Development of Density Control Technology for Improving Medical Radiation Shielding Performance of Waste Marble Powder Mixture

Abstract

:1. Introduction

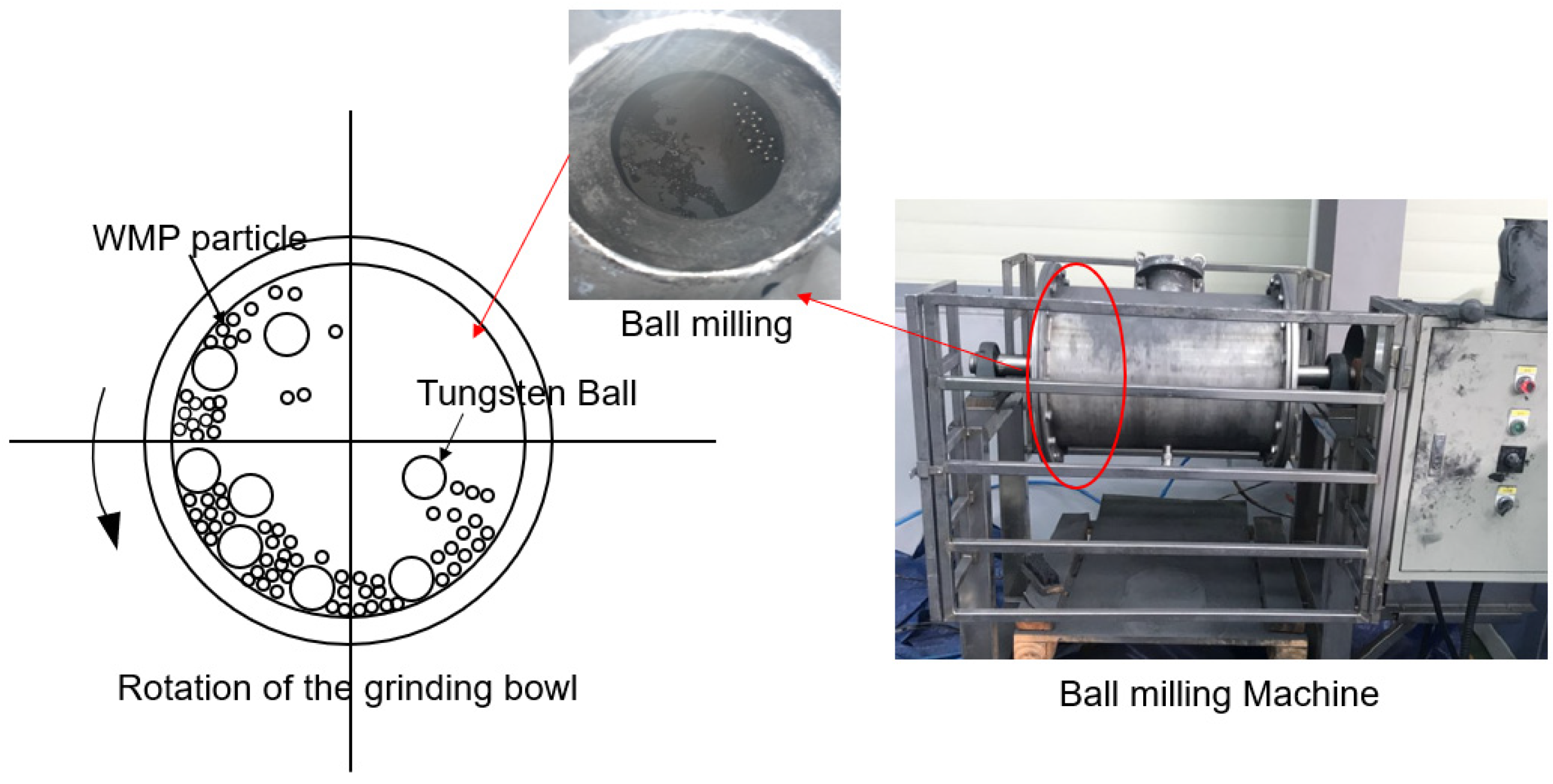

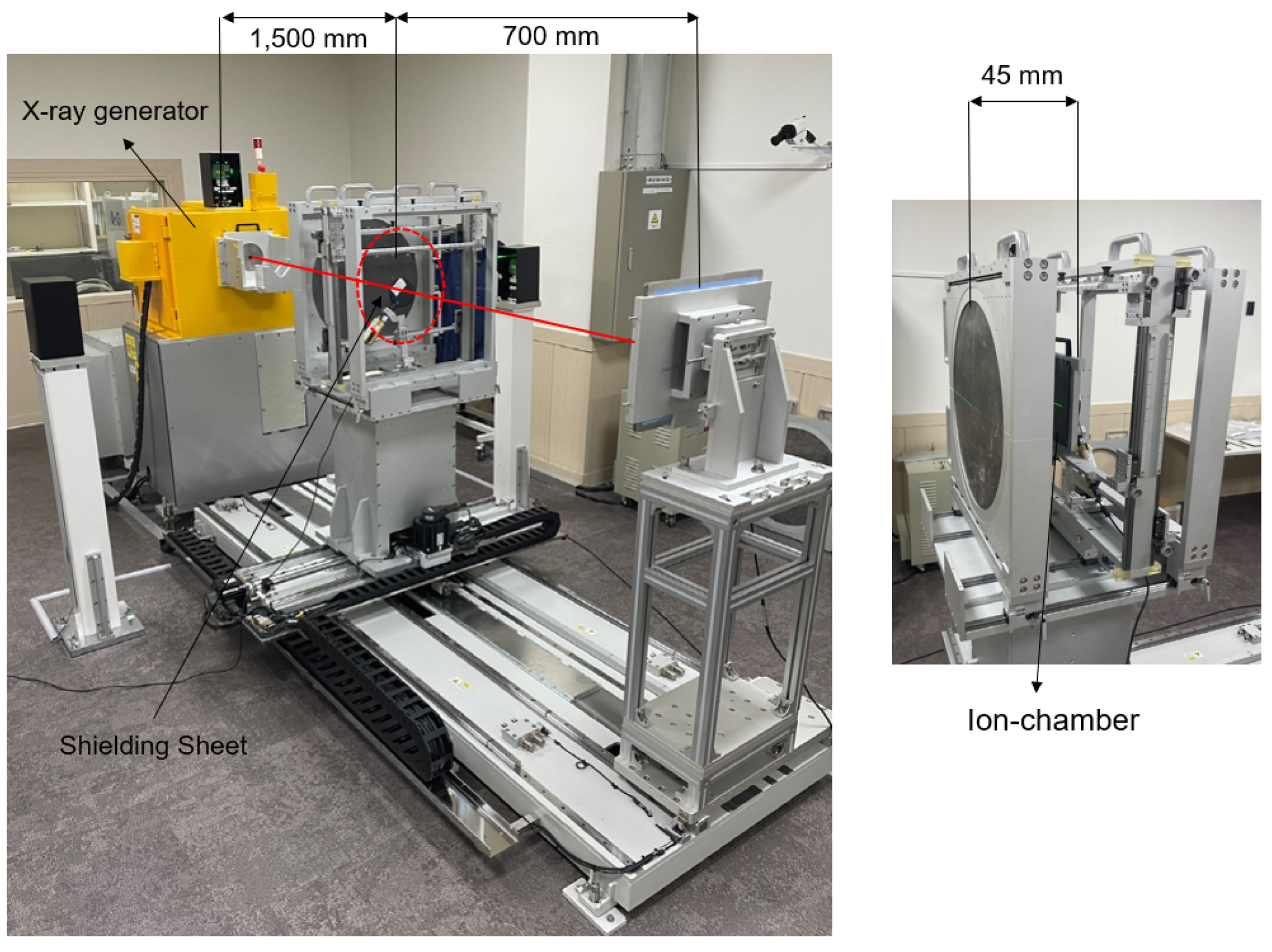

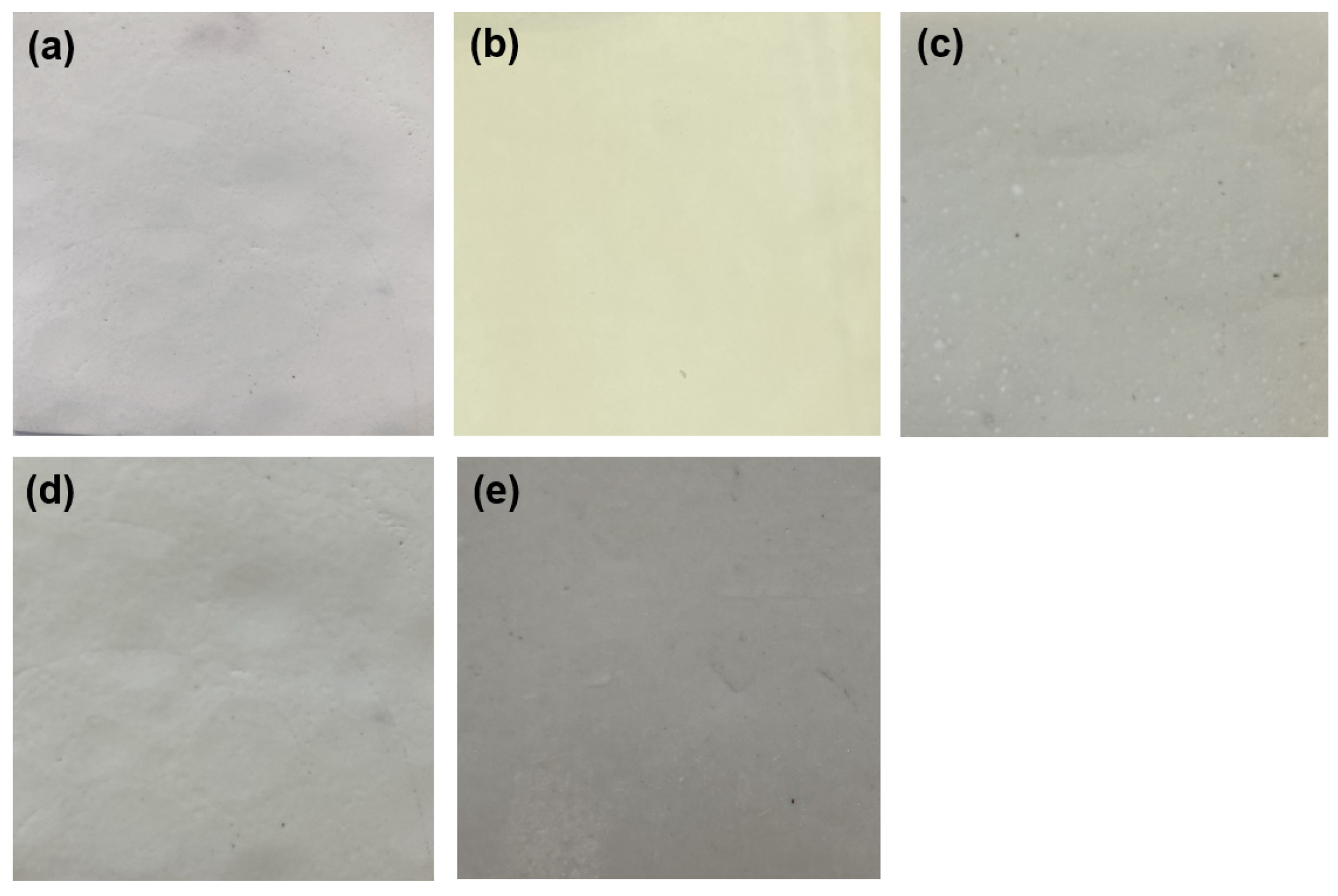

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, X.-M.; Le Bas, M.J. Chemical compositions of carbonate minerals from Bayan Obo, Inner Mongolia, China: Implications for petrogenesis. Lithos 2004, 72, 97–116. [Google Scholar] [CrossRef]

- Nikiforov, A.V.; Dubinina, E.O.; Polyakov, N.A.; Sugorakova, A.M.; Khertek, A.K. Influence of Host Marble Rocks on the Formation of Intrusive Alkaline Rocks and Carbonatites of Sangilen (E. Siberia, Russia). Minerals 2021, 11, 1–18. [Google Scholar] [CrossRef]

- Moghaddam, H.K.; Rajaei, A.; Moghaddam, H.K. Marble Slabs Classification System Based on Image Processing (Ark Marble Mine in Birjand). Civ. Eng. J. 2018, 4, 107–116. [Google Scholar] [CrossRef] [Green Version]

- Benjeddou, O.; Alwetaishi, M. Valorization of Powder Obtained from Marble Sludge Waste and Its Suitability as a Mineral Filler. Crystals 2021, 11, 619. [Google Scholar] [CrossRef]

- Zhou, Z.; Yang, Y.; Li, X.; Gao, W.; Liang, H.; Li, G. Coagulation efficiency and flocs characteristics of recycling sludge during treatment of low temperature and micro-polluted water. J. Environ. Sci. 2012, 24, 1014–1020. [Google Scholar] [CrossRef] [PubMed]

- Ergün, A. Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Alrashedi, M.F.; Almuqrin, A.H.; Elsafi, M. Recycling and optimizing waste lab glass with Bi2O3 nanoparticles to use as a transparent shield for photons. J. Mater. Res. Technol. 2022, 17, 2073–2083. [Google Scholar] [CrossRef]

- Harish, V.; Nagaiah, N.; Prabhu, T.N.; Varughese, K.T. Preparation and characterization of lead monoxide filled unsaturated polyester based polymer composites for gamma radiation shielding applications. J. Appl. Polym. Sci. 2009, 112, 1503–1508. [Google Scholar] [CrossRef]

- Azam, N.Z.N.; Siddiqui, S.A.; Hart, R.; Low, I.M. Microstructural design of lead oxide–epoxy composites for radiation shielding purposes. J. Appl. Polym. Sci. 2012, 128, 3213–3219. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Verma, H.K.; Mohnot, J.K. Recycling of dimensional stone waste in concrete: A review. J. Clean. Prod. 2016, 135, 312–331. [Google Scholar] [CrossRef]

- Murcia, D.H.; Çomak, B.; Soliman, E.; Taha, M.M.R. Flexural Behavior of a Novel Textile-Reinforced Polymer Concrete. Polymers 2022, 14, 176. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Zhang, X.; Gao, Y.; Guo, S. High-efficiency, flexibility and lead-free X-ray shielding multilayered polymer composites: Layered structure design and shielding mechanism. Sci. Rep. 2021, 11, 4384. [Google Scholar] [CrossRef] [PubMed]

- Levet, A.; Kavaz, E.; Özdemir, Y. An experimental study on the investigation of nuclear radiation shielding characteristics in iron-boron alloys. J. Alloys Compd. 2020, 819, 152946. [Google Scholar] [CrossRef]

- Jalali, M.; Mohammadi, A. Gamma ray attenuation coefficient measurement for neutron-absorbent materials. Radiat. Phys. Chem. 2008, 77, 523–527. [Google Scholar] [CrossRef]

- Li, Q.; Wei, Q.; Zheng, W.; Zheng, Y.; Okosi, N.; Wang, Z.; Su, M. Enhanced Radiation Shielding with Conformal Light-Weight Nanoparticle–Polymer Composite. ACS Appl. Mater. Interfaces 2018, 10, 35510–35515. [Google Scholar] [CrossRef]

- Hao, X.; Ball, B.C.; Culley, J.L.B.; Carter, M.R.; Parkin, G.W. Soil density and porosity. In Soil Sampling and Methods of Analysis, 2nd ed.; Carter, M.R., Gregorich, E.G., Eds.; CRC Press Taylor & Francis: Boca Raton, FL, USA, 2008; pp. 743–759. [Google Scholar]

- Rahman, T.; Nurdiana, J. The effect of Recycled HDPE Plastic Additions on Concrete Performance. Recycling 2021, 6, 18. [Google Scholar] [CrossRef]

- Abdalsalam, A.H.; Şakar, E.; Kaky, K.M.; Mhareb, M.H.A.; Şakar, B.C.; Sayyed, M.I.; Gürol, A. Investigation of gamma ray attenuation features of bismuth oxide nano powder reinforced high-density polyethylene matrix composites. Radiat. Phys. Chem. 2020, 168, 108537. [Google Scholar] [CrossRef]

- Jang, S.G.; Han, S.C.; Kang, S.J.; Lee, S.S. Preliminary Study for Development of Low Dose Radiation Shielding Material Using Liquid Silicon and Metalic Compound. J. Radiol. Sci. Technol. 2017, 40, 461–468. [Google Scholar] [CrossRef]

- Alansy, A.S.; Saeed, T.A.; Al-Attab, R.; Guo, Y.; Yang, Y.; Liu, B.; Fan, Z. Boron nitride nanosheets modified with zinc oxide nanoparticles as novel fillers of dental resin composite. Dent. Mater. 2022, 38, e266–e274. [Google Scholar] [CrossRef]

- Kaur, T.; Sharma, J.; Singh, T. Experimental evaluation of gamma rays shielding parameters for Zn-Cd-Sn-Pb quaternary alloy. Radiat. Phys. Chem. 2019, 156, 193–198. [Google Scholar] [CrossRef]

- Hubbell, J.H. Photon mass attenuation and energy absorption coefficients. Int. J. Appl. Radiat. Isot. 1982, 33, 1269–1290. [Google Scholar] [CrossRef]

- Wang, G.-H.; He, M.-L.; Chai, F.-C.; Feng, J.-D.; Dai, Y.-D. Enhancement of flame retardancy and radiation shielding properties of ethylene vinyl acetate based radiation shielding composites by EB irradiation. Prog. Nucl. Energy 2019, 112, 225–232. [Google Scholar] [CrossRef]

- Panuccio, G.; Greenberg, R.K.; Wunderle, K.; Mastracci, T.M.; Eagleton, M.G.; Davros, W. Comparison of indirect radiation dose estimates with directly measured radiation dose for patients and operators during complex endovascular procedures. J. Vasc. Surg. 2011, 53, 885–894. [Google Scholar] [CrossRef] [Green Version]

- Tasnim, A.; Sahadath, M.H.; Khan, M.N.I. Development of high-density radiation shielding materials containing BaSO4 and investigation of the gamma-ray attenuation properties. Radiat. Phys. Chem. 2021, 189, 109772. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; El-Khatib, A.M.; Badawi, M.S.; Rashad, A.R.; El-Sharkawy, R.M.; Thabet, A.A. Recycled high-density polyethylene plastics added with lead oxide nanoparticles as sustainable radiation shielding materials. J. Clean. Prod. 2018, 176, 276–287. [Google Scholar] [CrossRef]

- Baalamurugan, J.; Ganesh Kumar, V.; Chandrasekaran, S.; Balasundar, S.; Venkatraman, B.; Padmapriya, R.; Bupesh Raja, V.K. Recycling of steel slag aggregates for the development of high density concrete: Alternative & environment-friendly radiation shielding composite. Compos. Part B 2021, 216, 108885. [Google Scholar] [CrossRef]

- Saudi, H.A.; Ei-Mosallamy, E.H. Evaluation of Polymethyl Methacrylate Sheets as a Radiation Shielding Material. J. Pack. Technol. Res. 2020, 4, 227–233. [Google Scholar] [CrossRef]

- Fornalski, K.W. Simple empirical correction functions to cross sections of the photoelectric effect, Compton scattering, pair and triplet production for carbon radiation shields for intermediate and high photon energies. J. Phys. Commun. 2018, 2, 035038. [Google Scholar] [CrossRef]

- Almurayshid, M.; Alsagabi, S.; Alssalim, Y.; Alotaibi, Z.; Almsalam, R. Feasibility of polymer-based composite materials as radiation shield. Radiat. Phys. Chem. 2021, 183, 109425. [Google Scholar] [CrossRef]

- Lermen, R.T.; Prauchner, M.B.; Silva, R.A.; Bonsembiante, F.T. Using Wastes from the Process of Blasting with Steel Shot to Make a Radiation Shield in Mortar. Sustainability 2020, 12, 6674. [Google Scholar] [CrossRef]

- Ding, B.; Zhang, L.; Liu, J. Study on Shielding and Radiation Resistance of Basalt Fiber to Gamma Ray. Materials 2022, 15, 2522. [Google Scholar] [CrossRef]

- Tyagi, G.; Singhal, A.; Routroy, S.; Bhunia, D.; Lahoti, M. A review on sustainable utilization of industrial wastes in radiation shielding concrete. Mater. Today Proc. 2020, 32, 746–751. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Almurayshid, M.; Almasoud, F.I.; Alyahyawi, A.R.; Yasmin, S.; Elsafi, M. Developed a New Radiation Shielding Absorber Composed of Waste Marble, Polyester, PbCO3, and CdO to Reduce Waste Marble Considering Environmental Safety. Materials 2022, 15, 8371. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Ling, T.-C.; Kim, M.H. Recycling of wastes for value-added applications in concrete blocks: An overview. Resour. Conserv. Recycl. 2018, 138, 298–312. [Google Scholar] [CrossRef]

- Aral, N.; Nergis, F.B.; Candan, C. An alternative X-ray shielding material based on coated textiles. Text. Res. J. 2015, 86, 803–811. [Google Scholar] [CrossRef]

- Issa, S.A.M.; Zakaly, H.M.H.; Pyshkina, M.; Mostafa, M.Y.A.; Rashad, M.; Soliman, T.S. Structure, optical, and radiation shielding properties of PVA–BaTiO3 nanocomposite films: An experimental investigation. Radiat. Phys. Chem. 2021, 180, 109281. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric composite materials for radiation shielding: A review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef] [PubMed]

- Boonin, K.; Yasaka, P.; Limkitjaroenporn, P.; Rajaramakrishna, R.; Askin, A.; Sayyed, M.I.; Kothan, S.; Kaewkhao, J. Effect of BaO on lead free zinc barium tellurite glass for radiation shielding materials in nuclear application. J. Noncryst. Solids 2020, 550, 120386. [Google Scholar] [CrossRef]

- Olukotun, S.F.; Gbenu, S.T.; Ibitoye, F.I.; Oladejo, O.F.; Shittu, H.O.; Fasasi, M.K.; Balogun, F.A. Investigation of gamma radiation shielding capability of two clay materials. Nucl. Eng. Technol. 2018, 50, 957–962. [Google Scholar] [CrossRef]

| Item | Value | ||||

|---|---|---|---|---|---|

| WMP | WMP (Ball Milling) | WMP (+Bi2O3) | WMP (Defoaming) | WMP (Plastic Work) | |

| Sheet structure | Single structure | ||||

| Mixing ratio (polymer to WMP) | 1:3 | ||||

| Sheet weight (kg/m2) | 2.50 | 2.15 | 3.15 | 2.18 | 2.12 |

| Sheet thickness (mm) | 1.01 | 0.92 | 1.43 | 0.89 | 0.75 |

| Polyethylene (g) | 83.4 | 83.5 | 84.0 | 82.4 | 80.5 |

| WMP (g) | 250 | ||||

| Radiation Type | Effective Energy (keV) | Shielding Rate (%) | |||||

|---|---|---|---|---|---|---|---|

| Lead (0.1 mm) | WMP | WMP (Ball Milling) | WMP (Defoaming) | WMP (Plastic Work) | WMP (+Bi2O3) | ||

| X-ray | 23.5 | 81.54 | 31.2 | 36.4 | 39.4 | 58.9 | 72.2 |

| 27.4 | 83.47 | 26.2 | 27.4 | 34.2 | 56.4 | 68.8 | |

| 33.1 | 87.54 | 20.5 | 22.5 | 30.0 | 41.5 | 60.4 | |

| 47.9 | 90.25 | 18.4 | 19.1 | 24.9 | 35.2 | 54.1 | |

| 55.4 | 97.04 | 12.1 | 12.5 | 23.4 | 30.1 | 52.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-C. Development of Density Control Technology for Improving Medical Radiation Shielding Performance of Waste Marble Powder Mixture. Coatings 2023, 13, 272. https://doi.org/10.3390/coatings13020272

Kim S-C. Development of Density Control Technology for Improving Medical Radiation Shielding Performance of Waste Marble Powder Mixture. Coatings. 2023; 13(2):272. https://doi.org/10.3390/coatings13020272

Chicago/Turabian StyleKim, Seon-Chil. 2023. "Development of Density Control Technology for Improving Medical Radiation Shielding Performance of Waste Marble Powder Mixture" Coatings 13, no. 2: 272. https://doi.org/10.3390/coatings13020272