1. Introduction

Due to their excellent functional properties, Ti-based alloys are used in various branches of industry, such as aerospace, automotive, railway, marine, cutting and forming tools, and others. However, some disadvantages could be noted, such as low hardness and wear resistance [

1,

2]. There are various methods to overcome them, the most suitable being the techniques for modifying the structure and properties of the materials on the surface, since they are most actively exposed to exploitation.

There exist a number of technologies for surface treatment and modification, including thin film deposition [

3], ion implantation [

4], surface treatment by high energy fluxes (laser or electron beams) [

5,

6,

7], etc. Nowadays, the electron beam surface alloying (EBSA) methods are among the most promising. They have many advantages over conventional ones because of the very short time of the process, the uniform distribution of the energy of the electron beam, and the possibility of very accurate repeatability. The process of EBSA involves moving the specimen with a constant velocity where the workpiece is irradiated by accelerated electrons. The kinetic energy of the accelerated electrons is transferred into heat, leading to the formation of a temperature field from the surface to the depth of the material [

8]. The heating and cooling rates can reach quite high values (10

4–10

5 K/s), resulting in a transformation in the microstructure, phase and chemical composition, formation of a preferred crystallographic orientation, changes in the surface topography, etc. [

9,

10]. The technological conditions of the process can be selected so that the treated surface is melted—the formation of a melt pool. When alloying elements are introduced into the liquid phase, followed by subsequent solidification, composite layers and coatings are formed with significantly enhanced functional characteristics compared to the initial material [

11,

12]. A lot of examples exist in the scientific literature aiming to improve the surface properties of Ti substrates employing the electron beam surface alloying technology by forming surface coatings and structures such as Cr [

13], Al [

14], carbon [

15], etc. In all cases, composite Ti-based structures with improved functional properties were obtained, namely titanium aluminides, titanium carbides, etc.

On the other hand, titanium borides are characterized by very high hardness values and are extremely promising for the improvement of the mentioned mechanical characteristics [

16]. Typical values of the hardness of the bulk titanium borides reach values of 25 GPa [

17] and can exceed 40 GPa when the compound is in the form of coatings [

18]. This makes them very promising to be applied as reinforcement materials or in the form of protective films where high hardness is required. In [

19], a Ti-TiH

2 material was reinforced by titanium diboride powder and the results obtained showed a significant improvement in the mechanical properties. Similarly, in [

20] the possibilities of modifying composite titanium matrices by introducing TiB

2 particles by laser cladding technology were researched. The results presented in [

20] showed a significant rise in the hardness of the cladded zone after the application of the cladding procedure. The authors of [

21] described the mechanical properties of titanium borides fabricated on Si substrates by direct current magnetron sputtering and the results showed maximal values of the hardness of 23 GPa. However, the results published in [

22] show that the hardness of titanium borides fabricated on high-speed steel by DC magnetron sputtering can reach more than 40 GPa. Similarly, Kelesoglu et al. [

23] investigated the mechanical characteristics of titanium borides deposited on a molybdenum sheet by DC magnetron sputtering where the influence of the external magnetic field applied during the deposition procedure was studied. The results reported in [

23] pointed to hardness values ranging from 2200 to 6900 HV, where it was found that the application of the external magnetic field has a major impact on the enhancement of the mechanical properties. Nevertheless, in all considered cases, all measured values for the hardness of the fabricated titanium boride coatings and thin films significantly exceed that of the substrate materials used for experimental purposes.

Following the evaluation of the scientific literature, the application of titanium boride coatings leads to a great improvement in the mechanical characteristics of different substrates. A number of investigations consider the application of TiB compound in the form of reinforcement particles aiming to improve the functional properties of titanium-based materials [

19,

20]. Also, the formation of titanium borides in the form of thin films and coatings for protective purposes by magnetron sputtering technologies was also extensively investigated [

21,

22,

23]. However, the fabrication of Ti–B hard composite surface structures and coatings on Ti substrate by an electron beam surface alloying technology is currently not yet studied. For this reason, the present paper aims to study the possibilities of the fabrication of composite coatings in the system of Ti–B with a significantly increased hardness and improved coefficient of friction compared to the titanium substrate achieved via the EBSA technology.

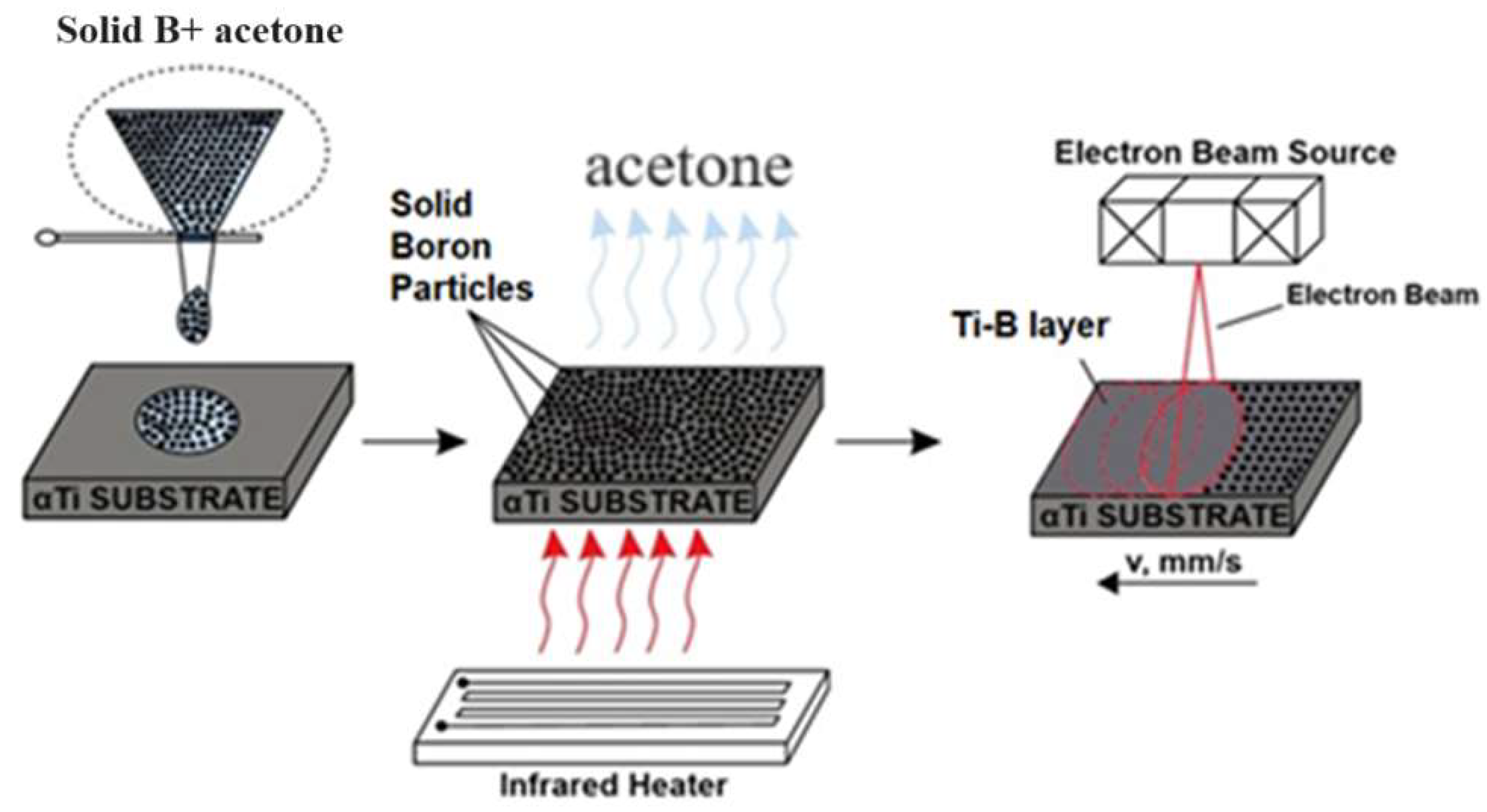

3. Results and Discussion

The XRD patterns of the fabricated surface alloys in the Ti–B system are shown in

Figure 2. Both diffractograms, corresponding to specimen movement speeds of 4 and 6 mm/s, respectively, are typical for polycrystalline materials. Diffraction maxima of pure α–Ti, pure B, as well as TiB

2 are present in both cases. The ICDD (International Center for Diffraction Data) database was used for the evaluation of the phase composition of the fabricated coatings, ICDD PDF# 44 1294 for α–Ti, ICDD PDF# 31 0207 for B, and ICDD PDF# 35 0741 for TiB

2. Also, the reference peak positions, according to the ICDD database of the aforementioned phases, are shown in

Figure 2. The results show good agreement between the positions of the experimentally obtained diffraction maxima and those available in the crystallographic database. Concerning the pure B phase, some peaks do not appear in the experimentally obtained diffraction patterns which, however, are characterized by very low intensities in the crystallographic database. This, together with the small amount of the boron content could be considered as the reason that some diffraction maxima of the B phase disappear from the experimentally obtained diffractograms. Nevertheless, according to the ICDD database, the main boron peaks located between 33 and 39° at a 2θ scale are well visible, meaning that some amount of undissolved boron exists in both considered cases. The intensities of the TiB

2 peaks are the highest. This means that the titanium diboride phase is the main one detected on the surfaces of the samples. It should be noted that no amorphous-like halos can be observed at the lower Bragg angles, meaning that the obtained surface alloys and coatings are fully crystalline. Additionally, the phase composition remains unchanged, which is proof that the movement speed of the specimens does not affect the phase formation during the process of EBSA within the presented technological conditions. It should be noted that the ratios between the intensities of the peaks of the TiB

2 phase are in good agreement with the ICDD database. Moreover, no changes in the intensities of the diffraction peaks were observed as a function of the movement speed of the specimens. This means that changing this technological parameter does not lead to a change in the texturing and formation of a preferred crystallographic orientation of the samples. Such texture changes and the formation of preferred crystallographic orientation significantly influence the resultant functional properties of the formed surface alloys and coatings [

25]. At the same time, no significant changes in the peak positions of the aforementioned phase are observable. The observed shift between the peaks of the coatings formed by the speed of the movement of the workpiece of 4 and 6 mm/s, respectively, is less than 0.01° at a 2θ scale, meaning that the lattice parameters and unit-cell volumes remain unchanged or their deviation from each other is insignificant. This again could be considered very important for the resultant functional properties of the fabricated Ti–B surface alloys and coatings [

26,

27].

Figure 3 presents a cross-sectional SEM micrograph of the specimen alloyed by the lower movement speed (i.e., 4 mm/s). The alloyed zone is marked as A, while the Ti substrate is indicated as B. The chemical composition of the specimen is studied by energy-dispersive X-ray spectroscopy (EDX) experiments. The points where the chemical composition was investigated are marked as 1 and 2. The experimentally obtained EDX spectra are presented in

Figure 4 and the results are summarized in

Table 1.

Figure 4a corresponds to Point 1 marked in

Figure 3 while

Figure 4b is associated with Point 2. The measured average thickness of the alloyed zone (i.e., Zone A from

Figure 3) is about 50 μm. The results obtained show that the applied technological conditions, particularly the selected movement speed of the sample of 4 mm/s, led to the formation of a clearly separated alloyed zone and base titanium substrate. Considering the structure of the obtained surface alloy, it is obvious that two regions can be distinguished—darker and brighter. The chemical composition of both zones was investigated where the darker region corresponds to Point 1 while the brighter one is to Point 2. The results revealed that Point 1 consists of undissolved boron meaning that it has not been completely dissolved into the Ti matrix. However, considering the brighter zone, the amount of Ti is 36.4 at% and the concentration of B is 63.6 at%. The binary Ti–B phase diagram shows that the analyzed brighter zone fully corresponds to the TiB

2 compound [

28]. Also, it should be noted that some defects, like pores, cracks, etc., exist (marked with black arrows in

Figure 3). They could be attributed to the existence of two different compounds (TiB

2 and pure boron) with different thermo-physical properties. The presence of two different elements within the alloyed zone could be considered as a prerequisite for the formation of such defects which can be formed during the process of miscibility between them. The results obtained by the SEM and EDX experiments are in agreement with those of XRD measurements confirming that the phase composition of the formed surface alloy in the system of Ti–B is in the form of a TiB

2 structure with some amount of undissolved boron. It is clearly visible that the undissolved boron element is not only on the surface but also within the depth of the formed surface alloy, meaning that the undissolved boron element penetrated during the alloying procedure but did not dissolve into the Ti matrix.

Figure 5 presents a cross-sectional SEM micrograph of the sample processed by the higher movement speed (i.e., 6 mm/s). The alloyed region is marked as Zone A, while the Ti plate is indicated as B. The average thickness of the alloyed zone formed with a movement speed of 6 mm/s is about 40 μm, which is slightly less compared to the alloyed zone produced with a movement speed of 4 mm/s. According to [

29], the speed of the samples during the electron-beam processing of the materials has an impact on the temperature of the surface, heat input, and depth of the alloyed zone. It was shown that the temperature on the surface increases with the decrease in the movement speed of the sample in all cases. This correlates with the results achieved in this study where the lower movement speed of 4 mm/s led to the formation of a thicker alloyed zone as compared to that obtained with the higher movement speed of 6 mm/s. The EDX results of the chemical composition of the fabricated coatings are shown in

Figure 6 and summarized in

Table 1.

Figure 6a corresponds to Point 3 while

Figure 6b corresponds to Point 4 marked on the cross-sectional image presented in

Figure 5. The results show that the darker regions (Point 3 from

Figure 5) of the alloyed zone fully correspond to undissolved boron. The chemical composition of the brighter zone (i.e., Point 4 indicated in

Figure 5) consists of Ti and B, indicating that a composite phase in the system of Ti–B has been successfully formed. It was found that the amount of boron is 67 at% while the titanium amount is 33 at%, corresponding to an ideal 2:1 ratio. The binary Ti–B phase diagram shows that the considered zone fully corresponds to the TiB

2 compound [

28]. When comparing the two alloyed zones, no noticeable difference between their phase compositions can be established, apart from a slightly higher concentration of pure undissolved boron in the structure of the specimen treated with the higher movement speed. This is undoubtedly caused by the reduced input temperature per unit of time. This temperature was apparently not enough to completely melt the solid boron particles atop the surface of the substrate. However, under the undissolved B particles, the top of the titanium substrate was melted, and some amount of the boron particles were introduced into the molten material, leading to the formation of the TiB

2 compound under the undissolved boron. Also, no or a very small number of structural imperfections, such as pores and cracks, can be observed, which could be attributed to the fact that the undissolved boron remains on the top of the surface alloy, not within the whole alloyed zone.

The results of the micro-hardness measurement of the fabricated coatings, as well as that of the pure titanium substrate, are shown in

Figure 7 and are presented in

Table 2. Micrographs of the experimentally obtained indentation imprints are also shown above the points. They indicate the micro-hardness values as proof of the very large difference of the studied mechanical characteristic between both types of coatings (i.e., obtained by the different speeds) and the substrate. The hardness of the substrate is about 210 HV

0.2. This value is typical for pure titanium. The average hardness of the surface alloy in the system of Ti–B obtained at the specimen’s movement speed of 4 mm/s is 2610 HV

0.2, or it is more than 12 times greater in comparison to that of the Ti substrate. The hardness of the specimen fabricated by the speed movement of 6 mm/s is even higher. The measured values reached more than 4540 HV

0.2 which is more than 20 times greater than the Ti plate. The hardness of the surface alloy formed by the velocity of the movement of the specimen of 4 mm/s is lower than the fabricated one by the velocity of 6 mm/s. This could be attributed to the significantly larger number of defects, such as pores, cracks, etc., resulting in the reduced density of the fabricated coating. As already mentioned, the fabricated coating by the velocity of 4 mm/s is characterized by much more structural imperfections leading to a decrease in the hardness, as well as to a much higher scattering in the measured results. Nevertheless, the values obtained for the specimen alloyed by the lower speed of the sample movement are 12 times greater than that of the titanium substrate, which is considered a significant improvement of the surface properties as well. As mentioned in the introduction, the authors of [

21] described the possibility of fabrication of thin TiB

2 films by DC magnetron sputtering where the bias voltage applied to the substrate was varied. It was shown that the hardness of the films reached 13–23 GPa (1300–2300 HV) which are values lower than those obtained in the present study. It was mentioned that the highest values for the hardness were measured at the film with the highest density which was achieved when the bias was changed from positive to negative. Moreover, the lower hardness values were attributed to the influence of the substrate on nanoindentation measurements, as well as to the selection of the radius of the indentation tip [

21]. However, ref. [

22] shows results for the hardness of TiB

2, fabricated by DC magnetron sputtering where the substrate was rotated or was in a stationary form. The measured values are in the range from 23 to 42 GPa (2300 to 4200 HV) where the highest hardness was measured on the samples fabricated at the stationary conditions. It was discussed that the enhancement in the mentioned mechanical characteristic is due to the formation of the preferred crystallographic orientation, as well as the much denser structure of the deposited coating when the substrate has not been rotated. The results published in [

22] are completely in accordance with those presented in this study. Similarly, other authors [

30,

31] reported results for the hardness of TiB

2 ranging from 4000 to 5000 HV, which is completely in accordance with those presented in this study. This means that the fabrication of titanium boride coatings by both DC magnetron sputtering [

22] and electron-beam surface alloying can lead to the formation of surface structures with very similar values for hardness, although the two technologies are very different. In [

22], the deposition of TiB

2 films was realized on high-speed steel substrate by a sputtering of a TiB

2 target, while in the present investigation, the Ti–B coatings were formed by the alloying of pure Ti substrate with B powder by a scanning electron beam. As already mentioned, in the case of the DC magnetron sputtering, the control of the structure and properties was carried out by the rotation of the sample or being in a stationary form [

22]. In this study, the control of the structure and properties of the TiB-based coatings fabricated by the EBSA was realized by the control of the speed movement of the specimen under the electron beam. As a result, the thicknesses of the coatings obtained by the DC magnetron sputtering range from 1.4 to 2.5 μm, while in this study the coatings are much thicker—from 40 to 50 μm due to the difference between both technologies. The fabrication of titanium borides by the laser beam surface alloying was shown in [

32]. The results showed that the hardness and the friction coefficient are a bit lower than the values obtained in the present study. It was found that the hardness is in the range of 800–3500 HV, and the coefficient of friction was 0.39–0.41, depending on the power of the laser beam [

32]. The modification of Ti substrates by a scanning electron beam where alloying elements have not been added leads to an increase in the hardness of only about 15%, which is much lower than the values obtained in this study [

33]. This means that the modification of Ti and Ti-based materials by the fabrication of surface alloys in the binary Ti–B system leads to a great enhancement of the surface characteristics as compared to the modification without adding alloying elements.

Figure 8 presents the distribution of the microhardness from the surface to the depth of the samples (i.e., fabricated by the speed movement of 4 and 6 mm/s).

Figure 8a presents the results of the coating obtained by 4 mm/s while

Figure 8b exhibits the results of the coating obtained by 6 mm/s. The hardness of the specimen fabricated by the lower speed movement of 4 mm/s is in the range of 2400–2700 HV at depths of up to 50 μm, followed by a decrease to values ranging from 300 to 370 HV at depths from 50 to 100 μm. The measured values at depths higher than 100 μm are about 200 HV. This is a typical value for the Ti substrate. The obtained values for the sample fabricated by the higher speed motion are in the range of 4100–4900 HV at depths of up to 40 μm. With an increase in the depth of the specimen, the hardness decreases significantly as it is in the range from 300 to 360 HV within the distances from 40 to 70 μm from the surface to the bulk. At higher depths, the hardness drops further to about 210 HV. These results are fully consistent with those for the microstructure and thickness of the obtained coatings in the system of Ti–B where the measured hardness remains relatively unchanged within the whole coating in both cases. After that, it decreases significantly but is still a bit higher than the titanium material because in both cases a heat-affected zone with improved mechanical properties exists. The existence of such a region is typical for electron-beam-processed materials [

34]. Below this heat-affected zone, the measured microhardness decreases to values that are typical for the titanium substrate.

The coefficient of friction (COF) of the Ti–B coatings formed by the speed motion of 4 and 6 mm/s as well as of the pure Ti substrate is shown in

Figure 9 and is presented in

Table 2. The measured values on the surface of the titanium substrate exhibit a value of 0.48. The coefficient of friction of the Ti–B coating formed by the velocity of the sample motion of 4 mm/s is 0.40 or it is lower in comparison with the Ti substrate. The values for the COF of the coating obtained by the speed movement of 6 mm/s are further reduced where the average measured value is 0.34. In all considered cases, the manufactured coatings in the system of Ti–B exhibit lower values of the coefficient of friction, whereas at the higher speed of the sample movement, it is the lowest one. This means that in all cases, the fabrication of coating in the system of Ti–B leads to a reduction in the COF, meaning that the tribo-properties on the surface of the coatings are better than that of the base Ti substrate. The measured values are lower than those reported in [

23] where the TiB

2 coatings were fabricated by DC magnetron sputtering, meaning that the fabricated surface alloys in the present study (i.e., by the electron-beam surface alloying technology) have better tribological properties. In the case of the deposition of the coatings by DC magnetron sputtering, the adhesion is significantly worsened in comparison with that obtained by the alloying by high energy fluxes, such as EBSA. This could be considered a prerequisite for the formation of surface alloys and coatings with a lower COF and, therefore, better tribo-properties. However, as already pointed out, the friction coefficient measured at the specimen alloyed by the higher velocity movement exhibits lower values than that obtained by the higher speed of the sample movement. This difference could be attributed to the significant number of structural imperfections, such as pores as well as undissolved boron material within the volume of the coating fabricated by 4 mm/s speed movement. As already mentioned, the undissolved B element within the coating formed by the speed movement of 4 mm/s is distributed within the whole volume of the surface alloy while in the case of fabrication of coatings in the system of Ti–B, it is only on the top of the alloyed layer. According to the authors of [

35], the larger number of structural imperfections as well as undissolved particles plays a major role in the deterioration of the friction properties of the materials. A comparison of the hardness and coefficient of friction between titanium borides fabri-cated via different technologies is shown in

Table 3.

This study presents the fabrication of surface alloys and coatings in the binary Ti–B system on Ti substrate by the electron-beam surface alloying technique. It was shown that the alloying procedure by the aforementioned technological conditions led to the formation of a surface alloy where the main phase is TiB

2 and some amount of undissolved boron is also observable. In the application of the lower velocity of the specimen motion of 4 mm/s, the undissolved B element is distributed within the whole alloyed zone, while the application of the higher velocity of 6 mm/s remains on the surface. The incorporation of alloying elements within an alloyed zone formed by high energy fluxes (such as electron or laser beams) is carried out by the so-called Marangoni flows formed due to the very high thermal gradient in the molten material [

36,

37]. It is suggested that the influence of the Marangoni flows on the miscibility between the materials and the homogeneous distribution is significant and can be characterized by the so-called surface tension number and can be expressed by (1).

In (1),

S is the surface tension number, (

dσ/dT) is the temperature coefficient of surface tension,

q is the net heat flow,

d is the beam diameter,

μ is the viscosity,

u0 is the velocity of the movement of the specimen, and

k corresponds to the thermal conductivity. In cases where the surface tension number is low, the convection flows are negligible and the incorporation of alloying elements and melt homogenization become insufficient. Moreover, the miscibility between the alloying elements and the base material is very low. In cases of high values of the surface tension number, strong convection flows exist which are responsible for the integration of the elements within the melt pool and the homogenization and miscibility between the alloying elements and the substrate are significant [

37]. This is in accordance with our results. It was found that the decrease in the speed of the specimen motion causes the fabrication of the surface alloy where the undissolved boron is within the whole alloyed zone. In contrast, the use of the higher velocity of the motion of the specimen leads to the formation of a surface alloy where some amount of undissolved boron appears on the surface. Following Equation (1), it is obvious that the speed of the movement of the samples is inversely proportional to the surface tension number and, therefore, the lower speed corresponds to a higher surface tension number and stronger convection flows which are responsible for the incorporation and homogeneity distribution of the B element within the molten Ti. However, in the present particular case, the application of the lower velocity of the sample motion leads to the formation of a much more inhomogeneous structure than that of the specimen fabricated by the higher velocity movement. In the case of the higher speed, the B powder was not completely melted, and a composite Ti–B structure was formed under the thin unmelted boron layer. In this case, the Ti substrate is melted and the molten titanium material heats further the lower part of the boron film, leading to the introduction of some B amount into the substrate and forming the composite Ti–B structure under the undissolved B film. With the application of 4 mm/s speed (i.e., the lower velocity of the motion of the specimen), both Ti and B materials were completely melted, and the boron element was successfully introduced into the Ti matrix. The existence of a significant amount of undissolved B within the fabricated surface alloy by the lower velocity of the sample’s movement has a great impact on the measured surface hardness and coefficient of friction and could be considered a prerequisite for the worse values of the discussed mechanical characteristic. Nevertheless, in both considered cases, some amount of undissolved boron exists. This means that further optimization of the technological conditions of the alloying procedure by a scanning electron beam has to be performed. Considering the velocity of the motion of the samples, at higher than 6 mm/s values, the amount of undissolved B element will be even higher. At the same time, the use of a speed lower than 4 mm/s will result in a significant modification of the morphology on the surface and a significant amount of evaporation will be predominant. Therefore, further optimizations are needed in light of the power of the electron beam and the frequency of scanning.