Cold Spray of Nickel-Based Alloy Coating on Cast Iron for Restoration and Surface Enhancement

Abstract

:1. Introduction

2. Materials and Methods

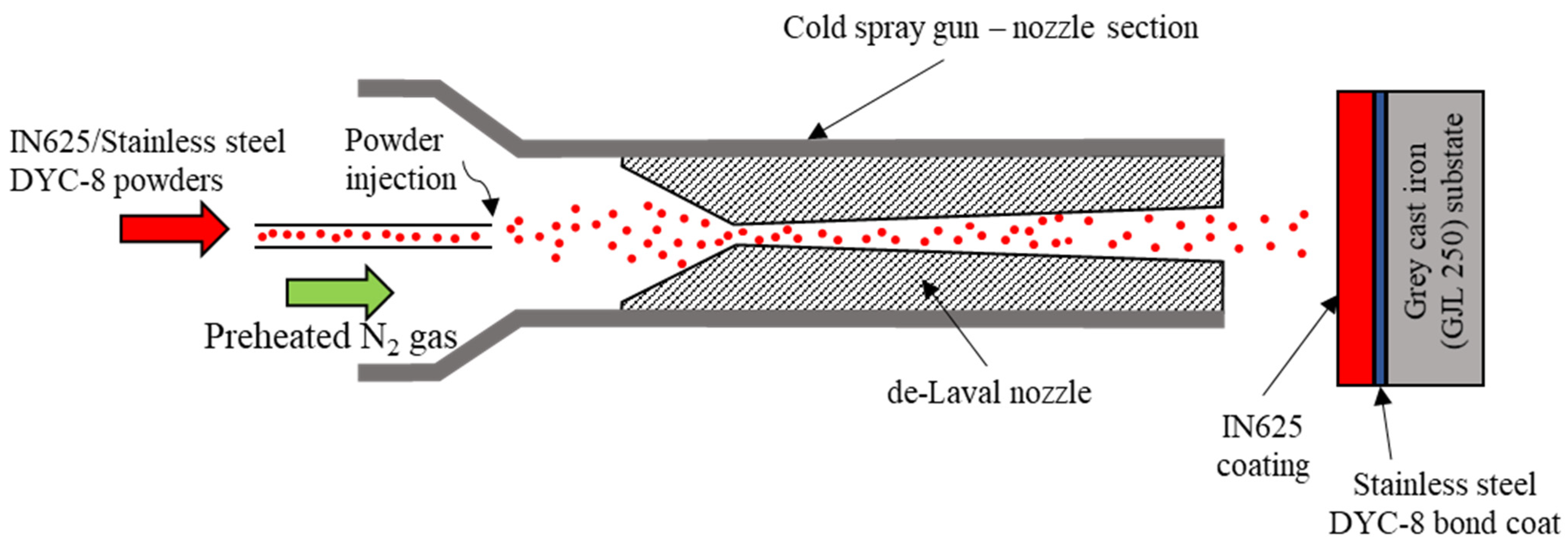

2.1. Materials and Coating Deposition

2.2. Heat Treatment Process

2.3. Characterisation

3. Results and Discussion

3.1. Cross-Section Analysis

3.2. Oxidation Changes

3.3. Microhardness Profile

4. Conclusions

- The IN625 coatings were found to be dense with low porosity, no cracks and delamination at the coating-substrate interface.

- The heat treatment of the samples significantly influences the atomic diffusion between the coating, bond coat, and substrate. Higher heat treatment temperatures with longer duration promote a thicker interface diffusion layer.

- Oxygen content was found to be absent in the coating at temperatures of 400 °C and below, which is an indication of a lack of activation energy. However, at temperatures above 600 °C, the oxygen concentration increases and may form oxides. Oxide growth is quite significant on the uncoated section of the grey cast iron substrate, especially for heat treatment temperatures above 850 °C, while the coated area has negligible oxide growth. Hence, cold sprayed IN625 coating is proven to be effective in preventing oxidation of grey cast iron.

- The hardness of IN625 coatings was found to have improved with heat treatment at 600 °C due to possible formation of recrystallised nanostructured grains, strengthening precipitates (γˊ and γ˝), and improvement of cohesion strength between different splats. However, heat treatment temperatures above 600 °C resulted in hardness reduction due to grain growth and reduction in dislocation densities within the grains.

- Cold sprayed IN625 coating onto grey cast iron is feasible, of high quality and beneficial in terms of oxidation reduction and surface enhancement (due to the higher hardness of IN625), thus providing possibilities to repair/restore grey cast iron components such as engine blocks, pump housings, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- NovaCast Limited. Grey Iron EN-GJL-250. Available online: https://www.novacast.co.uk/alloy-specifications/grey-iron-en-gjl-250/ (accessed on 29 December 2021).

- Gieterij Dijkkamp. Characteristics of GG25. Available online: https://www.dijkkamp.nl/en/materials/gg25-en-gjl-250/ (accessed on 29 December 2021).

- Laouissi, A.; Yallese, M.A.; Belbah, A.; Khellaf, A.; Haddad, A. Comparative study of the performance of coated and uncoated silicon nitride (Si3N4) ceramics when machining EN-GJL-250 cast iron using the RSM method and 2D and 3D roughness functional parameters. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 205. [Google Scholar] [CrossRef]

- Oerlikon Metco. Diamalloy 1005. Available online: https://mymetco.oerlikon.com/en-us/product/diamalloy1005 (accessed on 29 December 2021).

- Shankar, V.; Rao, K.B.S.; Mannan, S. Microstructure and mechanical properties of Inconel 625 superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Sun, W.; Tan, A.W.-Y.; King, D.J.Y.; Khun, N.W.; Bhowmik, A.; Marinescu, I.; Liu, E. Tribological behavior of cold sprayed Inconel 718 coatings at room and elevated temperatures. Surf. Coat. Technol. 2020, 385, 125386. [Google Scholar] [CrossRef]

- Gross, D. Fatigue design and safety factor for scroll compressor wraps. In 8th International Conference on Compressors and Their Systems; Woodhead Publishing: Sawston, UK, 2013; pp. 285–300. [Google Scholar]

- Dilthey, U. Schweißtechnische Fertigungsverfahren 2: Verhalten der Werkstoffe beim Schweißen; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- The Welding Institute (TWI). Weldability of Materials—Cast Irons. Available online: https://www.twi-global.com/technical-knowledge/job-knowledge/weldability-of-materials-cast-irons-025 (accessed on 29 December 2021).

- Gao, P.-H.; Chen, B.-Y.; Zhang, B.; Yang, Z.; Guo, Y.-C.; Li, J.-P.; Liang, M.-X.; Li, Q.-P. Preparations of iron-based alloy coatings on grey cast iron through plasma transfer arc welding. J. Adhes. Sci. Technol. 2021, 36, 833–844. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Champagne, V.K.; Nelson, K.A.; Schuh, C.A. Adiabatic shear instability is not necessary for adhesion in cold spray. Acta Mater. 2018, 158, 430–439. [Google Scholar] [CrossRef]

- Reddy, C.D.; Zhang, Z.-Q.; Msolli, S.; Guo, J.; Sridhar, N. Impact velocity-dependent bonding mechanisms in metal cold spray. Surf. Coat. Technol. 2022, 433, 128085. [Google Scholar] [CrossRef]

- Papyrin, A.; Kosarev, V.; Klinkov, S.; Alkhimov, A.; Fomin, V.M. Cold Spray Technology; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Dykhuizen, R.C.; Smith, M.F.; Gilmore, D.L.; Neiser, R.A.; Jiang, X.; Sampath, S. Impact of high velocity cold spray particles. J. Therm. Spray Technol. 1999, 8, 559–564. [Google Scholar] [CrossRef]

- Vlcek, J.; Gimeno, L.; Huber, H.; Lugscheider, E. A systematic approach to material eligibility for the cold-spray process. J. Therm. Spray Technol. 2005, 14, 125–133. [Google Scholar] [CrossRef]

- McCune, R.C.; Papyrin, A.N.; Hall, J.N.; Riggs, W.L.; Zajchowski, P.H. An Exploration of the Cold Gas-Dynamic Spray Method for Several Materials Systems; Advances in Thermal Spray Science and Technology; ASM International: Materials Park, OH, USA, 1995; pp. 1–5. [Google Scholar]

- Kosarev, V.F.; Klinkov, S.V.; Alkhimov, A.P.; Papyrin, A.N. On some aspects of gas dynamics of the cold spray process. J. Therm. Spray Technol. 2003, 12, 265–281. [Google Scholar] [CrossRef]

- Schmidt, T.; Gaertner, F.; Kreye, H. New developments in cold spray based on higher gas and particle temperatures. J. Therm. Spray Technol. 2006, 15, 488–494. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; DeRosset, W.S.; Helfritch, D. Adiabatic shear instability based mechanism for particles/substrate bonding in the cold-gas dynamic-spray process. Mater. Des. 2004, 25, 681–688. [Google Scholar] [CrossRef]

- Bae, G.; Kumar, S.; Yoon, S.; Kang, K.; Na, H.; Kim, H.J.; Lee, C. Bonding features and associated mechanisms in kinetic sprayed titanium coatings. Acta Mater. 2009, 57, 5654–5666. [Google Scholar] [CrossRef]

- Bae, G.; Xiong, Y.; Kumar, S.; Kang, K.; Lee, C. General aspects of interface bonding in kinetic sprayed coatings. Acta Mater. 2008, 56, 4858–4868. [Google Scholar] [CrossRef]

- Wu, K.; Chee, S.W.; Sun, W.; Tan, A.W.-Y.; Tan, S.C.; Liu, E.; Zhou, W. Inconel 713C coating by cold spray for surface enhancement of Inconel 718. Metals 2021, 11, 2048. [Google Scholar] [CrossRef]

- Neo, R.G.; Wu, K.; Tan, S.C.; Zhou, W. Effect of spray distance and powder feed rate on particle velocity in cold spray processes. Metals 2022, 12, 75. [Google Scholar] [CrossRef]

- Yang, Y.; Aprilia, A.; Wu, K.; Tan, S.C.; Zhou, W. Post-processing of cold sprayed CoNiCrAlY coatings on Inconel 718 by rapid induction heating. Metals 2022, 12, 396. [Google Scholar] [CrossRef]

- Shah, Z.; Vrinceanu, N.; Rooman, M.; Deebani, W.; Shutaywi, M. Mathematical modelling of ree-eyring nanofluid using koo-kleinstreuer and cattaneo-christov models on chemically reactive AA7072-AA7075 alloys over a magnetic dipole stretching surface. Coatings 2022, 12, 391. [Google Scholar] [CrossRef]

- Gul, T.; Nasir, S.; Islam, S.; Shah, Z.; Khan, M.A. Effective prandtl number model influences on the γAl2O3–H2O and γAl2O3–C2H6O2 nanofluids spray along a stretching cylinder. Arab. J. Sci. Eng. 2019, 44, 1601–1616. [Google Scholar] [CrossRef]

- Champagne, V.; Helfritch, D. Critical Assessment 11: Structural repairs by cold spray. Mater. Sci. Technol. 2015, 31, 627–634. [Google Scholar] [CrossRef]

- Tham, N.Y.S.; Chua, Y.S.; Wu, K.; Tan, A.W.-Y.; Tan, S.C.; Zhou, W. Effectiveness of Cold Spray Coating on Cast Iron to Prevent Oxidation. In Proceedings of the 2nd International Conference on Advanced Surface Enhancement (INCASE 2021), Singapore, 7–8 September 2021; pp. 155–158. [Google Scholar]

- Sun, W.; Tan, A.W.Y.; Bhowmik, A.; Marinescu, J.; Huong, Y.; Liu, E. Additive manufacturing of inconel 625 superalloy parts via high pressure cold spray. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing, Nanyang Technological University, Singapore, 14–17 May 2018; pp. 14–17. [Google Scholar]

- Chaudhuri, A.; Raghupathy, Y.; Srinivasan, D.; Suwas, S.; Srivastava, C. Microstructural evolution of cold-sprayed Inconel 625 superalloy coatings on low alloy steel substrate. Acta Mater. 2017, 129, 11–25. [Google Scholar] [CrossRef]

- Srinivasan, D.; Chandrasekhar, V.; Amuthan, R.; Lau, Y.C.; Calla, E. Characterization of cold-sprayed IN625 and NiCr coatings. J. Therm. Spray Technol. 2016, 25, 725–744. [Google Scholar] [CrossRef]

- Poza, P.; Múnez, C.J.; Garrido-Maneiro, M.A.; Vezzù, S.; Rech, S.; Trentin, A. Mechanical properties of Inconel 625 cold-sprayed coatings after laser remelting. Depth sensing indentation analysis. Surf. Coat. Technol. 2014, 243, 51–57. [Google Scholar] [CrossRef]

- Wu, K.; Sun, W.; Tan, A.W.-Y.; Marinescu, I.; Liu, E.; Zhou, W. An investigation into microstructure, tribological and mechanical properties of cold sprayed Inconel 625 coatings. Surf. Coat. Technol. 2021, 424, 127660. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; Wiley: New York, NY, USA, 2018; Volume 9. [Google Scholar]

- Ltd, C.I. Alloy 625/Inconel 625. Available online: https://www.corrotherm.co.uk/grades/inconel-625 (accessed on 30 May 2022).

- Matmatch. EN 1561 Grade GJL-250 Cast Condition. Available online: https://matmatch.com/materials/minfm36374-en-1561-grade-gjl-250-cast-condition (accessed on 30 May 2022).

- Birt, A.M.; Champagne, V.K.; Sisson, R.D.; Apelian, D. Microstructural analysis of cold-sprayed Ti-6Al-4V at the micro- and nano-scale. J. Therm. Spray Technol. 2015, 24, 1277–1288. [Google Scholar] [CrossRef]

- Tan, A.W.-Y.; Sun, W.; Phang, Y.P.; Dai, M.; Marinescu, I.; Dong, Z.; Liu, E. Effects of traverse scanning speed of spray nozzle on the microstructure and mechanical properties of cold-sprayed Ti6Al4V coatings. J. Therm. Spray Technol. 2017, 26, 1484–1497. [Google Scholar] [CrossRef]

- Poirier, D.; Geiger, G. Fick’s Law and Diffusivity of Materials. In Transport Phenomena in Materials Processing; Springer: Berlin/Heidelberg, Germany, 2016; pp. 419–461. [Google Scholar]

- Sukumaran, A.; Gupta, R.; Kumar, V.A. Effect of heat treatment parameters on the microstructure and properties of Inconel-625 superalloy. J. Mater. Eng. Perform. 2017, 26, 3048–3057. [Google Scholar] [CrossRef]

- Liu, H.; Tan, C.K.I.; Wei, Y.; Lim, S.H.; Lee, C.J.J. Laser-cladding and interface evolutions of inconel 625 alloy on low alloy steel substrate upon heat and chemical treatments. Surf. Coat. Technol. 2020, 404, 126684. [Google Scholar] [CrossRef]

- Shaikh, M.A.; Ahmad, M.; Shoaib, K.A.; Akhter, J.I.; Iqbal, M. Precipitation hardening in Inconel* 625. Mater. Sci. Technol. 2000, 16, 129–132. [Google Scholar] [CrossRef]

- VonRoll Casting ag. Grey Cast Iron. Available online: https://www.vonroll-casting.ch/en/grey-cast-iron.html (accessed on 8 May 2022).

- Singh, R.; Schruefer, S.; Wilson, S.; Gibmeier, J.; Vassen, R. Influence of coating thickness on residual stress and adhesion-strength of cold-sprayed Inconel 718 coatings. Surf. Coat. Technol. 2018, 350, 64–73. [Google Scholar] [CrossRef]

- Shrestha, D.; Azarmi, F.; Tangpong, X.W. Effect of Heat Treatment on Residual Stress of Cold Sprayed Nickel-based Superalloys. J. Therm. Spray Technol. 2021, 31, 197–205. [Google Scholar] [CrossRef]

- Bhowmik, A.; Wei-Yee Tan, A.; Sun, W.; Wei, Z.; Marinescu, I.; Liu, E. On the heat-treatment induced evolution of residual stress and remarkable enhancement of adhesion strength of cold sprayed Ti–6Al–4V coatings. Results Mater. 2020, 7, 100119. [Google Scholar] [CrossRef]

- Seddighi, S.; Ostovan, F.; Shafiei, E.; Toozandehjani, M. A study on the effect of stress relief heat treatment on the microstructure and mechanical properties of dissimilar GTAW weld joints of Inconel 625 and A106 carbon steel. Mater. Res. Express 2019, 6, 086582. [Google Scholar] [CrossRef]

| Nomenclature | Unit | Diamalloy 1005 (IN625) Powder [35,36] | Grey Cast Iron (GJL250) Substrate [37] |

|---|---|---|---|

| Density | kg/m3 | 8440 | 7200 |

| Young’s Modulus | GPa | 207 | 103–118 |

| Tensile strength | MPa | 930 | 250–300 |

| Melting point | °C | 1290–1350 | 1127–1204 |

| Thermal conductivity | W/m·K | 9.8 | 50 |

| Specific heat | J/kg·K | 410 | 460 |

| Thermal expansion coefficient | μstrain/K | 12.8 | 10–13 |

| Materials | Ref. | Elements (wt.%) | |||||

|---|---|---|---|---|---|---|---|

| Diamalloy 1005 (IN625) Powder | [4] | Ni | Cr | Mo | Fe | Nb + Ta | - |

| 63.3 | 21.5 | 9.0 | 2.5 | 3.7 | - | ||

| Grey cast iron (GJL250) substrate | [2] | Fe | C | Si | Mn | S | P |

| 92.35–94.4 | 2.9–3.65 | 1.8–2.9 | 0.5–0.7 | ≤0.1 | ≤0.3 | ||

| Sample ID (Temperature-Duration) | Temperature (°C) | Duration (h) |

|---|---|---|

| 400-3 | 400 | 3 |

| 400-6 | 400 | 6 |

| 600-3 | 600 | 3 |

| 600-6 | 600 | 6 |

| 850-3 | 850 | 3 |

| 850-6 | 850 | 6 |

| 1050-3 | 1050 | 3 |

| 1050-6 | 1050 | 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, A.W.-Y.; Tham, N.Y.S.; Chua, Y.S.; Wu, K.; Sun, W.; Liu, E.; Tan, S.C.; Zhou, W. Cold Spray of Nickel-Based Alloy Coating on Cast Iron for Restoration and Surface Enhancement. Coatings 2022, 12, 765. https://doi.org/10.3390/coatings12060765

Tan AW-Y, Tham NYS, Chua YS, Wu K, Sun W, Liu E, Tan SC, Zhou W. Cold Spray of Nickel-Based Alloy Coating on Cast Iron for Restoration and Surface Enhancement. Coatings. 2022; 12(6):765. https://doi.org/10.3390/coatings12060765

Chicago/Turabian StyleTan, Adrian Wei-Yee, Nataniel Yong Syn Tham, Yao Shian Chua, Kaiqiang Wu, Wen Sun, Erjia Liu, Sung Chyn Tan, and Wei Zhou. 2022. "Cold Spray of Nickel-Based Alloy Coating on Cast Iron for Restoration and Surface Enhancement" Coatings 12, no. 6: 765. https://doi.org/10.3390/coatings12060765