Comparison of Various Conversion Layers for Improved Friction Performance of Railway Wheel-End Bearings

Abstract

:1. Introduction

2. Experimental Section

2.1. Steel Substrates and Conversion Layers

2.2. Tribological Characterization

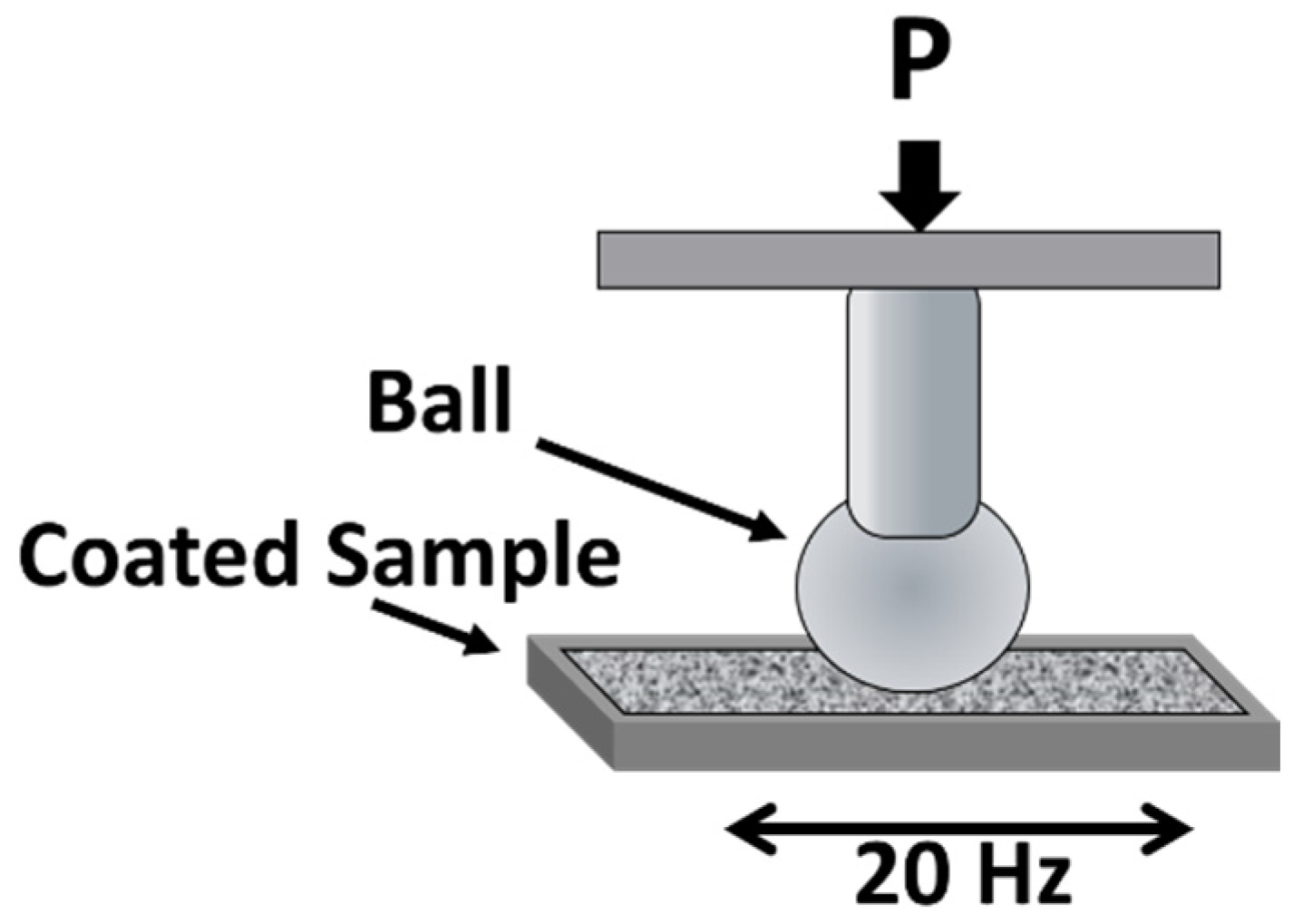

2.2.1. Reciprocating Sliding Test

2.2.2. Ball-on-Disk and Roller-on-Disk Rolling/Sliding Tests

2.2.3. Bearing Friction Test Rig

2.3. Morphological Characterizations

3. Results

3.1. Morphology and Mechanical Properties

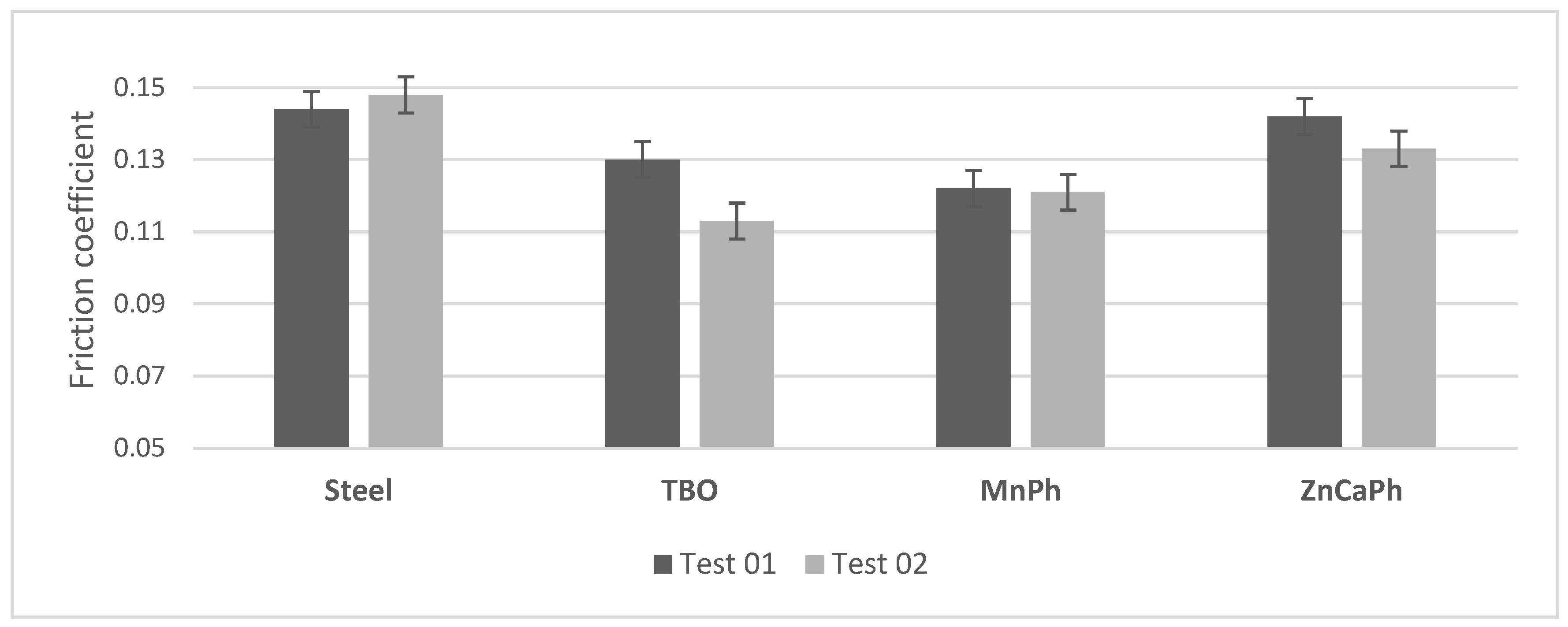

3.2. Reciprocating Sliding Tests

3.3. Rolling/Sliding Tests

3.4. Bearing Friction Tests

4. Discussion

4.1. Conversion Layers on the Rougher Surface to Facilitate Running-In

4.2. The Influence of Conversion Layers on the Flange Contacts

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Craven, N. “UIC Low Carbon Rail Challenge—Technical Report,” International Unions of Railway. Available online: https://uic.org/IMG/pdf/low_carbon_rail_challenge_technical_report.pdf (accessed on 6 March 2023).

- SKF. “SKF Coatings Catalogue,” SKF, [Online]. Available online: https://www.skf.com/binaries/pub12/Images/0901d19680a4e17f-18781-EN---Coating-catalogue_for-digital-use-only_noprint_tcm_12-549101.pdf (accessed on 6 March 2023).

- Broitman, E. Coatings to Improve Bearing Performance. Evolution 2022, 1–7. Available online: https://evolution.skf.com/coatings-to-improve-bearing-performance/ (accessed on 6 March 2023).

- Gregory, J.C. Chemical coatings of metals to resist scuffing and wear. Tribol. Int. 1978, 11, 105–112. [Google Scholar] [CrossRef]

- George, M.A. Factors Influencing Friction of Phosphate Coatings; Springfield Armory: Geneseo, IL, USA, 1964. [Google Scholar]

- Saffarzade, P.; Amadeh, A.A.; Agahi, N. Study of tribological and friction behavior of magnesium phosphate coating and comparison with traditional zinc phosphate coating under dry and lubricated conditions. Tribol. Int. 2019, 144, 106122. [Google Scholar] [CrossRef]

- Bhar, G.N.; Debnath, N.C.; Roy, S. Effects of Calcium Ions on the Morphology and Corrosion Resistance of Zinc-Phosphated Steel. Surf. Coat. Technol. 1988, 35, 171–179. [Google Scholar] [CrossRef]

- von Schleinitz, T.; Nentwig, K.; Bruckhaus, C.; Kachler, W. Brünierung: Die alte newe Hochleistungsschicht. Galvanotechnik 2018, 5, 889–894. [Google Scholar]

- Deutsches Institut fur Normung. DIN 50938—Black Oxide Coatings on Ferreous Metal Components—Requeriments and Test Methods; Deutsches Institut fur Normung e.V.: Berlin, Germany, 2018. [Google Scholar]

- ISO 11408; Chemical Conversion Coatings—Black Oxide Coating on Iron and Steel—Specification and Test Methods. International Organization for Standardization: Geneva, Switzerland, 1999.

- Broitman, E. Black Oxide and Carbon-Based Coatings for Roller Bearing Applications. In Proceedings of the 46th International Conference on Metallurgical Coatings and Thin Films, San Diego, CA, USA, 19–24 May 2019. [Google Scholar]

- Brizmer, V.; Stadler, K.; van Drogen, M.; Han, B.; Matta, C.; Piras, E. The Tribological Performance of Black Oxide Coating in Rolling/Sliding Contacts. Tribol. Trans. 2017, 60, 557–574. [Google Scholar] [CrossRef]

- Stadler, K. How black oxide coating can make an impact on cutting O&M costs for wind turbines. Evolution 2013, 4. Available online: https://evolution.skf.com/how-black-oxide-coated-bearings-can-make-an-impact-on-cutting-om-costs-for-wind-turbines/ (accessed on 6 March 2023).

- Dvorak, P. SKF Black Oxide Bearings Add Surface Layer of Protection to Promote Higher Reliability and Performance for Wind Turbines. Windpower Engineering and Development, vol. June. 2014. Available online: https://www.windpowerengineering.com/skf-black-oxide-bearings-add-surface-layer-protection-promote-higher-reliability-performance-wind-turbines/ (accessed on 6 March 2023).

- Ueda, M.; Spikes, H.; Kadiric, A. Influence of Black Oxide Coating on Micropitting and ZDDP Tribofilm Formation. Tribol. Trans. 2022, 65, 242–259. [Google Scholar] [CrossRef]

- Riggs, M.R.; Murthy, N.K.; Berkebile, S.P. ARL-TR-7815: Evaluation for Loss of Lubrication Performance of Black Oxide, Superfinished, and As-Ground Surfaces for Use in Rotorcraft Transmissions; US Army Research Laboratory, Aberdeen Proving Ground: Harford, MD, USA, 2016. [Google Scholar]

- Ernens, D.; de Rooij, M.B.; Pasaribu, H.R.; van Riet, E.J.; van Haaften, W.M.; Schipper, D.J. Mechanical characterization and single asperity scratch behaviour of dry zinc and manganese phosphate coatings. Tribol. Int. 2018, 118, 474–483. [Google Scholar] [CrossRef]

- Ozkan, D.; Kaleli, H.; Yuksek, L. Quantitative comparison of tribological performance of chromium- and zinc-phosphate-coated piston rings in tribotest rig. Proc. IMechE Part J J. Eng. Tribol. 2017, 231, 75–92. [Google Scholar] [CrossRef]

- Farias, M.C.M.; Santos, C.A.L.; Panossian, Z.; Sinatora, A. Friction behavior of lubricated zinc phosphate coatings. Wear 2009, 266, 873–877. [Google Scholar] [CrossRef]

- Hao, L.; Chen, Y.; Li, G.; Zhang, M.; Wu, Y.; Liu, R.; Chen, G. Study on the Friction Characteristics and Fatigue Life of Manganese Phosphate Coating Bearings. Lubricants 2023, 11, 99. [Google Scholar] [CrossRef]

- Leidich, E.; Maiwald, A.; Vidner, J. Extended studies on fretting wear criterion for coated systems with complete contact based on accumulated specific friction energy. WIT Trans. Eng. Sci. 2012, 76, 163–174. [Google Scholar]

- Kozlowski, A.; Czechowski, W. Wear resistance of manganese phosphate coatings. Electrodepos. Surf. Treat. 1975, 3, 55–63. [Google Scholar] [CrossRef]

- Hager, C.H.; Evans, R.D. Friction and wear properties of black oxide surfaces in rolling/sliding contacts. Wear 2015, 338–339, 221–231. [Google Scholar] [CrossRef]

- Zang, L.; Zhong, Q.; Chen, Y.; Hou, W.; Zhao, B.; Wu, Y. Effect of coating thickness on tribological properties of manganese phosphate conversion coating in different motion conditions. Tribol. Int. 2022, 176, 107894. [Google Scholar] [CrossRef]

- Tamura, Y.; Kobayashi, K.; Aratani, K.; Tanaka, S.; Kikuchi, M.; Masuko, M.; Ohtake, N. Influence of Wear Surface Morphology and Phosphorus-Containing Tribofilm on Crack Initiation of Manganese Phosphate Coated Steel under Rolling–Sliding Contact. Tribol. Online 2020, 15, 154–169. [Google Scholar] [CrossRef]

- Mendibil-Zaballa, E.; Sánchez-Galíndez, J.A.; Saenz-de-Ugarte-Sevilla, P.; Pombo-Rodillad, I.; Fernandez-Sisóne, A. Tribo-mechanical Characterisation of Wear Behaviour for Manufacturing of Wind Turbine Gearbox Structural Parts. Procedia Eng. 2015, 132, 918–925. [Google Scholar] [CrossRef]

- Waterhouse, R.B. The Formation, Structure and Wear Properties of Cerain Non-metallic Coatings on Metals. Wear 1965, 8, 421–447. [Google Scholar] [CrossRef]

- Waterhouse, R.B.; Allery, M. The effect of non-metallic coatings on the fretting corrosion of mild steel. Wear 1965, 8, 112–120. [Google Scholar] [CrossRef]

- SKF. Railway Technical Handbook—Volume 1; SKF Group: Goterborg, Sweden, 2011. [Google Scholar]

- ISO 9717; Metallic and Other Inorganic Coatings—Phosphate Conversion Coating of Metals. International Organization for Standardization: Geneva, Switzerland, 2017.

- De Vries, L.; Bin Yusof, N.; Van Eijk, M.C.P. Grease Selection for Wheelset Bearings in Passenger Trains. In Proceedings of the XIX International Wheelset Conference—IWC 2019, Venice, Italy, 16–20 June 2019. [Google Scholar]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Ooi, S.W.; Yan, P.; Vegter, R.H. Black oxide coating and its effectiveness on prevention of hydrogen uptake. Mater. Sci. Technol. 2019, 35, 12–25. [Google Scholar] [CrossRef]

- Kooi, B.J.; Somers, M.A.J.; Jutte, R.H.; Mittemeijer, E.J. On the oxidation ofα-Fe andε-Fe2 N1−z II. Residual strains and blisters in the oxide layer. Oxid. Met. 1997, 48, 111–128. [Google Scholar] [CrossRef]

- ISO-14577-1; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method. International Organization for Standardization: Geneve, Switzerland, 2015.

- Broitman, E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview. Tribol. Lett. 2017, 65, 23. [Google Scholar] [CrossRef]

- Brizmer, V.; Kligerman, Y.; Etsion, I. Elastic-plastic spherical contact under combined normal and tangential load in full stick. Tribol. Lett. 2007, 25, 61–70. [Google Scholar] [CrossRef]

| Parameter | Values |

|---|---|

| Ball Diameter | 12.7 mm |

| Load | 15.3 N |

| Initial Hertzian Contact Pressure | 1 GPa |

| Circular Contact Radius (a) | 85 µm |

| Reciprocal stroke | 100 µm |

| Frequency | 20 Hz |

| Temperature | Room Temperature |

| Number of Cycles | 72,000 |

| Total Distance | 7.2 m |

| Test Duration | 1 h |

| Lubricant | Railway grease (PAO base oil ISO VG100) |

| Setup | Ball-on-Disk | Roller-on-Disk |

|---|---|---|

| Initial Contact Pressure PH | 1.3 GPa | 0.27 GPa |

| Entrainment Speed | 0.5 m/s | 0.3 m/s |

| SRR (slide-to-rolling ratio) | 5% (except traction curves) | 9.6% (with spinning component) |

| Lubricant | Mineral oil of 32 cSt at 40 °C with no EP/AW additives | |

| Temperature | 60 °C | |

| Lubrication Parameter λ | λ = 0.3 | |

| Test Sequence | Traction; Stribeck; Duration 70 h; Traction; Stribeck | Stribeck; Duration 4.5 h; Stribeck |

| Bearings | NU2207 + NJ2207 |

| Radial load (N) | 7000 |

| Axial load (N) | Speed cycles: 250 Axial load cycles: from 200 to 1000 |

| Speed (rpm) | Speed cycles: from 300 to 4500 Axial load cycles: 1800 Direction: 0.5 h CW and 0.5 h CCW |

| Lubrication | Railway grease (PAO base oil ISO VG100) |

| Temperature | 60 °C |

| Repeats | Cycles repeated mini 6 times and up to 24 times |

| Running-in/Grease churning | 10 h at 3100 rpm and 250 N axial load |

| Step | Duration (h) | Axial Load (N) | Speed (rpm) |

|---|---|---|---|

| Run-in | 10 | 250 | 3100 |

| Step 1 | 1 | 250 | 3100 |

| Step 2 | 1 | 250 | 1800 |

| Step 3 | 1 | 250 | 1100 |

| Step 4 | 1 | 250 | 4500 |

| Step 5 | 1 | 250 | 300 |

| Step 6 | 1 | 100 | 1800 |

| Scheme 10 | Duration (h) | Axial Load (N) | Speed (rpm) |

|---|---|---|---|

| Run-in | 10 | 250 | 3100 |

| Step 1 | 1 | 200 | 1125 |

| Step 2 | 1 | 400 | 1800 |

| Step 3 | 1 | 500 | 3100 |

| Step 4 | 1 | 600 | 3100 |

| Step 5 | 1 | 700 | 4500 |

| Step 6 | 1 | 1000 | 4500 |

| Outside Track | Inside Track | |||

|---|---|---|---|---|

| HIT (GPa) | Er (GPa) | HIT (GPa) | Er (GPa) | |

| Steel | 8.98 ± 0.97 | 197.6 ± 8.4 | 11.9 ± 3.3 | 197 ± 25 |

| TBO | 2.5 ± 1.1 | 71 ± 22 | 10.2 ± 3.7 | 198 ± 32 |

| MnPh | 1.49 ± 0.44 | 88 ± 14 | 10.0 ± 3.8 | 196 ± 39 |

| ZnCaPh | 2.73 ± 0.79 | 58 ± 11 | 4.44 ± 0.74 | 109 ± 13 |

| Micrograph | Surface Topography | Profile | |

|---|---|---|---|

| Steel |  |  |  |

| TBO |  |  |  |

| MnPh |  |  |  |

| ZnCaPh |  |  |  |

| Ra (nm) | Outside Track | Inside Track Raceway | Inside Track Flange |

|---|---|---|---|

| Steel–Steel | 220 | 182 | 198 |

| MnPh–Steel | 1057 * | 225 | 150 |

| ZnCaPh–Steel | 858 * | 185 | 185 |

| TBO–Steel | 208 | 125 | 80 |

| TBO–TBO | 208 | 125 | 89 |

| MnPh–MnPh | 1057 * | Not measured | No measured |

| Variant | Inside Track Raceway | Inside Track Flange |

|---|---|---|

| Steel | 71% | 107% |

| MnPh | 149% | 168% |

| ZnCaPh | 140% | 141% |

| TBO | 48% | 75% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Broitman, E.; Ruellan, A.; Meeuwenoord, R.; Nijboer, D.; Brizmer, V. Comparison of Various Conversion Layers for Improved Friction Performance of Railway Wheel-End Bearings. Coatings 2023, 13, 1980. https://doi.org/10.3390/coatings13121980

Broitman E, Ruellan A, Meeuwenoord R, Nijboer D, Brizmer V. Comparison of Various Conversion Layers for Improved Friction Performance of Railway Wheel-End Bearings. Coatings. 2023; 13(12):1980. https://doi.org/10.3390/coatings13121980

Chicago/Turabian StyleBroitman, Esteban, Arnaud Ruellan, Ralph Meeuwenoord, Daan Nijboer, and Victor Brizmer. 2023. "Comparison of Various Conversion Layers for Improved Friction Performance of Railway Wheel-End Bearings" Coatings 13, no. 12: 1980. https://doi.org/10.3390/coatings13121980

APA StyleBroitman, E., Ruellan, A., Meeuwenoord, R., Nijboer, D., & Brizmer, V. (2023). Comparison of Various Conversion Layers for Improved Friction Performance of Railway Wheel-End Bearings. Coatings, 13(12), 1980. https://doi.org/10.3390/coatings13121980