Improving the Density of Functional Fabrics to Protect Radiation Workers in Radiology Departments

Abstract

:1. Introduction

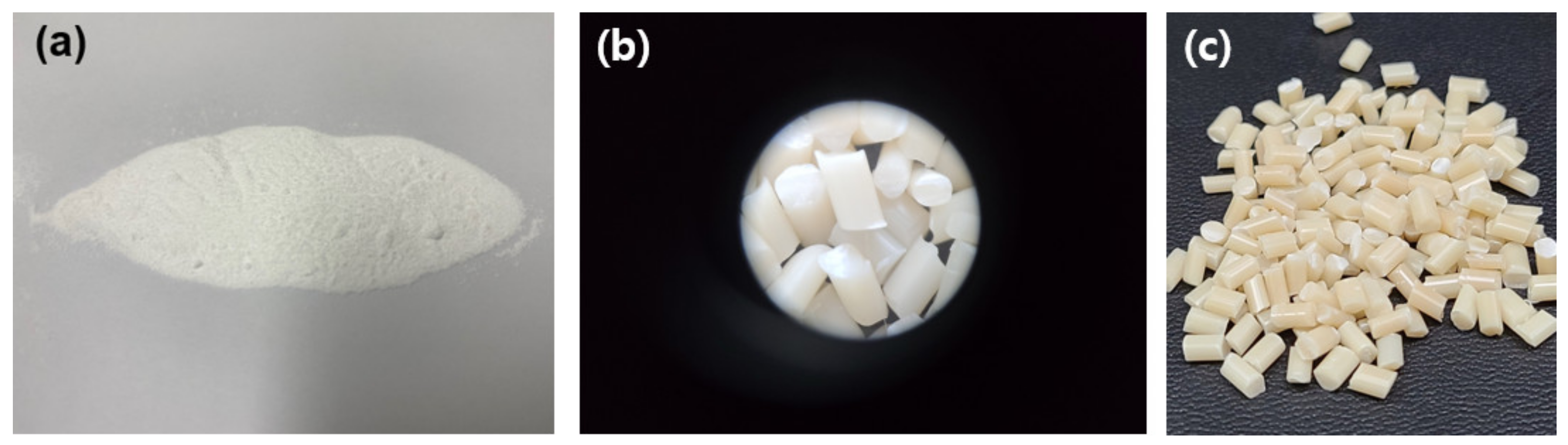

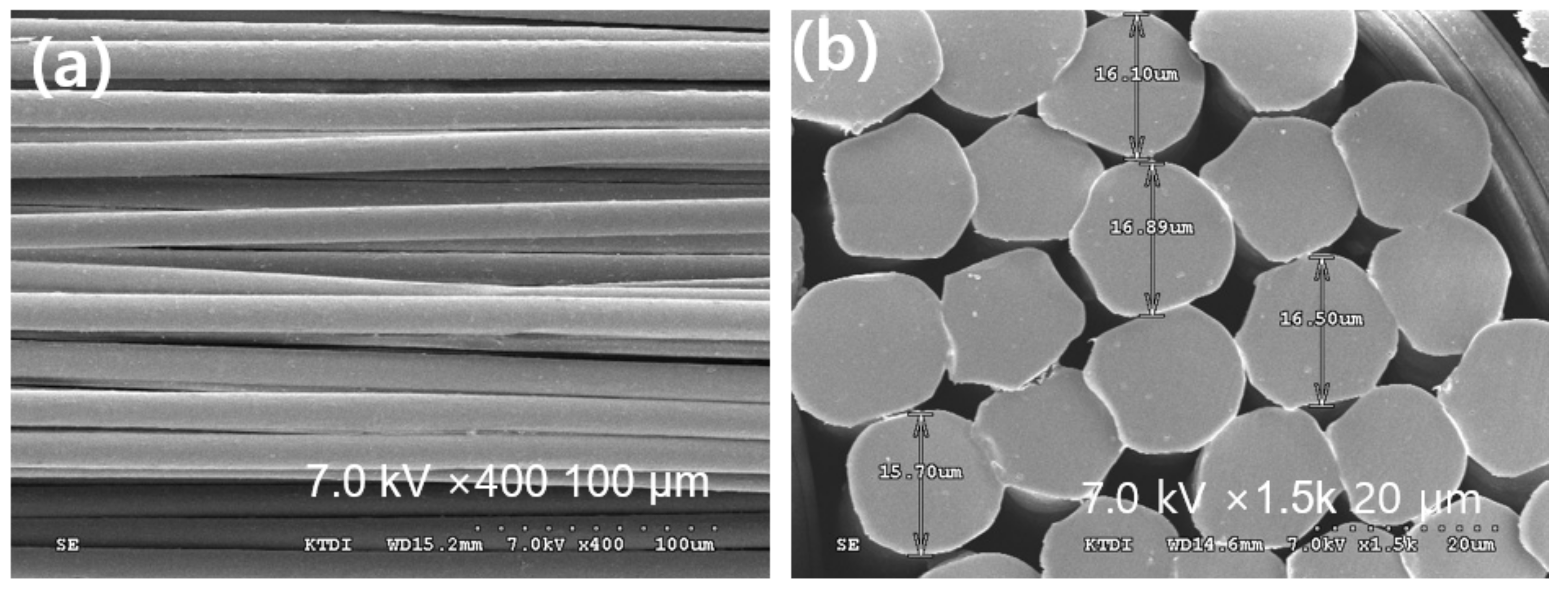

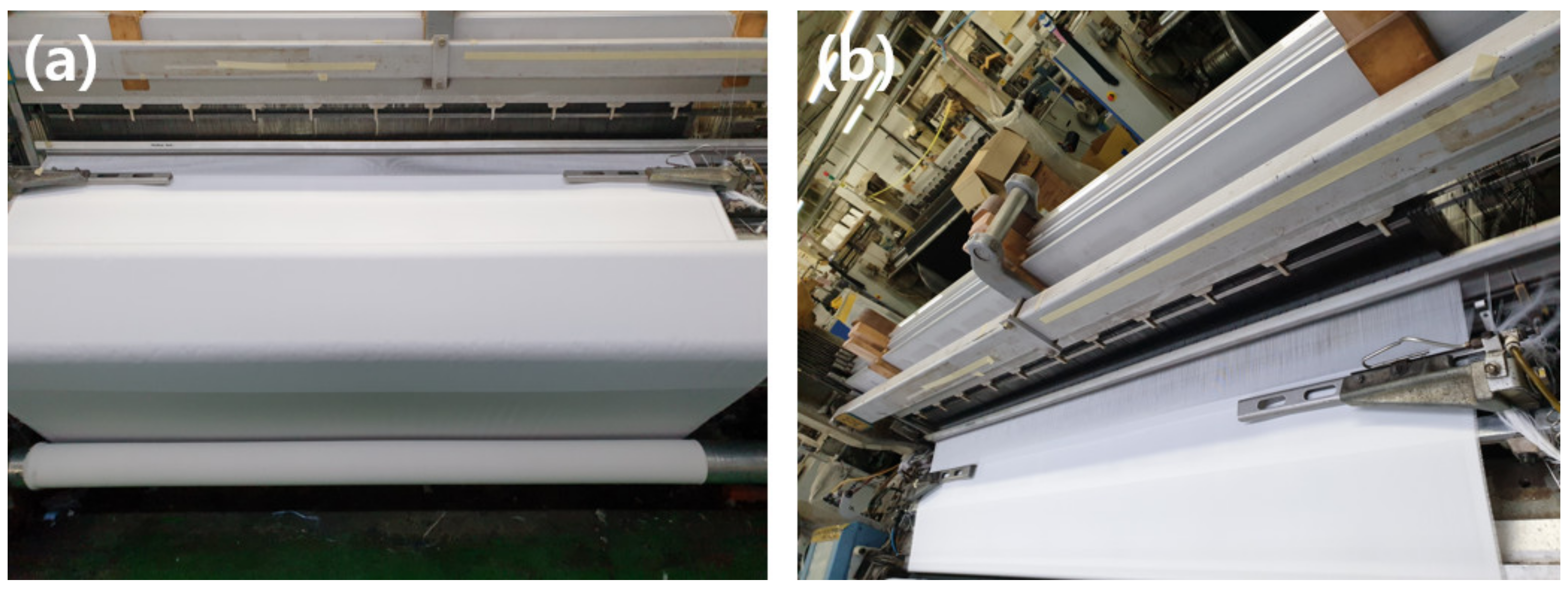

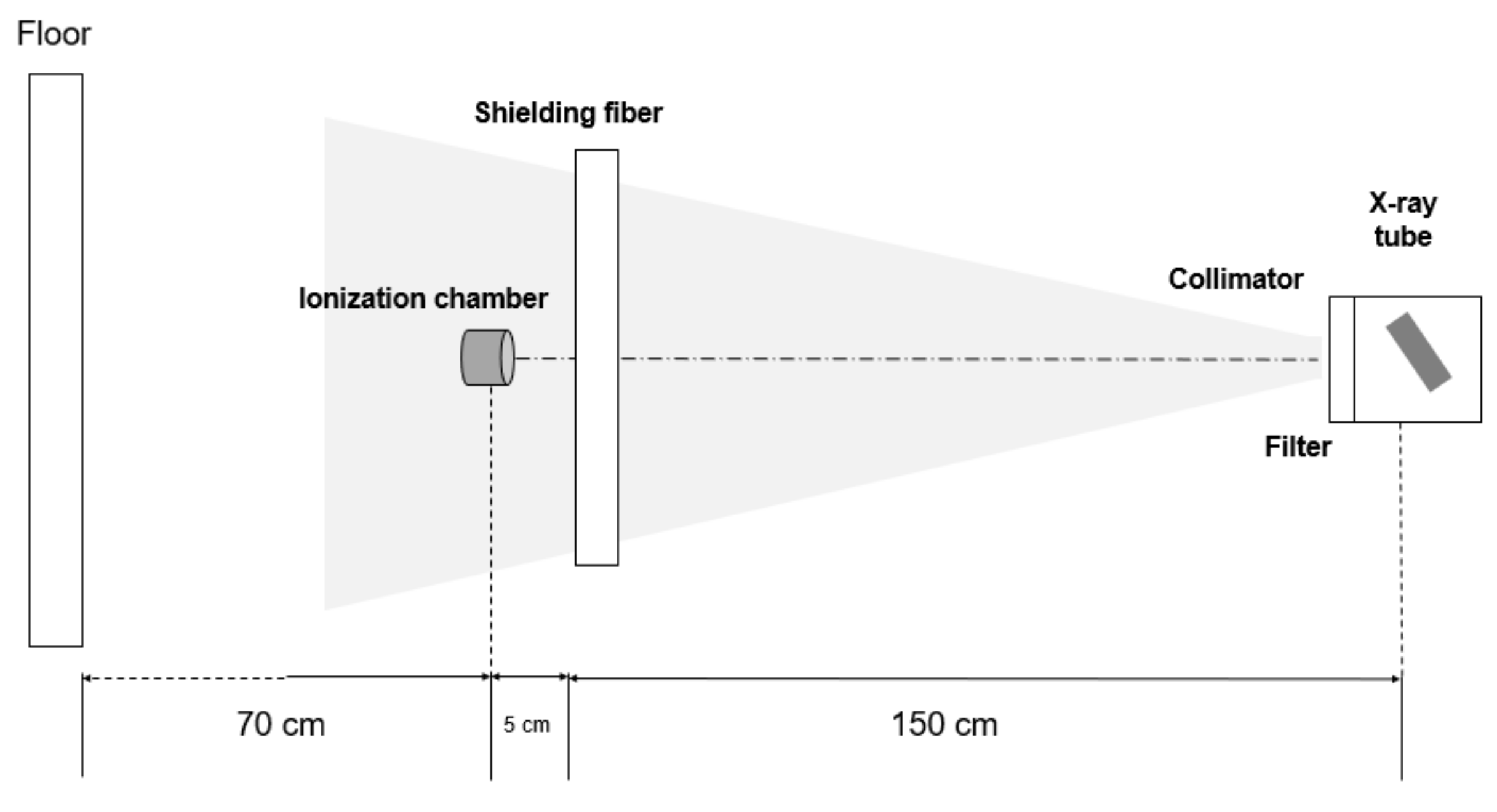

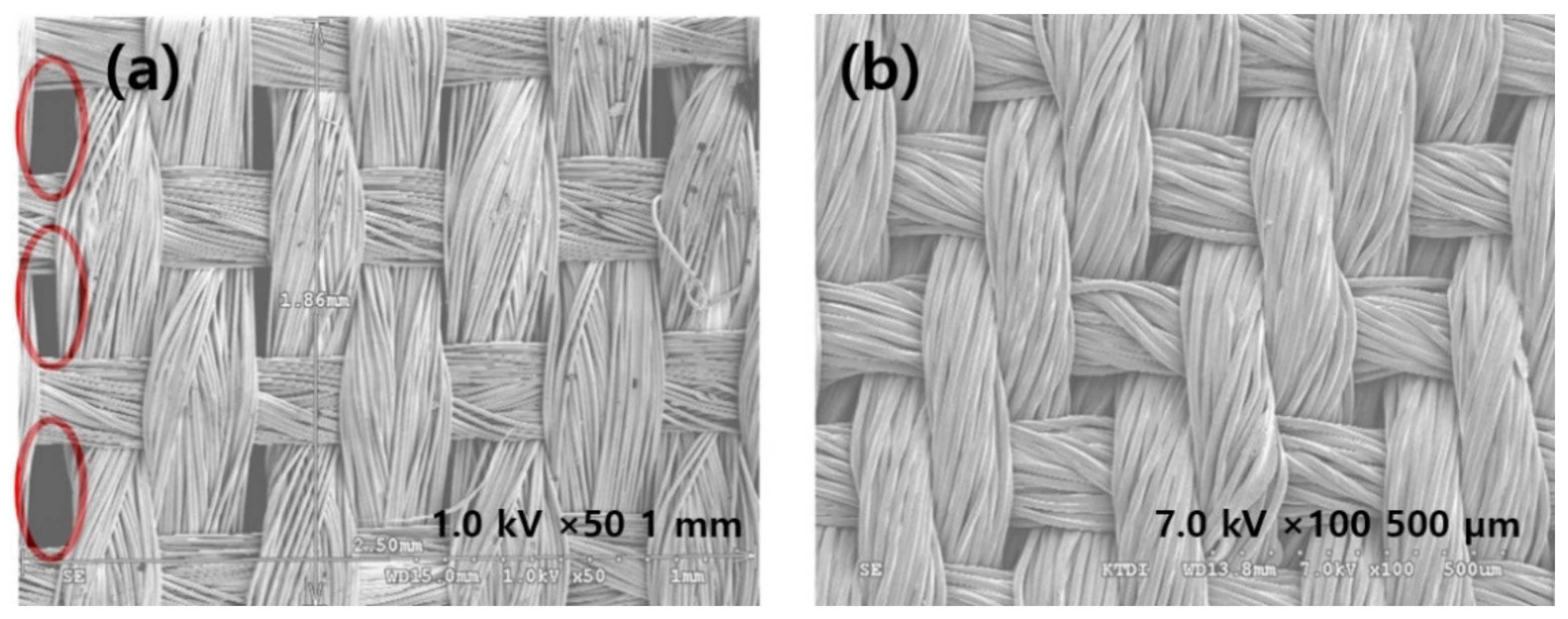

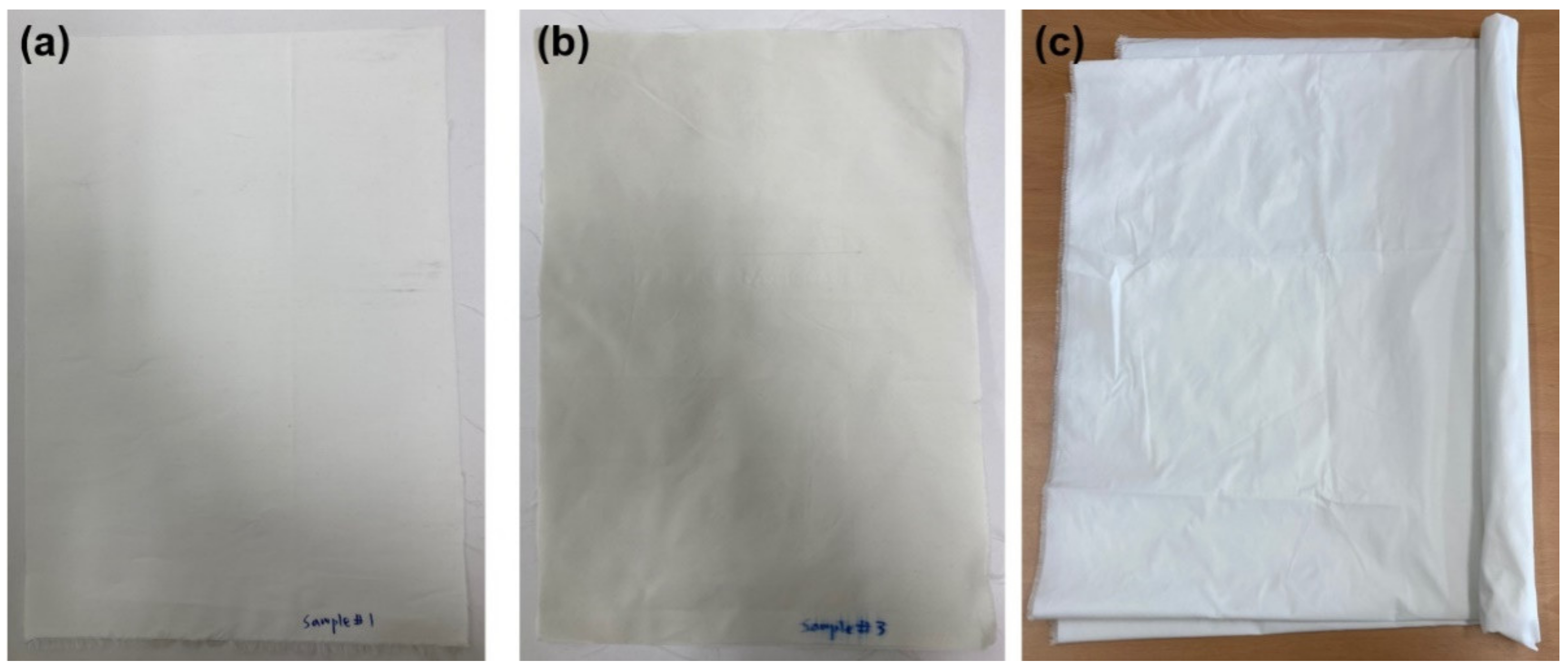

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Monaco, M.G.L.; Carta, A.; Tamhid, T.; Porru, S. Anti-X apron wearing and musculoskeletal problems among healthcare workers: A systematic scoping review. Int. J. Environ. Res. Public Health 2020, 17, 5877. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Gu, Y.; Wang, Y.; Yang, Z.; Li, M.; Zhang, Z. Effect of particle size on gamma radiation shielding property of gadolinium oxide dispersed epoxy resin matrix composite. Mater. Res. Express 2017, 4, 035035. [Google Scholar] [CrossRef]

- Koenig, A.M.; Maas, J.; Viniol, S.; Etzel, R.; Fiebich, M.; Thomas, R.P.; Mahnken, A.H. Scatter radiation reduction with a radiation-absorbing pad in interventional radiology examinations. Eur. J. Radiol. 2020, 132, 109245. [Google Scholar] [CrossRef] [PubMed]

- Adlienė, D.; Gilys, L.; Griškonis, E. Development and characterization of new tungsten and tantalum containing composites for radiation shielding in medicine. Nucl. Instrum. Meth Phys. Res. Sect. B 2020, 467, 21–26. [Google Scholar] [CrossRef]

- Herrman, K.; Baxter, L.N.; Mishra, K.; Benton, E.; Singh, R.P.; Vaidyanathan, R.K. Mechanical characterization of polyethylene-based thermoplastic composite materials for radiation shielding. Compos. Commun. 2019, 13, 37–41. [Google Scholar] [CrossRef]

- Jamal AbuAlRoos, N.; Azman, M.N.; Baharul Amin, N.A.; Zainon, R. Tungsten-based material as promising new lead-free gamma radiation shielding material in nuclear medicine. Phys. Med. 2020, 78, 48–57. [Google Scholar] [CrossRef]

- Laurenzi, S.; de Zanet, G.D.; Santonicola, M.G. Numerical investigation of radiation shielding properties of polyethylene-based nanocomposite materials in different space environments. Acta Astronaut. 2020, 170, 530–538. [Google Scholar] [CrossRef]

- Singh, A.K.; Singh, R.K.; Sharma, B.; Tyagi, A.K. Characterization and biocompatibility studies of lead free X-ray shielding polymer composite for healthcare application. Radiat. Phys. Chem. 2017, 138, 9–15. [Google Scholar] [CrossRef]

- Yu, L.; Pereira, A.L.C.; Tran, D.N.H.; Santos, A.M.C.; Losic, D. Bismuth oxide films for X-ray shielding: Effects of particle size and structural morphology. Mater. Chem. Phys. 2021, 260, 124084. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Xiao, X.; Zhong, R.; Liao, J.; Guo, J.; Liao, X.; Shi, B. Research on X-ray shielding performance of wearable bi/Ce-natural leather composite materials. J. Hazard. Mater. 2020, 398, 122943. [Google Scholar] [CrossRef]

- Kim, S.C. Effects of laminated structure and fiber coating on tensile strength of radiation shielding sheet. J. Korea Converg. Soc. 2020, 11, 83–88. [Google Scholar] [CrossRef]

- Mirzael, M.; Zarrebini, M.; Shirani, A.; Shanbeh, M.; Borhani, S. X-ray shielding by a novel garment woven with melt-spun monofilament weft yarn containing lead and tin particles. Text. Res. J. 2017, 89, 63–75. [Google Scholar] [CrossRef]

- Hakan, Ö.; Berkay, C. The gamma radiation shielding effectiveness of textured steel yarn based fabrics. Ind. Text. 2018, 69, 44–49. [Google Scholar] [CrossRef]

- Morris, H.; Murray, R. Medical textiles. Text. Prog. 2020, 52, 1–127. [Google Scholar] [CrossRef]

- Kim, S.C.; Son, J.S. Double-layered fiber for lightweight flexible clothing providing shielding from low-dose natural radiation. Sci. Rep. 2021, 11, 3676. [Google Scholar] [CrossRef]

- An, L.T.; Lin, M.C.; Lin, T.R.; Sim, K.S.; Lin, J.H.; Lou, C.W. High-strength protective polyester textiles incorporated with metallic materials: Characterizations and radiation-shielding effectiveness. J. Ind. Text. 2022, 51, 1585–1600. [Google Scholar] [CrossRef]

- Ji, Y.S.; Park, E.K.; Kwon, H.C.; Han, W.K.; Nahm, F.S. Radiation-shielding devices: The best combination for spine interventional procedures. J. Vasc. Interv. Rad. 2022, 33, 225–232. [Google Scholar] [CrossRef]

- Miller, D.L.; Schueler, B.A.; Fetterly, K.A.; Hindal, M.D. Effective use of accessory radiation shielding devices in fluoroscopy. Radiographics 2021, 41, E18–E19. [Google Scholar] [CrossRef]

- Vuolo, M.; Baiocco, G.; Barbieri, S.; Bocchini, L.; Giraudo, M.; Gheysens, T.; Lobascio, C.; Ottolenghi, A. Exploring innovative radiation shielding approaches in space: A material and design study for a wearable radiation protection spacesuit. Life Sci. Space Res. 2017, 15, 69–78. [Google Scholar] [CrossRef]

- Parvaresh, R.; Haghparast, A.; Khoshgard, K.; Jalili, M.; Eivazi, M.T.; Ghorbani, M. An investigation to determine an optimum protective garment material in nuclear medicine. J. Biomed. Phys. Eng. 2018, 8, 381–392. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.C.; Cho, S.H. Analysis of the correlation between shielding material blending characteristics and porosity for radiation shielding films. Appl. Sci. 2019, 9, 1765. [Google Scholar] [CrossRef] [Green Version]

- Cheewasukhanont, W.; Limkitjaroenporn, P.; Kothan, S.; Kedkaew, C.; Kaewkhao, J. The effect of particle size on radiation shielding properties for bismuth borosilicate glass. Radiat. Phys. Chem. 2020, 172, 108791. [Google Scholar] [CrossRef]

- AbuAlRoos, N.J.; Baharul Amin, N.A.; Zainon, R. Conventional and new lead-free radiation shielding materials for radiation protection in nuclear medicine: A review. Radiat. Phys. Chem. 2019, 165, 108439. [Google Scholar] [CrossRef]

- Aytaç, L.; Esra, K.; Yüksel, Ö. An experimental study on the investigation of nuclear radiation shielding characteristics in iron-boron alloys. J. Alloys Compd. 2020, 819, 152946. [Google Scholar] [CrossRef]

- Özdemir, H.; Camgöz, B. Gamma radiation shielding effectiveness of cellular woven fabrics. J. Ind. Text. 2018, 47, 712–726. [Google Scholar] [CrossRef]

- Agency for Toxic Substance and Disease Registry. Medical Management Guidelines for Barium (Elemental) and Selected Barium Compounds. Available online: https://wwwn.cdc.gov/TSP/MMG/MMGDetails.aspx?mmgid=321&toxid=57 (accessed on 21 October 2014).

- US Environmental Protection Agency. Toxicological review of barium and compounds. In Support of Summary Information on the Integrated Risk Information System (IRIS); Reference Dose Revised June 2005; US Environmental Protection Agency: Cincinnati, OH, USA, 2005. [Google Scholar]

- Lee, J.W.; Kweon, D.C. Evaluation of radiation dose reduction by barium composite shielding in an angiography system. Radiat. Eff. Defects Solids 2021, 176, 368–381. [Google Scholar] [CrossRef]

- Mirzaei, M.; Zarrebini, M.; Shirani, A.; Shanbeh, M.; Borhani, S. X-ray shielding behavior of garment woven with melt-spun polypropylene monofilament. Powder Technol. 2019, 345, 15–25. [Google Scholar] [CrossRef]

- Wang, G.-H.; He, M.-L.; Chai, F.-C.; Feng, J.-D.; Dai, Y.-D. Enhancement of flame retardancy and radiation shielding properties of ethylene vinyl acetate based radiation shielding composites by EB irradiation. Prog. Nucl. Energy 2019, 112, 225–232. [Google Scholar] [CrossRef]

- Korean Standards Association. Testing method of lead equivalent for X-ray protective devices. KSA 2017, 17, 4025. [Google Scholar]

- Hong, J.W.; Kim, D.H.; Kim, S.W.; Choi, S.H.; Lee, G.E.; Seo, H.K.; Kim, S.H.; Lee, Y.J. Effectiveness evaluation of self-produced micro- and nanosized tungsten materials for radiation shielding with diagnostic X-ray imaging system. Optik 2018, 172, 760–765. [Google Scholar] [CrossRef]

- Harwood, J.R.; Nelli, F.E. A model-based algorithm to correct for the loss of backscatter in superficial X-ray radiation therapy. Phys. Med. 2019, 65, 157–166. [Google Scholar] [CrossRef]

- Hunter, D.; Mauldon, E.; Anderson, N. Cost-containment in hypofractionated radiation therapy: A literature review. J. Med. Radiat. Sci. 2018, 65, 148–157. [Google Scholar] [CrossRef] [Green Version]

- Morishima, Y.; Chida, K.; Katahira, Y. The effectiveness of additional lead-shielding drape and low pulse rate fluoroscopy in protecting staff from scatter radiation during cardiac resynchronization therapy (CRT). Jpn. J. Radiol. 2019, 37, 95–101. [Google Scholar] [CrossRef]

- Biso, S.M.R.; Vidovich, M.I. IRadiation protection in the cardiac catheterization laboratory. J Thorac Dis 2020, 12, 1648–1655. [Google Scholar] [CrossRef]

- Kim, J.H. Three principles for radiation safety: Time, distance, and shielding. Korean J. Pain 2018, 31, 145–146. [Google Scholar] [CrossRef]

- Wang, Y.; Zhong, R.; Li, Q.; Liao, J.; Liu, N.; Joshi, N.S.; Shi, B.; Liao, X.; Guo, J. Lightweight and wearable X-ray shielding material with biological structure for low secondary radiation and metabolic saving performance. Adv. Mater. Technol. 2020, 5, 2000240. [Google Scholar] [CrossRef]

- Leide-Svegborn, S. Radiation exposure of patients and personnel from a PET/CT procedure with 18F-FDG. Radiat. Prot. Dosim. 2010, 139, 208–213. [Google Scholar] [CrossRef]

- Chartier, H.; Fassier, P.; Leuraud, K.; Jacob, S.; Baudin, C.; Laurier, D.; Bernier, M.O. Occupational low-dose irradiation and cancer risk among medical radiation workers. Occup. Med. 2020, 70, 476–484. [Google Scholar] [CrossRef]

- Zhu, G.; Fang, Y.; Zhao, L.; Wang, J.; Chen, W. Prediction of structural parameters and air permeability of cotton woven fabric. Text. Res. J. 2018, 88, 1650–1659. [Google Scholar] [CrossRef]

- Boice, J.; Dauer, L.T.; Kase, K.R.; Mettler, F.A.; Vetter, R.J. Evolution of radiation protection for medical workers. Br. J. Radiol. 2020, 93, 20200282. [Google Scholar] [CrossRef]

- Halimah, M.K.; Azuraida, A.; Ishak, M.; Hasnimulyati, L. Influence of bismuth oxide on gamma radiation shielding properties of borotellurite glass. J. Non-Cryst. Solids 2019, 512, 140–147. [Google Scholar] [CrossRef]

- Eskalen, H.; Kavun, Y.; Kerli, S.; Eken, S. An investigation of radiation shielding properties of boron doped ZnO thin films. Opt. Mater. 2020, 105, 109871. [Google Scholar] [CrossRef]

| Condition | Adjustable Value |

|---|---|

| Content of fine particles in fiber (wt%) | 5 |

| Extruder temperature range (°C) | 280–300 |

| Extruder pressure (Pa) | 1.2 × 10−4 |

| Spinning pack temperature (°C) | 295 |

| Spinning pack pressure (Pa) | 1.2 × 10−5 |

| Cooling time (s) | 0.52 |

| Take-off roll speed (revolutions per minute (rpm)) | 3.450 |

| Characteristic | Yarn Containing BaSO4 |

|---|---|

| Fineness (Denier) | 75.1 |

| Tensile strength (g/d) | 3.15 |

| Elongation at break (%) | 28.1 |

| Mineral contents (wt%) | 5 |

| Twist per meter | 75 deniers/36 filaments |

| Weaving Method | Tensile Strength (N) | Elongation at Break (%) | Tearing Strength (N) | Specific Weight (g/m²) | Thickness (mm) | Density (g/m³) | |||

|---|---|---|---|---|---|---|---|---|---|

| Twill | warp | 810 | warp | 3.13 | warp | 20.84 | 165–170 | 0.23–0.25 | 232 |

| weft | 460 | weft | 26.5 | weft | 17.51 | 120 | |||

| Plain | warp | 740 | warp | 34 | warp | 16 | 114–118 | 0.19–0.20 | 150 |

| weft | 290 | weft | 20 | weft | 9 | 74 | |||

| Radiation Type | X-ray Energy (kVp) | Mean of Exposure (µR) | Shielding Rate (%) | |||

|---|---|---|---|---|---|---|

| Nothing | Plain | Twill | Plain | Twill | ||

| X-ray | 40 | 121.23 | 90.91 | 74.87 | 24.01 | 37.24 |

| 60 | 421.22 | 337.19 | 294.22 | 18.95 | 29.15 | |

| 80 | 911.84 | 765.12 | 666.19 | 15.09 | 25.94 | |

| 100 | 1534.62 | 1313.33 | 1210.51 | 13.42 | 20.12 | |

| 120 | 1829.12 | 1698.89 | 1610.72 | 6.12 | 10.94 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, J.S.; Kim, S.-C. Improving the Density of Functional Fabrics to Protect Radiation Workers in Radiology Departments. Coatings 2022, 12, 1142. https://doi.org/10.3390/coatings12081142

Son JS, Kim S-C. Improving the Density of Functional Fabrics to Protect Radiation Workers in Radiology Departments. Coatings. 2022; 12(8):1142. https://doi.org/10.3390/coatings12081142

Chicago/Turabian StyleSon, Jun Sik, and Seon-Chil Kim. 2022. "Improving the Density of Functional Fabrics to Protect Radiation Workers in Radiology Departments" Coatings 12, no. 8: 1142. https://doi.org/10.3390/coatings12081142