The Fabrication of Full Chromatography SiO2@PDA Photonic Crystal Structural Colored Fabric with High Thermal Stability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Monodisperse SiO2@PDA Colloidal Microspheres

2.3. Preparation of Structured Colored Fabrics

2.4. Characterization

3. Results

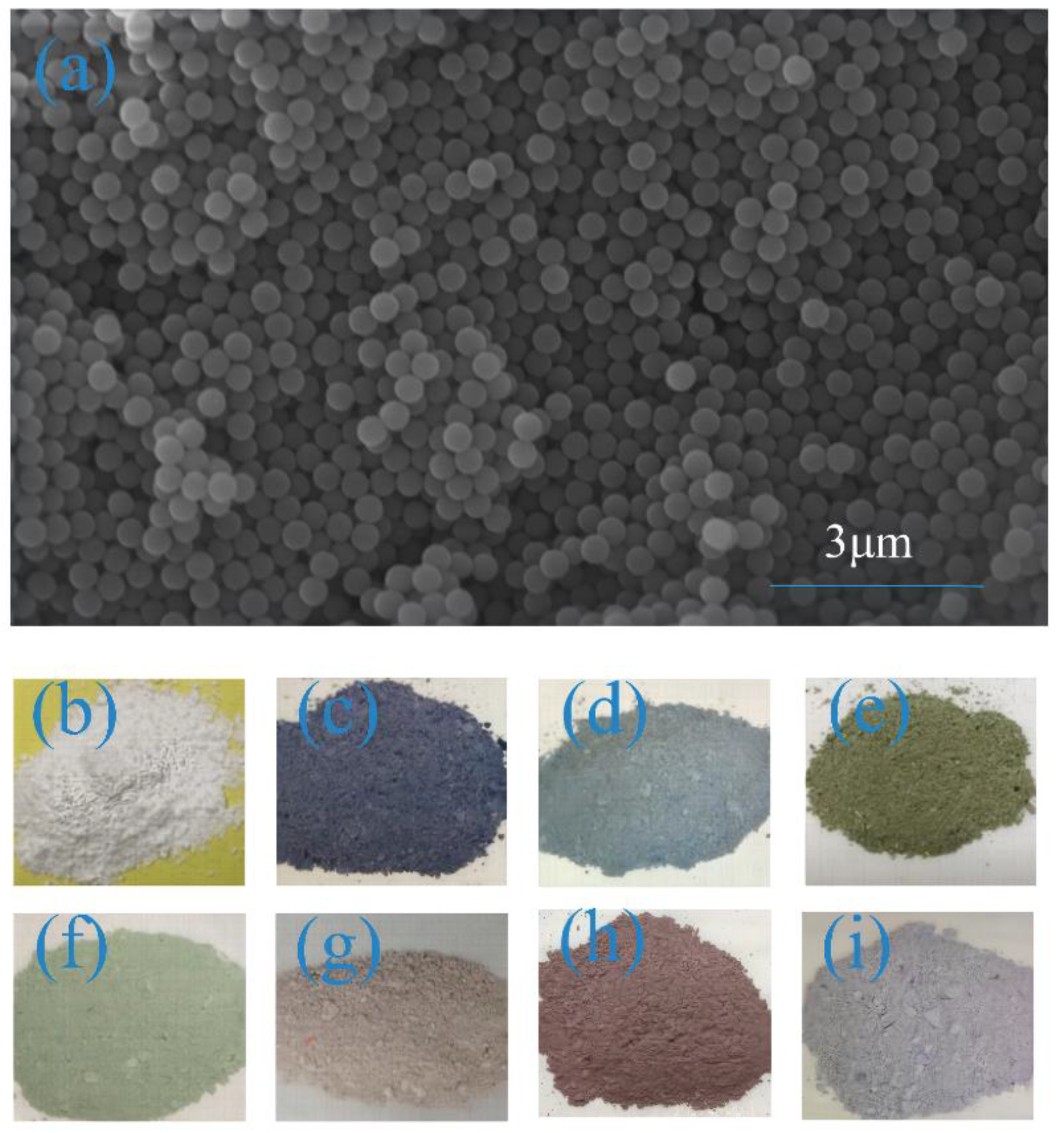

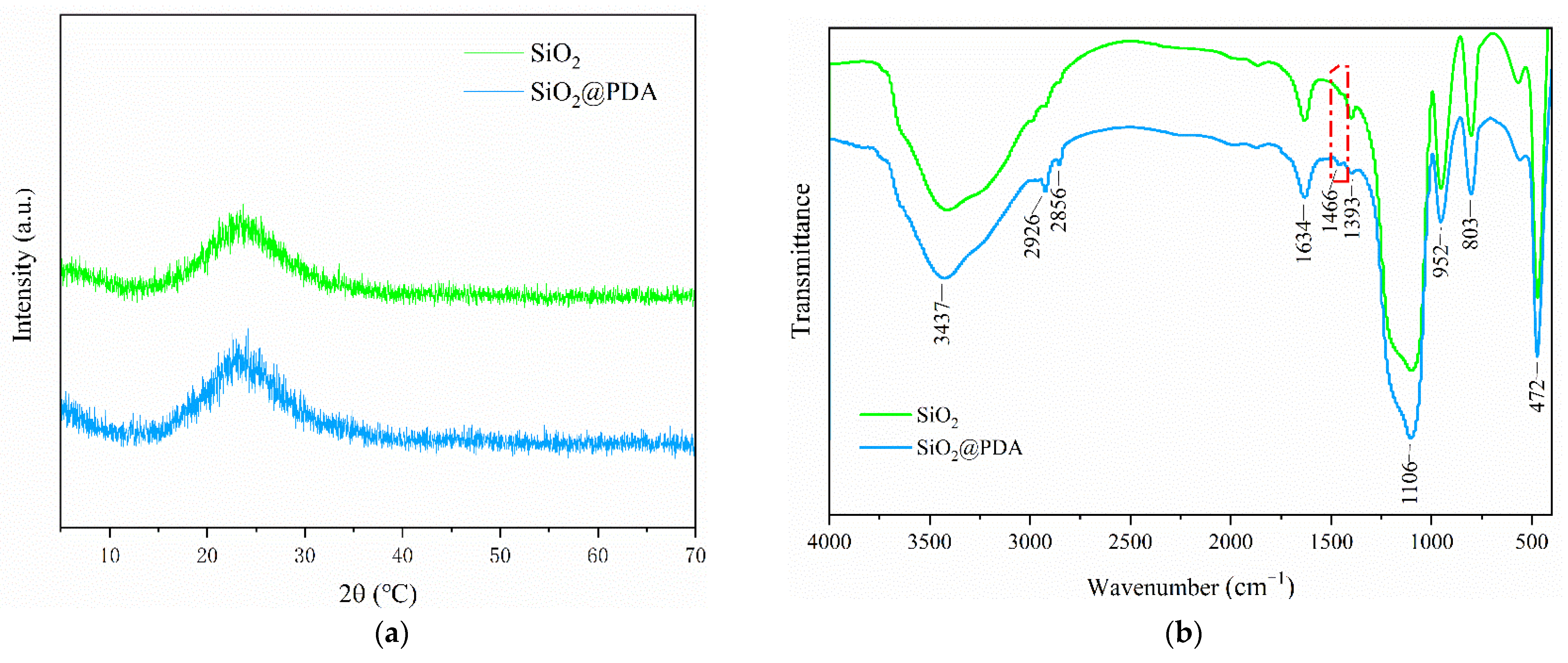

3.1. Characterization and Analysis of SiO2@PDA Core-shell Colloidal Microspheres

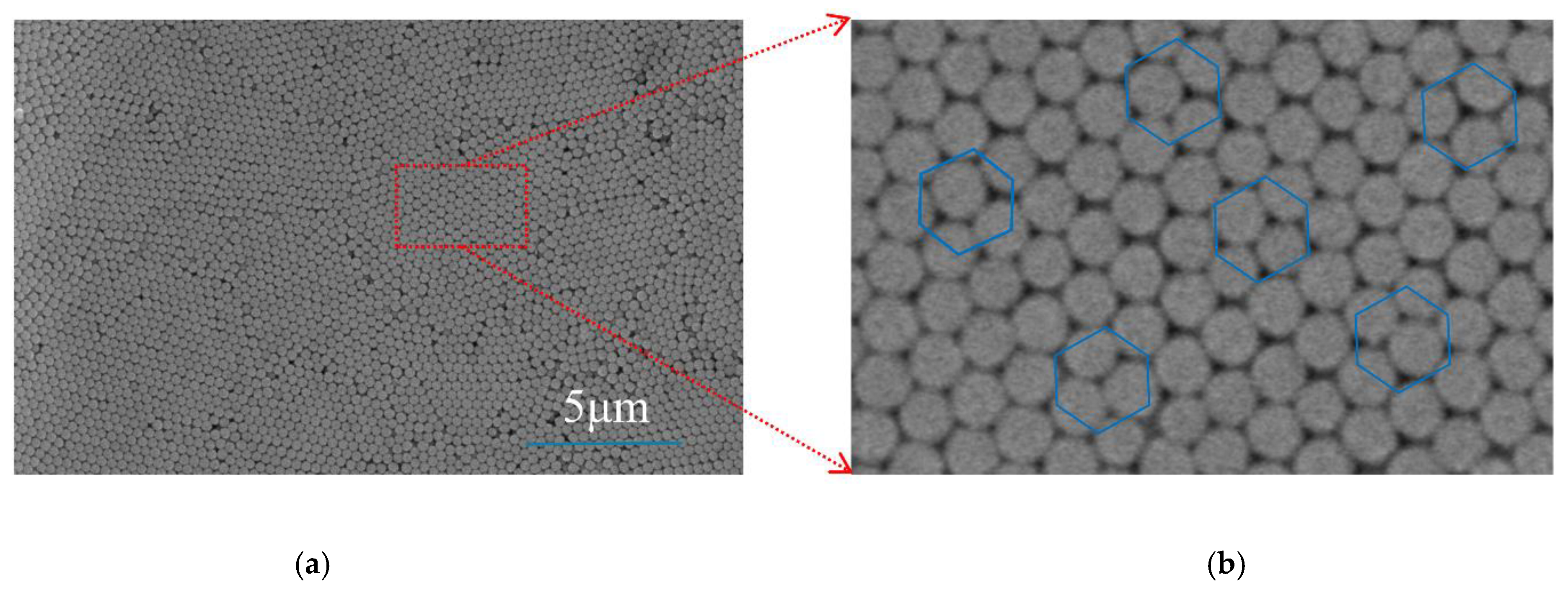

3.2. Ordered Structure of SiO2@PDA Photonic Crystals on Silk

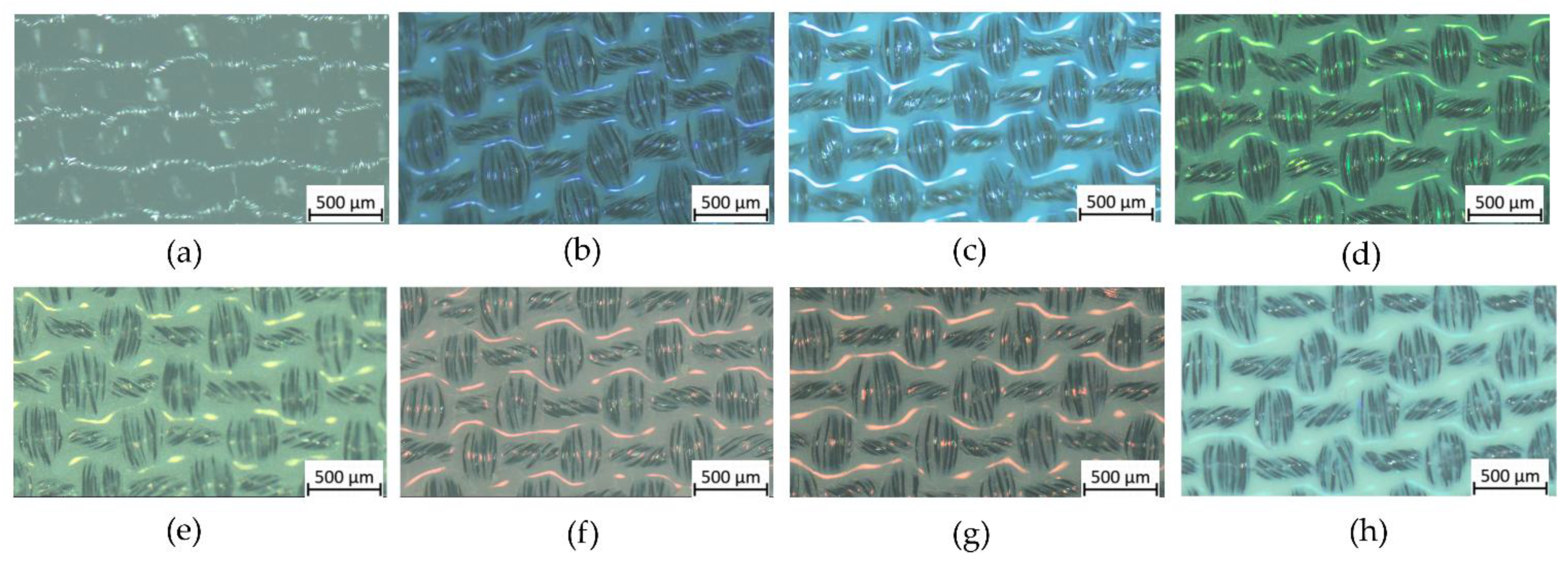

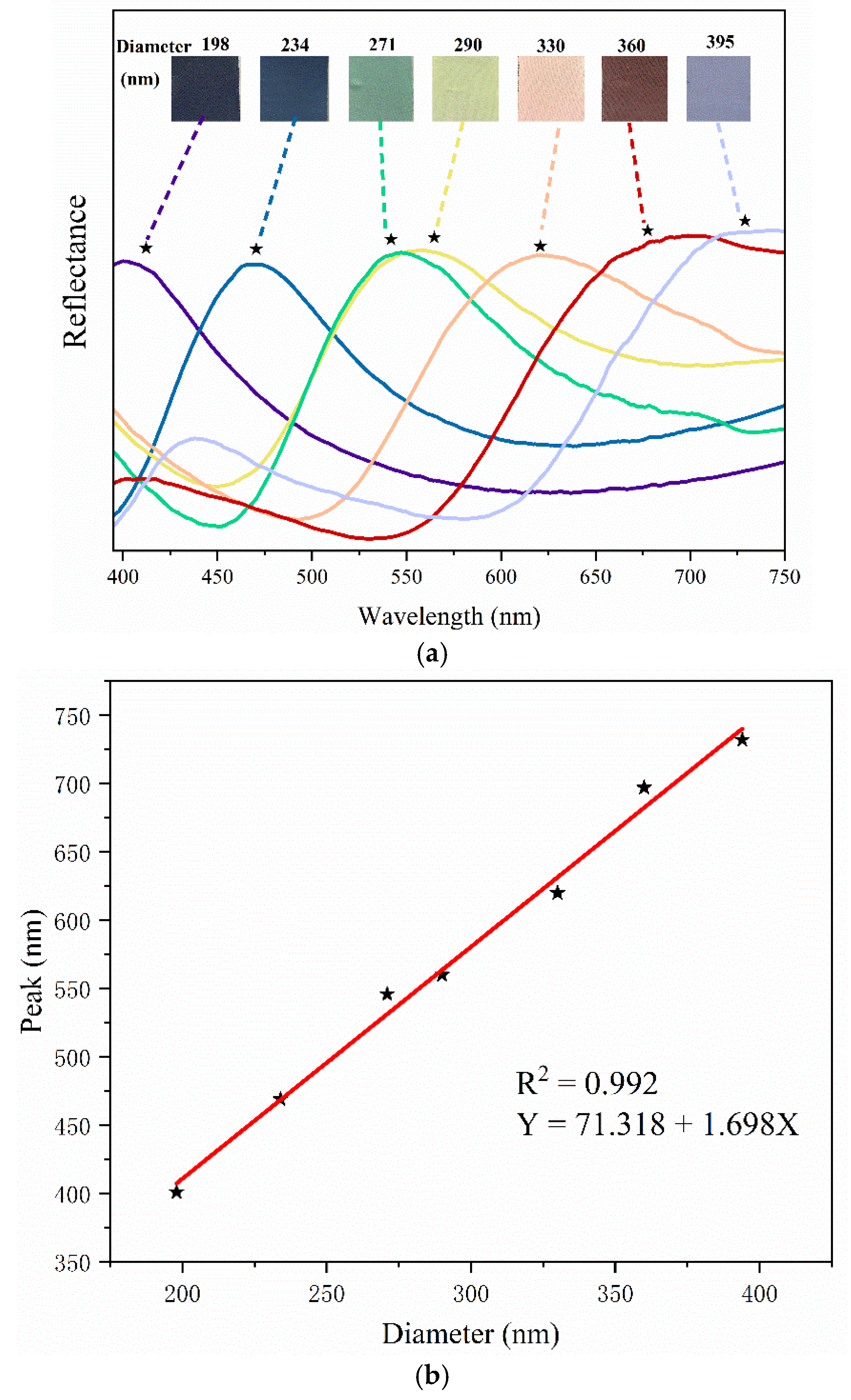

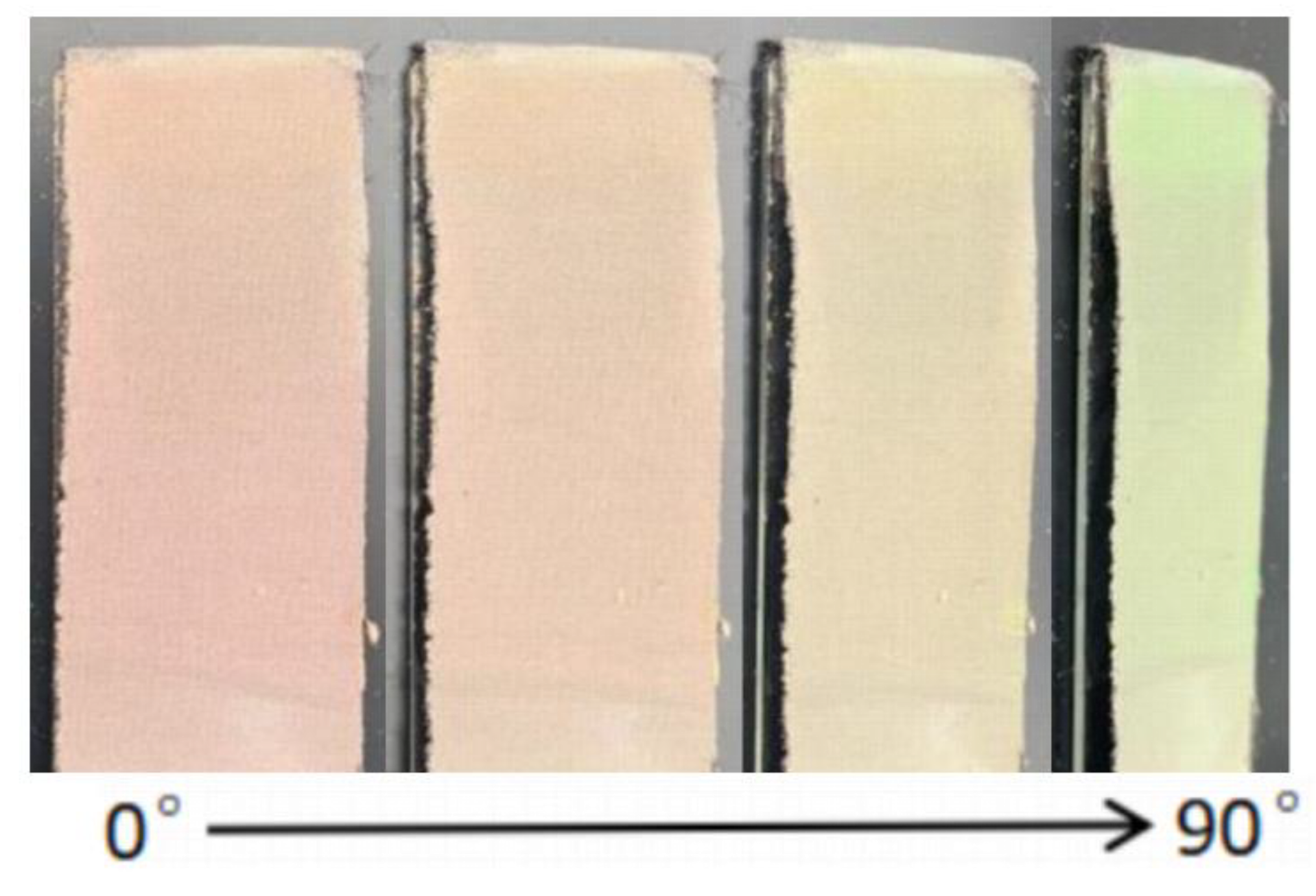

3.3. Optical Properties of Full-Color SiO2@PDA Photonic Crystals on Silk Fabrics

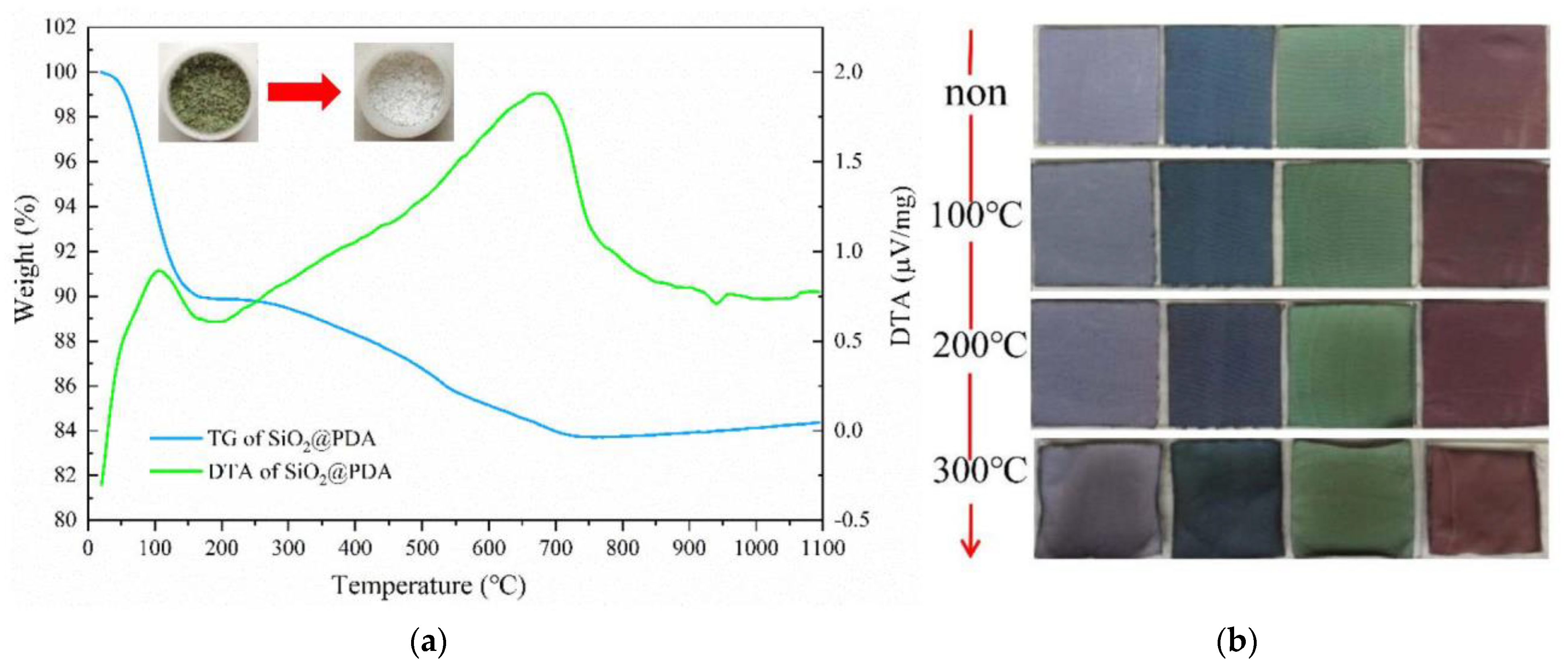

3.4. Thermal Resistance of the Structural Color of Photonic Crystals

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, G.; Yi, B.; Huang, Y.; Liang, Q.; Shen, H. Development of bright and low angle dependence structural colors from order-disorder hierarchical photonic structure. Dyes Pigment. 2019, 161, 464–469. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Shi, L.; Qiu, H.; Zhang, S.; Qi, N.; Hu, J.; Yuan, W.; Zhang, X.; Zhang, K.-Q. Additive mixing and conformal coating of noniridescent structural colors with robust mechanical properties fabricated by atomization deposition. ACS Nano 2018, 12, 3095–3102. [Google Scholar] [CrossRef]

- Bes-Pia, A.; Mendoza-Roca, J.; Alcaina-Miranda, M.; Iborra-Clar, A.; Iborra-Clar, M. Combination of physico-chemical treatment and nanofiltration to reuse wastewater of a printing, dyeing and finishing textile industry. Desalination 2003, 157, 73–80. [Google Scholar] [CrossRef]

- Wang, C.; Yediler, A.; Lienert, D.; Wang, Z.; Kettrup, A. Toxicity evaluation of reactive dyestuffs, auxiliaries and selected effluents in textile finishing industry to luminescent bacteria Vibrio fischeri. Chemosphere 2002, 46, 339–344. [Google Scholar] [CrossRef]

- Miyazaki, H.; Hase, M.; Miyazaki, H.T.; Kurokawa, Y.; Shinya, N. Photonic material for designing arbitrarily shaped waveguides in two dimensions. Phys. Rev. B 2003, 67, 235109. [Google Scholar] [CrossRef] [Green Version]

- Diao, Y.Y.; Liu, X.Y. Controlled colloidal assembly: Experimental modeling of general crystallization and biomimicking of structural color. Adv. Funct. Mater. 2012, 22, 1354–1375. [Google Scholar] [CrossRef]

- Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D.S.; Yang, S. A robust smart window: Reversibly switching from high transparency to angle-independent structural color display. Adv. Mater. 2015, 27, 2489–2495. [Google Scholar] [CrossRef]

- Chiappini, A.; Armellini, C.; Piccolo, V.; Zur, L.; Ristic, D.; Jovanovic, D.; Vaccari, A.; Zonta, D.; Righini, G.C.; Ferrari, M. Colloidal crystals based portable chromatic sensor for butanol isomers and water mixtures detection. Opt. Mater. 2019, 90, 152–158. [Google Scholar] [CrossRef]

- Couturier, J.P.; Sütterlin, M.; Laschewsky, A.; Hettrich, C.; Wischerhoff, E. Responsive inverse opal hydrogels for the sensing of macromolecules. Angew. Chem. Int. Ed. 2015, 54, 6641–6644. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhu, Z.; Yu, Z.; Ling, L.; Wang, C.-F.; Chen, S. Large-scale colloidal films with robust structural colors. Mater. Horiz. 2019, 6, 90–96. [Google Scholar] [CrossRef]

- Liu, P.; Chang, W.; Ju, L.; Chu, L.; Xie, Z.; Chen, J.; Yang, J. Bioinspired noniridescent structural color with hidden patterns for anticounterfeiting. ACS Appl. Nano Mater. 2019, 2, 5752–5760. [Google Scholar] [CrossRef]

- Meng, Y.; Qiu, J.; Wu, S.; Ju, B.; Zhang, S.; Tang, B. Biomimetic structural color films with a bilayer inverse heterostructure for anticounterfeiting applications. ACS Appl. Mater. Interfaces 2018, 10, 38459–38465. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Tang, B.; Ju, B.; Wu, S.; Zhang, S. Multiple colors output on voile through 3D colloidal crystals with robust mechanical properties. ACS Appl. Mater. Interfaces 2017, 9, 3024–3029. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Guo, Y.; Zhou, L.; Wu, Y.; Chen, M.; He, Z. Tough, structurally colored fabrics produced by photopolymerization. J. Mater. Sci. 2019, 54, 10929–10940. [Google Scholar] [CrossRef]

- Li, S.; Jia, L.; Dong, P.; Shan, G.; Liu, R. Construction of photonic crystal structural colors on white polyester fabrics. Opt. Mater. 2021, 116, 111115. [Google Scholar] [CrossRef]

- Liu, P.; Xie, Z.; Zheng, F.; Zhao, Y.; Gu, Z. Surfactant-free HEMA crystal colloidal paint for structural color contact lens. J. Mater. Chem. B 2016, 4, 5222–5227. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; Ye, B.; Ding, H.; Liu, C.; Zhao, Y.; Gu, Z. Non-iridescent structural color pigments from liquid marbles. J. Mater. Chem. C 2015, 3, 6607–6612. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, X.; Lin, Y.; Wang, L.; Zhu, J. Structural coloration pigments based on carbon modified ZnS@ SiO2 nanospheres with low-angle dependence, high color saturation, and enhanced stability. ACS Appl. Mater. Interfaces 2016, 8, 5009–5016. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Chen, J.; Zhang, Z.; Xie, Z.; Du, X.; Gu, Z. Bio-inspired robust non-iridescent structural color with self-adhesive amorphous colloidal particle arrays. Nanoscale 2018, 10, 3673–3679. [Google Scholar] [CrossRef]

- Nakamae, K.; Hano, N.; Ihara, H.; Takafuji, M. Thermally stable high-contrast iridescent structural colours from silica colloidal crystals doped with monodisperse spherical black carbon particles. Mater. Adv. 2021, 2, 5935–5941. [Google Scholar] [CrossRef]

- Liu, Y. Self-assembly of poly (styrene-methyl methacrylate-acrylic acid)(P (St-MMA-AA)) colloidal microspheres on wood surface by thermal-assisted gravity deposition. Wood Sci. Technol. 2021, 55, 403–417. [Google Scholar] [CrossRef]

- Hsieh, C.-H.; Lu, Y.-C.; Yang, H. Self-assembled mechanochromic shape memory photonic crystals by doctor blade coating. ACS Appl. Mater. Interfaces 2020, 12, 36478–36484. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Hu, J. Investigation of polystyrene-based microspheres from different copolymers and their structural color coatings on wood surface. Coatings 2020, 11, 14. [Google Scholar] [CrossRef]

- Panfilova, E.; Shramko, D.; Ibragimov, A.; Mozer, K. Features of the deposition of photonic crystal films of polystyrene and silica. J. Phys. Conf. Ser. 2021, 1866, 012002. [Google Scholar] [CrossRef]

- Shen, H.; Liang, Q.; Song, L.; Chen, G.; Pei, Y.; Wu, L.; Zhang, X. Facile fabrication of mechanically stable non-iridescent structural color coatings. J. Mater. Sci. 2020, 55, 2353–2364. [Google Scholar] [CrossRef]

- Miguez, H.; Meseguer, F.; Lopez, C.; Mifsud, A.; Moya, J.; Vazquez, L. Evidence of FCC crystallization of SiO2 nanospheres. Langmuir 1997, 13, 6009–6011. [Google Scholar] [CrossRef]

- Iwata, M.; Teshima, M.; Seki, T.; Yoshioka, S.; Takeoka, Y. Bio-Inspired Bright Structurally Colored Colloidal Amorphous Array Enhanced by Controlling Thickness and Black Background. Adv. Mater. 2017, 29, 1605050. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, D.; Huang, S. Amorphous photonic structures with brilliant and noniridescent colors via polymer-assisted colloidal assembly. ACS Omega 2019, 4, 18771–18779. [Google Scholar] [CrossRef] [Green Version]

- Takeoka, Y.; Yoshioka, S.; Takano, A.; Arai, S.; Nueangnoraj, K.; Nishihara, H.; Teshima, M.; Ohtsuka, Y.; Seki, T. Production of colored pigments with amorphous arrays of black and white colloidal particles. Angew. Chem. 2013, 125, 7402–7406. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, B.; Chen, A.; Liu, X.; Shi, L.; Zi, J. Using cuttlefish ink as an additive to produce non-iridescent structural colors of high color visibility. Adv. Mater. 2015, 27, 4719–4724. [Google Scholar] [CrossRef]

- Lee, C.H.; Yu, J.; Wang, Y.; Tang, A.Y.L.; Kan, C.W.; Xin, J.H. Effect of graphene oxide inclusion on the optical reflection of a silica photonic crystal film. RSC Adv. 2018, 8, 16593–16602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.; Han, P.; Zhou, H.; Wu, N.; Wei, Y.; Yao, X.; Zhou, J.; Song, Y. Highly brilliant noniridescent structural colors enabled by graphene nanosheets containing graphene quantum dots. Adv. Funct. Mater. 2018, 28, 1802585. [Google Scholar] [CrossRef]

- Song, L.; Chen, X.; Xie, Y.; Zhong, L.; Zhang, X.; Cheng, Z. Non-iridescent, crack-free, conductive structural colors enhanced by flexible nanosheets of reduced graphene oxide. Dyes Pigment. 2019, 164, 222–226. [Google Scholar] [CrossRef]

- Iwasaki, T.; Tamai, Y.; Yamamoto, M.; Taniguchi, T.; Kishikawa, K.; Kohri, M. Melanin precursor influence on structural colors from artificial melanin particles: PolyDOPA, polydopamine, and polynorepinephrine. Langmuir 2018, 34, 11814–11821. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Wu, B.-H.; Du, Y.; Ma, M.-Q.; Xu, Z.-K. Mussel-inspired polydopamine coatings for large-scale and angle-independent structural colors. J. Mater. Chem. C 2017, 5, 3898–3902. [Google Scholar] [CrossRef]

- Romanov, S.; Maka, T.; Torres, C.S.; Müller, M.; Zentel, R.; Cassagne, D.; Manzanares-Martinez, J.; Jouanin, C. Diffraction of light from thin-film polymethylmethacrylate opaline photonic crystals. Phys. Rev. E 2001, 63, 056603. [Google Scholar] [CrossRef] [PubMed]

- Shao, J.; Zhang, Y.; Fu, G.; Zhou, L.; Fan, Q. Preparation of monodispersed polystyrene microspheres and self-assembly of photonic crystals for structural colors on polyester fabrics. J. Textile Inst. 2014, 105, 938–943. [Google Scholar] [CrossRef]

| No. | SiO2@PDA(Dh 1)/nm | SiO2@PDA(Da 1)/nm | PDI |

|---|---|---|---|

| 1 | 198 | 196 | 0.036 |

| 2 | 234 | 234 | 0.031 |

| 3 | 271 | 267 | 0.037 |

| 4 | 290 | 284 | 0.038 |

| 5 | 330 | 328 | 0.024 |

| 6 | 360 | 356 | 0.023 |

| 7 | 394 | 386 | 0.029 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Yang, H.; Zhang, M.; Chen, T. The Fabrication of Full Chromatography SiO2@PDA Photonic Crystal Structural Colored Fabric with High Thermal Stability. Coatings 2022, 12, 1085. https://doi.org/10.3390/coatings12081085

Luo H, Yang H, Zhang M, Chen T. The Fabrication of Full Chromatography SiO2@PDA Photonic Crystal Structural Colored Fabric with High Thermal Stability. Coatings. 2022; 12(8):1085. https://doi.org/10.3390/coatings12081085

Chicago/Turabian StyleLuo, Huan, Hui Yang, Min Zhang, and Taihong Chen. 2022. "The Fabrication of Full Chromatography SiO2@PDA Photonic Crystal Structural Colored Fabric with High Thermal Stability" Coatings 12, no. 8: 1085. https://doi.org/10.3390/coatings12081085