1. Introduction

Cr

2O

3 coatings are widely used in various fields in order to reduce the wear of metallic parts and metallic surfaces from corrosion [

1,

2,

3,

4,

5,

6].

Plasma spraying is one of the commonly used techniques to deposit ceramic coatings, such as aluminum oxide, chromium oxide, titanium oxide, zirconium oxide, etc., on metallic surfaces [

2,

4,

7,

8,

9,

10]. The mechanical, tribological, thermal or corrosion properties of sprayed Cr

2O

3 coatings are easily controlled by changing the spraying conditions such as spraying distance, arc current, gas type, gas flow ratio, etc. [

2,

8,

11,

12]. Kiilakoski et al. [

8] indicated that the surface roughness, hardness, porosity and wear resistance of chromia coatings could be controlled by changing the spray distance, flow rate of air or suspension feed rate.

Another way to improve the hardness and toughness, reduce the friction coefficient, or enhance the wear and corrosion resistance of chromia coatings is to use additive materials. It was demonstrated that TiO

2, Al

2O

3, YSZ-SiC or CeO

2 is used to improve the properties of Cr

2O

3 coatings [

2,

13,

14,

15,

16,

17,

18]. Li et al. [

14] demonstrated that the addition of TiO

2 up to 32 wt.% will improve the tribological properties under dry friction and oil friction conditions. However, it was found that the friction coefficient of Cr

2O

3-TiO

2 coatings in most cases was enhanced from 0.60 up to 0.92 under dry sliding. Our previous investigations [

15] indicated that the friction coefficient was reduced, and the specific wear rate decreased from 2.69 × 10

−6 mm

3/(Nm) to 1.54 × 10

−6 mm

3/(Nm) after doping of chromium oxide coating with SiO

2-TiO

2. Mao et al. [

16] observed that the wear rate of the chromium oxide coating was 14.6 × 10

−7 mm

3/(Nm) and, depending on the alumina fraction, varied from 8.2 to 12.9 × 10

−7 mm3/(Nm) for Cr

2O

3-Al

2O

3 coatings. However, the friction coefficient values under dry-sliding conditions for Cr

2O

3 and Cr

2O

3-Al

2O

3 coatings remained similar. Bolelli et al. [

17] demonstrated that the friction coefficients and wear rates were enhanced with the addition of TiO

2, Al

2O

3 or ZrO

2 into Cr

2O

3 coatings. Singh et al. [

19] showed that the friction coefficient of conventional and nanostructured Cr

2O

3-3%TiO

2 coatings varied between 0.55 and 0.80 depending on the applied loads and sliding distances. Ding et al. [

20] showed that the properties of Cr

2O

3-20wt.% TiO

2 coatings could be improved with the addition of CeO

2. It was obtained that the surface roughness and the porosity were reduced, the bonding strength was enhanced and the friction coefficient was reduced from 0.68 to 0.62 with the addition of CeO

2 into Cr

2O

3-TiO

2 coatings. Hashemi et al. [

21] obtained that Cr

2O

3-YSZ and Cr

2O

3-YSZ-SiC coatings demonstrated higher porosity, lower bonding strength and slightly higher friction coefficient values, but the wear rate of the coatings was reduced up to three times compared to the Cr

2O

3 coating.

The tribological properties of plasma-sprayed ceramic coatings could be improved with the addition of solid lubricant materials such as graphene nanoplatelets [

22,

23], carbon nanotubes [

24], graphene oxide [

25] or graphite [

26,

27]. It was demonstrated that graphene oxide improved the fracture toughness and reduced the microhardness of alumina-graphene oxide-sprayed coatings [

25]. The addition of both carbon nanotubes (CNTs) and graphite nanoparticles (GNPs) increased the hardness, elastic modulus and fracture toughness of alumina coatings [

23]. Venturi et al. [

22] observed that the wear rate was reduced by ~20%, while the friction coefficient decreased from 0.60 to 0.51 with the incorporation of graphene nanoplatelets into Cr

2O

3 coatings. Bagde et al. [

27] indicated that the addition of Ni-graphite into the Cr

2O

3-TiO

2 coating decreased the friction coefficient values, while the abrasive wear resistance was enhanced from 1.3 up to 2 times depending on the used loads. Goyal et al. [

24] showed that the reinforcement of chromia coatings with carbon nanotubes drastically reduced corrosion rates. The performed studies demonstrated that the incorporation of TiO

2 improves the mechanical and tribological properties of the Cr

2O

3 coatings, but the properties of the coatings are greatly influenced by the concentration of TiO

2, type of used powder and spraying conditions [

13,

14,

15,

17,

19]. Another effective way to improve the tribological properties of ceramic coatings is to introduce carbon-based materials (graphite, graphene, graphene oxide, etc.) into the ceramic matrix [

22,

23,

24,

25,

26,

27]. It should be noted that studies on the incorporation of carbon-based materials into chromia coatings are very scarce in the scientific literature. In addition, the effect of graphite on the tribological behavior of chromium oxide composite coatings formed by atmospheric plasma spraying using air-hydrogen plasma was not studied previously.

The main aim was to investigate the effect of the addition of SiO2-TiO2 and SiO2-TiO2-graphite on the surface morphology, phase structure, elemental composition and tribological properties under the dry sliding of chromium oxide composite coatings deposited by atmospheric plasma spraying.

2. Experimental Section

The plasma torch used for the formation of the coatings was developed at the Lithuanian Energy Institute [

28]. The P265GH steel was used as a substrate to deposit the chromium (Cr

2O

3) and chromium composite (Cr

2O

3-SiO

2-TiO

2 and Cr

2O

3-SiO

2-TiO

2-graphite) coatings. The dimensions of the P265GH steel were: length, 40 mm; width, 10 mm; and thickness, 6 mm. The steel was located on a holder that was cooled by water. The deposition of the coatings was performed using atmospheric pressure air plasma spraying, and the parameters of the process were: arc current, 200 A; total gas flow rate, 3.7 g/s; hydrogen gas, which was used to enhance the degree of melting of the powder particles, 0.053 g/s. Such parameters resulted in ~41.0 kW of torch power and an average temperature of the plasma at the torch nozzle chamber (at the point of powder injection) of 3780 ± 50 K. The average plasma temperature at the torch nozzle exit was 3480 ± 30 K. Coatings were formed as the powders were injected into the plasma by a powder carrier gas (air) at a flow rate of 0.48 g/s. The distance between the plasma torch nozzle outlet and the coating surface was 70 mm, and the spraying duration was 40 s. The MOGUL PC 18 powder (MOGUL METALLIZING GmbH, Kottinbrunn, Austria) of Cr

2O

3 (purity, 99.7%; and mesh size, 45 + 22 μm) was used to deposit the chromium oxide coatings. Meanwhile, the Cr

2O

3 composite coatings were sprayed using Cr

2O

3-SiO

2-TiO

2 (92/5/3, MOGUL PC 17, mesh size: 45 + 22 m, MOGUL METALLIZING GmbH, Kottinbrunn, Austria) powders, in which SiO

2 and TiO

2 were mixed in 5% and 3% by weight, respectively [

15]. Graphite powders of nonregular shape (MOLYDUVAL Fondra NS, particle size: <25 μm) were also used [

29]. The graphite was mixed into the Cr

2O

3-SiO

2-TiO

2 at the weight ratio of 10% to produce Cr

2O

3-SiO

2-TiO

2-graphite feedstock powders. The powders were mechanically mixed for 24 hours. All feedstock powders were dried at ~350 K for at least 18 hours before the plasma spraying. For better adhesion between the coating and the substrate, Al as a bonding layer was deposited.

The top-view morphology of the deposited coatings was investigated by scanning electron microscopy (SEM) (Hitachi S-3400N (Hitachi, Tokyo, Japan)), and the elemental composition was measured using energy-dispersive X-ray spectroscopy (EDS) with a Bruker Quad 5040 spectrometer (AXS Microanalysis GmbH, Billerica, MA, USA). The measurement data were collected and measured from at least five different surface locations with a surface area magnification of x100. Linear surface roughness was measured using a Mitutoyo Surftest SJ-210 Series tester (version 2.00 with standard ISO 1997 Mitutoyo, Kawasaki, Japan). The roughness values given are the average of at least 15 separate measurements. The length of one track was 4 mm, the speed of the measurement was 0.50 mm/s, the detector measuring force was 0.75 mN and a diamond tip was used. The calculation of average roughness values (Ra, Rq) was performed by a roughness tester according to the ISO4287:1997 standard. Cut-off λc was equal to 0.8 mm. The surface roughness of all coatings was measured at the same conditions.

The phase analysis was carried out by the X-ray diffraction technique (XRD) using the D8 Discover apparatus (Bruker D8 Discover, Billerica, MA, USA) with a CuKα (λ = 0.154059 nm) cathode. The XRD patterns were recorded under standard Bragg–Brentano configuration in the range of 2θ from 10° to 80°. The diffraction patterns of the coatings were analyzed by DIFFRAC.EVA software. The tribological properties were determined using a CETR-UMT-2 tribometer (CETR, Campbell, CA, USA) and ball-on-flat configuration with 1 N and 3 N loads under dry-sliding conditions. The duration of the tribological tests was 120 min, the sliding speed was 0.1 m/s, and the total covered distance was 720 m. A 10 mm diameter Al2O3 ball (grade class 10 and 99.5%) was used as a counterpart, and the stroke length was 5 mm. The specific wear rate was calculated from the linear surface profiles that were obtained with Ambios XP-200 Profiler (Ambios Technology Inc., Santa Cruz, CA, USA). Tribological tests of Cr2O3 and chromia composite coatings were performed on two samples of each series, and average values (of at least four measurements) were determined.

3. Results and Discussion

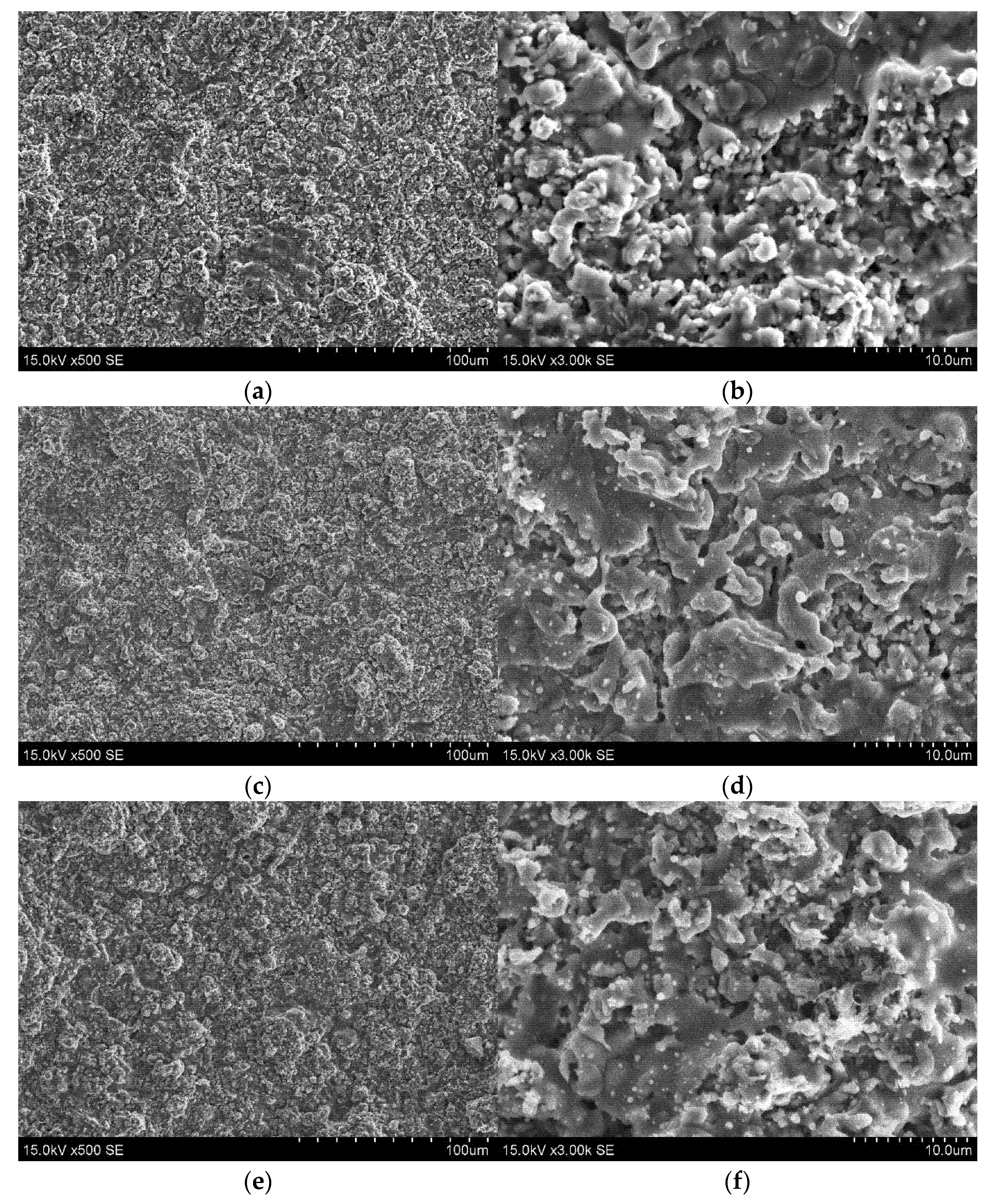

The as-sprayed chromia and chromia composite coatings’ surface morphology is shown in

Figure 1. It was obtained that the deposited coatings consisted of melted particle regions with partially melted particles. It should be noted that the amount of fully melted particle regions in the Cr

2O

3-SiO

2-TiO

2 coating was slightly higher compared to the Cr

2O

3 coating (

Figure 1b,d). Mostly, the surface of the Cr

2O

3-SiO

2-TiO

2-graphite coating was even and homogenous (

Figure 1e,f). All deposited coatings had a grain structure with a low amount of microcracks and pores (

Figure 1). The existence of the microcracks is a result of the rapid solidification of partly or fully melted particles on the substrate [

19]. The existence of various-shaped microsized particles on the surface when the particles hit the substrate could be related to the splashing of partly molten feedstock particles. The porosity of deposited coatings is related to the existence of coarse and fine pores. It was demonstrated that the coarse porosity in the plasma-sprayed coatings is attributed to structural defects. These defects were created by the incomplete filling of the voids between impacting powder particles to the surface [

14,

19]. SEM images of surface morphology demonstrated that the addition of TiO

2 and SiO

2 into Cr

2O

3 powders resulted in the formation of a slightly lower amount of larger-sized voids on the surface.

The distribution of chromium, oxygen, titanium, silicon and carbon on the Cr

2O

3-SiO

2-TiO

2 and Cr

2O

3-SiO

2-TiO

2-graphite coatings is presented in

Figure 2 and

Figure 3. The EDS results showed that the distribution of chromium, oxygen and titanium on the surface of the Cr

2O

3-SiO

2-TiO

2 and Cr

2O

3-SiO

2-TiO

2-graphite coatings is homogenous. The EDS map image (

Figure 3f) indicated that the graphite particles were quite homogeneously spread on the surface of the as-sprayed coating. In addition, single graphite particles with a size of up to 40 µm could be observed on the surface. It should be noted that silicon tends to agglomerate and form larger clusters on the surface of the chromia composite coatings (

Figure 2f and

Figure 3e). The existence of larger-sized SiO

2 inclusions is due to the fact that the SiO

2 particles were not homogenously distributed in the raw powders and/or were agglomerated into bigger-sized clusters during manufacturing. The Cr

2O

3-SiO

2-TiO

2 coating was composed of chromium (∼73.6 wt.%), oxygen (22.2 wt.%), titanium (3.3 wt.%) and silicon (∼0.8 wt.%), and a low amount of carbon was obtained due to the absorption of atmospheric air. The as-sprayed coating consisted of Cr (∼73.7 wt.%), O (∼21.4 wt.%), Ti (3.0 wt.%), Si (0.8 wt.%) and carbon (∼1.1 wt.%) when 10 wt.% of graphite was added to the initial Cr

2O

3-SiO

2-TiO

2 powders. The EDS measurements showed that the graphite content on the surface was up to 10 times lower compared to the feedstock powders. The chromia coating is composed of chromium (78.3 wt.%) and oxygen (21.3 wt.%), and a low amount of impurities (carbon and aluminum) was detected.

The surface roughness of the as-sprayed coatings is presented in

Figure 4. The average surface roughness (R

a) and the root-mean-square roughness (R

q) of the Cr

2O

3 coating were ∼3.02 ± 0.51 μm and ∼3.77 ± 0.61 μm, respectively. The surface roughness of the Cr

2O

3-SiO

2-TiO

2 coating was slightly, up to ~20%, higher. The R

a value was 3.85 μm, while the R

q value was 4.86 μm. Meanwhile, the roughness of the coating was drastically reduced (by 40%) when 10 wt.% of graphite was added to the Cr

2O

3-SiO

2-TiO

2 powders. The surface roughness R

a and R

q values for the Cr

2O

3-SiO

2-TiO

2-graphite coating were 2.22 μm and 2.77 μm, respectively. The reduction of surface roughness of the Cr

2O

3-SiO

2-TiO

2-graphite coating in comparison to the Cr

2O

3-SiO

2-TiO

2 coating could be related to the lower size and density of the graphite powders. If we compare the volume of both powders, there were almost equal parts of them in the feedstock mixture.

It was demonstrated that the addition of graphite nanoparticles (GNPs) or GNPs and carbon nanotubes (CNTs) into alumina reduced the surface roughness (up to 13%) of the as-sprayed alumina composite coatings [

29]. Wang et al. [

30] obtained that the addition of 3% or 6% of graphene into Al

2O

3-TiO

2 coatings reduced the porosity of the coatings. In addition, the surface of the coatings becomes flatter and denser after the addition of graphene. Similar results were found for the Cr

2O

3-SiO

2-TiO

2 coating with the addition of graphite into feedstock powders. The surface images of the Cr

2O

3-SiO

2-TiO

2 coating demonstrated that the amount of fully molten regions was higher compared to the Cr

2O

3 coating. However, the surface roughness of the Cr

2O

3-SiO

2-TiO

2 coating was enhanced. Zamani et al. [

2] also obtained that the surface roughness of the Cr

2O

3 coating was lower compared to Cr

2O

3-SiO

2-TiO

2 coatings. However, the surface roughness was reduced with the increased amount of Al

2O

3 due to the lower melting temperature. The fraction of splats increases on the surface of deposited chromia or chromia composite coatings with the increase of the plasma jet temperature or supplementation of the metal oxides with lower melting temperature into feedstock powders [

11,

15,

16,

31].

The XRD graphs of the Cr

2O

3 and Cr

2O

3 composite coatings are given in

Figure 5. It should be noted that the patterns of all coatings showed the same peaks, and only the intensities of the peaks are slightly different. The peaks are located at 24.6, 33.7, 36.3, 41.6, 50.3, 55.0, 63.6, 65.3 and 73.1 2θ degrees and are attributed to the (012), (104), (110), (202), (024), (116), (214), (300) and (1010) orientations of the Cr

2O

3 eskolaite phase, respectively [

10,

14,

15,

32]. The low- and broad-intensity peaks located at ~40.0°, ~44.4°, ~58.5°, and ~76.9° are assigned to the (006), (202), (122) and (220) planes of the eskolaite Cr

2O

3 phase, respectively [

14,

15,

23]. The normalized intensities of the initial powders and as-sprayed coatings are presented in

Table 1. It should be noted that the highest-intensity peak for the initial Cr

2O

3 powders was located at ~55.0°. Meanwhile, the as-sprayed chromia coatings had the highest peak at ~33.7°. The intensity of the peak at ~36.3° was slightly lower. It should be noted that the intensities of dominant peaks of the eskolaite Cr

2O

3 phase increased in the as-sprayed Cr

2O

3 coating (

Table 1). The highest-intensity peak for the Cr

2O

3 coating was related to the (104) orientation (

Figure 5). The addition of SiO

2-TiO

2 into the Cr

2O

3 coatings resulted in the intensity of the peak presented at ~33.7° (104) being slightly lower compared to the peak located at ~36.3° (110). The intensities of peaks for the Cr

2O

3-SiO

2-TiO

2-graphite and Cr

2O

3-SiO

2-TiO

2 coatings were similar (

Figure 5). The highest-intensity peak in the Cr

2O

3-SiO

2-TiO

2 feedstock powders was obtained at ~36.3°. The order of the five highest peaks according to normalized intensity remains unchanged in the as-sprayed Cr

2O

3-SiO

2-TiO

2 coating. Only a slight increase or decrease in the peak intensities was obtained (

Table 1.). The addition of graphite into Cr

2O

3-SiO

2-TiO

2 resulted only in a slight reduction in the intensities of most peaks. However, the intensities of the peaks at ~41.6° and ~63.6° were enhanced for the Cr

2O

3-SiO

2-TiO

2-graphite coating.

The TiO

2 or SiO

2 phases were not detected in the XRD data of the Cr

2O

3-SiO

2-TiO

2 and Cr

2O

3-SiO

2-TiO

2-graphite coatings. Usually, the presence of the TiO

2 rutile phase in the XRD patterns of thermally sprayed coatings is attributed to peaks located at 27.5, 41.3, 54.4 and 56.7° [

10,

14,

19]. However, it was observed that the TiO

2 rutile phase may not be detected in the XRD data of the chromia composite coatings with a low amount of TiO

2 (up to 5%) [

32]. The crystalline graphite peak (at 26.5°) was not obtained in the XRD pattern of the Cr

2O

3-SiO

2-TiO

2-graphite coating [

26,

33]. Our previous study [

26] demonstrated that the low-intensity crystalline graphite peak in alumina–graphite coatings was observed when the graphite content was 1.6 wt.%.

The variation of the friction coefficient curves depending on sliding time is given in

Figure 6. Similar behavior of the friction coefficient curves was obtained for all as-sprayed coatings. The average values of the friction coefficient for the Cr

2O

3, Cr

2O

3-SiO

2-TiO

2 and Cr

2O

3-SiO

2-TiO

2-graphite coatings using 1 N load were estimated as ~0.369, ~0.316 and ~0.405, respectively (

Figure 7a). The friction coefficient of the steel substrate was ~0.687 when 1 N load was used [

15]. The friction coefficients of the coatings slightly increased with the enhancement of the applied load (

Figure 7a). The lowest friction coefficient was obtained for the Cr

2O

3-SiO

2-TiO

2 coating and was ~0.378. Meanwhile, the highest value of the friction coefficient (~0.416) was observed for the Cr

2O

3-SiO

2-TiO

2-graphite coating. Thus, the friction coefficient slightly decreased (by 2%) when the SiO

2-TiO

2 additive was used. Meanwhile, the addition of SiO

2-TiO

2-graphite fractionally increased (up to 8%) the friction coefficient of the Cr

2O

3 composite coatings. Despite the fact that the friction coefficient of all the coatings increased with the increase in the applied load, it was significantly lower (up to 40%) than that of the P265GH steel (~0.630).

It was demonstrated that the addition of a low amount of graphene oxide could reduce the friction coefficient of alumina coatings by 15%. However, the friction coefficient could also be enhanced from 0.49 to 0.52 with the increase in the used load [

34]. Priyadershini et al. [

29] observed that the addition of a low amount of GNPs and CNTs into alumina coatings resulted in a higher friction coefficient at the initial (up to 300 m) sliding distances. It was obtained that the friction coefficient depends on the applied load, type of used counterpart, porosity, hardness, surface roughness of the material, etc. [

11,

14,

21,

34,

35]. Liang et al. [

35] observed that the average friction coefficient decreased with the increase in the initial roughness values of the material. Riedl et al. [

36] determined that the friction coefficient of Al

2O

3 coating with the alpha phase was slightly reduced after surface polishing. Meanwhile, the friction coefficient of the Al

2O

3 coating with the kappa phase demonstrated an opposite trend. The steady state of the friction coefficient for the Cr

2O

3 coating was reached after 1500 s of sliding time, while the steady state for the Cr

2O

3-SiO

2-TiO

2-graphite coating was reached after 200–300 s. The surface with a larger initial roughness will need more time to reach the steady friction coefficient values, because the sharp hilltops must be grounded off first [

35,

36]. In addition, the smoother the surface, the greater the contact area between the friction pair, which can lead to higher friction coefficient values. The slight increase in the friction coefficient versus time for ceramic coatings and ceramic-carbon-based coatings during the steady-state region was observed in several studies when dry-sliding and different loads were used [

11,

14,

30,

34].

The average specific wear rates of the deposited coatings using 3 N load are presented in

Figure 7b. The wear rate of the chromium oxide coating was ∼1.83 × 10

−6 mm

3/(Nm). The specific wear rate decreased to ∼1.27 × 10

−6 mm

3/(Nm) with the addition of SiO

2-TiO

2 into the chromium oxide powders. The addition of the graphite in the feedstock powders stipulated the formation of the coating with the lowest specific wear rate of ∼0.95 × 10

−6 mm

3/(Nm). It should be mentioned that the specific wear rates of the P265GH steel were 6.68 × 10

−5 mm

3/(Nm) and 4.22× 10

−5 mm

3/(Nm) when 1 N and 3 N loads were used, respectively. The reduction of the wear rate of the chromia composite coatings could be attributed to the enhanced densification, reduction of porosity, presence of transferred layer from the Al

2O

3 ball and formation of self-lubricating graphite layer (in the case of Cr

2O

3-SiO

2-TiO

2-graphite) [

29,

33]. The increase in the sliding wear rates of the Cr

2O

3 coatings with the incorporation of TiO

2 compared to the Cr

2O

3 coatings during the sliding tests against an Al

2O

3 counterpart was noticed by several authors [

13,

17,

19,

37,

38]. It was obtained that the reinforcement of TiO

2 decreased the hardness, and as a result, the resistance to wear of the Cr

2O

3-TiO

2 coatings was reduced [

13].

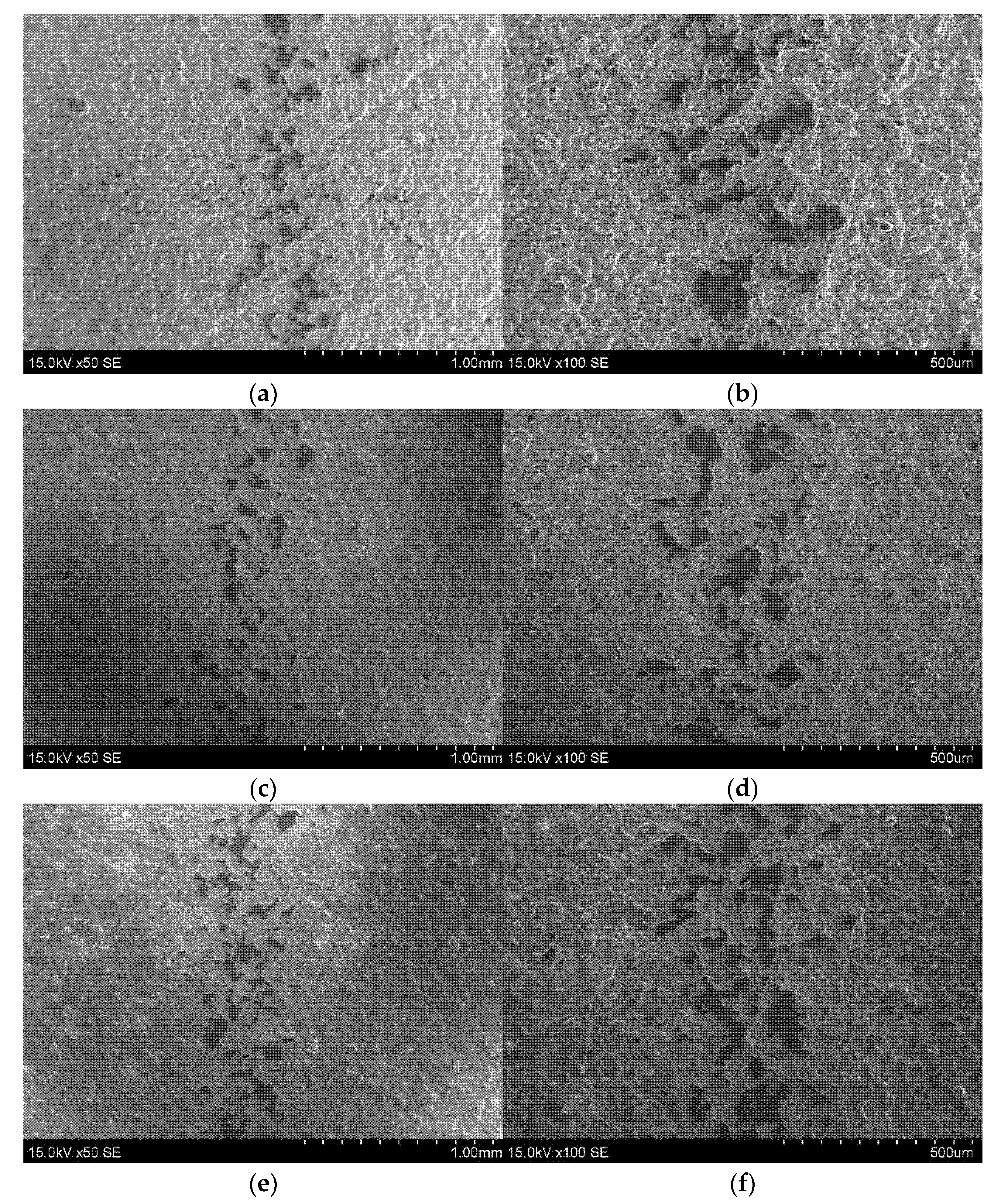

The wear tracks of the chromium oxide and its composite coatings under the loads of 1 N and 3 N are presented in

Figure 8. It should be noted that the surface of the as-sprayed coatings was only slightly damaged when 1 N load was applied (

Figure 8a,c,e). The randomly distributed worn areas of 10 μm to 30 μm in size could be seen on the surfaces. The surface profile measurements demonstrated similar profiles as for deposited coatings. Thus, it was not possible to calculate the wear rates of the as-sprayed coatings, as only the top hills were fractionally abraded when tribological tests were performed using a load of 1 N. Meanwhile, the specific wear rate of the steel substrate under 1 N load was 6.68 × 10

−5 mm

3/(Nm). Compared with 1 N, and with the increased load up to 3 N, the interfacial contact area of the coatings increased. The SEM images indicated that the wear scars became wider, brighter and more worn-out areas were observed (

Figure 8). These results indicate that the damage level and wear loss increased and resulted in a higher wear rate of the coatings.

The distribution of chemical elements on the wear scars of the coatings after tribological tests using 3 N load is presented in

Figure 9,

Figure 10 and

Figure 11. A low amount of aluminum from the alumina ball was obtained on the worn scars of all coatings (

Figure 9e,

Figure 10e and

Figure 11e). Additionally, due to the heat generated during the sliding process, the small concentrations of carbon at a contact zone were determined (

Figure 9f and

Figure 10f). The EDS results showed that the concentration of chromium was ~71.6 wt.%, oxygen ~27.1 wt.%, aluminum 0.9 wt.% and carbon 0.4 wt.% on the wear tracks of the chromia coating after the tribological tests with 3 N load. The amount of Cr was ~67.7 wt.%, O—26.4 wt.%, Ti—3.0 wt.%, Si—1.5 wt.%, C—0.5 wt.% and Al—0.9 wt.% on surface of the Cr

2O

3–SiO

2-TiO

2 coating. The concentration of chromium was ~68.7 wt.%, oxygen ~25.4 wt.%, titanium ~2.7 wt.%, silicon ~0.7 wt.%, aluminum 1.1 wt.% and carbon 1.4 wt.% on the wear track of the Cr

2O

3–SiO

2-TiO

2-graphite coating. The increase in the oxygen concentration and the reduction of chromium amount on the wear scars for all coatings were observed after the tribological tests. The slight oxidation of chromia ceramic coatings after tribological tests was observed by Amanov et al. [

18] and is a result of abrasive wear.

The EDS results indicated the presence of Al and an increase in carbon elemental concentration in the worn surfaces of the coatings after the tribological tests. A low amount of aluminum was (from 0.9 wt.% to 1.1 wt.%) observed for all coatings after the tribological tests. This confirms the formation of the tribolayer of Al and is a result of the wear between the counterpart (Al

2O

3 ball) and coating [

34]. The existence of carbon indicates the formation of a graphite-base film on the surface of the removed areas [

26,

33]. The graphite may act as a solid lubricant to prevent the direct contact between the Al

2O

3 ball and the surface of the coating. The SEM images indicated that the wear scars are noncontinuous (

Figure 8). Thus, effective lubrication would be provided only in the direct contact zone. The EDS results and mapping images indicated that the amount of carbon at the wear scar areas increased from ~1.1 to ~1.4 wt.%. Feng et al. [

33] demonstrated that the GNPs and graphite particles start to act as a self-lubricant, and a stable tribofilm layer is formed on the surface of the Al

2O

3-TiO

2 coatings when the applied loads are 15 N or higher. Thus, the friction coefficient values would remain similar or even higher compared to the Cr

2O

3-SiO

2-TiO

2 coating. In our case, the used 1 N and 3 N loads in tribological tests are considered as light loads. Thus, the wear volume was very low (see

Figure 8), and the graphite particles could not be effectively pulled out from the Cr

2O

3-SiO

2-TiO

2-graphite coating to act as a self-lubricant.

Wear debris in the form of small microsized particles was obtained on the surfaces of the coatings. The size of the debris was very similar for all coatings. Usually, the interfacial bonding between the formed splat starts to delaminate at higher loads or longer sliding distances. However, the lamellar debris was not produced under used loads. Severe abrasive wear is probably the main wear mechanism during the dry-sliding tests. As for the single one, parallel grooves can be obtained on the wear tracks of the coatings [

18,

27,

39,

40]. The particles are extracted from the coating and are crushed in the contact zone between the surface of the coating and the sliding Al

2O

3 ball. The pulled-out TiO

2 or TiO

2-graphite particles start to form a lubricative layer and improve the tribological properties (especially wear rate). Meanwhile, the hard Cr

2O

3 particles act as an abrasive and can tear up the formation of the tribolayer. The traces of Al on the worn surfaces also indicate that the Al

2O

3 ball slightly rubs and wears and could be involved in the formation of the tribolayer. The increase in the graphite amount on the wear scars is evidence of the initial tribofilm formation. It was reported that the graphite layer led to the reduction of the shear stress level and plastic deformation in the contact zone, which reduces the wear rate of ceramic coatings [

27,

39].

The tribological investigations demonstrated that the addition of SiO2-TiO2 and SiO2-TiO2-graphite additives had an insignificant effect on the friction coefficient of the chromia coating when 3 N load was used. However, the wear resistance of the chromia composite coatings under dry-sliding conditions was improved by up to ~45% compared to the chromia coating.