Concrete is a widely used building material for residential buildings, factories, and bridges. The mechanical properties of concrete, such as compressive strength and elastic modulus, exhibit dynamic growth patterns after pouring and remain stable until 28 days later. Evaluating the early mechanical properties of concrete can effectively guide the early construction and design of concrete engineering [

1,

2,

3,

4], such as prestressed tensioning or formwork removal. For example, in the production of large-volume concrete for bridge box girders, steel reinforcement prestressing should be applied as early as possible to prevent concrete cracks. Therefore, it is necessary to accurately evaluate the compressive strength and elastic modulus of concrete at an early stage to determine the time for steel reinforcement tensioning [

5]. In high-rise buildings and other projects that use a large amount of concrete, the cost of formwork engineering is very high. If the formwork can be removed as early as possible, it can accelerate the turnover of formwork and thus save construction costs. Thus, accurately evaluating the strength of concrete at early ages is also very important for determining the time of formwork removal [

6]. At present, there are two main methods for evaluating the early mechanical properties of concrete, namely machine learning-based evaluation methods and mathematical curve-based evaluation methods. Machine learning-based evaluation methods typically utilize large amounts of experimental data to train artificial neural network (ANN) models. The trained ANN models can then be used to evaluate the mechanical properties of concrete at various ages. Jaf et al. [

7] used machine learning technology to evaluate the effects of silicon dioxide and calcium oxide in fly ash on the compressive strength of green concrete. Ahmed et al. [

8] employed innovative machine learning techniques to predict the compressive strength of geopolymer concrete modified with nanoparticles. Trtnik et al. [

9] analyzed the relationship between ultrasonic pulse velocity, static and dynamic Young’s modulus, and shear modulus. Based on the experimental results, they demonstrated that the model constructed via artificial neural networks can estimate the compressive strength of concrete using only ultrasonic pulse velocity values and some mix ratio parameters of concrete. Yousif and Abdullah [

10] found that water–cement ratio is the most important factor affecting the output of neural network models, and neural networks have strong potential as a tool for predicting concrete compressive strength. Duan et al. [

11] constructed, trained, and tested a neural network model for predicting the compressive strength of recycled aggregate concrete using 146 sets of available data obtained from 16 different published literature sources. Nikoo et al. [

12] used an artificial neural network model to calculate the compressive strength of concrete and optimized it using genetic algorithms. Khashman and Akpinar [

13] designed an artificial neural network model for predicting the compressive strength of different concrete mixtures. Deng et al. [

14] proposed a prediction model based on deep learning theory, which learns the deep features of concrete components via convolutional neural networks. The research results indicate that the prediction model based on deep learning has the advantages of high accuracy, high efficiency, and strong generalization ability and can be used as a new method for calculating the strength of recycled concrete. Feng et al. [

15] proposed an intelligent prediction method for concrete compressive strength based on machine learning technology. Use adaptive boosting algorithm to predict the compressive strength of concrete. Muliauwan et al. [

16] used three artificial intelligence methods: ANN, support vector machines (SVM), and linear regression (LR) to predict the compressive strength of concrete. Asteris and Mokos [

17] studied the application of artificial neural networks in predicting the compressive strength of concrete in existing structures. Bka et al. [

18] constructed three different neural network models using the Levenberg Marquardt (LM) algorithm to predict the compressive strength of recycled aggregate concrete. The results indicate that the prediction model for compressive strength of recycled aggregate concrete based on artificial neural networks has high accuracy and can be further used for mix ratio optimization design. Cui et al. [

19] used seven machine learning algorithms to apply machine learning to predict the compressive strength of concrete. The experimental results indicate that the model has high prediction accuracy when the compressive strength is greater than 40 MPa. Kumar et al. [

20] used machine learning algorithms such as Gaussian progressive regression (GPR), support vector machine regression (SVMR), ensemble learning (EL), and optimized GPR, SVMR, and EL to predict the compressive strength of lightweight concrete (LWC). Pakzad et al. [

21] used machine learning (ML) and deep learning (DL) algorithms to predict the compressive strength (CS) of steel fiber-reinforced concrete (SFRC) containing hooked industrial steel fibers (ISF). Cünyt et al. [

22] studied the performance of adaptive neural fuzzy inference system (ANFIS) in predicting the elastic modulus of ordinary concrete and high-strength concrete. The results indicate that their proposed ANFIS outperforms other models in terms of predictive ability. Demir [

23] used collected data to establish, train, and test artificial neural network models and compared the predicted elastic modulus results with building codes and practical experience results. The results indicate that artificial neural networks have strong potential in predicting the elastic modulus of high-strength concrete and ordinary concrete. Ahmadi [

24] further validated the method for predicting elastic modulus based on the ANFIS model. The experimental comparison shows that the ANFIS model is superior to the other three nonlinear regression models. Han et al. [

25] proposed a comprehensive machine learning (ML) model for predicting the elastic modulus of concrete prepared from recycled concrete aggregates. They compared the predictive performance of the integrated ML model with five commonly used ML models. The results indicate that compared to independent models, integrated ML models always produce more accurate predictions. Hasanzadeh et al. [

26] utilized machine learning to predict the mechanical properties of basalt fiber-reinforced high-performance concrete by simulating the compressive strength and elastic modulus of concrete.

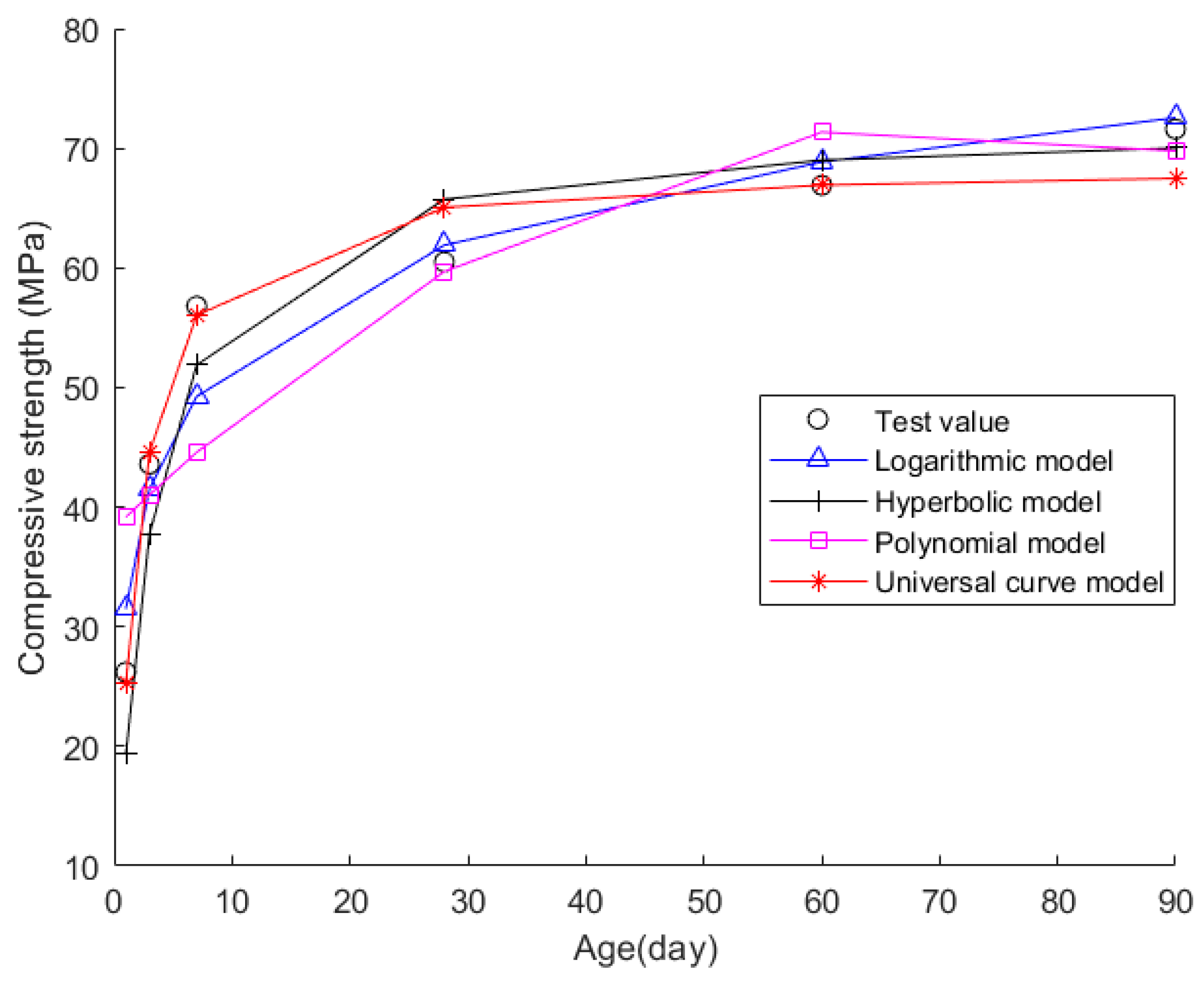

The second method is to evaluate the relationship between the mechanical properties of concrete and its age based on a certain function curve. The basic principle of this method is to obtain the functional equation between concrete mechanical parameters and age via data fitting based on early experimental data, and then calculate the concrete mechanical parameters at any time. The main advantage of this method is that it can be carried out with only a small amount of experimental data. At present, the commonly used concrete compressive strength–age curve models are the exponential model [

27,

28,

29], the logarithmic model [

30,

31], the hyperbolic model [

32,

33], and the polynomial model [

33,

34]. Yang et al. [

27] tested the compressive strength and elastic modulus of high-strength concrete within 28 days via experiments and proposed an exponential model for data fitting. Zhao et al. [

28] measured the compressive strength and elastic modulus of C50 concrete at 1, 2, 3, 5, 7, 11, 14, 28, and 40 days and fitted the exponential curves of compressive strength and elastic modulus with these data. Yang et al. [

29] combined regression fitting methods with exponential models to establish a prediction model for the relationship between the compressive strength and age of C60 concrete. Liu [

30] analyzed the changes in compressive strength and elastic modulus of C50 concrete over time via experiments. Zhao [

31] measured the compressive strength of concrete at 3, 7, 28, and 60 days via experiments and fitted the corresponding logarithmic function formula via data regression. Carino [

32] and Viviani [

33] fitted the changes in compressive strength of concrete over time using hyperbolic models, thereby establishing a prediction of compressive strength over age of concrete. Jin [

34] used a polynomial model to fit the test data of early-age compressive strength and elastic modulus of high-strength concrete. Ling [

35] identified the components that have an impact on the compressive strength of concrete by analyzing the composition of the concrete and built a prediction model for the compressive strength of mechanical sand concrete using a third-order nonlinear function. Jia et al. [

36] obtained the compressive strength of ordinary Portland concrete at 1 to 28 days via concrete compressive strength experiments and fitted the obtained data using a cubic polynomial model to obtain a fitting curve of concrete compressive strength over time. Yeh [

37] proposed a parametric trend regression and a four-parameter optimization method for predicting the compressive strength of concrete. Elaty [

38] analyzed experimental data and revealed that a model can be constructed using two constants to predict the compressive strength of concrete at any age. Guo et al. [

39] developed a time-dependent relationship model between concrete compressive strength and elastic modulus by referring to the existing curve models. Wang and Yue [

40] analyzed the existing time-varying models of compressive strength, summarized the advantages and disadvantages of these models, and proposed further research directions.

Generally, although existing prediction models can predict the mechanical properties of concrete to a certain extent, they also have certain shortcomings in some aspects. The limitations of the ANN-based evaluation models lie in two aspects. Firstly, the accuracy of the ANN model is greatly affected by the number of neurons. However, there is currently no rigorous mathematical basis for determining the optimal number of neurons in the ANN model. Secondly, the ANN model can only be used for evaluation after being trained and matured. Usually, the training of the ANN model requires a lot of experimental data, which increases the cost of the experiment. The limitations of current curve regression models mainly lie in their low fitting accuracy and weak universality. For example, polynomial models are inaccurate in predicting the mechanical properties of concrete in the later stage. Although logarithmic and exponential models can converge to a certain extent in the later stage, they cannot predict the mechanical properties of concrete well in the later stage. These types of prediction models do not perform well with data with high dispersion, resulting in low fitting accuracy. The three-parameter model has one more unknown fitting parameter than the two-parameter model, so more experimental data is needed to perform curve fitting accordingly. When there is little experimental data, the fitting accuracy of the three-parameter model may not be as good as that of the two-parameter model. In addition, the three-parameter model is more complex to calculate than the two-parameter model. In order to improve evaluation accuracy, it is necessary to overcome the shortcomings of existing curves and integrate the advantages of existing curves to study a new mathematical curve model for predicting the mechanical properties of concrete. The goal of this work is to develop a new dual parameter curve model that can more accurately evaluate the compressive strength and elastic modulus changes of concrete at early age compared to the existing curve models. Based on the evaluation results of the proposed model, it can more reliably guide the construction or mechanical calculation of concrete components at early age. To this end, this work first analyzes the advantages and disadvantages of the existing logarithmic model, exponential model, hyperbolic model, and polynomial model. Subsequently, this work develops a new curve model that overcomes the shortcomings of existing curve models, which can be used for the evaluation of concrete compressive strength at early ages as well as for the evaluation of elastic modulus at early ages. The improvements provided by the new model mainly lie in three aspects. The first is that the mathematical formula of the new model is concise, including only two unknown parameters, which is very convenient for engineering applications. The second is that the curves used by the new model are more in line with the changes in mechanical properties of concrete at early age, so the fitting accuracy of the new model is higher than that of existing models. Thirdly, the new model has better universality, can be applied to more types of concrete, and may also be applicable to other cementitious materials. This work focuses on the performance of the proposed new model in evaluating the compressive strength and elastic modulus of concrete at early age. Using 18 sets of experimental data from existing literature, a comparative study was conducted on the computational accuracy of the new model and existing models to illustrate the superiority of the proposed new model.