Print Quality of Coated Paper from Invasive Alien Plant Goldenrod

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating and Printing

2.3. Methods

3. Results and Discussion

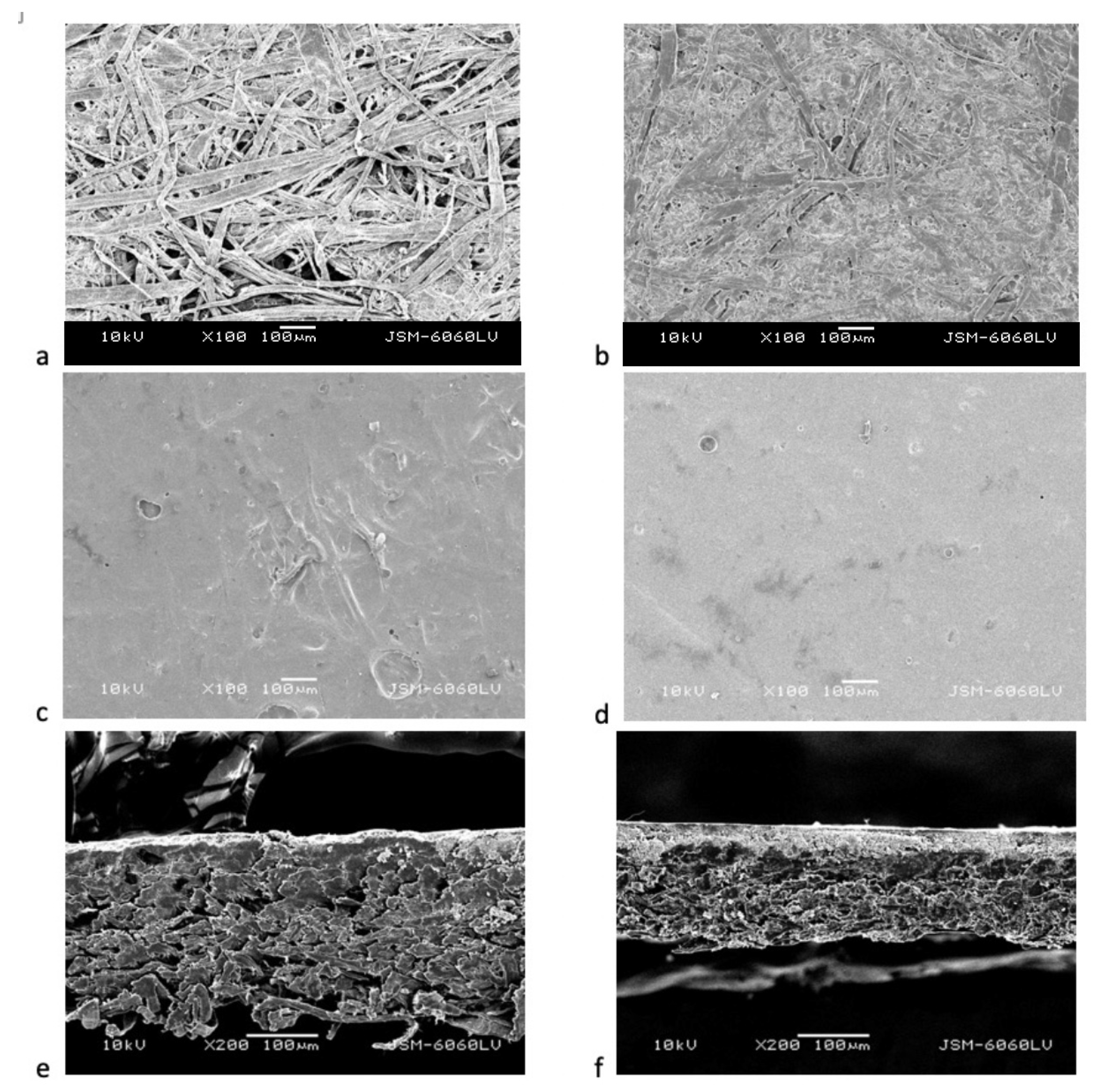

3.1. Paper Characteristics

3.2. Print Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Development Strategy of Slovenia 2030; Service of the Government of the Republic of Slovenia for Development and European Cohesion Policy: Ljubljana, Slovenia, 2017; pp. 154–196. Available online: https://www.gov.si/assets/ministrstva/MKRR/Strategija-razvoja-Slovenije-2030/Slovenian-Development-Strategy-2030.pdf (accessed on 3 June 2023).

- Birkeland, J. Design for Sustainability; Earthscan: London, UK, 2002. [Google Scholar]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; Vintage: London, UK, 2009. [Google Scholar]

- Ficko, T. Ljubljana Circular Economy. APPLAUSE—Alien Plant Species from Harmful to Useful with Citizens’ Led Activities. Available online: https://www.uia-initiative.eu/en/uia-cities/ljubljana (accessed on 13 May 2023).

- Starešinič, M.; Boh Podgornik, B.; Javoršek, D.; Leskovšek, M.; Možina, K. Fibers obtained from invasive alien plant species as a base material for paper production. Forests 2021, 12, 527. [Google Scholar] [CrossRef]

- Biermann, C.J. Handbook of Pulping and Papermaking; Academic Press Inc.: San Diego, CA, USA, 1996. [Google Scholar]

- Cabrera-García, P.; Marrero, M.D.; Benítez, A.N.; Paz, R. Valorization of Pennisetum setaceum: From Invasive Plant to Fiber Reinforcement of Injected Composites. Plants 2023, 12, 1777. [Google Scholar] [CrossRef] [PubMed]

- Ortega, Z.; Castellano, J.; Suárez, L.; Paz, R.; Diaz, N.; Benitez, A.N.; Marrero, M.D. Characterization of Agave americana L. plant as potential source of fibres for composites obtaining. SN Appl. Sci. 2019, 1, 987. [Google Scholar] [CrossRef]

- Razzak, A.; Mannai, F.; Khiari, R.; Moussaoui, Y.; Mohamed, N. Belgacem Cellulose Fibre from Schinus molle and Its Characterization. JRM 2022, 10, 2593–2606. [Google Scholar] [CrossRef]

- Wu, L.F.; Xu, Z.J.; Qin, Z.D.; Duns, G.; Chen, J.S. Pulping Utilization of Spartina alterniflora (common cordgrass) based on fiber characteristics. Appl. Mech. Mater. 2011, 130–134, 833–837. [Google Scholar] [CrossRef]

- Pintor-Ibarra, L.F.; Rivera-Prado, J.J.; Ngangyo-Heya, M.; Rutiaga-Quiñones, J.G. Evaluation of the chemical components of Eichhornia crassipes as an alternative raw material for pulp and paper. BioResources 2018, 13, 2800–2813. [Google Scholar] [CrossRef]

- Baptista, P.; Costa, A.P.; Simões, R.; Amral, M.E. Ailanthus altissima: An alternative fiber source for papermaking. Ind. Crop. Prod. 2014, 52, 32–37. [Google Scholar] [CrossRef]

- Kapun, T.; Zule, J.; Fabjan, E.; Hočevar, B.; Grilc, M.; Likozar, B. Engineered invasive plant cellulose fibers as resources for papermaking. Eur. J. Wood Prod. 2022, 80, 501–514. [Google Scholar] [CrossRef]

- Zihare, L.; Blumberga, D. Market opportunities for cellulose products from combined renewable resources. Environ. Clim. Technol. 2017, 19, 33–38. [Google Scholar] [CrossRef]

- Saldarriaga-Hernánde, S.; Velasco-Ayala, C.; Leal-Isla Flores, P.; Rostro-Alanis, M.J.; Parra-Saldivar, R.; Iqbal, H.M.N.; Carrillo-Nieves, D. Biotransformation of lignocellulosic biomass into industrially relevant products with the aid of fungi-derived lignocellulolytic enzymes. Int. J. Biol. Macromol. 2020, 161, 1099–1116. [Google Scholar] [CrossRef]

- Sánchez, Ó.J.; Montoya, S. Assessment of polysaccharide and biomass production from three white-rot fungi by solid-state fermentation using wood and agro-industrial residues: A kinetic approach. Forests 2020, 11, 1055. [Google Scholar] [CrossRef]

- Liu, Y.; Nie, Y.; Lu, X.; Zhang, X.; He, H.; Pan, F.; Zhou, L.; Liu, X.; Ji, X.; Zhang, S. Cascade utilization of lignocellulosic biomass to high-value products. Green Chem. 2019, 21, 3499–3535. [Google Scholar] [CrossRef]

- Gregor-Svetec, D.; Franken, G.; Možina, K. Papir in grafični izdelki iz invazivk. Pomurska Obz. 2020, 7, 28–31. Available online: http://www.dlib.si/details/URN:NBN:SI:doc-KTEVT89R (accessed on 11 July 2023).

- Lavrič, G.; Pleša, T.; Mendizza, A.; Ropret, M.; Karlovits, I.; Gregor-Svetec, D. Printability characteristics of paper made from a Japanese knotweed. In Proceedings of the 9th International Symposium on Graphic Engineering and Design GRID 2018, Novi Sad, Serbia, 8–10 November 2018. [Google Scholar]

- Karlovits, I.; Lavrič, G.; Kavčič, U.; Zorić, V. Electrophotography toner adhesion on agro-industrial residue and invasive plant papers. J. Adhes. Sci. Technol. 2021, 35, 2636–2651. [Google Scholar] [CrossRef]

- Li, H.; Qi, Y.; Zhao, Y.; Chi, J.; Cheng, C. Starch and its derivatives for paper coatings: A review. Prog. Org. Coat. 2019, 135, 213–227. [Google Scholar] [CrossRef]

- Adibi, A.; Trinh, B.M.; Mekonnen, T.H. Recent progress in sustainable barrier paper coating for food packaging applications. Prog. Org. Coat. 2023, 181, 107566. [Google Scholar] [CrossRef]

- Rastogi, V.K.; Samyn, P. Bio-based coatings for paper applications. Coatings 2015, 5, 887–930. [Google Scholar] [CrossRef]

- Khwaldia, K.; Basta, A.H.; Aloui, H.; El-Saied, H. Chitosan–caseinate bilayer coatings for paper packaging materials. Carbohyd. Polym. 2014, 99, 508–516. [Google Scholar] [CrossRef] [PubMed]

- Mhd Haniffa, M.A.C.; Ching, Y.C.; Abdullah, L.C.; Poh, S.C.; Chuah, C.H. Review of bionanocomposite coating films and their applications. Polymers 2016, 8, 246. [Google Scholar] [CrossRef]

- Maurer, H.W.; Kearney, R.L. Opportunities and challenges for starch in the paper industry. Starch-Stärke 1998, 50, 396–402. [Google Scholar] [CrossRef]

- Chi, K.; Wang, H.; Catchmark, J.M. Sustainable starch-based barrier coatings for packaging applications. Food Hydrocoll. 2020, 103, 105696. [Google Scholar] [CrossRef]

- Vrabič-Brodnjak, U.; Možina, K. Invasive Alien Plant Species for Use in Paper and Packaging Materials. Fibers 2022, 10, 94. [Google Scholar] [CrossRef]

- Možina, K.; Bračko, S.; Kovačević, D.; Blaznik, B.; Možina, K. Legibility of Prints on Paper Made from Japanese Knotweed. BioResources 2020, 15, 3999–4015. [Google Scholar] [CrossRef]

- Hornnberry, M.; Austin, M.E.; Deardurff, L. Color-to-Color Ink Bleed Control on Media. U.S. Patent US9708497B2, 20 April 2012. Available online: https://patents.google.com/patent/US9708497B2/en (accessed on 5 August 2023).

| Sample Identification | Sample Description |

|---|---|

| GP | Paper from IAPS Goldenrod; uncoated |

| GP-1 | Paper from IAPS Goldenrod; coated; bar No. 1 |

| GP-5 | Paper from IAPS Goldenrod; coated; bar No. 5 |

| GP-8 | Paper from IAPS Goldenrod; coated; bar No. 8 |

| RP | Recycled paper; uncoated |

| RP-1 | Recycled paper; coated; bar No. 1 |

| RP-5 | Recycled paper; coated; bar No. 5 |

| RP-8 | Recycled paper; coated; bar No. 8 |

| Sample | Grammage (g/m2) | Thickness (µm) | Density (kg/m3) | Roughness (mL/min) | Air Permeability (mL/min) | Specular Gloss (%) | ISO Brightness (%) |

|---|---|---|---|---|---|---|---|

| GP | 104.7 ± 1.1 | 188 ± 4 | 557 ± 13 | 1502 ± 151 | 1418 ± 68 | 3.6 ± 0.3 | / |

| GP-1 | 131.8 ± 1.8 | 198 ± 2 | 665 ± 14 | 1460 ± 207 | 229 ± 27 | 22.1 ± 4.0 | 67.0 ± 2.2 |

| GP-5 | 161.3 ± 5.1 | 228 ± 6 | 708 ± 31 | 1360 ± 240 | 368 ± 71 | 38.4 ± 3.6 | 83.7 ± 1.9 |

| GP-8 | 207.6 ± 2.7 | 260 ± 4 | 799 ± 16 | 1240 ± 277 | 256 ± 21 | 39.2 ± 1.1 | 86.3 ± 0.7 |

| RP | 77.6 ± 1.1 | 109 ± 2 | 712 ± 15 | 238 ± 28 | 64 ± 3 | 5.0 ± 0.2 | 60.0 ± 3.0 |

| RP-1 | 120.5 ± 1.6 | 145 ± 11 | 857 ± 15 | 1020 ± 239 | 19 ± 5 | 45.5 ± 1.4 | 81.8 ± 2.7 |

| RP-5 | 167.6 ± 12.3 | 158 ± 8 | 1080 ± 64 | 700 ± 146 | 9 ± 3 | 45.6 ± 1.4 | 85.9 ± 1.1 |

| RP-8 | 208.8 ± 20.78 | 190 ± 18.3 | 1100 ± 67.63 | 1430 ± 261 | 10 ± 3 | 44.6 ± 1.26 | 86.7 ± 0.32 |

| Sample | Eab* | |||||||

|---|---|---|---|---|---|---|---|---|

| C | M | Y | K | C | M | Y | K | |

| GP/GP-1 | 39.2 | 20.4 | 30.7 | 15.2 | 0.25 | 0.26 | 0.04 | 0.41 |

| GP/GP-5 | 39.5 | 19.4 | 27.5 | 17.3 | 0.37 | 0.26 | 0.10 | 0.53 |

| GP/GP-8 | 43.2 | 22.1 | 33.3 | 18.9 | 0.49 | 0.45 | 0.19 | 0.63 |

| RP/RP-1 | 28.5 | 24.4 | 21.7 | 20.0 | 0.51 | 0.65 | 0.29 | 0.65 |

| RP/RP-5 | 27.9 | 24.7 | 22.3 | 19.9 | 0.49 | 0.71 | 0.30 | 0.62 |

| RP/RP-8 | 30.8 | 26.2 | 23.3 | 21.0 | 0.54 | 0.60 | 0.47 | 0.86 |

| GP/RP | 16.7 | 8.4 | 15.2 | 1.4 | 0.06 | 0.12 | 0.15 | 0.03 |

| GP-1/RP-1 | 4.0 | 9.2 | 1.2 | 4.3 | 0.19 | 0.28 | 0.09 | 0.21 |

| GP-5/RP-5 | 2.9 | 10.9 | 5.9 | 2.2 | 0.10 | 0.33 | 0.05 | 0.07 |

| GP-8/RP-8 | 2.0 | 7.3 | 1.2 | 1.6 | 0.09 | 0.20 | 0.01 | 0.12 |

| Sample | Increase in Half Dot (%) | TTD (%) | ||||

|---|---|---|---|---|---|---|

| Black/White (E) | Black/Yellow (8) | Yellow/Black (8) | Black/White (E) | Black/Yellow (8) | Yellow/Black (8) | |

| GP | 1.00 | 1.07 | 2.15 | 24.44 | 28.43 | 29.51 |

| GP-1 | 1.44 | 9.91 | 1.80 | 24.88 | 37.27 | 29.16 |

| GP-5 | 1.36 | 14.55 | 0.69 | 24.80 | 41.91 | 28.05 |

| GP-8 | 1.94 | 16.63 | 1.53 | 25.38 | 43.99 | 28.89 |

| RP | 4.66 | 3.03 | 1.17 | 28.10 | 30.39 | 28.53 |

| RP-1 | 2.69 | 15.64 | 2.47 | 26.13 | 43.00 | 28.93 |

| RP-5 | 1.42 | 16.99 | 3.08 | 24.86 | 44.36 | 30.44 |

| RP-8 | 1.75 | 20.39 | 2.15 | 25.18 | 47.76 | 29.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarjanović, A.; Možina, K.; Gregor-Svetec, D. Print Quality of Coated Paper from Invasive Alien Plant Goldenrod. Coatings 2023, 13, 1754. https://doi.org/10.3390/coatings13101754

Sarjanović A, Možina K, Gregor-Svetec D. Print Quality of Coated Paper from Invasive Alien Plant Goldenrod. Coatings. 2023; 13(10):1754. https://doi.org/10.3390/coatings13101754

Chicago/Turabian StyleSarjanović, Anja, Klemen Možina, and Diana Gregor-Svetec. 2023. "Print Quality of Coated Paper from Invasive Alien Plant Goldenrod" Coatings 13, no. 10: 1754. https://doi.org/10.3390/coatings13101754

APA StyleSarjanović, A., Možina, K., & Gregor-Svetec, D. (2023). Print Quality of Coated Paper from Invasive Alien Plant Goldenrod. Coatings, 13(10), 1754. https://doi.org/10.3390/coatings13101754