Abstract

Biopolymer-based films were developed using a mixture of pullulan and agar, and the fabricated film was functionalized with bioactive functional components, Pickering emulsion of eucalyptus essential oil (PEU), and rutin. The color of the film with PEU and rutin supplemented was light yellow. As a result, the yellowness index increased while the whiteness index of the film reduced. The functional filler showed a biocompatibility with the pullulan/agar polymer matrix. The presence of bioactive functional materials enhanced the UV protection properties of the film. The films’ mechanical properties, vapor barrier properties, and thermal stability were not pointedly affected by the presence of essential oils and rutin alone or in combination. The presence of essential oils and rutin markedly enhanced the antioxidant activity of pullulan/agar-based films. Therefore, the bioactive functional film developed can be useful for active food packaging applications.

1. Introduction

Recently, natural bio-derived polymers as food packaging materials have received great attention due to concerns about the depletion of natural resources for producing plastic packaging films and their non-biodegradable properties and enormous environmental pollution [1,2]. Bio-based eco-friendly polymers are getting much attention in the food packaging system. Although biopolymers have promising properties, they are not suitable for practical use due to inherent limitations in the pure form [3,4,5]. As a result, recently, a composite biopolymer film to which a bioactive functional material is added has been mainly studied [3,6,7]. Various sources have already been studied as bioactive ingredients, and among all, the phytochemicals extracted from plant sources are highly promising due to the high antioxidant and antimicrobial activity, abundance, cost-effectiveness, and non-toxicity [8,9,10]. In addition, the functional composite film has the effect of delaying food oxidation and increasing food’s nutritional value by suppressing the proliferation of foodborne pathogens during storage [11,12,13]. The manufacture of bio-based functional packaging films can be useful for producing environmentally friendly packaging materials.

Polysaccharides, proteins, or combinations thereof are mainly used as biopolymers to develop packaging films [7,14]. Pullulan is a microbial-derived polysaccharide-based biopolymer known to have excellent gas and oil barrier properties, and agar is a seaweed-derived polysaccharide-based biopolymer [15,16]. Pullulan and agar can be a good combination as a polymer matrix to produce composite packaging films. According to a recent report, combining pullulan/agar can effectively improve the film’s physical properties by limiting each polymer’s disadvantages [17]. Pullulan/agar-based films with functional properties can be utilized in active food packaging applications. For this, the bioactive ingredients rutin and eucalyptus essential oil are good candidates. Rutin, a derivative of quercetin commonly found in plants, is a flavone known for its powerful antioxidant activity [18,19].

On the other hand, eucalyptus leaf essential oil contains various bioactive components such as phenols, flavonoids, and terpenoids known for their strong antioxidant and antibacterial activity [20,21,22]. The combination of eucalyptus essential oil and rutin is expected to enhance the antioxidant function of the film. A recent report suggests that films activated by various essential oils may effectively improve the life span of food goods [3,23]. It has been reported that the inclusion of rutin is also effective in prolonging the shelf life of food [24]. As far as we know, there is no reported work on fabricating pullulan/agar-based food packaging films containing eucalyptus essential oil and rutin.

Therefore, we developed a pullulan/agar-based film combining eucalyptus essential oil and rutin in this study. The prepared films were characterized and tested for several physical properties and antioxidant activity.

2. Materials and Methods

2.1. Materials

Pullulan was purchased from Korea Bio Polymer Co. Ltd. (Bucheon, Gyeonggi-do, Republic of Korea). Agar was obtained from Gel-Tec Co. Ltd. (Seoul, Republic of Korea). Eucalyptus essential oil (100% natural oil) was acquired from JK Group Co., Ltd. (Bucheon, Gyeonggi-do, Republic of Korea). 2,2-diphenyl-1-picrylhydrazyl (DPPH), 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), and rutin were procured from Sigma-Aldrich (St. Louis, MO, USA).

2.2. Methods

2.2.1. Fabrication of Film

The pullulan/agar-based functional film was synthesized using a solution-casting process [25]. For film production, 1.5 g of pullulan and agar were dissolved in 100 mL of distilled water separately while heating at 80 °C with vigorous stirring. After mixing the two completely dissolved biopolymer solutions, glycerol (30 wt.% based on polymer) was added to the polymer mixture. Pickering emulsion of eucalyptus essential oil (PEU) was prepared by shear mixing for 1 h at 5000 rpm with an Ultra-Turrax blender (IKA T25, Staufen, Germany) using defined amounts of cellulose nanofibers and eucalyptus essential oil [26]. Then, 5.0% (w/v) of PEU and 1.0% (w/v) of rutin were added to the film solution at 40 °C with gentle stirring. The film-forming solution was then cast onto a flat Teflon film-coated glass plate, dried at room temperature for 48 h, and then stored at ambient conditions. In addition, control pullulan/agar films without functional additives, pullulan/agar films with PEU, and pullulan/agar films with rutin were prepared following the same procedure. The produced films were named Pul/agar, Pul/agar/PEU, Pul/agar/Rut, and Pul/agar/PEU/Rut, according to the type of functional filler.

2.2.2. Characterization and Properties of Films

Details of the method for characterizing PEU- and rutin-functionalized pullulan/agar-based films and methods for property determination of the films are given in the Supplementary Materials.

3. Results and Discussion

3.1. Morphology

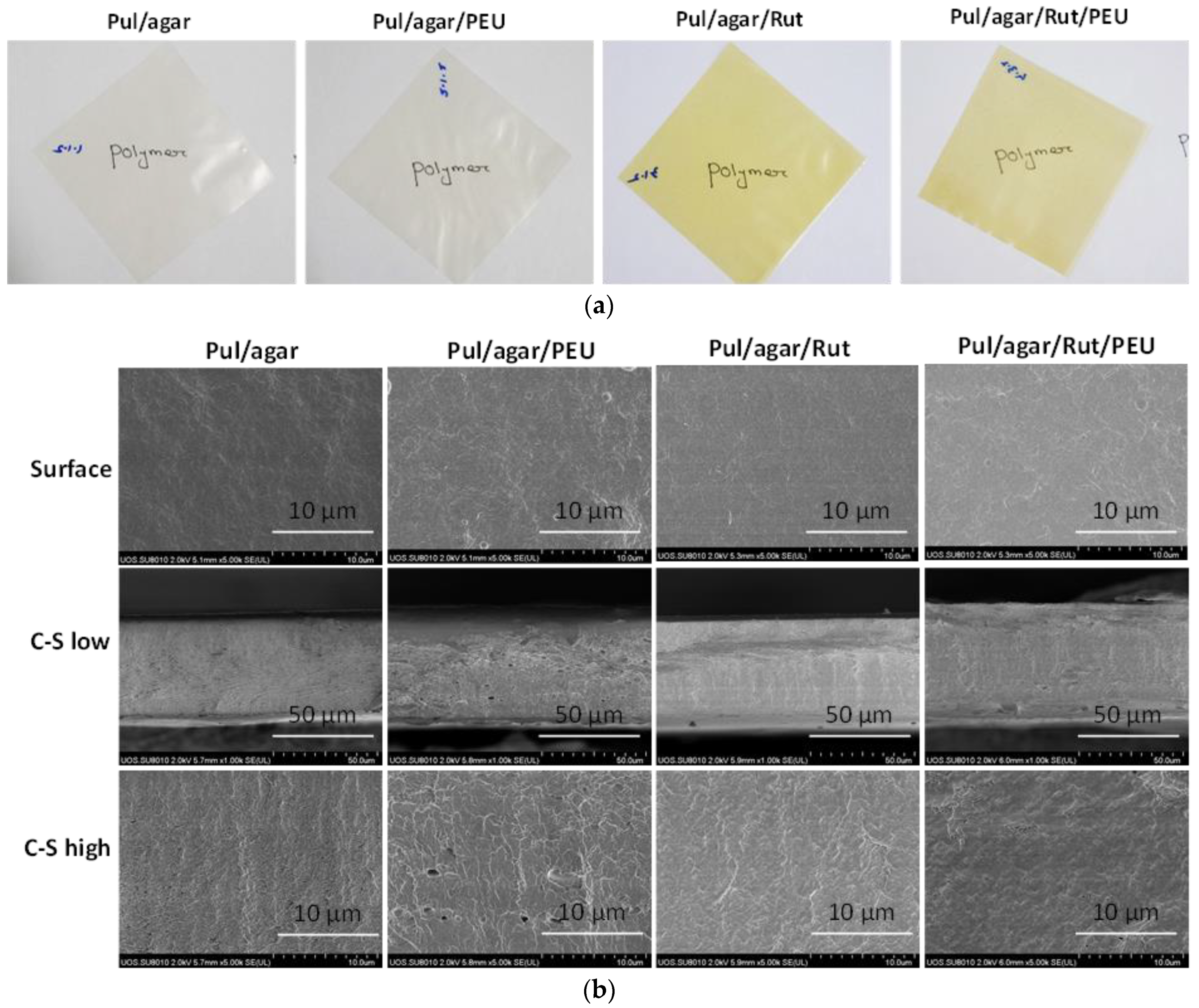

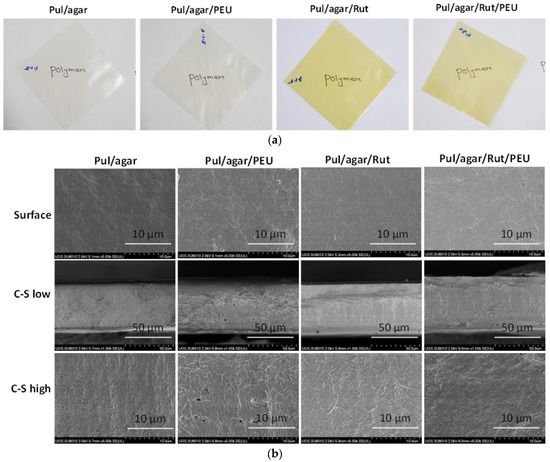

The apparent images of all films are shown in Figure 1. The neat pullulan/agar film and the PEU-added films were almost colorless, whereas the rutin-added film was yellowish due to the yellow color of the rutin [27]. The microstructures (surface and cross-section) of all films are also shown in Figure 1. The pristine film showed good compactness without cracks or voids, demonstrating good compatibility among pullulan and agar biopolymers. The observed microstructure was similar to previously reported pullulan/agar-based packaging films [17]. The inclusion of PEU and rutin somewhat changed the film’s surface morphology, although it appeared regularly disseminated in the polymer matrix. Even in the cross-section of the film, an appropriate distribution of the filler was observed only in the film to which PEU was added. Some cracks were detected, which may be due to the incompatibility of the cellulose nanofibers present in the Pickering emulsion and the pullulan/agar polymer. Overall, the surface morphology results showed good compatibility between the polymer and filler. Mixing cinnamon essential oil and rutin and rosemary essential oil and quercetin with the gelatin/chitosan film showed a microstructure similar to this report [18,28].

Figure 1.

(a) Digital images and (b) SEM images of the surface and cross-section (C-S) of the pullulan/agar-based films.

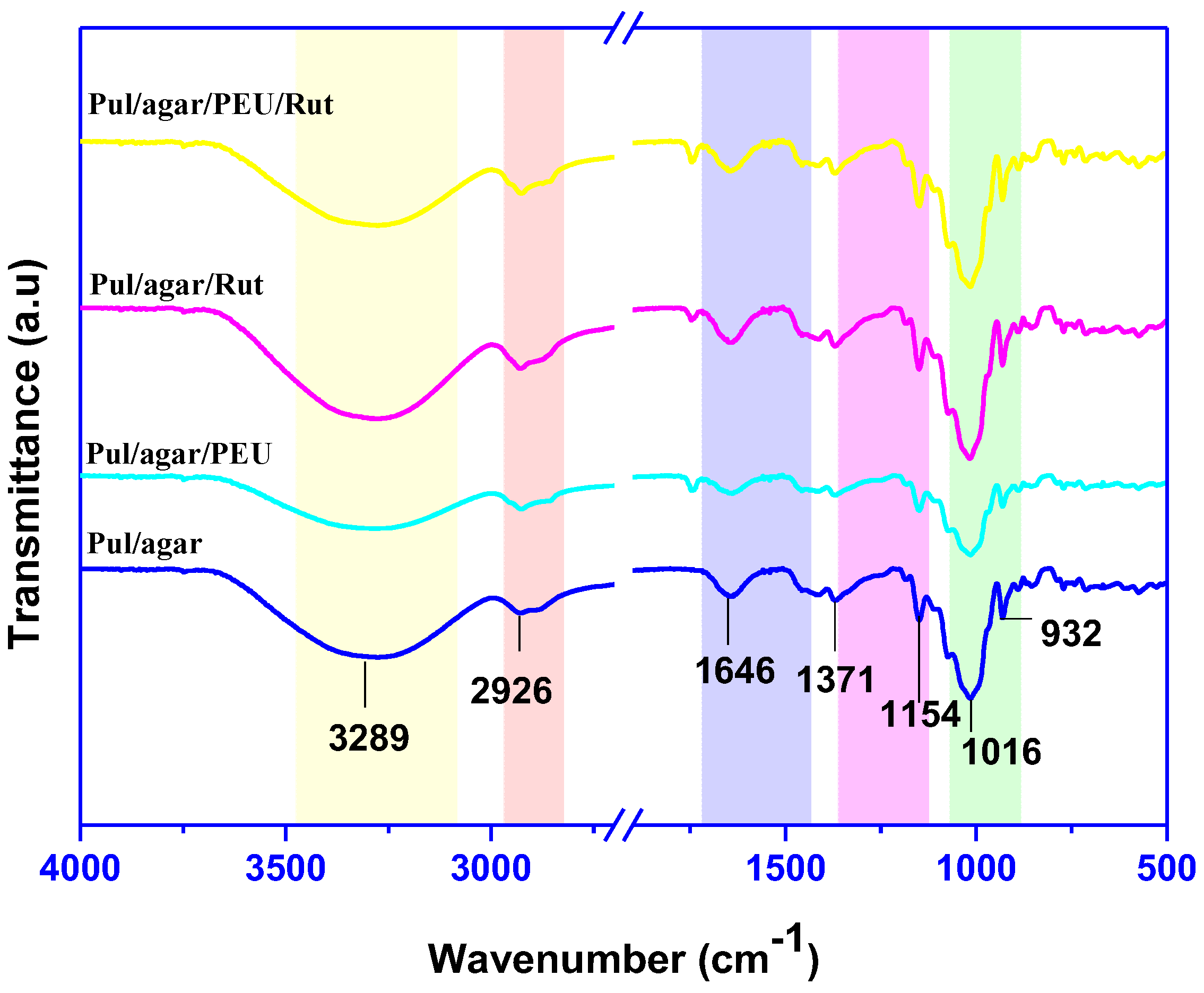

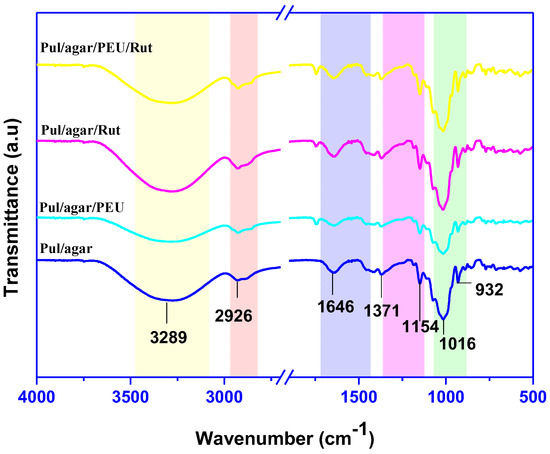

3.2. FTIR Analysis

The chemical interaction between the pullulan and agar and bioactive fillers was studied using FTIR, and the results are shown in Figure 2. The peak observed at 3289 cm−1 was due to the O-H stretching vibration of the pullulan and agar [16,29]. The peak at 2926 cm−1 was owing to the C-H stretching vibrations of the alkane groups of pullulan and agar [30]. The peak found at 1646 cm−1 was attributed to the stretching vibration of the carbonyl group of agar [31]. The peak observed at 1371 cm−1 was accredited to the C-H deformation of agar [17]. The peak observed at 1154 cm−1 was due to the stretching vibration of the (α-1–4) glycosidic bond of pullulan, while the peak at 1016 cm−1 denoted the C-O stretching bond of pullulan [32]. The peak at 932 cm−1 was designated as the 3,6-anhydro-D-galactose of agar [33]. The peaks for pullulan and agar were detected in the control and all other films, indicating good miscibility and compatibility between the pullulan and agar polymers. The observed FTIR spectra were similar to the previously reported pullulan/agar-based packaging films [17]. When PEU or rutin was added, the peak intensity slightly changed or the peak position moved without generating a new peak, suggesting that the interactions between fillers and polymers are based on physical forces (van der Waals forces, electrostatic interactions, and hydrogen bonding) [14,34]. Similar results have recently been reported for rutin-containing and essential-oil-added biopolymer-based packaging films [18,35].

Figure 2.

FTIR spectra of the pullulan/agar-based films.

3.3. Optical Properties of the Film

The surface color of the pullulan/agar-based film was studied using a digital chromameter (Table 1). The brightness of the pristine film was high, and the addition of PEU did not affect the brightness, but rutin alone or in combination with PEU slightly reduced the brightness, which may be due to the dark yellow color of rutin. On the other hand, the film’s b-value (yellowness/greenness) was three- to four-fold improved in the presence of rutin, indicating the yellowness increased, whereas the a-value (redness/blueness) only slightly increased. The film’s total color difference (ΔE) also improved pointedly (seven- to eight-fold) when PEU/rutin was added. The whiteness index (WI) of the neat pullulan/agar film was high, as with the film’s high brightness (L-value), but the presence of rutin pointedly reduced the WI. Again, the presence of rutin increased the film’s yellowness index (YI) about four-fold, which is quite analogous to the variation in b-value [36]. The addition of color ingredients into the film matrix often showed changes in the surface color parameters [37].

Table 1.

Surface color and light transmittance of the pullulan/agar films.

Interestingly, the PEU/rutin-doped films had less YI than the rutin-doped films, which could be due to the masking of the yellow color in the presence of the cellulose nanofiber-based essential oil Pickering emulsion. By reasoning, it can be concluded that the addition of PEU did not change the surface color much, while the presence of rutin changed it equally significantly. Similar results were reported for biopolymer-based packaging films incorporating rutin [19,24].

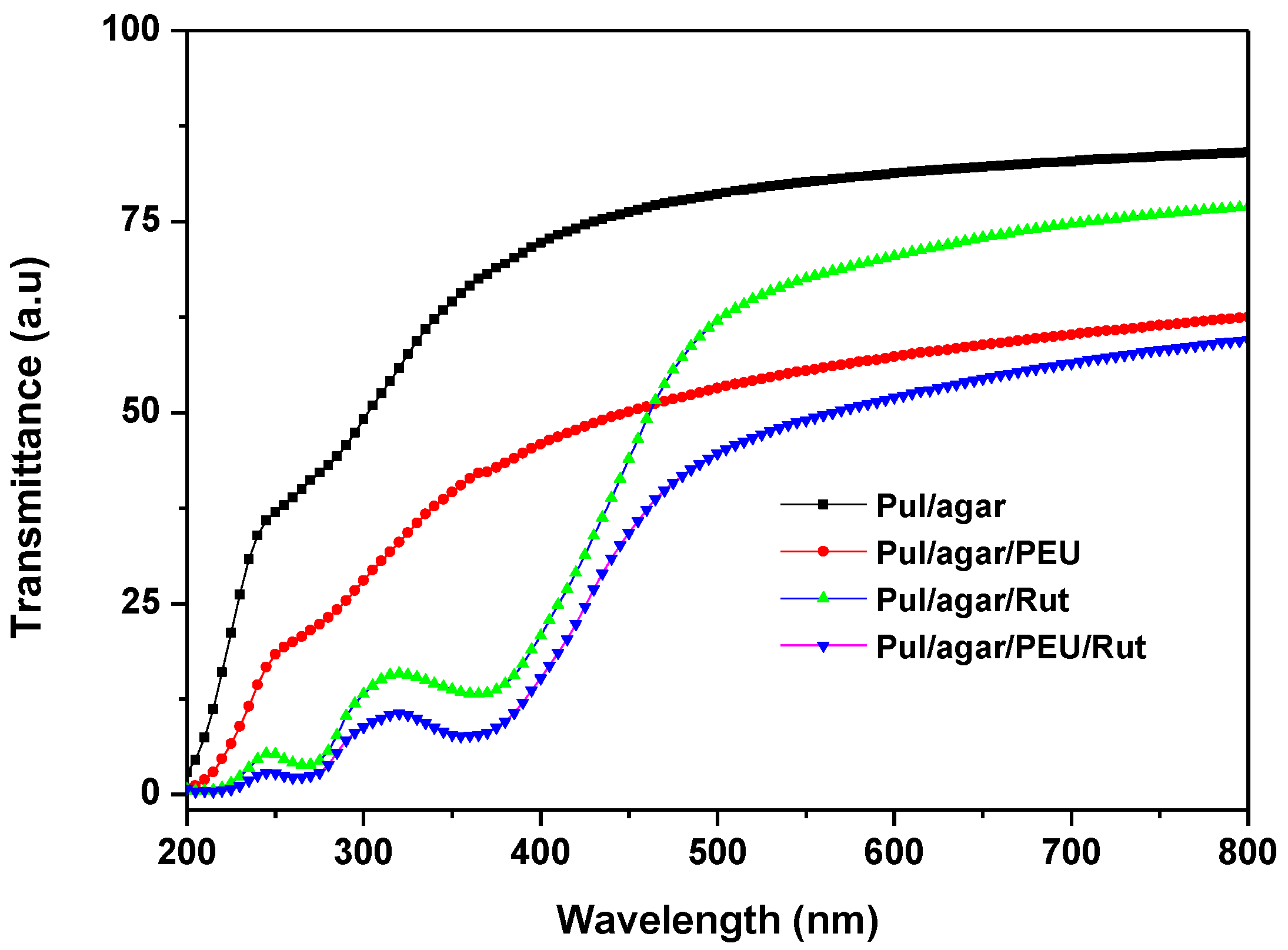

The UV-vis transmittance spectra were tested to get more insight into the optical properties of the pullulan/agar-based films (Figure 3). The experiential findings of optical transmittance were similar to previously reported pullulan/agar-based packaging films [17]. The pristine pullulan/agar film displayed high light transmittance, and the incorporation of PEU and rutin significantly condensed the transmittance. The film’s UV-blocking property and transparency were confirmed, and the results are also shown in Table 1. It can be seen that the UV protection phenomena are improved in the presence of PEU and significantly improved in the case of rutin-activated films.

Figure 3.

UV-vis light transmission spectra of the pullulan/agar-based films.

Most importantly, PEU/rutin showed synergistic effects on the sun protection properties. The increase in sunscreen properties is due to the bioactive compounds present in PEU and the light-absorbing rutin [38]. Then again, the transparency of the film was high, analogous to formerly stated data [17]. The addition of PEU significantly reduced the transparency, likely due to the cellulose nanofiber-based essential oil Pickering emulsion [39]. The presence of rutin also slightly reduces the transparency of the film due to its yellow color and suppresses light at 660 nm. The combined addition of PEU/rutin reduced the transparency of the film slightly more, which may be a synergistic action of the bioactive components present in the added filler. Similar results have been stated for rutin-containing biopolymer-based packaging films to which essential oils have been added [18].

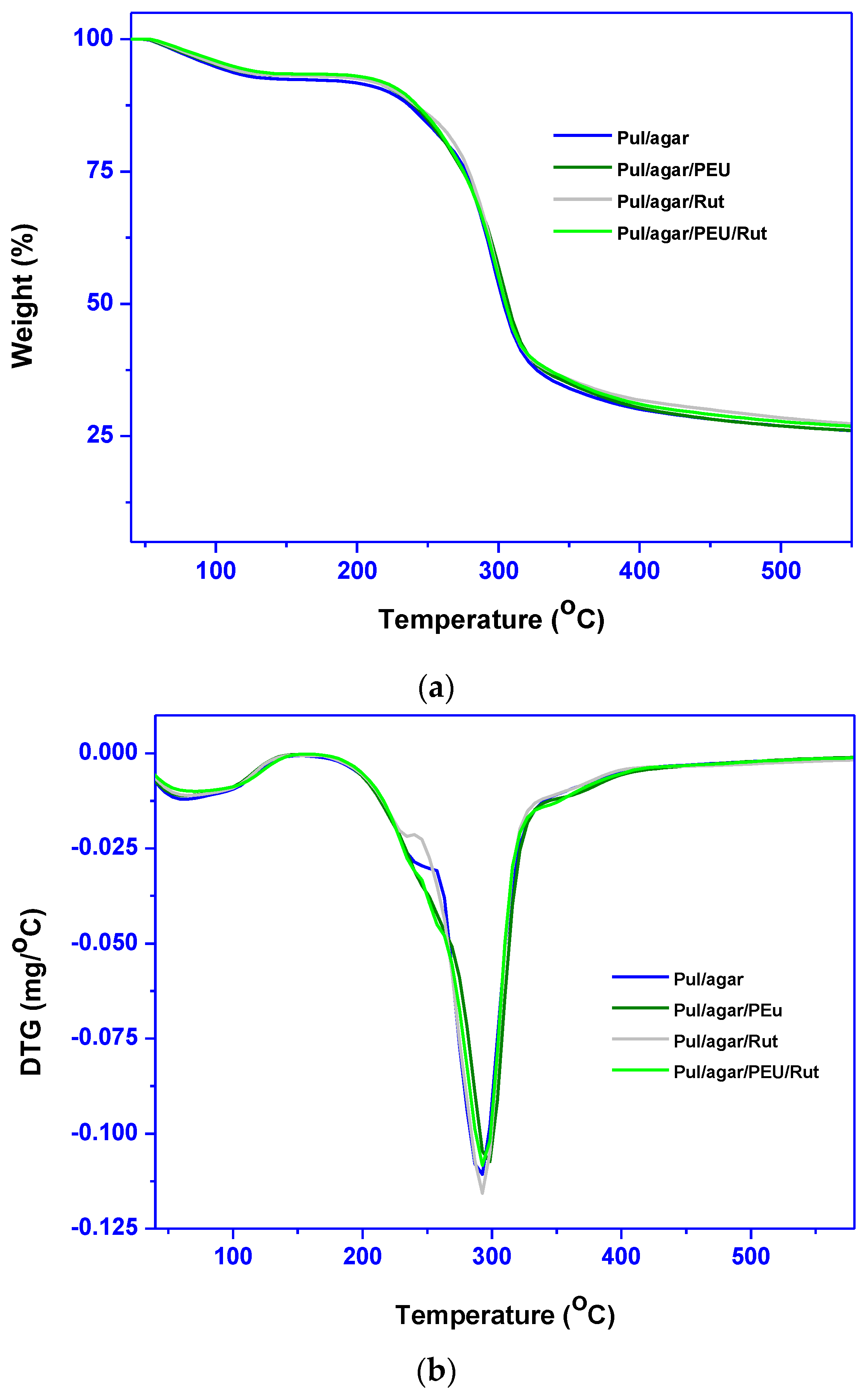

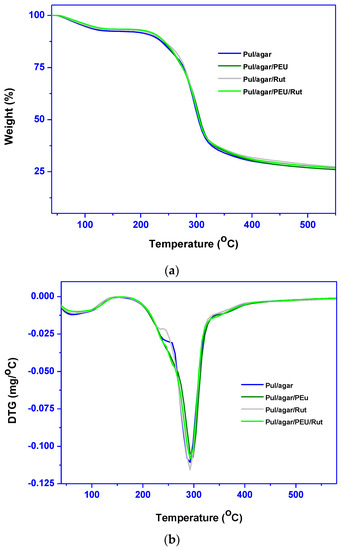

3.4. Thermal Stability

The thermal stability results of the pullulan/agar-based films are presented in Figure 4. In the TGA and DTG thermograms, it can be observed that all films showed two degradation peaks and that the mixing of PEU and rutin did not vary the thermal degradation pattern significantly. The thermal degradation pattern of the films was similar to previously reported pullulan/agar-based films [17]. The first degradation maximum found at around 80–100 °C were due to moisture evaporation in the film [17]. A second and main thermal degradation peak maximum appeared around 300 °C, which was due to the degradation of the biopolymer and plasticizer (glycerol) [12,17]. A slight change in the peak maxima was observed in the presence of PEU and rutin, apart from a slight increase in the final char amount of the films. It can be inferred that the thermal stability of pullulan/agar-based films did not change significantly (p < 0.05) in the presence of PEU/rutin. Similar results have been reported for essential oils and rutin with biopolymer-based packaging films [18].

Figure 4.

TGA (a) and DTG (b) thermograms of the pullulan/agar-based films.

The fabricated film contains pullulan and agar, and both of them are biodegradable polymers. As a result, it is expected that the 1:1 combination of pullulan/agar should also be degradable. The pullulan film showed visual changes after two weeks and became almost completely degraded in five weeks in the soil [40]. Then again, agar film showed distinctive visual changes and partial degradation after three weeks in soil [41]. Therefore, pullulan/agar-based films can be a promising alternative to non-biodegradable petrochemical-based synthetic plastics.

3.5. Mechanical and Water Vapor Barrier Properties

The mechanical properties (strength, flexibility, and stiffness) of the pullulan/agar-based films were checked using Instron (Table 2). The thickness of the pullulan/agar film increased significantly by adding PEU and rutin alone or in combination due to the increased solids content [42]. The mechanical strength of the pullulan/agar film was ~50 MPa, and it remains almost unchanged with the addition of PEU or rutin. The tensile strength (TS) of the current pullulan/agar-based film is two-fold higher in other respects, but the flexibility is 7.5-fold lower than previously reported pullulan/agar-based films [17]. The mechanical properties were not affected even in the combination of PEU and rutin, which could be attributed to the good interfacial interaction between polymer and filler [17,32].

Table 2.

Mechanical properties and water vapor permeability (WVP) of the pullulan/agar films.

Then again, the film’s elongation (EB) and stiffness (EM) did not change significantly (p < 0.05), as did the tensile strength of the film. The mechanical property test results showed that the strength of the pullulan/agar film was increased by adding bioactive functional ingredients (PEU and rutin), but the flexibility of the film was reduced. Similar results have been stated for films containing emulsions of essential oil and rutin-added biopolymer-based packaging films [18,24].

The water vapor permeability (WVP) of the studied films is also shown in Table 2. The WVP of the films was not pointedly affected in the presence of PEU but was somewhat enhanced in the presence of rutin, and the combination of PEU/rutin was comparable to the pristine pullulan/agar film. The water vapor barrier properties are inversely proportional to the water vapor permeability of the film, yielding insights indicating that the barrier properties of pullulan/agar films are only slightly affected or remain unaltered in the presence of bioactive fillers. Similar results have recently been reported for essential oils and rutin-containing gelatin/chitosan-based packaging films [18].

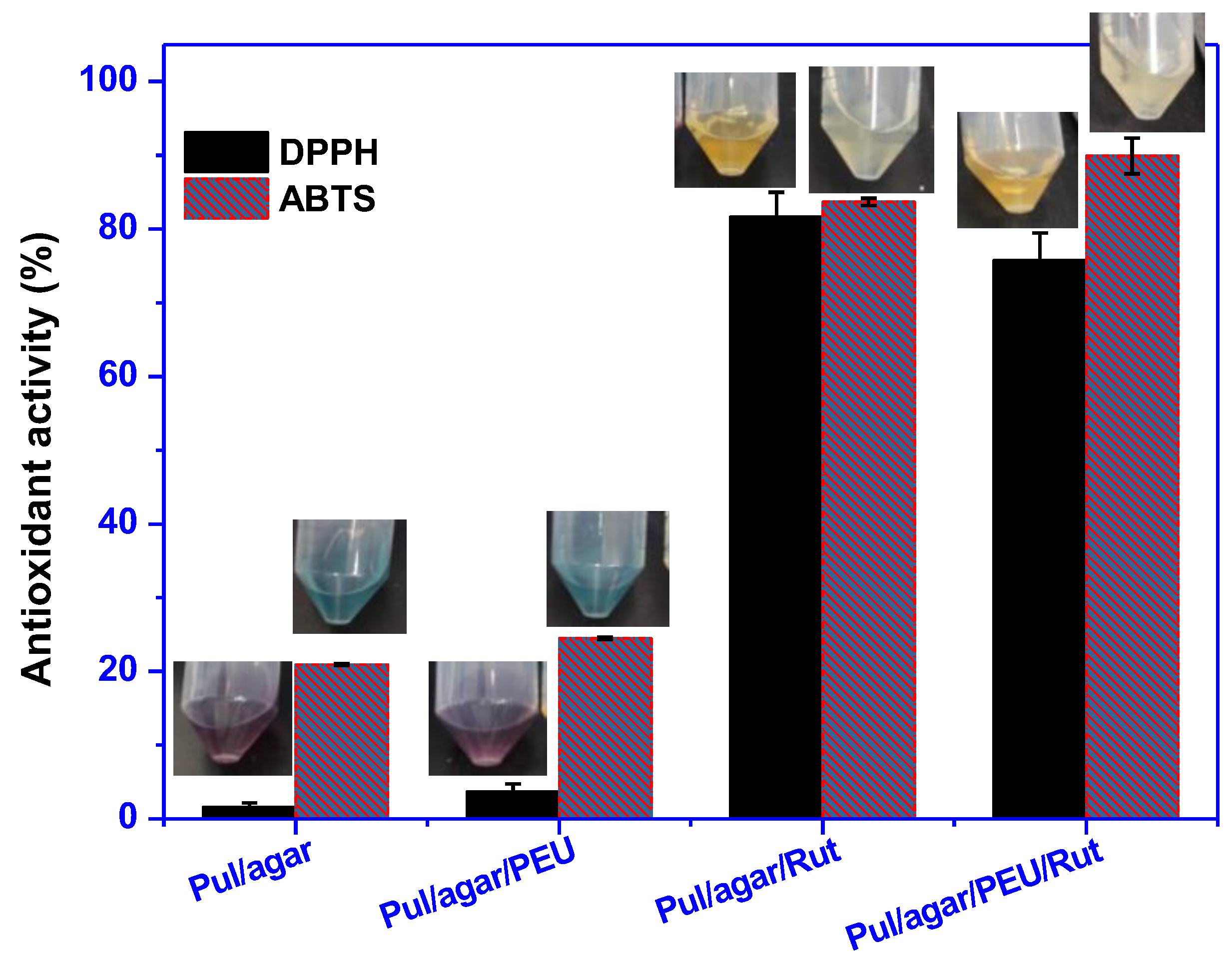

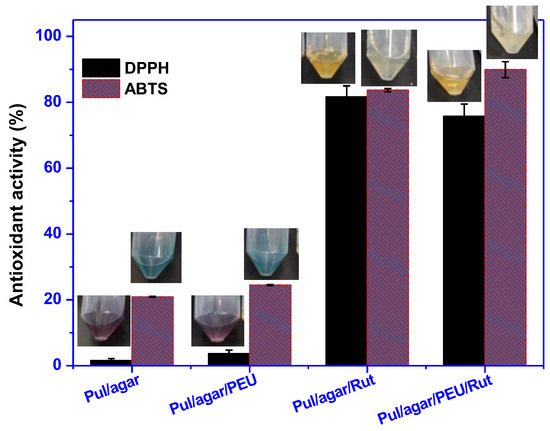

3.6. Antioxidant Activity

The antioxidant activity of the tested films is presented in Figure 5. The pristine pullulan/agar films presented some antioxidant activity and higher action in the ABTS assay compared to DPPH due to the higher solubility of the biopolymer in ABTS’ aqueous solvents than in DPPH’s alcoholic solvents [43]. The antioxidant action of the pure film is probably owing to the bioactive functional groups present in the biopolymer chains [16,44]. The antioxidant activity of the pullulan/agar films was significantly improved in both PEU and rutin due to the strong antioxidant potential of eucalyptus essential oil and rutin. The antioxidant activity of the film was also apparently perceived from the changes in the color of DPPH and ABTS solutions in the presence of the film (Figure 5). Eucalyptus essential oil contains many highly effective physiologically active ingredients that remove active oxygen, such as phenols, flavonoids, and terpenoids, showing strong antioxidant activity [20,21]. On the other hand, rutin is a flavone known to have strong antioxidant activity [45,46].

Figure 5.

Antioxidant activity of the pullulan/agar-based films.

Interestingly, the antioxidant activity in the combination of PEU/rutin was nearly comparable to that of rutin or its PEU counterpart. Analogous results have previously been stated for gelatin/chitosan packaging films with the addition of essential oils and rutin [18]. Similar strong antioxidant activity was also reported in the case of eucalyptus-leaf-oil-added corn starch film [21].

4. Conclusions and Future Perspectives

A pullulan/agar functional film was fabricated using a eucalyptus essential oil and rutin, a physiologically active vegetable compound. The pullulan and agar mixtures are compatible and produce films with good film properties. Due to the presence of yellow rutin, the whiteness index of the films decreased while the yellowness index enhanced. The UV-blocking and antioxidant activities of the pullulan/agar composite films were significantly enhanced when functional compounds were added alone or in combination. The films’ mechanical and barrier properties were not significantly modified in the presence of functional components. Fabricated films with better functional properties may be suitable for active food packaging uses.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/coatings13020460/s1. These references [47,48,49,50] are cited in Supplementary Materials file.

Author Contributions

Conceptualization: S.R.; investigation: S.R.; writing—original draft: S.R.; writing—review & editing: J.-W.R. and S.R.; visualization: S.R.; supervision: J.-W.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare there is no conflict of interest.

References

- Kumari, S.V.G.; Pakshirajan, K.; Pugazhenthi, G. Recent Advances and Future Prospects of Cellulose, Starch, Chitosan, Polylactic Acid and Polyhydroxyalkanoates for Sustainable Food Packaging Applications. Int. J. Biol. Macromol. 2022, 221, 163–182. [Google Scholar] [CrossRef] [PubMed]

- Harding, K.G.; Gounden, T.; Pretorius, S. “Biodegradable” Plastics: A Myth of Marketing? Procedia Manuf. 2017, 7, 106–110. [Google Scholar] [CrossRef]

- Smaoui, S.; Ben Hlima, H.; Tavares, L.; Ennouri, K.; Ben Braiek, O.; Mellouli, L.; Abdelkafi, S.; Mousavi Khaneghah, A. Application of Essential Oils in Meat Packaging: A Systemic Review of Recent Literature. Food Control 2022, 132, 108566. [Google Scholar] [CrossRef]

- Mesgari, M.; Aalami, A.H.; Sathyapalan, T.; Sahebkar, A. A Comprehensive Review of the Development of Carbohydrate Macromolecules and Copper Oxide Nanocomposite Films in Food Nanopackaging. Bioinorg. Chem. Appl. 2022, 2022, 7557825. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.; Biswas, D.; Roy, S. A Comprehensive Review of Biodegradable Polymer-Based Films and Coatings and Their Food Packaging Applications. Materials 2022, 15, 5899. [Google Scholar] [CrossRef]

- Atarés, L.; Chiralt, A. Essential Oils as Additives in Biodegradable Films and Coatings for Active Food Packaging. Trends Food Sci. Technol. 2016, 48, 51–62. [Google Scholar] [CrossRef]

- Nehra, A.; Biswas, D.; Siracusa, V.; Roy, S. Natural Gum-Based Functional Bioactive Films and Coatings: A Review. Int. J. Mol. Sci. 2022, 24, 485. [Google Scholar] [CrossRef]

- Fan, B.; Zhao, X.; Liu, Z.; Xiang, Y.; Zheng, X. Inter-Component Synergetic Corrosion Inhibition Mechanism of Passiflora edulia Sims Shell Extract for Mild Steel in Pickling Solution: Experimental, DFT and Reactive Dynamics Investigations. Sustain. Chem. Pharm. 2022, 29, 100821. [Google Scholar] [CrossRef]

- Irkin, R.; Esmer, O.K. Novel Food Packaging Systems with Natural Antimicrobial Agents. J. Food Sci. Technol. 2015, 52, 6095–6111. [Google Scholar] [CrossRef]

- Nogueira, G.F.; Oliveira, R.A.D.; Velasco, J.I.; Fakhouri, F.M. Methods of Incorporating Plant-Derived Bioactive Compounds into Films Made with Agro-Based Polymers for Application as Food Packaging: A Brief Review. Polymers 2020, 12, 2518. [Google Scholar] [CrossRef]

- Roy, S.; Zhang, W.; Biswas, D.; Ramakrishnan, R.; Rhim, J.-W. Grapefruit Seed Extract-Added Functional Films and Coating for Active Packaging Applications: A Review. Molecules 2023, 28, 730. [Google Scholar] [CrossRef]

- Ramakrishnan, R.; Kulandhaivelu, S.V.; Roy, S.; Viswanathan, V.P. Characterisation of Ternary Blend Film of Alginate/Carboxymethyl Cellulose/Starch for Packaging Applications. Ind. Crop. Prod. 2023, 193, 116114. [Google Scholar] [CrossRef]

- Qian, M.; Liu, D.; Zhang, X.; Yin, Z.; Ismail, B.B.; Ye, X.; Guo, M. A Review of Active Packaging in Bakery Products: Applications and Future Trends. Trends Food Sci. Technol. 2021, 114, 459–471. [Google Scholar] [CrossRef]

- Grzebieniarz, W.; Biswas, D.; Roy, S.; Jamróz, E. Advances in Biopolymer-Based Multi-Layer Film Preparations and Food Packaging Applications. Food Packag. Shelf Life 2023, 35, 101033. [Google Scholar] [CrossRef]

- Mostafavi, F.S.; Zaeim, D. Agar-Based Edible Films for Food Packaging Applications—A Review. Int. J. Biol. Macromol. 2020, 159, 1165–1176. [Google Scholar] [CrossRef]

- Roy, S.; Priyadarshi, R.; Rhim, J.-W. Development of Multifunctional Pullulan/Chitosan-Based Composite Films Reinforced with ZnO Nanoparticles and Propolis for Meat Packaging Applications. Foods 2021, 10, 2789. [Google Scholar] [CrossRef]

- Rukmanikrishnan, B.; Lee, J. Montmorillonite Clay and Quaternary Ammonium Silane-Reinforced Pullulan/Agar-Based Nanocomposites and Their Properties for Packaging Applications. Int. J. Biol. Macromol. 2021, 191, 956–963. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Fabrication of Bioactive Binary Composite Film Based on Gelatin/Chitosan Incorporated with Cinnamon Essential Oil and Rutin. Colloids Surf. B Biointerfaces 2021, 204, 111830. [Google Scholar] [CrossRef]

- Dammak, I.; de Carvalho, R.A.; Trindade, C.S.F.; Lourenço, R.V.; do Amaral Sobral, P.J. Properties of Active Gelatin Films Incorporated with Rutin-Loaded Nanoemulsions. Int. J. Biol. Macromol. 2017, 98, 39–49. [Google Scholar] [CrossRef]

- Hafsa, J.; Ali Smach, M.; Ben Khedher, M.R.; Charfeddine, B.; Limem, K.; Majdoub, H.; Rouatbi, S. Physical, Antioxidant and Antimicrobial Properties of Chitosan Films Containing Eucalyptus Globulus Essential Oil. LWT-Food Sci. Technol. 2016, 68, 356–364. [Google Scholar] [CrossRef]

- Chen, M.; Yan, X.; Cheng, M.; Zhao, P.; Wang, Y.; Zhang, R.; Wang, X.; Wang, J.; Chen, M. Preparation, Characterization and Application of Poly(Lactic Acid)/Corn Starch/Eucalyptus Leaf Essential Oil Microencapsulated Active Bilayer Degradable Film. Int. J. Biol. Macromol. 2022, 195, 264–273. [Google Scholar] [CrossRef] [PubMed]

- Sugumar, S.; Mukherjee, A.; Chandrasekaran, N. Eucalyptus Oil Nanoemulsion-Impregnated Chitosan Film: Antibacterial Effects against a Clinical Pathogen, Staphylococcus Aureus, in Vitro. Int. J. Nanomed. 2015, 10, 67. [Google Scholar] [CrossRef]

- Kong, I.; Degraeve, P.; Pui, L.P. Polysaccharide-Based Edible Films Incorporated with Essential Oil Nanoemulsions: Physico-Chemical, Mechanical Properties and Its Application in Food Preservation— A Review. Foods 2022, 11, 555. [Google Scholar] [CrossRef] [PubMed]

- Narasagoudr, S.S.; Hegde, V.G.; Chougale, R.B.; Masti, S.P.; Vootla, S.; Malabadi, R.B. Physico-Chemical and Functional Properties of Rutin Induced Chitosan/Poly (Vinyl Alcohol) Bioactive Films for Food Packaging Applications. Food Hydrocoll. 2020, 109, 106096. [Google Scholar] [CrossRef]

- Roy, S.; Min, S.-J.; Biswas, D.; Rhim, J.-W. Pullulan/Chitosan-Based Functional Film Incorporated with Curcumin-Integrated Chitosan Nanoparticles. Colloids Surfaces A Physicochem. Eng. Asp. 2023, 660, 130898. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Gelatin/Agar-Based Functional Film Integrated with Pickering Emulsion of Clove Essential Oil Stabilized with Nanocellulose for Active Packaging Applications. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 627, 127220. [Google Scholar] [CrossRef]

- Lipatova, I.M.; Makarova, L.I.; Yusova, A.A. Rutin-Containing Chitosan Films Produced Using in Situ Mechanoactivated Precipitation Process. Food Hydrocoll. 2021, 110, 106157. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Genipin-Crosslinked Gelatin/Chitosan-Based Functional Films Incorporated with Rosemary Essential Oil and Quercetin. Materials 2022, 15, 3769. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Fabrication of Carboxymethyl Cellulose/Agar-Based Functional Films Hybridized with Alizarin and Grapefruit Seed Extract. ACS Appl. Bio Mater. 2021, 4, 4470–4478. [Google Scholar] [CrossRef]

- Hasanin, M.S.; Youssef, A.M. Ecofriendly Bioactive Film Doped CuO Nanoparticles Based Biopolymers and Reinforced by Enzymatically Modified Nanocellulose Fibers for Active Packaging Applications. Food Packag. Shelf Life 2022, 34, 100979. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Preparation of Carbohydrate-Based Functional Composite Films Incorporated with Curcumin. Food Hydrocoll. 2020, 98, 105302. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Ji, R.; Li, K.; Zhang, W. Preparation and Characterization of Pullulan/Carboxymethyl Cellulose/Nano-TiO2 Composite Films for Strawberry Preservation. Food Biophys. 2021, 16, 460–473. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, B.; Zhao, S.; Qiao, D.; Xie, F. Plasticized Starch/Agar Composite Films: Processing, Morphology, Structure, Mechanical Properties, and Surface Hydrophilicity. Coatings 2021, 11, 311. [Google Scholar] [CrossRef]

- Mansur, H.S.; Sadahira, C.M.; Souza, A.N.; Mansur, A.A.P. FTIR Spectroscopy Characterization of Poly (Vinyl Alcohol) Hydrogel with Different Hydrolysis Degree and Chemically Crosslinked with Glutaraldehyde. Mater. Sci. Eng. C 2008, 28, 539–548. [Google Scholar] [CrossRef]

- Fasihi, H.; Noshirvani, N.; Hashemi, M. Novel Bioactive Films Integrated with Pickering Emulsion of Ginger Essential Oil for Food Packaging Application. Food Biosci. 2023, 51, 102269. [Google Scholar] [CrossRef]

- Ganeshpurkar, A.; Saluja, A.K. The Pharmacological Potential of Rutin. Saudi Pharm. J. 2017, 25, 149–164. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Fabrication of chitosan-based functional nanocomposite films: Effect of quercetin-loaded chitosan nanoparticles. Food Hydrocoll. 2021, 121, 107065. [Google Scholar] [CrossRef]

- Jridi, M.; Boughriba, S.; Abdelhedi, O.; Nciri, H.; Nasri, R.; Kchaou, H.; Kaya, M.; Sebai, H.; Zouari, N.; Nasri, M. Investigation of Physicochemical and Antioxidant Properties of Gelatin Edible Film Mixed with Blood Orange (Citrus Sinensis) Peel Extract. Food Packag. Shelf Life 2019, 21, 100342. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Carrageenan/Agar-Based Functional Film Integrated with Zinc Sulfide Nanoparticles and Pickering Emulsion of Tea Tree Essential Oil for Active Packaging Applications. Int. J. Biol. Macromol. 2021, 193, 2038–2046. [Google Scholar] [CrossRef]

- Ganduri, V.S.; Kiranmayi, U.M.; Rao, K.R.S.; Poda, S. Formulation of Pullulan/Plasticizer Blended Films for Their Physical and Biodegradability Studies. Curr. Trends Biotechnol. Pharm. 2020, 14, 263–270. [Google Scholar] [CrossRef]

- Dungani, R.; Sumardi, I.; Suhaya, Y.; Aditiawati, P.; Dody, S.; Rosamah, E.; Karliati, T. Reinforcing Effects of Seaweed NanoParticles in Agar-Based Biopolymer Composite: Physical, Water Vapor Barrier, Mechanical, and Biodegradable Properties. BioResources 2021, 16, 5118. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Effect of Chitosan Modified Halloysite on the Physical and Functional Properties of Pullulan/Chitosan Biofilm Integrated with Rutin. Appl. Clay Sci. 2021, 211, 106205. [Google Scholar] [CrossRef]

- Vasconcelos, L.; de Souza, M.; de Oliveira, J.; Filho, E.S.; Silva, A.; Mazzetto, S.E.; Pereira, E.S.; Oliveira, R.L.; Bezerra, L. Elaboration and Characterization of Bioactive Films Obtained from the Incorporation of Cashew Nut Shell Liquid into a Matrix of Sodium Alginate. Antioxidants 2021, 10, 1378. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Agar-Based Antioxidant Composite Films Incorporated with Melanin Nanoparticles. Food Hydrocoll. 2019, 94, 391–398. [Google Scholar] [CrossRef]

- Yang, R.; Zhou, Z.; Sun, G.; Gao, Y.; Xu, J.; Strappe, P.; Blanchard, C.; Cheng, Y.; Ding, X. Synthesis of Homogeneous Protein-Stabilized Rutin Nanodispersions by Reversible Assembly of Soybean (Glycine Max) Seed Ferritin. RSC Adv. 2015, 5, 31533–31540. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, H. Preparation and Properties of Zein–Rutin Composite Nanoparticle/Corn Starch Films. Carbohydr. Polym. 2017, 169, 385–392. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Preparation of Carrageenan-Based Functional Nanocomposite Films Incorporated with Melanin Nanoparticles. Colloids Surf. B Biointerfaces 2019, 176, 317–324. [Google Scholar] [CrossRef]

- Rhim, J.-W. Physical-Mechanical Properties of Agar/κ-Carrageenan Blend Film and Derived Clay Nanocomposite Film. J. Food Sci. 2012, 77, N66–N73. [Google Scholar] [CrossRef]

- Rhim, J.-W. Effect of Clay Contents on Mechanical and Water Vapor Barrier Properties of Agar-Based Nanocomposite Films. Carbohydr. Polym. 2011, 86, 691–699. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Preparation of Antimicrobial and Antioxidant Gelatin/Curcumin Composite Films for Active Food Packaging Application. Colloids Surf. B Biointerfaces 2020, 188, 110761. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).