Design of Ti-Zr-Ta Alloys with Low Elastic Modulus Reinforced by Spinodal Decomposition

Abstract

:1. Introduction

2. Experimental Methods

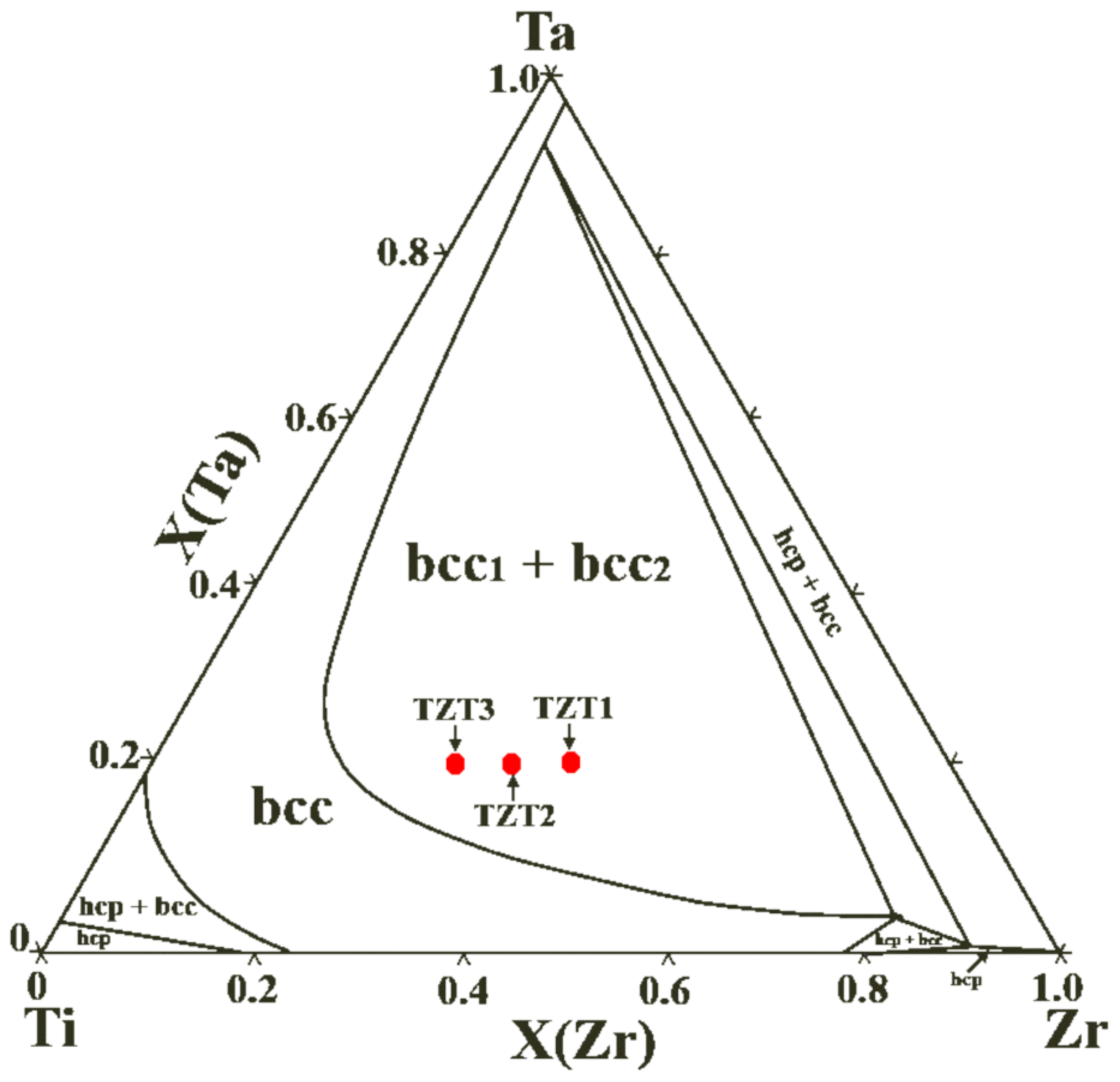

2.1. Design of Ti-Zr-Ta Alloys with Spinodal Decomposition

2.2. Preparation of Ti-Zr-Ta Alloys

2.3. Microstructure and Mechanical Properties’ Characterization

3. Results and Discussion

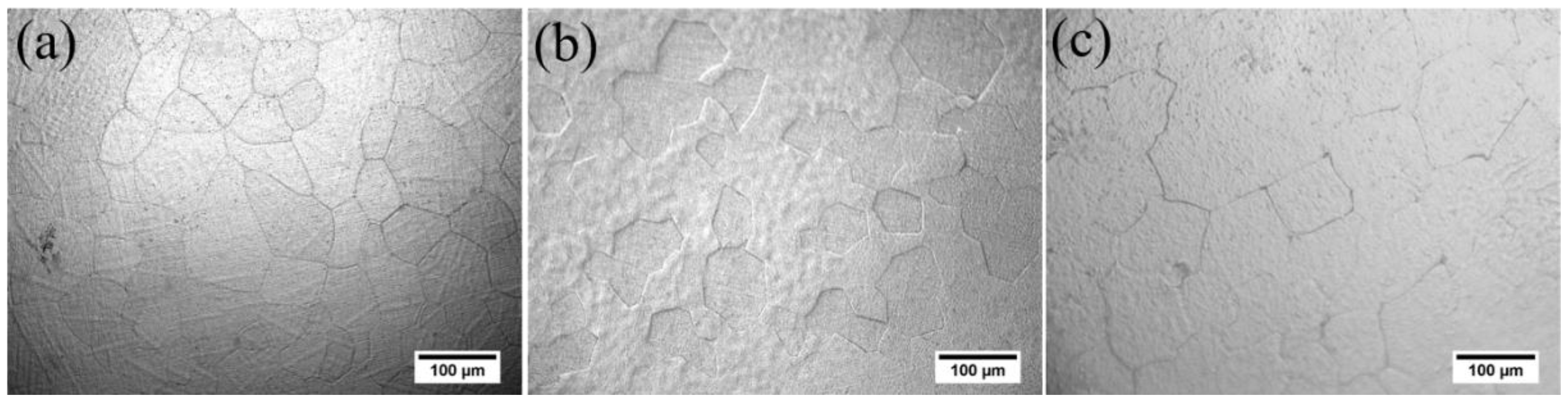

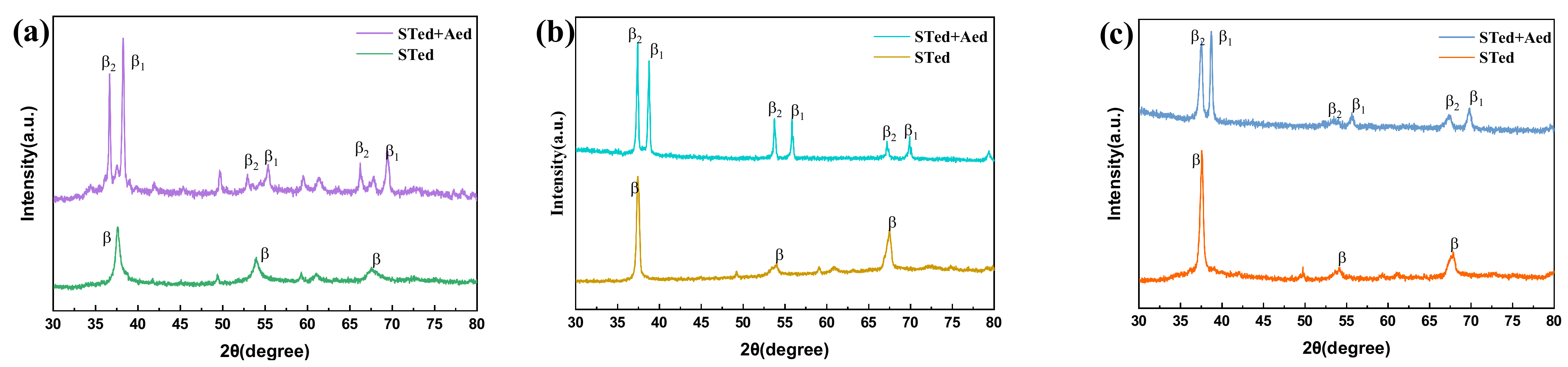

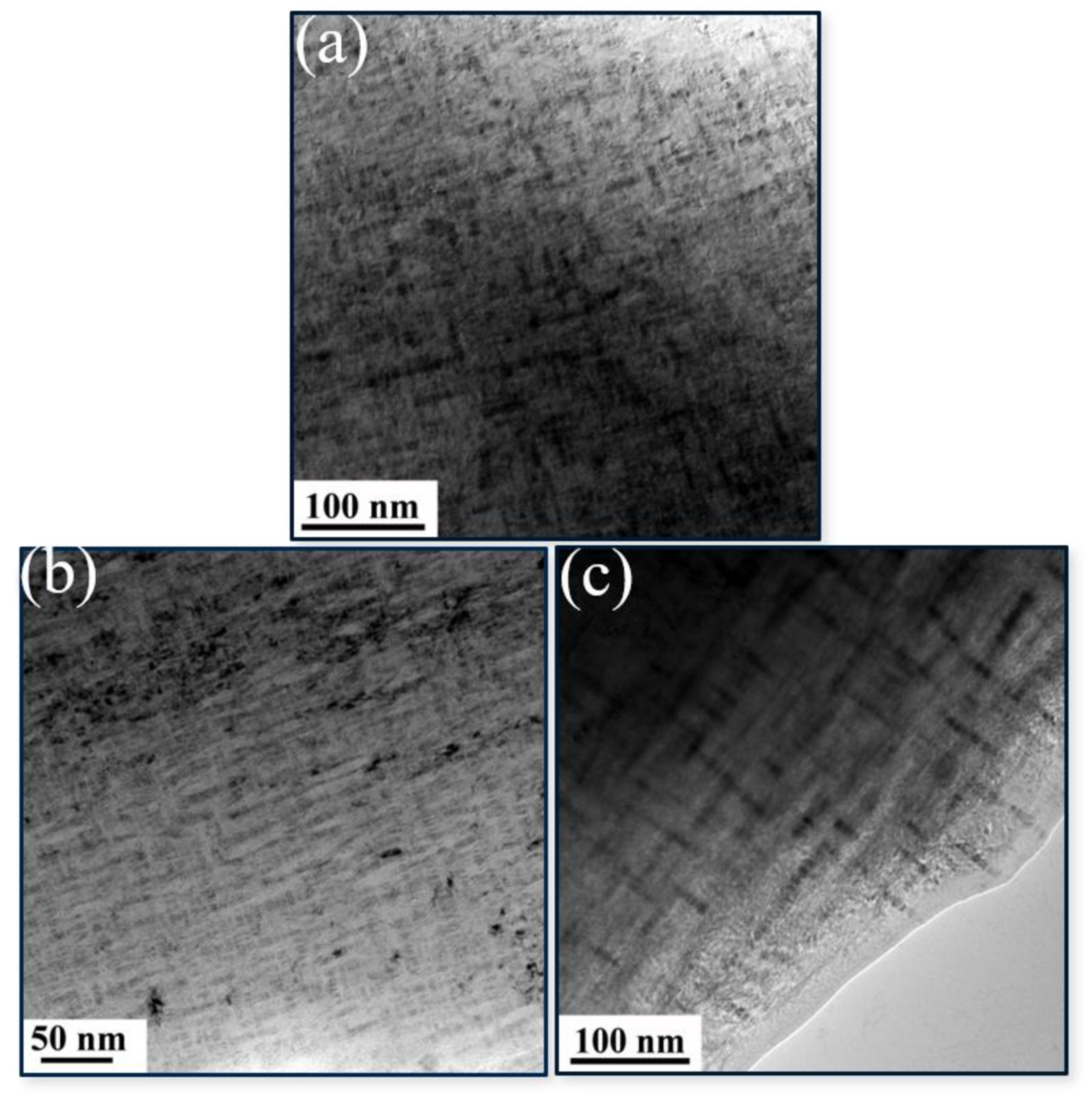

3.1. Microstructure

3.2. Mechanical Properties

4. Conclusions

- (1)

- The microstructure of the designed alloys consisted of β-equiaxed grains after solution treatment at 1173 K for 3 h. After being aged at 973 K for 6 h, spinodal decomposition occurred, forming the self-organized, tweed-like microstructure with a modulated contrast along [100] and [010] directions in the three alloys.

- (2)

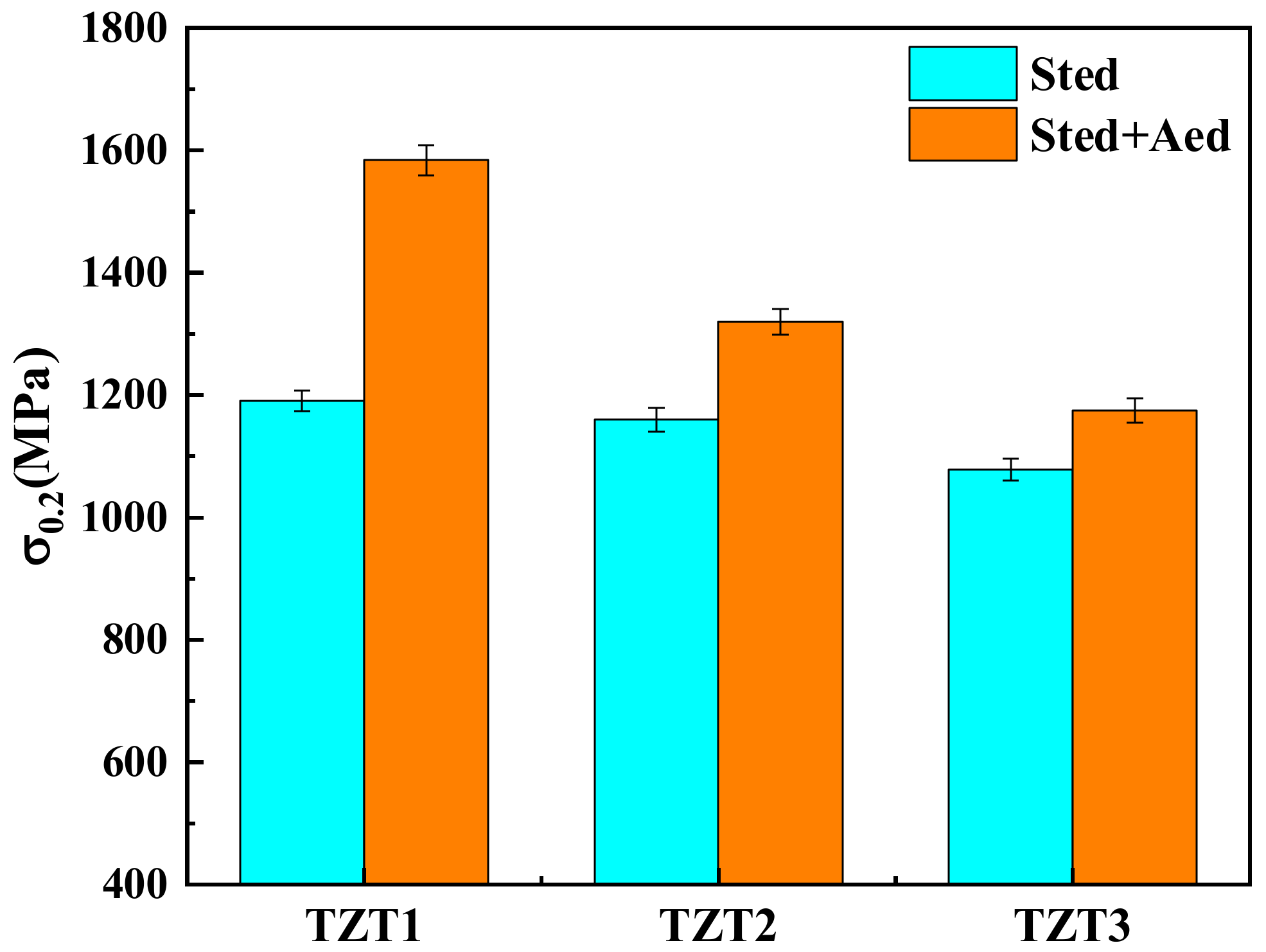

- The yield strength of the STed alloys of TZT1, TZT2 and TZT3 were 1191 MPa, 1150 MPa and 1075 MPa, respectively, after being aged at 973 K for 6 h. The yield strengths of the three alloys were increased to 1580 MPa, 1320 MPa and 1180 MPa, respectively. The spinodal strengthening may be responsible for the increase in the strength of the alloys.

- (3)

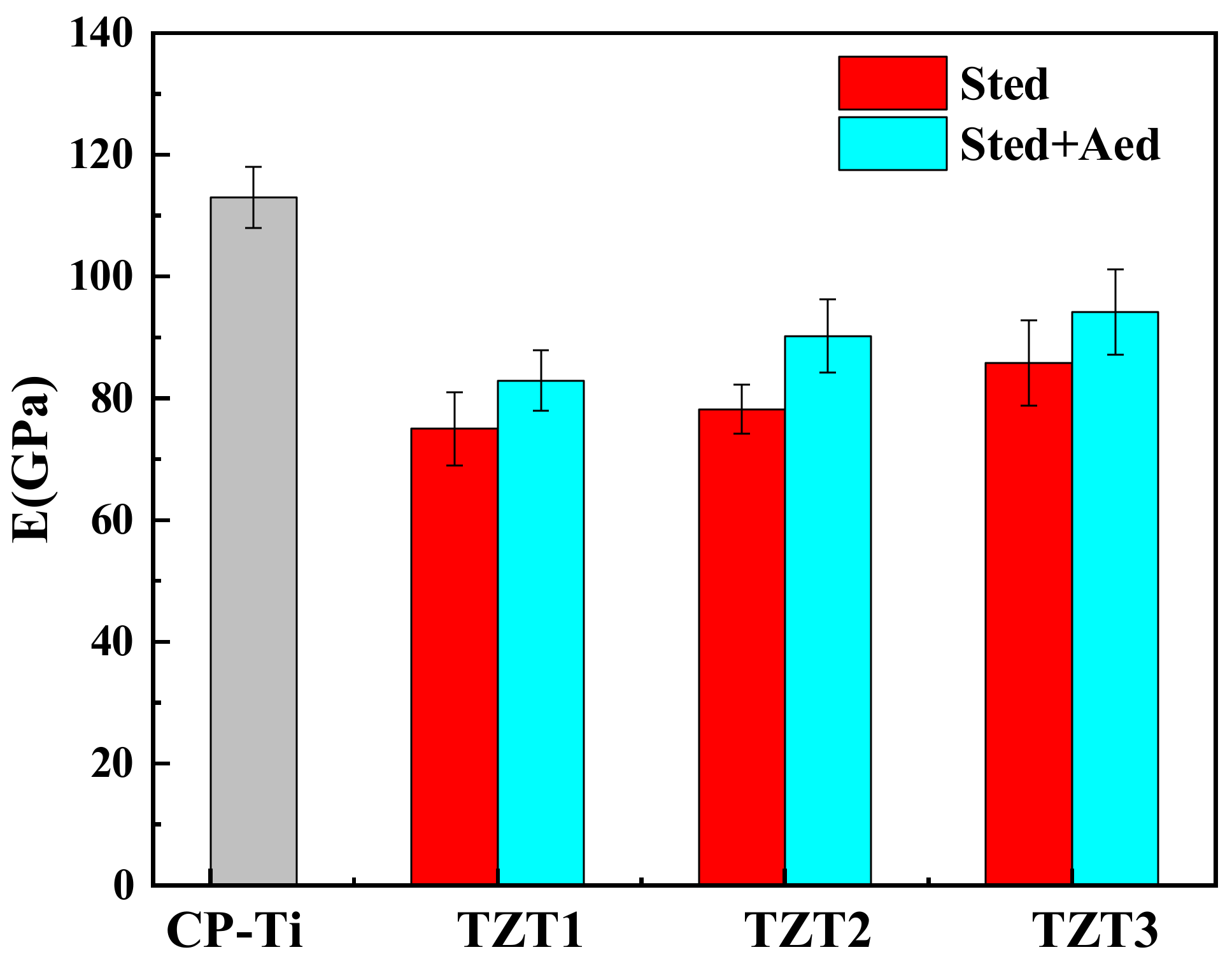

- The elastic moduli of the three alloys after solid-solution treatment were 75.0 GPa, 78.2 GPa and 85.8 GPa, respectively, which was much lower than that of pure titanium (about 113 GPa). The TZT1 alloy exhibited the lowest elastic modulus due to its high value of .

- (4)

- After being aged at 973 K for 6 h, the elastic moduli of the three alloys slightly increased. Spinodal decomposition can significantly promote the strength of the Ti-Zr-Ta alloys without a large increase in their elastic modulus.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, L.; Naghavi, S.A.; Wang, Z.; Varma, S.N.; Han, Z.; Yao, Z.; Wang, L.; Wang, L.; Liu, C. On the design evolution of hip implants: A review. Mater. Des. 2022, 216, 110552. [Google Scholar] [CrossRef]

- Besinis, A.; Hadi, S.D.; Le, H.; Tredwin, C.; Handy, R. Antibacterial activity and biofilm inhibition by surface modified titanium alloy medical implants following application of silver, titanium dioxide and hydroxyapatite nanocoatings. Nanotoxicology 2017, 11, 327–338. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.C.; Chen, L.Y. A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef] [Green Version]

- Kyzioł, K.; Kaczmarek, Ł.; Brzezinka, G.; Kyzioł, A. Structure, characterization and cytotoxicity study on plasma surface modified Ti–6Al–4V and γ-TiAl alloys. Chem. Eng. J. 2014, 240, 516–526. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Xiong, J.; Hodgson, P.D. Porous TiNbZr alloy scaffolds for biomedical applications. Acta Biomater. 2009, 5, 3616–3624. [Google Scholar] [CrossRef] [PubMed]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Welsch, G.; Boyer, R.; Collings, E. Materials Properties Handbook: Titanium Alloys; ASM International: Almere, The Netherlands, 1993. [Google Scholar]

- Abigail, M.N. The Design and Development of a Novel Beta Ti Alloys with Low Elastic Modulus for Biomedical Application. Master’s Thesis, University of Johannesburg, Johannesburg, South Africa, 2020. [Google Scholar]

- Hagihara, K.; Nakano, T.; Maki, H.; Umakoshi, Y.; Niinomi, M. Isotropic plasticity of β-type Ti-29Nb-13Ta-4.6 Zr alloy single crystals for the development of single crystalline β-Ti implants. Sci. Rep. 2016, 6, 29779. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Y.; Castany, P.; Cornen, M.; Prima, F.; Li, S.; Hao, Y.; Gloriant, T. Characterization of the martensitic transformation in the superelastic Ti–24Nb–4Zr–8Sn alloy by in situ synchrotron X-ray diffraction and dynamic mechanical analysis. Acta Mater. 2015, 88, 25–33. [Google Scholar] [CrossRef]

- Langer, J.S. Theory of spinodal decomposition in alloys. Ann. Phys. 1971, 65, 53–86. [Google Scholar] [CrossRef]

- Tang, Y.; Goto, W.; Hirosawa, S.; Horita, Z.; Lee, S.; Matsuda, K.; Terada, D. Concurrent strengthening of ultrafine-grained age-hardenable Al-Mg alloy by means of high-pressure torsion and spinodal decomposition. Acta Mater. 2017, 131, 57–64. [Google Scholar] [CrossRef]

- Wang, J.L. Study on phase diagram, thermodynamics of phase equilibrium and alloy design of titanium alloy. Doctoral Dissertation, Central South University, Changsha, China, 2015. (Unpublished). [Google Scholar]

- Zhang, D.; Lin, J.; Jiang, W.; Ma, M.; Peng, Z. Shape memory and superelastic behavior of Ti–7.5 Nb–4Mo–1Sn alloy. Mater. Des. 2011, 32, 4614–4617. [Google Scholar] [CrossRef]

- Abdel-Hady, M.; Hinoshita, K.; Morinaga, M. General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scr. Mater. 2006, 55, 477–480. [Google Scholar] [CrossRef]

- Sung, H.H.; Sang, W.P.; Chan, H.P.; Jong, T.Y.; Ki, B.K. Relationship between phase stability and mechanical properties on near/metastable β-type Ti–Cr-(Mn) cast alloys. J. Alloys Compd. 2020, 821, 153516. [Google Scholar]

- Bolzoni, L.; Alqattan, M.; Yang, F.; Peters, L. Design of β-eutectoid bearing ti alloys with antibacterial functionality. Mater. Lett. 2020, 278, 128445. [Google Scholar] [CrossRef]

- Shao, L.F.; Du, Y.H.; Dai, K.; Wu, H.; Wang, Q.G.; Liu, J.; Tang, Y.J.; Wang, L.Q. β-Ti alloys for orthopedic and dental applications: A review of progress on improvement of properties through surface modification. Coatings 2021, 11, 1446. [Google Scholar] [CrossRef]

| Alloys | Bo | Md |

|---|---|---|

| TZT1 | 2.9792 | 2.6586 |

| TZT2 | 2.9644 | 2.6342 |

| TZT3 | 2.9496 | 2.6099 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, R.; Yi, Q.; Lei, S.; Dai, Y.; Lin, J. Design of Ti-Zr-Ta Alloys with Low Elastic Modulus Reinforced by Spinodal Decomposition. Coatings 2022, 12, 756. https://doi.org/10.3390/coatings12060756

Wu R, Yi Q, Lei S, Dai Y, Lin J. Design of Ti-Zr-Ta Alloys with Low Elastic Modulus Reinforced by Spinodal Decomposition. Coatings. 2022; 12(6):756. https://doi.org/10.3390/coatings12060756

Chicago/Turabian StyleWu, Rong, Qionghua Yi, Shan Lei, Yilong Dai, and Jianguo Lin. 2022. "Design of Ti-Zr-Ta Alloys with Low Elastic Modulus Reinforced by Spinodal Decomposition" Coatings 12, no. 6: 756. https://doi.org/10.3390/coatings12060756

APA StyleWu, R., Yi, Q., Lei, S., Dai, Y., & Lin, J. (2022). Design of Ti-Zr-Ta Alloys with Low Elastic Modulus Reinforced by Spinodal Decomposition. Coatings, 12(6), 756. https://doi.org/10.3390/coatings12060756