Study on Effect of High-Entropy Alloy Binder on Microstructure and Properties of WC Cemented Carbide Doped with Rare Earth Oxide

Abstract

:1. Introduction

2. Experimental Method

2.1. Materials Preparation

2.2. Sample Characterization

3. Results and Discussion

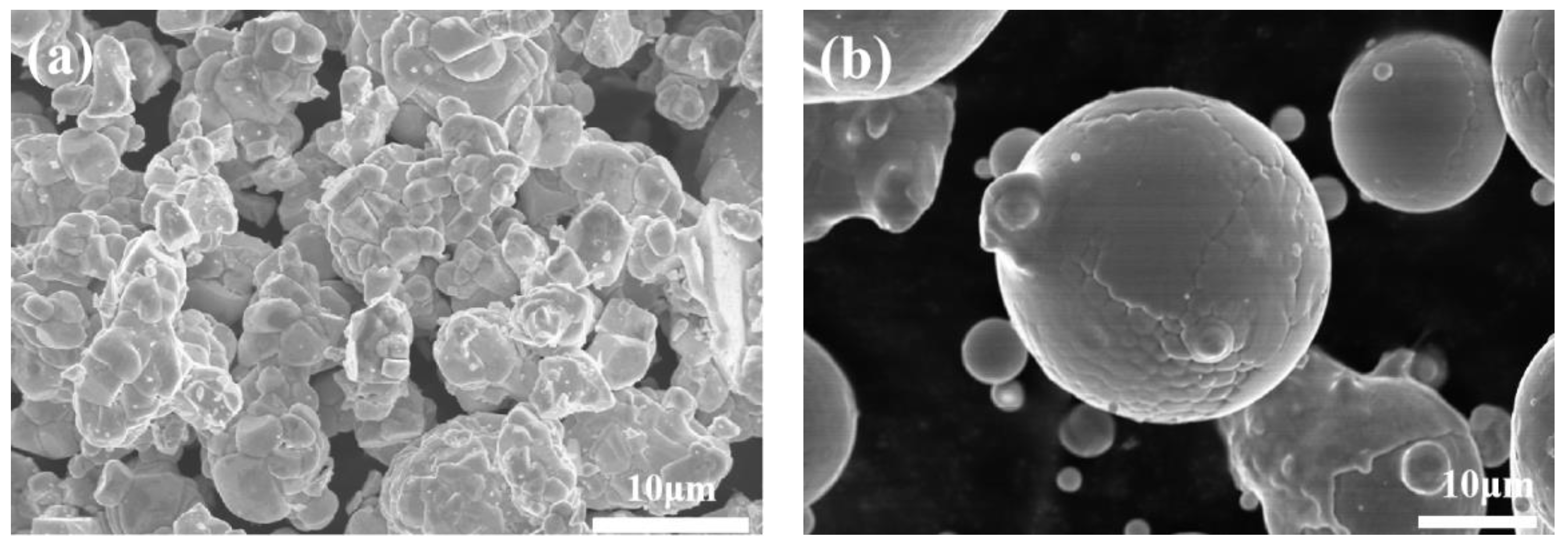

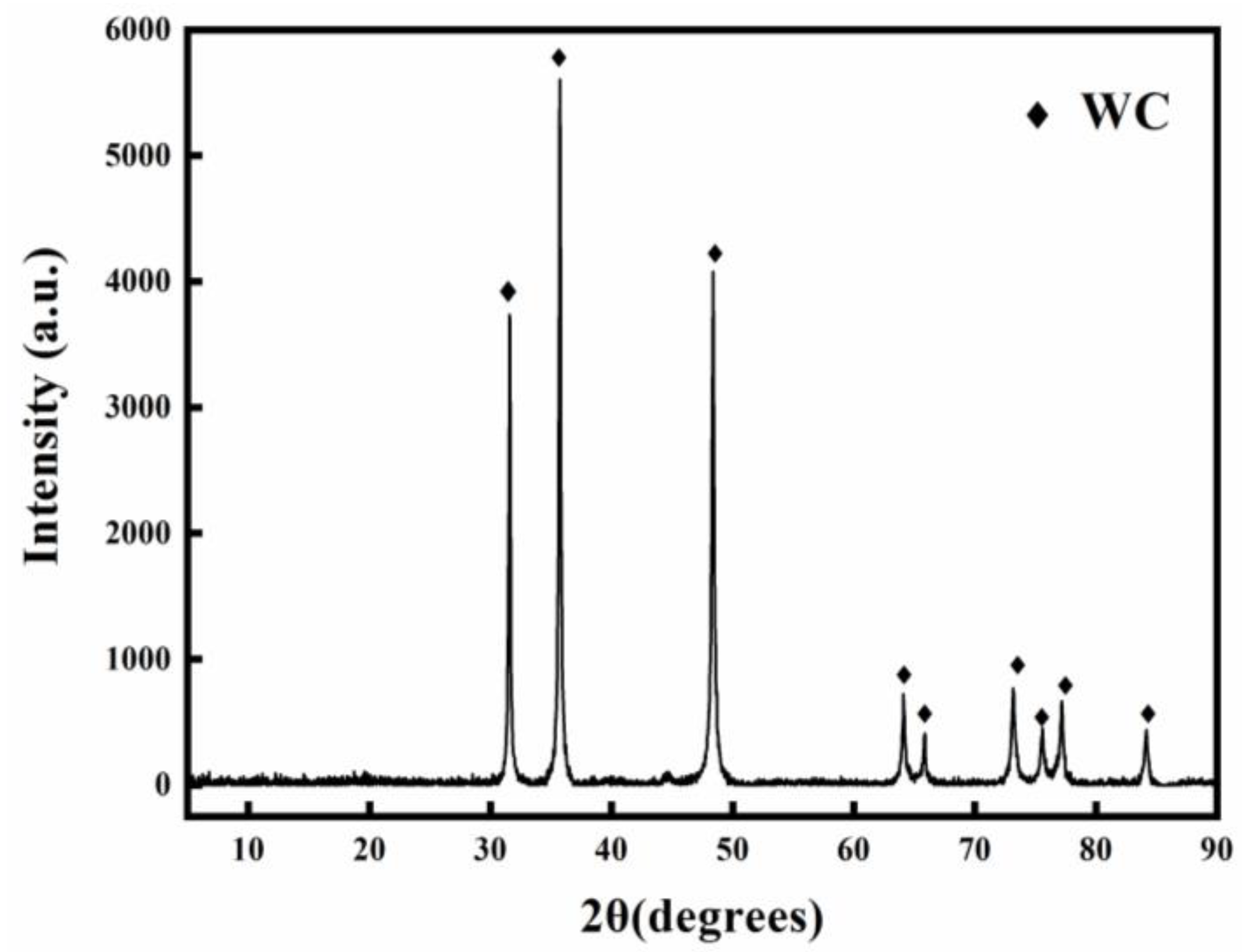

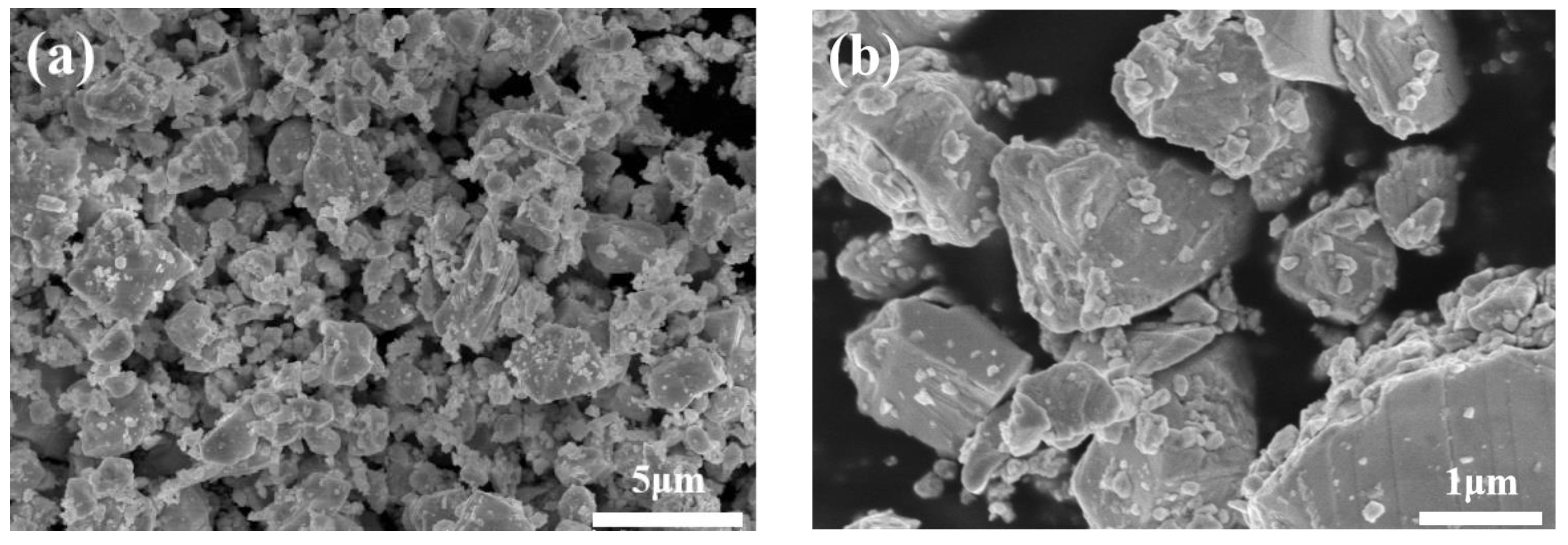

3.1. Microstructure and Composition of WC-Y2O3-ZrO2-10AlCoCrFeNi Powder

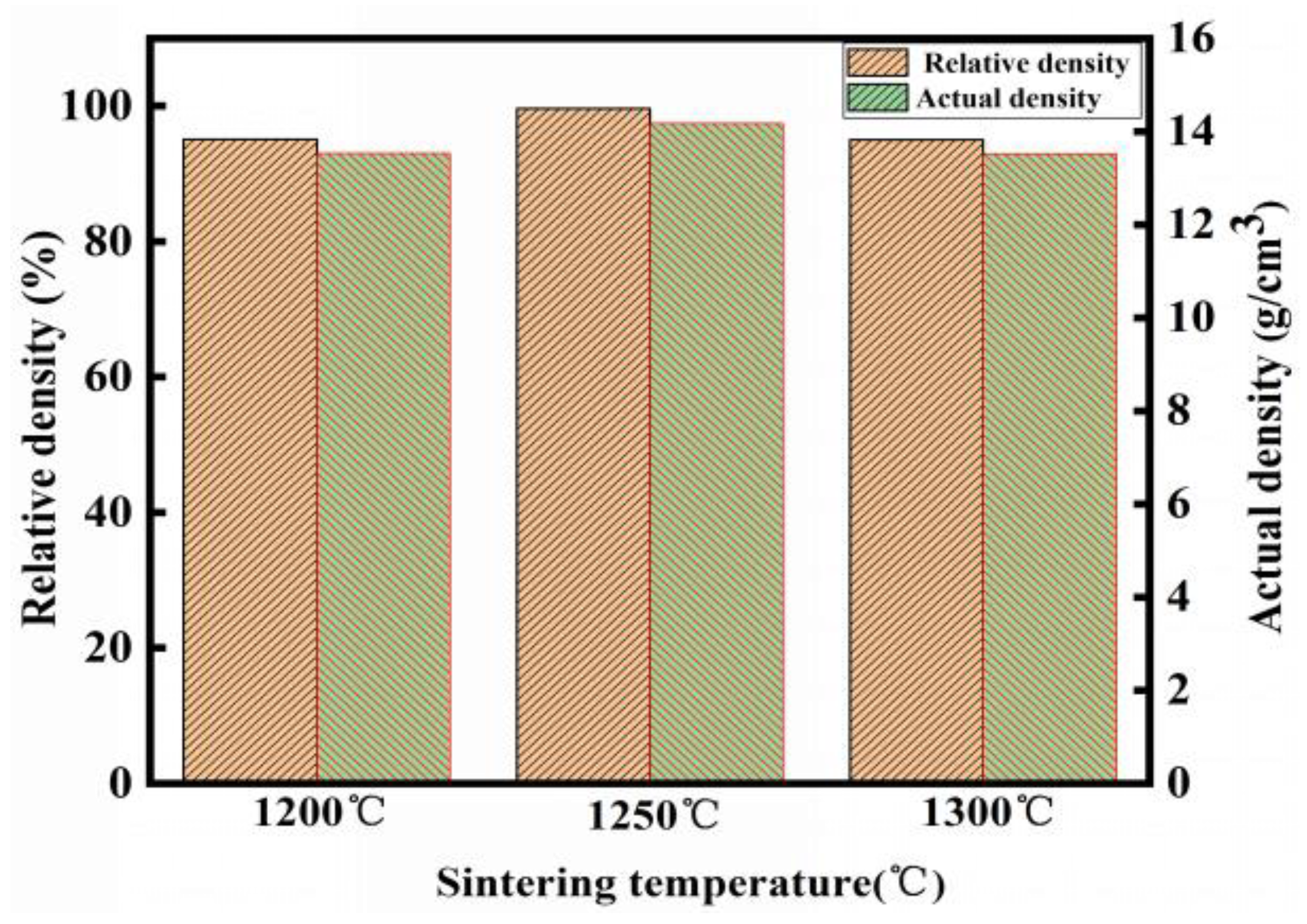

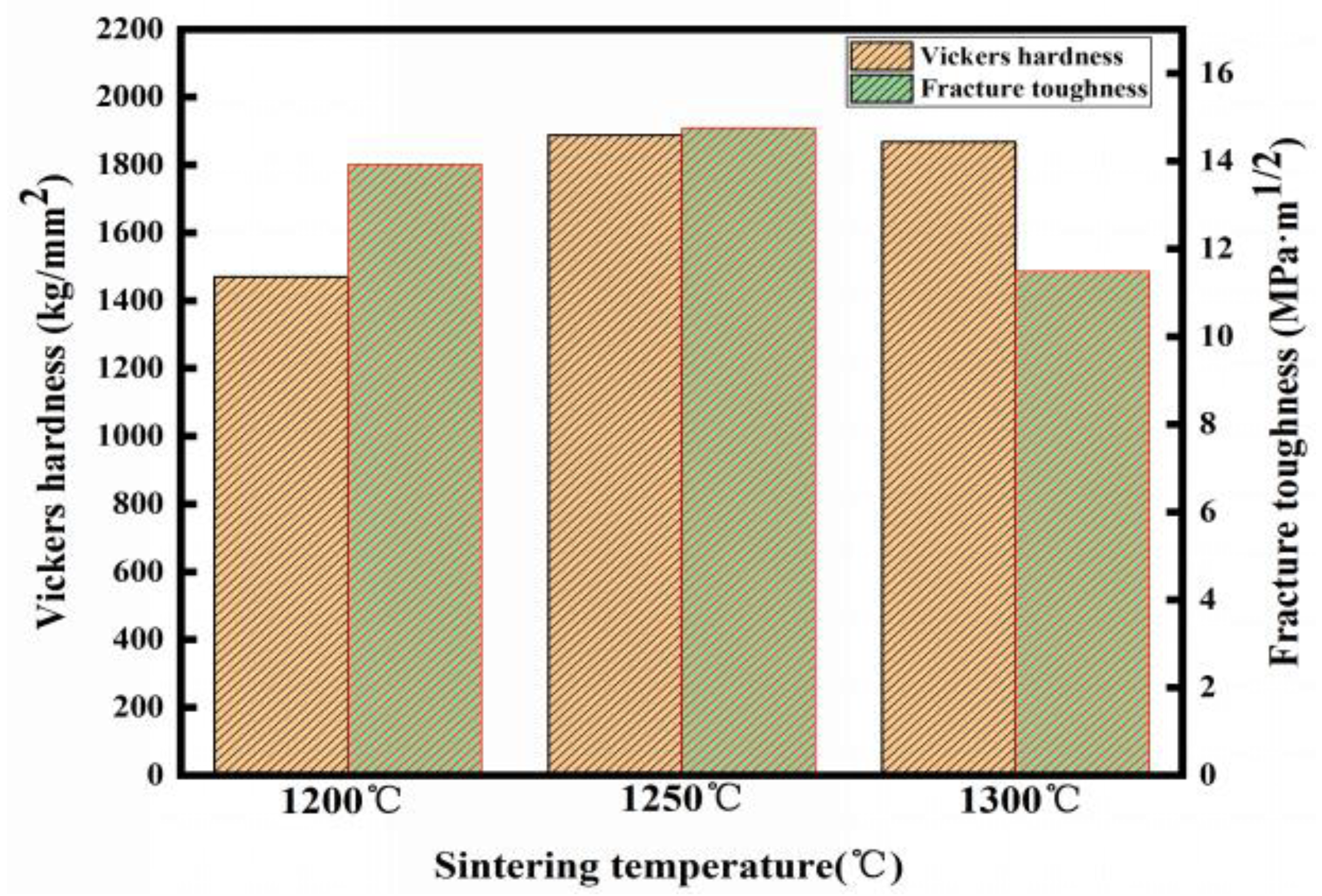

3.2. Effect of Sintering Temperature on WC-Y2O3-ZrO2-10AlCoCrFeNi Cemented Carbides

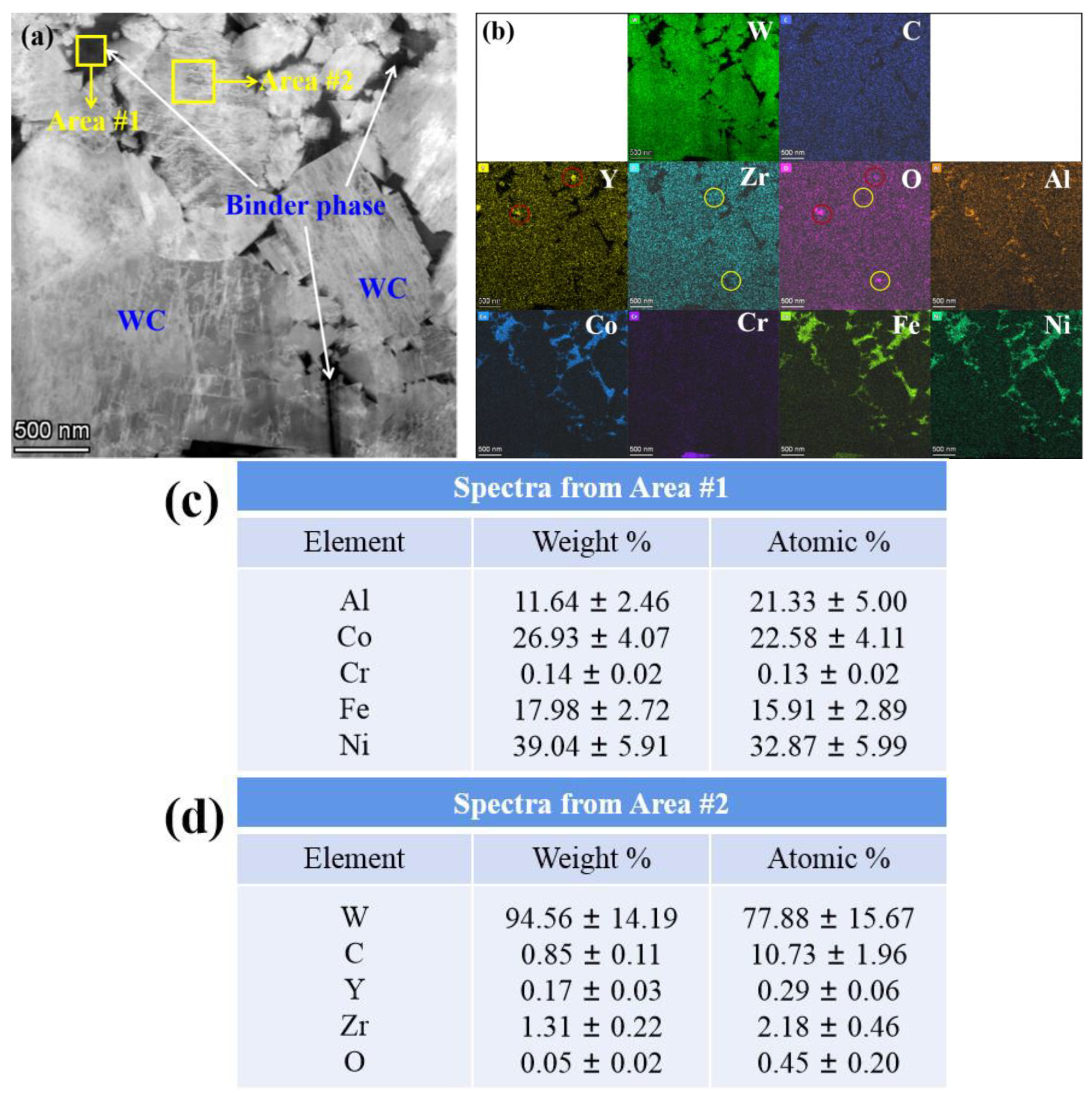

3.3. Microstructure of WC-Y2O3-ZrO2-10AlCoCrFeNi

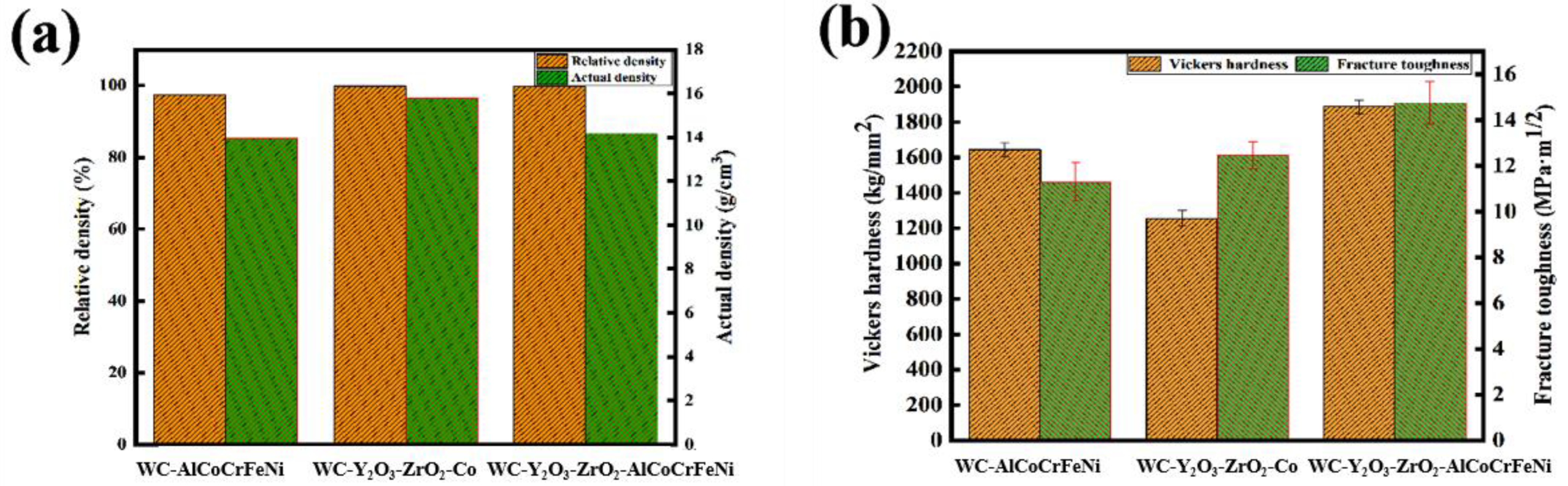

4. Conclusions

- (1)

- A highly densified WC-Y2O3-ZrO2-10AlCoCrFeNi cemented carbide was obtained by spark plasma sintering technology. Among the three samples of WC-Y2O3-ZrO2-10AlCoCrFeNi cemented carbide sintered at 1200 °C, 1250 °C, and 1300 °C, the WC grains of the alloy were smallest, the densification achieved the best effect, and the hardness and fracture toughness were the best in the sample sintered at 1250 °C.

- (2)

- AlCoCrFeNi diffused slowly within the WC matrix due to the delayed diffusion effect of the high-entropy alloy AlCoCrFeNi, which inhibited the growth of the WC grains and improved the hardness and fracture toughness of the alloy. Chromium had a low affinity for the WC. During the dynamic process of the WC particle dissolution and precipitation growth, the Fe, Co, and Ni that diffused to the WC grain surface had a better affinity for the WC, which increased the strength and toughness of the alloy. The WC-Y2O3-ZrO2-10AlCoCrFeNi cemented carbide had an extremely high density, with a Vickers hardness of 1888.14 HV and fracture toughness of 14.76 MPa·m1/2. Compared with WC-10AlCoCrFeNi and WC-Y2O3-ZrO2-10Co, the Vickers hardness increased by 12.97% and 50.28%, and the fracture toughness increased by 30.62% and 18.46%, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Roa, J.J.; Phani, P.S.; Oliver, W.C.; Llanes, L. Mapping of mechanical properties at microstructural length scale in WC-Co cemented carbides: Assessment of hardness and elastic modulus by means of high speed massive nanoindentation and statistical analysis. Int. J. Refract. Met. Hard Mater. 2018, 75, 211–217. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.M.; Wang, J.; Zheng, Z.B.; Luo, T.G.; Zheng, K.H.; Long, J. Effect of sintering temperature on the microstructure and properties of Ti/W-C reinforced Fe-based composites. Vacuum 2021, 194, 110617. [Google Scholar] [CrossRef]

- Xu, B.P.; Zhou, Y.C.; Liu, Y.D.; Hu, S.J.; Zhang, G.D. Effect of different contents of WC on microstructure and properties of CrMnFeCoNi high-entropy alloy-deposited layers prepared by PTA. J. Mater. Res. 2022, 37, 719–727. [Google Scholar] [CrossRef]

- Chen, Z.W.; Wang, Z.H.; Wang, B.X.; Yuan, J.T.; Huang, L.; Yin, Z.B. Microstructure and properties of WC-8Co cemented carbides prepared by multiple spark plasma sintering. Int. J. Appl. Ceram. Technol. 2021, 18, 2010–2019. [Google Scholar] [CrossRef]

- Sun, J.L.; Huang, Z.F.; Zhao, J. High-hard and high-tough WC-TiC-Co cemented carbide reinforced with graphene. Mater. Today Commun. 2021, 29, 102841. [Google Scholar] [CrossRef]

- Liu, K.; Wang, Z.H.; Yin, Z.B.; Cao, L.Y.; Yuan, J.T. Effect of Co content on microstructure and mechanical properties of ultrafine grained WC-Co cemented carbide sintered by spark plasma sintering. Ceram. Int. 2018, 44, 18711–18718. [Google Scholar] [CrossRef]

- Lv, Z.P.; Wu, Y.J.; Dang, J.; Liu, D.; Hu, L.W.; Du, K.P.; Sun, H.B. Effect of yttrium on morphologies and size of tungsten carbide particles prepared through CO reduction. J. Mater. Res. Technol. 2020, 9, 10166–10174. [Google Scholar] [CrossRef]

- Yu, B.H.; Li, Y.P.; Lei, Q.; Nie, Y. Microstructures and mechanical properties of WC-Co-xCr-Mo cement carbides. J. Alloy Compd. 2019, 771, 636–642. [Google Scholar] [CrossRef]

- Kresse, T.; Meinhard, D.; Bernthaler, T.; Schneider, G. Hardness of WC-Co hard metals: Preparation, quantitative microstructure analysis, structure-property relationship and modelling. Int. J. Refract. Met. Hard Mater. 2018, 75, 287–293. [Google Scholar] [CrossRef]

- Ocak, B.C.; Goller, G. Investigation the effect of FeNiCoCrMo HEA addition on properties of B4C ceramic prepared by spark plasma sintering. J. Eur. Ceram. Soc. 2021, 41, 6290–6301. [Google Scholar] [CrossRef]

- Li, J.M.; Li, X.Q.; Xia, X.J. Effects of Al2O3-ZrO2 content on the densification, microstructure, and mechanical properties of cemented tungsten carbides. Mater. Chem. Phys. 2022, 276, 125330. [Google Scholar] [CrossRef]

- He, S.W.; Wang, M.H.; Bai, Q.; Xia, S.; Zhou, B.X. Effect of TaC Content on Microstructure and Mechanical Properties of WC-TiC-TaC-Co Cemented Carbide. Acta Metall. Sin. 2020, 56, 1015–1024. [Google Scholar]

- Khuengpukheiw, R.; Wisitsoraat, A.; Saikaew, C. Wear behaviors of HVOF-sprayed NiSiCrFeB, WC-Co/NiSiCrFeB and WC-Co coatings evaluated using a pin-on-disc tester with C45 steel pins. Wear 2021, 484, 203699. [Google Scholar] [CrossRef]

- Solodkyi, I.; Teslia, S.; Bezdorozhev, O.; Trosnikova, I.; Yurkova, O.; Bogomol, I.; Loboda, P. Hardmetals prepared from WC-W2C eutectic particles and AlCrFeCoNiV high entropy alloy as a binder. Vacuum 2022, 195, 110630. [Google Scholar] [CrossRef]

- Edtmaier, C.; Wolf, M.; Calderon, R.D.; Schubert, W.D. Effect of nickel on the formation of gamma/gamma’ microstructures in WC/Co-Ni-Al-W. Int. J. Refract. Met. Hard Mater. 2021, 100, 105652. [Google Scholar] [CrossRef]

- Zhang, H.; Xiong, J.; Guo, Z.X.; Yang, T.N.; Liu, J.B.; Hua, T. Microstructure, mechanical properties, and cutting performances of WC-Co cemented carbides with Ru additions. Ceram. Int. 2021, 47, 26050–26062. [Google Scholar] [CrossRef]

- Yadav, S.; Zhang, Q.F.; Behera, A.; Haridas, R.S.; Agrawal, P.; Gong, J.D.; Mishra, R.S. Role of binder phase on the microstructure and mechanical properties of a mechanically alloyed and spark plasma sintered WC-FCC HEA composites. J. Alloy Compd. 2021, 877, 160265. [Google Scholar] [CrossRef]

- Vinnik, D.A.; Zhivulin, V.E.; Trofimov, E.A.; Gudkova, S.A.; Punda, A.Y.; Valiulina, A.N.; Gavrilyak, M.; Zaitseva, O.V.; Taskaev, S.V.; Khandaker, M.U.; et al. A-site cation size effect on structure and magnetic properties of Sm(Eu,Gd)Cr0.2Mn0.2Fe0.2Co0.2Ni0.2O3 high entropy solid solutions. Nanomaterials 2022, 12, 36. [Google Scholar] [CrossRef]

- Zhivulin, V.E.; Sherstyuk, D.P.; Zaitseva, O.V.; Cherkasova, N.A.; Vinnik, D.A.; Taskaev, S.V.; Trofimov, E.A.; Trukhanov, S.V.; Latushka, S.I.; Tishkevich, D.I.; et al. Creation and magnetic study of ferrites with magnetoplumbite structure multisubstituted by Al3+, Cr3+, Ga3+, and In3+ cations. Nanomaterials 2022, 12, 1306. [Google Scholar] [CrossRef]

- Mueller-Grunz, A.; Alveen, P.; Rassbach, S.; Useldinger, R.; Moseley, S. The manufacture and characterization of WC-(Al)CoCrCuFeNi cemented carbides with nominally high entropy alloy binders. Int. J. Refract. Met. Hard Mater. 2019, 84, 105032. [Google Scholar] [CrossRef]

- Luo, W.Y.; Liu, Y.Z.; Luo, Y.; Wu, M. Fabrication and characterization of WC-AlCoCrCuFeNi high-entropy alloy composites by spark plasma sintering. J. Alloy Compd. 2018, 754, 163–170. [Google Scholar] [CrossRef]

- Wei, Z.; Wu, Y.P.; Hong, S.; Cheng, J.B.; Qiao, L.; Ceng, J.; Zhu, S.S. Electrochemical properties and cavitation erosion behaviors of HVOF sprayed (AlCoCrFeNi)(1-X)(WC-10Co)(X) composite coatings in NaCl medium. Ceram. Int. 2021, 47, 29410–29422. [Google Scholar] [CrossRef]

- Liu, X.M.; Wang, H.B.; Feng, H.; Hu, H.X.; Chen, J.H.; Zhao, Z.; Wu, G.C.; Liu, C.; Lu, H.; Song, X.Y. On the enhanced wear resistance of ultra-coarse WC-Co cemented carbides by WCoB addition. J. Alloy Compd. 2022, 894, 162449. [Google Scholar] [CrossRef]

- Qin, Y.Q.; Peng, Y.Q.; Tian, Y.; Luo, L.M.; Ma, Y.; Zan, X.; Zhu, X.Y.; Wu, Y.C. Effect of Y2O3 on microstructure and mechanical properties of WC-Co-cemented carbides prepared via solid-liquid doping method and spark plasma sintering. Mater. Today Commun. 2020, 24, 101096. [Google Scholar] [CrossRef]

- Yang, T.E.; Xiong, J.; Sun, L.; Guo, Z.X.; Qin, K.C. Effects of nano-Al2O3 and nano-ZrO2 on the microstructure, behavior and abrasive wear resistance of WC-8Co cemented carbide. Rare Metals. 2011, 30, 533–538. [Google Scholar] [CrossRef]

- Kadyrzhanov, K.K.; Shlimas, D.I.; Kozlovskiy, A.L.; Zdorovets, M.V. Research of the shielding effect and radiation resistance of composite CuBi2O4 films as well as their practical applications. J. Mater. Sci. Mater. Electron. 2020, 31, 11729–11740. [Google Scholar] [CrossRef]

- Zubar, T.I.; Usovich, T.I.; Tishkevich, D.I.; Kanafyev, O.D.; Fedkin, V.A.; Kotelnikova, A.N.; Panasyuk, M.I.; Kurochka, A.S.; Nuriev, A.V.; Idris, A.M.; et al. Features of galvanostatic electrodeposition of NiFe films with composition gradient: Influence of substrate characteristics. Nanomaterials 2022, 12, 2926. [Google Scholar] [CrossRef]

- Li, J.F.; Cheng, J.G.; Wei, B.Z.; Chen, P.Q. Preparation and performance of ultrafine grained WC-10Co alloys with added La2O3. Ceram. Int. 2019, 45, 3969–3976. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, L.M.; Zan, X.; Zhu, X.Y.; Zhu, L.; Wu, Y.C. Synthesis of Y2O3-doped WC-Co powders by wet chemical method and its effect on the properties of WC-Co cemented carbide alloy. Int. J. Refract. Met. Hard Mater. 2020, 92, 105324. [Google Scholar] [CrossRef]

- Cai, H.; Jing, W.W.; Guo, S.D.; Liu, L.; Ye, Y.; Wen, Y.; Wu, Y.X.; Wang, S.L.; Huang, X.; Zhang, J.B. Effects of micro/nano CeO2 on the microstructure and properties of WC-10Co cemented carbides. Int. J. Refract. Met. Hard Mater. 2020, 95, 105432. [Google Scholar] [CrossRef]

- Tokarewicz, M.; Gradzka-Dahlke, M. Review of Recent Research on AlCoCrFeNi High-Entropy Alloy. Metals 2021, 11, 1302. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.F.; Zhou, J.H.; Fu, K.; Wei, W.; Du, M.; Zhao, X.F. Effects of Y2O3 addition on microstructures and mechanical properties of WC-Co functionally graded cemented carbides. Int. J. Refract. Met. Hard Mater. 2015, 50, 53–58. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Yao, G.; Luo, L.M.; Zan, X.; Xu, Q.; Wu, Y.C. Anisotropy and stability of the mechanical properties of the W alloy plate reinforced with Y-Zr-O particles and prepared by a wet chemical method. Int. J. Refract. Met. Hard Mater. 2021, 99, 105597. [Google Scholar] [CrossRef]

- Trukhanov, S.V.; Trukhanov, A.V.; Vasiliev, A.N.; Balagurov, A.M.; Szymczak, H. Magnetic state of the structural separated anion-deficient La0.70Sr0.30MnO2.85 manganite. J. Exp. Theor. Phys. 2011, 113, 819–825. [Google Scholar] [CrossRef]

- Kozlovskiy, A.; Egizbek, K.; Zdorovets, M.V.; Ibragimova, M.; Shumskaya, A.; Rogachev, A.A.; Ignatovich, Z.V.; Kadyrzhanov, K. Evaluation of the efficiency of detection and capture of manganese in aqueous solutions of FeCeOx nanocomposites doped with Nb2O5. Sensors 2020, 20, 4851. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Luo, L.M.; Zan, X.; Zhu, X.Y.; Zhu, L.; Wu, Y.C. Study on preparation and properties of WC-8Co cemented carbide doped with rare earth oxide. Int. J. Refract. Met. Hard Mater. 2021, 98, 105536. [Google Scholar] [CrossRef]

- Chang, S.H.; Chen, S.L. Characterization and properties of sintered WC-Co and WC-Ni-Fe hard metal alloys. J. Alloys Compd. 2014, 585, 407–413. [Google Scholar] [CrossRef]

- Lu, K.L.; Shen, C.J.; He, Y.Z.; Huang, S.; Ba, Y.E. Effect of solute elements (Cr, Mo, Fe, Co) on the adhesion properties of WC/Ni-based binder interface: A first-principles study. Int. J. Refract. Met. Hard Mater. 2021, 98, 105563. [Google Scholar] [CrossRef]

- Fransson, E.; Gren, M.; Wahnstrom, G. Complexions and grain growth retardation: First-principles modeling of phase boundaries in WC-Co cemented carbides at elevated temperatures. Acta Mater. 2021, 216, 117128. [Google Scholar] [CrossRef]

- Ghanbariha, M.; Farvizi, M.; Ebadzadeh, T.; Samiyan, A.A. Effect of ZrO2 particles on the nanomechanical properties and wear behavior of AlCoCrFeNi-ZrO2 high entropy alloy composites. Wear 2021, 484, 204032. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Yuan, J.; Zhuang, Y.; Ma, B.; Luo, L.; Wu, Y. Study on Effect of High-Entropy Alloy Binder on Microstructure and Properties of WC Cemented Carbide Doped with Rare Earth Oxide. Coatings 2023, 13, 273. https://doi.org/10.3390/coatings13020273

Qin Y, Yuan J, Zhuang Y, Ma B, Luo L, Wu Y. Study on Effect of High-Entropy Alloy Binder on Microstructure and Properties of WC Cemented Carbide Doped with Rare Earth Oxide. Coatings. 2023; 13(2):273. https://doi.org/10.3390/coatings13020273

Chicago/Turabian StyleQin, Yongqiang, Jian Yuan, Yi Zhuang, Bing Ma, Laima Luo, and Yucheng Wu. 2023. "Study on Effect of High-Entropy Alloy Binder on Microstructure and Properties of WC Cemented Carbide Doped with Rare Earth Oxide" Coatings 13, no. 2: 273. https://doi.org/10.3390/coatings13020273

APA StyleQin, Y., Yuan, J., Zhuang, Y., Ma, B., Luo, L., & Wu, Y. (2023). Study on Effect of High-Entropy Alloy Binder on Microstructure and Properties of WC Cemented Carbide Doped with Rare Earth Oxide. Coatings, 13(2), 273. https://doi.org/10.3390/coatings13020273