Design Methodology and Application of Surface Texture: A Review

Abstract

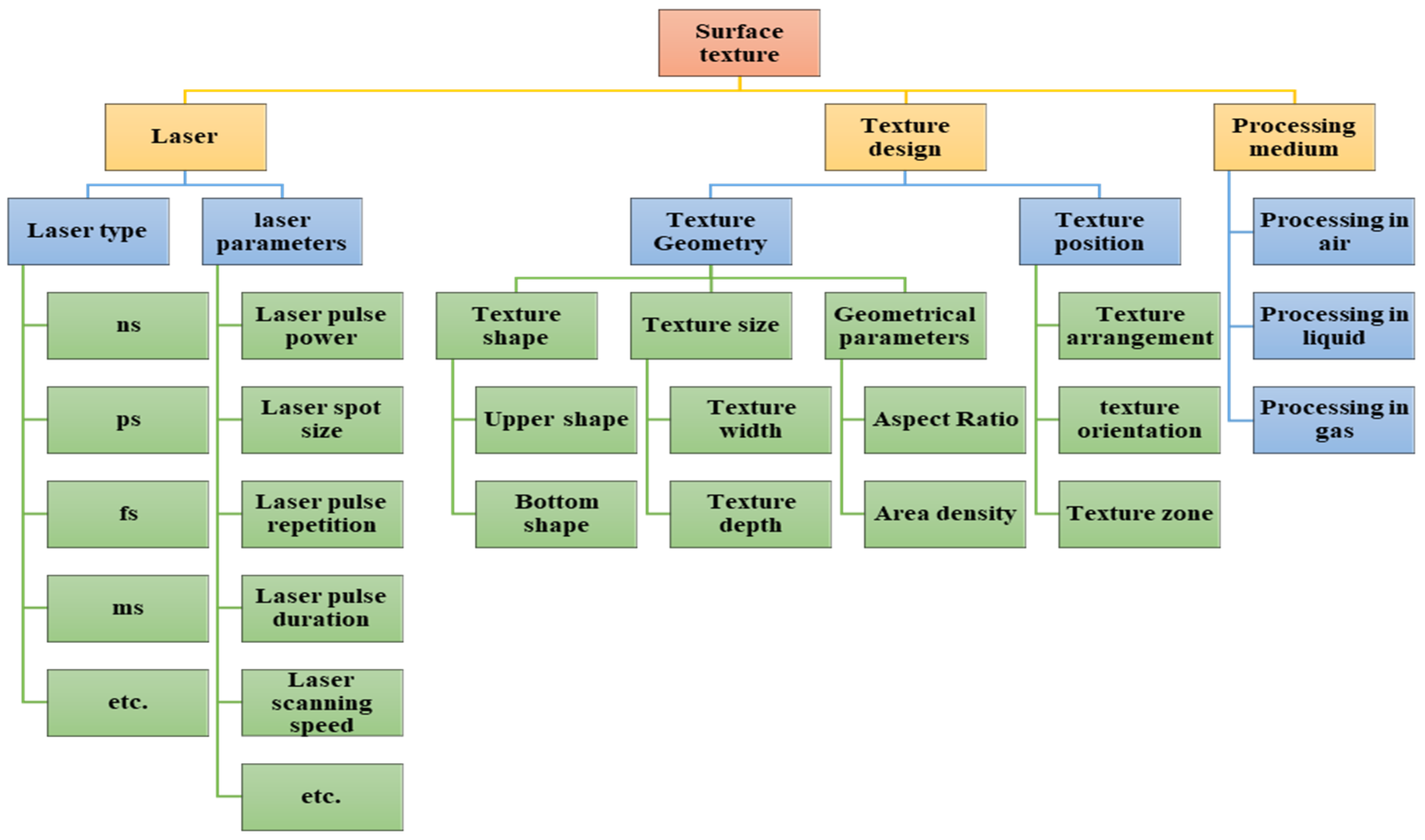

:1. Introduction

2. Effect of Laser Pulse Properties

2.1. Laser Type

2.2. Laser Power Intensity and Scanning Speed

2.3. Pulse Repetition Rate

3. Effect of Geometric Characteristics of Textured Surfaces

3.1. Effect of the Texture Shape

3.2. Effect of the Texture Size

3.3. Effect of Area Density and Area Ratio

3.4. Effect of Texture Arrangement, Orientation, and Sliding Direction

4. Laser Surface Texture Processing Medium

4.1. Pulse Laser Ablation Processing with Liquids

4.2. Pulse Laser Ablation Processing with Gases

5. Effect of Surface Texture on Lubricated Condition

6. Application of Surface Texturing

6.1. Surface Texture for Superhydrophobic Surfaces

6.2. Surface Texture for Anti-Drag Application

6.3. Surface Texture for Vibration and Noise in Mechanical Equipment

7. Conclusions and Outcomes

- Depending on the material and the machining instrument, different pulse durations (ns, fs, and ps) have different effects. The ablation of 50CrMo4 steel required 1.5 W for the fs laser, 13.5 W for the ps laser, and >90 W for the ns laser. For silicon nitride, 1 W was required for the ps laser, with a maximum of 3 and 1.6 W for the ns laser. A lower pulse power lowered the HAZ and created burrs in both situations. Short and ultra-short lasers can withstand a high laser power while causing less heat damage and defects.

- Low scanning speeds (less than 10 mm/s) provide high-quality surface textures in a wide range of materials, but high scanning speeds may result in smaller widths and deeper depths. A high repetition rate could reduce the size and volume of craters.

- Using an assist processing medium, such as a liquid or gas, can enhance crater structure, eliminate microcracks and debris redeposition, and reduce HAZ. The accumulation of fatigue on the target surface can be caused by ionization of water, recurrent high pressure, and thermal stress. The laser-induced gas bubble might scatter the laser beam, compromising the treated surface’s accuracy. Alcohol solution, KOH, or a shielding oil can be used to avoid gas bubbles and oxidation, thereby improving the surface’s finish. There are few investigations of laser ablation with a gas medium; this might be a future study subject.

- The texture characteristics have an indisputable effect on the tribological performance of mechanical equipment. The area density and area ratio are critical characteristics that have a significant impact on the tribological performance, with the area density affecting the performance in the range of 5%–20% and the area ratio less than 1. The design parameters should be carefully selected to ensure the generation of a thick lubricating film, lubricant storage, release, and a self-lubricating system.

- Oil lubricant is made of natural hydrocarbon elements that have low thermal stability, degrade quickly, and can move outside the friction contact when subjected to higher loads and sliding frequencies. The introduction of new lubricants provides a clear mechanism for the friction and wear reduction in extreme conditions. Furthermore, the synergistic usage of the surface texture and coating in the case of solid lubricants can increase the tribological behavior.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Todhunter, L.D.; Leach, R.K.; Lawes, S.D.A.; Blateyron, F. Industrial survey of ISO surface texture parameters. CIRP J. Manuf. Sci. Technol. 2017, 19, 84–92. [Google Scholar] [CrossRef]

- Macek, W. Fracture surface formation of notched 2017A-T4 aluminium alloy under bending fatigue. Int. J. Fract. 2022, 234, 141–157. [Google Scholar] [CrossRef]

- Boidi, G.; Grutzmacher, P.G.; Kadiric, A.; Profito, F.J.; Machado, I.F.; Gachot, C.; Dini, D. Fast laser surface texturing of spherical samples to improve the frictional performance of elasto-hydrodynamic lubricated contacts. Friction 2021, 9, 1227–1241. [Google Scholar] [CrossRef]

- Akbarzadeh, A.; Khonsari, M.M. Effect of Untampered Plasma Coating and Surface Texturing on Friction and Running-in Behavior of Piston Rings. Coatings 2018, 8, 110. [Google Scholar] [CrossRef] [Green Version]

- Rosenkranz, A.; Grutzmacher, P.G.; Gachot, C.; Costa, H.L. Surface Texturing in Machine Elements—A Critical Discussion for Rolling and Sliding Contacts. Adv. Eng. Mater 2019, 21, 1900194. [Google Scholar] [CrossRef]

- Etsion, I.; Burstein, L. A model for mechanical seals with regular microsurface structure. Tribol. Trans. 1996, 39, 677–683. [Google Scholar] [CrossRef]

- Costa, H.; Hutchings, I. Some innovative surface texturing techniques for tribological purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 429–448. [Google Scholar] [CrossRef] [Green Version]

- Roy, T.; Choudhury, D.; Mamat, A.B.; Pingguan-Murphy, B. Fabrication and characterization of micro-dimple array on Al2O3 surfaces by using a micro-tooling. Ceram. Int. 2014, 40, 2381–2388. [Google Scholar] [CrossRef]

- Lee, H.; Yi, A.; Choi, J.; Ko, D.H.; Kim, H.J. Texturing of polydimethylsiloxane surface for anti-reflective films with super-hydrophobicity in solar cell application. Appl. Surf. Sci. 2022, 584, 152625. [Google Scholar] [CrossRef]

- Chatterjee, S.; Shariff, S.M.; Majumdar, J.D.; Choudhury, A.R. Development of nano-structured Al2O3-TiB2-TiN coatings by combined SHS and laser surface alloying. Int. J. Adv. Manuf. Technol. 2008, 38, 938–943. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. Comparing tribological effects of various chevron-based surface textures under lubricated unidirectional sliding. Tribol. Int. 2020, 146, 106205. [Google Scholar] [CrossRef]

- Guo, Y.B.; Caslaru, R. Fabrication and characterization of micro dent arrays produced by laser shock peening on titanium Ti-6Al-4V surfaces. J. Mater. Process. Technol. 2011, 211, 729–736. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Bieda, M.; Schmadicke, C.; Roch, T.; Lasagni, A. Ultra-Low Friction on 100Cr6-Steel Surfaces After Direct Laser Interference Patterning. Adv. Eng. Mater. 2015, 17, 102–108. [Google Scholar] [CrossRef]

- Costil, S.; Lamraoui, A.; Langlade, C.; Heintz, O.; Oltra, R. Surface modifications induced by pulsed-laser texturing-Influence of laser impact on the surface properties. Appl. Surf. Sci. 2014, 288, 542–549. [Google Scholar] [CrossRef]

- Cernasejus, O.; Skamat, J.; Markovic, V.; Visniakov, N.; Indrisiunas, S. Effect of Laser Processing on Surface Properties of Additively Manufactured 18-Percent Nickel Maraging Steel Parts. Coatings 2020, 10, 600. [Google Scholar] [CrossRef]

- Trucchi, D.M.; Bellucci, A.; Girolami, M.; Mastellone, M.; Orlando, S. Surface Texturing of CVD Diamond Assisted by Ultrashort Laser Pulses. Coatings 2017, 7, 185. [Google Scholar] [CrossRef] [Green Version]

- Maharjan, N.; Zhou, W.; Zhou, Y.; Guan, Y.C.; Wu, N.E. Comparative study of laser surface hardening of 50CrMo4 steel using continuous-wave laser and pulsed lasers with ms, ns, ps and fs pulse duration. Surf. Coat. Technol. 2019, 366, 311–320. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V. Cavity formation and surface modeling of laser milling process under a thin-flowing water layer. Appl. Surf. Sci. 2016, 386, 51–64. [Google Scholar] [CrossRef]

- SHsu, M.; Jing, Y.; Hua, D.; Zhang, H. Friction reduction using discrete surface textures: Principle and design. J. Phys. D Appl. Phys. 2014, 47, 335307. [Google Scholar] [CrossRef]

- Lu, L.B.; Zhang, Z.; Guan, Y.C.; Zheng, H.Y. Comparison of the effect of typical patterns on friction and wear properties of chromium alloy prepared by laser surface texturing. Opt. Laser Technol. 2018, 106, 272–279. [Google Scholar] [CrossRef]

- Xu, X.J.; van der Zwaag, S.; Xu, W. The effect of martensite volume fraction on the scratch and abrasion resistance of a ferrite-martensite dual phase steel. Wear 2016, 348, 80–88. [Google Scholar] [CrossRef]

- Trevisiol, C.; Jourani, A.; Bouvier, S. Effect of martensite volume fraction and abrasive particles size on friction and wear behaviour of a low alloy steel. Tribol. Int. 2017, 113, 411–425. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. A Novel Surface Texture Shape for Directional Friction Control. Tribol. Lett. 2018, 66, 51. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Zhang, D.Y.; Hua, M.; Dong, G.N.; Chin, K.S. A Study on the Tribological Behavior of Surface Texturing on Babbitt Alloy under Mixed or Starved Lubrication. Tribol. Lett. 2014, 56, 305–315. [Google Scholar] [CrossRef]

- Gu, C.X.; Meng, X.H.; Xie, Y.B.; Yang, Y.M. Effects of surface texturing on ring/liner friction under starved lubrication. Tribol. Int. 2016, 94, 591–605. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Profito, F.; Gachot, C.; Medina, S.; Dini, D. Influence of surface texturing on hydrodynamic friction in plane converging bearings—An experimental and numerical approach. Tribol. Int. 2019, 134, 190–204. [Google Scholar] [CrossRef]

- Hingawe, N.D.; Bhore, S.P. Tribological performance of a surface textured meso scale air bearing. Ind. Lubr. Tribol. 2020, 72, 599–609. [Google Scholar] [CrossRef]

- Hu, S.; Zheng, L.; Guo, Q.G.; Ren, L.Q. Influence of Cross-Grooved Texture Shape on Tribological Performance under Mixed Lubrication. Coatings 2022, 12, 305. [Google Scholar] [CrossRef]

- Sun, S.N.; Long, R.S.; Jin, Z.H.; Zhang, Y.M.; Ju, Z.C.; Du, X.Y. Research on the Friction and Wear Properties of Dents Textured Rolling Element Bearings under Dry Wear. Coatings 2022, 12, 684. [Google Scholar] [CrossRef]

- Profito, F.J.; Vladescu, S.C.; Reddyhoff, T.; Dini, D. Transient experimental and modelling studies of laser-textured micro-grooved surfaces with a focus on piston-ring cylinder liner contacts. Tribol. Int. 2017, 113, 125–136. [Google Scholar] [CrossRef]

- Ma, Z.; Song, J.J.; Fan, H.Z.; Hu, T.C.; Hu, L.T. Preparation and Study on Fretting Tribological Behavior of Composite Lubrication Structure on the Titanium Alloy Surface. Coatings 2022, 12, 332. [Google Scholar] [CrossRef]

- Grutzmacher, P.G.; Rosenkranz, A.; Szurdak, A.; Konig, F.; Jacobs, G.; Hirt, G.; Mucklich, F. From lab to application—Improved frictional performance of journal bearings induced by single- and multi-scale surface patterns. Tribol. Int. 2018, 127, 500–508. [Google Scholar] [CrossRef]

- Grutzmacher, P.G.; Rosenkranz, A.; Szurdak, A.; Gruber, M.; Gachot, C.; Hirt, G.; Mucklich, F. Multi-scale surface patterning—An approach to control friction and lubricant migration in lubricated systems. Ind. Lubr. Tribol. 2019, 71, 1007–1016. [Google Scholar] [CrossRef]

- Ahmed, N.; Rafaqat, M.; Pervaiz, S.; Umer, U.; Alkhalefa, H.; Shar, M.A.; Mian, S.H. Controlling the material removal and roughness of Inconel 718 in laser machining. Mater Manuf Process. 2019, 34, 1169–1181. [Google Scholar] [CrossRef]

- Li, X.; Arthanari, S.; Guan, Y.C.; Ramakrishna, S. Influence of assist gas on surface quality and microstructure development of laser metal processing. Opt. Laser Technol. 2021, 143, 107310. [Google Scholar] [CrossRef]

- Bharatish, A.; Harish, V.; Bathe, R.N.; Senthilselvan, J.; Soundarapandian, S. Effect of scanning speed and tin content on the tribological behavior of femtosecond laser textured tin-bronze alloy. Opt. Laser Technol. 2018, 108, 17–25. [Google Scholar] [CrossRef]

- He, X.; Zhong, L.; Wang, G.R.; Liao, Y.; Liu, Q.Y. Tribological behavior of femtosecond laser textured surfaces of 20CrNiMo/beryllium bronze tribo-pairs. Ind. Lubr. Tribol. 2015, 67, 630–638. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Ye, T.; Ma, J.W.; Cao, X.K.; Liu, W.; Yu, W.J.; Gao, J. Effect of Process Parameters on the Hardness of Laser Surface Textured 5A06 Aluminum Alloy. J. Mater. Eng. Perform. 2021, 30, 5858–5867. [Google Scholar] [CrossRef]

- Soltani, B.; Azarhoushang, B.; Zahedi, A. Laser ablation mechanism of silicon nitride with nanosecond and picosecond lasers. Opt. Laser Technol. 2019, 119, 105644. [Google Scholar] [CrossRef]

- Huang, J.Y.; Guan, Y.C.; Ramakrishna, S. Tribological behavior of femtosecond laser-textured leaded brass. Tribol. Int. 2021, 162, 107115. [Google Scholar] [CrossRef]

- Zhang, J.J.; Yang, D.H.; Song, C.W.; Yan, Y.D.; Sun, T. Effect of pulse duration on tribological behavior of textured stainless steel by laser surface texturing. In Proceedings of the Asia International Conference on Tribology 2018, Kuching, Malaysia, 17 September 2018; Asiatrib 2018; pp. 8–10. [Google Scholar]

- Gedvilas, M.; Indrisiunas, S.; Voisiat, B.; Stankevicius, E.; Selskis, A.; Raciukaitis, G. Nanoscale thermal diffusion during the laser interference ablation using femto-, pico-, and nanosecond pulses in silicon. Phys. Chem. Chem. Phys. 2018, 20, 12166–12174. [Google Scholar] [CrossRef] [PubMed]

- Garasz, K.; Tański, M.; Kocik, M.; Iordanova, E.; Yankov, G.; Karatodorov, S.; Grozeva, M. The Effect of Process Parameters in Femtosecond Laser Micromachining. Bulg. J. Phys. 2016, 43, 110–120. [Google Scholar]

- Mroczkowska, K.M.; Dzienny, P.; Budnicki, A.; Antonczak, A.J. Corrosion Resistance of AISI 304 Stainless Steel Modified Both Femto- and Nanosecond Lasers. Coatings 2021, 11, 592. [Google Scholar] [CrossRef]

- Pou-Alvarez, P.; Riveiro, A.; Novoa, X.R.; Fernandez-Arias, M.; del Val, J.; Comesana, R.; Boutinguiza, M.; Lusquinos, F.; Pou, J. Nanosecond, picosecond and femtosecond laser surface treatment of magnesium alloy: Role of pulse length. Surf. Coat. Technol. 2021, 427, 127802. [Google Scholar] [CrossRef]

- Shaheen, M.E.; Gagnon, J.E.; Fryer, B.J. Studies on laser ablation of silicon using near IR picosecond and deep UV nanosecond lasers. Opt. Laser Eng. 2019, 119, 18–25. [Google Scholar] [CrossRef]

- Ma, Q.; Tong, Z.; Wang, W.; Dong, G.N. Fabricating robust and repairable superhydrophobic surface on carbon steel by nanosecond laser texturing for corrosion protection. Appl. Surf. Sci. 2018, 455, 748–757. [Google Scholar] [CrossRef]

- Wang, Y.T.; Zhao, X.Y.; Ke, C.J.; Yu, J.; Wang, R. Nanosecond laser fabrication of superhydrophobic Ti6Al4V surfaces assisted with different liquids. Colloid Interface Sci. Commun. 2020, 35, 100256. [Google Scholar] [CrossRef]

- Yu, Z.; Hu, J.; Li, K.M. Investigating the multiple-pulse drilling on titanium alloy in picosecond laser. J. Mater. Process. Technol. 2019, 268, 10–17. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Y.; Li, X.; Dong, G.N. Pulse laser-induced cell-like texture on surface of titanium alloy for tribological properties improvement. Wear 2021, 477, 203784. [Google Scholar] [CrossRef]

- Allahyari, E.; Nivas, J.J.; Avallone, G.; Valadan, M.; Singh, M.; Granata, V.; Cirillo, C.; Vecchione, A.; Bruzzese, R.; Altucci, C.; et al. Femtosecond laser surface irradiation of silicon in air: Pulse repetition rate influence on crater features and surface texture. Opt. Laser Technol. 2020, 126, 106073. [Google Scholar] [CrossRef]

- Salguero, J.; del Sol, I.; Vazquez-Martinez, J.M.; Schertzer, M.J.; Iglesias, P. Effect of laser parameters on the tribological behavior of Ti6Al4V titanium microtextures under lubricated conditions. Wear 2019, 426, 1272–1279. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Long, Y.; Liao, S.X.; Lin, H.T.; Wang, C.Y. Effect of laser scanning speed on geometrical features of Nd:YAG laser machined holes in thin silicon nitride substrate. Ceram. Int. 2017, 43, 2938–2942. [Google Scholar] [CrossRef]

- Allahyari, E.; Nivas, J.J.J.; Valadan, M.; Fittipaldi, R.; Vecchione, A.; Parlato, L.; Bruzzese, R.; Altucci, C.; Amoruso, S. Plume shielding effects in ultrafast laser surface texturing of silicon at high repetition rate in air. Appl. Surf. Sci. 2019, 488, 128–133. [Google Scholar] [CrossRef]

- Sedao, X.; Lenci, M.; Rudenko, A.; Faure, N.; Pascale-Hamri, A.; Colombier, J.P.; Mauclair, C. Influence of pulse repetition rate on morphology and material removal rate of ultrafast laser ablated metallic surfaces. Opt. Laser Eng. 2019, 116, 68–74. [Google Scholar] [CrossRef]

- Qiu, M.F.; Delic, A.; Raeymaekers, B. The Effect of Texture Shape on the Load-Carrying Capacity of Gas-Lubricated Parallel Slider Bearings. Tribol. Lett. 2012, 48, 315–327. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Zhang, X.G.; Matsoukasb, G. Numerical study of surface texturing for improving tribological properties of ultra-high molecular weight polyethylene. Biosurf. Biotribol. 2015, 1, 270–277. [Google Scholar] [CrossRef] [Green Version]

- Suh, M.S.; Chae, Y.H.; Kim, S.S.; Hinoki, T.; Kohyama, A. Effect of geometrical parameters in micro-grooved crosshatch pattern under lubricated sliding friction. Tribol. Int. 2010, 43, 1508–1517. [Google Scholar] [CrossRef] [Green Version]

- Hsu, S.M.; Jing, Y.; Zhao, F. Self-adaptive surface texture design for friction reduction across the lubrication regimes. Surf. Topogr. Metrol. Prop. 2016, 4, 014004. [Google Scholar] [CrossRef] [Green Version]

- Ding, S.P.; Xu, J.; Liu, P.F.; Shi, Z.L.; Yang, O.X.; Hu, Y.P. Geometric influence on friction and wear performance of cast iron with a micro-dimpled surface. Results Eng. 2021, 9, 100211. [Google Scholar] [CrossRef]

- Yuan, S.H.; Huang, W.; Wang, X.L. Orientation effects of micro-grooves on sliding surfaces. Tribol. Int. 2011, 44, 1047–1054. [Google Scholar] [CrossRef]

- Galda, L.; Pawlus, P.; Sep, J. Dimples shape and distribution effect on characteristics of Stribeck curve. Tribol. Int. 2009, 42, 1505–1512. [Google Scholar] [CrossRef]

- Segu, D.Z.; Hwang, P. Friction control by multi-shape textured surface under pin-on-disc test. Tribol. Int. 2015, 91, 111–117. [Google Scholar] [CrossRef]

- Li, J.B.; Liu, S.; Yu, A.B.; Xiang, S.T. Effect of laser surface texture on CuSn6 bronze sliding against PTFE material under dry friction. Tribol. Int. 2018, 118, 37–45. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Li, Z.W.; Zhao, F.F.; Gao, F.; Gao, Z.Q.; Zhang, H.; Dong, G.N. Study on tribological behavior of grooved-texture surfaces under sand-oil boundary lubrication conditions. Tribol. Trans. 2021, 64, 167–177. [Google Scholar] [CrossRef]

- Maldonado-Cortes, D.; Pena-Paras, L.; Martinez, N.R.; Leal, M.P.; Correa, D.I.Q. Tribological characterization of different geometries generated with laser surface texturing for tooling applications. Wear 2021, 477, 203856. [Google Scholar] [CrossRef]

- Tu, Z.R.; Meng, X.K.; Yi, M.; Peng, X.D. Shape optimization of hydrodynamic textured surfaces for enhancing load-carrying capacity based on level set method. Tribol. Int. 2021, 162, 107136. [Google Scholar] [CrossRef]

- Meng, F.M.; Yu, H.Y.; Gui, C.; Chen, L. Experimental study of compound texture effect on acoustic performance for lubricated textured surfaces. Tribol. Int. 2019, 133, 47–54. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G.Z.; Zhang, D.Y.; Chen, W.J.; Dong, G.N. Optimization of texture shape based on Genetic Algorithm under unidirectional sliding. Tribol. Int. 2017, 115, 222–232. [Google Scholar] [CrossRef]

- Wang, W.; He, Y.Y.; Zhao, J.; Mao, J.Y.; Hu, Y.T.; Luo, J.B. Optimization of groove texture profile to improve hydrodynamic lubrication performance: Theory and experiments. Friction 2020, 8, 83–94. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M. Effect of Dimple’s Internal Structure on Hydrodynamic Lubrication. Tribol. Lett. 2013, 52, 415–430. [Google Scholar] [CrossRef]

- YNiu, X.; Pang, X.J.; Yue, S.W.; Shangguan, B.; Zhang, Y.Z. The friction and wear behavior of laser textured surfaces in non-conformal contact under starved lubrication. Wear 2021, 476, 203723. [Google Scholar] [CrossRef]

- Kasem, H.; Stav, O.; Grutzmacher, P.; Gachot, C. Effect of Low Depth Surface Texturing on Friction Reduction in Lubricated Sliding Contact. Lubricants 2018, 6, 62. [Google Scholar] [CrossRef] [Green Version]

- Segu, D.Z.; Lu, C.X.; Hwang, P.; Kang, S.W. Optimization of Tribological Characteristics of a Combined Pattern Textured Surface Using Taguchi Design. J. Mater. Eng. Perform. 2021, 30, 3786–3794. [Google Scholar] [CrossRef]

- Konig, F.; Rosenkranz, A.; Grutzmacher, P.G.; Mucklich, F.; Jacobs, G. Effect of single- and multi-scale surface patterns on the frictional performance of journal bearings A numerical study. Tribol. Int. 2020, 143, 106041. [Google Scholar] [CrossRef]

- Zhao, H.X.; Sun, Q.Q.; Deng, X.; Cui, J.X. Earthworm-Inspired Rough Polymer Coatings with Self-Replenishing Lubrication for Adaptive Friction-Reduction and Antifouling Surfaces. Adv. Mater. 2018, 30, 1802141. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, W.H.; Liu, Y.; Zhang, H.; Hua, M.; Dong, G.N.; Tam, H.Y.; Chin, K.S. A Pocket-Textured Surface for Improving the Tribological Properties of Point Contact under Starved Lubrication. Materials 2021, 14, 1789. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Hafezi, M.; Hua, M.; Dong, G.N. A distribution design for circular concave textures on sectorial thrust bearing pads. Tribol. Int. 2020, 149, 105733. [Google Scholar] [CrossRef]

- Wang, Q.W.; Yang, Y.; Yao, P.; Zhang, Z.Y.; Yu, S.M.; Zhu, H.T.; Huang, C.Z. Friction and cutting characteristics of micro-textured diamond tools fabricated with femtosecond laser. Tribol. Int. 2021, 154, 106720. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.H.; Tong, Z.; Ma, Q.; Ni, Y.Q.; Dong, G.N. Enhanced lubrication effect of gallium-based liquid metal with laser textured surface. Tribol. Int. 2019, 129, 407–415. [Google Scholar] [CrossRef]

- Schneider, J.; Braun, D.; Greiner, C. Laser Textured Surfaces for Mixed Lubrication: Influence of Aspect Ratio, Textured Area and Dimple Arrangement. Lubricants 2017, 5, 32. [Google Scholar] [CrossRef] [Green Version]

- Hua, M.; Dong, G.N.; Zhang, H.; Ho, J.K.L.; Chow, F.C. The wet tribological behaviors of doughnut patterns laser-textured on DF2 tool steel under different loading conditions. Appl. Phys. A-Mater. 2013, 111, 997–1011. [Google Scholar] [CrossRef]

- Ren, N.; Nanbu, T.; Yasuda, Y.; Zhu, D.; Wang, Q. Micro textures in concentrated-conformal-contact lubrication: Effect of distribution patterns. Tribol. Lett. 2007, 28, 275–285. [Google Scholar] [CrossRef]

- Mahdieh, M.H.; Jafarabadi, M.A. Bubble formation induced by nanosecond laser ablation in water and its diagnosis by optical transmission technique. Appl. Phys. A-Mater. 2014, 116, 1211–1220. [Google Scholar] [CrossRef]

- Nichols, W.T.; Sasaki, T.; Koshizaki, N. Laser ablation of a platinum target in water. III. Laser-induced reactions. J. Appl. Phys. 2006, 100, 114911. [Google Scholar] [CrossRef]

- Krstulovic, N.; Shannon, S.; Stefanuik, R.; Fanara, C. Underwater-laser drilling of aluminum. Int. J. Adv. Manuf. Technol. 2013, 69, 1765–1773. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Li, B.T.; Hua, M.; Dong, G.N. Improving processing quality and tribological behavior of laser surface textures using oil layer method. Tribol. Int. 2020, 150, 106353. [Google Scholar] [CrossRef]

- Dai, F.Z.; Wen, D.P.; Zhang, Y.K.; Lu, J.Z.; Ren, X.D.; Zhou, J.Z. Micro-dimple array fabricated on surface of Ti6Al4V with a masked laser ablation method in air and water. Mater. Des. 2015, 84, 178–184. [Google Scholar] [CrossRef]

- Arjun, K.K.; Anoop, K.K.; Philip, R. Nanosecond laser surface texturing of crystalline silicon in ambient air and water. AIP Conf. Proc. 2020, 2244, 070010. [Google Scholar] [CrossRef]

- Ren, J.; Kelly, M.; Hesselink, L. Laser ablation of silicon in water with nanosecond and femtosecond pulses. Opt. Lett. 2005, 30, 1740–1742. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Chen, C.G.; Chen, F.; Zhan, Z.L.; Xie, S.S.; Ye, Q. In vitro investigation on Ho: YAG laser-assisted bone ablation underwater. Laser Med. Sci. 2016, 31, 891–898. [Google Scholar] [CrossRef] [PubMed]

- Tsai, C.H.; Li, C.C. Investigation of underwater laser drilling for brittle substrates. J. Mater. Process. Technol. 2009, 209, 2838–2846. [Google Scholar] [CrossRef]

- Hu, J.; Xu, H.B. Friction and wear behavior analysis of the stainless steel surface fabricated by laser texturing underwater. Tribol. Int. 2016, 102, 371–377. [Google Scholar] [CrossRef]

- Shulyatyev, V.; Malikov, A.; Orishich, A. The effect of assist gases on the quality of edge surfaces of Al-Li alloys cut with a pulsed Q-switched CO2 laser. Optik 2021, 231, 166420. [Google Scholar] [CrossRef]

- Kang, H.W.; Lee, H.; Welch, A.J. Laser ablation in a liquid-confined environment using a nanosecond laser pulse. J. Appl. Phys. 2008, 103, 083101. [Google Scholar] [CrossRef]

- Wee, L.M.; Ng, E.Y.K.; Prathama, A.H.; Zheng, H. Micro-machining of silicon wafer in air and under water. Opt. Laser Technol. 2011, 43, 62–71. [Google Scholar] [CrossRef]

- Feng, W.H.; Guo, J.; Yan, W.J.; Wan, Y.C.; Zheng, H.Y. Deep channel fabrication on copper by multi-scan underwater laser machining. Opt. Laser Technol. 2019, 111, 653–663. [Google Scholar] [CrossRef]

- Xiang, D.H.; Zhang, Z.Q.; Chen, Y.B.; Hu, Y.W.; Lei, X.F. Study of Tribological Properties of Textured Boron-Doped Diamond Film under Water Lubrication. Surf Interfaces 2021, 23, 100983. [Google Scholar] [CrossRef]

- Zheng, Q.Z.; Fan, Z.J.; Jiang, G.D.; Pan, A.F.; Yan, Z.X.; Lin, Q.Y.; Cui, J.L.; Wang, W.J.; Mei, X.S. Mechanism and morphology control of underwater femtosecond laser microgrooving of silicon carbide ceramics. Opt. Express 2019, 27, 26264–26280. [Google Scholar] [CrossRef]

- Muhammad, N.; Li, L. Underwater femtosecond laser micromachining of thin nitinol tubes for medical coronary stent manufacture. Appl. Phys. A-Mater. 2012, 107, 849–861. [Google Scholar] [CrossRef]

- Shaheen, M.E.; Gagnon, J.E.; Fryer, B.J. Femtosecond laser ablation of brass in air and liquid media. J. Appl. Phys. 2013, 113, 213106. [Google Scholar] [CrossRef]

- Wee, L.M.; Khoong, L.E.; Tan, C.W.; Lim, G.C. Solvent-Assisted Laser Drilling of Silicon Carbide. Int. J. Appl. Ceram. Technol. 2011, 8, 1263–1276. [Google Scholar] [CrossRef]

- Ouyang, P.X.; Li, P.J.; Leksina, E.G.; Michurin, S.V.; He, L.J. Effect of liquid properties on laser ablation of aluminum and titanium alloys. Appl. Surf. Sci. 2016, 360, 880–888. [Google Scholar] [CrossRef]

- HWang, X.; Xu, Y.; Zheng, H.Y.; Zhou, W.; Ren, N.F.; Ren, X.D.; Li, T. Monitoring and analysis of millisecond laser drilling process and performance with and without longitudinal magnetic assistance and/or assist gas. J. Manuf. Process. 2019, 48, 297–312. [Google Scholar] [CrossRef]

- Low, D.K.Y.; Li, L.; Corfe, A.G. Effects of assist gas on the physical characteristics of spatter during laser percussion drilling of NIMONIC 263 alloy. Appl. Surf. Sci. 2000, 154, 689–695. [Google Scholar] [CrossRef]

- Reg, Y.; Leitz, K.H.; Schmidt, M. Influence of Processing Gas on the Ablation Quality at ns-Laser Beam Ablation, Lasers in Manufacturing 2011. In Proceedings of the Sixth International Wlt Conference on Lasers in Manufacturing, Munich, Germany, 23–26 May 2011; Pt B; Volume 12, pp. 182–187. [Google Scholar] [CrossRef] [Green Version]

- Riveiro, A.; Quintero, F.; Lusquinos, F.; Comesana, R.; del Val, J.; Pou, J. The Role of the Assist Gas Nature in Laser Cutting of Aluminum Alloys. Phys. Proc. 2011, 12, 548–554. [Google Scholar] [CrossRef] [Green Version]

- Antoszewski, B.; Kurp, P. Effect of Surface Texture on the Sliding Pair Lubrication Efficiency. Lubricants 2022, 10, 80. [Google Scholar] [CrossRef]

- Hsu, C.J.; Stratmann, A.; Medina, S.; Jacobs, G.; Mucklich, F.; Gachot, C. Does laser surface texturing really have a negative impact on the fatigue lifetime of mechanical components? Friction 2021, 9, 1766–1775. [Google Scholar] [CrossRef]

- Joshi, G.S.; Putignano, C.; Gaudiuso, C.; Stark, T.; Kiedrowski, T.; Ancona, A.; Carbone, G. Effects of the micro surface texturing in lubricated non-conformal point contacts. Tribol. Int. 2018, 127, 296–301. [Google Scholar] [CrossRef] [Green Version]

- Holey, H.; Codrignani, A.; Gumbsch, P.; Pastewka, L. Height-Averaged Navier-Stokes Solver for Hydrodynamic Lubrication. Tribol. Lett. 2022, 70, 36. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Krupp, F.; Reinert, L.; Mucklich, F.; Sauer, B. Tribological performance of laser-patterned chain links Influence of pattern geometry and periodicity. Wear 2017, 370, 51–58. [Google Scholar] [CrossRef]

- Aziz, R.; Haq, M.I.U.; Raina, A. Effect of surface texturing on friction behaviour of 3D printed polylactic acid (PLA). Polym. Test. 2020, 85, 106434. [Google Scholar] [CrossRef]

- Vladescu, S.C.; Ciniero, A.; Tufail, K.; Gangopadhyay, A.; Reddyhoff, T. Optimization of Pocket Geometry for Friction Reduction in Piston-Liner Contacts. Tribol. Trans. 2018, 61, 522–531. [Google Scholar] [CrossRef]

- FMeng, M.; Zhou, R.; Davis, T.; Cao, J.; Wang, Q.J.; Hua, D.; Liu, J. Study on effect of dimples on friction of parallel surfaces under different sliding conditions. Appl. Surf. Sci. 2010, 256, 2863–2875. [Google Scholar] [CrossRef]

- Guo, J.; Cheng, J.; Tan, H.; Zhu, S.Y.; Qiao, Z.H.; Yang, J.; Liu, W.M. Ga-based liquid metal: Lubrication and corrosion behaviors at a wide temperature range. Materialia 2018, 4, 10–19. [Google Scholar] [CrossRef]

- Cheng, J.; Zhu, S.Y.; Tan, H.; Yu, Y.; Yang, J.; Li, W.M. Lead-bismuth liquid metal: Lubrication behaviors. Wear 2019, 430, 67–72. [Google Scholar] [CrossRef]

- Li, X.; Qi, P.H.; Liu, Q.; Dong, G.N. Improving tribological behaviors of gallium-based liquid metal by h-BN nano-additive. Wear 2021, 484, 203852. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological performance of nanoparticles as lubricating oil additives. J. Nanopart. Res. 2016, 18, 223. [Google Scholar] [CrossRef]

- Guglea, D.; Ionescu, T.F.; Dima, D.; Georgescu, C.; Deleanu, L. Tribological behavior of rapeseed oil additivated with boron nitride. IOP Conf. Ser.-Mater. Sci. 2020, 724, 012046. [Google Scholar] [CrossRef]

- Kumari, S.; Sharma, O.P.; Khatri, O.P. Alkylamine-functionalized hexagonal boron nitride nanoplatelets as a novel material for the reduction of friction and wear. Phys. Chem. Chem. Phys. 2016, 18, 22879–22888. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, J.; Lu, G.C.; Shi, X.L.; Yang, Z.Y.; Xue, Y.W.; Zhou, H.Y. Improving Tribological Performance of Inconel 625 by Combining Groove-Textured Surfaces with Sn-Ag-Cu Solid Lubricant. J. Mater. Eng. Perform. 2021, 30, 154–164. [Google Scholar] [CrossRef]

- Fu, J.G.; Xu, C.Q.; Ma, D.Q.; Zhu, X.H.; Cheng, D.; Yan, Z.J.; Ma, C.S.; Liu, G.S.; Fu, Y.Y. Tribological properties and releasing behavior of solid lubricant WS2 in the dimples on cylinder liner surface of diesel engine. Tribol. Int. 2021, 158, 106936. [Google Scholar] [CrossRef]

- Koszela, W.; Pawlus, P.; Reizer, R.; Liskiewicz, T. The combined effect of surface texturing and DLC coating on the functional properties of internal combustion engines. Tribol. Int. 2018, 127, 470–477. [Google Scholar] [CrossRef]

- Meng, R.; Deng, J.X.; Duan, R.; Liu, Y.Y.; Zhang, G.L. Modifying tribological performances of AISI 316 stainless steel surfaces by laser surface texturing and various solid lubricants. Opt. Laser Technol. 2019, 109, 401–411. [Google Scholar] [CrossRef]

- Arenas, M.A.; Ahuir-Torres, J.I.; Garcia, I.; Carvajal, H.; de Damborenea, J. Tribological behaviour of laser textured Ti6Al4V alloy coated with MoS2 and graphene. Tribol. Int. 2018, 128, 240–247. [Google Scholar] [CrossRef]

- Zhang, Z.; Yamaguchi, E.S.; Kasrai, M.; Bancroft, G.M. Tribofilms generated from ZDDP and DDP on steel surfaces: Part 1, growth, wear and morphology. Tribol. Lett. 2005, 19, 211–220. [Google Scholar] [CrossRef]

- Hsu, C.J.; Stratmann, A.; Rosenkranz, A.; Gachot, C. Enhanced Growth of ZDDP-Based Tribofilms on Laser-Interference Patterned Cylinder Roller Bearings. Lubricants 2017, 5, 39. [Google Scholar] [CrossRef] [Green Version]

- Segu, D.Z.; Kim, J.H.; Choi, S.G.; Jung, Y.S.; Kim, S.S. Application of Taguchi techniques to study friction and wear properties of MoS2 coatings deposited on laser textured surface. Surf. Coat. Technol. 2013, 232, 504–514. [Google Scholar] [CrossRef]

- XWang, L.; Adachi, K.; Otsuka, K.; Kato, K. Optimization of the surface texture for silicon carbide sliding in water. Appl. Surf. Sci. 2006, 253, 1282–1286. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Fu, Q.; Wood, R.J.K.; Wu, J.; Wang, S.C. Influence of bionic non-smooth surface texture on tribological characteristics of carbon-fiber-reinforced polyetheretherketone under seawater lubrication. Tribol. Int. 2020, 144, 106100. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.K.; Dong, G.N. Preparation of nanoscale liquid metal droplet wrapped with chitosan and its tribological properties as water-based lubricant additive. Tribol. Int. 2020, 148, 106349. [Google Scholar] [CrossRef]

- Bai, P.P.; Li, S.W.; Jia, W.P.; Ma, L.R.; Meng, Y.G.; Tian, Y. Environmental atmosphere effect on lubrication performance of gallium-based liquid metal. Tribol. Int. 2020, 141, 105904. [Google Scholar] [CrossRef]

- Qi, P.H.; Wang, S.J.; Li, J.; Li, Y.; Dong, G.N. Synergistic lubrication effect of antioxidant and low content ZDDP on PFPE grease. Ind. Lubr. Tribol. 2021, 73, 830–838. [Google Scholar] [CrossRef]

- Li, X.; Yan, C.; Liu, Q.; Dong, G.N. An In Situ Fabrication of CuGa2 Film on Copper Surface With Improved Tribological Properties. J. Tribol. 2021, 143, 071404. [Google Scholar] [CrossRef]

- Li, X.; Lu, H.L.; Guo, J.D.; Tong, Z.; Dong, G.N. Synergistic water lubrication effect of self-assembled nanofilm and graphene oxide additive. Appl. Surf. Sci. 2018, 455, 1070–1077. [Google Scholar] [CrossRef]

- Li, X.; Liu, Q.; Dong, G.N. Self-assembly membrane on textured surface for enhancing lubricity of graphene oxide nano-additive. Appl. Surf. Sci. 2020, 505, 144572. [Google Scholar] [CrossRef]

- Dalhat, M.A. Water resistance and characteristics of asphalt surfaces treated with micronized-recycled-polypropylene waste: Super-hydrophobicity. Constr. Build. Mater. 2021, 285, 122870. [Google Scholar] [CrossRef]

- Dongre, G.; Rajurkar, A.; Raut, R.; Jangam, S. Preparation of super-hydrophobic textures by using nanosecond pulsed laser. Mater. Today Proc. 2021, 42, 1145–1151. [Google Scholar] [CrossRef]

- Emelyanenko, A.M.; Shagieva, F.M.; Domantovsky, A.G.; Boinovich, L.B. Nanosecond laser micro- and nanotexturing for the design of a superhydrophobic coating robust against long-term contact with water, cavitation, and abrasion. Appl. Surf. Sci. 2015, 332, 513–517. [Google Scholar] [CrossRef]

- Ta, V.D.; Dunn, A.; Wasley, T.J.; Li, J.; Kay, R.W.; Stringer, J.; Smith, P.J.; Esenturk, E.; Connaughton, C.; Shephard, J.D. Laser textured superhydrophobic surfaces and their applications for homogeneous spot deposition. Appl. Surf. Sci. 2016, 365, 153–159. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.H.; Kim, M.H.; Yun, H.W.; Paik, T.; Lee, H. Solution-processed fabrication of superhydrophobic hierarchical zinc oxide nanostructures via nanotransfer printing and hydrothermal growth. Surf. Coat. Technol. 2017, 331, 189–195. [Google Scholar] [CrossRef]

- Boinovich, L.B.; Modin, E.B.; Sayfutdinova, A.R.; Emelyanenko, K.A.; Vasiliev, A.L.; Emelyanenko, A.M. Combination of Functional Nanoengineering and Nanosecond Laser Texturing for Design of Superhydrophobic Aluminum Alloy with Exceptional Mechanical and Chemical Properties. ACS Nano 2017, 11, 10113–10123. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.M.; Sun, P.F.; Tian, G.Z. Recent Developments of Superhydrophobic Surfaces (SHS) for Underwater Drag Reduction Opportunities and Challenges. Adv. Mater. Interfaces 2022, 9, 2101616. [Google Scholar] [CrossRef]

- HDong, Y.; Cheng, M.J.; Zhang, Y.J.; Wei, H.; Shi, F. Extraordinary drag-reducing effect of a superhydrophobic coating on a macroscopic model ship at high speed. J. Mater. Chem. A 2013, 1, 5886–5891. [Google Scholar] [CrossRef]

- Ibrahim, M.D.; Amran, S.N.A.; Yunos, Y.S.; Rahman, M.R.A.; Mohtar, M.Z.; Wong, L.K.; Zulkharnain, A. The Study of Drag Reduction on Ships Inspired by Simplified Shark Skin Imitation. Appl. Bionics Biomech. 2018, 2018, 7854321. [Google Scholar] [CrossRef] [Green Version]

- Yu, C.M.; Liu, M.F.; Zhang, C.H.; Yan, H.; Zhang, M.H.; Wu, Q.S.; Liu, M.J.; Jiang, L. Bio-inspired drag reduction: From nature organisms to artificial functional. Giant 2020, 2, 100017. [Google Scholar] [CrossRef]

- Qin, L.G.; Ma, Z.Y.; Sun, H.J.; Lu, S.; Zeng, Q.F.; Zhang, Y.L.; Dong, G.N. Drag reduction and antifouling properties of non-smooth surfaces modified with ZIF-67. Surf. Coat. Technol. 2021, 427, 127836. [Google Scholar] [CrossRef]

- Wu, L.; Qin, W.; He, Y.Z.; Zhu, W.F.; Ren, X.H.; York, P.; Xiao, T.Q.; Yin, X.Z.; Zhang, J.W. Material distributions and functional structures in probiotic microcapsules. Eur. J. Pharm. Sci. 2018, 122, 1–8. [Google Scholar] [CrossRef]

- Dai, W.; Alkahtani, M.; Hemmer, P.R.; Liang, H. Drag-reduction of 3D printed shark-skin-like surfaces. Friction 2019, 7, 603–612. [Google Scholar] [CrossRef] [Green Version]

- Emami, B.; Hemeda, A.A.; Amrei, M.M.; Luzar, A.; Gad-el-Hak, M.; Tafreshi, H.V. Predicting longevity of submerged superhydrophobic surfaces with parallel grooves. Phys. Fluids 2013, 25, 062108. [Google Scholar] [CrossRef] [Green Version]

- Xue, Y.W.; Shi, X.L.; Zhou, H.Y.; Yang, Z.Y.; Zhang, J.; Wu, C.H.; Xue, B. Effects of Textured Surface Combined with Sn-Ag-Cu Coating on Tribological Properties and Friction-Induced Noise of Ti-6Al-4V Alloy. Tribol. Trans. 2021, 64, 562–577. [Google Scholar] [CrossRef]

- Xue, Y.W.; Shi, X.L.; Zhou, H.Y.; Lu, G.C.; Zhang, J. Effects of groove-textured surface combined with Sn-Ag-Cu lubricant on friction-induced vibration and noise of GCr15 bearing steel. Tribol. Int. 2020, 148, 106316. [Google Scholar] [CrossRef]

- Mo, J.L.; Wang, Z.G.; Chen, G.X.; Shao, T.M.; Zhu, M.H.; Zhou, Z.R. The effect of groove-textured surface on friction and wear and friction-induced vibration and noise. Wear 2013, 301, 671–681. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Z.L.; Cheng, Q.C.; Liu, X.K.; Deng, T.Y. The effect of wear on the frictional vibration suppression of water-lubricated rubber slat with/without surface texture. Wear 2019, 426, 1304–1317. [Google Scholar] [CrossRef]

- Liu, X.Y.; Shi, X.L.; Huang, Y.C.; Deng, X.B.; Lu, G.C.; Yan, Z.; Xue, B. Tribological behavior and self-healing functionality of M50 material covered with surface micropores filled with Sn-Ag-Cu. Tribol. Int. 2018, 128, 365–375. [Google Scholar] [CrossRef]

| Material | Type of Laser | Laser Pulse Power (w) | Laser Pulse Repetition Rate (kHz) | Laser Scanning Speed (mm/s) | Micro Hardness (HV) | Depth (μm) | Width (μm) | Findings | Ref |

|---|---|---|---|---|---|---|---|---|---|

| 50CrMo4 steel | Millisecond laser | 27 | 0.01 | 2 | 700 HV | 200 | — | A depth of 1000 μm can be achieved with ms laser parameters. | [18] |

| Nanosecond laser | 90 | 500 | 200 | 642 HV | 80 | — | |||

| Tin Bronze | Femtosecond laser | 0.1 | — | 5–10 | — | 1.256–2.94 | 12.21–14.21 | Lower scanning speed, led to deeper and wider grooves. | [37] |

| 20CrNiMo beryllium bronze | Femtosecond laser | 5 × 1022–25 × 1022 | 100 | — | — | 28.007–33.983 | 169.266–70.398 | Laser peak power and exposure duration produced the optimal crater size. | [38] |

| 5A06 aluminum alloy | Nanosecond laser | 15 × 105 | 50 | 41.66 | 355.08 | — | — | For the nanosecond laser, the HAZ was clearly visible. | [39] |

| Silicon Nitride | Nanosecond laser | 50 | 100 | 2–100 | — | — | — | At a low pulse intensity, the laser cuts created by the ps laser had smoother surfaces and straighter edges than the ns laser with a decreased HAZ and thermal damages. | [40] |

| Picosecond laser | 50 | 100 | 2–100 | — | — | — | |||

| Leaded brass | Femtosecond laser | 5–15 | 100–300 | 5–15 | 168–189 | 100–200 | 10–25 | The improved surface roughness and the hardness of the material decreased the friction; wear increased in dry conditions. | [41] |

| Ref | Geometric Characteristics | Observation | ||||

|---|---|---|---|---|---|---|

| shape | Diameter (μm) | Depth (μm) | Area ratio | Area density | The dimple contour profile appears to have an influence on the area density (35%), as does the depth on the area ratio; the ellipsoidal shape provided the highest LCC. | |

| [57] | spherical | — | — | 0.0070 | 15% | |

| ellipsoidal | — | — | 0.0036, 0.0081 | 35% | ||

| circular | — | — | 0.0035 | 15% | ||

| elliptical | — | — | 0.0017, 0.0038 | 35% | ||

| triangular | — | — | 0.0035 | 10% | ||

| chevron | — | — | 0.0035 | 10% | ||

| [58] | circular | 40–90 | 9.6 | — | 26% | The rectangular texture was discovered to have the highest LCC of all the patterns. |

| rectangular | 40–90 | 7.2 | — | 17% | ||

| square | 40–90 | 7.2 | — | 20% | ||

| Triangular | 40–90 | 9.6 | — | 21% | ||

| [59] | Crosshatch groove texture | 5 | 10–100 | 0.0—5–0.125 | 20% | The crosshatch angle and area ratio of the pattern appeared to be crucial to obtaining the lowest COF |

| [60] | Overlap droplet + parallelogram | 9.5, 45 | 2.08, 0.90 | — | 5%–17.5% | Both mixture and overlaps had an impact on the friction coefficient with up to an 80% reduction. The overlap with the 5% area density outperformed that of the 7% and the mixture. |

| Mixture droplet + parallelogram | 12.8, 45 | 2.26, 0.90 | — | 5%–17.5% | ||

| [61] | circular | — | 7.5–10 | — | 4%–9.5% | Elliptical dimples reduced friction by up to 20%, followed by circles, rectangles, and diamonds. With a 0° orientation angle, the optimal area density was chosen as 4%. |

| elliptical | — | 7.5–10 | — | 4%–9.5% | ||

| diamond | — | 7.5–10 | — | 4%–9.5% | ||

| rectangular | — | 7.5–10 | — | 4%–9.5% | ||

| [62] | Linear groove | 100 | 7–19 | 0.07, 0.19 | 10% | Grooves oriented between 0° and 90° to the sliding direction reduced friction by 44%. Grooves of 7-depth worked better at low pressure, reducing friction by 38.2%, while 19-depth grooves performed better at high pressure. |

| [63] | Spherical Long drop spherical Short drop spherical | 900 | 60 | — | 7.5%–20% | The lubrication regime was influenced positively by the dimple shapes with an area density of less than 20%. The long drop and the spherical oil pocket outperformed the short drop. |

| 500 | 55 | — | 7.5%–20% | |||

| 800 | 60 | — | 10%–20% | |||

| [64] | Circular + elliptical | 300 | 6.5 | — | 12%, 20% | Multi-shape patterns with an area density of less than 20% reduced the COF under prolonged sliding situations, thereby maintaining the surface quality. |

| Circular + square | 500, 250 | 6.5 | — | 12%, 20% | ||

| Circular + triangular | 500, 250 | 6.5 | — | 12%, 20% | ||

| [65] | Grid groove | — | — | — | — | The COFs of the grid, asterisk, and circle’s groove patterns decreased by 10.55%, 6.03%, and 9.50%, respectively, while their wear rates increased by 47.05%, 41.48%, and 27.21%, respectively, when compared to the smooth surface. |

| Circle groove | — | — | — | — | ||

| Asterix groove | — | — | — | — | ||

| Materials | Processing Environment | Findings | Ref |

|---|---|---|---|

| Ti6Al4V | Air and water | Underwater ablation produced a better upper and bottom shape with an efficient control of laser parameters. | [89] |

| Crystalline Silicon | Air and water | The roughness of the textured surfaces was 7.2 μm in air and 5.5 μm in water. | [90] |

| Aluminum | Air and distilled water | Obvious bubble formation in water that led to control of the ablation rate. | [85] |

| — | Air and water | In water, there was an improvement in laser energy coupling to the target surface and more energy was delivered to the cavity’s sidewalls. | [91] |

| Titanium | Flowing water | A uniform feature was achieved by combining a high laser pulse frequency with a large water flow speed. | [19] |

| Bone Tissue | Underwater | The bubble’s hydrokinetic forces helped to reduce heat damage and improved the crater’s geometry. | [92] |

| LCD glass, Alumina | Air and water | In comparison to air, underwater processing reduced microcracking and the heat-affected zone by the synergistic use of laser power and pulse repetition rate. | [93] |

| Stainless Steel | [94] | ||

| Ti6Al4V | Ethanol, saturated, sodium bicarbonate | The water contact angle and the rolling angle in the ethanol medium were 54.9° and 9.8°. Furthermore, the textured surface in the saturated sodium bicarbonate solution exhibited excellent water adhesion. | [49] |

| Al-Li Alloys | Argon or air | The cut-edge surfaces of air were gritty, and dross was visible at the bottom. Using argon, grooves were produced, and the range of cutting speeds was discovered with no dross. | [95] |

| Aluminum | Underwater | The drilling was most enhanced for a 3-mm thick water layer. | [87] |

| Type of Lubricants | Surface Texture | Observation | Ref |

|---|---|---|---|

| Water, oil | Micro grids | Friction was reduced by up to 27.64% for water lubrication compared to oil lubrication. Wear was reduced by up to 88.39% compared to water lubrication. | [41] |

| Water | Elliptical and groove textures | The groove surface texture exhibited lower friction and wear. | [99] |

| Graphene or MoS2 solid lubricant | Cross groove | For 18 and 40% area densities, graphene had a longer lifetime than MoS2. | [128] |

| DLC coating | Dimple | Patterned chambers and the DLC covering increased the peak energy by approximately 5.8%. | [126] |

| ZDDP, DDP lubricants additives | — | It was found that under all conditions, the performance of ZDDP as an anti-wear film was superior to that of DDP. | [129] |

| Paraffin oil | Micro-grooved crosshatch | It has been discovered that each texture’s geometric parameter had an effect on friction. | [59] |

| Polyalphaolefin (PAO) | Dimple | The best dimple arrangement was hexagonal with a 10% area density and a 0.1 area ratio. | [82] |

| ZDDP | Dimple, cross | The cross patterns reduced the wear loss by two orders of magnitude via lubricant storage in the textured pockets and anti-wear tribo-film formation. | [110,130] |

| h-BN | — | An h-BN lamellae tribo-chemical thin layer on contact surfaces decreased friction and protected the contact interface. | [122,123] |

| MoS2 | Multi-dimple pattern | The dimple combined with MoS2 increased tribological performance for most applied loads. | [131] |

| Sn-Ag-Cu | Groove | The groove-textured surfaces with 20 and 25% area densities filled with Sn-Ag-Cu solid lubricant had the lowest friction. | [124] |

| Seawater lubrication | Hemispherical, triangular, elliptical | The ellipsoidal pits had the highest frictional performance, followed by triangular pits; hemispherical pits had the poorest frictional performance. | [133] |

| Liquid metal droplet wrapped in chitosan (NLMWC) in water | — | NLMWC added in water reduced the friction and wear rate by 40% and 69%, respectively. | [134] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nsilani Kouediatouka, A.; Ma, Q.; Liu, Q.; Mawignon, F.J.; Rafique, F.; Dong, G. Design Methodology and Application of Surface Texture: A Review. Coatings 2022, 12, 1015. https://doi.org/10.3390/coatings12071015

Nsilani Kouediatouka A, Ma Q, Liu Q, Mawignon FJ, Rafique F, Dong G. Design Methodology and Application of Surface Texture: A Review. Coatings. 2022; 12(7):1015. https://doi.org/10.3390/coatings12071015

Chicago/Turabian StyleNsilani Kouediatouka, Ange, Qiang Ma, Qi Liu, Fagla Jules Mawignon, Faisal Rafique, and Guangneng Dong. 2022. "Design Methodology and Application of Surface Texture: A Review" Coatings 12, no. 7: 1015. https://doi.org/10.3390/coatings12071015

APA StyleNsilani Kouediatouka, A., Ma, Q., Liu, Q., Mawignon, F. J., Rafique, F., & Dong, G. (2022). Design Methodology and Application of Surface Texture: A Review. Coatings, 12(7), 1015. https://doi.org/10.3390/coatings12071015