2.1. Materials

For the experimental design, the following mortars were chosen: in situ-made cement mortar, in situ-made hydraulic lime mortar, and pre-dosed one coat air lime mortar. The materials used for the mortar’s formulation were the following: CEM II/B-L 32.5 N cement, NHL 3.5 hydraulic lime, washed river sand with well-distributed particle size, and industrial air lime. The following substrates (

Figure 1) were used: regular hollow ceramic bricks (30 cm × 20 cm × 7 cm), solid ceramic bricks (20 cm × 10 cm × 5 cm), concrete slabs (30 cm × 20 cm × 7 cm), lightweight concrete blocks (50 cm × 20 cm × 10 cm), and natural stone slabs (30 cm × 20 cm × 7 cm,

Figure 1e).

The cement mortar was produced with a binder:sand ratio of 1:4, by volume, and with a water/binder ratio of 1, by mass. In the case of the hydraulic lime mortar, the binder:sand ratio was of 1:3, in volume, and the water/binder ratio of 1.2, by mass. For both types of mortar, these are the binder:sand ratios commonly used in construction practice. The amount of water was adjusted so that the mortars showed good workability. Regarding the air lime mortar, an industrial mortar was selected, which was produced according to the manufacturer’s instructions. According to the technical sheet, this mortar has the following composition: calcium hydroxide, pozzolanic binders, aggregates of selected particle size distribution, chemical admixtures, and fibres.

For the chosen mortars and substrates, the intention was to cover materials used both in new constructions and in the rehabilitation of old constructions. Solid brick and natural stone are commonly found in old buildings and the other substrates are generally used in new constructions. Cement mortars are usually applied in new constructions and lime mortars are suitable for application to traditional substrates—although hydraulic lime mortar is also suitable for use on modern substrates.

The cement mortar was applied to the following substrates: hollow ceramic brick, concrete slab, and lightweight concrete block. The hydraulic lime mortar, in addition to the substrates used for the cement mortar, was also applied to the natural stone and solid ceramic brick substrates. The air lime mortar was applied only to the natural stone and solid ceramic brick substrates.

Table 1 shows the different types of mortar used and the corresponding application substrates.

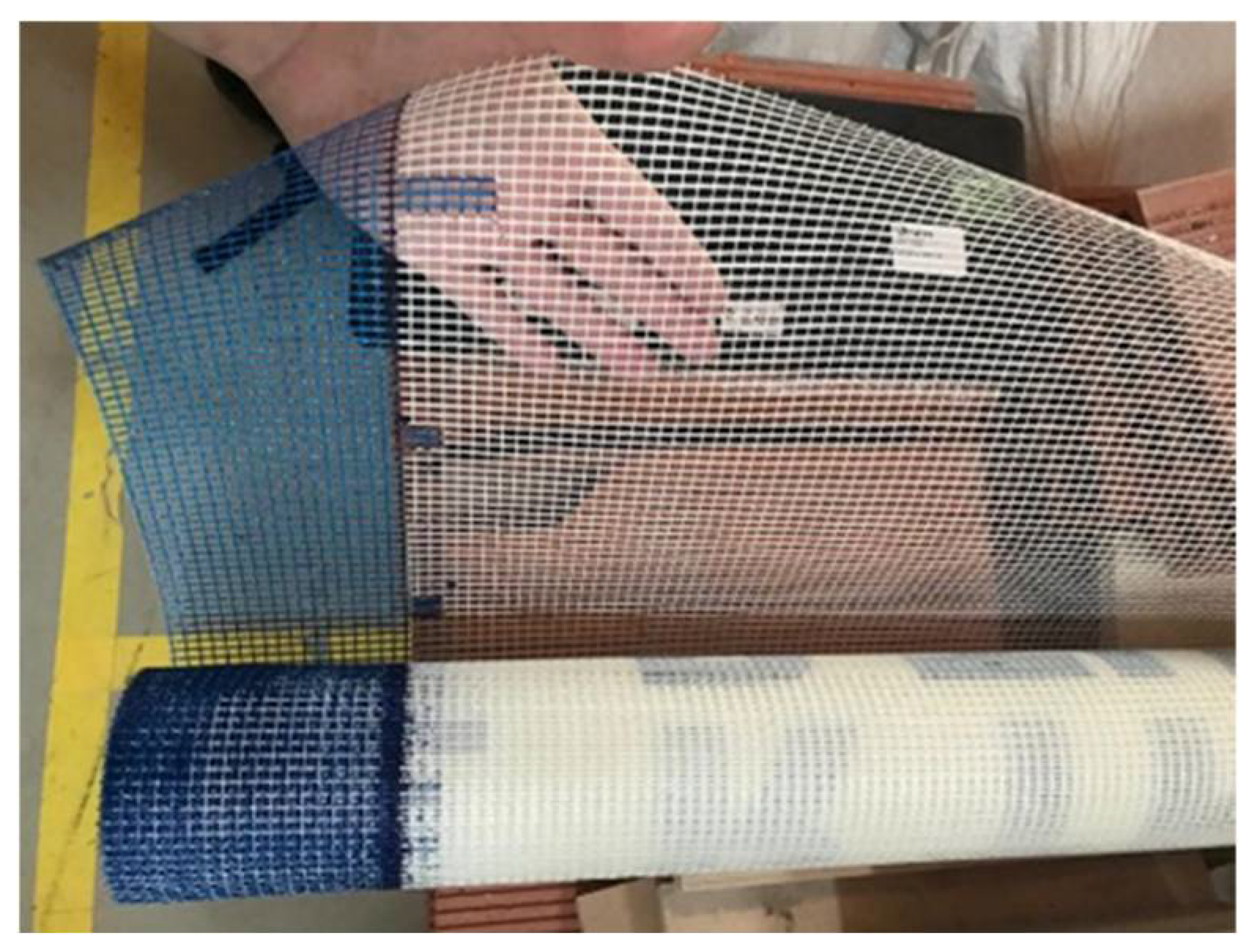

The fiberglass mesh used, shown in

Figure 2, was THERM 160, resistant to alkalinity, with a mesh opening of 5 mm × 5 mm and a specific mass of 158 g/m². This material was chosen because it had already been applied in the work by Torres et al. [

9] with good results,

Figure 2.

2.2. Methods

The methodology of this work was essentially experimental, comparing mortars applied, cured, and detached from the substrates with the use of fibreglass mesh in the interface between the two materials (

Figure 3a) and without the use of fibreglass mesh (

Figure 3b). For the application of mortars on the substrates, wooden molds were used in order to guarantee a constant mortar thickness of 1.5 cm.

Before applying the mortar, each substrate was moistened by spraying water in the following amounts: 100 mL and 33 mL in the case of the hollow ceramic bricks (

Figure 3c) and solid ceramic bricks, respectively, and 75 mL for the remaining substrates (lightweight concrete block, concrete slab, and natural stone).

Figure 4a,b illustrate the coating surface levelling process and the mortar after application on the substrate. To carry out the tests and compare the results, immediately after applying the mortars, “square” specimens (40 mm × 40 mm) and “circular” specimens (diameter of 100 mm) were marked in the fresh mortar (

Figure 4c). These dimensions were used as they match those of the moulds indicated in standards for mortar testing (except for the thickness, in the case of the square specimens). The disks were produced for the water vapour permeability test, and the rest of the tests (bulk density, open porosity, drying index, and compressive strength) were carried out on the specimens with dimensions of 40 mm × 40 mm × 15 mm. Subsequently, after the curing process, the specimens were detached and submitted to characterisation tests.

Regarding the curing conditions, the indications of standard EN 1015-11 [

22] were followed, namely:

For first 2 days, in the case of cement and hydraulic lime mortars, and for the first 5 days, in the case of air lime mortar: temperature of 20 °C +/− 2 °C, relative humidity of 95% +/− 5% or in a polyethylene bag (in the mould);

Following 5 days (for cement and hydraulic lime mortars, the following 2 days), in the case of air lime mortar: temperature of 20 °C +/− 2 °C, relative humidity of 95% +/− 5% or in a polyethylene bag (without the mould);

Remaining 21 days (for cement and hydraulic lime mortars, remaining 83 days), in the case of air lime mortar: temperature of 20 °C +/− 2 °C, relative humidity of 65% +/− 5% (without the mould).

After the curing process, tests were carried out to evaluate the following properties: bulk density and open porosity (NP EN 1936 [

23]); percentage and distribution of pore sizes, through mercury intrusion porosimetry (ISO 15901–1 [

24]); capillary water absorption coefficient (ISO 15148 [

25]); drying index (EN 16322 [

26]); water vapour permeability (ISO 12572 [

27]); and compressive strength (EN 1015-11 [

22]).

The tests were conducted according to the following procedures:

To carry out the test, the specimens were dried in an oven at 60 °C until reaching constant mass and were weighed (Ms). Then, they were immersed in water until saturation, for 48 h, and were weighed while immersed (Mh) (hydrostatic weighing). After that, they were removed from the water, the excess water was removed, and they were weighed again to obtain the saturated mass (Msat).

With this, the bulk density was calculated through the expression in Equation (1):

Open porosity was calculated using the expression in Equation (2):

In the Equations:

BD is the bulk density in kg/m3;

Ms is the mass of the dry specimen, in g;

Mh is the mass of the specimen immersed in water, in g;

Msat is the mass of the saturated specimen, in g;

ρrh is the density of water at room temperature, in kg/m3;

OP is the open porosity in %.

The specimens were waterproofed on their side faces to ensure a unidirectional water flow. All samples were placed in a vat with a lid (avoiding water evaporation) with a water depth of approximately 5 to 7 mm, and the level was periodically checked.

The samples were removed from the water, weighed, and placed again after 5 min, 10 min, 20 min, 30 min, 1 h, 1 h and 30 min, 2 h, 4 h, 8 h, 24 h, 48 h, and 72 h.

The capillary water absorption coefficient represents the speed at which the material absorbs water. First, the amount of water absorbed at the different weighing times must be determined; then, the graph of the change in mass per unit area as a function of the square root of time must be plotted. The capillary absorption coefficient was calculated using the following Equation (3):

where

∆m’tf is the mass change, per unit area, on the straight line, at time tf, in kg/m2;

∆m’0 is the mass change, per unit area, at the intersection of the straight line with the mass change axis, in kg/m2;

tf is the time elapsed between the start and end of the straight portion of the test curve, in seconds.

For this test, specimens approximately 10 cm in diameter and 1.5 cm in thickness were placed in a glass cup with water (wet cup method), with an air height of about 15 mm between the water and the specimen. The side face of the specimen and the area of connection with the cup were properly waterproofed, so the vapour diffusion occurred exclusively through the specimen (through its lower and upper faces).

The assembly was placed in a climatic chamber with a constant temperature and humidity (23 °C and 50% relative humidity). The initial and periodic weighing was carried out until the mass variation per unit time was constant (steady-state diffusion current).

From the weighing records, a graphic representation of the weight variation as a function of time was performed. When the vapour transmission proved to be constant, the slope of the line joining the points where this circumstance occurred, and which is equal to the water vapour diffusion flux, Equation (4), was determined:

where

G is the water vapour flow rate, in kg/s;

m2 − m1 is the change in mass after the steady-state diffusion current is established, in kg;

t2 − t1 is the time interval corresponding to the mass change, in s.

From this value, the density of water vapour flow rate can be obtained through the expression Equation (5):

where

g is the density of water vapour flow rate in kg/(s·m2);

G is the water vapour flow rate, in kg/s;

A is the sample area, in m².

The water vapour permeance (W) is given by Equations (6) and (7):

where

psat is the saturation pressure at the test temperature (23 °C), in Pa;

∅1–∅2 is the difference between the relative humidity values inside and outside the test cup, in %.

The water vapour permeability is given by expression 8:

where

δ is the water vapour permeability, in kg/(m·s·Pa);

W is the water vapour permeance, in kg/(m²·s·Pa);

d is the thickness of the specimens, in m.

Saturated specimens had their faces waterproofed, except the upper face, and were placed in a climatic chamber at 23 ± 2 °C and at a relative humidity of 50 ± 5 °C.

The specimens were weighed every 10 min in the first hour and every hour until completing 8 h. After this, the specimens were weighed every 24 h until the difference in mass between two consecutive weightings was less than 0.1%.

After stabilization, the drying index was determined according to the following expression:

where

ti is the test time i, in hours;

Wi is the moisture content at time i, in %;

tf is the final test time, in hours.

Mercury intrusion porosimetry is a test that quantifies the percentage and distribution of pore sizes in each solid sample. A Micromeritics mercury porosimeter, model Autopore IV 9500, with a capacity to reach 60,000 psi, was used.

For the test’s execution, fragments of the mortars were used, and all were subjected to drying to constant mass before the test.

The mechanical strength of the mortar is the material’s ability to resist induced stresses.

In this test, a compressive load is applied without chock, at a rate of 100 N/s, so that failure occurs between 30 and 90 s. The compressive strength is calculated according to the following expression:

where

Rc is the compressive strength, in MPa;

Fc is the compressive failure load, in N;

S is the load application area, in mm2.

After the tests were carried out, the t-test for independent samples was performed to evaluate the statistical significance of the differences found between the results of the specimens with and without the fibreglass mesh applied between the coating and the substrate.

For this, the following hypotheses were established: “H0: there is no difference between the samples with and without the fibreglass mesh” and “H1: the samples can be considered statistically different”. So, to reject hypothesis H0 and consequently accept hypothesis H1, a p-value of 0.05 was considered, where p-value < 0.05 rejects H0.