Influence of Nozzle Design on Flow Characteristic in the Continuous Casting Machinery

Abstract

:1. Introduction

2. Nozzle Structure

3. Proposed Model

- (1)

- The fluid steel flow is an incompressible steady flow.

- (2)

- The influence of the mold vibration and mold slag on the flow is ignored.

- (3)

- The natural convection caused by density changes is ignored.

- (4)

- The influence of the heat transfer and slab condensate on the flow is ignored.

- (5)

- The calculation boundary is a no-slip boundary.

- (1)

- Continuity equation:

- (2)

- Momentum equation:

- (3)

- Energy conservation equation:

- (1)

- The nozzle inlet is defined as the velocity inlet.

- (2)

- The computational domain exit is defined as the speed exit, while the speed is equal to the casting speed.

- (3)

- The mold liquid level is set as free liquid level, and the shear force is null.

- (4)

- Mold wall: Both the mold wall and nozzle wall are treated as non-slip solid walls, while the flow field near the wall is treated as a standard wall function. The temperature boundary condition of the nozzle wall is treated as adiabatic. The mold wall is calculated using the second type of heat transfer boundary condition, and the heat flow is applied to the surface of the billet in the mold using a profile file.

4. Results and Discussion

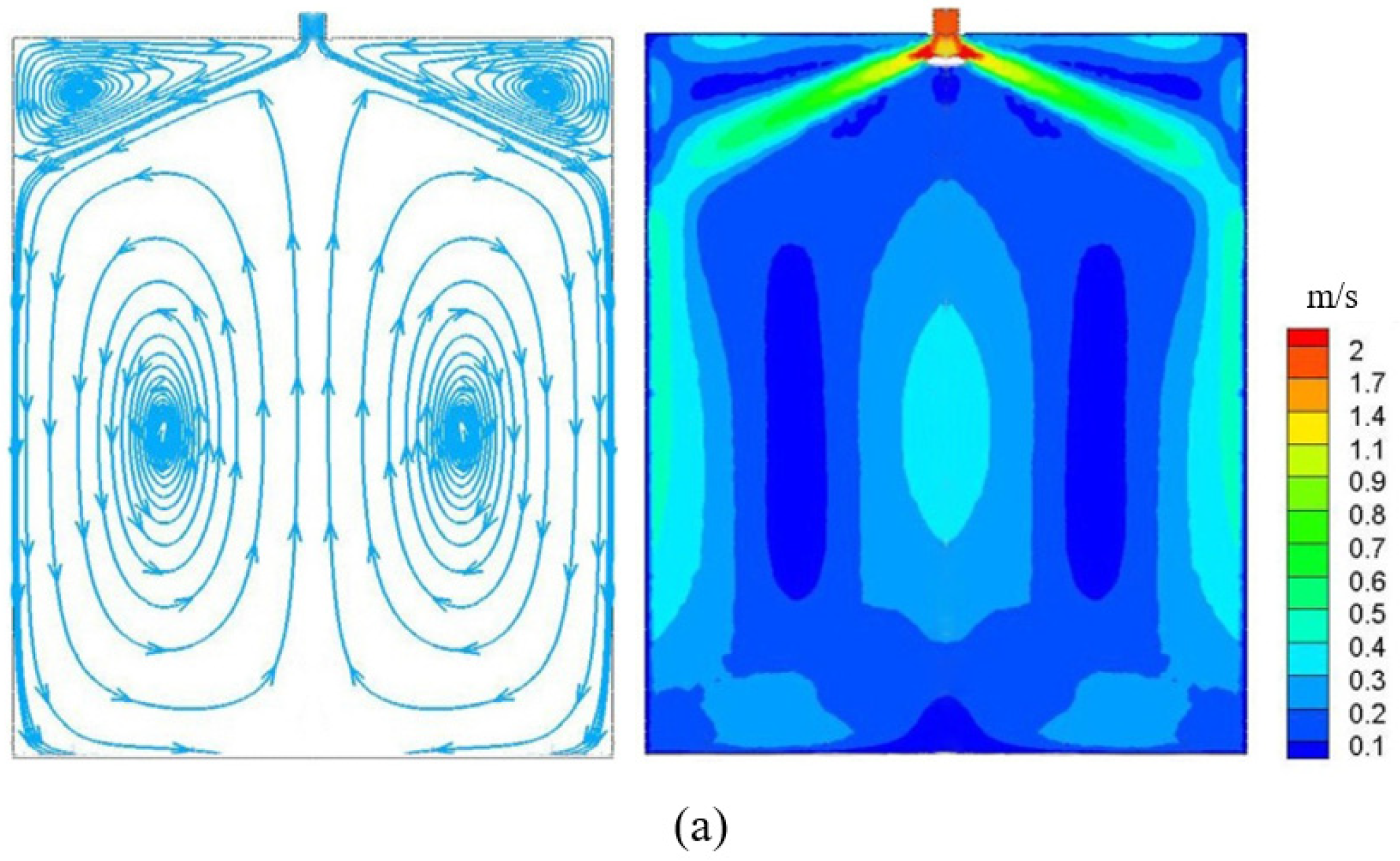

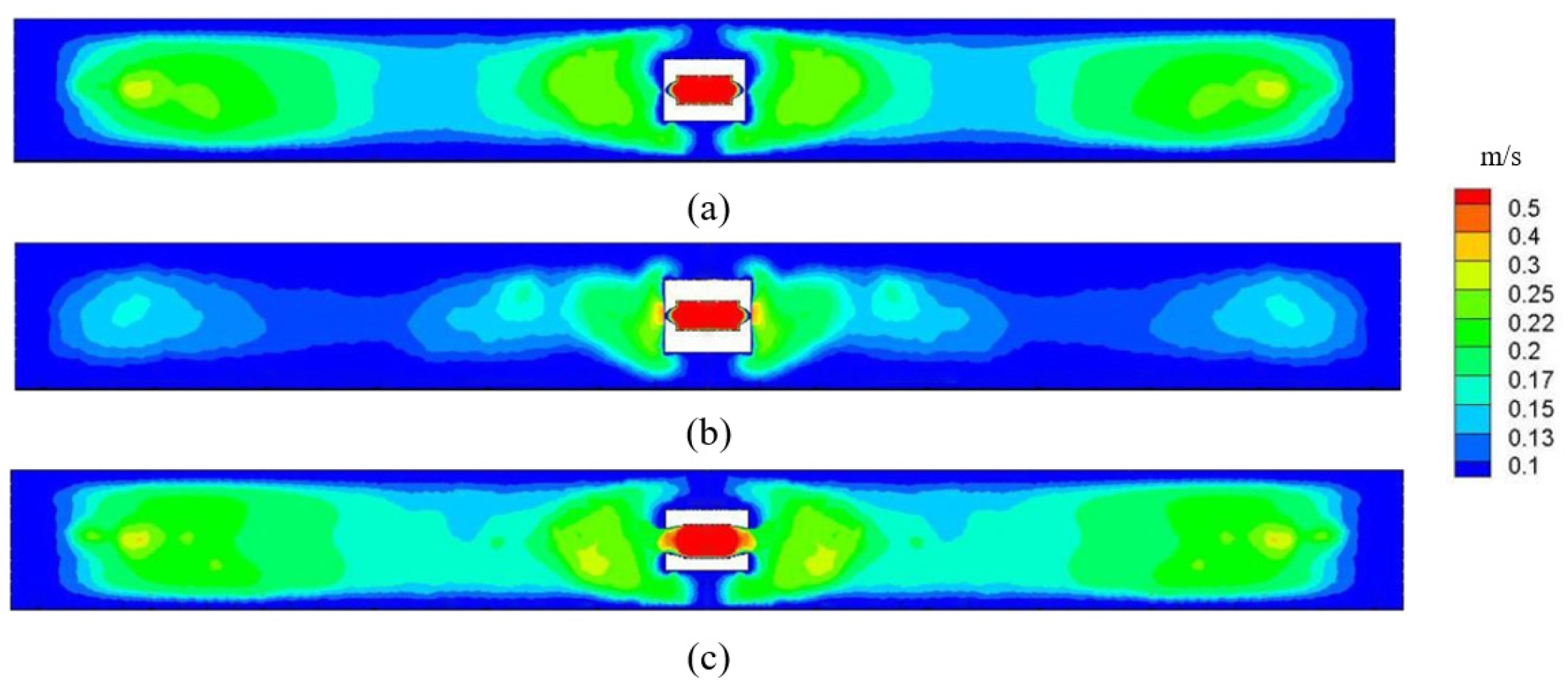

4.1. Fluid Characteristics of Fluid Steel

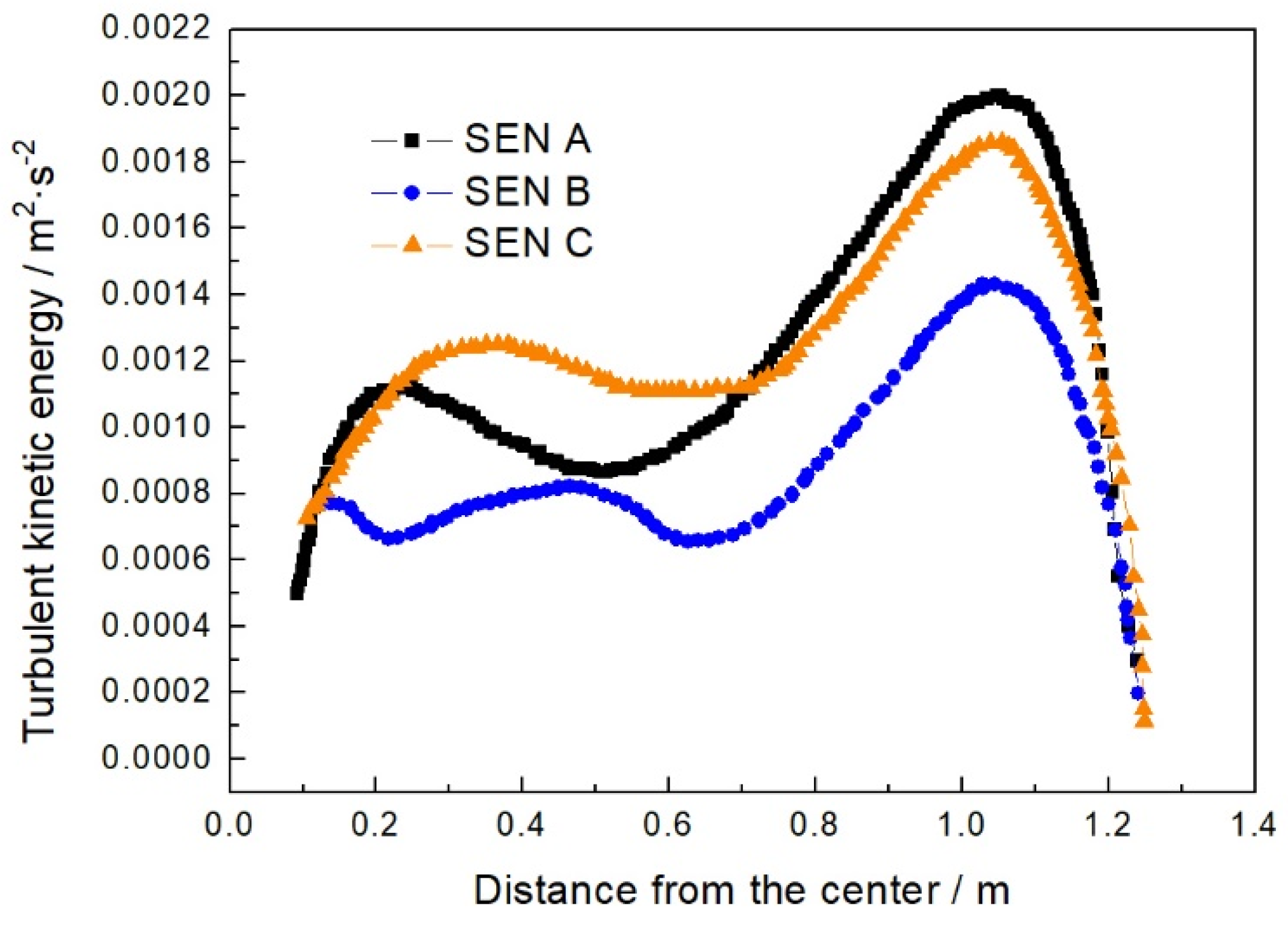

4.2. Nozzle Outlet Flow Field

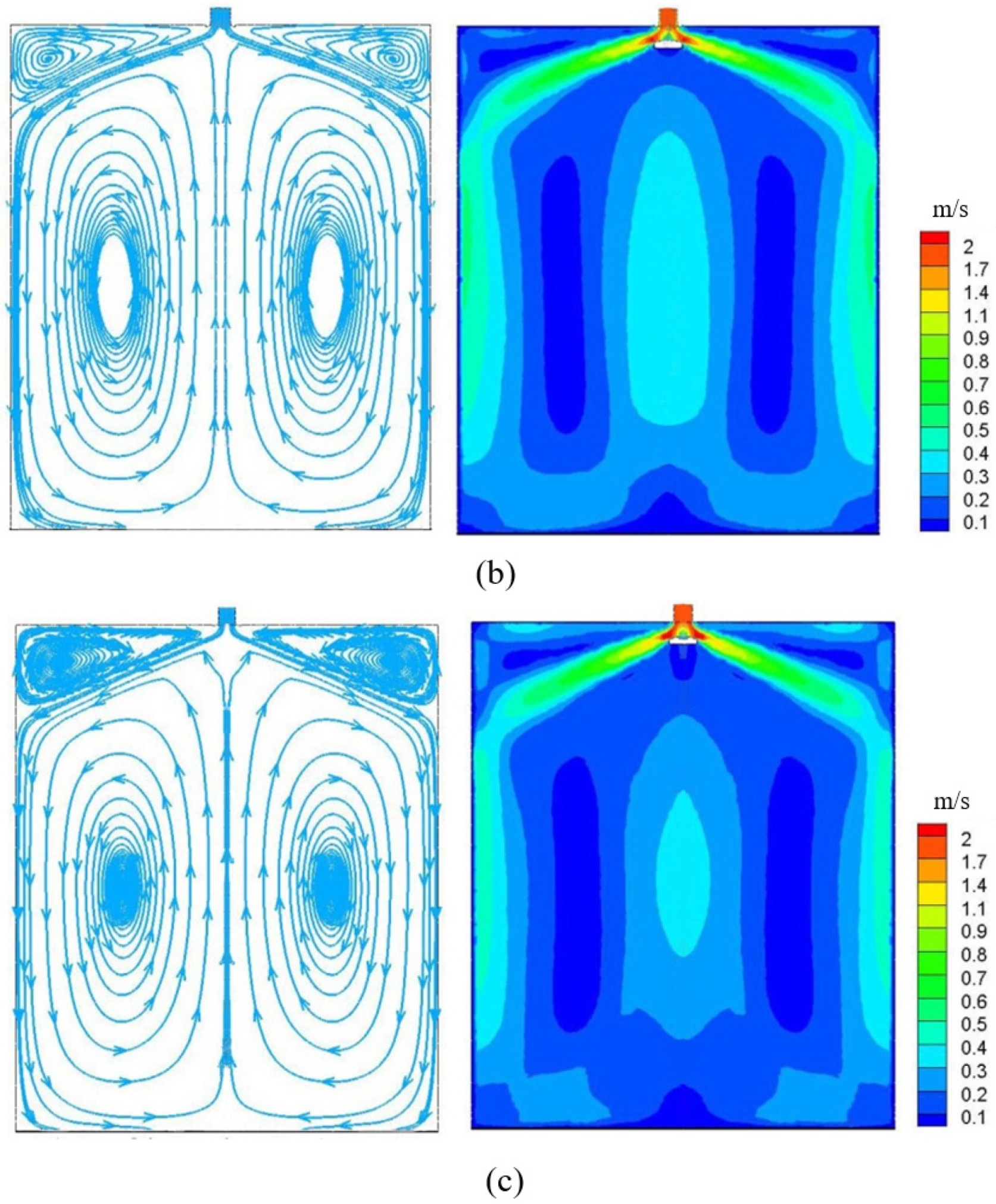

4.3. Free-Surface Turbulent Kinetic Energy

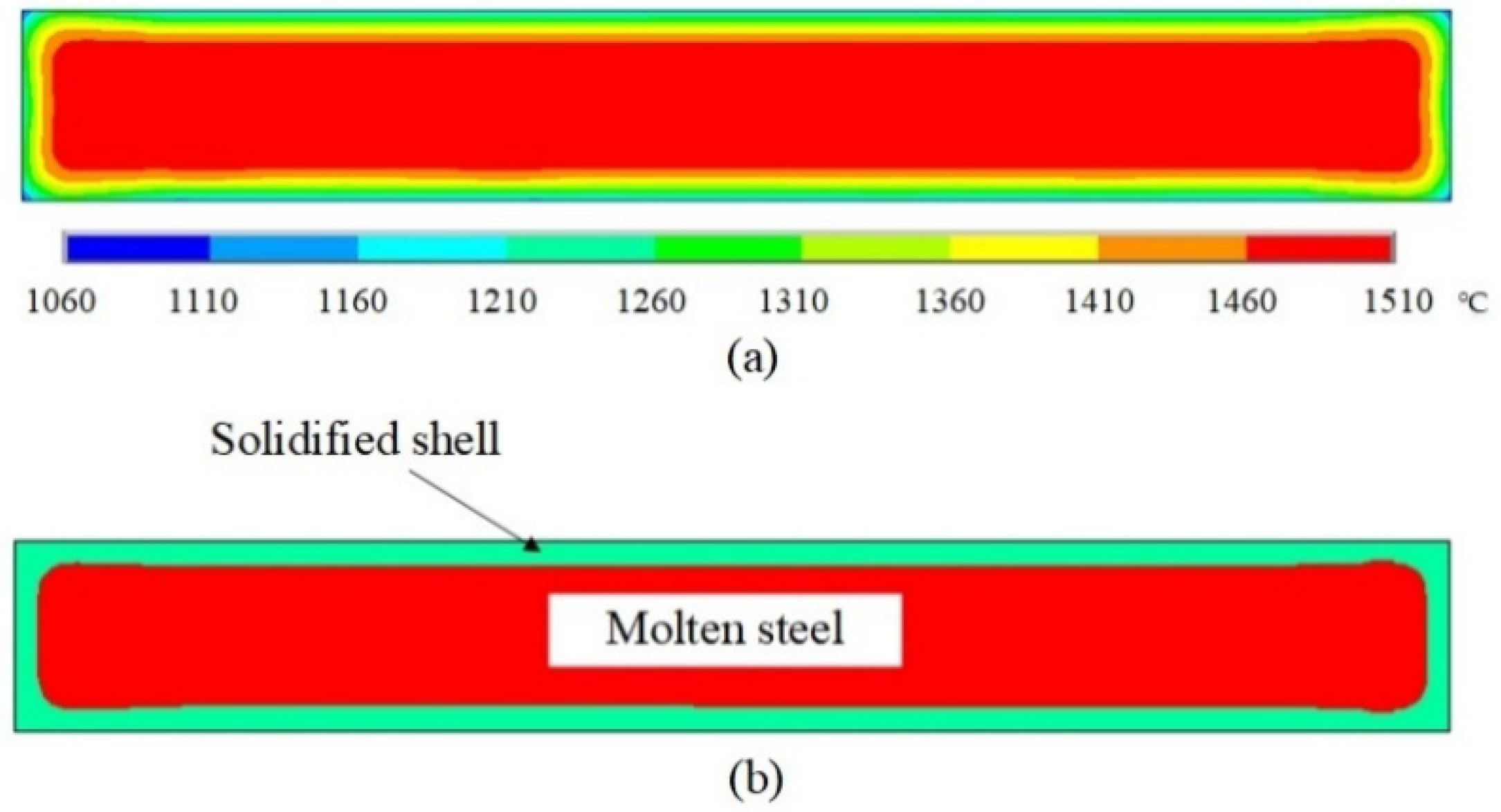

4.4. Heat Transfer and Solidification

5. Conclusions

- The fluid steel flows out from the nozzle at a certain angle. When the main stream approaches the narrow surface, the flow rate and momentum of the fluid steel gradually decrease and two split streams are formed.

- The spherical area at the bottom of the nozzle can reduce the flow rate of the fluid steel at the outlet of the nozzle. In addition, the speed of the rising stream is significantly reduced, the fluctuation of the free liquid surface of the fluid steel is small and the liquid level is more stable.

- The turbulent kinetic energy of the free liquid surface of nozzles A, B and C are 0.00204, 0.00154 and 0.00193 m2·s−2, respectively, which shows that nozzle B is the best.

- In the future work, more nozzle structures will be researched to compare the influence of the nozzle structure on the flow and solidification characteristics. In addition, more of the actual slab quality in a steel factory will be examined to reveal the corresponding relationship between the nozzle structure and slab quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| SEN | Submerged entry nozzle |

| v | Velocity vector |

| ρ | Density |

| t | Time |

| p | Pressure |

| F | External volume force |

| τ | Stress tensor |

| I | Unit tensor |

| cρ | Specific heat capacity |

| T | Temperature |

| k | Heat transfer coefficient |

| ST | Viscous dissipation term |

| Top | The top of the mold |

| Bottom | The exit of the mold |

| Narrow face | The narrow copper plate of the mold |

| Wide face | The wide copper plate of the mold |

References

- Rasheed, H.U.; Islam, S.; Zeeshan; Khan, J.; Abbas, T.; Mohmand, M.I. Numerical solution of chemically reactive and thermally radiative MHD Prandtl nanofluid over a curved surface with convective boundary conditions. ZAMM-J. Appl. Math. Mech. 2021, e202100125. [Google Scholar] [CrossRef]

- Thomas, B.G.; Zhang, L. Mathematical modeling of fluid flow in continuous casting. ISIJ Int. 2001, 10, 1181–1193. [Google Scholar] [CrossRef]

- Gupta, D.; Chakraborty, S.; Lahiri, A.K. Asymmetry and oscillation of the fluid flow pattern in a continuous casting mould: A water model study. ISIJ Int. 1997, 37, 654–658. [Google Scholar] [CrossRef]

- Korti, A.I.N.; Khadraoui, Y. A numerical simulation of the DC continuous casting using average heat capacity. Scand. J. Met. 2004, 33, 347. [Google Scholar] [CrossRef]

- Rasheed, H.U.; AL-Zubaidi, A.; Islam, S.; Saleem, S.; Khan, Z.; Khan, W. Effects of joule heating and viscous dissipation on magnetohydrodynamic boundary layer flow of jeffrey nanofluid over a vertically stretching cylinder. Coatings 2021, 11, 353. [Google Scholar] [CrossRef]

- Khan, Z.; Rasheed, H.U.; Khan, I.; Abu-Zinadah, H.; Aldahlan, M.A. Mathematical simulation of casson MHD flow through a permeable moving wedge with nonlinear chemical reaction and nonlinear thermal radiation. Materials 2022, 15, 747. [Google Scholar] [CrossRef]

- Zeeshan. Second law and entropy generation analysis of magnetized viscous fluid flow over a permeable expandable sheet with nonlinear thermal radiation: Brownian and thermophoresis effect. Adv. Mech. Eng. 2022, 14, 16878140221075295. [Google Scholar] [CrossRef]

- Thomas, B.G. Modeling of the continuous casting of steel—Past, present, and future. Metall. Mater. Trans. B 2002, 33, 795–812. [Google Scholar] [CrossRef]

- Du, F.; Chen, C.; Zhang, K. Fluid characteristics analysis of the lubricating oil film and the wear experiment investigation of the sliding bearing. Coatings 2022, 12, 67. [Google Scholar] [CrossRef]

- Takatani, K.; Tanizawa, Y.; Mizukami, H.; Nishimura, K. Mathematical model for transient fluid flow in a continuous casting mold. ISIJ Int. 2001, 41, 1252–1261. [Google Scholar] [CrossRef] [Green Version]

- Zeeshan; Rasheed, H.U.; Khan, W.; Khan, I.; Alshammari, N.; Hamadneh, N. Numerical computation of 3D Brownian motion of thin film nanofluid flow of convective heat transfer over a stretchable rotating surface. Sci. Rep. 2022, 12, 2708. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Gao, J.; Rohatgi, P.K.; Zhao, H.; Li, Y. Effect of the depth of the submerged entry nozzle in the mold on heat, flow and solution transport in double-stream-pouring continuous casting. J. Mater. Process. Technol. 2009, 209, 5536–5544. [Google Scholar] [CrossRef]

- Tsukaguchi, Y.; Nakamura, O.; Jnsson, P.R.; Yokoya, S.; Tanaka, T. Design of swirling flow submerged entry nozzles for optimal head consumption between tundish and mold. ISIJ Int. 2007, 47, 1436–1443. [Google Scholar] [CrossRef] [Green Version]

- Najera-Bastida, A.; Morales, R.D.; Garcia-Hernandez, S.; Torres-Alonso, E.; Espino-Zarate, A. Shell thinning phenomena affected by heat transfer, nozzle design and flux chemistry in billets moulds. ISIJ Int. 2010, 50, 830–838. [Google Scholar] [CrossRef] [Green Version]

- Torren, A.E.; Morales, R.D.; Garcia-Hernandez, S.; Najera-Bastida, A.; Sandoval-Ramos, A. Influence of straight nozzles on fluid flow in mold and billet quality. Metall. Mater. Trans. B 2008, 39, 840–852. [Google Scholar] [CrossRef] [Green Version]

- Rasheed, H.U.; Islam, S.; Khan, Z.; Khan, J.; Mashwani, W.K.; Abbas, T.; Shah, Q.Y. Computational analysis of hydromagnetic boundary layer stagnation point flow of nano liquid by a stretched heated surface with convective conditions and radiation effect. Adv. Mech. Eng. 2021, 13, 16878140211053142. [Google Scholar] [CrossRef]

- Zeeshan; Khan, I.; Amina; Alshammari, N.; Hamadneh, N. Double-layer coating using MHD flow of third-grade fluid with Hall current and heat source/sink. Open Phys. 2021, 19, 683–692. [Google Scholar] [CrossRef]

- Shamsi, M.; Ajmani, S.K. Three dimensional turbulent fluid flow and heat transfer mathematical model for the analysis of a continuous slab caster. ISIJ Int. 2007, 47, 433–442. [Google Scholar] [CrossRef] [Green Version]

- Tripathi, A.; Ajmani, S.K.; Chandra, S. Numerical investigation of bias flow in a slab caster mould. Can. Metall. Quart. 2021, 60, 203–214. [Google Scholar] [CrossRef]

- Gupta, D.; Lahiri, A.K. Water modeling study of the jet characteristics in a continuous-casting mold. Steel Res. Int. 1992, 63, 201–204. [Google Scholar] [CrossRef]

- Bai, H.; Thomas, B.G. Turbulent flow of liquid steel and argon bubbles in slide-gate tundish nozzles: Part II. Effect of operation conditions and nozzle design. Metall. Mater. Trans. B 2001, 32, 269–284. [Google Scholar] [CrossRef]

- Bao, Y.; Zhu, J.; Jiang, W.; Wang, C.; Xu, B. Water modeling research on slag-entrapment in the mould of thin slab continuous caster. J. Univ. Sci. Technol. Beijing 1999, 21, 530. [Google Scholar] [CrossRef]

- Zhang, X.-W.; Jin, X.-L.; Wang, Y.; Deng, K.; Ren, Z.-M. Comparison of standard k-ε model and RSM on three dimensional turbulent flow in the SEN of slab continuous caster controlled by slide gate. ISIJ Int. 2011, 51, 581–587. [Google Scholar] [CrossRef] [Green Version]

- Takatani, K. Effects of electromagnetic brake and meniscus electromagnetic stirrer on transient molten steel flow at meniscus in a continuous casting mold. ISIJ Int. 2003, 6, 915–922. [Google Scholar] [CrossRef]

- Li, B.; Tsukihashi, F. Effects of electromagnetic brake on vortex flows in thin slab continuous casting mold. ISIJ Int. 2006, 12, 1833–1838. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.F.; Zhang, L.F. Transient fluid flow phenomena during continuous casting: Part I—Casting start. ISIJ Int. 2010, 12, 1777–1782. [Google Scholar] [CrossRef] [Green Version]

- Lu, B.W.; Yuan, F.L.; Wang, H.L.; Bai, H. Water model experimental study on the behavior of fluid flow in slab caster mold. Res. Iron Steel 2015, 43, 24–27. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Mold height (mm) | 900 |

| Nozzle immersion depth (mm) | 130 |

| Casting speed (m·min−1) | 0.8 |

| Density of steel (kg·m−3) | 7200 |

| Viscosity of steel (kg·m−1·s−1) | 0.0055 |

| Pour point (°C) | 1510 |

| Liquidius temperature (°C) | 1490 |

| Solidus temperature (°C) | 1420 |

| Specific heat of steel (J∙kg−1∙°C−1) | 740 |

| Latent heat (J∙kg−1) | 274,950 |

| Number of Grid | Maximum Free-Surface Turbulent Kinetic Energy | Deviation |

|---|---|---|

| 75,684 | 0.00136 | - |

| 195,634 | 0.00179 | 0.00037 |

| 380,523 | 0.00201 | 0.00022 |

| 456,951 | 0.00204 | 0.00003 |

| 506,587 | 0.00205 | 0.00001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, F.; Li, T.; Zeng, Y.; Zhang, K. Influence of Nozzle Design on Flow Characteristic in the Continuous Casting Machinery. Coatings 2022, 12, 631. https://doi.org/10.3390/coatings12050631

Du F, Li T, Zeng Y, Zhang K. Influence of Nozzle Design on Flow Characteristic in the Continuous Casting Machinery. Coatings. 2022; 12(5):631. https://doi.org/10.3390/coatings12050631

Chicago/Turabian StyleDu, Fengming, Tianyi Li, Yunbo Zeng, and Kaiguang Zhang. 2022. "Influence of Nozzle Design on Flow Characteristic in the Continuous Casting Machinery" Coatings 12, no. 5: 631. https://doi.org/10.3390/coatings12050631