Processing and Advancements in the Development of Thermal Barrier Coatings: A Review

Abstract

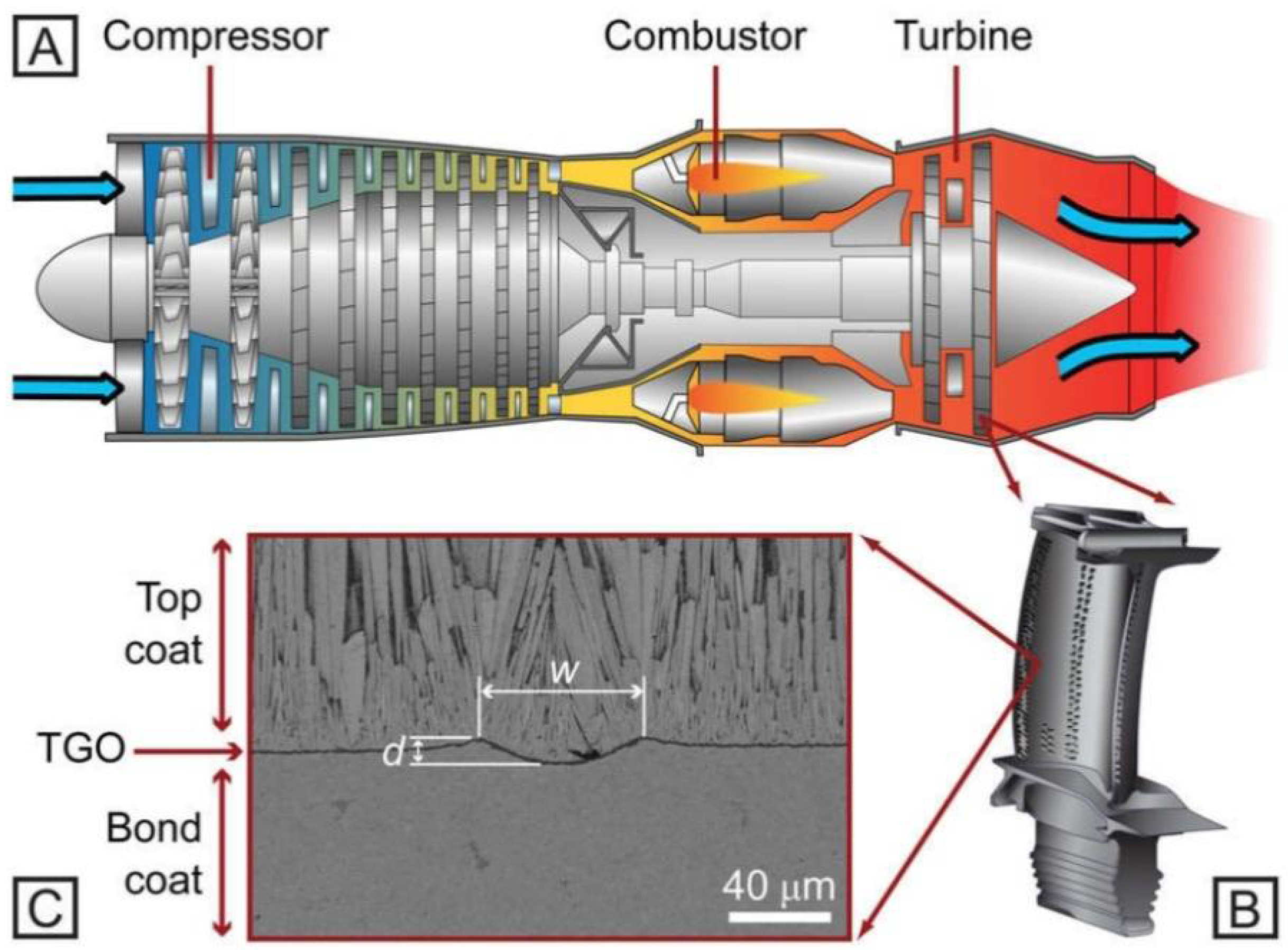

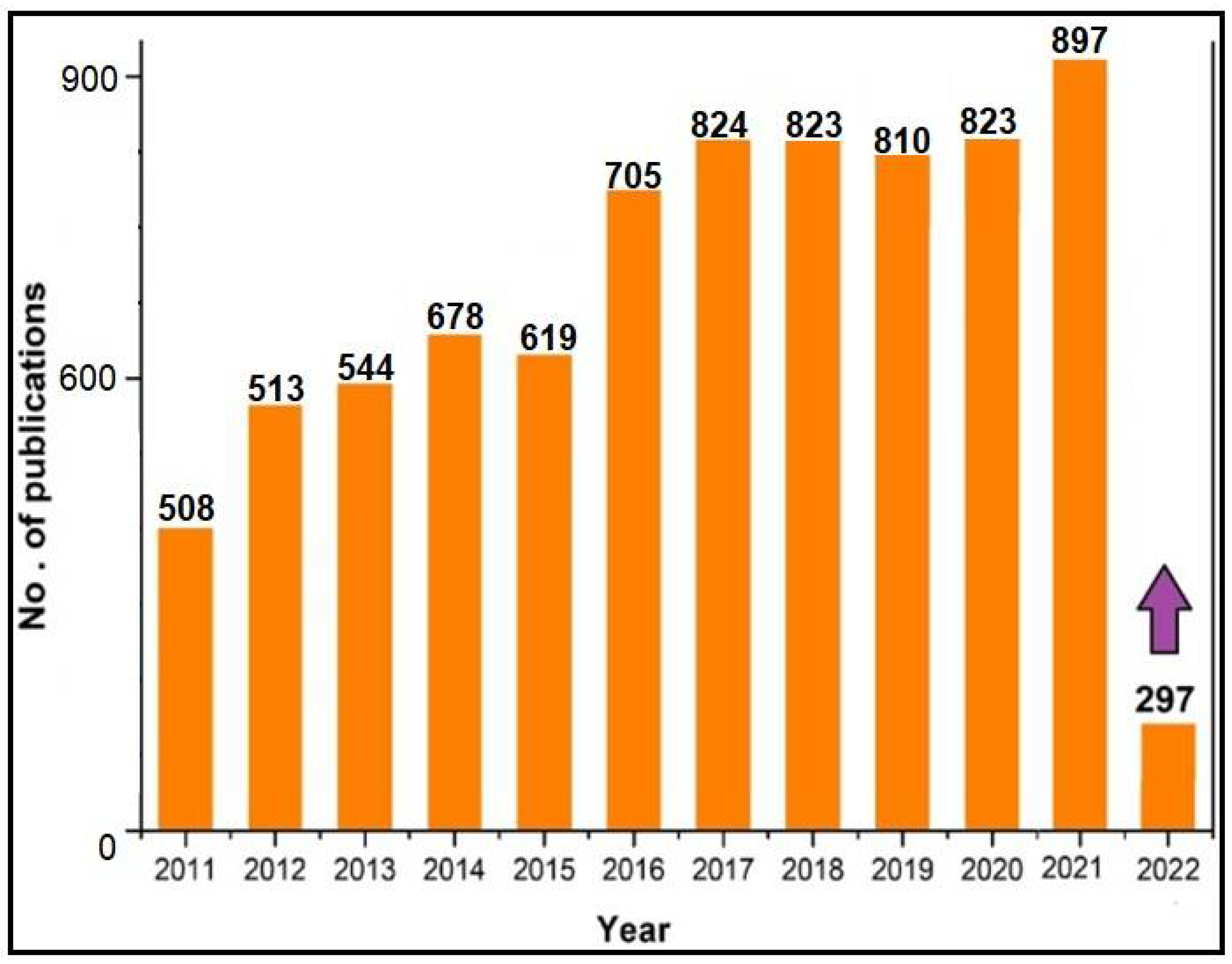

:1. Introduction

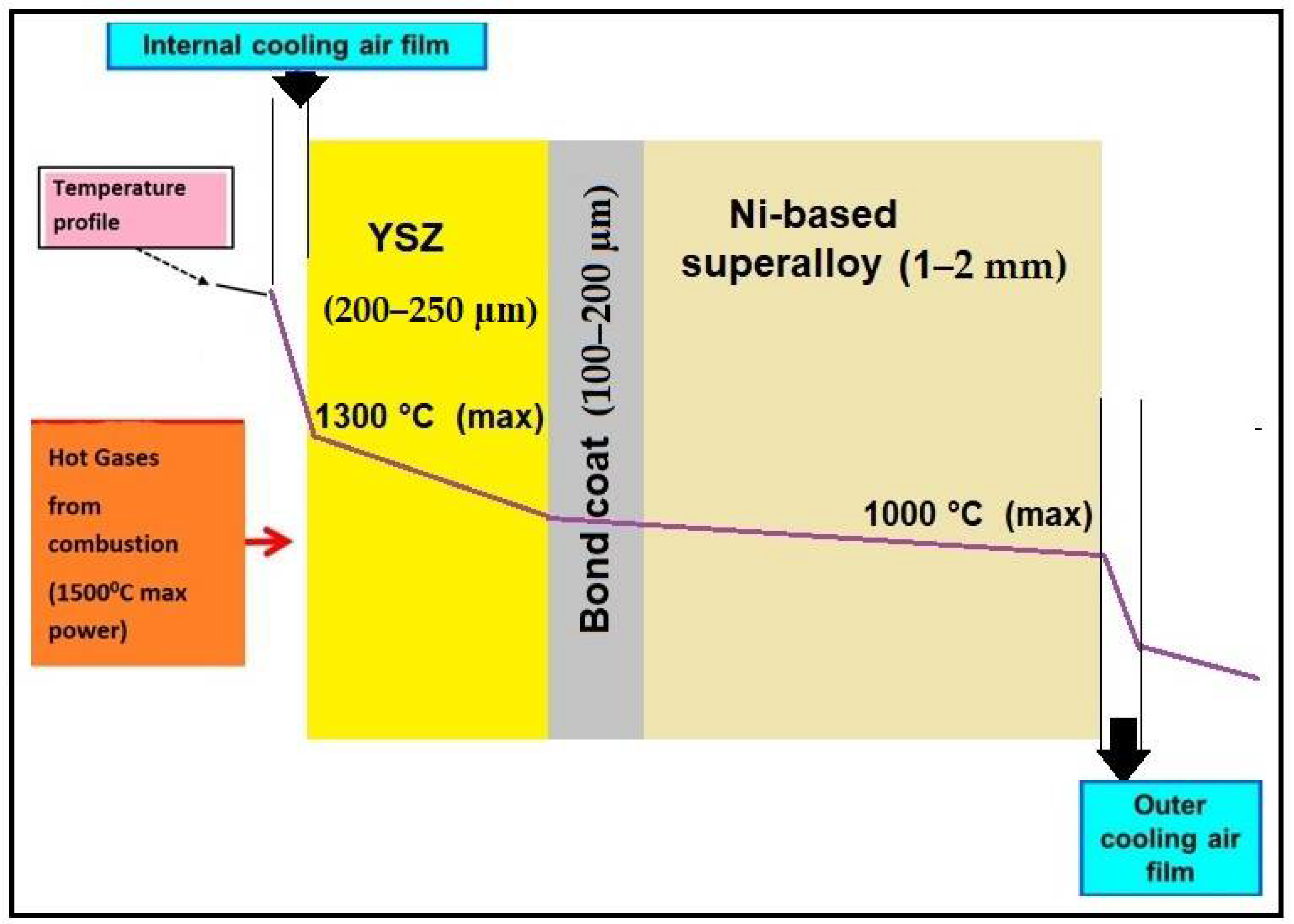

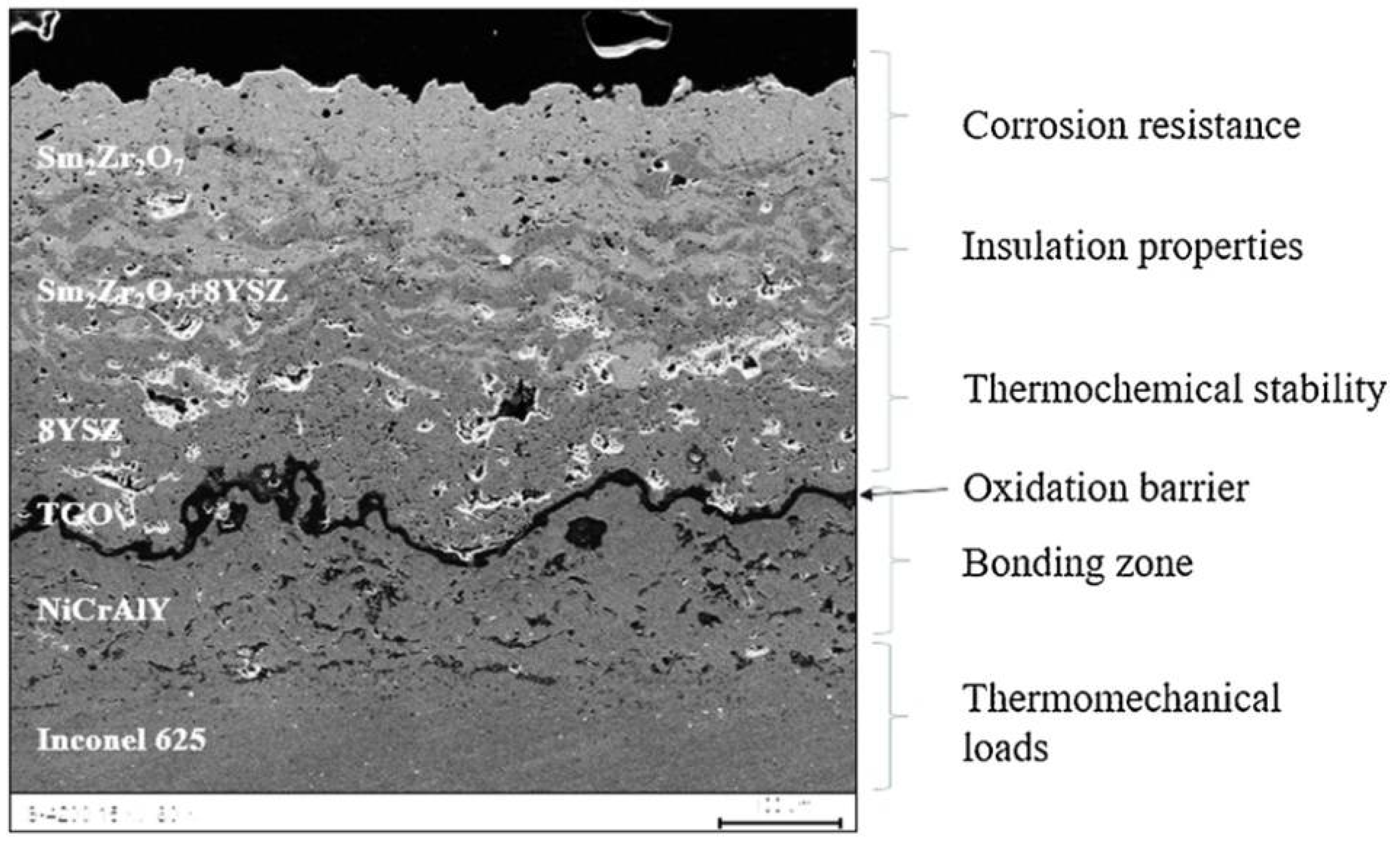

2. Thermal Barrier Coating System

2.1. Material in a TBC System

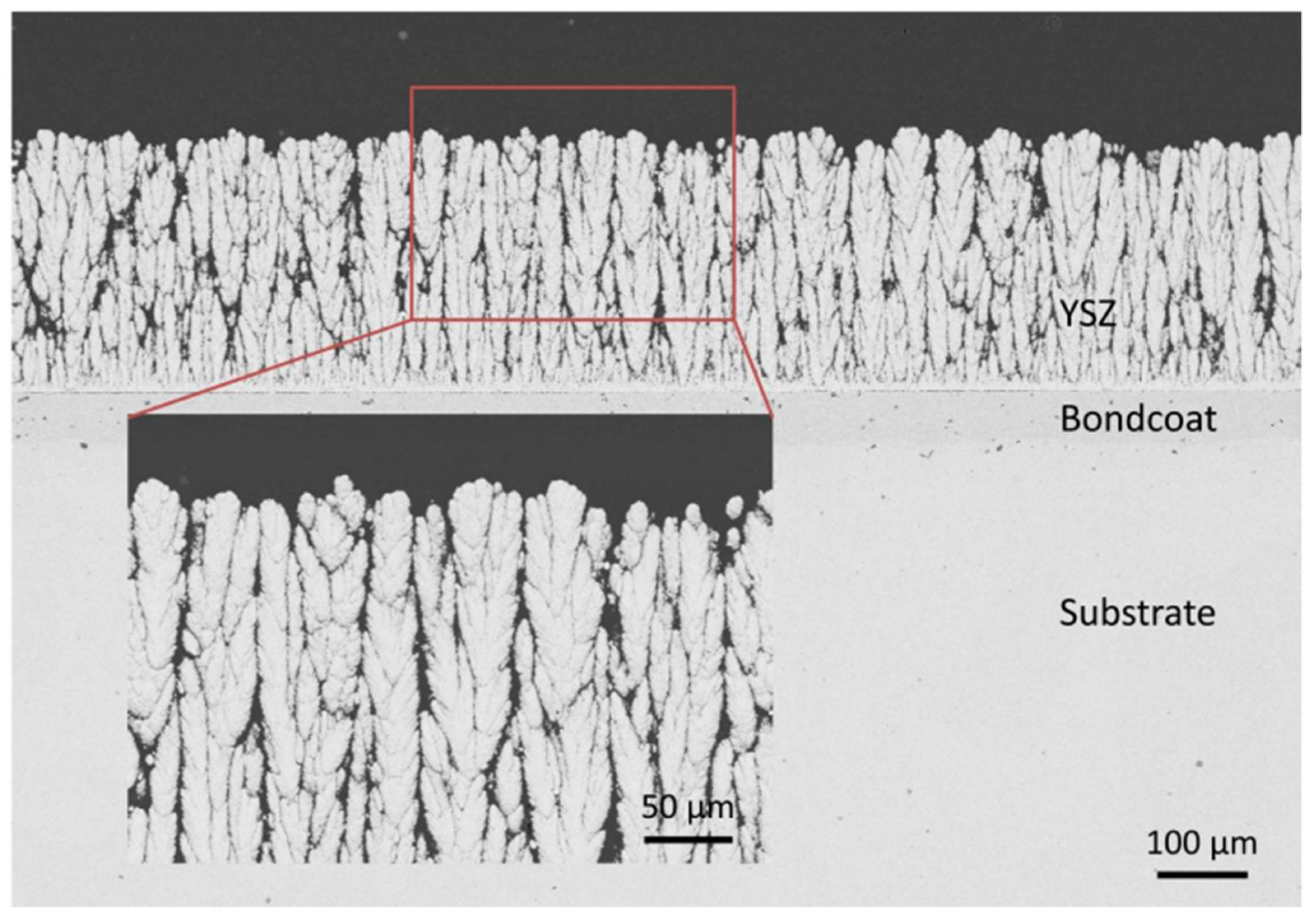

2.1.1. TopCoat

2.1.2. Bond Coat

2.2. TBC Processing Methods

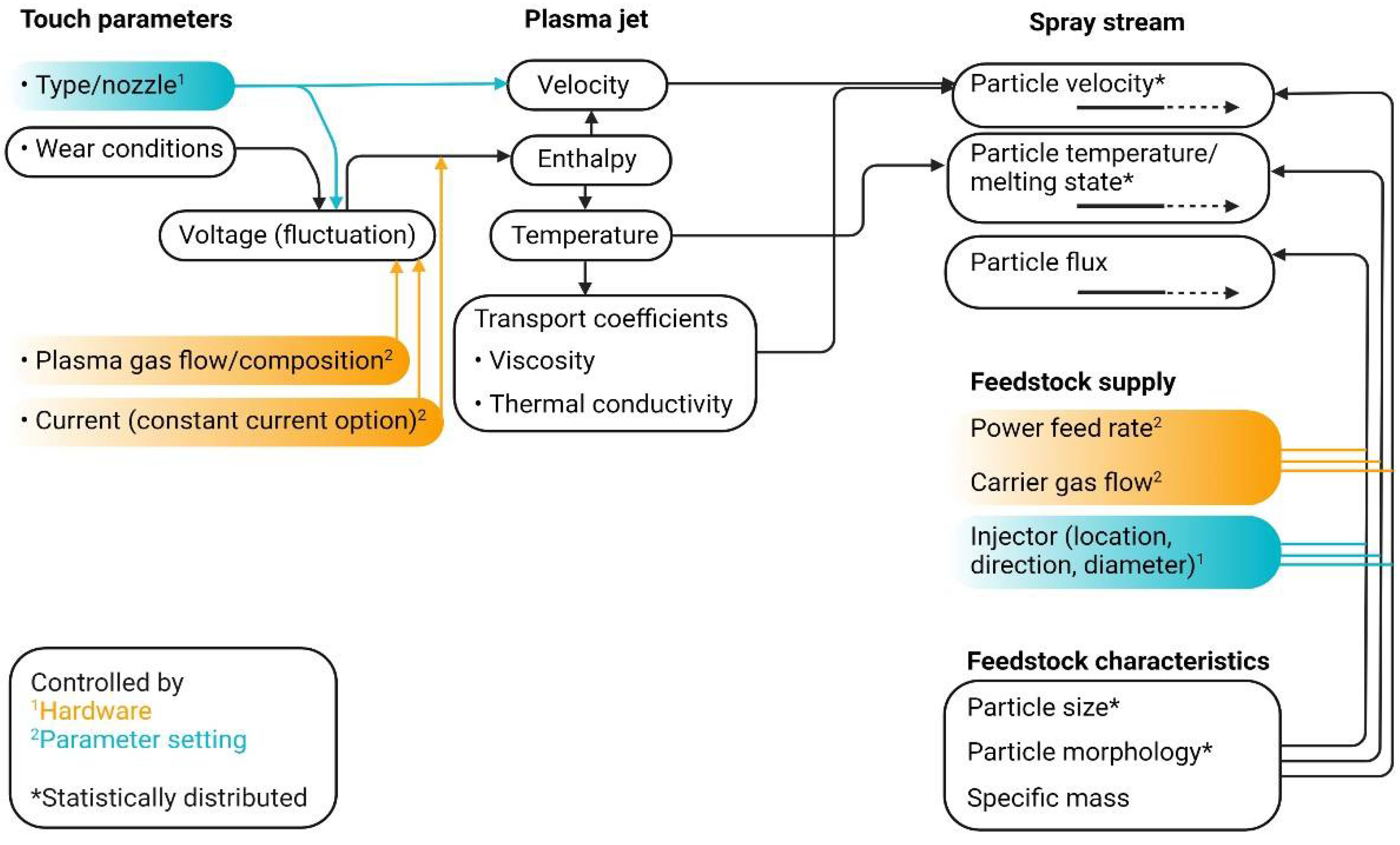

2.2.1. Air Plasma Spray (APS)

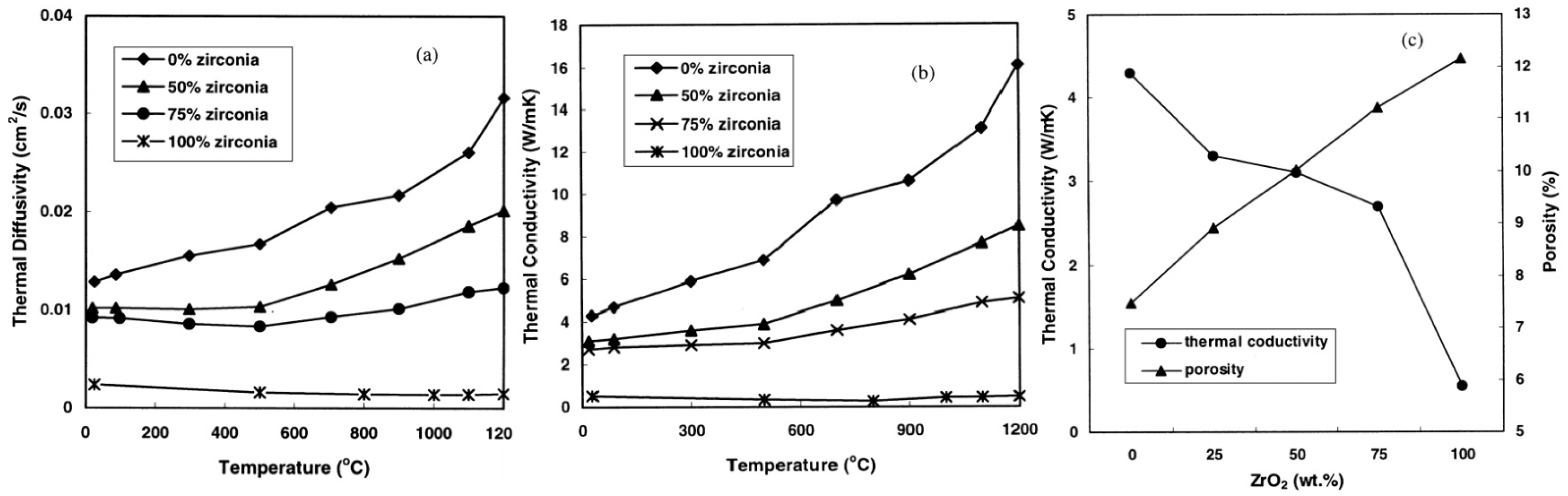

2.2.2. Functionally Graded Coatings

2.2.3. Multi-Layered Coatings

2.2.4. Suspension Plasma Spraying (SPS)

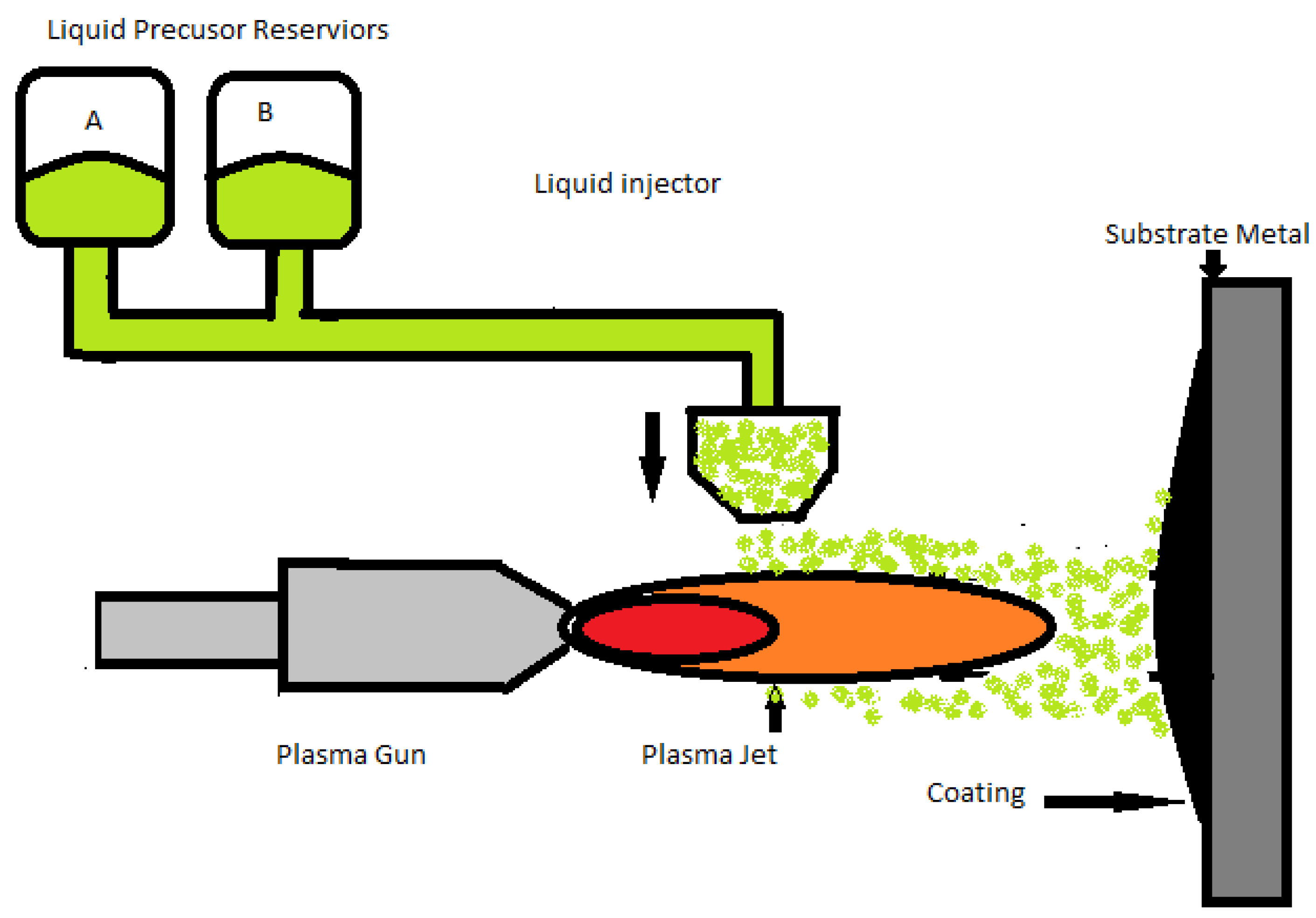

2.2.5. Solution Precursor Plasma Spray (SPPS)

2.2.6. Plasma Spraying-Physical Vapor Deposition (PS-PVD)

3. Failure Mechanism in Thermal Barrier Coatings

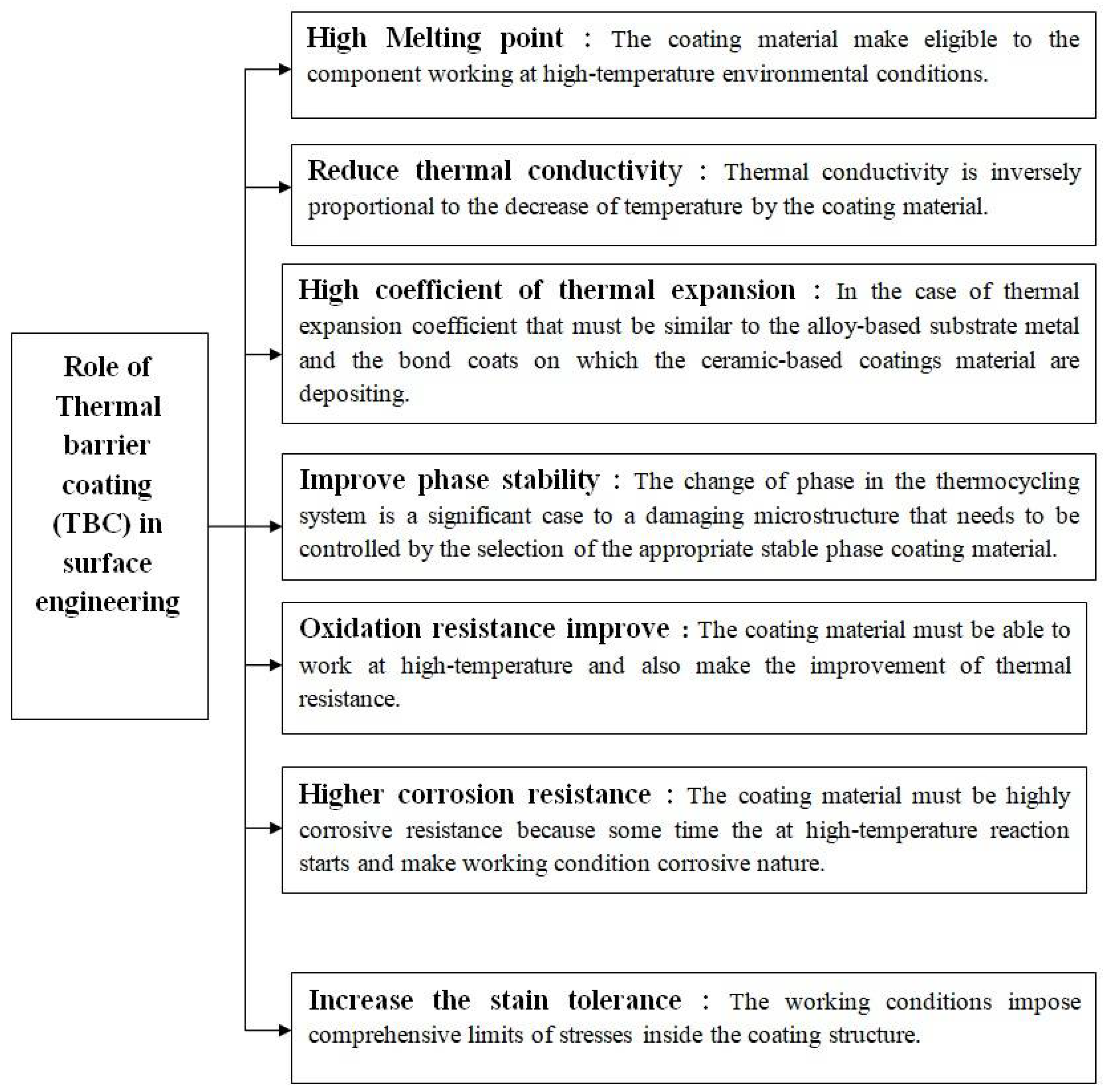

3.1. Some Challenges and Required Properties in the Selection of Coating Material

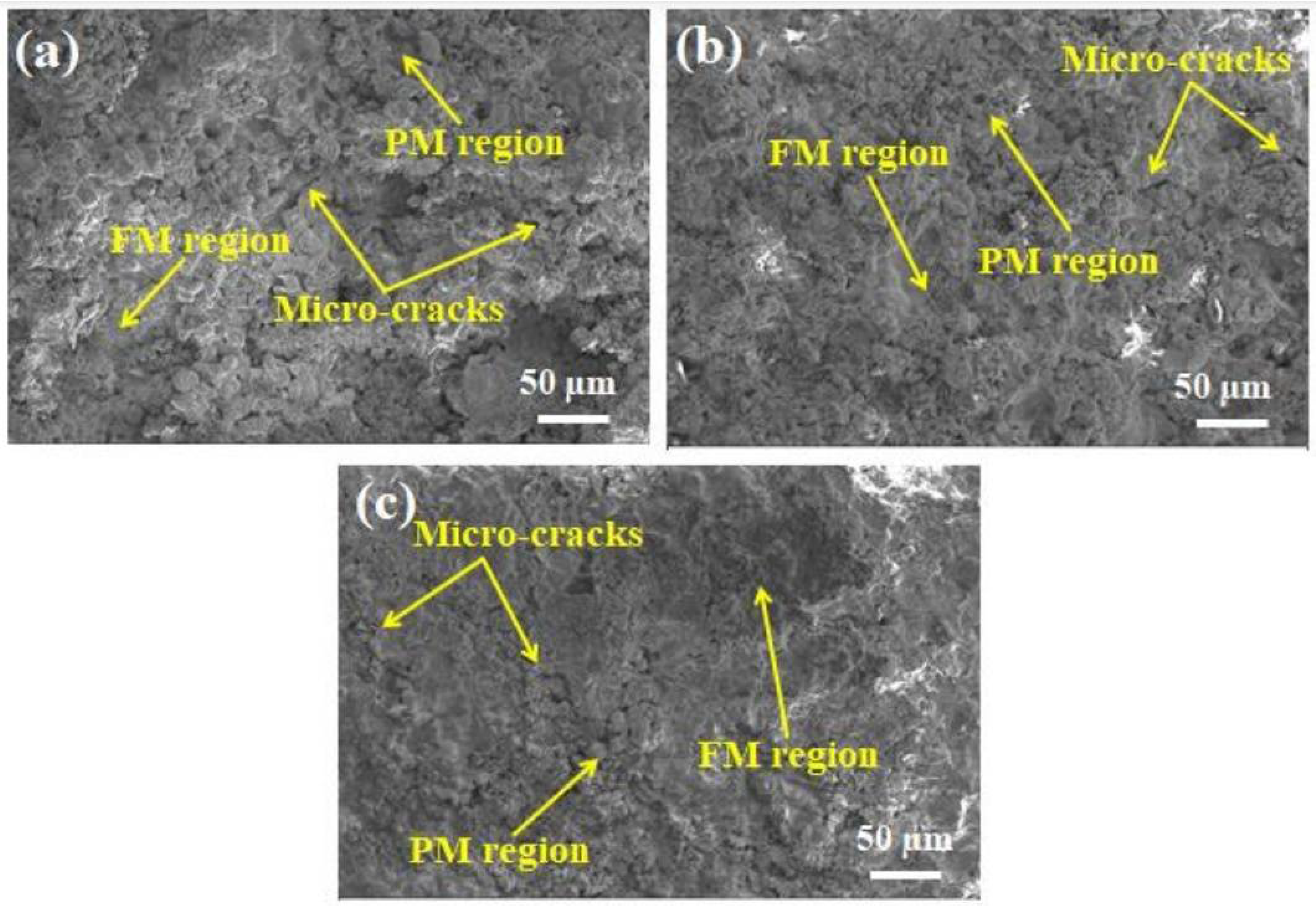

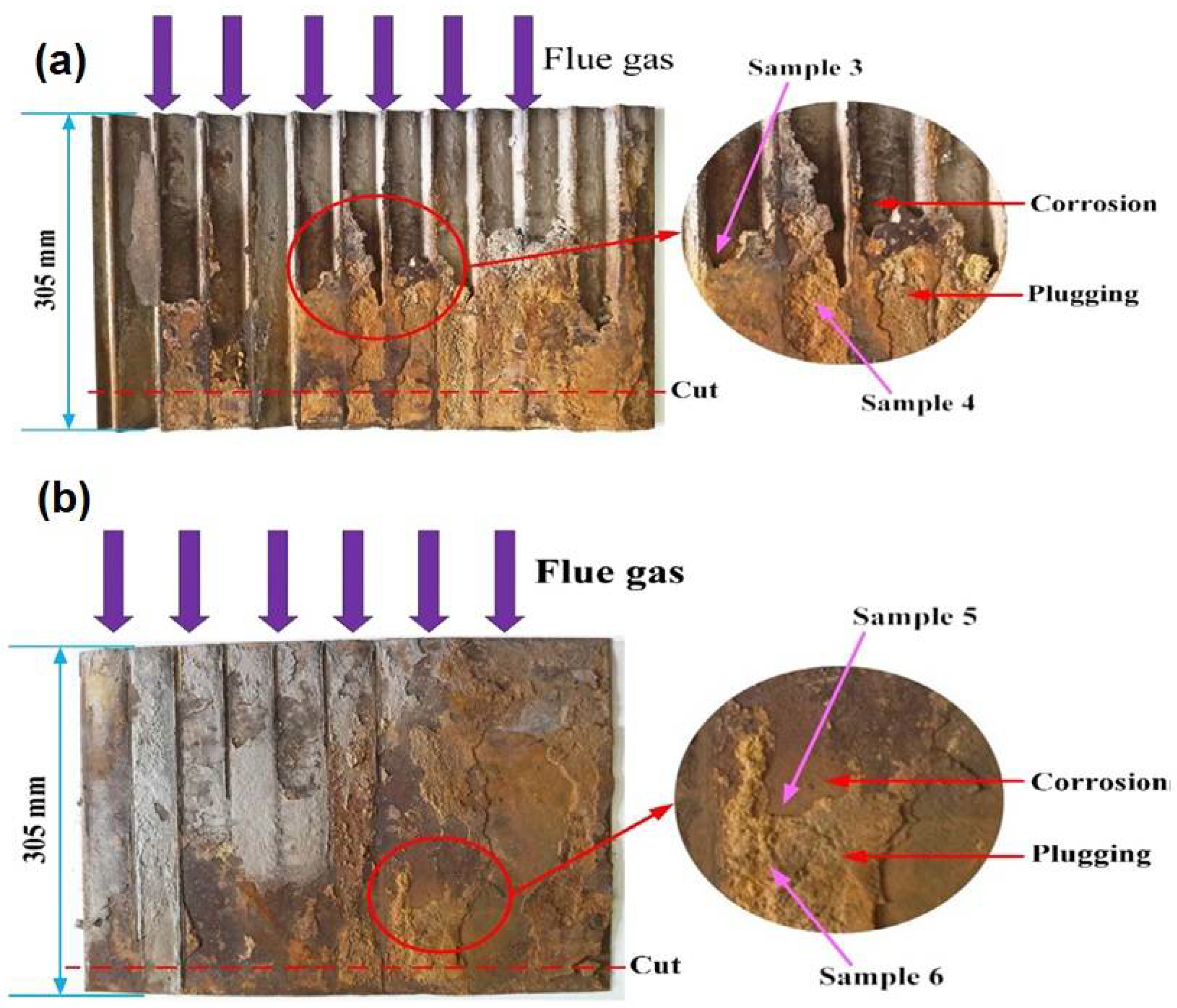

3.1.1. Hot Corrosion

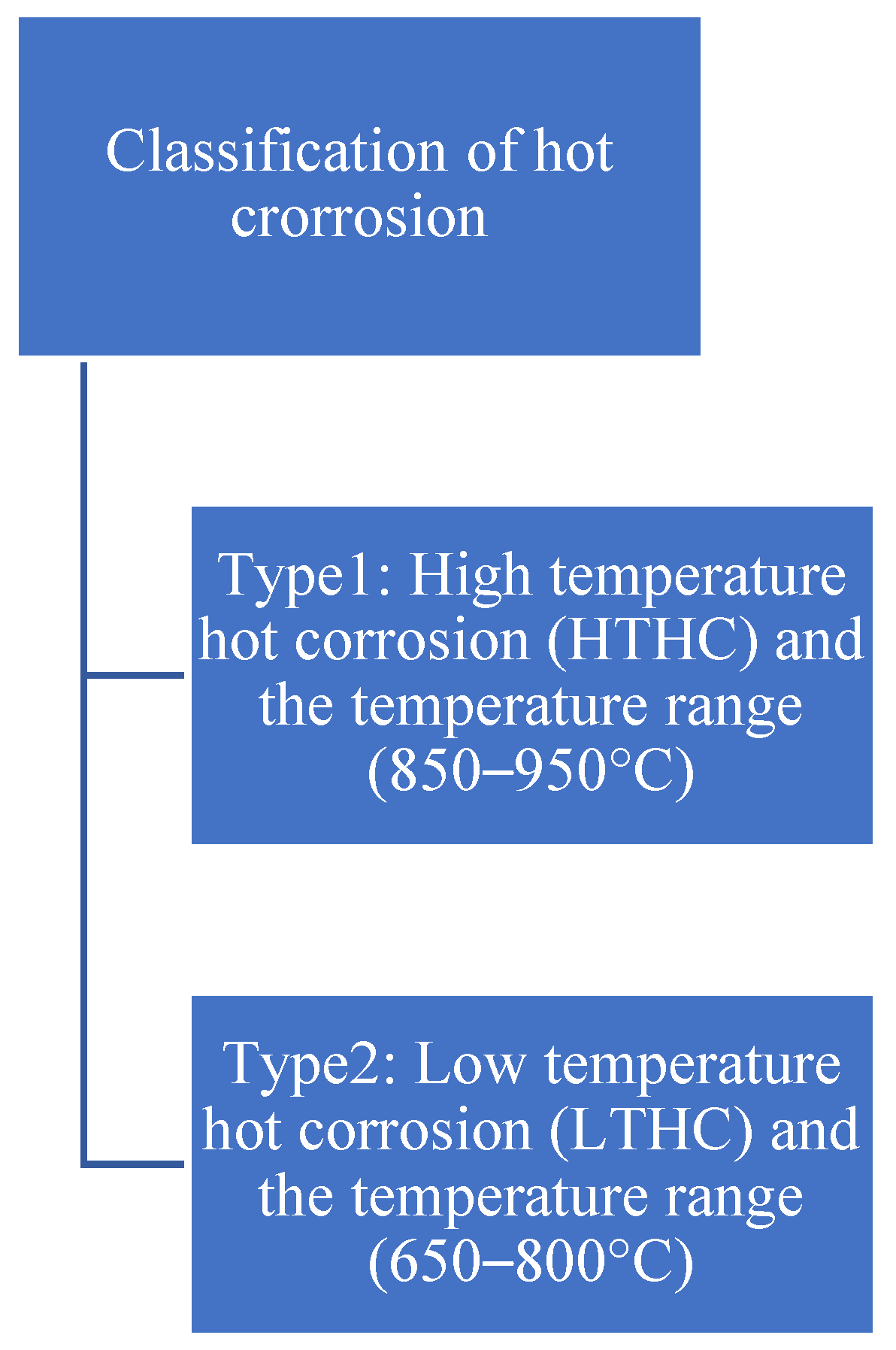

Different Kinds of Hot Corrosion

- (a)

- High-temperature hot corrosion (HTHC)

- (b)

- Low-temperature hot corrosion (LTHC)

Mechanism of Hot Corrosion and Stages

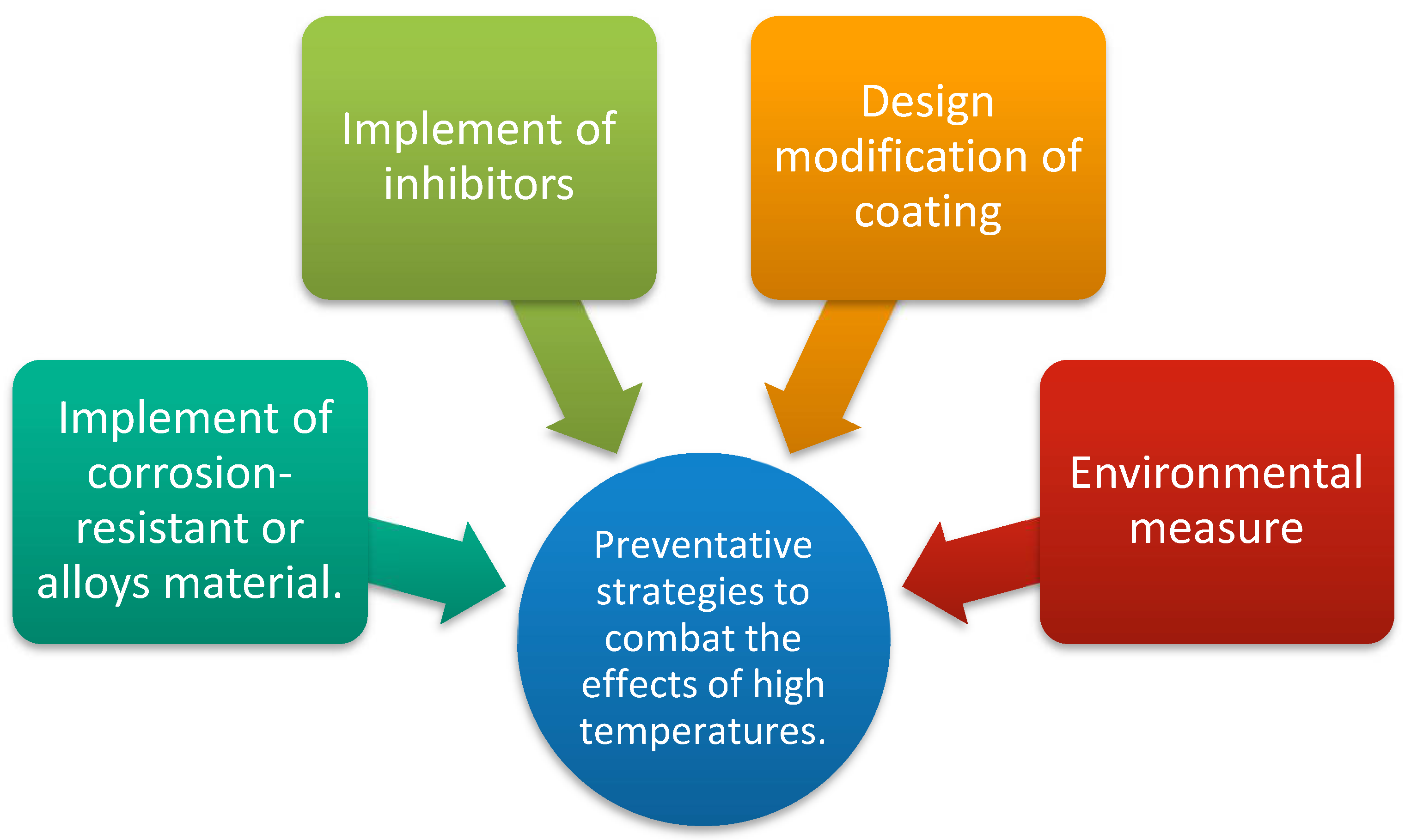

Preventive Strategies to Combat the Effect of High Temperature

Composite Coating Hot Corrosion Behavior

3.1.2. Thermal Oxidation Performance

3.1.3. Recent Approach Use for Improving Hardness and Toughness Values

4. Perspectives and Summary

- It discusses the context and applications of TBCs, the elements of a traditional TBC framework and their function and required properties.

- A TBC system’s output is closely related to the methods used in its development. Different processing techniques and advancements in material depositing methods have versatile tailoring of their microstructure and combinations for special engineering applications.

- Approaches used to TBC design and coating materials. Develop TBC; the different design methodologies are implemented to address the coating’s working specifications and stability. Those involve functionally graded coating, composite coating, and multi-layered coating arrangements, which are also discussed in this review.

- Some challenges of TBC include improving performance during testing thermal oxidation, mechanical properties, such as hardness and toughness, and hot corrosion obtained from different coating materials and other material deposition techniques.

- The recommendations for thermal barrier coatings include the use of electron beam-physical vapor deposition (EB-PVD) or plasma spray. Both of these processes can best rain compliant, have low thermal conductivity, and generate erosion-resistant coatings whose microstructures can be tailored for the desired application. Moreover, the composition of the top coat can vary with the addition of other phases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anheden, M. Analysis of Gas Turbine Systems for Sustainable Energy Conversion. Ph.D. Thesis, KTH, Stockholm, Sweden, 2000. [Google Scholar]

- Gupta, K.; Rehman, A.; Sarviya, R. Bio-fuels for the gas turbine: A review. Renew. Sustain. Energy Rev. 2010, 14, 2946–2955. [Google Scholar] [CrossRef]

- Myoung, S.-W.; Lee, S.-S.; Kim, H.-S.; Kim, M.-S.; Jung, Y.-G.; Jung, S.-I.; Woo, T.-K.; Paik, U. Effect of post heat treatment on thermal durability of thermal barrier coatings in thermal fatigue tests. Surf. Coat. Technol. 2013, 215, 46–51. [Google Scholar] [CrossRef]

- Ahmaniemi, S.; Vuoristo, P.; Mäntylä, T.; Gualco, C.; Bonadei, A.; Di Maggio, R. Thermal cycling resistance of modified thick thermal barrier coatings. Surf. Coat. Technol. 2005, 190, 378–387. [Google Scholar] [CrossRef]

- Bhatia, T.; Ozturk, A.; Xie, L.; Jordan, E.H.; Cetegen, B.M.; Gell, M.; Ma, X.; Padture, N. Mechanisms of ceramic coating deposition in solution-precursor plasma spray. J. Mater. Res. 2002, 17, 2363–2372. [Google Scholar] [CrossRef]

- Hille, T.S.; Nijdam, T.J.; Suiker, A.S.; Turteltaub, S.; Sloof, W.G. Damage growth triggered by interface irregularities in thermal barrier coatings. Acta Mater. 2009, 57, 2624–2630. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Boyce, M. Gas Turbine Engineering Handbook, 4th ed.; Elsevier Inc.: Cambridge, MA, USA, 2012. [Google Scholar]

- Bose, S. High Temperature Coatings; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Kaysser, W. Surface Modifications in Aerospace Applications. Surf. Eng. 2001, 17, 305–312. [Google Scholar] [CrossRef]

- Ahmad, A.; Khan, S.; Tariq, S.; Luque, R.; Verpoort, F. Self-sacrifice MOFs for heterogeneous catalysis: Synthesis mechanisms and future perspectives. Mater. Today 2022, 55, 137–169. [Google Scholar] [CrossRef]

- Shankar, A.R.; Bellam, J.B.; Sole, R.; Mudali, U.K.; Khatak, H.S. Laser remelting of plasma sprayed zirconia based ceramic coating for pyrochemical reprocessing applications. Surf. Eng. 2007, 23, 147–154. [Google Scholar] [CrossRef]

- Jamali, H.; Mozafarinia, R.; Razavi, R.S.; Ahmadi-Pidani, R. Comparison of thermal shock resistances of plasma-sprayed nanostructured and conventional yttria stabilized zirconia thermal barrier coatings. Ceram. Int. 2012, 38, 6705–6712. [Google Scholar] [CrossRef]

- Weng, W.-X.; Zheng, Z.-H.; Li, Q. Cracking evolution of atmospheric plasma-sprayed YSZ thermal barrier coatings subjected to isothermal heat treatment. Surf. Coat. Technol. 2020, 402, 125924. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, Y.H.; Wang, Z.; Fu, Q.Q.; Han, Z.H. Influence of unmelted nanoparticles on properties of YSZ nano-coatings. Surf. Eng. 2014, 30, 568–572. [Google Scholar] [CrossRef]

- Pourbafrani, M.; Razavi, R.S.; Bakhshi, S.R.; Loghman-Estarki, M.R.; Jamali, H. Effect of microstructure and phase of nanostructured YSZ thermal barrier coatings on its thermal shock behaviour. Surf. Eng. 2014, 31, 64–73. [Google Scholar] [CrossRef]

- Lima, R.; Marple, B.R. Nanostructured YSZ thermal barrier coatings engineered to counteract sintering effects. Mater. Sci. Eng. A 2008, 485, 182–193. [Google Scholar] [CrossRef]

- Deng, W.; Zhao, X.; An, Y.; Chen, J.; Zhou, H. Study on preparation and tribological properties of as-sprayed 8YSZ/Graphite coating. Surf. Eng. 2019, 36, 1097–1106. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, Y. Deposition of nanostructured YSZ coating from spray-dried particles with no heat treatment. Appl. Surf. Sci. 2015, 346, 406–414. [Google Scholar] [CrossRef]

- Aruna, S.T.; Srinivas, G. Wear and corrosion resistant properties of electrodeposited Ni composite coating containing Al2O3–TiO2 composite powder. Surf. Eng. 2015, 31, 708–713. [Google Scholar] [CrossRef]

- Wang, J.; Sun, J.; Zhang, H.; Dong, S.; Jiang, J.; Deng, L.; Zhou, X.; Cao, X. Effect of spraying power on microstructure and property of nanostructured YSZ thermal barrier coatings. J. Alloys Compd. 2018, 730, 471–482. [Google Scholar] [CrossRef]

- Da, B.; Yongxin, G.; Yaxuan, L.; Yongguang, W.; Yongwu, Z. Mechanical behaviour of graded chemically bonded ceramic coating. Surf. Eng. 2020, 37, 618–623. [Google Scholar] [CrossRef]

- Gao, M.; Xu, N.; Zhang, J.; Luan, S.; Chang, H.; Hou, W.; Chang, X. Influence of mechanical properties on thermal shock resistance of TBCs. Surf. Eng. 2020, 37, 572–580. [Google Scholar] [CrossRef]

- Wang, H.-X.; Zhang, Y.; Cheng, J.-L.; Li, Y.-S. High temperature oxidation resistance and microstructure change of aluminized coating on copper substrate. Trans. Nonferrous Met. Soc. China 2015, 25, 184–190. [Google Scholar] [CrossRef]

- Che, C.; Wu, G.Q.; Qi, H.Y.; Huang, Z.; Yang, X.G. Effect of bond coat surface roughness on oxidation behaviour of air plasma sprayed thermal barrier coatings. Surf. Eng. 2008, 24, 276–279. [Google Scholar] [CrossRef]

- Staia, M.H.; Mejias, A.; La Barbera, J.; Puchi-Cabrera, E.; Villalobos-Gutierrez, C.; Santana, Y.Y.; Montagne, A.; Iost, A.; Rodriguez, M.A. Mechanical properties of WC/Co-CNT HVOF sprayed coatings. Surf. Eng. 2018, 36, 1156–1164. [Google Scholar] [CrossRef]

- Ghosh, D.; Das, S.; Roy, H.; Mitra, S.K. Oxidation behaviour of nanostructured YSZ plasma sprayed coated Inconel alloy. Surf. Eng. 2016, 34, 22–29. [Google Scholar] [CrossRef]

- Yin, B.; Zhou, H.D.; Yi, D.L.; Chen, J.M.; Yan, F.Y. Microsliding wear behaviour of HVOF sprayed conventional and nanostructured WC–12Co coatings at elevated temperatures. Surf. Eng. 2010, 26, 469–477. [Google Scholar] [CrossRef]

- Cetegen, B.M.; Yu, W. In-situ particle temperature, velocity, and size measurements in DC arc plasma thermal sprays. J. Therm. Spray Technol. 1999, 8, 57–67. [Google Scholar] [CrossRef]

- Han, M.-C.; Cai, S.-Z.; Wang, J.; He, H.-W. Single-Side Superhydrophobicity in Si3N4-Doped and SiO2-Treated Polypropylene Nonwoven Webs with Antibacterial Activity. Polymers 2022, 14, 2952. [Google Scholar] [CrossRef]

- Das, D.; Sivakumar, R. Modelling of the temperature and the velocity of ceramic powder particles in a plasma flame—II. Zirconia. Acta Met. Mater. 1990, 38, 2193–2198. [Google Scholar] [CrossRef]

- Shin, D.; Hamed, A. Influence of micro–structure on erosion resistance of plasma sprayed 7YSZ thermal barrier coating under gas turbine operating conditions. Wear 2018, 396–397, 34–47. [Google Scholar] [CrossRef]

- Mehta, A.; Vasudev, H.; Singh, S. Recent developments in the designing of deposition of thermal barrier coatings—A review. Mater. Today Proc. 2020, 26, 1336–1342. [Google Scholar] [CrossRef]

- Kulkarni, A.; Vaidya, A.; Goland, A.; Sampath, S.; Herman, H. Processing effects on porosity-property correlations in plasma sprayed yttria-stabilized zirconia coatings. Mater. Sci. Eng. A 2003, 359, 100–111. [Google Scholar] [CrossRef]

- Huang, J.B.; Wang, W.Z.; Li, Y.J.; Fang, H.J.; Ye, D.D.; Zhang, X.C.; Tu, S.T. A novel strategy to control the microstructure of plasma-sprayed YSZ thermal barrier coatings. Surf. Coat. Technol. 2020, 402, 126304. [Google Scholar] [CrossRef]

- Mukherjee, B.; Islam, A.; Pandey, K.K.; Rahman, O.A.; Kumar, R.; Keshri, A.K. Impermeable CeO2 overlay for the protection of plasma sprayed YSZ thermal barrier coating from molten sulfate-vanadate salts. Surf. Coat. Technol. 2018, 358, 235–246. [Google Scholar] [CrossRef]

- Kane, K.; Lance, M.; Sweet, M.; Pint, B. The effect of bond coating surface modification on the performance of atmospheric plasma spray thermal barrier coatings. Surf. Coat. Technol. 2019, 378, 125042. [Google Scholar] [CrossRef]

- Shi, M.; Xue, Z.; Zhang, Z.; Ji, X.; Byon, E.; Zhang, S. Effect of spraying powder characteristics on mechanical and thermal shock properties of plasma-sprayed YSZ thermal barrier coating. Surf. Coat. Technol. 2020, 395, 125913. [Google Scholar] [CrossRef]

- Limarga, A.M.; Widjaja, S.; Yip, T.H. Mechanical properties and oxidation resistance of plasma-sprayed multilayered Al2O3/ZrO2 thermal barrier coatings. Surf. Coat. Technol. 2005, 197, 93–102. [Google Scholar] [CrossRef]

- Tailor, S.; Modi, A.; Modi, S. Effect of controlled segmentation on the thermal cycling behavior of plasma sprayed YSZ thick coatings. Ceram. Int. 2018, 44, 6762–6768. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, X.; Kou, L.; Zheng, L.; Zhang, H. Prediction of control parameters corresponding to in-flight particles in atmospheric plasma spray employing convolutional neural networks. Surf. Coat. Technol. 2020, 394, 125862. [Google Scholar] [CrossRef]

- Li, G.-R.; Cheng, B.; Yang, G.-J.; Li, C.-X. Strain-induced stiffness-dependent structural changes and the associated failure mechanism in TBCs. J. Eur. Ceram. Soc. 2017, 37, 3609–3621. [Google Scholar] [CrossRef]

- Xu, Z.; He, L.; Mu, R.; Zhong, X.; Zhang, Y.; Zhang, J.; Cao, X. Double-ceramic-layer thermal barrier coatings of La2Zr2O7/YSZ deposited by electron beam-physical vapor deposition. J. Alloys Compd. 2009, 473, 509–515. [Google Scholar] [CrossRef]

- Polat, A.; Sarikaya, O.; Celik, E. Effects of porosity on thermal loadings of functionally graded Y2O3–ZrO2/NiCoCrAlY coatings. Mater. Des. 2002, 23, 641–644. [Google Scholar] [CrossRef]

- Widjaja, S.; Limarga, A.M.; Yip, T.H. Oxidation behavior of a plasma-sprayed functionally graded ZrO2/Al2O3 thermal barrier coating. Mater. Lett. 2002, 57, 628–634. [Google Scholar] [CrossRef]

- Tsukamoto, H. Design against fracture of functionally graded thermal barrier coatings using transformation toughening. Mater. Sci. Eng. A 2010, 527, 3217–3226. [Google Scholar] [CrossRef]

- Moskal, G.; Jucha, S.; Mikuśkiewicz, M.; Migas, D.; Jasik, A. Atypical decomposition processes of Sm2Zr2O7 + 8YSZ dual-phase TBCs during hot corrosion. Corros. Sci. 2020, 170, 108681. [Google Scholar] [CrossRef]

- Khor, K.; Gu, Y. Thermal properties of plasma-sprayed functionally graded thermal barrier coatings. Thin Solid Films 2000, 372, 104–113. [Google Scholar] [CrossRef]

- Carpio, P.; Salvador, M.; Borrell, A.; Sánchez, E. Thermal behaviour of multilayer and functionally-graded YSZ/Gd2Zr2O7 coatings. Ceram. Int. 2017, 43, 4048–4054. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, H.; Sun, C.; Dai, J. Microstructure and wear properties of multi ceramics reinforced metal-matrix composite coatings on Ti–6Al–4V alloy fabricated by laser surface alloying. Surf. Eng. 2019, 35, 683–691. [Google Scholar] [CrossRef]

- Ekberg, J.; Klement, U.; Björklund, S. Analysis of single splats produced by axial suspension plasma spraying. Surf. Eng. 2017, 34, 407–411. [Google Scholar] [CrossRef]

- Pawlowski, L. Finely grained nanometric and submicrometric coatings by thermal spraying: A review. Surf. Coat. Technol. 2008, 202, 4318–4328. [Google Scholar] [CrossRef]

- Gitzhofer, F.; Bouyer, E.; Boulos, M. Suspension Plasma Spray. U.S. Patent No. 5,609,921, 11 March 1997. [Google Scholar]

- Vaßen, R.; Kaßner, H.; Mauer, G.; Stöver, D. Suspension Plasma Spraying: Process Characteristics and Applications. J. Therm. Spray Technol. 2009, 19, 219–225. [Google Scholar] [CrossRef]

- Curry, N.; VanEvery, K.; Snyder, T.R.; Susnjar, J.; Bjorklund, S. Performance Testing of Suspension Plasma Sprayed Thermal Barrier Coatings Produced with Varied Suspension Parameters. Coatings 2015, 5, 338–356. [Google Scholar] [CrossRef] [Green Version]

- Kozerski, S.; Łatka, L.; Pawlowski, L.; Cernuschi, F.; Petit, F.; Pierlot, C.; Podlesak, H.; Laval, J. Preliminary study on suspension plasma sprayed ZrO2+ 8 wt.% Y2O3 coatings. J. Eur. Ceram. Soc. 2011, 31, 2089–2098. [Google Scholar] [CrossRef]

- Zhou, D.; Guillon, O.; Vaßen, R. Development of YSZ Thermal Barrier Coatings Using Axial Suspension Plasma Spraying. Coatings 2017, 7, 120. [Google Scholar] [CrossRef]

- Ma, X.; Ruggiero, P. Practical Aspects of Suspension Plasma Spray for Thermal Barrier Coatings on Potential Gas Turbine Components. J. Therm. Spray Technol. 2018, 27, 591–602. [Google Scholar] [CrossRef]

- Joulia, A.; Bolelli, G.; Gualtieri, E.; Lusvarghi, L.; Valeri, S.; Vardelle, M.; Rossignol, S.; Vardelle, A. Comparing the deposition mechanisms in suspension plasma spray (SPS) and solution precursor plasma spray (SPPS) deposition of yttria-stabilised zirconia (YSZ). J. Eur. Ceram. Soc. 2014, 34, 3925–3940. [Google Scholar] [CrossRef]

- VanEvery, K.; Krane, M.J.M.; Trice, R.W.; Wang, H.; Porter, W.; Besser, M.; Sordelet, D.; Ilavsky, J.; Almer, J. Column Formation in Suspension Plasma-Sprayed Coatings and Resultant Thermal Properties. J. Therm. Spray Technol. 2011, 20, 817–828. [Google Scholar] [CrossRef]

- Xie, L.; Ma, X.; Ozturk, A.; Jordan, E.H.; Padture, N.P.; Cetegen, B.M.; Xiao, D.T.; Gell, M. Processing parameter effects on solution precursor plasma spray process spray patterns. Surf. Coat. Technol. 2004, 183, 51–61. [Google Scholar] [CrossRef]

- Hwang, I.; Jeong, J.; Lim, K.; Jung, J. Microstructural characterization of spray-dried NiO-8YSZ particles as plasma sprayable anode materials for metal-supported solid oxide fuel cell. Ceram. Int. 2017, 43, 7728–7735. [Google Scholar] [CrossRef]

- Fauchais, P.; Rat, V.; Coudert, J.-F.; Etchart-Salas, R.; Montavon, G. Operating parameters for suspension and solution plasma-spray coatings. Surf. Coat. Technol. 2008, 202, 4309–4317. [Google Scholar] [CrossRef]

- Xie, L.; Chen, D.; Jordan, E.H.; Ozturk, A.; Wu, F.; Ma, X.; Cetegen, B.M.; Gell, M. Formation of vertical cracks in solution-precursor plasma-sprayed thermal barrier coatings. Surf. Coat. Technol. 2006, 201, 1058–1064. [Google Scholar] [CrossRef]

- Lu, F.; Huang, W.; Liu, H. Thermal shock resistance and failure analysis of plasma-sprayed thick 8YSZ-Al2O3 composite coatings. Surf. Coat. Technol. 2019, 384, 125290. [Google Scholar] [CrossRef]

- Ajay, A.; Raja, V.S.; Sivakumar, G.; Joshi, S.V. Hot corrosion behavior of solution precursor and atmospheric plasma sprayed thermal barrier coatings. Corros. Sci. 2015, 98, 271–279. [Google Scholar] [CrossRef]

- Jadhav, A.; Padture, N.P.; Wu, F.; Jordan, E.H.; Gell, M. Thick ceramic thermal barrier coatings with high durability deposited using solution-precursor plasma spray. Mater. Sci. Eng. A 2005, 405, 313–320. [Google Scholar] [CrossRef]

- Waldbillig, D.; Kesler, O. The effect of solids and dispersant loadings on the suspension viscosities and deposition rates of suspension plasma sprayed YSZ coatings. Surf. Coat. Technol. 2009, 203, 2098–2101. [Google Scholar] [CrossRef]

- Wang, W.Z.; Coyle, T.; Zhao, D. Preparation of Lanthanum Zirconate Coatings by the Solution Precursor Plasma Spray. J. Therm. Spray Technol. 2014, 23, 827–832. [Google Scholar] [CrossRef]

- Vasiliev, A.L.; Padture, N.P.; Ma, X. Coatings of metastable ceramics deposited by solution-precursor plasma spray: I. Binary ZrO2–Al2O3 system. Acta Mater. 2006, 54, 4913–4920. [Google Scholar] [CrossRef]

- Killinger, A.; Gadow, R.; Mauer, G.; Guignard, A.; Vaßen, R.; Stöver, D. Review of New Developments in Suspension and Solution Precursor Thermal Spray Processes. J. Therm. Spray Technol. 2011, 20, 677–695. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, M.; Goutier, S. Key Challenges and Opportunities in Suspension and Solution Plasma Spraying. Plasma Chem. Plasma Process. 2014, 35, 511–525. [Google Scholar] [CrossRef]

- Marchand, O.; Girardot, L.; Planche, M.P.; Bertrand, P.; Bailly, Y.; Bertrand, G. An Insight into Suspension Plasma Spray: Injection of the Suspension and Its Interaction with the Plasma Flow. J. Therm. Spray Technol. 2011, 20, 1310–1320. [Google Scholar] [CrossRef]

- Hospach, A.; Mauer, G.; Vaßen, R.; Stöver, D. Columnar-Structured Thermal Barrier Coatings (TBCs) by Thin Film Low-Pressure Plasma Spraying (LPPS-TF). J. Therm. Spray Technol. 2010, 20, 116–120. [Google Scholar] [CrossRef]

- Goral, M.; Kotowski, S.; Nowotnik, A.; Pytel, M.; Drajewicz, M.; Sieniawski, J. PS-PVD deposition of thermal barrier coatings. Surf. Coat. Technol. 2013, 237, 51–55. [Google Scholar] [CrossRef]

- Harder, B.J.; Zhu, D. Plasma Spray-Physical Vapor Deposition (PS-PVD) of Ceramics for Protective Coatings. In Proceedings of the 35th International Conference and Exposition on Advanced Ceramics and Composites, Daytona Beach, FL, USA, 23–28 January 2011; pp. 71–84. [Google Scholar] [CrossRef]

- Mauer, G.; Jarligo, M.O.; Rezanka, S.; Hospach, A.; Vaßen, R. Novel opportunities for thermal spray by PS-PVD. Surf. Coat. Technol. 2015, 268, 52–57. [Google Scholar] [CrossRef]

- Gurrappa, I. Hot corrosion of protective coatings. Mater. Manuf. Process. 2000, 15, 761–773. [Google Scholar] [CrossRef]

- Natesan, K. Corrosion-Erosion Behavior of Materials in a Coal-Gasification Environment. Corrosion 1976, 32, 364–370. [Google Scholar] [CrossRef]

- Chen, H.; Pan, P.; Shao, H.; Wang, Y.; Zhao, Q. Corrosion and viscous ash deposition of a rotary air preheater in a coal-fired power plant. Appl. Therm. Eng. 2017, 113, 373–385. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, M.; Handa, A. Combating hot corrosion of boiler tubes–A study. Eng. Fail. Anal. 2018, 94, 379–395. [Google Scholar] [CrossRef]

- Heath, G.; Heimgartner, P.; Irons, G.; Miller, R.D.; Gustafsson, S. An Assessment of Thermal Spray Coating Technologies for High Temperature Corrosion Protection. Mater. Sci. Forum 1997, 251–254, 809–816. [Google Scholar] [CrossRef]

- Konar, R.; Mukhopadhyay, J.; Sharma, A.D.; Basu, R.N. Synthesis of Cu-YSZ and Ni-Cu-YSZ cermets by a novel electroless technique for use as solid oxide fuel cell anode: Application potentiality towards fuel flexibility in biogas atmosphere. Int. J. Hydrog. Energy 2016, 41, 1151–1160. [Google Scholar] [CrossRef]

- Morales-Rodríguez, A.; Bravo-León, A.; Domínguez-Rodríguez, A.; López-Esteban, S.; Moya, J.; Jiménez-Melendo, M. High-temperature mechanical properties of zirconia/nickel composites. J. Eur. Ceram. Soc. 2003, 23, 2849–2856. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, Y.; Han, X.; Jiang, G.; Shi, J.; Liu, P.; Khan, M.Z.; Huhtinen, H.; Zhu, J.; Jin, Z.; et al. Ultra-fast growth of cuprate superconducting films: Dual-phase liquid assisted epitaxy and strong flux pinning. Mater. Today Phys. 2021, 100400. [Google Scholar] [CrossRef]

- Venkadesan, G.; Muthusamy, J. Experimental investigation of Al2O3/8YSZ and CeO2/8YSZ plasma sprayed thermal barrier coating on diesel engine. Ceram. Int. 2019, 45, 3166–3176. [Google Scholar] [CrossRef]

- Song, X.; Lu, J.; Zhang, T.; Ma, J. Sintering behavior and mechanisms of NiO-doped 8 mol% yttria stabilized zirconia. J. Eur. Ceram. Soc. 2011, 31, 2621–2627. [Google Scholar] [CrossRef]

- Zhou, L.; Li, X.; He, D.; Guo, W.; Huang, Y.; He, G.; Xing, Z.; Wang, H. Study on Properties of Potassium Sodium Niobate Coating Prepared by High Efficiency Supersonic Plasma Spraying. Actuators 2022, 11, 28. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Wang, X.-Y.; Wang, X.-L.; Yang, Y.; Cui, Y.-H.; Ma, Y.-D.; Sun, W.-W. Microstructure and properties of in-situ composite coatings prepared by plasma spraying MoO3–Al composite powders. Ceram. Int. 2020, 47, 1109–1120. [Google Scholar] [CrossRef]

- López-Honorato, E.; Dessoliers, M.; Shapiro, I.; Wang, X.; Xiao, P. Improvements to the sintering of yttria-stabilized zirconia by the addition of Ni. Ceram. Int. 2012, 38, 6777–6782. [Google Scholar] [CrossRef]

- Yilmaz, O.; Erdogan, M.; Karakaya, I. Combined effects of ALS and SLS on Al2O3 reinforced composite nickel coatings. Surf. Eng. 2018, 36, 477–484. [Google Scholar] [CrossRef]

- Noor-A-Alam, M.; Choudhuri, A.; Ramana, C. Effect of composition on the growth and microstructure of hafnia–zirconia based coatings. Surf. Coat. Technol. 2011, 206, 1628–1633. [Google Scholar] [CrossRef]

- Wang, N.; Wang, D.P.; Yang, Z.W.; Wang, Y. Interfacial microstructure and mechanical properties of zirconia ceramic and niobium joints vacuum brazed with two Ag-based active filler metals. Ceram. Int. 2016, 42, 12815–12824. [Google Scholar] [CrossRef]

- Arantes, V.; Coutinho, R.; Martins, S.; Huang, S.; Vleugels, J. Solid state sintering behavior of zirconia-nickel composites. Ceram. Int. 2019, 45, 22120–22130. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, Y.; Gu, L.; Zou, B.; Wang, Y.; Cao, X. Hot corrosion behaviour of plasma sprayed YSZ/LaMgAl11O19 composite coatings in molten sulfate–vanadate salt. Corros. Sci. 2011, 53, 2335–2343. [Google Scholar] [CrossRef]

- Park, S.; Kim, J.; Kim, M.; Song, H.; Park, C. Microscopic observation of degradation behavior in yttria and ceria stabilized zirconia thermal barrier coatings under hot corrosion. Surf. Coat. Technol. 2005, 190, 357–365. [Google Scholar] [CrossRef]

- Hajizadeh-Oghaz, M.; Razavi, R.S.; Ghasemi, A.; Valefi, Z. Na2SO4 and V2O5 molten salts corrosion resistance of plasma-sprayed nanostructured ceria and yttria co-stabilized zirconia thermal barrier coatings. Ceram. Int. 2016, 42, 5433–5446. [Google Scholar] [CrossRef]

- Ahmadi-Pidani, R.; Razavi, R.S.; Mozafarinia, R.; Jamali, H. Evaluation of hot corrosion behavior of plasma sprayed ceria and yttria stabilized zirconia thermal barrier coatings in the presence of Na2SO4+V2O5 molten salt. Ceram. Int. 2012, 38, 6613–6620. [Google Scholar] [CrossRef]

- Habibi, M.H.; Wang, L.; Liang, J.; Guo, S.M. An investigation on hot corrosion behavior of YSZ-Ta2O5 in Na2SO4 + V2O5 salt at 1100 °C. Corros. Sci. 2013, 75, 409–414. [Google Scholar] [CrossRef]

- Lashmi, P.; Ananthapadmanabhan, P.; Chakravarthy, Y.; Unnikrishnan, G.; Balaji, N.; Aruna, S. Hot corrosion studies on plasma sprayed bi-layered YSZ/La2Ce2O7 thermal barrier coating fabricated from synthesized powders. J. Alloys Compd. 2017, 711, 355–364. [Google Scholar] [CrossRef]

- Pakseresht, A.; Javadi, A.; Ghasali, E.; Shahbazkhan, A.; Shakhesi, S. Evaluation of hot corrosion behavior of plasma sprayed thermal barrier coatings with graded intermediate layer and double ceramic top layer. Surf. Coat. Technol. 2016, 288, 36–45. [Google Scholar] [CrossRef]

- Batista, C.; Portinha, A.; Ribeiro, R.; Teixeira, V.; de Oliveira, C.A.R. Evaluation of laser-glazed plasma-sprayed thermal barrier coatings under high temperature exposure to molten salts. Surf. Coat. Technol. 2006, 200, 6783–6791. [Google Scholar] [CrossRef]

- Soleimanipour, Z.; Baghshahi, S.; Razavi, R.S.; Salehi, M. Hot corrosion behavior of Al2O3 laser clad plasma sprayed YSZ thermal barrier coatings. Ceram. Int. 2016, 42, 17698–17705. [Google Scholar] [CrossRef]

- Mishra, N.; Mishra, S.B. Hot corrosion performance of LVOF sprayed Al2O3–40% TiO2 coating on Superni 601 and Superco 605 superalloys at 800 and 900 °C. Bull. Mater. Sci. 2015, 38, 1679–1685. [Google Scholar] [CrossRef]

- Thakur, L.; Arora, N. A study of processing and slurry erosion behaviour of multi-walled carbon nanotubes modified HVOF sprayed nano-WC-10Co-4Cr coating. Surf. Coat. Technol. 2017, 309, 860–871. [Google Scholar] [CrossRef]

- Afzal, M.A.F.; Kesarwani, P.; Reddy, K.M.; Kalmodia, S.; Basu, B.; Balani, K. Functionally graded hydroxyapatite-alumina-zirconia biocomposite: Synergy of toughness and biocompatibility. Mater. Sci. Eng. C 2012, 32, 1164–1173. [Google Scholar] [CrossRef]

- Kaushal, G.; Singh, H.; Prakash, S. Comparative High Temperature Analysis of HVOF-Sprayed and Detonation Gun Sprayed Ni–20Cr Coating in Laboratory and Actual Boiler Environments. Oxid. Met. 2011, 76, 169–191. [Google Scholar] [CrossRef]

- Saini, H.; Kumar, D.; Shukla, V. Hot Corrosion behaviour of Nanostructured Cermet based Coatings Deposited by Different Thermal Spray Techniques: A Review. Mater. Today Proc. 2017, 4, 541–545. [Google Scholar] [CrossRef]

- Gond, D.; Lalbondre, R.; Puri, D.; Prakash, S. High Temperature Oxidation and Hot Corrosion Behaviour of Yttria- Stabilised Zirconia as Plasma Sprayed Coating in Air and Salt at 900 °C under Cyclic Condition. J. Miner. Mater. Charact. Eng. 2012, 11, 285–302. [Google Scholar] [CrossRef]

- Kai, T.; Zhou, X.-L.; Hua, C.; Zhang, J.-S. Oxidation and hot corrosion behaviors of HVAF-sprayed conventional and nanostructured NiCrC coatings. Trans. Nonferrous Met. Soc. China 2009, 19, 1151–1160. [Google Scholar]

- Katiki, K.; Yadlapati, S.; Chidepudi, S.N.S.; Manikandan, M.; Arivarasu, M.; Devendranath Ramkumar, K.; Arivazhagan, N. Performance of plasma spray coatings on Inconel 625 in Air oxidation and molten salt environment at 800 °C. Int. J. ChemTech Res. 2014, 6, 2744–2749. [Google Scholar]

- Katiki, K.; Yadlapati, S.; Chidepudi, S.N.S.; Hari, P.R. Comparative high temperature corrosion studies on zirconium dioxide coated Inconel 625 in air and molten salt environment. Int. J. ChemTech Res. 2014, 6, 4579–45845. [Google Scholar]

- Singh, G.; Goyal, K.; Bhatia, R. Hot corrosion studies of plasma-sprayed chromium oxide coatings on boiler tube steel at 850 C in simulated boiler environment. Iran. J. Sci. Technol. Trans. Mech. Eng. 2018, 42, 149–159. [Google Scholar] [CrossRef]

- Hong, C.-Q.; Zhang, X.-H.; Li, W.-J.; Han, J.-C.; Meng, S.-H. A novel functionally graded material in the ZrB2–SiC and ZrO2 system by spark plasma sintering. Mater. Sci. Eng. A 2008, 498, 437–441. [Google Scholar] [CrossRef]

- Yongming, L.; Wei, P.; Shuqin, L.; Ruigang, W.; Jianqiang, L. A novel functionally graded material in the Ti–Si–C system. Mater. Sci. Eng. A 2003, 345, 99–105. [Google Scholar] [CrossRef]

- Zhang, Z.; Shen, X.; Zhang, C.; Wei, S.; Lee, S.; Wang, F. A new rapid route to in-situ synthesize TiB–Ti system functionally graded materials using spark plasma sintering method. Mater. Sci. Eng. A 2012, 565, 326–332. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, H.; Du, D.; Qu, D.; Hu, C.; Xie, R.; Feng, Y. Fabrication of W–Cu functionally graded material by spark plasma sintering method. Int. J. Refract. Met. Hard Mater. 2014, 42, 193–199. [Google Scholar] [CrossRef]

- Lee, S.-H.; Tanaka, H.; Kagawa, Y. Spark plasma sintering and pressureless sintering of SiC using aluminum borocarbide additives. J. Eur. Ceram. Soc. 2009, 29, 2087–2095. [Google Scholar] [CrossRef]

- Qiao, Z.; Räthel, J.; Berger, L.-M.; Herrmann, M. Investigation of binderless WC–TiC–Cr3C2 hard materials prepared by spark plasma sintering (SPS). Int. J. Refract. Met. Hard Mater. 2013, 38, 7–14. [Google Scholar] [CrossRef]

- Demirkıran, A.; Avcı, E. Evaluation of functionally gradient coatings produced by plasma-spray technique. Surf. Coat. Technol. 1999, 116–119, 292–295. [Google Scholar] [CrossRef]

- Shanmugavelayutham, G.; Kobayashi, A. Mechanical properties and oxidation behaviour of plasma sprayed functionally graded zirconia–alumina thermal barrier coatings. Mater. Chem. Phys. 2007, 103, 283–289. [Google Scholar] [CrossRef]

- Tekmen, C.; Ozdemir, I.; Celik, E. Failure behaviour of functionally gradient materials under thermal cycling conditions. Surf. Coat. Technol. 2003, 174–175, 1101–1105. [Google Scholar] [CrossRef]

- Cannillo, V.; Lusvarghi, L.; Sola, A. Production and characterization of plasma-sprayed TiO2–hydroxyapatite functionally graded coatings. J. Eur. Ceram. Soc. 2008, 28, 2161–2169. [Google Scholar] [CrossRef]

- Sharma, V.; Kaur, M.; Bhandari, S. Development and Characterization of High-Velocity Flame Sprayed Ni/TiO2/Al2O3 Coatings on Hydro Turbine Steel. J. Therm. Spray Technol. 2019, 28, 1379–1401. [Google Scholar] [CrossRef]

- Thakur, L.; Arora, N. An investigation on the development and wear performance of chromium-MWCNTs transformed HVOF sprayed nano-WC-CoCr coatings. Surf. Coat. Technol. 2020, 388, 125610. [Google Scholar] [CrossRef]

- Shivamurthy, R.; Kamaraj, M.; Nagarajan, R.; Shariff, S.; Padmanabham, G. Laser surface modification of steel for slurry erosion resistance in power plants. In Laser Surface Modification of Alloys for Corrosion and Erosion Resistance; Woodhead Publishing: Sawston, UK, 2012; pp. 177–287. [Google Scholar] [CrossRef]

- Arji, R.; Dwivedi, D.; Gupta, S.R. Some studies on slurry erosion of flame sprayed Ni-Cr-Si-B coating. Ind. Lubr. Tribol. 2009, 61, 4–10. [Google Scholar] [CrossRef]

- Chauhan, A.K.; Goel, D.B.; Prakash, S. Erosive wear of a surface coated hydroturbine steel. Bull. Mater. Sci. 2010, 33, 483–489. [Google Scholar] [CrossRef] [Green Version]

- Ramesh, C.; Devaraj, D.; Keshavamurthy, R.; Sridhar, B. Slurry erosive wear behaviour of thermally sprayed Inconel-718 coatings by APS process. Wear 2011, 271, 1365–1371. [Google Scholar] [CrossRef]

- Grewal, H.S.; Bhandari, S.; Singh, H. Parametric Study of Slurry-Erosion of Hydroturbine Steels with and without Detonation Gun Spray Coatings using Taguchi Technique. Met. Mater. Trans. A 2012, 43, 3387–3401. [Google Scholar] [CrossRef]

- Goyal, D.K.; Singh, H.; Kumar, H.; Sahni, V. Slurry erosion behaviour of HVOF sprayed WC–10Co–4Cr and Al2O3+13TiO2 coatings on a turbine steel. Wear 2012, 289, 46–57. [Google Scholar] [CrossRef]

- Goyal, D.K.; Singh, H.; Kumar, H.; Sahni, V. Slurry Erosive Wear Evaluation of HVOF-Spray Cr2O3 Coating on Some Turbine Steels. J. Therm. Spray Technol. 2012, 21, 838–851. [Google Scholar] [CrossRef]

- Bhandari, S.; Singh, H.; Kumar, H.; Rastogi, V. Slurry erosion performance study of detonation gun-sprayed WC-10Co-4Cr coatings on CF8M steel under hydro-accelerated conditions. J. Therm. Spray Technol. 2012, 21, 1054–1064. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.X.; Suo, H.L. Mechanical properties of YSZ thermal barrier coatings with segmented structure. Surf. Eng. 2012, 28, 329–332. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Turk, A.; Ozdemir, I. Effect of sintering on mechanical properties of cold sprayed thermal barrier coatings. Surf. Eng. 2016, 32, 686–690. [Google Scholar] [CrossRef]

- Shang, F.L.; Zhang, X.; Guo, X.C.; Zhao, P.F.; Chang, Y. Determination of high temperature mechanical properties of thermal barrier coatings by nanoindentation. Surf. Eng. 2014, 30, 283–289. [Google Scholar] [CrossRef]

- Singh, J.; Thakur, L.; Angra, S. A study of tribological behaviour and optimization of WC-10Co-4Cr Cladding. Surf. Eng. 2020, 37, 70–79. [Google Scholar] [CrossRef]

- Keyvani, A.; Bahamirian, M. Hot corrosion and mechanical properties of nanostructured Al2O3/CSZ composite TBCs. Surf. Eng. 2017, 33, 433–443. [Google Scholar] [CrossRef]

- Liu, X.-B.; Kang, J.-J.; Yue, W.; Fu, Z.-Q.; Zhu, L.-N.; She, D.-S.; Liang, J.; Wang, C.-B. Performance evaluation of HVOF sprayed WC-10Co4Cr coatings under slurry erosion. Surf. Eng. 2018, 35, 816–825. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Gao, W.W.; Wang, B.; Guo, W.M.; Lin, J.R. Microstructural characterisation and microhardness distribution of HVOF sprayed WC–10Co–4Cr coating. Surf. Eng. 2013, 30, 53–58. [Google Scholar] [CrossRef]

- Upadhyaya, R.; Tailor, S.; Shrivastava, S.; Modi, S.C. High performance thermal-sprayed WC-10Co-4Cr coatings in narrow and complex areas. Surf. Eng. 2017, 34, 412–421. [Google Scholar] [CrossRef]

- Borkar, T.; Harimkar, S. Microstructure and wear behaviour of pulse electrodeposited Ni–CNT composite coatings. Surf. Eng. 2011, 27, 524–530. [Google Scholar] [CrossRef]

- Ramalingam, S.; Balakrishnan, K.; Shanmugasamy, S.; Subramania, A. Electrodeposition and characterisation of Cu–MWCNTs nanocomposite coatings. Surf. Eng. 2016, 33, 369–374. [Google Scholar] [CrossRef]

- La Barbera-Sosa, J.G.; Santana, Y.Y.; Caro, J.; Chicot, D.; Lesage, J.; Staia, M.H.; Puchi-Cabrera, E.S. Mechanical properties of WC coatings evaluated using instrumented indentation technique. Surf. Eng. 2014, 30, 498–510. [Google Scholar] [CrossRef]

- Santana, Y.Y.; La Barbera-Sosa, J.G.; Bencomo, A.; Lesage, J.; Chicot, D.; Bemporad, E.; Puchi-Cabrera, E.S.; Staia, M.H. Influence of mechanical properties of tungsten carbide–cobalt thermal spray coatings on their solid particle erosion behaviour. Surf. Eng. 2012, 28, 237–243. [Google Scholar] [CrossRef]

- Lavasani, H.Q.; Valefi, Z.; Ehsani, N.; Masoule, S.T. Comparison of the effect of sintering on the microstructure, micro hardness and phase composition of conventional and nanostructured YSZ TBCs. Ceram. Int. 2017, 43, 12497–12504. [Google Scholar] [CrossRef]

- Zhou, F.; Deng, C.; Wang, Y.; Liu, M.; Wang, L.; Wang, Y.; Zhang, X. Characterization of multi-scale synergistic toughened nanostructured YSZ thermal barrier coatings: From feedstocks to coatings. J. Eur. Ceram. Soc. 2020, 40, 1443–1452. [Google Scholar] [CrossRef]

- Demir, H.; Cosgun, A.E. The Effect on Energy Efficiency of Yttria-Stabilized Zirconia on Brass, Copper and Hardened Steel Nozzle in Additive Manufacturing. Coatings 2022, 12, 690. [Google Scholar] [CrossRef]

- Demir, H. The Effects on Thermal Efficiency of Yttria-Stabilized Zirconia and Lanthanum Zirconate-Based Thermal Barrier Coatings on Aluminum Heating Block for 3D Printer. Coatings 2021, 11, 792. [Google Scholar] [CrossRef]

- Veselý, P. Nozzle temperature effect on 3D printed structure properties. In Proceedings of the Zborník Príspevkov z Medzinárodnej Konferencie Elektrotechnológia, Zuberec, Slovakia, 21–23 May 2019; pp. 126–131. [Google Scholar]

- Demir, H.; Coşgun, A.E. 3B Yazıcılarda Kullanılan Farklı Tip Ekstüderlerin ANSYS Programı ile Termal Analizlerinin Gerçekleştirilmesi. Düzce Üniversitesi Bilim Ve Teknol. Derg. 2021, 10, 275–284. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Grabchikov, S.S.; Tsybulskaya, L.S.; Shendyukov, V.S.; Perevoznikov, S.S.; Trukhanov, S.V.; Trukhanova, E.L.; Trukhanov, A.V.; Vinnik, D.A. Electrochemical deposition regimes and critical influence of organic additives on the structure of Bi films. J. Alloys Compd. 2018, 735, 1943–1948. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Grabchikov, S.S.; Lastovskii, S.B.; Trukhanov, S.V.; Zubar, T.I.; Vasin, D.S.; Trukhanov, A.V. Correlation of the synthesis conditions and microstructure for Bi-based electron shields production. J. Alloys Compd. 2018, 749, 1036–1042. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, Z.; Wu, Y.; Wang, Y.; Ma, G.; Shi, J.; Zhong, Z.; Hong, Z.; Jin, Z.; Zhao, Y. Synergic realization of electrical insulation and mechanical strength in liquid nitrogen for high-temperature superconducting tapes with ultra-thin acrylic resin coating. Supercond. Sci. Tech. 2022, 35, 075014. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Zubar, T.I.; Zhaludkevich, A.L.; Razanau, I.U.; Vershinina, T.N.; Bondaruk, A.A.; Zheleznova, E.K.; Dong, M.; Hanfi, M.Y.; Sayyed, M.I.; et al. Isostatic Hot Pressed W–Cu Composites with Nanosized Grain Boundaries: Microstructure, Structure and Radiation Shielding Efficiency against Gamma Rays. Nanomaterials 2022, 12, 1642. [Google Scholar] [CrossRef]

- Singh, H.; Prakash, C.; Singh, S. Plasma spray deposition of HA-TiO2 on β-phase Ti-35Nb-7Ta-5Zr alloy for hip stem: Characterization of bio-mechanical properties, wettability, and wear resistance. J. Bionic Eng. 2020, 17, 1029–1044. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C.; Singh, H.J.S.; Technology, C. Deposition of HA-TiO2 by plasma spray on β-phase Ti-35Nb-7Ta-5Zr alloy for hip stem: Characterization, mechanical properties, corrosion, and in-vitro bioactivity. Surf. Coat. Technol. 2020, 398, 126072. [Google Scholar] [CrossRef]

- Prakash, C.; Kansal, H.K.; Pabla, B.; Puri, S. Powder mixed electric discharge machining: An innovative surface modification technique to enhance fatigue performance and bioactivity of β-Ti implant for orthopedics application. J. Comput. Inf. Sci. Eng. 2016, 16, 041006. [Google Scholar] [CrossRef]

- Singh, H.; Kumar, R.; Prakash, C.; Singh, S. HA-based coating by plasma spray techniques on titanium alloy for orthopedic applications. Mater. Today Proc. 2021, 50, 612–628. [Google Scholar] [CrossRef]

| Substrate Material | Powder Feed Rate (g/min) | Current (A) | Voltage (V) | Power (kW) | Stand-Off Distance (mm) |

|---|---|---|---|---|---|

| stainless steel [34] | 20–40 | 600 | 66–68 | - | 100 |

| IN-738LC [35] | 25 | 600 | 60 | 36 | 150 |

| IN-738LC [40] | 38 | 600 | - | 64 | 100 |

| Amdry 995C [37] | 60 | 600 | 65 | - | 120 |

| 204B-NS [37] | 40 | 600 | 65 | - | 130 |

| stainless steel [38] | 30 | 600 | 63 | 50 | 100 |

| stainless steel [38] | 35 | 600 | 67 | 42 | 120 |

| Inconel 718 [39] | 35–40 | 600 | 60 | 35 | 130 |

| Substrate Material | Corrosive Salt Used (wt.%) | Composite Materials | Temperature and Time of Exposure | Technique | Infiltration of Molten Salt in Coating |

|---|---|---|---|---|---|

| Ni-based superalloy | 50 Na2SO4 + 50 V2O5 | YSZ [95] | (950 °C, 60 h) | APS | Completely |

| Ni-based superalloy | NaVO3 | YSZ [96] | (900 °C, 300 h) | APS | Completely |

| Ni-based superalloy | 45 Na2SO4 + 55 V2O5 | YSZ + CeO2 [97] | (1000 °C, 300 h) | APS | Partially |

| Inconel 738LC superalloy | 55 V2O5 + 45 Na2SO4 | YSZ + CeO2 [98] | (1000 °C, 30 h) | APS | Partially |

| Superalloy (Ni3Al) plates | 45 Na2SO4 + 55 V2O5 | 8YSZ + Al2O3 [99] | (900 °C, 380 h) | APS | Partially |

| Ni-based superalloy | NaVO3 | YSZ + CeO2 [96] | (900 °C, 300 h) | APS | Partially |

| Ni-based superalloy | 50 Na2SO4 + 50 V2O5 | YSZ/LaMgAl11O19 [95] | (950 °C, 60 h) | APS | Partially |

| Inconel 738LC superalloy | 50 Na2SO4 + 50 V2O5 | YSZ-Ta2O5 [100] | (1100 °C, 4 h) | Sintering | Partially |

| Nickel superalloy | 45 Na2SO4 + 55 V2O5 | YSZ/La2Ce2O7 [101] | (910 °C, 30 h) | APS | Partially |

| Inconel 738LC, Ni-15Cr-8.5Co | 45 Na2SO4 + 55 V2O5 | YSZ/Al2O3 [102] | (1050 °C, 40 h) | APS | Partially |

| Inconel 738 LC superalloy | 60 V2O5 + 40 Na2SO4 | YSZ [103] | (1000 °C, 100 h) | APS + lasercladding | Completely |

| Inconel 738 | 55 V2O5 + 45 Na2SO4 | YSZ/Al2O3 [104] | (1000 °C, 30 h) | APS + lasercladding | Partially |

| Year | Substrate Material | Coating Material | Coating Method | Temperature (°C) | Weight Gain of the Coated Substrate (mg/cm2) | Weight Gain of the Uncoated Substrate (mg/cm2) | Percentage Drop after Hot Oxidation |

|---|---|---|---|---|---|---|---|

| 2015 | SC 605 | Al2O3-40% TiO2 [105] | low-velocity oxy-fuel spray | 800 | 49.12 | 52.79 | 5.64 |

| 2011 | T-22 | Ni-20Cr [108] | Detonation Gun spray | 800 | 16.1 | 46.54 | 65.58 |

| 2006 | T-22 | Ni-20Cr [109] | High-velocity oxy-fuel spray (HVOF) | 900 | 8.26 | 14.99 | 44.98 |

| 2012 | T-91 | Yttria-stabilized zirconia (YSZ) [110] | Plasma spray (PS) | 800 | 8.31 | 69.1 | 73.61 |

| 2014 | ASTM1020 Steel | NiCrC nano [111] | HVOF | 550 | 0.12 | 12.98 | 99.24 |

| NiCrC Conventional [111] | HVOF | 550 | 0.29 | 12.99 | 97.69 | ||

| NiCrC nano [111] | HVOF | 650 | 1.1 | 34.1 | 97.07 | ||

| NiCrC Conventional [111] | HVOF | 650 | 1.51 | 34.1 | 95.6 | ||

| 2014 | INCONEL 625 | Al2O3-TiO2 [112] | Plasma spray (PS) | 800 | 5 | 15 | 66.68 |

| 2014 | INCONEL 625 | ZrO2 [113] | (PS) | 800 | 1.12 | 15 | 92.68 |

| 2017 | T22 | CrO3 [114] | (PS) | 800 | 50.94 | 65.17 | 21.85 |

| Year | Substrate Metal | Coating Material | Fabrication Process | Hardness Value (HV) | Toughness (MPa√m) |

|---|---|---|---|---|---|

| 2008 | MS | ZrB2–SiC/ZrO2 [115] | Suspension plasma spraying (SPS) | 20–18 GPa | |

| 2003 | MS | Al2O3–Ti3SiC2 [116] | (SPS) | 4–17 GPa | |

| 2013 | SS-316 | TiB–Ti [117] | (SPS) | 5.8–17 GPa | |

| 2012 | SS-316 | HAp–Al2O3–YSZ [107] | (SPS) | 6–13.9 GPa | |

| 2014 | IN-738LC | W–Cu [118] | (SPS) | 4–5 GPa | 1.4 ± 0.11 |

| 2009 | IN-800LC | SiC–Al3BC3 [119] | (SPS) | 18.5–26.4 GPa | 1.6 ± 0.09 |

| 2013 | IN-738LC | WC–TiC–Cr3C2 [120] | (SPS) | 18.4–23.2 GPa | 0.9 ± 0.12 |

| 1999 | SS-304 | NiCrAl-MgZrO3 [121] | Plasma spray (PS) | 900–350 BHN | |

| 2007 | IN-625LC | ZrO2–Al2O3 [122] | (PS) | 1170–870 | |

| 2003 | SS-304 | NiCrAl/MgZrO3 [123] | (PS) | 150–220 | |

| 2008 | AISI-410 | TiO2–HAp [124] | (PS) | 363.9–513.7 | |

| 2019 | CA6NM | Ni-40TiO2 [125] | (HVFS) | 605 ± 37 | 1.8 ± 0.2 |

| Ni-20TiO2 + 20Al2O3 [125] | (HVFS) | 585 ± 33 | 1.6 ± 0.2 | ||

| 2016 | SS-304 | WC-10Co-4Cr nanostructure [106] | HVOF sprayed | 1696 ± 46 | 2.01 ± 0.04 |

| WC-10Co-4Cr conventional [106] | HVOF sprayed | 1147 ± 50 | 3.61 ± 0.31 | ||

| 2020 | SS-304 | MWCNTs reinforced with nano-WC-Co-Cr [126] | HVOF sprayed | 1530 ± 143 | 9.14 ± 1.30 |

| 2012 | 13Cr–4Ni | Colmonoy 88 and stellite-6 [127] | Laser surface modification | 674–800 | |

| 2006 | MS | Ni-Cr-Si-B [128] | Flame sprayed | 280 | |

| 2010 | 21Cr–4Ni–N steel | stellite-6 [129] | D-Gun | 1098 | |

| Cr3C2-NiCr [129] | D-Gun | 824 | |||

| WC-Co-Cr [129] | D-Gun | 990 | |||

| 2011 | MS | Inconel-718 [130] | APS process | 340 | |

| 2012 | 13Cr4Ni and 16Cr5Ni steels | WC-Co-Cr on 13Cr4Ni [131] | D-Gun | 1401 | |

| WC-Co-Cr on 16Cr5Ni [131] | D-Gun | 1422 | |||

| 2012 | CF8M | WC-10Co-4Cr [132] | D-Gun | 1160 | |

| Al2O3 + 13TiO2 [132] | D-Gun | 830 | |||

| 2012 | CF8M and CA6NM | Cr2O3 on CF8M [133] | HVOF sprayed | 1200 | |

| Cr2O3 on CA6NM [133] | 1400 | ||||

| 2012 | CF8M | WC-10Co-4Cr [134] | D-Gun | 1120 | |

| 2012 | Ni based superalloy | ZrO2–8 mass-%Y2O3 [135] | (APS) | 72 GPa | 2.0 ± 0.3 |

| 2016 | IN-718LC | YSZ (ZrO2 + Y2O3) [136] | (APS) | 680 | |

| IN-718LC | YSZ (ZrO2 + Y2O3) [136] | CGDS | 740 | ||

| 2014 | IN-718LC | 8YSZ [137] | (APS) | 58.04 GPa | 1.58 ± 0.15 |

| 2020 | Stainless steel | WC-10Co-4Cr [138] | TIG welding | 713.13–879.51 | 3.84 ± 0.11 |

| 2017 | IN-738LC | Al2O3/CSZ [139] | (APS) | 172.05 GPa | |

| 2019 | 35CrMo | WC-10Co4Cr [140] | HVOF | 1316 ± 45 | 7.11 ± 0.10 |

| 2014 | AISI 1045 steel | WC–10Co–4Cr [141] | HVOF | 983 | |

| 2018 | CA6NM steel | WC-10Co-4Cr [142] | High-Velocity Oxy Liquid Fuel (HVOLF) | 1402 ± 16 | |

| 2011 | Stainless steel | Ni [143] | Electrodeposition | 320 ± 15 | |

| Ni–CNT [143] | Electrodeposition | 580 ± 15 | |||

| 2017 | Pure Brass | Cu–MWCNTs [144] | Electrodeposition | 335 | |

| 2014 | SAE 1045 steel | WC–10Co–4Cr [145] | HVOF | 11.1 GPa | |

| WC–12Co [145] | HVOF | 9.3 GPa | |||

| 2012 | SAE 1045 steel | WC–10Co–4C [146] | HVOF | 261 ± 10 | 1.42 ± 0.80 |

| WC–12Co [146] | HVOF | 254 ± 12 | 4.56 ± 0.90 | ||

| 2017 | IN-738LC | 8YSZ conventional [147] | (APS) | 421 | |

| 8YSZ nanostructured [147] | (APS) | 327 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehta, A.; Vasudev, H.; Singh, S.; Prakash, C.; Saxena, K.K.; Linul, E.; Buddhi, D.; Xu, J. Processing and Advancements in the Development of Thermal Barrier Coatings: A Review. Coatings 2022, 12, 1318. https://doi.org/10.3390/coatings12091318

Mehta A, Vasudev H, Singh S, Prakash C, Saxena KK, Linul E, Buddhi D, Xu J. Processing and Advancements in the Development of Thermal Barrier Coatings: A Review. Coatings. 2022; 12(9):1318. https://doi.org/10.3390/coatings12091318

Chicago/Turabian StyleMehta, Amrinder, Hitesh Vasudev, Sharanjit Singh, Chander Prakash, Kuldeep K. Saxena, Emanoil Linul, Dharam Buddhi, and Jinyang Xu. 2022. "Processing and Advancements in the Development of Thermal Barrier Coatings: A Review" Coatings 12, no. 9: 1318. https://doi.org/10.3390/coatings12091318

APA StyleMehta, A., Vasudev, H., Singh, S., Prakash, C., Saxena, K. K., Linul, E., Buddhi, D., & Xu, J. (2022). Processing and Advancements in the Development of Thermal Barrier Coatings: A Review. Coatings, 12(9), 1318. https://doi.org/10.3390/coatings12091318

___2018_Amrinder_Photo_With_date.jpg)