The Characterization of Running-In Coatings on the Surface of Tin Bronze by Electro-Spark Deposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Experimental Materials

2.2. Deposition Process Parameters

2.3. Properties Investigation

3. Results and Discussion

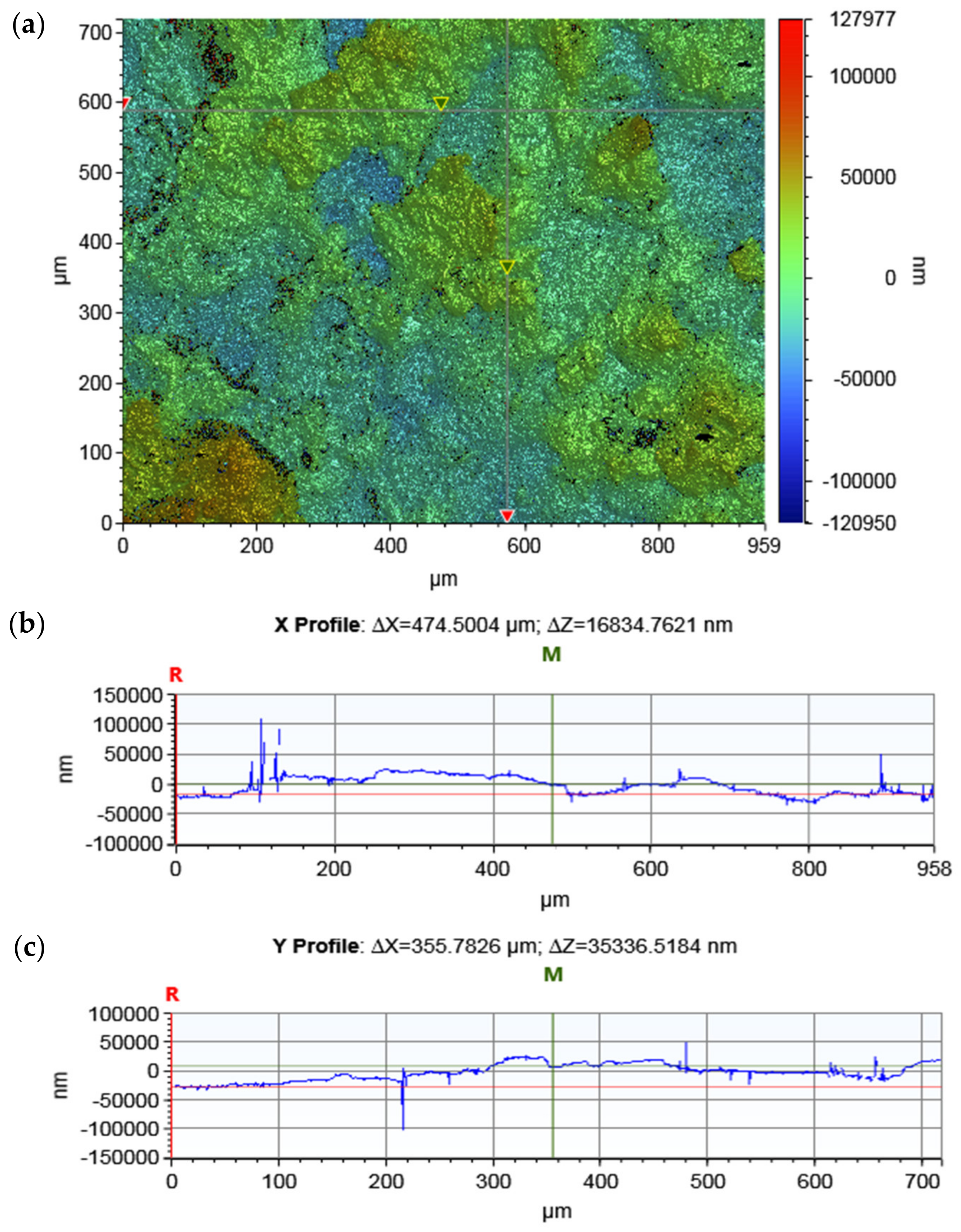

3.1. The Mass Transfer, Roughness, and Thickness Characteristics of the Running-In Coatings

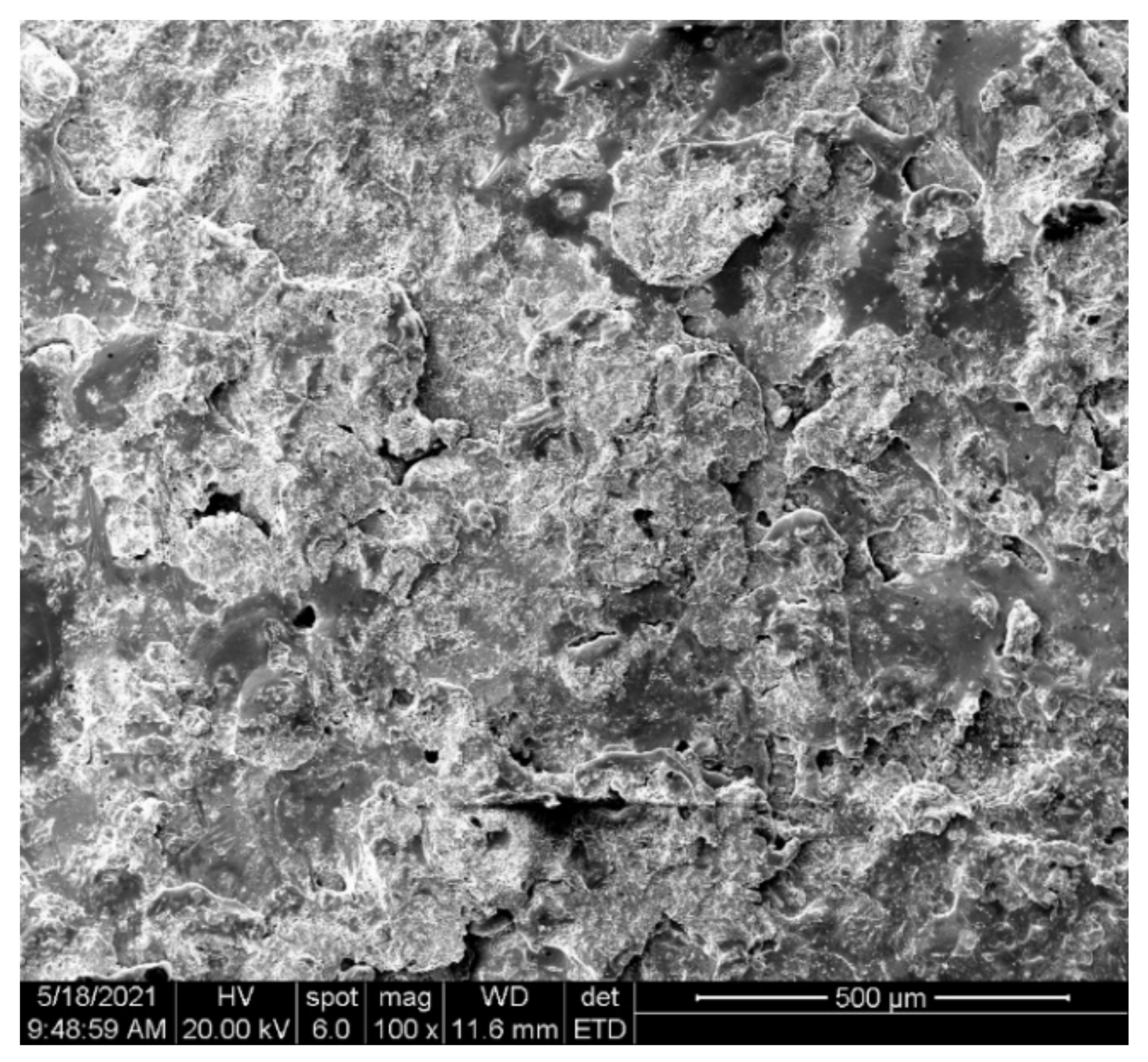

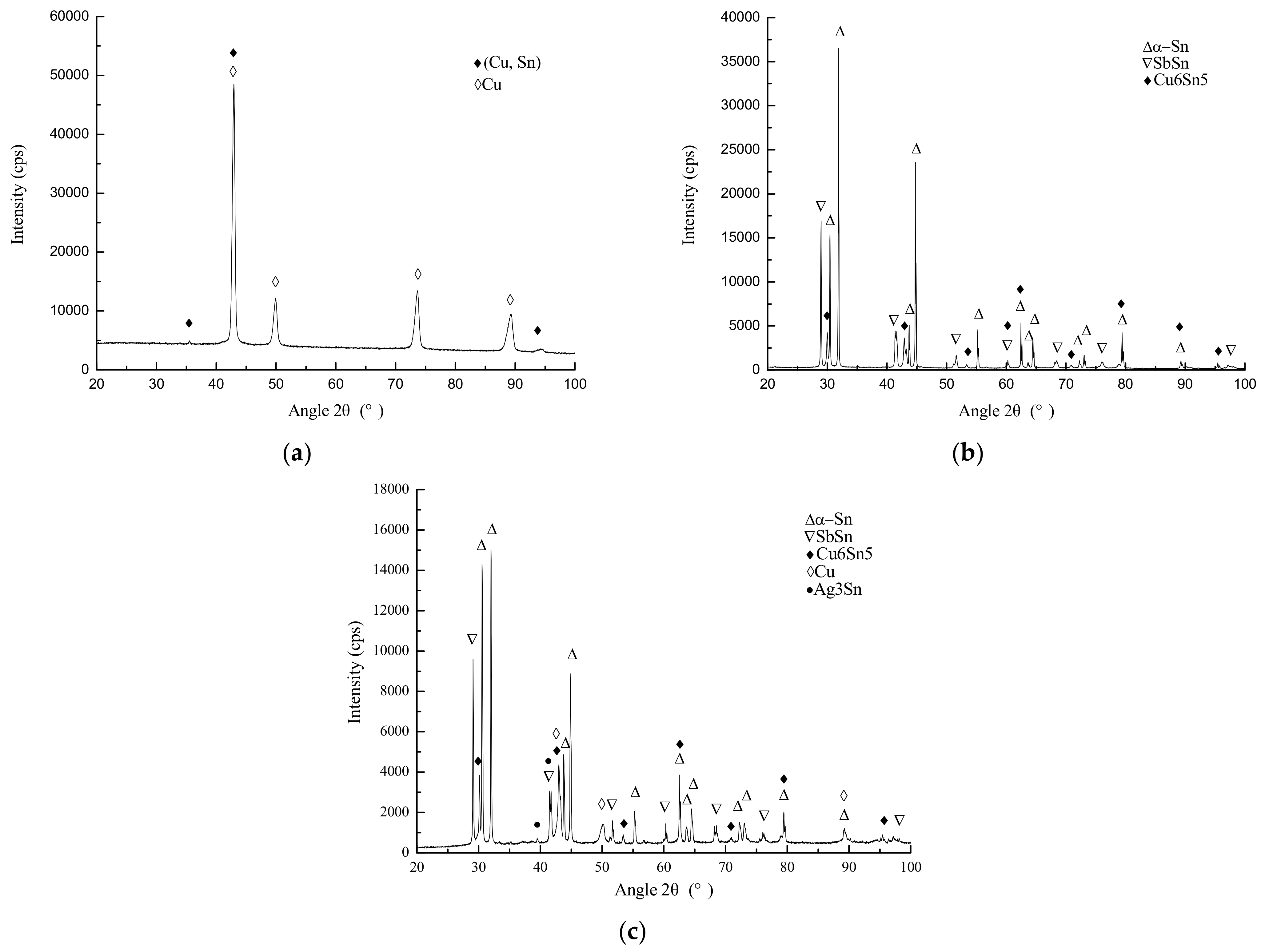

3.2. The Morphology, Element Composition, and Phase Composition of the Running-In Coating Surface

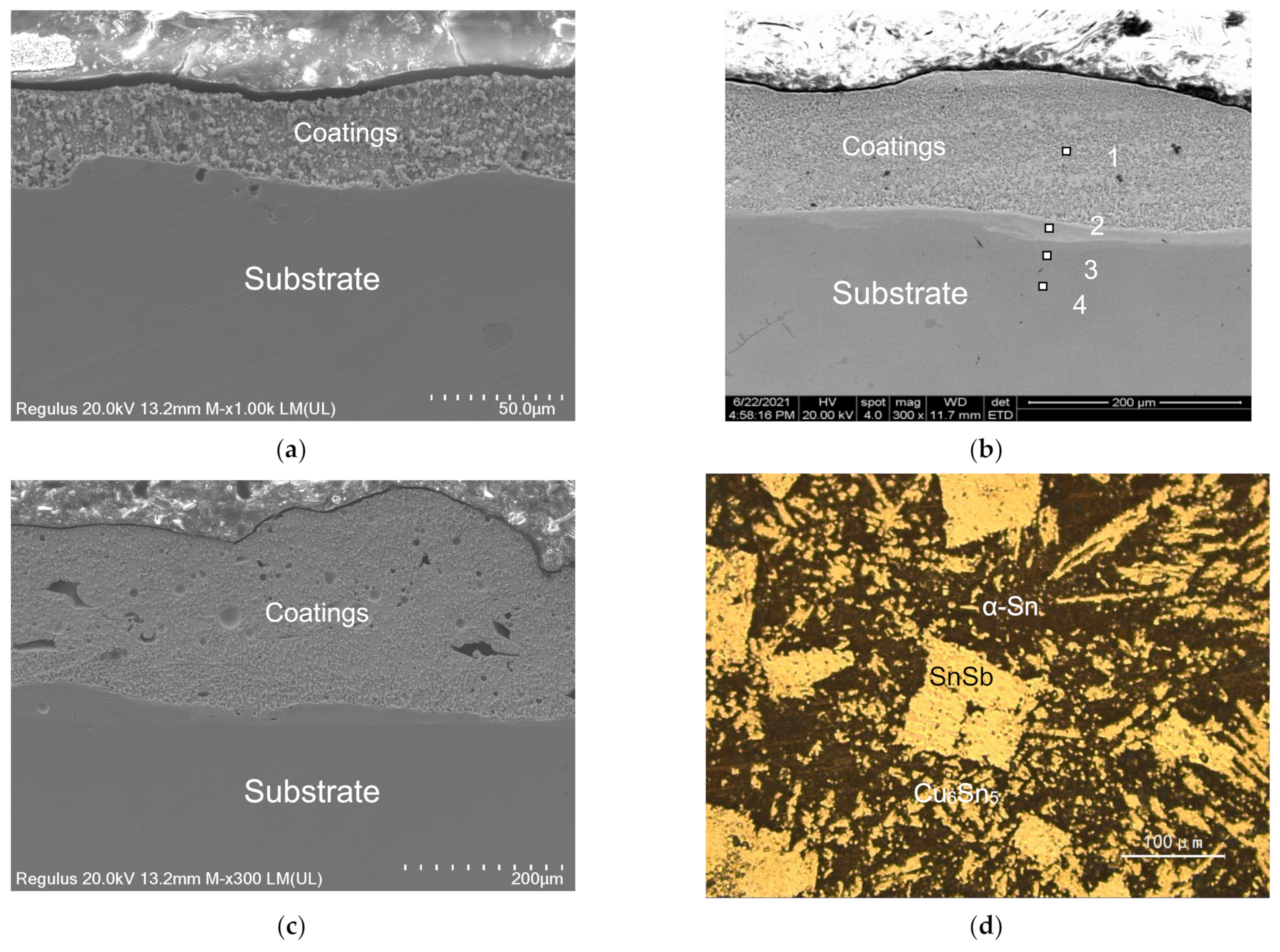

3.3. The Cross-Section Morphology of the Running-In Coatings

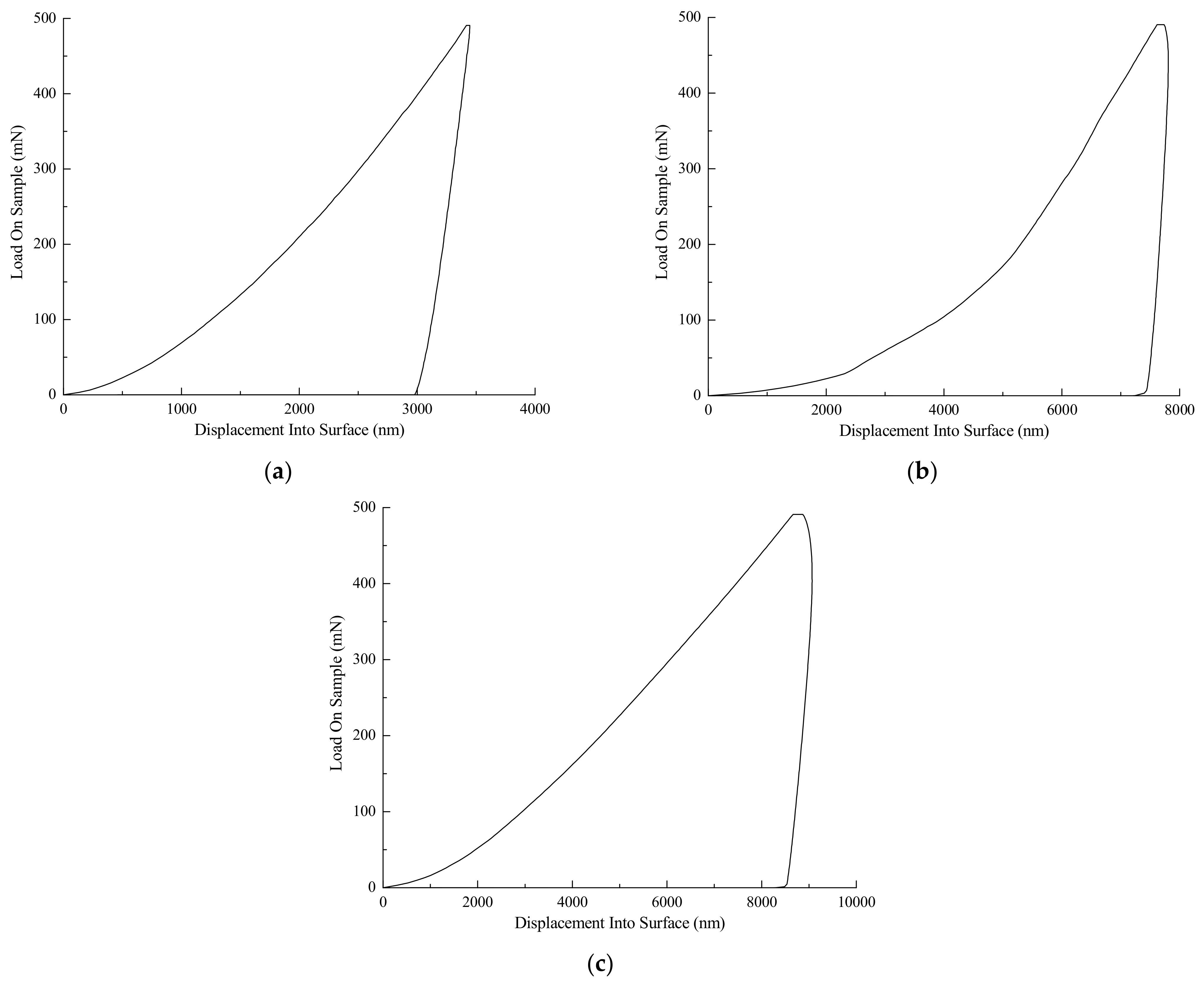

3.4. The Nanoindentation Properties of the Running-In Coatings

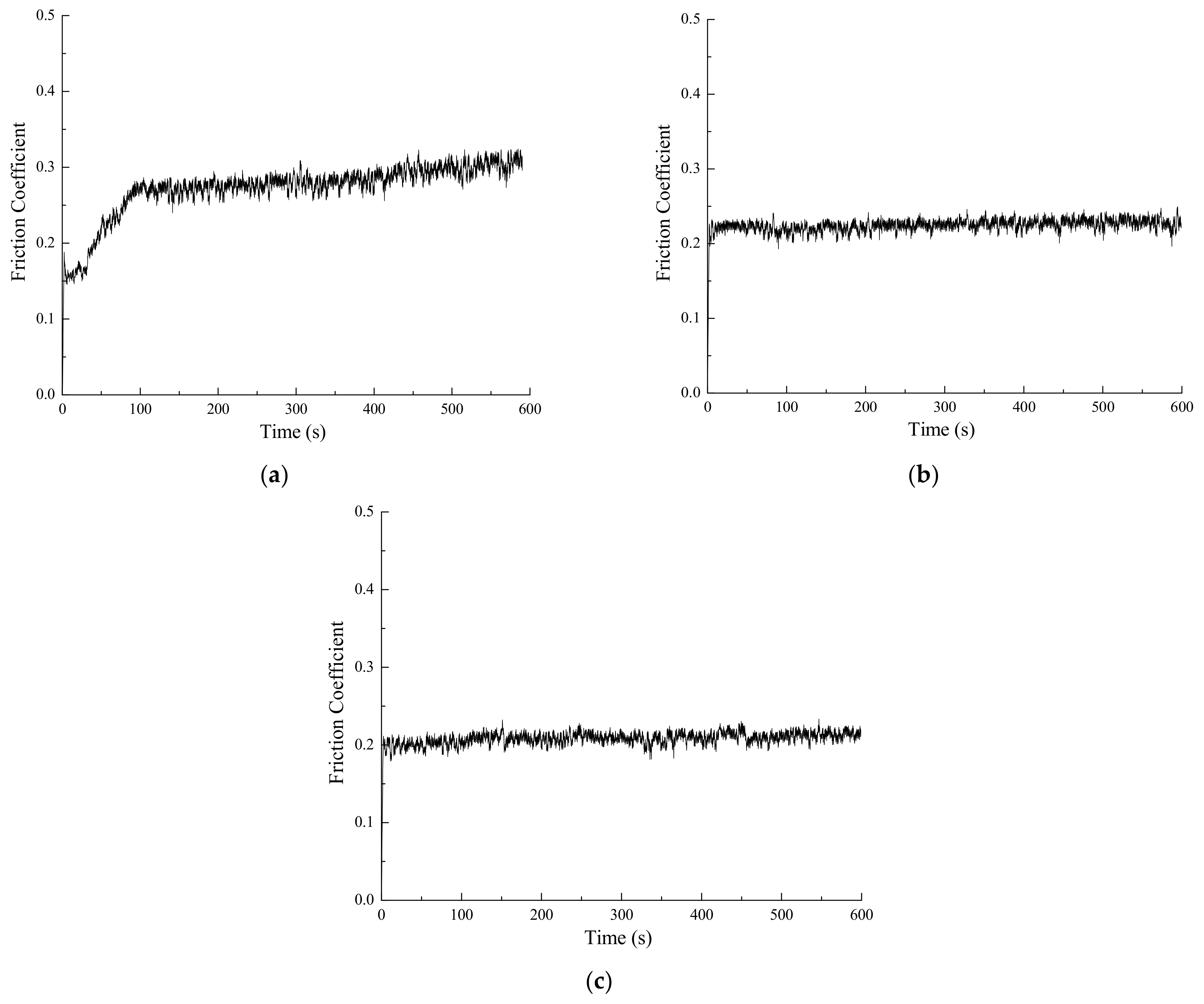

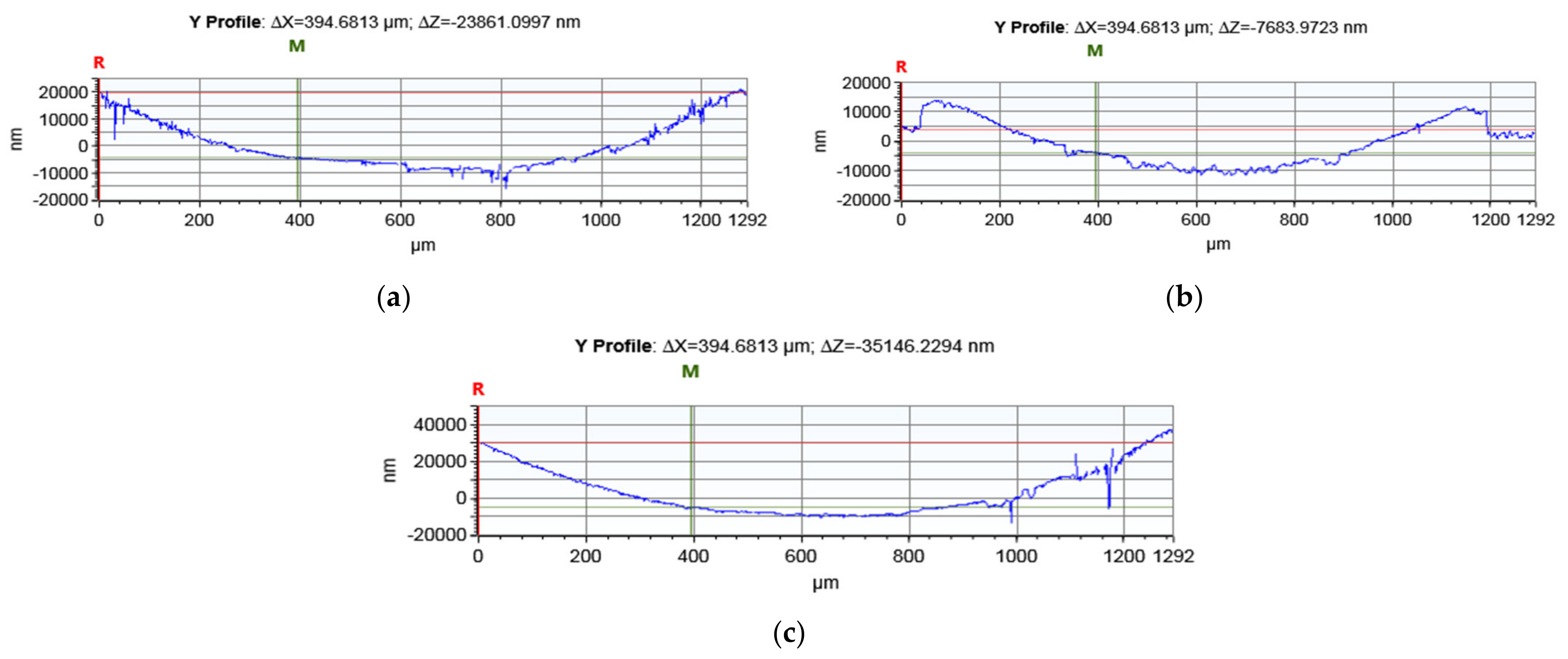

3.5. Tribological Properties of the Running-In Coatings

4. Conclusions

- (1)

- The running-in coatings of silver, copper, Babbitt B83, and graphene oxide were deposited on the tin bronze QSn10-1 by electro-spark deposition. At optimum process parameters, the mass transfer was 244.2 mg, the surface roughness of the composite coatings was 15.9 μm, and the thickness was 160 μm. The diffraction peaks observed for the running-in coating surface clearly indicated the phases corresponding to α-Sn, SbSn, Cu6Sn5, and Cu, and a phase of Ag3Sn appeared, which is conducive to strengthening the metallurgical bonding as well as grain refinement.

- (2)

- The grains in the running-in coatings were very dense, refined, uniformly distributed by ESD technology, and in a metallurgical bond state with the tin bronze substrate.

- (3)

- The modulus of the running-in coatings was 36.4% for Babbitt B83 and 24.9% for the tin bronze substrate. The hardness of the running-in coatings was 79.8% for Babbitt B83 and 14.2% for the bronze substrate. The deformation ratio of the running-in coatings was 1.9% higher than that of Babbitt B83 and 10.2% higher than that of the substrate.

- (4)

- The friction coefficient stabilized after running-in and became stable during the test. The friction coefficient of the running-in coatings (0.210) was 64.8% for the substrate (0.324), which was similar to that of Babbitt B83 (0.192). The wear mechanism of the running-in coatings was dominated by plastic deformation, scratching, and slight polishing. The running-in coating deformation under the action of high specific loads provides automatic adjustment of parts and compensation for manufacturing errors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Philip, J.T.; Kumar, D.; Mathew, J.; Kuriachen, B. Tribological investigations of wear resistant layers developed through EDA and WEDA techniques on Ti6Al4V surfaces: Part II—High temperature. Wear 2021, 466, 203540–203551. [Google Scholar] [CrossRef]

- Chen, S.; Wei, L.; Cheng, B.X.; Jin, Y.L.; Li, C.; Jia, D.; Duan, H.T. Dry sliding tribological properties of PI/UHMWPE blends for high speed application. Tribol. Int. 2020, 146, 106262–106276. [Google Scholar] [CrossRef]

- Tang, Y.C.; Wan, N.; Shen, M.X.; Jiao, H.T.; Liu, D.J.; Tang, X.C.; Zhao, L.Z. A comparison of the microstructures and hardness values of non-equiatomic (FeNiCo)-(AlCrSiTi) high entropy alloys having thermal histories related to laser direct metal deposition or vacuum remelting. J. Mater. Res. Technol. 2021, 15, 696–707. [Google Scholar] [CrossRef]

- Kobernik, N.V.; Mikheev, R.S.; Brzhezinskaya, M.; Aleshin, N.P. Effect of carbon nanotubes on structure and properties of the antifriction coatings produced by plasma cladding. Fuller. Nanotub. Carbon Nanostruct. 2020, 28, 515–520. [Google Scholar] [CrossRef]

- Wang, D.; Gao, J.H.; Deng, S.J.; Wang, W.Q. A novel particle planting process based on electrospark deposition. Mater. Lett. 2022, 306, 130872–130886. [Google Scholar] [CrossRef]

- Radek, N.; Konstanty, J.; Pietraszek, J.; Orman, L.J.; Szczepaniak, M.; Przestacki, D. The effect of laser beam processing on the properties of WC-Co coatings deposited on steel. Materials 2021, 14, 538–550. [Google Scholar] [CrossRef]

- Shafudah, N.H.; Nagai, H.; Suwazono, Y.; Ozawa, R.; Kudoh, Y.; Takahashi, T.; Onuma, T.; Sato, M. Hydrophilic titania thin films from a molecular precursor film formed via electrospray deposition on a quartz glass substrate precoated with carbon nanotubes. Coatings 2020, 10, 1050–1063. [Google Scholar] [CrossRef]

- Cao, J.; Huang, H.B.; Li, S.X.; Wu, X.C.; Yin, Z.W.; Abbas, Z. Tribological and mechanical behaviors of engine bearing with CuSn10 layer and h-BN/graphite coating prepared by spraying under different temperatures. Tribol. Int. 2020, 152, 106445–106456. [Google Scholar] [CrossRef]

- Dinesh, D.; Megalingam, A. Dry sliding friction and wear behaviour of leaded tin bronze for bearing and bushing application. Arch. Metall. Mater. 2021, 66, 1095–1104. [Google Scholar] [CrossRef]

- Ribeiro, R.M.; Camara, M.A. Study of the tribological behavior of the Babbitt alloy—Steel ABNT 1045 pair when varied thickness and roughness of the coating. Materia 2020, 25, 1061–1075. [Google Scholar] [CrossRef]

- Dyachkova, L.N. Tribological characteristics and wear features of powder tin bronze with the addition of ultrafine oxides. J. Frict. Wear 2020, 41, 295–299. [Google Scholar] [CrossRef]

- Bazhenov, V.E.; Titov, A.Y.; Shkalei, I.V.; Sannikov, A.V.; Nikitina, A.A.; Plisetskaya, I.V.; Bazlov, A.I.; Mezrin, A.M.; Koltygin, A.V. Effect of the cooling rate on the microstructure and properties of C92900 bronze. Russ. J. Non-Ferr. Met. 2021, 62, 274–285. [Google Scholar] [CrossRef]

- Ren, X.Y.; Zhang, G.W.; Xu, H.; Wang, Z.J.; Liu, Y.J.; Sun, F.E.; Kang, Y.Y.; Wang, M.J.; Lv, W.Z.; Yin, Z. Effects of B on the structure and properties of Lead-Tin bronze alloy and the mechanism of strengthening and toughening. Materials 2021, 14, 7806. [Google Scholar] [CrossRef]

- Gajmal, S.S.; Raut, D.N. An investigation on wear behaviour of ASTM B23 Tin-Based Babbitt alloy developed through microwave-assisted casting. Int. J. Metalcast. 2022, 1, 1–19. [Google Scholar] [CrossRef]

- Kamal, M.; El-Bediwi, A.; Lashin, A.R.; El-Zarka, A.H. Copper effects in mechanical properties of rapidly solidified Sn-Pb-Sb Babbitt bearing alloys. Mater. Sci. Eng. A-Struct. 2011, 530, 327–332. [Google Scholar] [CrossRef]

- Dong, Q.; Yin, Z.W.; Li, H.L.; Gao, G.Y.; Zhong, N.; Chen, Y.H. Simulation and experimental verification of fatigue strength evaluation of journal bearing bush. Eng. Fail. Anal. 2020, 109, 104275–104286. [Google Scholar] [CrossRef]

- Ni, Y.Q.; Li, X.; Dong, G.N.; Tong, Z.; Mei, T.J. The combined effect of La and heat treatment on the tribological performances of tin-Babbitt alloy. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 1117–1126. [Google Scholar] [CrossRef]

- Ni, Y.Q.; Dong, G.N.; Tong, Z.; Li, X.; Wang, W. Effect of laser remelting on tribological properties of Babbitt alloy. Mater. Res. Express 2019, 6, 096570. [Google Scholar] [CrossRef]

- Choi, J.; Okimura, N.; Yamada, T.; Hirata, Y.; Ohtake, N.; Akasaka, H. Deposition of Graphene–Copper composite film by cold spray from particles with graphene grown on copper particles. Diam. Relat. Mater. 2021, 116, 108384–108396. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Lu, X.T.; Xu, J.R.; Luo, H.J. Characterization and tribological properties of Graphene/Copper composites fabricated by electroless plating and powder metallurgy. Acta Met. Sin. Engl. 2020, 33, 903–912. [Google Scholar] [CrossRef]

- Wang, L.; Gong, P.W.; Li, W.; Luo, T.; Cao, B.Q. Mono-dispersed Ag/Graphene nanocomposite as lubricant additive to reduce friction and wear. Tribol. Int. 2020, 146, 106228. [Google Scholar] [CrossRef]

- Wu, F.; Zhao, W.J.; Chen, H.; Zeng, Z.X.; Wu, X.D.; Xue, Q.J. Interfacial structure and tribological behaviours of epoxy resin coating reinforced with graphene and graphene oxide. Surf. Interface Anal. 2017, 49, 85–92. [Google Scholar] [CrossRef]

- Guler, O.; Bagci, N. A short review on mechanical properties of graphene reinforced metal matrix composites. J. Mater. Res. Technol. 2020, 9, 6808–6833. [Google Scholar] [CrossRef]

- Song, W.; Chen, P.; Yan, J.C.; Zhu, W.S.; Ji, H.B. The tribological properties of reduced graphene oxide doped by N and B species with different configurations. ACS Appl. Mater. Interfaces 2020, 12, 29737–29746. [Google Scholar] [CrossRef] [PubMed]

- Sheveyko, A.N.; Kuptsov, K.A.; Kiryukhantsev-Korneev, P.V.; Kaplansky, Y.Y.; Orekhov, A.S.; Levashov, E.A. Protective coatings for LPBF Ni-based superalloys using a combination of electrospark deposition and pulsed arc evaporation methods. Appl. Surf. Sci. 2022, 581, 152357–152369. [Google Scholar] [CrossRef]

- Khan, M.S.; Enrique, P.; Ghatei-Kalashami, A.; Lopes, J.G.; Schell, N.; Oliveira, J.P.; Biro, E.; Zhou, Y.N. The influence of in-situ alloying of electro-spark deposited coatings on the multiscale morphological and mechanical properties of laser welded Al-Si coated 22MnB5. Mater. Sci. Eng. A-Struct. 2022, 839, 142830–142839. [Google Scholar] [CrossRef]

- Liang, Z.; Zhang, H.; Wang, S.; Zhang, L.; Zhu, C.; Jin, H.; Guo, C. Comparative research of electrospark deposited Tungsten alloy coating in two kinds of gas. Dig. J. Nanomater. Bios. 2021, 16, 793–800. [Google Scholar]

- Wang, X.R.; Wang, Z.Q.; Lin, T.S.; He, P. Mass transfer trends of A1CoCrFeNi high-entropy alloy coatings on TC11 substrate via electrospark—Computer numerical control deposition. J. Mater. Process. Technol. 2017, 241, 93–102. [Google Scholar] [CrossRef]

- Korkmaz, K.; Ribalko, A.V. Effect of pulse shape and energy on the surface roughness and mass transfer in the electrospark coating process. Kov. Mater. 2011, 49, 265–270. [Google Scholar] [CrossRef]

- Xue, Y.W.; Shi, X.L.; Zhou, H.Y.; Yang, Z.Y.; Zhang, J.; Wu, C.H.; Xue, B. Effects of textured surface combined with Sn-Ag-Cu coating on tribological properties and friction-induced noise of Ti-6Al-4V alloy. Tribol. Trans. 2021, 64, 562–577. [Google Scholar] [CrossRef]

- Dong, Q.; Yin, Z.W.; Li, H.L.; Zhang, X.Y.; Jiang, D.; Zhong, N. Effects of Ag micro-addition on structure and mechanical properties of Sn-11Sb-6Cu Babbitt. Mater. Sci. Eng. A-Struct. 2018, 722, 225–230. [Google Scholar] [CrossRef]

- Kuptsov, K.A.; Sheveyko, A.N.; Manakova, O.S.; Sidorenko, D.A.; Shtansky, D.V. Comparative investigation of single-layer and multilayer Nb-doped TiC coatings deposited by pulsed vacuum deposition techniques. Surf. Coat. Technol. 2020, 385, 125422. [Google Scholar] [CrossRef]

- Zhao, H.; Gao, C.; Wu, X.Y.; Xu, B.; Lu, Y.J.; Zhu, L.K. A novel method to fabricate composite coatings via ultrasonic-assisted electro-spark powder deposition. Ceram. Int. 2019, 45, 22528–22537. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, L.; Wang, X.M.; Zhao, Y.; Chang, Q.; Wang, W.Y.; Xu, A.Y. Experimental study on aluminum bronze coating fabricated by electro-spark deposition with subsequent ultrasonic surface rolling. Surf. Coat. Technol. 2021, 426, 127772–127783. [Google Scholar] [CrossRef]

- Kuptsov, K.A.; Antonyuk, M.N.; Bondarev, A.V.; Sheveyko, A.N.; Shtansky, D.V. Electrospark deposition of wear and corrosion resistant Ta(Zr)C-(Fe,Mo,Ni) coatings to protect stainless steel from tribocorrosion in seawater. Wear 2021, 486, 204094–204104. [Google Scholar] [CrossRef]

- Holubets, V.M.; Pashechko, M.I.; Borc, J.; Tisov, O.V.; Shpuliar, Y.S. Wear resistance of electrospark-deposited coatings in dry sliding friction conditions. Powder Metall. Met. Ceram. 2021, 60, 90–96. [Google Scholar] [CrossRef]

| Specimens | Coatings | Voltage (V) | Capacitance (μF) | Efficiency (min/cm2) |

|---|---|---|---|---|

| 1 | Ag + Cu + B83 + GO + B83 | 60/40/30 --/20 | 90/90/30 --/30 | 2/1/1 --/2 |

| 2 | Ag + Cu + B83 + GO + B83 | 60/40/30 --/25 | 150/90/30 --/90 | 2/1/1 --/2 |

| 3 | Ag + Cu + B83 + GO + B83 | 60/40/30 --/30 | 150/150/90 --/150 | 2/1/1 --/2 |

| Specimens | Coatings | Mass Transfer (mg) | Roughness Ra (μm) | Thickness (μm) |

|---|---|---|---|---|

| 1 | Ag + Cu + B83 + GO + B83 | 90.8 ± 10.4 | 17.5 ± 5.5 | 50 ± 15 |

| 2 | Ag + Cu + B83 + GO + B83 | 244.2 ± 23.3 | 15.9 ± 3.9 | 160 ± 60 |

| 3 | Ag + Cu + B83 + GO + B83 | 550.1 ± 78.0 | 24.6 ± 7.1 | 200 ± 125 |

| Specimens | Cu (Weight %) | Ag (Weight %) | Sn (Weight %) | Sb (Weight %) |

|---|---|---|---|---|

| 1 | 9.48 ± 0.10 | 1.54 ± 0.10 | 77.21 ± 0.10 | 16.78 ± 0.10 |

| 2 | 7.08 ± 0.10 | 1.51 ± 0.10 | 77.01 ± 0.10 | 14.41 ± 0.10 |

| 3 | 7.09 ± 0.10 | 0.52 ± 0.10 | 83.32 ± 0.10 | 9.08 ± 0.10 |

| Research Area | Cu (Weight%) | Ag (Weight%) | Sn (Weight%) | Sb (Weight%) |

|---|---|---|---|---|

| 1 | 6.49 ± 0.10 | 0 | 82.95 ± 0.10 | 10.56 ± 0.10 |

| 2 | 64.76 ± 0.10 | 13.97 ± 0.10 | 17.53 ± 0.10 | 3.74 ± 0.10 |

| 3 | 55.82 ± 0.10 | 40.28 ± 0.10 | 3.90 ± 0.10 | 0 |

| 4 | 91.03 ± 0.10 | 0± | 8.97 ± 0.10 | 0 |

| Specimens | Modulus (GPa) | Hardness (GPa) | Deformation Ratio (%) |

|---|---|---|---|

| substrate | 77.1 ± 16.1 | 1.983 ± 0.287 | 86.49 |

| B83 | 52.8 ± 14.3 | 0.352 ± 0.224 | 93.48 |

| coatings | 19.2 ± 8.8 | 0.281 ± 0.061 | 95.30 |

| Specimens | 5 N | 10 N | 15 N |

|---|---|---|---|

| substrate | 0.333 ± 0.051 | 0.330 ± 0.032 | 0.324 ± 0.034 |

| B83 | 0.206 ± 0.022 | 0.188 ± 0.017 | 0.192 ± 0.021 |

| 1 | 0.265 ± 0.021 | 0.175 ± 0.015 | 0.208 ± 0.019 |

| 2 | 0.287 ± 0.032 | 0.227 ± 0.017 | 0.210 ± 0.018 |

| 3 | 0.374 ± 0.030 | 0.326 ± 0.028 | 0.217 ± 0.020 |

| Specimens | O (Weight %) | Cu (Weight %) | Ag (Weight %) | Sn (Weight %) | Sb (Weight %) |

|---|---|---|---|---|---|

| 1 | 13.88 ± 0.10 | 23.14 ± 0.10 | 2.75 ± 0.10 | 54.35 ± 0.10 | 5.89 ± 0.10 |

| 2 | 22.10 ± 0.10 | 6.07 ± 0.10 | 0 | 62.04 ± 0.10 | 9.78 ± 0.10 |

| 3 | 12.77 ± 0.10 | 4.54 ± 0.10 | 0 | 71.21 ± 0.10 | 11.49 ± 0.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Konoplianchenko, I.; Tarelnyk, V.; Liu, G.; Du, X.; Yu, H. The Characterization of Running-In Coatings on the Surface of Tin Bronze by Electro-Spark Deposition. Coatings 2022, 12, 930. https://doi.org/10.3390/coatings12070930

Zhang Z, Konoplianchenko I, Tarelnyk V, Liu G, Du X, Yu H. The Characterization of Running-In Coatings on the Surface of Tin Bronze by Electro-Spark Deposition. Coatings. 2022; 12(7):930. https://doi.org/10.3390/coatings12070930

Chicago/Turabian StyleZhang, Zhengchuan, Ievgen Konoplianchenko, Viacheslav Tarelnyk, Guanjun Liu, Xin Du, and Hua Yu. 2022. "The Characterization of Running-In Coatings on the Surface of Tin Bronze by Electro-Spark Deposition" Coatings 12, no. 7: 930. https://doi.org/10.3390/coatings12070930

APA StyleZhang, Z., Konoplianchenko, I., Tarelnyk, V., Liu, G., Du, X., & Yu, H. (2022). The Characterization of Running-In Coatings on the Surface of Tin Bronze by Electro-Spark Deposition. Coatings, 12(7), 930. https://doi.org/10.3390/coatings12070930