A Study on the Influence of the Electroplating Process on the Corrosion Resistance of Zinc-Based Alloy Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Formulation and Methodology

2.3. Electrochemical Tests

2.4. Microstructure Characterization

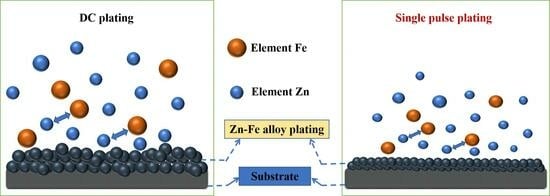

3. Results and Discussion

3.1. Surface and Cross-Section Morphology

3.2. Corrosion Resistance

3.3. Composition Analysis

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jyotheender, K.S.; Srivastava, C. Deposition current density induced alterations in texture and grain boundary constitution of electrodeposited zinc coatings for enhanced corrosion resistance performance. Metall. Mater. Trans. A 2023, 54, 2384–2393. [Google Scholar] [CrossRef]

- Liao, Z.; Hua, N.; Chen, W.; Huang, Y.; Zhang, T. Effects of noble elements on the glass-forming ability, mechanical property, electrochemical behavior and tribocorrosion resistance of Ni- and Cu-free Zr-Al-Co bulk metallic glass. Intermetallics 2017, 725, 403–414. [Google Scholar]

- Bosio, F.; Bassini, E.; Salazar, C.G.O.; Ugues, D.; Peila, D. The influence of microstructure on abrasive wear resistance of selected cemented carbide grades operating as cutting tools in dry and foam conditioned soil. Wear 2018, 394, 203–216. [Google Scholar] [CrossRef]

- Sfirloaga, P.; Poienar, M.; Malaescu, I.; Lungu, A.; Mihali, C.V.; Vlazana, P. Electrical conductivity of Ca-substituted lanthanum manganites. Ceram. Int. 2018, 44, 5823–5828. [Google Scholar] [CrossRef]

- Zhang, M.; Bi, J.; Chen, W.; Zhang, X.; Lu, J. Evaluation of calculation models for the thermal conductivity of soils. Int. Commun. Heat Mass Transfer 2018, 94, 14–23. [Google Scholar] [CrossRef]

- Carroll, A.M. Chapter One-Pattern Generators for Reflective Electron-Beam Lithography (REBL). Adv. Imag. Elect. Phys. 2015, 188, 1–23. [Google Scholar]

- Takamura, K.; Mori, A.; Watanabe, F. Structural effects of nucleic acid bases, nucleosides and nucleotides on their adsorption at a gold electrode studied by specular reflectivity measurement. Bioelectrochem. Bioenerg. 1981, 8, 125–136. [Google Scholar] [CrossRef]

- Park, H.J.; Park, J.M. Electrophoretic deposition of graphene oxide on mild carbon steel for anti-corrosion application. Bioelectrochem. Bioenerg. 2014, 254, 167–174. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Liu, R.; Wang, B.; Hua, M.; Xue, W. Anti-corrosion layer prepared by plasma electrolytic carbonitriding on pure aluminum. Appl. Surf. Sci. 2015, 347, 673–678. [Google Scholar] [CrossRef]

- Saber, K.; Koch, C.C.; Fedkiw, P.S. Pulse current electrodeposition of nanocrystalline zinc. Mater. Sci. Eng. A 2003, 341, 174–181. [Google Scholar] [CrossRef]

- Li, M.C.; Jiang, L.; Zhang, W.Q.; Qian, Y.H.; Luo, S.Z.; Shen, J.N. Electrochemical corrosion behavior of nanocrystalline zinc coatings in 3.5% NaCl solutions. J. Solid State Electrochem. 2007, 11, 1319–1325. [Google Scholar] [CrossRef]

- Youssef, K.M.S.; Koch, C.C.; Fedkiw, P.S. Influence of Additives and pulse electrodeposition parameters on production of nanocrystalline zinc from zinc chloride electrolytes. J. Electrochem. Soc. 2004, 151, 103–111. [Google Scholar] [CrossRef]

- Shibli, S.; Meena, B.; Remya, R.A. Review on Recent Approaches in the Field of Hot Dip Zinc Galvanizing Process. Surf. Coat. Technol. 2015, 262, 210–215. [Google Scholar] [CrossRef]

- Sajjadnejad, M.; Mozafari, A.; Omidvar, H.; Javanbakht, M. Preparation and corrosion resistance of pulse electrodeposited zn and Zn–SiC nanocomposite coatings. Appl. Surf. Sci. 2014, 300, 1–7. [Google Scholar] [CrossRef]

- Bajat, J.B.; Stankovic, S.; Jokic, B.M. Electrochemical deposition and corrosion stability of Zn-Co alloys. J. Solid State Electrochem. 2009, 13, 755–762. [Google Scholar] [CrossRef]

- Panagopoulos, C.N.; Georgarakis, K.G.; Giannakopoulos, K.I. Zn–Fe multilayered alloy coatings produced by electrodeposition. SN Appl. Sci. 2019, 1, 1–10. [Google Scholar] [CrossRef]

- Cammarata, R.C.; Schlesinger, T.E.; Kim, C.; Qadri, S.B.; Edelstein, A.S. Nanoindentation study of the mechanical properties of copper–nickel multilayered thin flms. Appl. Phys. Lett. 1990, 56, 1862. [Google Scholar] [CrossRef]

- Hansen, Μ. Constitution of Binary Alloys, 2nd ed.; Mc Graw Hill: New York, NY, USA, 1958. [Google Scholar]

- De Wit, Κ.; De Boeck, A.; De Cooman, B.C. Study of the infuence of phase composition and iron content on the formability characteristics of zinc–iron electroplated sheet steel. J. Mater. Eng. Perform. 1999, 8, 531. [Google Scholar] [CrossRef]

- Minggyuan, G.; Notis, M.R.; Marder, A.R. The efect of continuous heating on the phase transformations in zinc-iron electrodeposited coatings. Met. Metall. Trans. A 1991, 22, 1737. [Google Scholar] [CrossRef]

- Short, N.R.; Abibsi, A.; Dennis, J.K. Corrosion resistance of electroplated zinc alloy coatings. Trans. Inst. Met. Finish. 1989, 67, 73–77. [Google Scholar] [CrossRef]

- Abibsi, A.; Dennis, J.K.; Short, N.R. The effect of plating variables on zinc-nickel alloy electrodeposition. Trans. Inst. Met. Finish. 1991, 69, 145–148. [Google Scholar] [CrossRef]

- Ramanauskas, R.; Juskenas, R.; Kalinicenko, L.; Garfias-Mesias, F. Microstructure and corrosion resistance of electrodeposited zinc alloy coatings. J. Solid State Electrochem. 2004, 8, 416–421. [Google Scholar] [CrossRef]

- Akdogan, C.; Bakkaloglu, O.F.; Bedir, M.; Erdogan, P.Y.; Yavuz, A. Electrodeposition of Fe-Zn, Fe-Mn and Fe-Zn-Mn alloys on steel from ionic liquids. Dig. J. Nanomater. Bios. 2022, 17, 589–596. [Google Scholar] [CrossRef]

- Warfsmann, S.; Taffa, D.H.; Wark, M. Reprint of “photoelectrocatalytic behavior of electrodeposited zinc ferrite films with varying Zn: Fe ratio”. J. Photochem. 2018, 366, 18–26. [Google Scholar]

- Arrighi, C.; Savall, C.; Cohendoz, S.; Grosseau-Poussard, J.L.; Baissac, L.; Olivier, M.G.; Creus, J. Optimization of the morphology, structure and properties of high iron content Zn–Fe coatings by pulse electrodeposition. Mater. Chem. Phys. 2021, 263, 124366. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, W.; Yu, F.; Wang, Y.; Qi, M.; Zhao, Y.; Wang, Y. Effects of pulse frequency and current density on microstructure and properties of biodegradable Fe-Zn alloy. J. Mater. Res. Technol. 2022, 18, 44–58. [Google Scholar] [CrossRef]

- Ramanauskas, R.; Gudavičiūtė, L.; Juškėnas-Chemija, R. Effect of pulse plating on the composition and corrosion properties of Zn–Co and Zn–Fe alloy coatings. Chemijia 2008, 19, 7–13. [Google Scholar]

- Istrate, B.; Munteanu, C.; Baltatu, M.S.; Cimpoesu, R.; Ioanid, N. Microstructural and Electrochemical Influence of Zn in MgCaZn Biodegradable Alloys. Materials 2023, 16, 2487. [Google Scholar] [CrossRef] [PubMed]

- Shourgeshty, M.; Aliofkhazraei, M.; Karimzadeh, A. Study on functionally graded Zn-Ni-Al2O3 coatings fabricated by pulse-electrodeposition. Surf. Eng. 2018, 35, 167–176. [Google Scholar] [CrossRef]

- Ma, C.; Zhao, D.; Liu, W.; Xia, F.; Jin, P.; Sun, C. Magnetic assisted pulse electrodeposition and characterization of Ni-TiC nanocomposites. Ceram. Int. 2020, 46, 17631–17639. [Google Scholar] [CrossRef]

- Slavash, I.G.; Ali, S.; Shiva, N.; Rezvan, Y. Influence of pulse electrodeposition parameters on microhardness, grain size and surface morphology of Ni-Co/SiO2 nanocomposite coating. Bull. Mater. Sci. 2016, 39, 1–11. [Google Scholar]

- Barati Darband, G.; Aliofkhazraei, M.; Hyun, S.; Shanmugam, S. Pulse electrodeposition of a superhydrophilic and binder-free Ni-Fe-P nanostructure as highly active and durable electrocatalyst for both hydrogen and oxygen evolution reactions. ACS Appl. Mater. Interfaces 2020, 12, 53719–53730. [Google Scholar] [CrossRef] [PubMed]

- Jin, P.; Sun, C.; Zhang, Z.; Zhou, C.; Williams, T. Fabrication of the Ni-W-SiC thin film by pulse electrodeposition. Surf. Coat. Technol. 2020, 392, 125738. [Google Scholar] [CrossRef]

- Krajaisri, P.; Puranasiri, R.; Chiyasak, P.; Rodchanarowan, A. Investigation of pulse current densities and temperatures on electrodeposition of tin-copper alloys. Surf. Coat. Technol. 2022, 435, 128244. [Google Scholar] [CrossRef]

- Vamsi, M.V.N.; Wasekar, N.P.; Sundararajan, G. Influence of heat treatment on microstructure and mechanical properties of pulse electrodeposited Ni-W alloy coatings. Surf. Coat. Technol. 2017, 319, 403–414. [Google Scholar] [CrossRef]

- Parunyoo, K.; Michael, L.F.; Akeel, A.S.; Aphichart, R. The effects of duty cycles on pulsed current electrodeposition of Znsingle bondNisingle bondAl2O3 composite on steel substrate: Microstructures, hardness and corrosion resistance. Int. J. Hydrogen Energy 2017, 42, 20783–20790. [Google Scholar]

- Victoria, B.L.; Liliana, A.D.; Gabriela, I.L.; Graciela, C.A.; Esteban, A.F. Effect of duty cycle on NiMo alloys prepared by pulsed electrodeposition for hydrogen evolution reaction. J. Alloys Compd. 2022, 897, 163161. [Google Scholar]

- Elmkhah, H.; Abdollah-Zadeh, A.; Mahboubi, F.; Rouhaghdam, A.R.S.; Fattah-Alhosseini, A. Correlation between the duty cycle and the surface characteristics for the nanostructured titanium aluminum nitride coating deposited by pulsed-DC PACVD technique. J. Alloys Compd. 2017, 711, 530–540. [Google Scholar] [CrossRef]

- Ibl, N.; Puippe, J.C.; Angerer, H. Electrocrystallization in pulse electrolysis. Surf. Technol. 1978, 6, 287–300. [Google Scholar] [CrossRef]

- Mandich, N.V. Pulse and pulse-reverse electroplating. Met. Finish. 2000, 98, 375–380. [Google Scholar] [CrossRef]

- Ramanauskas, R.; Gudavičiūtė, L.; Kaliničenko, A.; Juškėnas, R. Pulse plating effect on microstructure and corrosion properties of Zn-Ni alloy coatings. J. Solid State Electrochem. 2005, 9, 900–908. [Google Scholar] [CrossRef]

- Mišković-Stanković, V.B.; Zotović, J.B.; Kačarević-Popović, Z.; Maksimović, M.D. Corrosion behaviour of epoxy coatings electrodeposited on steel electrochemically modified by Zn-Ni alloy. Electrochim. Acta 1999, 44, 4269–4277. [Google Scholar] [CrossRef]

- Bajat, J.B.; Kačarević-Popović, Z.; Mišković-Stanković, V.B.; Maksimović, M.D. Corrosion behaviour of epoxy coatings electrodeposited on galvanized steel and steel modified by Zn-Ni alloys. Prog. Org. Coat. 2000, 39, 127–135. [Google Scholar] [CrossRef]

- Brenner, A. Structure of electrodeposited alloys. In Electrodeposition of Alloys, 1st ed.; Academic Press Inc: New York, NY, USA, 1963; Volume 2, pp. 194–227. [Google Scholar]

- Kondo, K.; Hinotani, S.; Ohmori, Y. Crystal structure and morphology of electrodeposited zinc-iron binary alloys. J. Appl. Electrochem. 1988, 18, 154–161. [Google Scholar] [CrossRef]

- Powder Diffraction File. Inorganic Volume PD/S 5iRB, Sets 1–5. In American Society for Testing and Materials; ASTM International: Philadelphia, PA, USA, 1969. [Google Scholar]

- Ramanauskas, R. Structural factor in Zn alloy electrodeposit corrosion. Appl. Surf. Sci. 1999, 153, 53–64. [Google Scholar] [CrossRef]

- Guo, R.; Weinberg, F.; Tromans, D. Pitting Corrosion of Passivated Zinc Monocrystals. Corrosion 1995, 51, 356–366. [Google Scholar] [CrossRef]

- Ashton, R.F.; Hepworth, M.P. Effect of Crystal Orientation on the Anodic Polarization and Passivity of Zinc. Corrosion 1968, 24, 50–53. [Google Scholar] [CrossRef]

- Park, C.J.; Lohrengel, M.M.; Hamelmann, T.; Kwon, H.S.; Pilaski, M. Grain-dependent passivation of surfaces of polycrystalline zinc. Electrochim. Acta 2002, 47, 3395–3399. [Google Scholar] [CrossRef]

- Thangaraj, V. Electrodeposition and corrosion behaviour of some Zn-Fe group metal alloys by pulsed current. Trans. Inst. Met. Finish. 2009, 87, 208–216. [Google Scholar] [CrossRef]

- Feng, Z.B.; Li, Q.Y.; Zhang, J.Q.; Yang, P.X.; An, M.Z. Electrochemical Behaviors and Properties of Zn-Ni Alloys Obtained from Alkaline Non-Cyanide Bath Using 5,5’-Dimethylhydantoin as Complexing Agent. J. Electrochem. Soc. 2015, 162, 412–422. [Google Scholar] [CrossRef]

- Nayana, K.O.; Prashanth, S.A.; Venkatesha, T.V.; Pandurangappa, M. Effect of additives on nanocrystalline bright Zn-Ni-Fe alloy electrodeposit properties. Surf. Eng. 2019, 35, 1061–1069. [Google Scholar] [CrossRef]

- Wang, X.M.; Li, Y.Y.; Gu, Z.F.; Shang, Y.X.; Wang, J.P.; Shi, L.; Wu, C.X.; Li, H.; Huang, S.X.; Chen, Y.F. The Method for Plating Door and Window Hardware with a Green Finish. P.R.China ZL202110139215.1, 25 February 2022. [Google Scholar]

| Composition and Parameter Selection | Concentration and Parameter Value |

|---|---|

| ZnO (g/L) | 10–14 |

| NaOH (g/L) | 100–150 |

| FeCl2 (g/L) | 1–2 |

| Ascorbic acid (g/L) | 15–20 |

| EDTA-Na2 (g/L) | 15–20 |

| DPE-III (ml/L) | 5–10 |

| BH-336 (ml/L) | 2–6 |

| Temperature (°C) | 25 |

| pH | 12 |

| Mean current density (A/dm2) | 9 |

| Duty cycle (r) | 30% |

| Work time (min) | 15 |

| Frequency (Hz) | 1000 |

| Parameter Selection | Parameter Value |

|---|---|

| Temperature (°C) | 25 |

| pH | 12 |

| Mean current density (A/dm2) | 9 |

| Working time (min) | 15 |

| The Surface Type | Ecorr (mV) | icorr (A∙cm−2) | Rp(Ω∙cm2) | Corrosion Rate (10−5 g∙m−2∙h−1) | Anodic Slope (mV/Decade) | Cathodic Slope (mV/Decade) |

|---|---|---|---|---|---|---|

| Monopulse plating | −1008 | 0.321 × 10−5 | 898 | 0.386 | 7.899 | 8.183 |

| DC plating | −1031 | 3.122 × 10−5 | 123 | 3.75 | 3.670 | 5.285 |

| The Surface Type | Rs (Ω·cm2) | CPE-T (10−4 Ω−1·cm−2·sn) | Rct (Ω·cm2) | Rp (Ω·cm2) |

|---|---|---|---|---|

| Monopulse plating 1 | 15.86 | 23.83 | 545.64 | 561.50 |

| DC plating 2 | 9.56 | 51.87 | 213.54 | 223.10 |

| Element | Monopulse (wt.%) | DC (wt.%) |

|---|---|---|

| Zn | 79.6 | 77.3 |

| Fe | 5.9 | 6.6 |

| O | 1.6 | 1.8 |

| C | 7.8 | 8.4 |

| Na | 5.1 | 6.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, F.; Wang, J.; Lian, Y.; Wang, Y.; Wang, X.; Wang, X.; Song, A.; Shi, L. A Study on the Influence of the Electroplating Process on the Corrosion Resistance of Zinc-Based Alloy Coatings. Coatings 2023, 13, 1774. https://doi.org/10.3390/coatings13101774

Cao F, Wang J, Lian Y, Wang Y, Wang X, Wang X, Song A, Shi L. A Study on the Influence of the Electroplating Process on the Corrosion Resistance of Zinc-Based Alloy Coatings. Coatings. 2023; 13(10):1774. https://doi.org/10.3390/coatings13101774

Chicago/Turabian StyleCao, Fan, Jianpeng Wang, Yuli Lian, Yuanhao Wang, Xue Wang, Xiaomin Wang, Aiqing Song, and Lei Shi. 2023. "A Study on the Influence of the Electroplating Process on the Corrosion Resistance of Zinc-Based Alloy Coatings" Coatings 13, no. 10: 1774. https://doi.org/10.3390/coatings13101774