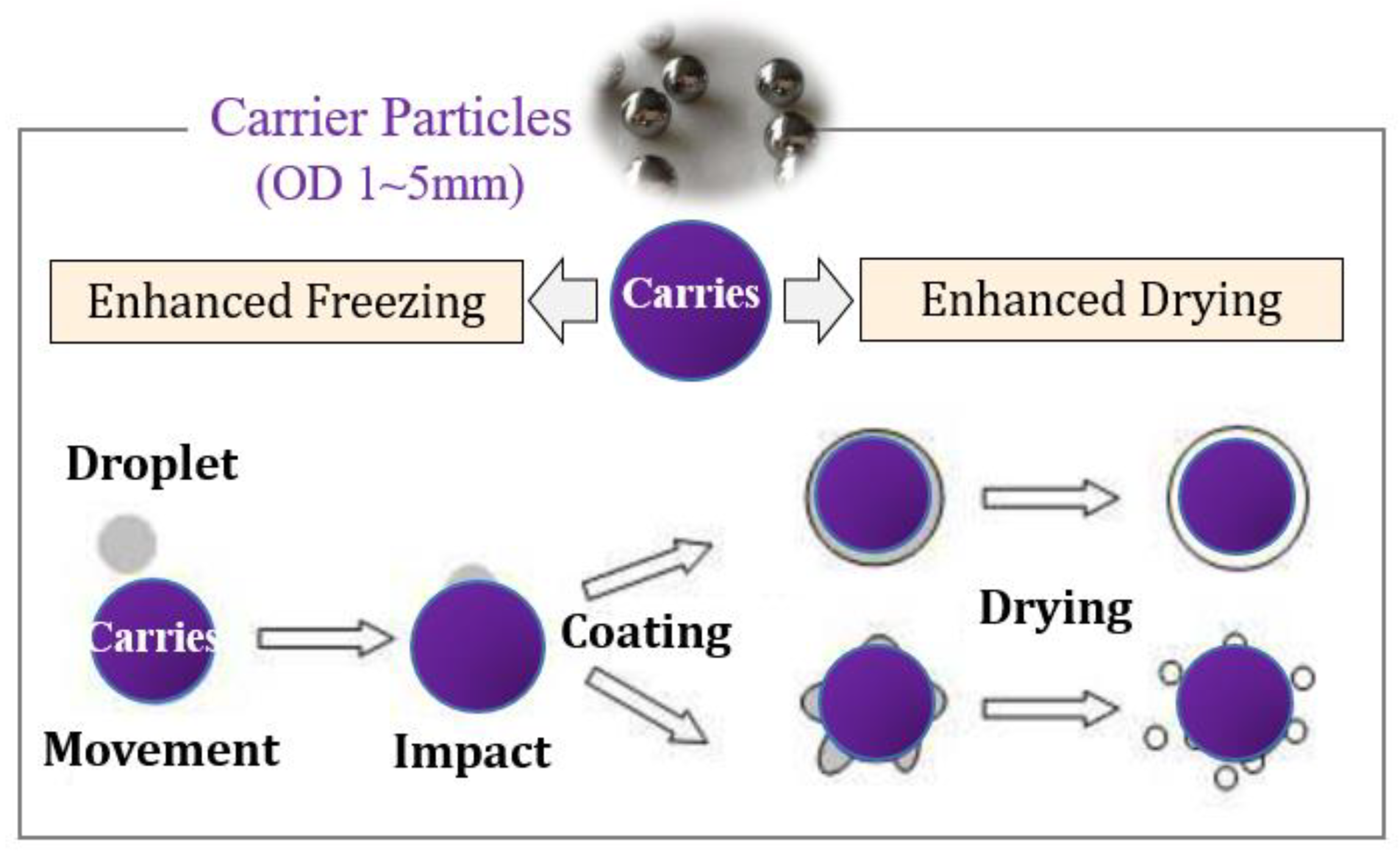

Spray Freezing Coating on the Carrier Particles for Powder Preparation

Abstract

:1. Introduction

2. Method

3. Microscopic Analysis of Dancing Single Droplet

3.1. Coating Process of Single Droplet Impacting on Spherical Surface

3.2. Freezing Process of Single Droplet Impacting on Spherical Surface

4. Spray Freeze Coating on the Stationary Carrier Particles

4.1. Freezing and Flow of Atomized Droplets in Flow Field

4.2. Three Cases of Spray Freeze Coating

5. Spray Freeze Coating on Moving Carrier Particles

6. Integrated Spray Freeze Coating Equipment and its Engineering Application

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, Q.; Geng, X.R.; Li, Z.Y. Morphology of particle produced by spray-freeze drying. Chem. Ind. Eng. Prog. 2013, 32, 270–275. [Google Scholar] [CrossRef]

- Wanning, S.; Süverkrüp, R.; Lamprecht, A. Pharmaceutical spray freeze drying. Int. J. Pharmaceut. 2015, 488, 136–153. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Okuyama, K. Progress in developing spray-drying methods for the production of controlled morphology particles: From the nanometer to submicrometer size ranges. Adv. Powder Technol. 2011, 22, 1–19. [Google Scholar] [CrossRef]

- Huang, L.X.; Zhou, R.J.; Mujumdar, A.S. Studies on the spray freeze drying of milk powders. Chem. Eng. Mach. 2009, 36, 219–222. [Google Scholar]

- Lei, H. Towards Tuning Microparticle Properties via Spray Drying Technique Invesitgation on Particle Formation Mechanism. Master’s Thesis, Suzhou University, Suzhou, China, 2016. [Google Scholar]

- Xu, Q.; Yao, Y.; Zhao, T.; Shi, Q.Q.; Li, Z.Y.; Tian, W. Dissolution characteristics of freeze-dried pullulan particles affected by solution concentration and freezing medium. Int. J. Food Eng. 2018, 14, 20180073. [Google Scholar] [CrossRef]

- Kamlesh, C.P.; Chen, X.D. Production of spherical and uniform-sized particles using a laboratory ink-jet spray dryer. Asia-Pac. J. Chem. Eng. 2007, 2, 415–430. [Google Scholar] [CrossRef]

- Zheng, X.D. A Fully Automatic Closed Spray Freeze-Drying Production Equipment and Method. Chinese Patent ZL201510790555.5, 10 February 2016. [Google Scholar]

- Li, Z.Y.; Xu, Q.; Wu, Z.H.; Ye, J.S.; Geng, X.R. The Invention Relates to an Inert Particle Spray Freeze Drying Device and a Method Thereof. Chinese Patent ZL201110103036.9, 26 October 2011. [Google Scholar]

- Zhang, F.; Wang, L.S.; Ma, X.Y.; Xu, Q.; Tian, W.; Li, Z.Y. Microstructure of spray freezing dried powders affected by the presence of inert particles. Int. J. Food Eng. 2020, 16, 1357–1366. [Google Scholar] [CrossRef]

- Li, Z.Y.; Pan, B.; Gao, X.Y.; Hu, Y.J. Particle mixing and segregation of binary mixtures in fluidized beds with additional pulsating air flow. Trans. Chin. Soc. Agric. Mach. 2015, 46, 247–253. [Google Scholar] [CrossRef]

- Zhu, W.Y. A Visual Experimental Study on a Droplet Impacting onto Solid Surfaces. Master’s Thesis, Dalian University of Technology, Dalian, China, 2007. [Google Scholar]

- Worthington, A.M. On the forms assumed by drops of liquids falling vertically on a horizontal plate. Proc. R. Soc. Lond. 1876, 25, 261–271. [Google Scholar] [CrossRef]

- Naber, J.D.; Reitz, R.D. Modeling engine spray wall impingement. SAE Trans. 1988, 97, 118–140. [Google Scholar]

- Wachters, L.H.J.; Westerling, N.A.J. The heat transfer from a hot wall to impinging water drops in the spheroidal state. Chem. Eng. Sci. 1966, 21, 1047–1056. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Zhang, H.; Zheng, L.L. Simulation of droplet spreading, splashing and solidification using smoothed particle hydrodynamics method. Int. J. Heat Mass Transf. 2008, 51, 3410–3419. [Google Scholar] [CrossRef]

- Xu, Q.; Li, Z.Y.; Wang, R.F.; Zhu, S.G. Coating and the impact of single droplet on the spherical surface. J. Tianjin Univ. Sci. Technol. 2013, 28, 50–54. [Google Scholar] [CrossRef]

- Bakshi, S.; Roisman, I.V.; Tropea, C. Investigations on the impact of a drop onto a small spherical target. Phys. Fluids 2007, 19, 32102. [Google Scholar] [CrossRef]

- Li, Y.P.; Wang, H.R. Numerical study on deposition characteristics of a droplet impinging onto spherical surface with low impact energy. J. Xi’an Jaotong Univ. 2009, 43, 21–24. [Google Scholar]

- Li, X.Y.; Ma, X.H.; Lan, Z. Behavioral patterns of drop impingement onto rigid substrates with a wide range of wettability and different surface temperatures. AIChE J. 2009, 55, 1983–1992. [Google Scholar] [CrossRef]

- Mendez-Vilas, A.; Jodar-Reyes, A.B.; Gonzalez-Martin, M.L. Ultrasmall liquid droplets on solid surfaces: Production, imaging, and relevance for current wetting research. Small 2009, 5, 1366–1390. [Google Scholar] [CrossRef]

- Šikalo, Š.; Tropea, C.; Ganić, E.N. Dynamic wetting angle of a spreading droplet. Exp. Therm. Fluid Sci. 2005, 29, 795–802. [Google Scholar] [CrossRef]

- Lunkad, S.F.; Maiti, R.N.; Buwa, V.V.; Nigam, K.D.P. Numerical study of drop spreading over saturated pores. Can. J. Chem. Eng. 2010, 88, 661–670. [Google Scholar] [CrossRef]

- Mantle, M.D.; Reis, N.C.; Griffiths, R.F.; Gladden, L.F. MRI studies of the evaporation of a single liquid droplet from porous surfaces. Magn. Reson. Imaging 2003, 21, 293–297. [Google Scholar] [CrossRef]

- Gunjal, P.R.; Ranade, V.V.; Chaudhari, R.V. Experimental and computational study of liquid drop over flat and spherical surfaces. Catal. Today 2003, 79–80, 267–273. [Google Scholar] [CrossRef]

- Bang, B.H.; Yoon, S.S.; Kim, H.Y.; Heister, S.D.; Park, H.; James, S.C. Assessment of gas and liquid velocities induced by an impacting liquid drop. Int. J. Multiph. Flow 2011, 37, 55–66. [Google Scholar] [CrossRef]

- Cossali, G.E.; Marengo, M.; Santini, M. Thermally induced secondary drop atomisation by single drop impact onto heated surfaces. Int. J. Heat Fluid Flow 2008, 29, 167–177. [Google Scholar] [CrossRef]

- Bhardwaj, R.; Longtin, J.P.; Attinger, D. A numerical investigation on the influence of liquid properties and interfacial heat transfer during microdroplet deposition onto a glass substrate. Int. J. Heat Mass Transf. 2007, 50, 2912–2923. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.G.; Zhu, F.Q.; Zhang, H.; New, T.H.; Jin, L.W.; Yang, C. Triple condensate halo from a single water droplet impacting upon a cold surface. Appl. Phys. Lett. 2019, 114, 183703. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Li, Z.Y.; Wang, J.; Wang, R.F. Characteristics of single droplet impact on cold plate surfaces. Dry. Technol. 2012, 30, 1756–1762. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.Y.; XU, Q.; Wang, R.F. Numerical simulation of the impact of single droplet oncold horizontal plate surface. J. Tianjin Univ. Sci. Technol. 2014, 29, 36–41. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, J.; Li, M.M.; Li, Z.Y. Experiments and simulation of a single droplet impacting on cold surfaces. Ciesc J. 2016, 67, 4160–4168. [Google Scholar] [CrossRef]

- Ju, J.J.; Jin, Z.Y.; Zhang, H.H.; Yang, Z.G.; Zhang, J. The impact and freezing processes of a water droplet on different cold spherical surfaces. Exp. Therm. Fluid Sci. 2018, 96, 430–440. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.S.; Xu, Q.; Wang, R.F.; Li, Z.Y. Impact of coating droplet on low temperature spherical particles. J. Tianjin Univ. Sci. Technol. 2019, 34, 43–48. [Google Scholar] [CrossRef]

- Wu, X.S. Uniformity of Liquid Film on Inert Particles by Spray Freezing Coating. Master’s Thesis, Tianjin University of Science and Technology, Tianjin, China, 2019. [Google Scholar]

- Sebastiao, I.B.; Bhatnagar, B.; Tchessalov, S.; Ohtake, S.; Plitzko, M.; Luy, B.; Alexeenko, A. Bulk dynamic spray Freeze-Drying part 1: Modeling of droplet cooling and phase change. J. Pharm. Sci. 2019, 108, 2063–2085. [Google Scholar] [CrossRef] [PubMed]

- Geng, X.R.; Xu, Q.; Li, Z.Y.; Song, J.T. Numerical simulation of a single droplet freezing process. Chem. Ind. Eng. Prog. 2012, 31, 981–986. [Google Scholar] [CrossRef]

- Li, M.M.; Xu, J.; Wang, X.; Xu, Q. Numerical simulation of droplets atomization in spray-freezing fluidized bed based on DPM and PBM. China Powder Sci. Technol. 2018, 24, 46–51. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, L.S.; Wu, X.S.; Zhang, F.; Li, Z.Y. Liquid film growth of spray-freezing coating on low temperature spherical particles. J. Tianjin Univ. Sci. Technol. 2021, 36, 42–47. [Google Scholar] [CrossRef]

- Xu, Q.; Wu, X.S.; Xu, J.; Li, Z.Y. System and Method for Use in Freezing and Coating after Impact of Micron-Sized Droplets onto Sphercial Surfaces. Australian Patent 2020100794, 10 June 2020. [Google Scholar]

- Li, Z.Y.; Ma, X.Y.; Zhang, F.; Xu, Q. An Image Analysis Method of Spray Freezing Coating Effect Based on Image J. China Patent CN201910670255.1, 13 December 2019. [Google Scholar]

- Zhang, F.; Ma, X.Y.; Wu, X.S.; Xu, Q.; Tian, W.; Li, Z.Y. Inert particles as process aid in spray-freeze drying. Dry. Technol. 2020, 38, 71–79. [Google Scholar] [CrossRef]

- Ma, X.Y.; Zhang, F.; Li, Z.Y.; Xu, Q. Effect of Inert Carrier Particles on Morphology of Spray Freeze-Drying Powders. In Proceedings of the 17th National Drying Technology Exchange Conference, Nanjing, China, 26 September 2019. [Google Scholar]

- Zhang, F.; Wang, L.S.; Xu, Q.; Tian, W.; Li, Z.Y. Stability of spouted bed during spray cold coating on the surface of carrier particles. Int. J. Food Eng. 2022, 18, 119–128. [Google Scholar] [CrossRef]

- Li, Z.Y.; Zhang, F.; Wang, L.S.; Xu, Q. An Inert Particle Spray Freeze Drying Device and Method. China Patent CN201911249506.5, 19 June 2020. [Google Scholar]

- Li, Z.Y.; Zhang, F.; Xu, Q.; Wang, L.S.; Gao, H.P.; Lin, B. Spouting Stability Self-Regulating Spray Freezing Spouted Bed Drying Device and Drying Method. China Patent CN202011633545.8, 18 June 2021. [Google Scholar]

- Sebastião, I.B.; Bhatnagar, B.; Tchessalov, S.; Ohtake, S.; Plitzko, M.; Luy, B.; Alexeenko, A. Bulk dynamic spray Freeze-Drying part 2: Model-Based parametric study for Spray-Freezing process characterization. J. Pharm. Sci. 2019, 108, 2075–2085. [Google Scholar] [CrossRef]

- Bruttini, R.; Liapis, A.I. The drying rates of spray freeze drying systems increase through the use of stratified packed bed structures. Int. J. Heat Mass Transf. 2015, 90, 515–522. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, L.S.; Wang, H.Y.; Wang, J.J.; Dai, X.Y. Drying Device and Method for Judging the Critical Point of Primary and Secondary Drying in Freeze-Drying Process. China Patent CN202111331012.9, 15 March 2022. [Google Scholar]

- Li, Z.Y.; Zhang, F.; Ma, X.Y.; Xu, Q. Large-Scale Drying Device and Method of Probiotics Liquid Freeze Drying Time. China Patent ZL201910670268.9, 3 December 2019. [Google Scholar]

- Li, Z.Y.; Xu, Q.; Xu, J.; Li, M.M. Spray Freezing Microchannel Dryer. China Patent ZL201611020004.1, 3 May 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Q.; Wang, R.; Zhang, F.; Wang, R.; Wu, L.; Lin, B. Spray Freezing Coating on the Carrier Particles for Powder Preparation. Coatings 2022, 12, 896. https://doi.org/10.3390/coatings12070896

Xu Q, Wang R, Zhang F, Wang R, Wu L, Lin B. Spray Freezing Coating on the Carrier Particles for Powder Preparation. Coatings. 2022; 12(7):896. https://doi.org/10.3390/coatings12070896

Chicago/Turabian StyleXu, Qing, Ruixin Wang, Fan Zhang, Ruifang Wang, Long Wu, and Bo Lin. 2022. "Spray Freezing Coating on the Carrier Particles for Powder Preparation" Coatings 12, no. 7: 896. https://doi.org/10.3390/coatings12070896

APA StyleXu, Q., Wang, R., Zhang, F., Wang, R., Wu, L., & Lin, B. (2022). Spray Freezing Coating on the Carrier Particles for Powder Preparation. Coatings, 12(7), 896. https://doi.org/10.3390/coatings12070896