Relaxor Ferroelectric AgNbO3 Film Fabricated on (110) SrTiO3 Substrates via Pulsed Laser Deposition

Abstract

:1. Introduction

2. Experimental Procedure

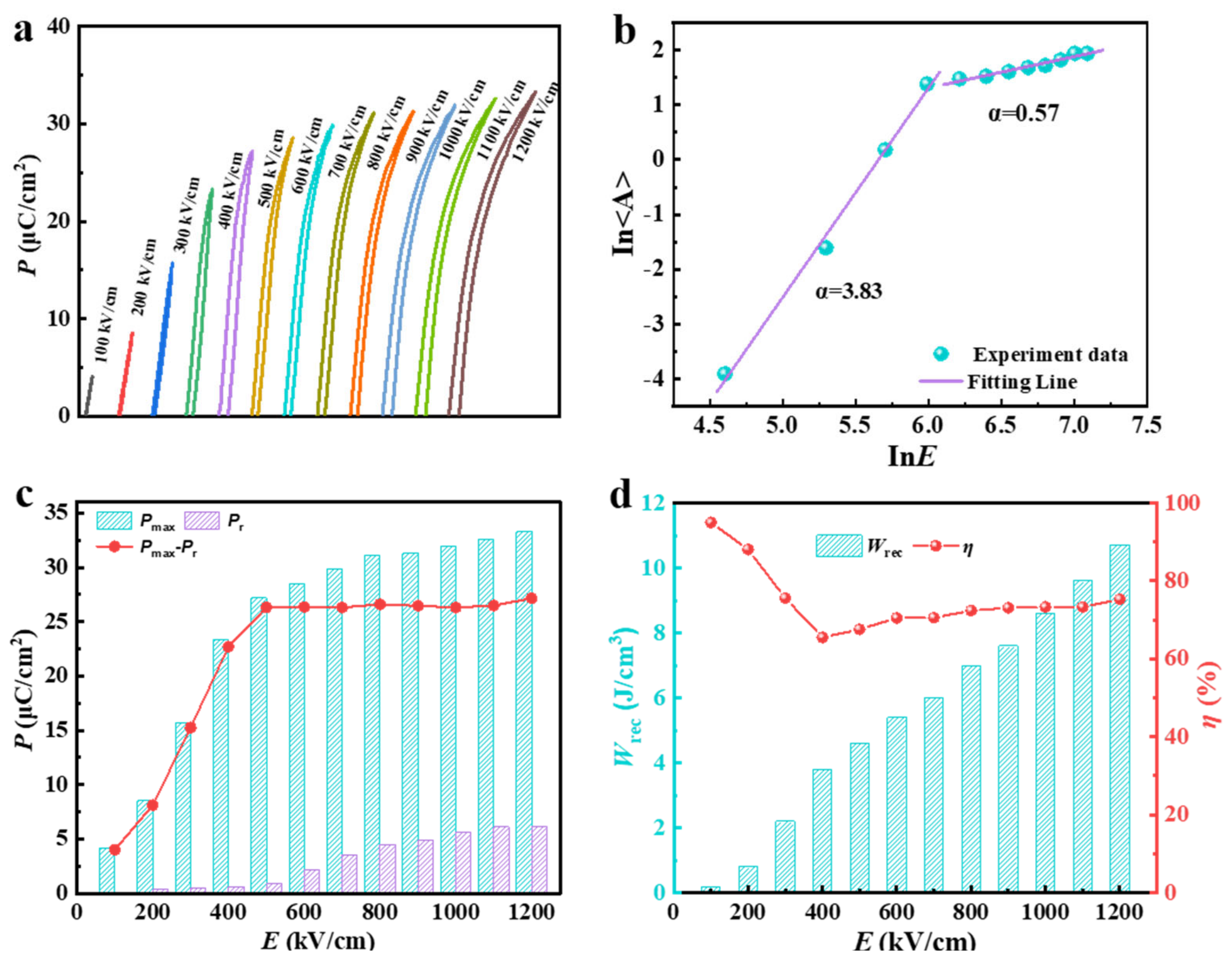

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, H.U.; Iagodkine, E.; Chen, L.Q.; Jackson, T.N. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.H.; Song, Z.; Hao, H.; Yu, Z.Y.; Liu, H.X. Homogeneous/inhomogeneous-structured dielectrics and their energy-storage performances. Adv. Mater. 2017, 29, 1601727. [Google Scholar] [CrossRef] [PubMed]

- Chu, B.J.; Zhou, X.; Ren, K.L.; Neese, B.; Lin, M.R.; Wang, Q.; Bauer, F.; Zhang, Q.M. A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313, 334–336. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Ma, J.; Zhang, Q.H.; Liu, X.Z.; Guan, B.; Gu, L.; Zhang, X.; Zhang, Y.J.; Li, L.L.; Shen, Y.; et al. Giant energy density and high efficiency achieved in bismuth ferrite-based film capacitors via domain engineering. Nat. Commun. 2018, 9, 1813. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.L.; Zhang, Q.; Li, X.; Sun, T.Y.; Fan, H.Q.; Ke, S.M.; Ye, M.; Wang, Y.; Lu, W.; Niu, H.B.; et al. Large energy storage density and high thermal stability in a highly textured (111)-oriented Pb0.8Ba0.2ZrO3 relaxor thin film with the coexistence of antiferroelectric and ferroelectric phases. ACS Appl. Mater. Interfaces 2015, 7, 13512–13517. [Google Scholar] [CrossRef]

- Li, J.L.; Shen, Z.H.; Chen, X.H.; Li, J.L.; Shen, Z.H.; Chen, X.H.; Yang, S.; Zhou, W.L.; Wang, M.W.; Wang, L.H.; et al. Grain-orientation-engineered multilayer ceramic capacitors for energy storage applications. Nat. Mater. 2020, 19, 999–1005. [Google Scholar]

- Yang, L.T.; Kon, X.; Li, F.; Hao, H.; Cheng, Z.X.; Liu, H.X.; Li, J.F.; Zhang, S.J. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 2019, 102, 72–108. [Google Scholar] [CrossRef]

- Liu, X.H.; Li, Y.; Hao, X.H. Ultra-high energy-storage density and fast discharge speed of (Pb0.98-xLa0.02Srx)(Zr0.9Sn0.1)0.995O3 antiferroelectric ceramics prepared via the tape-casting method. J. Mater. Chem. A 2019, 7, 11858–11866. [Google Scholar] [CrossRef]

- Peng, B.L.; Zhang, Q.; Gang, B.; Leighton, G.J.T.; Shaw, C.; Milne, S.J.; Zou, B.S.; Sun, W.H.; Huang, H.T.; Wang, Z.L. Phase-transition induced giant negative electrocaloric effect in a lead-free relaxor ferroelectric thin film. Energy. Environ. Sci. 2019, 12, 1708–1717. [Google Scholar] [CrossRef]

- Fu, D.; Itoh, M.; Koshihara, S.Y. Dielectric, ferroelectric, and piezoelectric behaviors of AgNbO3-KNbO3 solid solution. J. Appl. Phys. 2009, 106, 104104. [Google Scholar] [CrossRef]

- Yao, K.; Chen, S.T.; Rahimabady, M.; Mirshekarloo, M.S.; Yu, S.H.; Tay, F.E.H.; Sritharan, T.; Lu, L. Nonlinear dielectric thin films for high-power electric storage with energy density comparable with electrochemical supercapacitors. IEEE. Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 1968–1974. [Google Scholar] [PubMed]

- Sakurai, H.; Yamazoe, S.; Wada, T. Ferroelectric and antiferroelectric properties of AgNbO3 films fabricated on (001), (110), and (111)SrTiO3 substrates by pulsed laser deposition. Appl. Phys. Lett. 2010, 97, 042901. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Li, X.B.; Song, J.M.; Zhang, S.W.; Wang, J.; Dai, X.H.; Liu, B.T.; Dong, G.Y.; Zhao, L. AgNbO3 antiferroelectric film with high energy storage performance. J. Mater. 2021, 7, 1294–1300. [Google Scholar] [CrossRef]

- Shu, L.; Zhang, X.; Li, W.; Gao, J.; Wang, H.L.; Huang, Y.; Cheng, Y.Y.S.; Li, Q.; Liu, L.S.; Li, J.F. Phase-pure antiferroelectric AgNbO3 films on Si substrates: Chemical solution deposition and phase transitions. J. Mater. Chem. A 2022, 10, 12632–12642. [Google Scholar] [CrossRef]

- Luo, N.N.; Han, K.; Zhuo, F.P.; Liu, L.J.; Chen, X.Y.; Peng, B.L.; Wang, X.P.; Feng, Q.; Wei, Y.Z. Design for high energy storage density and temperature-insensitive lead-free antiferroelectric ceramics. J. Mater. Chem. A. 2019, 7, 14118–14128. [Google Scholar] [CrossRef]

- Ma, L.; Che, Z.Y.; Xu, C.; Cen, Z.Y.; Feng, Q.; Chen, X.Y.; Toyohisa, F.; Li, J.-F.; Zhang, S.J.; Luo, N.N. High energy storage density and efficiency in AgNbO3 based relaxor antiferroelectrics with reduced silver content. J. Eur. Cream. Soc. 2023, 43, 3228–3235. [Google Scholar] [CrossRef]

- Zhou, J.; Du, J.H.; Chen, L.M.; Li, Y.; Xu, L.Z.; Zhao, Q.R.; Yang, H.L.; Ding, J.X.; Sun, Z.M.; Hao, X.H.; et al. Enhanced the energy storage performance in AgNbO3-based antiferroelectric ceramics via manipulation of oxygen vacancy. J. Eur. Ceram. Soc. 2023, 43, 6059–6068. [Google Scholar] [CrossRef]

- Wang, J.; Wan, X.H.; Rao, Y.; Zhao, L.; Zhu, K.J. Hydrothermal synthesized AgNbO3 powders: Leading to greatly improved electric breakdown strength in ceramics. J. Eur. Ceram. Soc. 2020, 40, 5589–5596. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Wang, J.; Chen, L.; Yuan, H.; Zhang, M.H. Enhanced breakdown strength and energy storage density of AgNbO3 ceramics via casting. Rare Met. 2023, 42, 495–502. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Wang, J.; Zhang, J.; Zhu, L.F.; Zhao, L. Ultrahigh energy storage performance realized in AgNbO3-based antiferroelectric materials via multiscale engineering. J. Adv. Ceram. 2023, 12, 1166–1177. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; San, X.Y.; Wang, N.; Zhao, L. High energy storage performance in AgNbO3 relaxor ferroelectric films induced by nanopillar structure. J. Mater. Sci. Technol. 2023, 155, 160–166. [Google Scholar] [CrossRef]

- Xie, A.W.; Fu, J.; Zuo, R.Z.; Jiang, X.W.; Li, T.Y.; Fu, Z.Q.; Yin, Y.W.; Li, X.G.; Zhang, S.J. Achieving stable relaxor antiferroelectric P phase in NaNbO3-based lead-free ceramics for energy-storage applications. Adv. Mater. 2022, 34, 2204356. [Google Scholar] [CrossRef]

- Yu, G.; Dong, X.L.; Wang, G.S.; Gao, F.; Chen, X.F.; Nie, H.C. Three-stage evolution of dynamic hysteresis scaling behavior in 63PbTiO3-37BiScO3 bulk ceramic. J. Appl. Phys. 2010, 107, 106102. [Google Scholar] [CrossRef]

- Yimnirun, R.; Wongmaneerung, R.; Wongsaenmai, S.; Ngamjarurojana, A.; Ananta, S.; Laosiritaworn, Y. Temperature scaling of dynamic hysteresis in soft lead zirconate titanate bulk ceramic. Appl. Phys. Lett. 2007, 90, 112908. [Google Scholar] [CrossRef]

- Shi, J.P.; Chen, X.L.; Li, X.; Sun, J.; Sun, C.C.; Pang, F.H.; Zhou, H.F. Realizing ultrahigh recoverable energy density and superior charge-discharge performance in NaNbO3-based lead-free ceramics via a local random field strategy. J. Mater. Chem. C 2020, 8, 3784–3794. [Google Scholar] [CrossRef]

- Pan, H.; Lan, S.; Xu, S.Q.; Zhang, Q.H.; Yao, H.B.; Liu, Y.Q.; Meng, F.Q.; Guo, E.J.; Gu, L.; Lin, Y.-H. Ultrahigh energy storage in superparaelectric relaxor ferroelectrics. Science 2021, 374, 100–104. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.H.; Zhou, Y.P.; Jiang, N.; Guo, F.; Chen, J.Y.; Yang, B.; Zhao, S.F. Leakage-limitation engineering derived from an interfacial charge barrier for dielectric energy storage in relaxation ferroelectric films. J. Phys. Chem. C 2023, 127, 15078–15086. [Google Scholar] [CrossRef]

- Sciau, P.; Kania, A.; Dkhil, B.; Suard, E.; Ratuszna, A. Structural investigation of AgNbO3 phases using x-ray and neutron diffraction. J. Phys. Condens. Matter 2004, 16, 2795–2810. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Q.; Yao, Y.; Su, D.; Zhang, S.; Zhao, L. Relaxor Ferroelectric AgNbO3 Film Fabricated on (110) SrTiO3 Substrates via Pulsed Laser Deposition. Coatings 2023, 13, 1834. https://doi.org/10.3390/coatings13111834

Ma Q, Yao Y, Su D, Zhang S, Zhao L. Relaxor Ferroelectric AgNbO3 Film Fabricated on (110) SrTiO3 Substrates via Pulsed Laser Deposition. Coatings. 2023; 13(11):1834. https://doi.org/10.3390/coatings13111834

Chicago/Turabian StyleMa, Qingzhu, Yao Yao, Dandan Su, Suwei Zhang, and Lei Zhao. 2023. "Relaxor Ferroelectric AgNbO3 Film Fabricated on (110) SrTiO3 Substrates via Pulsed Laser Deposition" Coatings 13, no. 11: 1834. https://doi.org/10.3390/coatings13111834

APA StyleMa, Q., Yao, Y., Su, D., Zhang, S., & Zhao, L. (2023). Relaxor Ferroelectric AgNbO3 Film Fabricated on (110) SrTiO3 Substrates via Pulsed Laser Deposition. Coatings, 13(11), 1834. https://doi.org/10.3390/coatings13111834