Effect of Different Etching Processes on Surface Defects of Quartz Crystals

Abstract

:1. Introduction

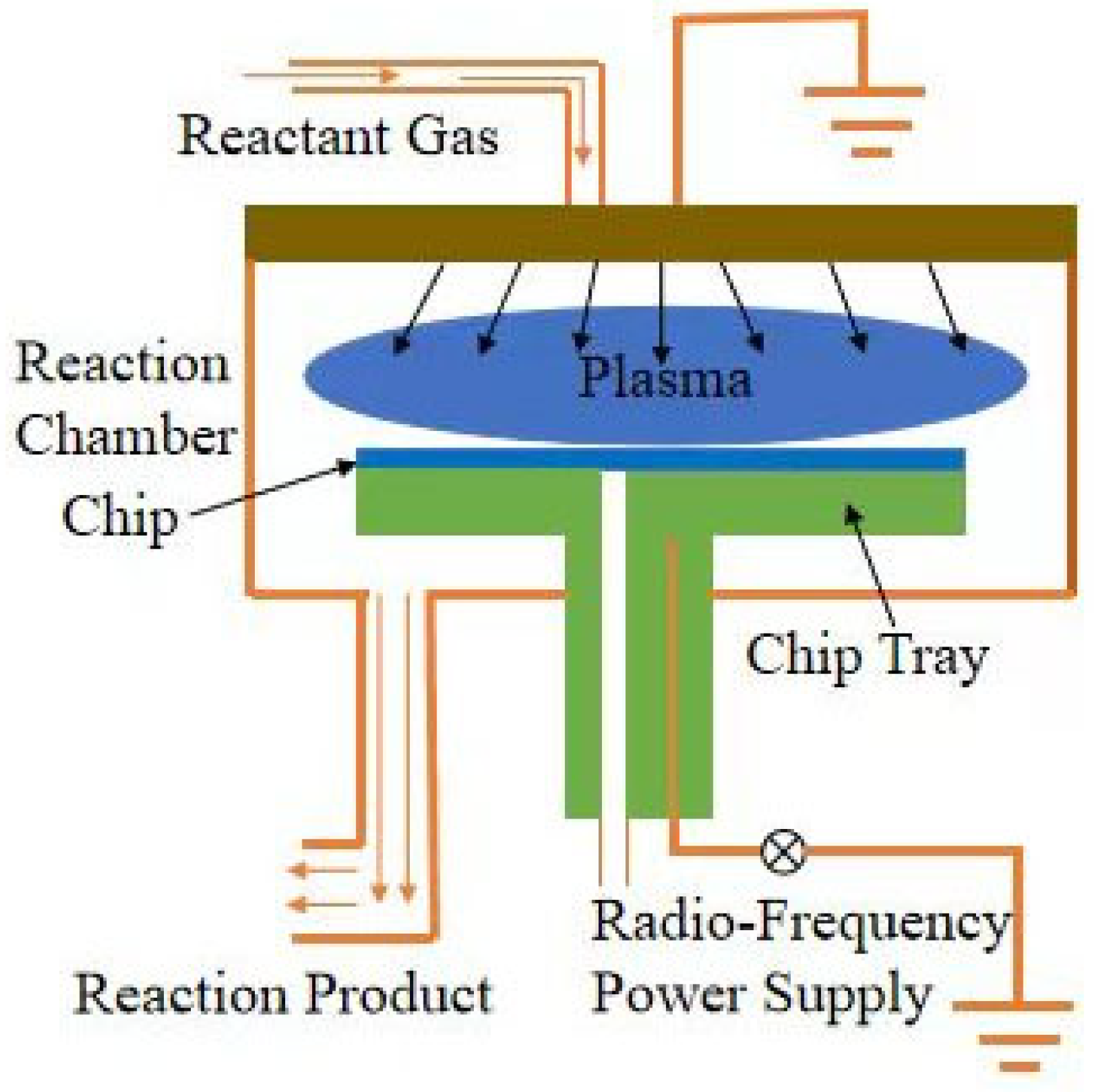

2. Experimental Section

3. Results and Discussion

3.1. Etching Rate Calibration

3.2. Surface Roughness Analysis

3.3. Chemical Structure Analysis

3.4. Fluorescence Spectral Analysis

3.5. Photothermal Weak Absorption Analysis

3.6. X-ray Diffraction Analysis

3.7. Laser Damage Threshold of the Sample

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Ding, Y.; Xie, J.; Xu, L.; Jeong, I.W.; Yang, L. One-step femtosecond laser irradiation of single-crystal silicon: Evolution of micro-nano structures and damage investigation. Mater. Des. 2023, 225, 111443. [Google Scholar] [CrossRef]

- Michine, Y.; Yoneda, H. Ultra high damage threshold optics for high power lasers. Commun. Phys. 2020, 3, 24. [Google Scholar] [CrossRef]

- Yang, D.; Cheng, J.; Zhao, L.; Chen, M.; Liu, H.; Wang, J.; Han, C.; Liu, Z.; Wang, S.; Geng, F.; et al. Evolution of the point defects involved under the action of mechanical forces on mechanically machined fused silica surfaces. Opt. Express 2023, 31, 7684–7706. [Google Scholar] [CrossRef] [PubMed]

- Bercegol, H.; Boscheron, A.; Di-Nicola, J.M.; Journot, E.; Lamaignère, L.; Něauport, J.; Razě, G. Laser damage phenomena relevant to the design and operation of an ICF laser driver. J. Phys. Conf. Ser. 2008, 112, 032013. [Google Scholar] [CrossRef]

- Caird, J.; Agrawal, V.; Bayramian, A.; Beach, R.; Britten, J.; Chen, D.; Cross, R.; Ebbers, C.; Erlandson, A.; Feit, M.; et al. Nd: Glass laser design for laser ICF fission energy (LIFE). Fusion Sci. Technol. 2009, 56, 607–617. [Google Scholar] [CrossRef]

- Yoshida, H.; Fujita, H.; Nakatsuka, M.; Ueda, T.; Fujinoki, A. Temporal compression by stimulated Brillouin scattering of Q-switched pulse with fused-quartz and fused-silica glass from 1064 nm to 266 nm wavelength. Laser Part. Beams 2007, 25, 481–488. [Google Scholar] [CrossRef]

- Qiao, S.; Shi, F.; Tian, Y.; Song, C.; Tie, G.; Shen, X.; Song, J. Modeling and experiment on elastic region low defect jet polishing for fused quartz. J. Manuf. Process. 2022, 77, 831–837. [Google Scholar] [CrossRef]

- Bude, J.; Miller, P.; Baxamusa, S.; Shen, N.; Laurence, T.; Steele, W.; Suratwala, T.; Wong, L.; Carr, W.; Cross, D.; et al. High fluence laser damage precursors and their mitigation in fused silica. Opt. Express 2014, 22, 5839–5851. [Google Scholar] [CrossRef]

- Laurence, T.A.; Bude, J.D.; Ly, S.; Shen, N.; Feit, M.D. Extracting the distribution of laser damage precursors on fused silica surfaces for 351 nm, 3 ns laser pulses at high fluences (20–150 J/cm2). Opt. Express 2012, 20, 11561–11573. [Google Scholar] [CrossRef]

- Wang, G.; Cai, C.; He, X.; Huang, J.Y.; Ma, P.; Yan, D.Y. The effect of ion beam etching process on laser damage resistance of fused silica. In Proceedings of the 9th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Advanced Optical Manufacturing Technologies, Chengdu, China, 26–29 June 2018; SPIE: Bellingham, WA, USA, 2019; Volume 10838, pp. 269–276. [Google Scholar]

- Shi, F.; Tian, Y.; Peng, X.; Dai, Y. Combined technique of elastic magnetorheological finishing and HF etching for high-efficiency improving of the laser-induced damage threshold of fused silica optics. Appl. Opt. 2014, 53, 598–604. [Google Scholar] [CrossRef]

- Néauport, J.; Ambard, C.; Bercegol, H.; Cahuc, O.; Champreux, J.P.; Charles, J.L.; Cormont, P.; Darbois, N.; Darnis, P.; Destribats, J.; et al. Optimizing fused silica polishing processes for 351nm high-power laser application. In Laser-Induced Damage in Optical Materials; SPIE: Bellingham, WA, USA, 2008; Volume 7132, pp. 462–468. [Google Scholar]

- Shen, N.; Bude, J.D.; Carr, C.W. Model laser damage precursors for high quality optical materials. Opt. Express 2014, 22, 3393–3404. [Google Scholar] [CrossRef] [PubMed]

- Kato, D.; Suzuki, H.; Okada, M. C007 Uniform Polishing of Large Aspheric Lenses by Magnetic Field-Assisted Polishing. In Proceedings of the International Conference on Leading Edge Manufacturing in 21st century: LEM21, Miyagi, Japan, 7–8 November 2013; The Japan Society of Mechanical Engineers: Tokyo, Japan, 2013; pp. 333–336. [Google Scholar]

- Wang, Y.; Zhang, F.; Li, C. Surface Shape Evolution of Optical Elements during Continuous Polishing of Fused Quartz. Crystals 2022, 12, 736. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, Z.; Meng, F.; Liu, L.; Liu, D.; Shi, C.; Cui, X.; Wang, J.; Wen, W. Atomic-scale surface of fused silica induced by chemical mechanical polishing with controlled size spherical ceria abrasives. J. Manuf. Process. 2023, 85, 783–792. [Google Scholar] [CrossRef]

- Bao, J.; Hu, H.; Peng, X.; Wang, Y.; Zhong, Y. Ultra-precision grinding and polishing of fused quartz material. In Proceedings of the Seventh Asia Pacific Conference on Optics Manufacture and 2021 International Forum of Young Scientists on Advanced Optical Manufacturing (APCOM and YSAOM 2021), Hong Kong, China, 13–16 August 2021; SPIE: Bellingham, WA, USA, 2022; Volume 12166, pp. 337–346. [Google Scholar]

- Hou, J.; Chen, X.; Li, J.; Bo, Z.; Deng, W. Processing technology of magnetorheological finishing for large-aperture optical components. In Freeform Optics; Optica Publishing Group: Washington, DC, USA, 2019; paper JT5A.22. [Google Scholar]

- Griscom, D.L. Point Defects in Amorphous SiO2: What Have We Learned from 30 Years of Experimentation? MRS Online Proceedings Library (OPL): Warrendale, PA, USA, 1985; Volume 61, p. 213. [Google Scholar]

- Abyzov, A.S.; Androsch, R.; Baidakov, V.G.; Fokin, V.M.; Gutzov, S.; Gutzow, I.S.; Johari, G.P.; Jordanov, N.; Karamanov, A.; Zhuravlev, E.; et al. Glass: Selected Properties and Crystallization; Walter de Gruyter: Berlin, Germany, 2014. [Google Scholar]

- Jiao, Y.; Wang, K.-M.; Wang, X.-L.; Wang, L.; Jia, C.-L.; Jiang, Y.; Zhang, J.-H.; Lu, F. Ion beam etched diffraction gratings in fused quartz and lithium niobate. Surf. Coat. Technol. 2007, 201, 5046–5049. [Google Scholar] [CrossRef]

- Luo, J.; Zeng, B.; Wang, C.; Gao, P.; Liu, K.; Pu, M.; Jin, J.; Zhao, Z.; Li, X.; Yu, H.; et al. Fabrication of anisotropically arrayed nano-slots metasurfaces using reflective plasmonic lithography. Nanoscale 2015, 7, 18805–18812. [Google Scholar] [CrossRef]

- Nagarah, J.M.; Wagenaar, D.A. Ultradeep fused silica glass etching with an HF-resistant photosensitive resist for optical imaging applications. J. Micromech. Microeng. 2012, 22, 035011. [Google Scholar] [CrossRef]

- Wang, Y.; Asadian, M.H.; Shkel, A.M. Modeling the effect of imperfections in glassblown micro-wineglass fused quartz resonators. J. Vib. Acoust. 2017, 139, 040909. [Google Scholar] [CrossRef]

- Ye, X.; Huang, J.; Liu, H.; Geng, F.; Sun, L.; Jiang, X.; Wu, W.; Qiao, L.; Zu, X.; Zheng, W. Advanced mitigation process (AMP) for improving laser damage threshold of fused silica optics. Sci. Rep. 2016, 6, 31111. [Google Scholar] [CrossRef]

- Jung, H.K.; Hwang, Y.S.; Hyeon, I.J.; Kim, Y.K.; Baek, C.W. Silicon/quartz bonding and quartz deep RIE for the fabrication of quartz resonator structures. In Proceedings of the 2008 3rd IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Sanya, China, 6–9 January 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1172–1176. [Google Scholar]

- Asadian, M.H.; Wang, D.; Shkel, A.M. Fused quartz dual-shell resonator gyroscope. J. Microelectromech. Syst. 2022, 31, 533–545. [Google Scholar] [CrossRef]

- Schmitt, J.; Meier, A.; Wallrabe, U.; Völklein, F. Reactive ion etching (CF4/Ar) and ion beam etching of various glasses for diffractive optical element fabrication. Int. J. Appl. Glass Sci. 2018, 9, 499–509. [Google Scholar] [CrossRef]

- Mutilba, U.; Gomez-Acedo, E.; Kortaberria, G.; Olarra, A.; Yagüe-Fabra, J.A. Traceability of on-machine tool measurement: A review. Sensors 2017, 17, 1605. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Zhang, Y.; Zhou, X.; Duan, M.; Ye, X.; Li, W.; Li, Y.; Yang, L. Towards investigating surface quality of single-crystal silicon optics polished with different processes. Coatings 2022, 12, 158. [Google Scholar] [CrossRef]

| Sample | Ar (sccm) | CHF3 (sccm) | Intensity of Pressure (mtorr) | Power (W) | Etching Rate (µm/h) | Etching Time (min) |

|---|---|---|---|---|---|---|

| A | 5 | 72 | 20 | 200 | 2.14 ± 0.01 | 28.0 |

| B | 5 | 72 | 20 | 150 | 1.50 ± 0.01 | 40.0 |

| C | 5 | 72 | 20 | 250 | 2.36 ± 0.01 | 25.5 |

| D | 38 | 39 | 20 | 200 | 1.67 ± 0.01 | 36.0 |

| E | 50 | 27 | 20 | 200 | 2.00 ± 0.01 | 30.0 |

| F | 5 | 72 | 10 | 200 | 1.92 ± 0.01 | 31.5 |

| G | 5 | 72 | 30 | 200 | 1.94 ± 0.01 | 31.0 |

| Sample | Pre-Etch (rad) | Post-Etch (rad) |

|---|---|---|

| A | 0.009 | 0.007 |

| B | 0.008 | 0.0075 |

| C | 0.009 | 0.0085 |

| D | 0.0075 | 0.008 |

| E | 0.007 | 0.0065 |

| F | 0.0085 | 0.007 |

| G | 0.0075 | 0.0065 |

| Sample | Pre-Etch | Post-Etch |

|---|---|---|

| A | 0.9807764 × 10−6 | 1.260998 × 10−6 |

| B | 1.103373 × 10−6 | 1.176932 × 10−6 |

| C | 0.980776 × 10−6 | 1.038469 × 10−6 |

| D | 1.176932 × 10−6 | 1.103373 × 10−6 |

| E | 1.260998 × 10−6 | 1.357998 × 10−6 |

| F | 1.038469 × 10−6 | 1.260998 × 10−6 |

| G | 1.176932 × 10−6 | 1.357998 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Zhang, Y.; Shi, Z.; Li, W.; Ye, X. Effect of Different Etching Processes on Surface Defects of Quartz Crystals. Coatings 2023, 13, 1785. https://doi.org/10.3390/coatings13101785

Li Q, Zhang Y, Shi Z, Li W, Ye X. Effect of Different Etching Processes on Surface Defects of Quartz Crystals. Coatings. 2023; 13(10):1785. https://doi.org/10.3390/coatings13101785

Chicago/Turabian StyleLi, Qingzhi, Yubin Zhang, Zhaohua Shi, Weihua Li, and Xin Ye. 2023. "Effect of Different Etching Processes on Surface Defects of Quartz Crystals" Coatings 13, no. 10: 1785. https://doi.org/10.3390/coatings13101785

APA StyleLi, Q., Zhang, Y., Shi, Z., Li, W., & Ye, X. (2023). Effect of Different Etching Processes on Surface Defects of Quartz Crystals. Coatings, 13(10), 1785. https://doi.org/10.3390/coatings13101785