/surface/parameters.jsp (accessed on 26 March 2022).

- Ugulino, B.; Hernandez, R.E. Analysis of sanding parameters on surface properties and coating performance of red oak wood. Wood Mater. Sci. Eng. 2018, 13, 64–72. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Sun, X.; Luo, B.; Li, L.; Liu, H. Research on Failure Mechanism of Abrasive Belt and Effect on Sanding of Medium-Density Fiberboard (MDF). Coatings 2022, 12, 621. https://doi.org/10.3390/coatings12050621

Du Y, Sun X, Luo B, Li L, Liu H. Research on Failure Mechanism of Abrasive Belt and Effect on Sanding of Medium-Density Fiberboard (MDF). Coatings. 2022; 12(5):621. https://doi.org/10.3390/coatings12050621

Chicago/Turabian StyleDu, Yao, Xinmiao Sun, Bin Luo, Li Li, and Hongguang Liu. 2022. "Research on Failure Mechanism of Abrasive Belt and Effect on Sanding of Medium-Density Fiberboard (MDF)" Coatings 12, no. 5: 621. https://doi.org/10.3390/coatings12050621