Effect of Various Lubricating Strategies on Machining of Titanium Alloys: A State-of-the-Art Review

Abstract

:1. Introduction

2. Minimum Quantity Lubrication (MQL) Machining Strategy

3. Wet Machining Strategy

4. Cryogenic Machining Strategy

5. Hybrid Cryogenic Machining Strategy

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| MQL—Minimum quantity lubrication |

| CF—Cutting fluid |

| UAM—Ultrasonic-assisted machining |

| MQCL—Minimum quantity cooling lubrication |

| MWF—Metal working fluid |

| NMQL—Nanofluid minimum quantity lubrication |

| MoS2—Molybdenum disulphide |

| GO—Graphene oxide |

| MWCNT—Multi-walled carbon nanotube |

| HBN—Hexagonal boron nitride |

| PVD—Physical vapor deposition |

| TiAlN—Titanium aluminum nitride |

| CVD—Carbon vapor deposition |

| RHVT-MQCF—Ranque–Hilsch vortex tube |

| MQCF—Minimum quantity cutting fluids |

| EMCL—Emulsion mist cooling/lubrication |

| EHDA—Electrohydrodynamic atomization |

| UVAM—Ultrasonic vibration-assisted milling |

| CNT—Carbon nanotube |

| BMIM—PF6-1-butyl-3-methylimidazolium hexafluorophosphate |

| ACF—Atomization-based cutting fluid |

| NFEAL—Nanofluid electrostatic atomization lubrication |

| AF-ESL—Air flow-assisted electrostatic lubrication |

| HPC—High-pressure coolant |

| LN2—Liquid nitrogen |

| LCO2—Liquid carbon dioxide |

| CAMQL—Cryogenic air mixed with MQL |

| CBN—Cubic Boron Nitride |

| WC—Tungsten Carbide |

| PCBN—Polycrystalline cubic boron nitride |

References

- Singh, G.; Gupta, M.K.; Mia, M.; Sharma, V.S. Modeling and optimization of tool wear in MQL-assisted milling of Inconel 718 superalloy using evolutionary techniques. Int. J. Adv. Manuf. Technol. 2018, 97, 481–494. [Google Scholar] [CrossRef]

- Gupta, M.K.; Sood, P.K. Machining comparison of aerospace materials considering minimum quantity cutting fluid: A clean and green approach. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 231, 1445–1464. [Google Scholar] [CrossRef]

- Deng, J.; Zhou, J.; Zhang, H.; Yan, P. Wear mechanisms of cemented carbide tools in dry cutting of precipitation hardening semi-austenitic stainless steels. Wear 2011, 270, 520–527. [Google Scholar] [CrossRef]

- Sujova, E. Contamination of the working air via metalworking fluids aerosols. In Engineering Review: Međunarodni Časopis Namijenjen Publiciranju Originalnih Istraživanja s Aspekta Analize Konstrukcija, Materijala i Novih Tehnologija u Području Strojarstva, Brodogradnje, Temeljnih Tehničkih Znanosti, Elektrotehnike, Računarstva i Građevinarstva; Faculty of Engineering/Faculty of Civil Engineering, University of Rijeka: Rijeka, Croatia, 2012; Volume 32, pp. 9–15. [Google Scholar]

- Sanchez, J.A.; Pombo, I.; Alberdi, R.; Izquierdo, B.; Ortega, N.; Plaza, S.; Martinez-Toledano, J. Machining evaluation of a hybrid MQL-CO2 grinding technology. J. Clean. Prod. 2010, 18, 1840–1849. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. A critical assessment of lubrication techniques in machining processes: A case for minimum quantity lubrication using vegetable oil-based lubricant. J. Clean. Prod. 2013, 41, 210–221. [Google Scholar] [CrossRef]

- Astkhov, V.P.; Joksch, S. Metal Working Fluids for Cutting and Grinding—Fundamentals and Recent Advances; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Dureja, J.S.; Singh, R.; Singh, T.; Singh, P.; Dogra, M.; Bhatti, M.S. Performance evaluation of coated carbide tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. Technol. 2015, 2, 123–129. [Google Scholar] [CrossRef]

- da Silva, R.B.; Machado, Á.R.; Ezugwu, E.O.; Bonney, J.; Sales, W.F. Tool life and wear mechanisms in high speed machining of Ti-6Al-4V alloy with PCD tools under various coolant pressures. J. Mater. Process. Technol. 2013, 213, 1459–1464. [Google Scholar] [CrossRef]

- Sharma, V.S.; Dogra, M.; Suri, N.M. Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 2009, 49, 435–453. [Google Scholar] [CrossRef]

- Srikanth, K.S.; Jaisankar, V.; Vasisht, J.S. Evaluation of tool wear and surface finish of AISI 316l stainless steel using nano cutting environment. Int. J. Mech. Prod. Eng. 2014, 2, 73–76. [Google Scholar]

- Su, Y.; Gong, L.; Li, B.; Liu, Z.; Chen, D. Performance evaluation of nanofluid MQL with vegetable-based oil and ester oil as base fluids in turning. Int. J. Adv. Manuf. Technol. 2015, 83, 2083–2089. [Google Scholar] [CrossRef]

- Ramesh, G.; Prabhu, N.K. Review of thermo-physical properties, wetting and heat transfer characteristics of nanofluids and their applicability in industrial quench heat treatment. Nanoscale Res. Lett. 2011, 6, 334. [Google Scholar] [CrossRef] [PubMed]

- Tanvir, S.; Qiao, L. Surface tension of Nanofluid-type fuels containing suspended nanomaterials. Nanoscale Res. Lett. 2012, 7, 226. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.J.; Bang, I.C.; Buongiorno, J.; Hu, L.W. Surface wettability change during pool boiling of nanofluids and its effect on critical heat flux. Int. J. Heat Mass Transf. 2007, 50, 4105–4116. [Google Scholar] [CrossRef]

- Golubovic, M.N.; Madhawa Hettiarachchi, H.D.; Worek, W.M.; Minkowycz, W.J. Nanofluids and critical heat flux, experimental and analytical study. Appl. Therm. Eng. 2009, 29, 1281–1288. [Google Scholar] [CrossRef]

- Silliman, J.D. Cutting and Grinding Fluids: Selection and Application; Society of Manufacturing Engineers: Dearborn, MI, USA, 1992. [Google Scholar]

- Yan, L.; Zhang, Q.; Yu, J. Effects of continuous minimum quantity lubrication with ultrasonic vibration in turning of titanium alloy. Int. J. Adv. Manuf. Technol. 2018, 98, 827–837. [Google Scholar] [CrossRef]

- Pervaiz, S.; Rashid, A.; Deiab, I.; Nicolescu, C.M. An experimental investigation on effect of minimum quantity cooling lubrication (MQCL) in machining titanium alloy (Ti6Al4V). Int. J. Adv. Manuf. Technol. 2016, 87, 1371–1386. [Google Scholar] [CrossRef]

- Rao, C.M.; Rao, S.S.; Herbert, M.A. Development of novel cutting tool with a micro-hole pattern on PCD insert in machining of titanium alloy. J. Manuf. Process. 2018, 36, 93–103. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Deiab, I.; Eltaggaz, A. Sustainability Assessment during Machining Ti-6Al-4V with Nano-Additives-Based Minimum Quantity Lubrication. J. Manuf. Mater. Process. 2019, 3, 61. [Google Scholar] [CrossRef]

- Singh, R.; Dureja, J.S.; Dogra, M.; Gupta, M.K.; Mia, M.; Song, Q. Wear behavior of textured tools under graphene-assisted minimum quantity lubrication system in machining Ti-6Al-4V alloy. Tribol. Int. 2020, 145, 106183. [Google Scholar] [CrossRef]

- Li, G.; Yi, S.; Li, N.; Pan, W.; Wen, C.; Ding, S. Quantitative analysis of cooling and lubricating effects of graphene oxide nanofluids in machining titanium alloy Ti6Al4V. J. Mater. Process. Technol. 2019, 271, 584–598. [Google Scholar] [CrossRef]

- Moura, R.R.; Da Silva, M.B.; Machado, Á.R.; Sales, W.F. The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy. Wear 2015, 332–333, 762–771. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Deiab, I.; Kishawy, H. Performance evaluation of Ti-6Al-4V machining using nano-cutting fluids under minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2018, 95, 4229–4241. [Google Scholar] [CrossRef]

- Anand, N.; Kumar, A.S.; Paul, S. Effect of cutting fluids applied in MQCL mode on machinability of Ti-6Al-4V. J. Manuf. Process. 2019, 43, 154–163. [Google Scholar] [CrossRef]

- Revuru, R.S.; Zhang, J.Z.; Posinasetti, N.R.; Kidd, T. Optimization of titanium alloys turning operation in varied cutting fluid conditions with multiple machining performance characteristics. Int. J. Adv. Manuf. Technol. 2017, 95, 1451–1463. [Google Scholar] [CrossRef]

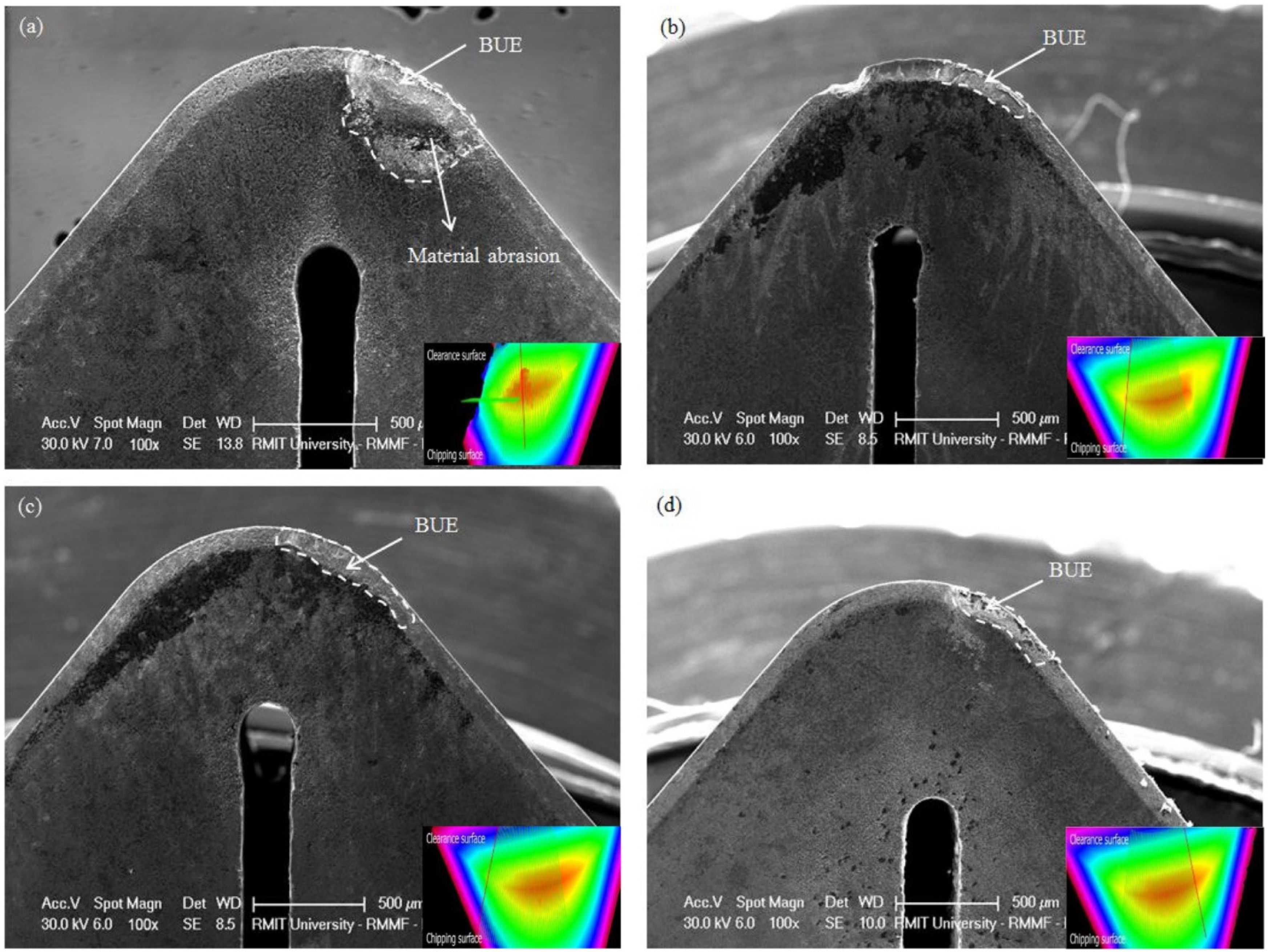

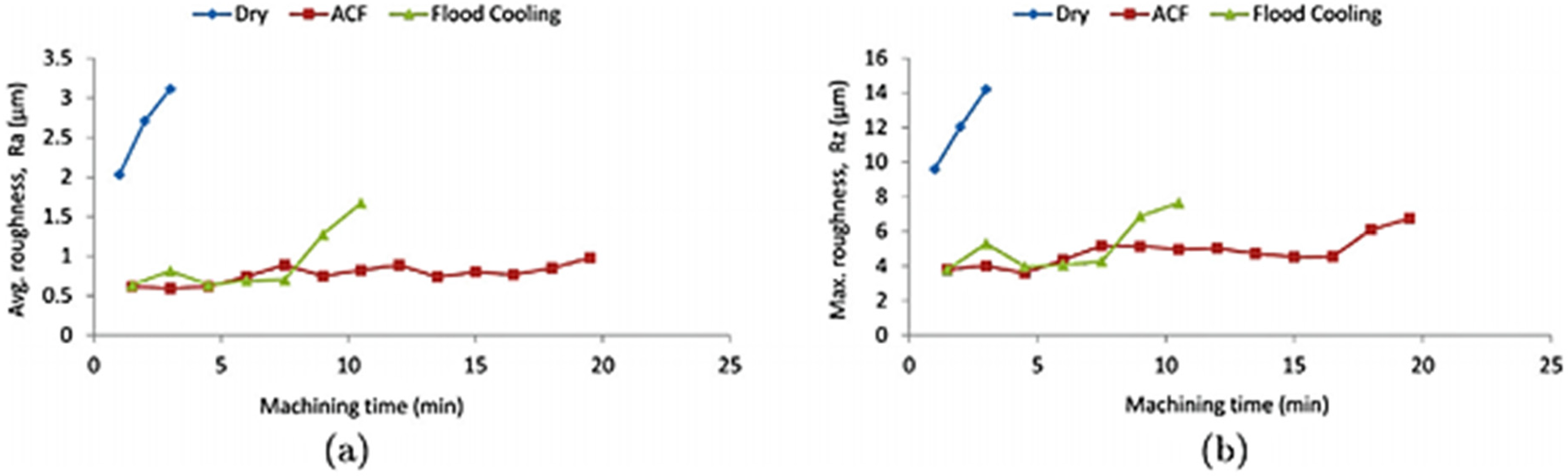

- Raza, S.W.; Pervaiz, S.; Deiab, I. Tool wear patterns when turning of titanium alloy using sustainable lubrication strategies. Int. J. Precis. Eng. Manuf. 2014, 15, 1979–1985. [Google Scholar] [CrossRef]

- Ramana, M.V. Optimization and Influence of Process Parameters on Surface Roughness in Turning of Titanium Alloy under Different Lubricant Conditions. Mater. Today Proc. 2017, 4, 8328–8335. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Pruncu, C.I.; Mia, M.; Singh, G.; Lozano, J.A.; Carou, D.; Khan, A.M.; Jamil, M.; et al. Machining characteristics based life cycle assessment in eco-benign turning of pure titanium alloy. J. Clean. Prod. 2019, 251, 119598. [Google Scholar] [CrossRef]

- Faga, M.G.; Priarone, P.C.; Robiglio, M.; Settineri, L.; Tebaldo, V. Technological and sustainability implications of dry, near-dry, and wet turning of Ti-6Al-4V alloy. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 129–139. [Google Scholar] [CrossRef]

- Khan, A.; Maity, K. Influence of cutting speed and cooling method on the machinability of commercially pure titanium (CP-Ti) grade II. J. Manuf. Process. 2018, 31, 650–661. [Google Scholar] [CrossRef]

- Sartori, S.; Ghiotti, A.; Bruschi, S. Solid Lubricant-assisted Minimum Quantity Lubrication and Cooling strategies to improve Ti6Al4V machinability in finishing turning. Tribol. Int. 2018, 118, 287–294. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Iulian Pruncu, C.; Khan, A.M.; Rahman, M.A.; Jamil, M.; Sharma, V.S. Modeling and performance evaluation of Al2O3, MoS2 and graphite nanoparticle-assisted MQL in turning titanium alloy: An intelligent approach. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 207. [Google Scholar] [CrossRef]

- Limin, S. Investigation of tool wear and surface roughness when turning titanium alloy (Ti6Al4V) under different cooling and lubrication conditions. Ferroelectrics 2018, 526, 199–205. [Google Scholar] [CrossRef]

- Singh, R.; Dureja, J.S.; Dogra, M.; Gupta, M.K.; Mia, M. Influence of graphene-enriched nanofluids and textured tool on machining behavior of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2019, 105, 1685–1697. [Google Scholar] [CrossRef]

- Singh, R.; Dureja, J.; Dogra, M.; Gupta, M.K.; Jamil, M.; Mia, M. Evaluating the sustainability pillars of energy and environment considering carbon emissions under machining ofTi-3Al-2.5 V. Sustain. Energy Technol. Assess. 2020, 42, 100806. [Google Scholar] [CrossRef]

- Yi, S.; Li, N.; Solanki, S.; Mo, J.; Ding, S. Effects of graphene oxide nanofluids on cutting temperature and force in machining Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 103, 1481–1495. [Google Scholar] [CrossRef]

- Yi, S.; Li, G.; Ding, S.; Mo, J.P. Performance and mechanisms of graphene oxide suspended cutting fluid in the drilling of titanium alloy Ti-6Al-4V. J. Manuf. Process. 2017, 29, 182–193. [Google Scholar] [CrossRef]

- Nam, J.; Lee, S.W. Machinability of titanium alloy (Ti-6Al-4V) in environmentally-friendly micro-drilling process with nanofluid minimum quantity lubrication using nanodiamond particles. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 29–35. [Google Scholar] [CrossRef]

- Niketh, S.; Samuel, G. Surface texturing for tribology enhancement and its application on drill tool for the sustainable machining of titanium alloy. J. Clean. Prod. 2017, 167, 253–270. [Google Scholar] [CrossRef]

- Li, M.; Yu, T.; Zhang, R.; Yang, L.; Li, H.; Wang, W. MQL milling of TC4 alloy by dispersing graphene into vegetable oil-based cutting fluid. Int. J. Adv. Manuf. Technol. 2018, 99, 1735–1753. [Google Scholar] [CrossRef]

- Yin, Q.; Li, C.; Dong, L.; Bai, X.; Zhang, Y.; Yang, M.; Jia, D.; Hou, Y.; Liu, Y.; Li, R. Effects of the physicochemical properties of different nanoparticles on lubrication performance and experimental evaluation in the NMQL milling of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2018, 99, 3091–3109. [Google Scholar] [CrossRef]

- Priarone, P.C.; Robiglio, M.; Settineri, L.; Tebaldo, V. Milling and Turning of Titanium Aluminides by Using Minimum Quantity Lubrication. Procedia CIRP 2014, 24, 62–67. [Google Scholar] [CrossRef]

- De Bartolomeis, A.; Shokrani, A. Electrohydrodynamic Atomization for Minimum Quantity Lubrication (EHDA-MQL) in End Milling Ti6Al4V Titanium Alloy. J. Manuf. Mater. Process. 2020, 4, 70. [Google Scholar] [CrossRef]

- Dong, L.; Li, C.; Bai, X.; Zhai, M.; Qi, Q.; Yin, Q.; Lv, X.; Li, L. Analysis of the cooling performance of Ti-6Al-4V in minimum quantity lubricant milling with different nanoparticles. Int. J. Adv. Manuf. Technol. 2019, 103, 2197–2206. [Google Scholar] [CrossRef]

- Cai, C.; Liang, X.; An, Q.; Tao, Z.; Ming, W.; Chen, M. Cooling/Lubrication Performance of Dry and Supercritical CO2-Based Minimum Quantity Lubrication in Peripheral Milling Ti-6Al-4V. Int. J. Precis. Eng. Manuf. Technol. 2020, 8, 405–421. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, L. Investigation on machining characteristics of TC4 alloy by simultaneous application of ultrasonic vibration assisted milling (UVAM) and economical-environmental MQL technology. J. Mater. Process. Technol. 2019, 278, 116518. [Google Scholar] [CrossRef]

- Davis, B.; Schueller, J.K.; Huang, Y. Study of ionic liquid as effective additive for minimum quantity lubrication during titanium machining. Manuf. Lett. 2015, 5, 1–6. [Google Scholar] [CrossRef]

- Ziberov, M.; da Silva, M.B.; Jackson, M.; Hung, W.N. Effect of Cutting Fluid on Micromilling of Ti-6Al-4V Titanium Alloy. Procedia Manuf. 2016, 5, 332–347. [Google Scholar] [CrossRef]

- Zou, L.; Li, H.; Yang, Y.; Huang, Y. Feasibility study of minimum quantity lubrication assisted belt grinding of titanium alloys. Mater. Manuf. Process. 2020, 35, 961–968. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. Machining performance evaluation of Ti6Al4V alloy with laser textured tools under MQL and nano-MQL environments. J. Manuf. Process. 2020, 53, 174–189. [Google Scholar] [CrossRef]

- An, Q.; Cai, C.; Zou, F.; Liang, X.; Chen, M. Tool wear and machined surface characteristics in side milling Ti6Al4V under dry and supercritical CO2 with MQL conditions. Tribol. Int. 2020, 151, 106511. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, A.M.; Gupta, M.K.; Mia, M.; He, N.; Li, L.; Sivalingam, V.K. Influence of CO2-snow and subzero MQL on thermal aspects in the machining of Ti-6Al-4V. Appl. Therm. Eng. 2020, 177, 115480. [Google Scholar] [CrossRef]

- Zheng, K.; Yang, F.; Zhang, N.; Liu, Q.; Jiang, F. Study on the Cutting Performance of Micro Textured Tools on Cutting Ti-6Al-4V Titanium Alloy. Micromachines 2020, 11, 137. [Google Scholar] [CrossRef] [PubMed]

- Gunda, R.K.; Narala, S.K.R. Analysis of electrostatic solid lubricant spray process parameters during turning Ti-6Al-4V alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1402–1414. [Google Scholar] [CrossRef]

- Yi, S.; Li, J.; Zhu, J.; Wang, X.; Mo, J.; Ding, S. Investigation of machining Ti-6Al-4V with graphene oxide nanofluids: Tool wear, cutting forces and cutting vibration. J. Manuf. Process. 2020, 49, 35–49. [Google Scholar] [CrossRef]

- Nath, C.; Kapoor, S.G.; Srivastava, A.K. Finish turning of Ti-6Al-4V with the atomization-based cutting fluid (ACF) spray system. J. Manuf. Process. 2017, 28, 464–471. [Google Scholar] [CrossRef]

- Sahu, N.K.; Andhare, A.; Raju, R.A. Evaluation of performance of nanofluid using multiwalled carbon nanotubes for machining of Ti-6Al-4V. Mach. Sci. Technol. 2017, 22, 476–492. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, D.; Zhang, X.; Peng, Z. Effects of high-pressure coolant on cutting performance of high-speed ultrasonic vibration cutting titanium alloy. J. Mater. Process. Technol. 2020, 279, 116584. [Google Scholar] [CrossRef]

- Mia, M.; Dhar, N.R. Effects of duplex jets high-pressure coolant on machining temperature and machinability of Ti-6Al-4V superalloy. J. Mater. Process. Technol. 2018, 252, 688–696. [Google Scholar] [CrossRef]

- Ganguli, S.; Kapoor, S.G. Improving the performance of milling of titanium alloys using the atomization-based cutting fluid application system. J. Manuf. Process. 2016, 23, 29–36. [Google Scholar] [CrossRef]

- Su, Y.; Lu, Q.; Yu, T.; Liu, Z.; Zhang, C. Machining and environmental effects of electrostatic atomization lubrication in milling operation. Int. J. Adv. Manuf. Technol. 2019, 104, 2773–2782. [Google Scholar] [CrossRef]

- Zhou, C.; Guo, X.; Zhang, K.; Cheng, L.; Wu, Y. The coupling effect of micro-groove textures and nanofluids on cutting performance of uncoated cemented carbide tools in milling Ti-6Al-4V. J. Mater. Process. Technol. 2019, 271, 36–45. [Google Scholar] [CrossRef]

- Su, Y.; Jiang, H.; Liu, Z. A study on environment-friendly machining of titanium alloy via composite electrostatic spraying. Int. J. Adv. Manuf. Technol. 2020, 110, 1305–1317. [Google Scholar] [CrossRef]

- Mittal, R.K.; Kulkarni, S.S.; Singh, R. Effect of lubrication on machining response and dynamic instability in high-speed micromilling of Ti-6Al-4V. J. Manuf. Process. 2017, 28, 413–421. [Google Scholar] [CrossRef]

- Lee, P.-H.; Kim, J.W.; Lee, S.W. Experimental characterization on eco-friendly micro-grinding process of titanium alloy using air flow assisted electrospray lubrication with nanofluid. J. Clean. Prod. 2018, 201, 452–462. [Google Scholar] [CrossRef]

- Grguraš, D.; Sterle, L.; Pušavec, F. Cutting forces and chip morphology in LCO2 + MQL assisted robotic drilling of Ti6Al4V. Procedia CIRP 2021, 102, 299–302. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Pereira, O.; González, H.; Calleja, A.; Rodríguez, A.; Urbikaín, G.; de Lacalle, L.L. Manufacturing of human knee by cryogenic machining: Walking towards cleaner processes. Procedia Manuf. 2019, 41, 257–263. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A. Cryogenic Machining of Titanium Ti-5553 Alloy. J. Manuf. Sci. Eng. 2019, 141, 041012. [Google Scholar] [CrossRef]

- Gajrani, K.K. Assessment of cryo-MQL environment for machining of Ti-6Al-4V. J. Manuf. Process. 2020, 60, 494–502. [Google Scholar] [CrossRef]

- Rodríguez, A.; Calleja, A.; de Lacalle, L.N.L.; Pereira, O.; Rubio-Mateos, A.; Rodríguez, G. Drilling of CFRP-Ti6Al4V stacks using CO2-cryogenic cooling. J. Manuf. Process. 2021, 64, 58–66. [Google Scholar] [CrossRef]

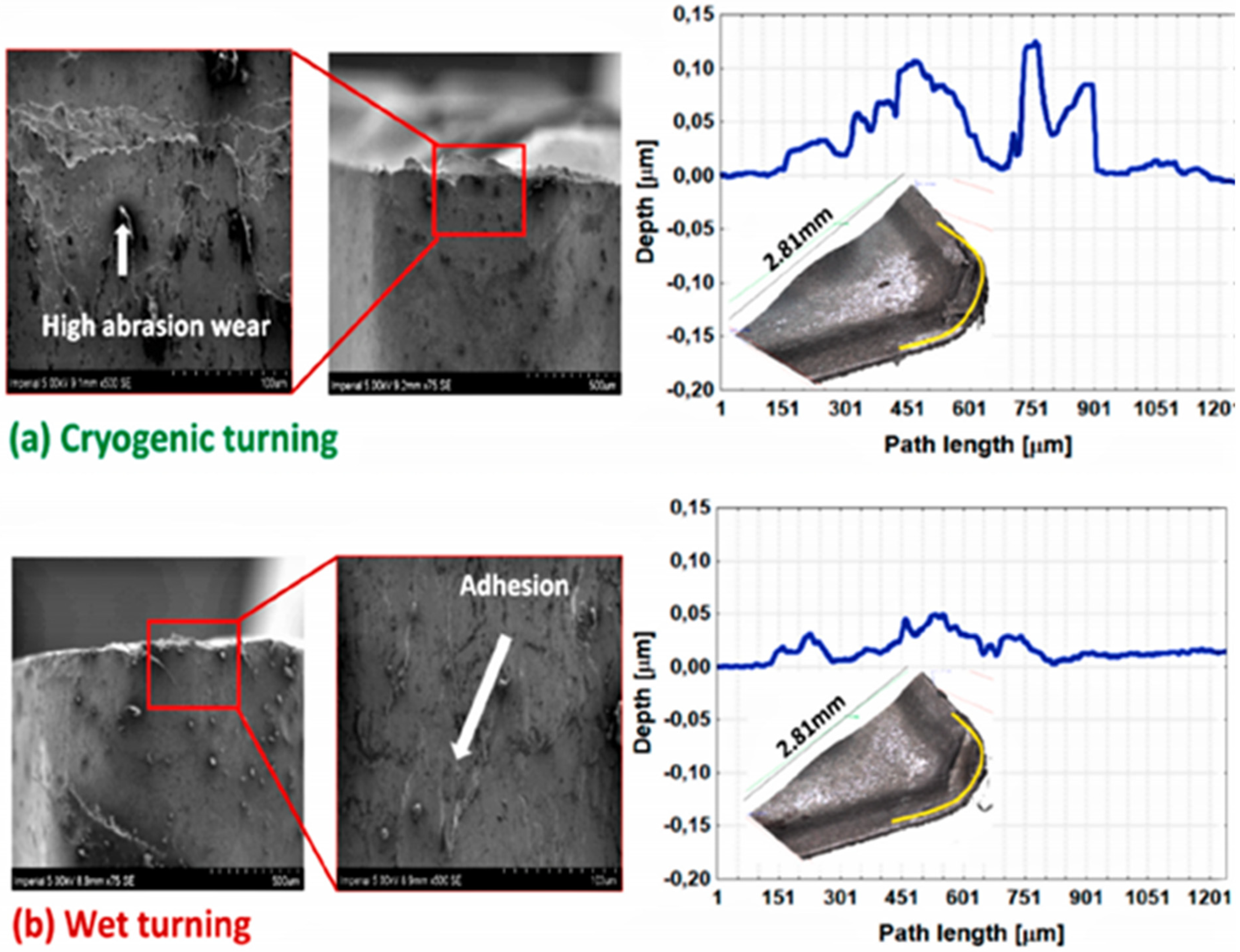

- Agrawal, C.; Wadhwa, J.; Pitroda, A.; Pruncu, C.I.; Sarikaya, M.; Khanna, N. Comprehensive analysis of tool wear, tool life, surface roughness, costing and carbon emissions in turning Ti-6Al-4V titanium alloy: Cryogenic versus wet machining. Tribol. Int. 2021, 153, 106597. [Google Scholar] [CrossRef]

- Ayed, Y.; Germain, G.; Melsio, A.P.; Kowalewski, P.; Locufier, D. Impact of supply conditions of liquid nitrogen on tool wear and surface integrity when machining the Ti-6Al-4V titanium alloy. Int. J. Adv. Manuf. Technol. 2017, 93, 1199–1206. [Google Scholar] [CrossRef]

- Perçin, M.; Aslantas, K.; Ucun, I.; Kaynak, Y.; Cicek, A. Micro-drilling of Ti-6Al-4V alloy: The effects of cooling/lubricating. Precis. Eng. 2016, 45, 450–454. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S. Investigation of the effects of cryogenic machining on surface integrity in CNC end milling of Ti-6Al-4V titanium alloy. J. Manuf. Process. 2016, 21, 172–179. [Google Scholar] [CrossRef]

- Masood, I.; Jahanzaib, M.; Haider, A. Tool wear and cost evaluation of face milling grade 5 titanium alloy for sustainable machining. Adv. Prod. Eng. Manag. 2016, 11, 239–250. [Google Scholar] [CrossRef]

- Chen, G.; Caudill, J.; Chen, S.; Jawahir, I.S. Machining-induced surface integrity in titanium alloy Ti-6Al-4V: An investigation of cutting edge radius and cooling/lubricating strategies. J. Manuf. Process. 2022, 74, 353–364. [Google Scholar] [CrossRef]

- Chen, G.; Chen, S.; Schoop, J.; Caudill, J.; Jawahir, I.S. The Influence of Sustainable Cooling Strategies and Uncut Chip Thickness on Surface Integrity in Finish Machining of Ti-6Al-4V Alloy. ASME Int. Mech. Eng. Congr. Expo. Proc. 2021. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Barreiro, J.; Fernández-Abia, A.I.; De Lacalle, L.N.L. Nozzle design for combined use of MQL and cryogenic gas in machining. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 87–95. [Google Scholar] [CrossRef]

- Gross, D.; Appis, M.; Hanenkamp, N. Investigation on the productivity of milling ti6al4v with cryogenic minimum quantity lubrication. MM Sci. J. 2019, 2019, 3393–3398. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Khanna, N.; Krolczyk, G. Experimental characterisation of the performance of hybrid cryo-lubrication assisted turning of Ti-6Al-4V alloy. Tribol. Int. 2021, 153, 106582. [Google Scholar] [CrossRef]

- Huang, P.; Li, H.; Zhu, W.-L.; Wang, H.; Zhang, G.; Wu, X.; To, S.; Zhu, Z. Effects of eco-friendly cooling strategy on machining performance in micro-scale diamond turning of Ti-6Al-4V. J. Clean. Prod. 2020, 243, 118526. [Google Scholar] [CrossRef]

- Lin, H.; Wang, C.; Yuan, Y.; Chen, Z.; Wang, Q.; Xiong, W. Tool wear in Ti-6Al-4V alloy turning under oils on water cooling comparing with cryogenic air mixed with minimal quantity lubrication. Int. J. Adv. Manuf. Technol. 2015, 81, 87–101. [Google Scholar] [CrossRef]

- Sartori, S.; Ghiotti, A.; Bruschi, S. Hybrid lubricating/cooling strategies to reduce the tool wear in finishing turning of difficult-to-cut alloys. Wear 2017, 376–377, 107–114. [Google Scholar] [CrossRef]

- Wakabayashi, T.; Kuhara, J.; Atsuta, T.; Tsukuda, A.; Sembongi, N.; Shibata, J.; Suda, S. Near-Dry Machining of Titanium Alloy with MQL and Hybrid Mist Supply. Key Eng. Mater. 2015, 656–657, 341–346. [Google Scholar] [CrossRef]

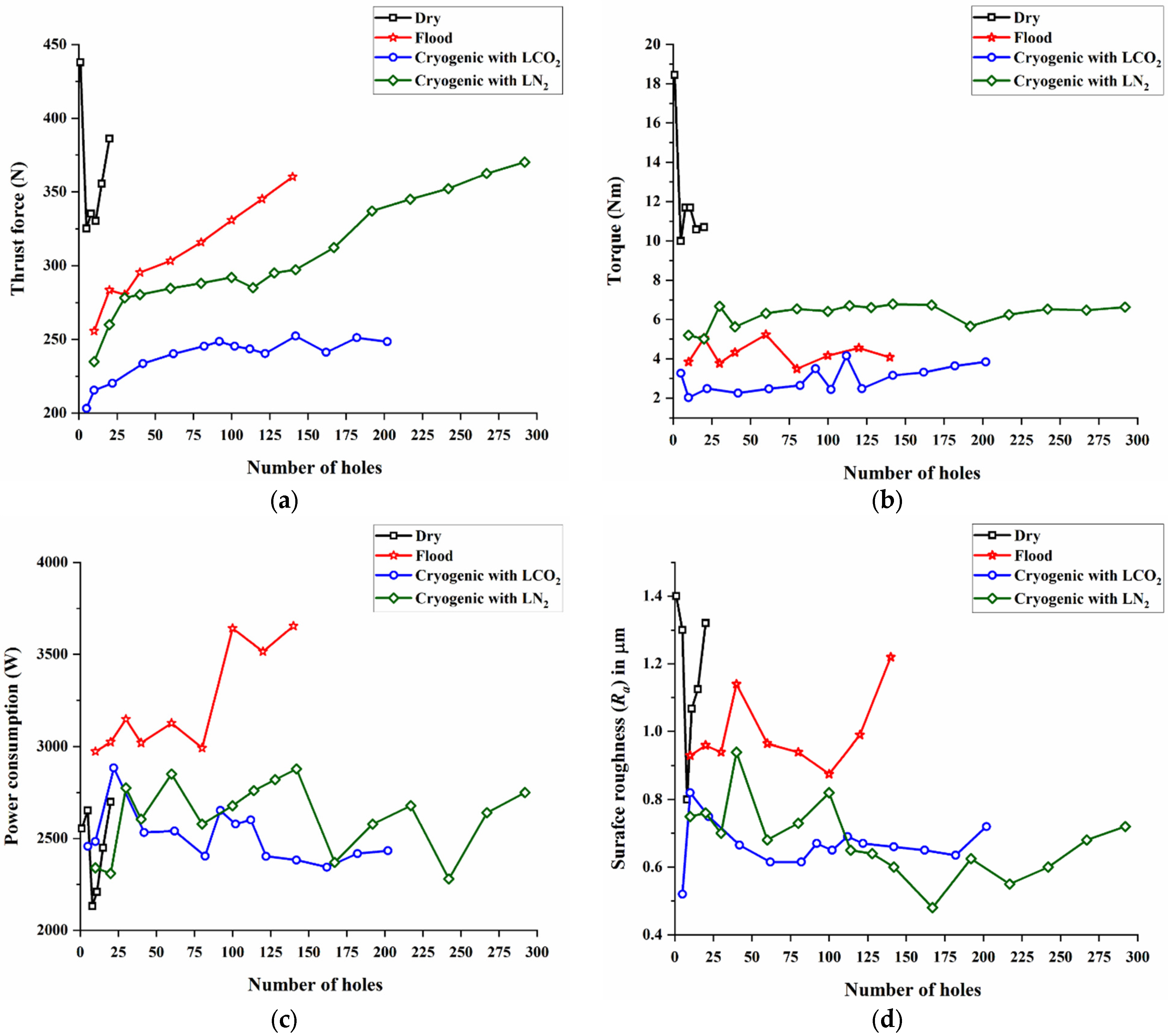

- Shah, P.; Khanna, N. Chetan Comprehensive machining analysis to establish cryogenic LN2 and LCO2 as sustainable cooling and lubrication techniques. Tribol. Int. 2020, 148, 106314. [Google Scholar] [CrossRef]

- Shokrani, A.; Al-Samarrai, I.; Newman, S.T. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J. Manuf. Process. 2019, 43, 229–243. [Google Scholar] [CrossRef]

- Suhaimi, M.A.; Yang, G.-D.; Park, K.-H.; Hisam, M.J.; Sharif, S.; Kim, D.-W. Effect of cryogenic machining for titanium alloy based on indirect, internal and external spray system. Procedia Manuf. 2018, 17, 158–165. [Google Scholar] [CrossRef]

- Park, K.-H.; Yang, G.-D.; Suhaimi, M.A.; Lee, D.Y.; Kim, T.-G.; Kim, D.-W.; Lee, S.-W. The effect of cryogenic cooling and minimum quantity lubrication on end milling of titanium alloy Ti-6Al-4V. J. Mech. Sci. Technol. 2015, 29, 5121–5126. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, J.W.; Lee, S.W. Experimental characterization on micro-end milling of titanium alloy using nanofluid minimum quantity lubrication with chilly gas. Int. J. Adv. Manuf. Technol. 2017, 91, 2741–2749. [Google Scholar] [CrossRef]

- Iqbal, A.; Suhaimi, H.; Zhao, W.; Jamil, M.; Nauman, M.M.; He, N.; Zaini, J. Sustainable milling of Ti-6Al-4V: Investigating the effects of milling orientation, cutter’s helix angle, and type of cryogenic coolant. Metals 2020, 10, 258. [Google Scholar] [CrossRef]

- Iqbal, A.; Biermann, D.; Abbas, H.; Al-Ghamdi, K.A.; Metzger, M. Machining β-titanium alloy under carbon dioxide snow and micro-lubrication: A study on tool deflection, energy consumption, and tool damage. Int. J. Adv. Manuf. Technol. 2018, 97, 4195–4208. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; de Lacalle, L.N.L.; Rodríguez, A.; Pereira, O. In pursuit of sustainable cutting fluid strategy for machining Ti-6Al-4V using life cycle analysis. Sustain. Mater. Technol. 2021, 29, e00301. [Google Scholar] [CrossRef]

- Gonzalez, H.; Pereira, O.; de Lacalle, L.N.L.; Calleja, A.; Ayesta, I.; Muñoa, J. Flank-Milling of Integral Blade Rotors Made in Ti6Al4V Using Cryo CO2 and Minimum Quantity Lubrication. J. Manuf. Sci. Eng. 2021, 143, 091011. [Google Scholar] [CrossRef]

| Ref No. | Process | Coolant/Lubricant Strategy | Coolant/Lubricant Type | Workpiece | Tool | Cutting Parameters |

|---|---|---|---|---|---|---|

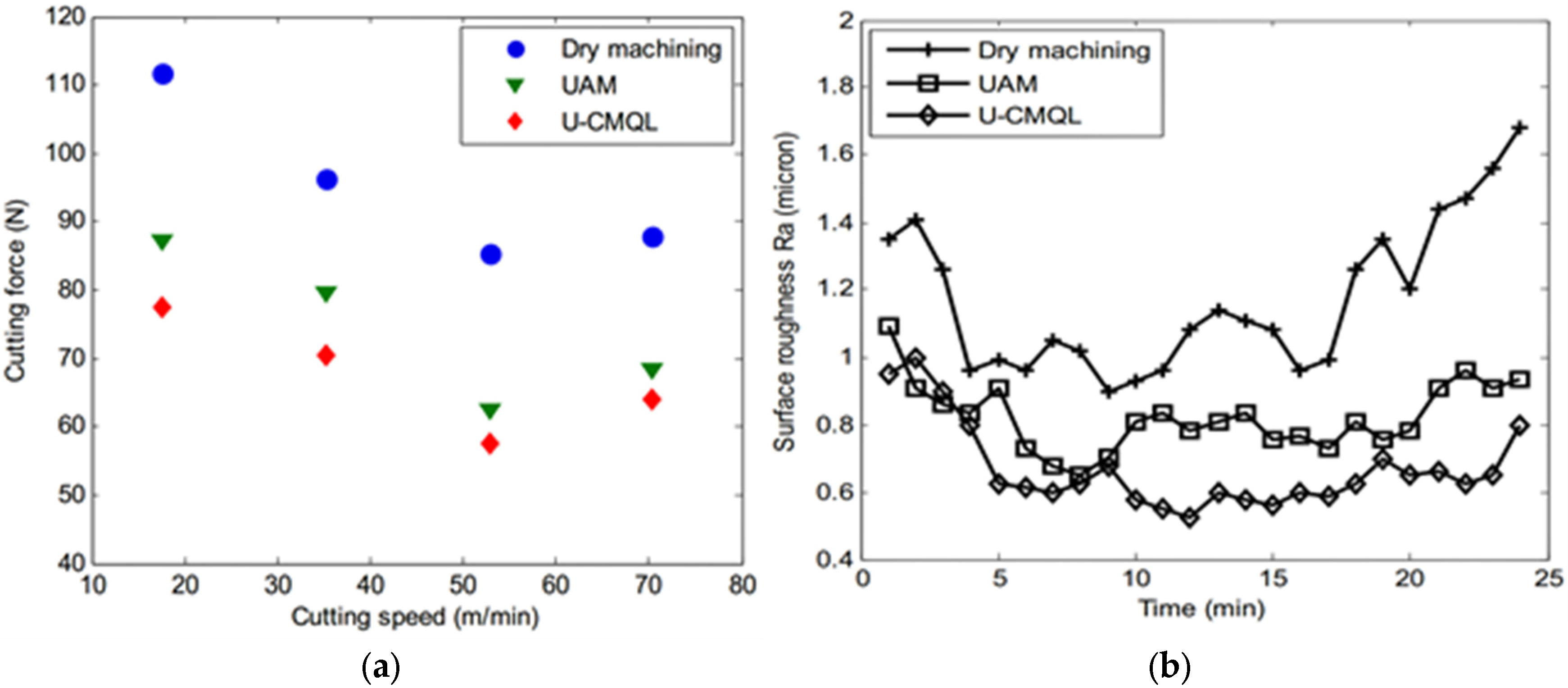

| [18] | Turning | Dry, U-CMQL | Vegetable oil | Ti-6Al-4V | 40Cr, insert-cemented carbide | Vc-17.6–70.4 m/min ap-0.75 mm f-0.15 mm/rev |

| [19] | Turning | MQL, MQCL | Vegetable oil-based | Ti-6Al-4V | CCMT 12 04 04 MM H 13A | Vc-90–150 m/min ap-0.8 mm f-0.1–0.3 mm/rev |

| [20] | Turning | MQL | Coconut oil | Ti-6Al-4V | PCD insert | Vc-100–200 m/min ap-1 mm f-0.5 mm/rev |

| [21] | Turning | MQL, NMQL | ECOLUBRIC E200 | Ti-6Al-4V | Carbide insert | Vc-120–220 m/min ap-0.2 mm f-0.1–0.2 mm/rev |

| [22] | Turning | MQL, NMQL | Canola oil | Ti-6Al-4V | Uncoated carbide | Vc-80–180 m/min ap-0.2 mm f-0.15 mm/rev |

| [23] | Turning | NMQL | ROCOL Ultracut Clear with 0.1% and 0.5% graphene nanosheet | Ti-6Al-4V | CBN | Vc-80–240(m/min) ap-1(mm) f-0.01(mm/rev) |

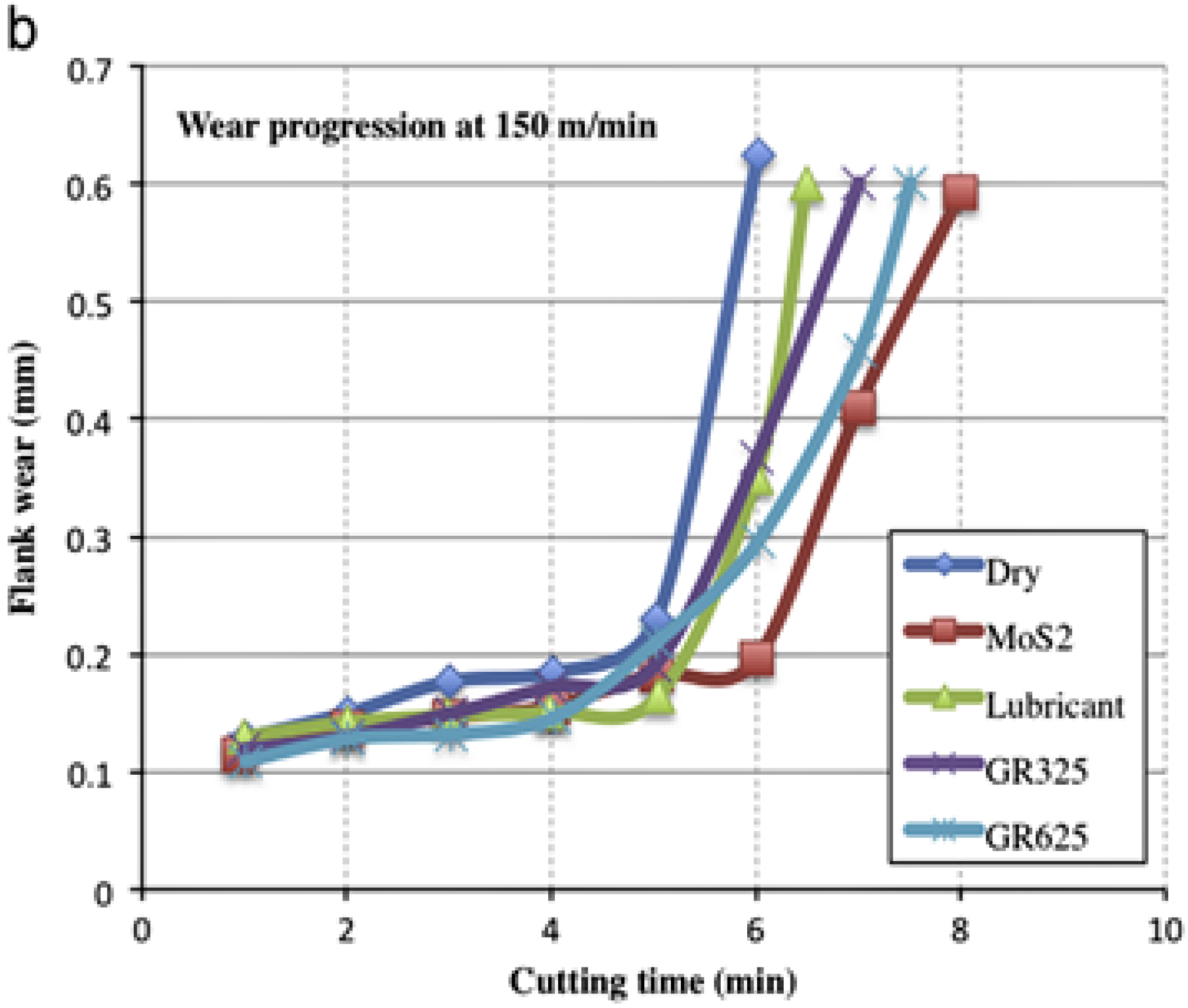

| [24] | Turning | NMQL | Synthetic oil with graphite mesh 625, graphite mesh 325, molybdenum disulphide (MoS2) | Ti-6Al-4V | TiAlN-coated carbide | Vc-130, 150(m/min) ap-1(mm) f-0.2(mm/rev) |

| [25] | Turning | NMQL | ECOLUBRIC E200 MWCNT nanoadditives (wt.%) 2%, 4% | Ti-6Al-4V | CNMG 120416MR (ISO) | Vc-200, 220 (m/min) f-0.15, 0.2 (mm/rev) |

| [26] | Turning | MQCL with nanofluid | Flood, MQCL (Al2O3 nanofluid, hBN nanofluid, soluble oil) | Ti-6Al-4V | Straight carbide (K20) | Vc-80 m/min f-0.16 mm/rev ap-1.5 mm |

| [27] | Turning | MQL, NMQL | Soybean oil-based lubricants 40 mL/h dry, wet | Ti6Al4V | PVD-coated carbide tools | Vc-90 m/min f-0.3 mm/rev ap-0.5 mm |

| [28] | Turning | Dry, cooled air, flood cooling, cryogenic, MQL, MQCL | ECOLUBRIC E200 | Ti-6Al-4V | Uncoated carbide | Vc-90,120 m/min ap-0.8 mm f-0.1,0.2 mm/rev |

| [29] | Turning | Dry, MQL, flood cooling | Sunflower-based vegetable oil | Ti-6Al-4V | Uncoated, PVD coated carbide, CVD coated carbide | Vc-63–99 (m/min) f-0.206–0.343(mm/rev) ap-0.6–1.6 (mm) |

| [30] | Turning | MQL | Commercially available cutting fluid | Titanium (Grade-2) alloy | Uncoated carbide, ISO Designation: CCMT 09 T3 08, 7° relief angle | Vc-250–300 m/min ap-0.3–0.5 mm f-0.05–0.13 mm/rev |

| [31] | Turning | Dry, MQL, and wet | An emulsion of 7% miscible oil in (93%) water and vegetable oil; an emulsion of 5% ester-based oil in (95%) water | Ti-6Al-4V | Uncoated carbide round inserts (RCMT 12 04 M0-SM H13A) | Vc-90–150 m/min ap-0.5 mm f-0.15 mm/rev |

| [32] | Turning | Dry, flood and MQL | Water soluble oil (flood) and vegetable oil (MQL) | Titanium (CP-Ti) grade II | Carbide inserts | Vc-51–87 m/min ap-0.5 mm f-0.12 mm/rev |

| [33] | Turning | MQL and MQC | Vegetable oil enriched PTFE particles + Graphite particles | Ti-6Al-4V | TiAlN-coated tungsten carbide insert | Vc-80 m/min ap-0.25 mm f-0.2 mm/rev |

| [34] | Turning | NFMQL | Vegetable base oil Al2O3 nanofluid MoS2 nanofluid Graphite nanofluid | Ti alloy (grade II) | CBN inserts (rhombic shape CNMG 120408) | Vc-200–300 m/min ap-1.0 mm f-0.1–0.2 mm/rev |

| [35] | Turning | Dry, wet, MQL | LUBROIL oil (MQL) | Ti-6Al-4V | Fine grain-coated carbide tool | Vc-40–120 m/min ap-0.5 mm f-0.1–0.2 mm/rev |

| [36] | Turning | Dry, MQL, NMQL | Canola oil (MQL), graphene-mixed canola oil (NMQL) | Ti-6Al-4V | Carbide tool | Vc-80–200 m/min ap-0.2 mm f-0.05–0.15 mm/rev |

| [37] | Turning | Dry, compressed air wet cooling, Ranque-–Hilsch vortex tube (RHVT), MQL, wet oil cooling | Canola oil (MQL), soluble oil (wet oil cooling) | Ti-3Al-2.5V | AlTiN-coated carbide tool | Vc-80–130 m/min ap-0.2 mm f-0.1 mm/rev |

| [38] | Turning | NMQL | Graphene oxide mixed in ROCOL Ultracut Clear | Ti-6Al-4V | PCBN tool | Vc-80–240 m/min ap-0.1 mm f-0.05–0.1 mm/rev |

| [39] | Drilling | NMQL | ROCOL Ultracut Clear with graphene oxide suspended | Ti-6Al-4V | WC | N-800–2880 (rpm) f-0.1–0.18(mm/rev) ap-8 (mm) |

| [40] | Drilling | NMQL | Compressed air, Veg.-based MQL, NMQL | Ti-6Al-4V | Uncoated tungstate carbide twist drill | N-60,000 r/min f-10, 50 (mm/min) ap-0.4 mm |

| [41] | Drilling | Dry | Dry | Ti-6Al-4V | Textured- and non-textured-carbide drill tool | N-80–6000 rpm ap-10 mm f-0.04–0.07 mm/r |

| [42] | Milling | MQL, NMQL | LB2000 vegetable-based oil | Ti-6Al-4V | TiAlN-coated | N-796 rpm f-0.016, 0.04 mm/tooth ap-0.2 mm ae-0.1 mm |

| [43] | Milling | NMQL | Cottonseed oil with Al2O3, MoS2, SiO2, carbon nanotubes, SiC, graphite | Ti-6Al-4V | Quenched 42CrMo | N-8000 r/min f-10,000 mm/min |

| [44] | Milling | MQL, dry, flood cooling | LB2000 vegetable-based oil | Ti-48Al-2Cr-2Nb | TiAlN coated | Vc-50 m/min f-0.08 mm/tooth ap-0.3 mm |

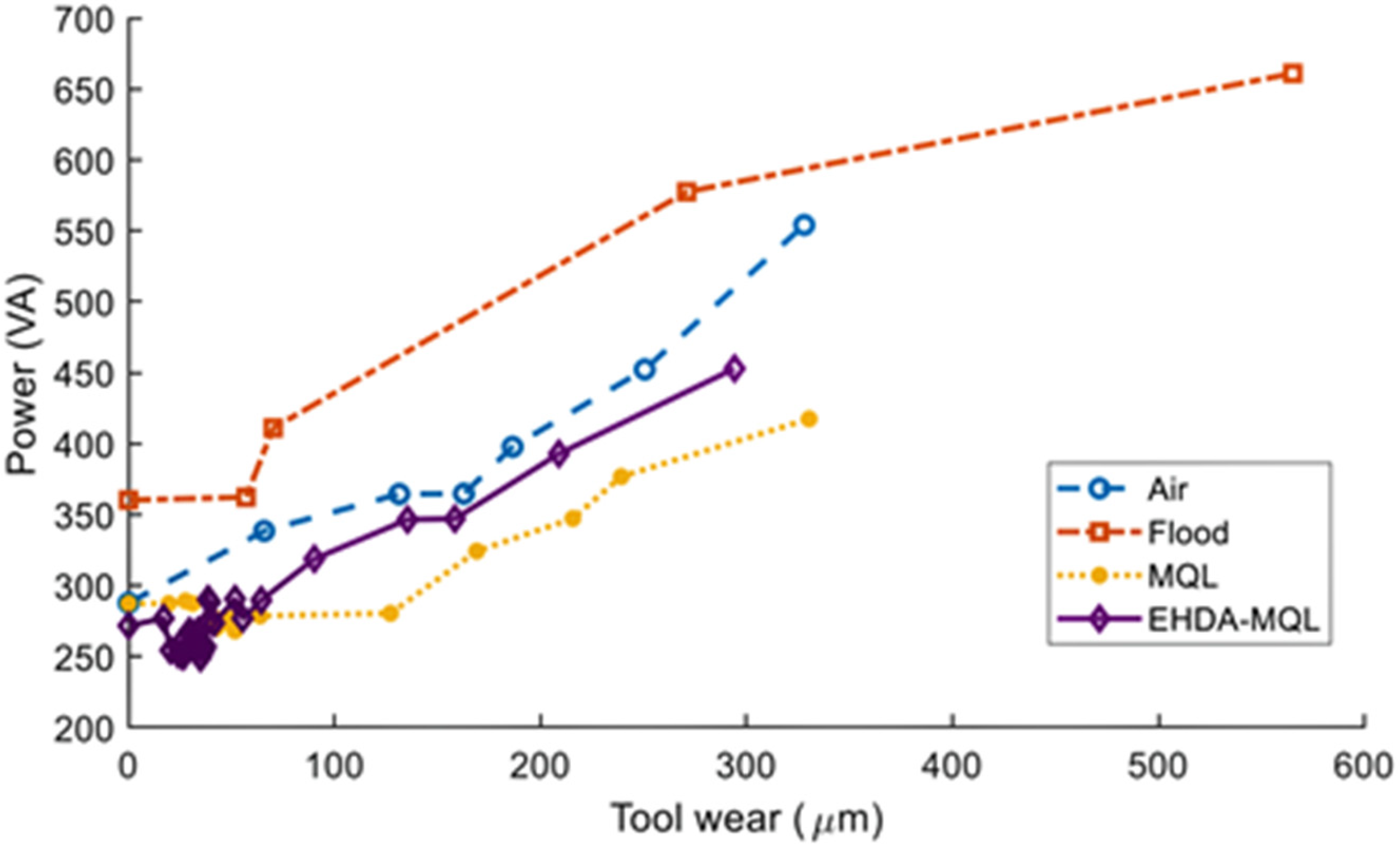

| [45] | Milling | Flood cooling, air, MQL and EHDA-MQL | Rapeseed oil | Ti-6Al-4V | WC tool with 5 flutes and TiSiN coating | Vc-120 m/min N-3183 rpm ap-3 mm f-0.05 mm/tooth |

| [46] | Milling | NMQL | Cottonseed oil with 1.5 wt.% Al2O3, MoS2, SiO2, CNTs, SiC, or graphite | Ti-6Al-4V | Bap300r-c16-160-160l milling tool bar with an APMT1135PEDR blade | Vc-1200 r/min N-3183 rpm ap-0.25 mm f-500 mm/min |

| [47] | Milling | MQL | Supercritical carbon dioxide (scCO2) | Ti-6Al-4V | A 4-edge cemented carbide end mill with CVD coating | Vc-20–60 m/min ap-0.025–0.055 mm f-0.3–0.9 mm/rev |

| [48] | Milling (UVAM) | MQL | Vegetable oil-based cutting fluid | TC4 | - | N-600–2400 rpm ap-0.2 mm |

| [49] | Milling | MQL | Ionic liquid | Titanium alloy | Cubic boron nitride (CBN) inserts | Vc-120 m/min ap-0.1 mm f-0.5 mm/rev |

| [50] | Milling | MQL, Dry | Coolube 2210EP | Ti-6Al-4V | WC tool | N-20,000 rpm ap-10 μm f-0.1 mm/r |

| [51] | Grinding | MQL | Castor oil | Ti-6Al-4V | Abrasive belt | Vc-2–12 m/min f-0.5 mm/min |

| [52] | Turning | MQL, nano–MQL | Vegetable oil-based MQL, alumina suspended DI water-based nMQL | Ti-6Al-4V | Laser-textured cutting tools | Vc-60–12 m/min f-0.1–0.2 mm/rev dc-50 μm ap-1 mm afr-6 bar |

| Ref No. | Process | Coolant/Lubricant Strategy | Coolant/Lubricant Type | Workpiece | Tool | Cutting Parameters |

|---|---|---|---|---|---|---|

| [53] | Milling | Dry, scCO2, scCO2-WMQL, scCO2-OoWMQL | Antifreeze water droplets and oil-on-water droplets | Ti-6Al-4V | Cemented carbide flat end mill with diamond coating | Vc-20–60 m/min f-0.010 mm/rev ae-0.2 mm ap-3 mm |

| [54] | Milling | CO2-snow and MQL | Flood cooling: Castrol Syntilo-9913 + water (10:90); Subzero-MQL: Blaser SWISSLUBE oil + refrigerated air; CO2-snow | Ti-6Al-4V | FIRE-coated tungsten carbide end-mill EMC6210010 | Vc-90–10 m/min f-0.06–0.10 mm/tooth |

| [55] | Turning | Wet | Concentrated ZJ-846 was diluted in 1:20 proportion | Ti-6Al-4V | YG8 | Vc-22.7–90.4 (m/min) ap-0.1–0.4 (mm) f-0.2 (mm/rev) |

| [56] | Turning | Electrostatic-charged solid lubricant spray system (ECSL) | MoS2 solid lubricant, water-soluble synthetic oil | Ti-6Al-4V | Coated carbide cutting tool, CNMG 120412 | Vc-100 m/min ap-0.5 mm f-0.1 mm/rev |

| [57] | Turning | Nanofluid | Conventional coolant and 0.1–0.5 wt.%, graphene oxide-suspended fluid | Ti-6Al-4V | Polycrystalline cubic boron nitride (PCBN) | Vc-80–240 m/min ap-0.1 mm f-0.05–0.1 mm/rev |

| [58] | Turning | Wet (atomization-based cutting fluid (ACF)) | Mixture of air and CO2 (66:34) | Ti-6Al-4V | Uncoated micro crystalline carbide insert | Vc-100–150 m/min ap-0.06–0.1 mm f-0.04–0.06 mm/rev |

| [59] | Turning | Dry, Wet | Blasocut 4000, MWCNT-based nanofluid | Ti-6Al-4V | TiCN+Al2O3+TiN-coated carbide insert | Vc-90–150 m/min ap-1 mm f-0.1 mm/rev |

| [60] | Turning | HPC | Water soluble oil 6% in water | Ti-6Al-4V | Triangular cemented carbide inserts | Vc-200–500 m/min ap-0.05 mm f-0.005–0.015 mm/rev |

| [61] | Turning | Dry, HPC | Coolant at 80 bar pressure | Ti-6Al-4V | TiCN+Al2O3+TiN-coated carbide insert | Vc-78–156 m/min ap-1 mm f-0.12–0.16 mm/rev |

| [62] | Milling | Dry, flood, and atomization-based cutting fluid spray system | Water-soluble S-1001 at 10% dilution | Ti-6Al-4V | Uncoated carbide tool with 30˚ helix angle | N-1500 rpm ap-2 mm f-0.1–0.14 mm/tooth |

| [63] | Milling | Electrostatic atomization lubrication (EAL) and nanofluid electrostatic atomization lubrication (NFEAL) | LB2000 oil (MQL and EAL) and 0.5 wt.% graphite-LB2000 oil (NFEAL) | Ti-6Al-4V | Uncoated carbide inserts | Vc-100 m/min ap-0.5 mm f-0.1 mm/rev |

| [64] | Milling | Wet | 0.5 wt.% Fe2O3 in conventional cutting fluid | Ti-6Al-4V | YG6X-cemented carbide tool | N-1000–4000 rpm ap-0.6 mm f-0.06 mm/r |

| [65] | Milling | Electrostatic spraying, composite electrostatic spraying | LB2000 + deionized water | Titanium alloy | Uncoated carbide milling inserts (type: R390-11T308M-KM H13A) | Vc-70–130 m/min ap-0.2 mm f-0.5 mm/rev |

| [66] | Milling | Dry, Wet | 10% Hocut 795H oil in water | Ti-6Al-4V | Uncoated tungsten carbide | N-20,000–100,000 rpm ap-20 μm f-0.5–5 μm/r |

| [67] | Grinding | Air flow-assisted electrospray lubrication (AF-ESL) | Dry air, AF-ESL using nanofluid (0.2–0.8 wt.% nano diamond particle) | Titanium alloy | CBN grinding tool | N-50,000 rpm f-120 mm/min ap-0.005 mm |

| [68] | Drilling | Dry, Wet + MQL | Liquid CO2 | Ti-6Al-4V | SumiDrill SDP0300U3HAK with AlCrTiN coating | Vc-15 m/min (N = 1592 RPM) f-0.025 mm/rev |

| Ref No. | Process | Coolant/Lubricant Strategy | Coolant/Lubricant Type | Workpiece | Tool | Cutting Parameters |

|---|---|---|---|---|---|---|

| [69] | Turning | Cryogenic machining technologies | MQL oil with L CO2 | AISI 304 | TiN-coated carbide DNMG 150608-MM (GC2025) with chip-break | Vc-225 m/min f-0.25 mm/rev ap-1.5 mm |

| [70] | Drilling | Cryogenic machining | CO2 | Ti6Al4V grade 23 | TiAlN-coated carbide inserts | Vc-40 m/s f-0.03 mm/teeth ae-12, 3 mm ap-1, 0.1 mm |

| [71] | Turning | Cryogenic cooling | Liquid nitrogen (LN2) and carbon dioxide (CO2) | Ti-5553 Alloy | Uncoated 883 grade carbide inserts (CNMG120408-M1) | Vc-30 210 m/min f-0.12 mm/teeth ae-3 mm ap-0.2 mm |

| [72] | Turning | Dry, MQL, and cryo-MQL | MOL and liquid nitrogen (LN2) | Ti-6Al-4V Alloy | Uncoated carbide TNMA 220,412 inserts | Vc-80–120 m/min f-0.2 mm/rev a-1 mm |

| [73] | Drilling | Dry, CO2-cryogenic cooling | Liquefied CO2 | CFRP-Ti6Al4V stacks | Carbide tools coated with diamond CVD | Vc-70 and 15 m/min f-0.025 mm/teeth |

| [74] | Turning | Wet and cryogenic cooling | LN2 | Ti-6Al-4V | CNMG 120,408 PR1535 Megacoat Nano | Vc-70–110 m/min ap-0.5 mm f-0.3 mm/rev |

| [75] | Turning | Cryogenic cooling | LN2 | Ti-6Al-4V | uncoated H13A carbide inserts have been used (CCMT 12-04–08 KM) | Vc-80 m/min ap-1 mm f-0.2 mm/rev |

| [76] | Drilling | Dry cutting, traditional cooling (flood cooling), cryogenic cooling, and MQL | LN2 | Ti-6Al-4V | Micro-drill containing n 90% WC and 10% Co | N-1000–10,000 rev/min ap-3 mm f-5–70 mm/min |

| [77] | End Milling | Cryogenic | Liquid nitrogen (LN2) | Ti-6Al-4V | TiN-TiAlN-coated solid carbide | Vc-30–200 (m/min) ap-1–5 (mm) f-0.03–0.1 (mm/tooth) |

| [78] | Milling | Dry, cryogenic cooling, | LN2 | Ti-6Al-4V | PVD-coated carbide inserts | Vc-20–50 m/min ap-0.05–0.15 mm f-0.1–0.2 mm/tooth |

| [79] | Turning | Dry, MQL, LN2, Hybrid (LN2 and MQL) | LN2 | Ti-6Al-4V | Uncoated carbide tool inserts, TPG432 k313 | Vc-100 m/min Uncut chip thickness-0.06 |

| [80] | Turning | Dry, MQL, Cryogenic | - | Ti-6Al-4V | - | - |

| Ref No. | Process | Coolant/Lubricant Strategy | Coolant/Lubricant Type | Workpiece | Tool | Cutting Parameters |

|---|---|---|---|---|---|---|

| [81] | Milling | MQL and cryogenic gas (CryoMQL) | MQL oil microdroplets with liquefied CO2 gas | Inconel 718 | TiN-coated carbide inserts | Vc-120 m /min f-0.12 mm/teeth ae-3 mm ap-0.2 mm |

| [82] | Milling | Cryogenic MQL | CO2 | Ti-6Al-4V | Four-edged carbide end mill | Vc-70; 130 m/min fz-0,04 mm ap-2 mm ae-2 mm |

| [83] | Turning | Cryogenic + MQL | LN2 + vegetable oil | Ti-6Al-4V | Rhombic shape CNMG 120408 | Vc-100–150 m/min ap-0.5 mm f-0.05–0.15 mm/rev |

| [84] | Turning | Cryogenic + MQL | LN2 | Ti-6Al-4V | Diamond tool | N-500–2000 ap-0.06 mm f-0.08 mm/rev |

| [85] | Turning | Oil in water (OoW), Hybrid, wet, dry | Fatty alcohol, synthetic ester | Ti-6Al-4V | Coated carbide tool | Vc-70–110 m/min ap-1 mm f-0.25 mm/rev |

| [86] | Turning | Dry, wet, MQL, Cryogenic, Hybrid | Semi synthetic oil (wet), Bechem Berecut MQL A20, LN2,LCO2 (cryogenic) | Ti-6Al-4V | WC insert with TiAlN-coated tool | Vc-80 m/min ap-0.25 mm f-0.2 mm/rev |

| [87] | Turning | Dry, MQL, hybrid mist cooling (HMC) | UE-3, CO-1 (MQL), vegetable-based oil (HMC) | Ti-6Al-4V | JIS K10-cemented carbide tool | Vc-80 m/min ap-0.5 mm f-0.15 mm/rev |

| [88] | Drilling | Dry, flood cooling, cryogenic | Dry, flood, cryogenic (LCO2 and LN2) | VT-20 | Solid carbide (coating KC05) | Vc-80 m/min f-100 mm/min |

| [89] | End Milling | Hybrid cryogenic, flood, cryogenic, MQL | Flood cooling-water based, MQL-rapeseed oil, cryogenic-LN2, hybrid combination of MQL and Cryogenic | Ti-6Al-4V | TiSiN coated | Vc-90–180 (m/min) |

| [90] | End Milling | Flood cooling, hybrid cryogenic | Flood coolants, MQL with nanoparticles, external cryogenic, internal cryogenic, Nano-MQL + internal cryogenic and Nano-MQL + indirect cryogenic | Ti-6Al-4V | AlCrN | Vc-86 m/min ap-24.5 mm f-1026 mm/min width of cut-1.2 mm |

| [91] | Milling | Hybrid, flood cooling | MQL + hBN nanoparticle + cryogenic, flood | Ti-6Al-4V | AlCrN-coated tool | Vc-72–86 m/min f-0.1 mm/rev ap-24.5 mm ae-1.2 mm |

| [92] | Micro-end-milling process | Hybrid | Nanodiamond fluid MQL, gas CO2 | Ti-6Al-4V | WC | N-45,000 rpm ap-100 μm |

| [93] | Milling | Cryo-MQL | (LN2/CO2/MQL) | Ti-6Al-4V | - | Vc-100–175 m/min ap-0.5 mm f-0.3 mm/rev |

| [94] | Grooving | Hybrid cryogenic | CO2 snow, vegetable-based MQL, hybrid | Ti-10V-2Fe-3Al | Carbide coated | Vc-50,100 m/min f-0.1 mm/min |

| [95] | Turning | Conventional flood coolant with MQL, Cryogenic coolant | Canola-based vegetable oil, liquid CO2 | Ti-6Al-4V | TiAlN-coated carbide inserts (VNMG110404 FN) | Vc-75 m/min ap-1 mm f-0.3 mm/rev |

| [96] | Milling | CryoMQL | CO2 | Ti6Al4V | Polycrystalline diamond (PCD) tools | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumari, S.; Shah, M.; Modi, Y.; Bandhu, D.; Zadafiya, K.; Abhishek, K.; Saxena, K.K.; Msomi, V.; Mohammed, K.A. Effect of Various Lubricating Strategies on Machining of Titanium Alloys: A State-of-the-Art Review. Coatings 2022, 12, 1178. https://doi.org/10.3390/coatings12081178

Kumari S, Shah M, Modi Y, Bandhu D, Zadafiya K, Abhishek K, Saxena KK, Msomi V, Mohammed KA. Effect of Various Lubricating Strategies on Machining of Titanium Alloys: A State-of-the-Art Review. Coatings. 2022; 12(8):1178. https://doi.org/10.3390/coatings12081178

Chicago/Turabian StyleKumari, Soni, Meet Shah, Yug Modi, Din Bandhu, Kishan Zadafiya, Kumar Abhishek, Kuldeep K. Saxena, Velaphi Msomi, and Kahtan A. Mohammed. 2022. "Effect of Various Lubricating Strategies on Machining of Titanium Alloys: A State-of-the-Art Review" Coatings 12, no. 8: 1178. https://doi.org/10.3390/coatings12081178

APA StyleKumari, S., Shah, M., Modi, Y., Bandhu, D., Zadafiya, K., Abhishek, K., Saxena, K. K., Msomi, V., & Mohammed, K. A. (2022). Effect of Various Lubricating Strategies on Machining of Titanium Alloys: A State-of-the-Art Review. Coatings, 12(8), 1178. https://doi.org/10.3390/coatings12081178