Abstract

Due to the harsh climatic conditions in high altitude and cold regions with large temperature differences, asphalt pavement is generally prone to cracking, and the cracks propagate rapidly, which reduces the service life and service level of the road. The factors influencing the fracture characteristics of asphalt mixtures were analyzed in this paper, and the mixtures with different aggregate gradations from various types of asphalt were prepared. The fracture characteristics were explored using the thermal stress restrained specimen test (TSRST) and low-temperature bending test, and the good consistency of the low-temperature fracture performance was identified according to the results of frost-break temperature, flexural strength, and fracture toughness. The frost-break temperature was confirmed as the best indicator of the material crack resistance and could be used as the index to evaluate the performance of asphalt mixtures at low temperatures. The frost-break temperature of matrix asphalt mixture is 8–10 °C higher than that of modified asphalt mixture, and AC asphalt mixture is 2–4 °C higher than that of SMA asphalt mixture. The excellent asphalt performance has a more important influence on the fracture characteristics of asphalt mixture. The asphalt mixture of the same type had similar fracture toughness at varying notch depths, the most deviation is 3.78% which shows that the initial crack depth has little effect on the fracture toughness of asphalt mixture at low temperature. The results of the study can provide a basis for the selection of asphalt pavement surface materials and the optimization of mixtures in high altitude and cold regions with large temperature differences.

1. Introduction

With a climate featuring cold weather, long duration of low temperature, and large temperature differences, the asphalt concrete pavement in the high altitude and cold regions with large temperature differences is generally vulnerable to severe cracks and other distress. Moreover, natural factors such as the strong ultraviolet light, lead to premature aging of the surface layer of the asphalt pavement. This thus greatly shortens the service life of the pavement, increases the maintenance cost of the road, and restricts the highway development in the Qinghai Tibet Plateau and other high altitude and cold regions with large temperature differences.

The factors affecting the low-temperature fracture characteristics of asphalt mixtures can be divided into two categories: internal and external factors. The internal factors refer to the material and structural characteristics of asphalt mixture components, including the aggregate type, asphalt type, asphalt content, gradation type, admixture material, etc. External factors include the traffic load, environmental factors, etc. Vinson et al. claimed that low-temperature cracking and rutting were two temperature-related asphalt concrete pavement damage forms in cold regions. They proposed a design method based on the asphalt binder and aggregate test results, and this method could reduce the occurrence of low-temperature cracks and ruts in asphalt pavement structures [1]. Guy Dore believed that the asphalt concrete pavement in cold regions mainly suffered from low-temperature and frost heaving cracking [2].

In high altitude and cold regions with large temperature differences, owing to the long duration of low temperature, the temperature stress accumulates, and the mixture is in a tensile state for a long period of time. Consequently, the mixture strength decreases continuously, eventually leading to damage. On account of large temperature differences and repeated heating and cooling cycles in this area, the failure strain of the material is reduced despite the small temperature stress. In addition, the aging effect of the material further gives rise to fatigue cracking. The faster the cooling rate, the greater the shrinkage strain rate of the mixture, the more difficult it is to exert the stress relaxation of the material, and the higher the accumulated temperature stress, the more likely it is to be destroyed. Different types of asphalt have varied viscosities and toughness. The asphalt with a greater viscosity exhibits better toughness under low-temperature conditions, and it can bond more tightly to aggregates. Besides, asphalt mixtures made from high-viscosity asphalt have better low-temperature performance. Aggregate is the skeleton and main body of asphalt mixtures. Asphalt mixtures prepared from mineral aggregates with different gradation designs are composed of particles of various sizes, and they have different asphalt contents. In addition, the embedded extrusion force and internal friction resistance between mineral aggregates of different size also vary. Therefore, the gradation design directly affects the performance of asphalt mixtures [3].

Research on temperature fatigue of asphalt mixtures began in the 1970s in the United States. Shahin et al. established the temperature fatigue damage model of asphalt pavement by using the phenomenon method [4]. Mahboub et al. studied the formation process of temperature fatigue cracks in asphalt pavement, as well as the factors contributing to fissure generation. Their research results showed that the crack development process notably influenced the prediction of pavement fatigue life [5]. Lytton et al. analyzed the fatigue mechanism of pavements with increasing number of temperature fatigue effects and established the corresponding temperature fatigue life equation. According to their study result, the temperature fatigue was ascribed to both thermal fatigue and low-temperature cracking [6,7]. Eshan V. Dave held that the one-dimensional stress evaluation model of temperature cracks in the AASHTO Mechanical Experience Pavement Design Guide was oversimplified and unable to characterize the nonlinear fracture behavior of asphalt concrete, so it was not sound. Based on the nonlinear finite element method, he proposed an interactive temperature cracking prediction model. This model included a time and temperature-dependent viscoelastic material model, as well as a viscous material fracture model that could accurately simulate the initiation and propagation of temperature load-induced cracks [8].

Wei Youpo et al. simulated the high and cold conditions in Qinghai-Tibet region with large temperature differences and conducted indoor flexural strength tests of asphalt mixtures. They also studied how the flexural strength of asphalt mixtures changed with different gradations, oil-stone ratios, temperatures, etc. Their research results help perfect the current asphalt pavement design method, improve the performance of asphalt pavement in permafrost areas, and prolong the service life of asphalt pavement. Moreover, their findings take on great application value to construction projects, and can guide the design of asphalt pavement structures in the cold highland [9,10]. Guo Bo and Li Dongqing et al. investigated the influence of different material compositions on the high- and low-temperature performance and water stability of asphalt mixtures in regions with large temperature differences. They evaluated the high temperature stability, low-temperature crack resistance, and water stability of asphalt mixtures using the dynamic stability, low-temperature failure strain, and freeze-thaw splitting strength indexes, respectively. Through range analysis and experimental verification, the order of sensitivity of factors affecting the high- and low-temperature performance of asphalt mixtures was determined. Finally, the optimal mix proportion was obtained, which provided a basis for the raw material selection and composition design of asphalt mixtures in areas with large temperature differences [11,12]. In the research of Hao Peiwen, the crack resistance of asphalt mixtures was assessed by the low-temperature crack resistance coefficient. A larger crack resistance coefficient suggested better low-temperature crack resistance [13]. Lu Songtao et al. explored the temperature fatigue life of asphalt concrete through low circle temperature fatigue testing, and made an analysis using the temperature fatigue damage model based on dissipated energy. The results revealed a linear relationship between the dissipated energy and the plastic strain of asphalt mixtures [14]. Guo Weiwei et al. examined the influence of different aging degrees on the low-temperature performance of asphalt mixtures through the splitting test, beam bending test and low-temperature shrinkage test. They also characterized the low-temperature crack resistance of asphalt mixtures under different aging conditions [15].

Zhang Yi studied the asphalt mixture after short-term aging and long-term aging with 0 °C bending creep test and −10 °C bending test, and analyzed the low-temperature crack resistance of asphalt mixture under different aging conditions. Based on the experimental results, the key properties of low-temperature cracking resistance, aging resistance and frost resistance in permafrost areas were combined to propose the design method of asphalt mixture ratio for permafrost areas [16]. Fu Qiang et al. constructed a numerical simulation finite element model based on fracture mechanics to analyze the propagation process of surface cracks and base reflection cracks. The results suggested a nonlinear relationship between surface cracks and the stress intensity factor in the propagation process when the reference temperature was lower than 5 °C. The comprehensive research results above show that the asphalt mixture will produce temperature fatigue when the temperature cycle changes, and the effect of temperature fatigue is greater when the reference temperature is lower, so the role of temperature in the analysis of the effect of freeze-thaw cycles on asphalt mixtures cannot be ignored [17].

In high altitude and cold regions with large temperature differences, asphalt mixtures are apt to crack, so the low-temperature crack resistance of mixtures has vital influence on asphalt pavement performance in such areas. Existing domestic and abroad methods for assessing the low-temperature performance of asphalt mixtures mainly include the low-temperature bending test, notch low-temperature bending test, asphalt mixture splitting test, shrinkage coefficient test, relaxation test, and the thermal stress restrained specimen test (TSRST). The United States Highway Strategic Research Program (SHRP) examined the performance of the above-mentioned approaches in simulating field conditions, the applicability of their test results to the mechanical model, their practicality in aging and wet conditions, their operation, and the instrument cost. The results show that the TSRST can well simulate the field conditions and accurately evaluate the low-temperature cracking performance of the asphalt mixture. Meanwhile, the TSRST can directly measure the temperature-stress curve of the asphalt mixture during the cooling process, and obtain the values of such indices as frost-break temperature and frost-break stress [18,19,20].

Previous research results have shown that severe cold and large temperature difference conditions have a notable effect on the low-temperature performance of asphalt mixtures. However, further research on the fracture characteristics of asphalt mixtures under said conditions is still needed. In this paper, we simulated the conditions in the high altitude and cold regions with large temperature differences, and prepared a variety of asphalt mixtures with different aggregate gradations from various types of asphalt. Then the TSRST and low-temperature bending test were carried out to study how the fracture characteristics of asphalt mixtures varied with the asphalt type, mixture type, and cooling rate. This study provides a foundation for the optimal design of asphalt pavement surface mixtures in high altitude and cold regions with large temperature differences.

2. Asphalt Mixture Composition Design

In this study, the effect of cold and large temperature differences on the fracture performance of fine-graded asphalt mixture (AC-13), medium-graded asphalt mixture (AC-16), and stone matrix asphalt (SMA-13) was investigated. These three materials are widely applied to the asphalt pavement upper layer. Matrix asphalt and SBS-modified asphalt were selected as binders.

2.1. Raw Material Technical Standard

The raw materials used in this research mainly included matrix and modified asphalt, coarse and fine aggregates.

No. 90 matrix asphalt (unmodified asphalt) and SBS-modified asphalt widely used in high altitude and cold regions in China were compared in this study. The specific technical indicators of the two types of asphalt are shown in Table 1.

Table 1.

Technical index value of asphalt.

The basalt stone and 0–3 mm machine-made sand were taken as coarse and fine aggregates, respectively. The performance of the coarse and fine aggregates was measured. Their main technical indexes are listed in Table 2, which meet the technical requirement.

Table 2.

Technical index value of aggregates.

2.2. Mix Design

The mix ratio design method for asphalt mixtures in “Technical Specification for Construction of Highway Asphalt Pavement” (JTG F40-2004) [21] was adopted in this study. According to the screening results of raw materials and the grading range and mineral aggregate grading selection method stipulated in the current specification, the gradations of the three types of asphalt mixtures were determined. The design gradations of asphalt mixture are shown in Table 3.

Table 3.

Gradation range.

The Marshall test was carried out, and the asphalt content in each mixture was obtained. The results are shown in Table 4.

Table 4.

Marshall test results.

From the test results, it can be seen that under the same mix type, the asphalt dosage, stability and asphalt saturation of the modified asphalt mix were higher than those of the matrix asphalt mix, and the asphalt dosage of SMA-13 was higher than those of AC-13 and AC-16. The Marshall test results met the requirements of “Technical Specification for Construction of Highway Asphalt Pavement” (JTG F40-2004). The asphalt mixture specimens were prepared according to the determined mineral aggregate gradation and asphalt content. Then their fracture characteristics under large temperature differences were investigated.

3. Fracture Characteristics of Asphalt Mixtures

3.1. Test Scheme

- (1)

- Thermal stress restrained specimen test (TSRST) for asphalt mixtures

The TSRST device consists of a refrigeration system, a load/displacement system, a data acquisition and control system, and a high-precision displacement sensor, with test accuracy higher than 0.0025 mm. This TSRST instrument could simulate the actual temperature change and the forces acting on the mixture, and well reflect the low-temperature cracking performance of the asphalt mixture.

According to the mix proportion determined in Section 2.2, the beam specimens of AC-13, SBS-modified AC-13, AC-16, SBS-modified AC-16, SMA-13, and SBS-modified SMA-13 asphalt mixtures were prepared. All samples had a size of 40 mm × 40 mm × 200 mm. Before the test, the beam specimen was suspended inside the TSRST device. The temperature of the specimen was measured in real time by four temperature sensors attached to the four surfaces of the specimen. A temperature sensor was clamped by a fixed clip and hung inside the TSRST device to measure the internal ambient temperature. Displacement sensors were installed on both sides of the specimen. During the test, the liquid nitrogen tank kept introducing liquid nitrogen to the interior of the TSRST instrument, so as to constantly lower the internal temperature. As the temperature declined, the beam specimen continued to shrink. Once the temperature contraction stress of the specimen was greater than the ultimate tensile strength of the beam, the specimen cracked.

During the experiment, the specimen was cooled at different cooling rates (5 °C/h, 10 °C/h, and 15 °C/h). The initial temperature of the test was set at 10 °C and the test was conducted after the temperature stabilized. In the cooling process, the lowest temperature reached −50 °C. The test ceased if the specimen fractured. If the specimen did not brake, it was left in the −50 °C environment for an hour, and then the test automatically stopped.

- (2)

- Low-temperature bending test

Under the action of environmental factors in high altitude and cold regions with large temperature differences, small cracks may occur after the asphalt mixture pavement is laid. These small cracks result in stress concentration at the bottom of the mixture, and then expand due to the influence of prolonged low temperature and large temperature differences. In order to simulate this phenomenon, the low-temperature bending testing of pre-cracked beams was conducted to evaluate the low-temperature crack resistance of the mixture in the paper. The test process is detailed in Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering (JTG E20-2011) [22].

In accordance with the mix proportion determined in Section 2.2, the beam specimens of SBS-modified AC-13, SBS-modified AC-16, and SBS-modified SMA-13 asphalt mixtures were manufactured. All samples had a size of 250 mm × 30 mm × 35 mm. In addition, the beam specimens were subject to pre-cracked treatment according to the test requirements. There were five notch depths: 0, 4, 8, 12, and 16mm. The test temperature were 20, 10, 0, −10, and −20 °C. The test loading rate was 50 mm/min.

3.2. Thermal Stress Restrained Specimen Test (TSRST) for Asphalt Mixture Specimens

3.2.1. TSRST Results and Evaluation Indicators

Four evaluation indexes, namely, frost-break temperature, frost-break stress, transformation point temperature, and temperature curve slope dS/dT, were obtained by TSRST. The frost-break temperature is the temperature when the asphalt mixture breaks, and it is the minimum temperature that the mixture may withstand. The lower the fracture temperature, the better the low-temperature crack resistance of the mixture. The frost-break stress is the maximum stress when the asphalt mixture breaks during the cooling process, which reflects the mixture strength in low-temperature shrinking. The transition point temperature can reflect the rheological properties of asphalt mixtures during cooling. Asphalt mixtures with a lower transition point temperature have a stronger stress relaxation ability and better low-temperature performance. The temperature-stress curve slope dS/dT refers to the slope of the linear part, which represents the temperature stress growth rate. The test results are summarized in Table 5.

Table 5.

TSRST results of asphalt mixture specimens.

Each of the four evaluation indexes obtained has its own significance. To simplify the analysis, the most representative index was used to evaluate the low-temperature performance of the mixture. While choosing the most representative analysis index, we tried to minimize the loss of information contained in the original index. Therefore, based on the test results, the frost-break temperature, frost-break stress, transition point temperature, and temperature curve slope were analyzed using the principal component analysis method. The analysis results are shown in Table 6 and Table 7.

Table 6.

Correlation coefficient matrix.

Table 7.

Variance decomposition principal component extraction analysis results.

In some cases, eigenvalues can be regarded as an indicator to measure the influence of principal components. Therefore, the principle of extracting the number of principal components is that the corresponding eigenvalue of the principal components is greater than 1 and the cumulative percentage is greater than 80%. According to the analysis results, the first principal components (Frost-break temperature) reflected 56.290% of the information, and the first two principal components reflected 81.094% of the information, and their eigenvalues were both greater than 1. Among the four indexes, the frost-break temperature had the largest weight coefficient. This suggests that the frost-break temperature is the best indicator of low-temperature performance and can be used to evaluate the mixture specimens in TSRST. Meanwhile, considering that the frost-break temperature is directly related to the low-temperature cracking of asphalt pavement and has a clear physical significance, it is recommended to use the frost-break temperature as the evaluation index of the low-temperature performance of asphalt mixtures.

3.2.2. Effect of the Asphalt Type

The influence of the asphalt type and cooling rate on the frost-break temperature of mixtures was studied. The covariance analysis was performed by taking the frost-break temperature as the dependent variable. The analysis results are shown in Table 8.

Table 8.

Covariance analysis of the influence of the asphalt type (AC-13).

α = 0.05 was considered statistically significant. According to the above table, the p value for the interaction between the asphalt type and cooling rate is p = 0.225 > 0.05, so the covariance analysis was made. In the meantime, the asphalt type has a p = 0.021 < 0.05, indicating that the asphalt type greatly affects the frost-break temperature.

Based on the test and analysis results, the asphalt type notably affected the frost-break temperature of mixtures. The matrix asphalt had a higher frost-break temperature than the modified asphalt. Compared with the matrix asphalt, the modified asphalt had a higher viscosity, as well as better toughness at low temperatures. In addition, the mixture prepared from modified asphalt had relatively larger viscous resistance. The modified asphalt could improve the adhesion between asphalt and aggregates, so the mixture prepared from modified asphalt had better low-temperature performance than that made from matrix asphalt.

3.2.3. Effect of the Mixture Type

The impact of the mixture type and cooling rate on the frost-break temperature of mixtures composed of the same asphalt type was examined. The frost-break temperature was taken as the dependent variable for variance analysis. The analysis results are described in Table 9.

Table 9.

Covariance analysis of the effect of the mixture type (matrix asphalt).

A significance level of α = 0.05 was used. In the above table, the interaction between the mixture type and the cooling rate has a p = 0.457 > 0.05, so the covariance analysis of the data was adopted. Meanwhile, the mixture type has a p = 0.047 < 0.05, suggesting that the mixture type significantly influences the frost-break temperature.

According to the test and analysis results, the mixture type had a marked effect on the frost-break temperature. The frost-break temperature of the SMA asphalt mixture was lower than that of the AC asphalt mixture, and the AC-13 mixture had a lower frost-break temperature than that of the AC-16 asphalt mixture. The reason is that the SMA asphalt mixture has a dense skeleton structure, and it is formed by a large number of coarse aggregates, filled by sufficient fine aggregates. Due to the high content of coarse aggregates, mineral powder, and asphalt, the SMA asphalt mixture has better low-temperature performance than the AC asphalt mixture with a suspended-dense structure. The gradation of AC-16 mixtures is thicker than that of AC-13 mixtures. Previous studies have confirmed that asphalt mixtures with a smaller nominal maximum particle size and a finer aggregate gradation have better low-temperature crack resistance. Therefore, the AC-13 asphalt mixture has a lower frost-break temperature than the AC-16 asphalt mixture.

3.2.4. Effect of the Cooling Rate

The effect of the mixture type and cooling rate on the frost-break temperature of mixtures made of the same asphalt type was analyzed. The oblique variance analysis was performed by taking the frost-break temperature as the dependent variable. The analysis results are summarized in Table 10.

Table 10.

Covariance analysis of the effect of the cooling rate (SBS-modified asphalt).

α = 0.05 was taken as the significance level in this study. It can be seen from the above table that the p value of the interaction between the mixture type and the cooling rate is p = 0.364 > 0.05, so the covariance analysis was made. At the same time, the cooling rate has a p = 0.003 < 0.05, indicating that the cooling rate has marked influence on the frost-break temperature. As the cooling rate increases, the frost-break temperature of the mixture shows an ascending trend, because the stress accumulates faster in the mixture. The temperature stress generated in the mixture cannot be released in time through deformation. As a result, the mixture fractures earlier.

3.3. Low-Temperature Bending Test for Pre-Cracked Asphalt Mixture Beams

3.3.1. Load Deflection Curve Analysis

- (1)

- Test results at different temperatures

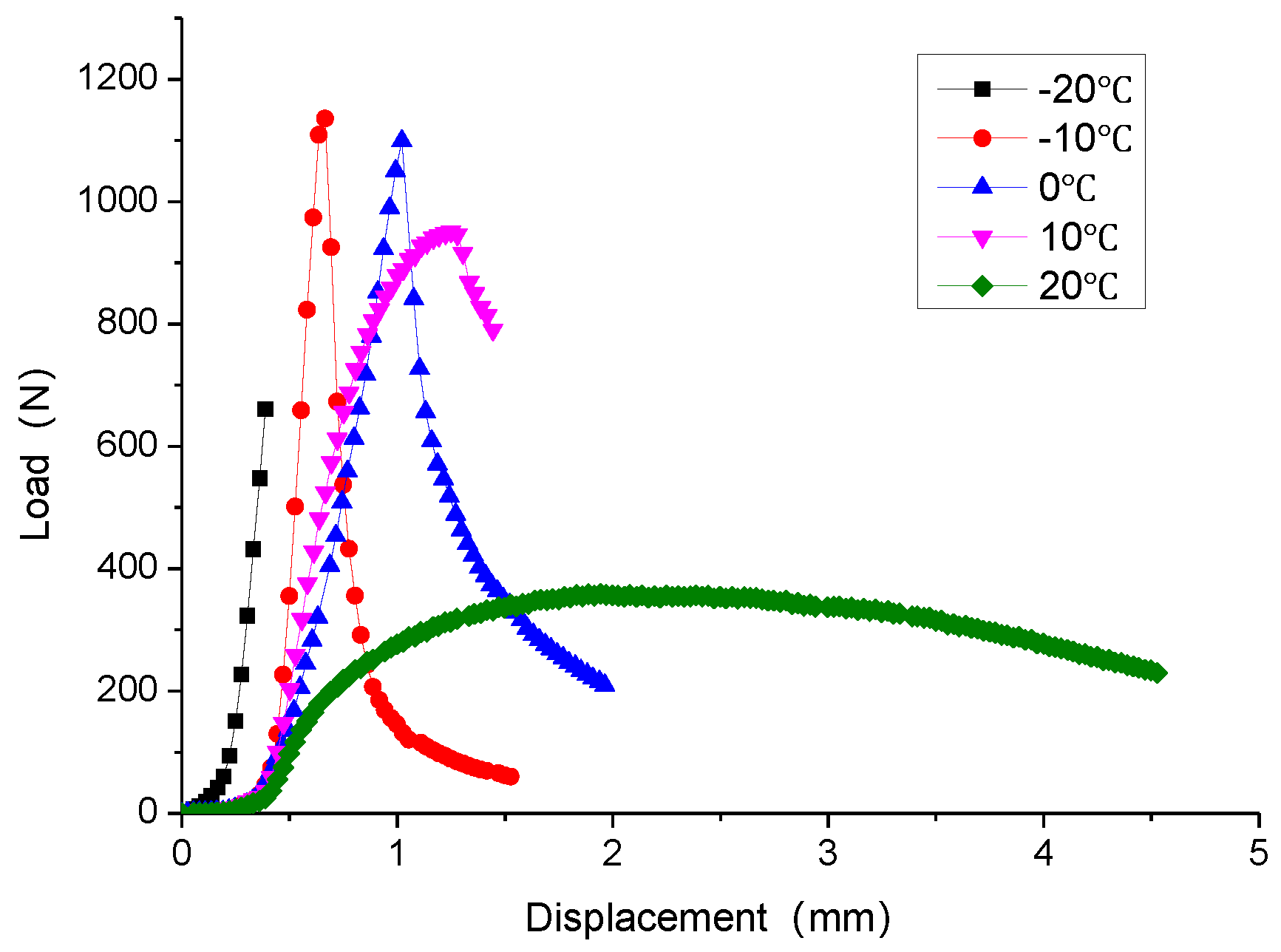

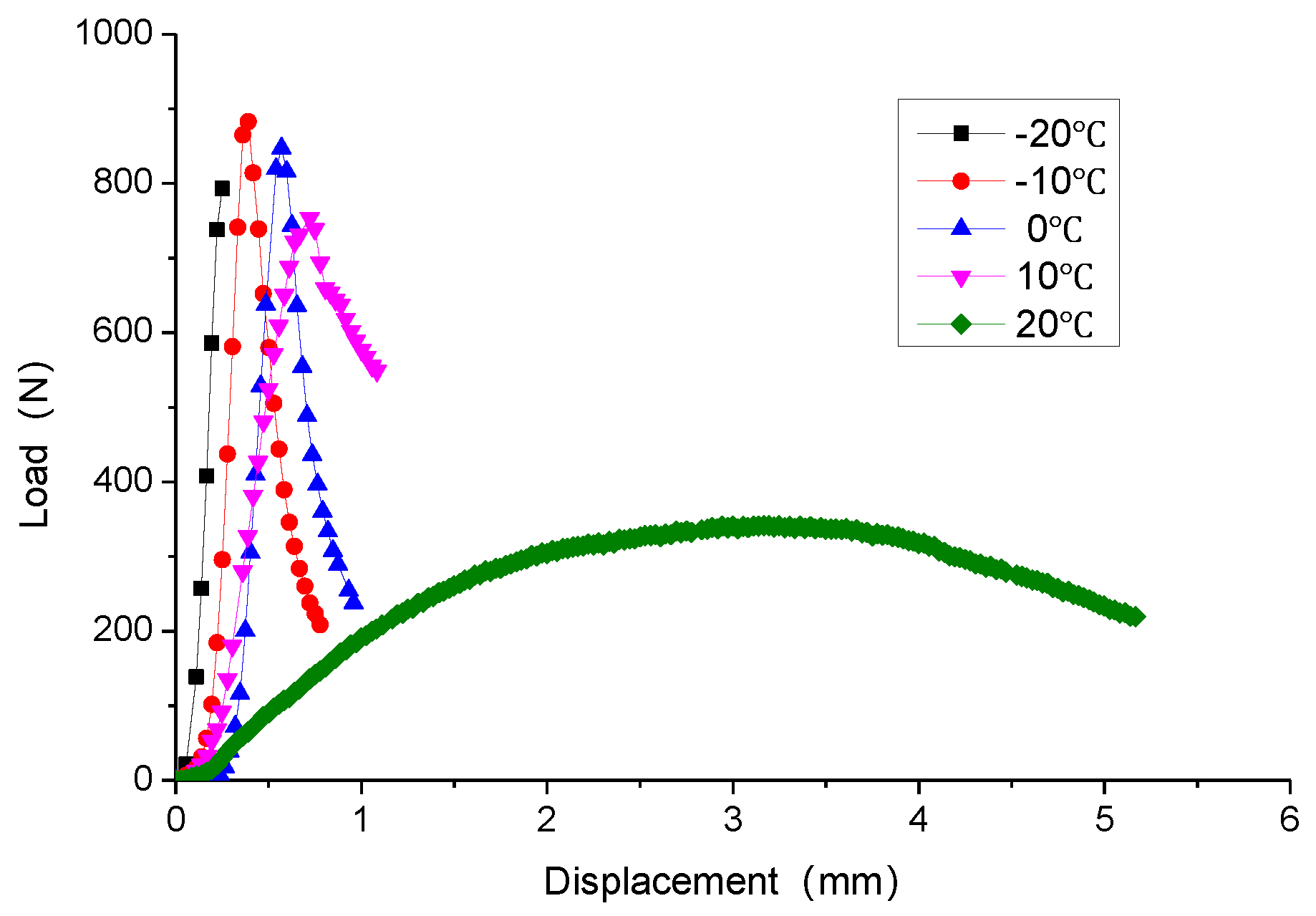

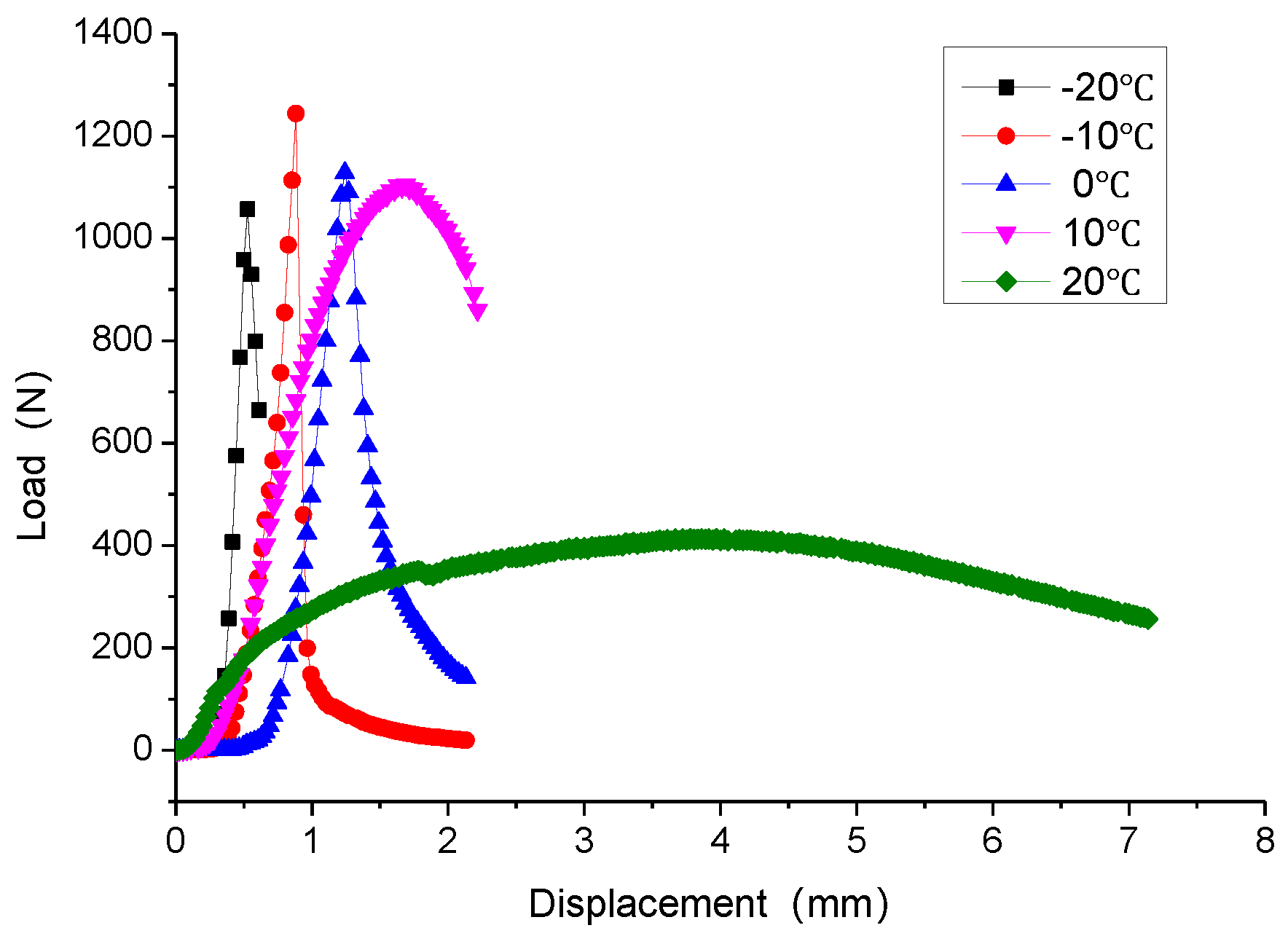

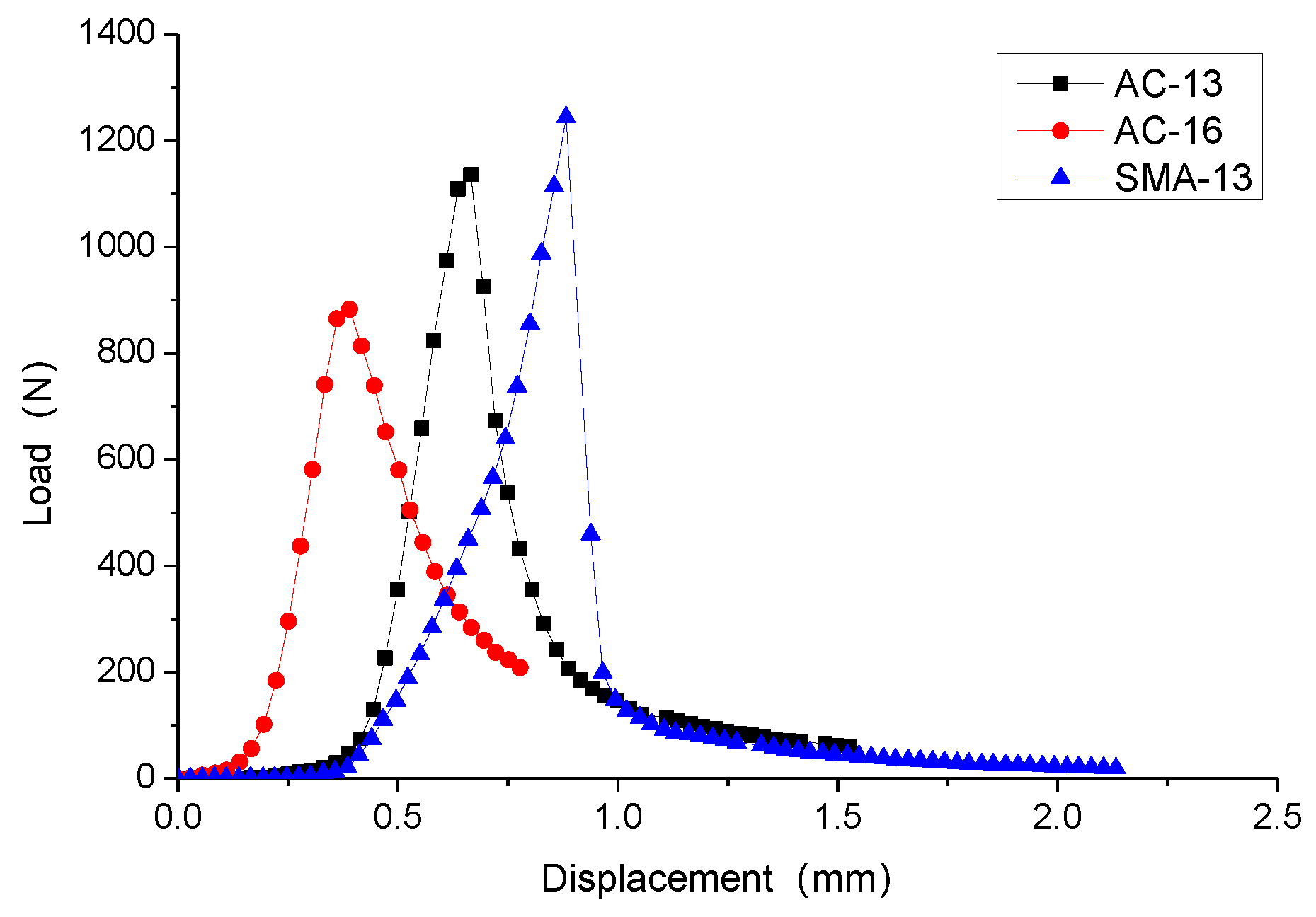

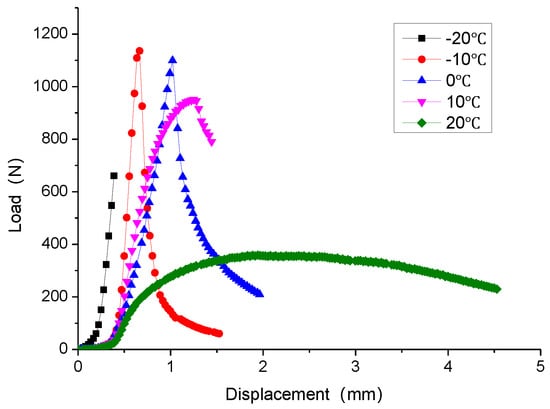

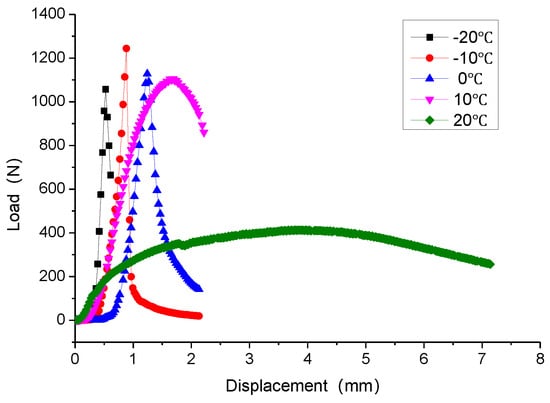

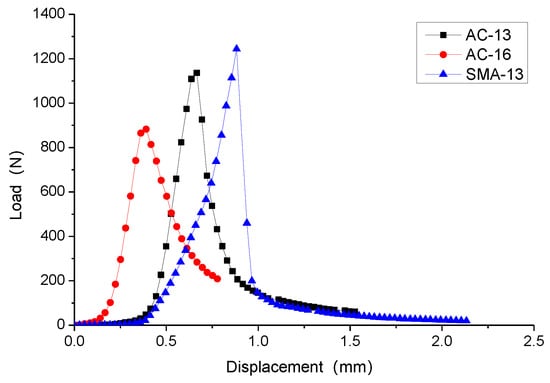

SBS-modified AC-13, SBS-modified AC-16, and SBS-modified SMA-13 asphalt mixtures were tested for the notched beam bending analysis. The beam notch was 4 mm deep and the test temperatures were 20, 10, 0, −10 and −20 °C. The load deflection curve is drawn in Figure 1, Figure 2 and Figure 3.

Figure 1.

Load-displacement diagram of AC-13 at different temperatures.

Figure 2.

Load-displacement diagram of AC-16 at different temperatures.

Figure 3.

Load-displacement diagram of SMA-13 at different temperatures.

As shown in the above figures, the change rate of the load-displacement curves increases with the declining temperature, and the mixture transforms from the viscoelastic state to the elastic state. At −20 °C, both AC-13 and AC-16 break. As the temperature continues to rise, the three curves tend to coincide before the specimen failure. This demonstrates a large difference in the deformation ability and crack resistance among the three types of asphalt mixtures at low temperatures. At high temperatures, their deformation ability is similar. According to the change trend of load-displacement curves at different temperatures, and the maximum load and displacement at failure, it is found that the SMA-13 mixture has the best low-temperature performance (Compared with AC-13, the performance is improved about 6.48%), followed by AC-13 and AC-16 successively.

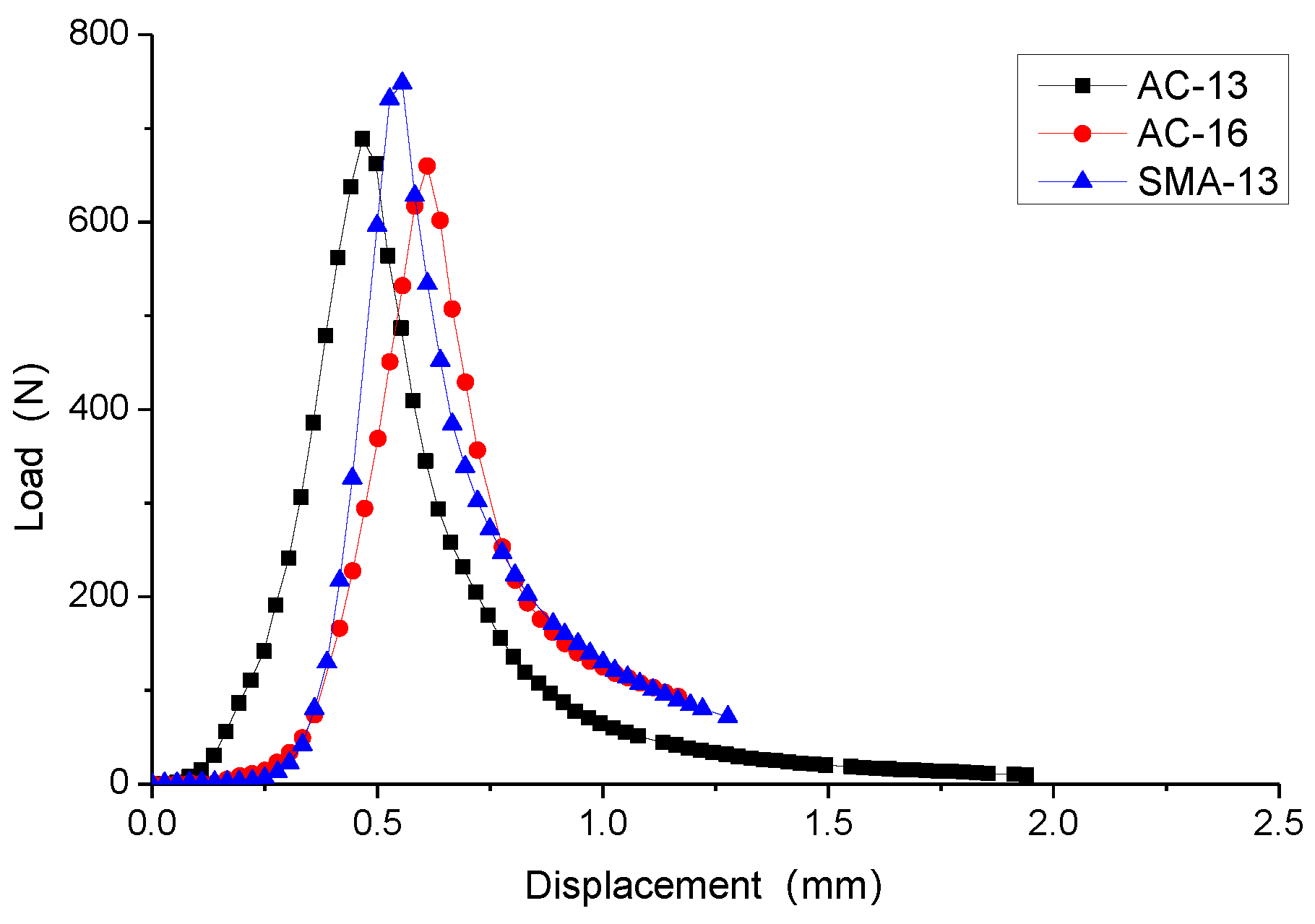

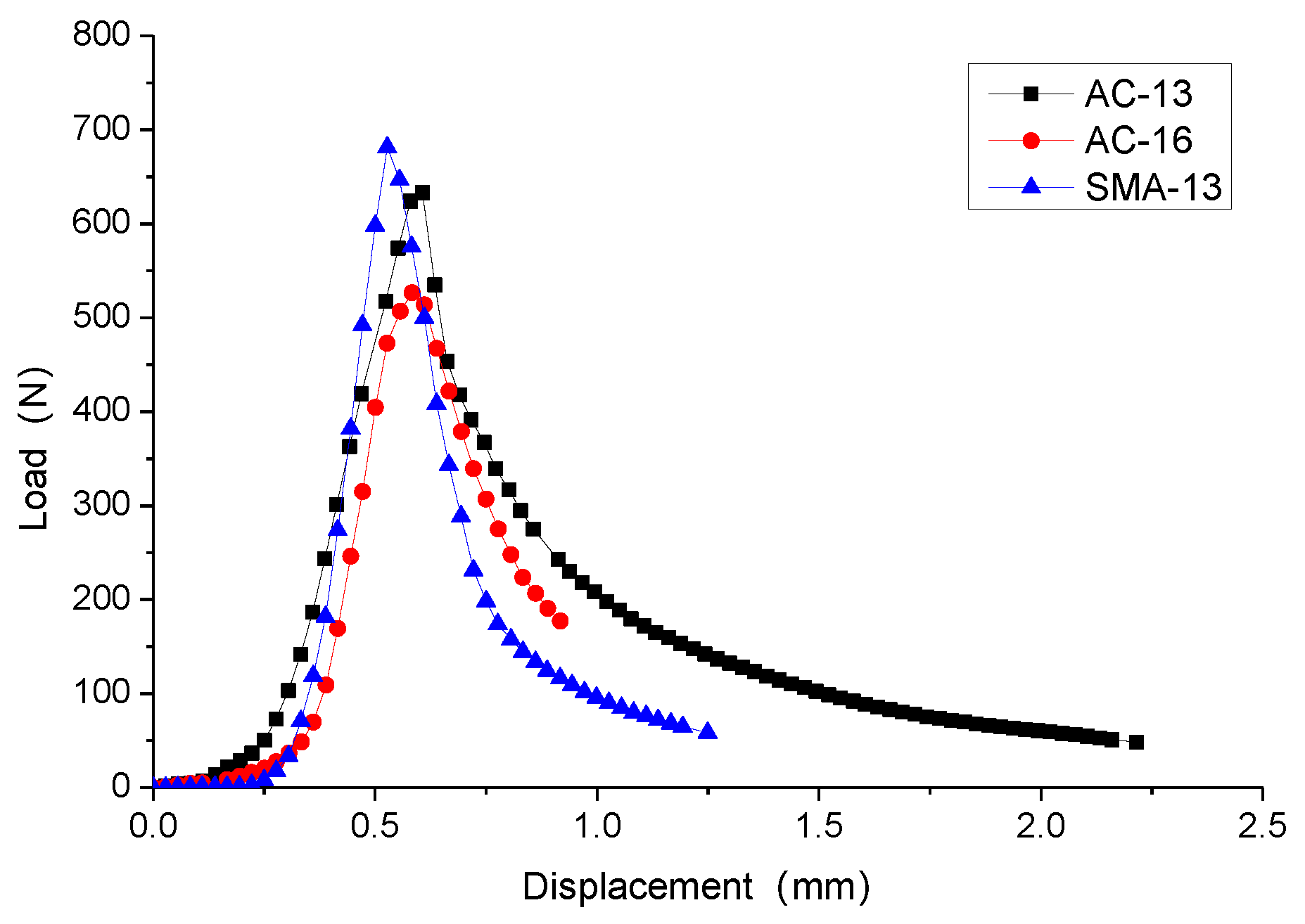

- (2)

- Test results at different notch depths

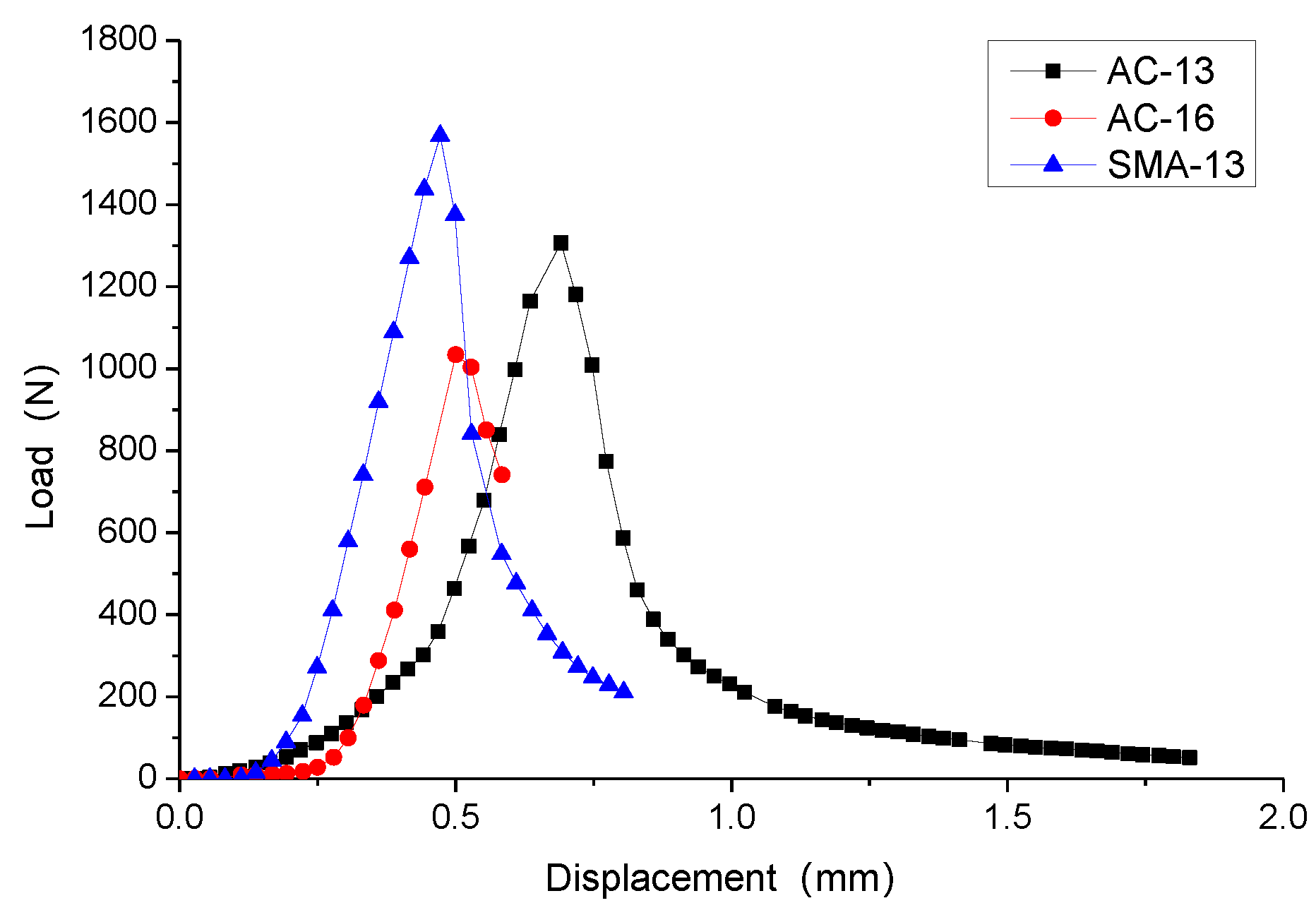

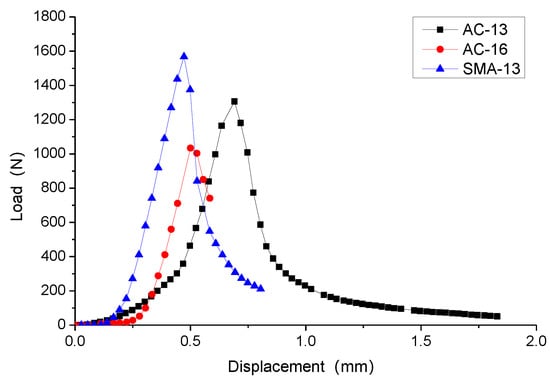

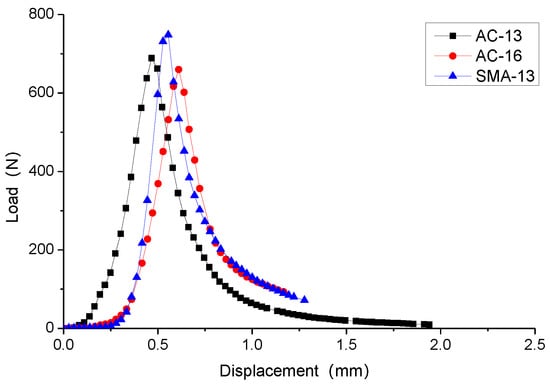

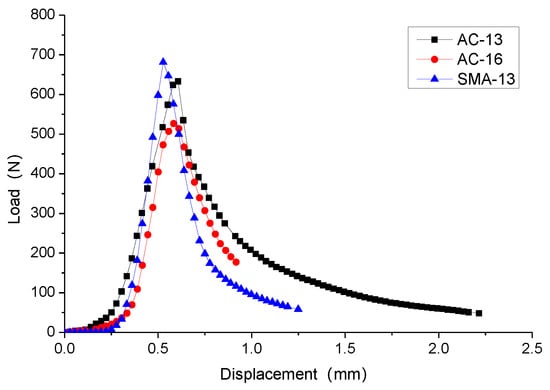

The pre-cracked beam bending test of SBS-modified AC-13, SBS-modified AC-16, and SBS-modified SMA-13 asphalt mixtures was conducted at the temperature of −10 °C. The depths of the beam notch were 0, 4, 8, and 12 mm. The load deflection curve is shown in Figure 4, Figure 5, Figure 6 and Figure 7.

Figure 4.

Load-displacement diagram of asphalt mixture beams with a notch depth of 0 mm.

Figure 5.

Load-displacement diagram of asphalt mixture beams with a notch depth of 4 mm.

Figure 6.

Load-displacement diagram of asphalt mixture beams with a notch depth of 8 mm.

Figure 7.

Load-displacement diagram of asphalt mixture beams with a notch depth of 12 mm.

In the above figures, no evident change is observed in the variation rate of the three load-displacement curves at different notch depths. This shows that the deformation resistance and low-temperature crack resistance of mixtures are not correlated with the notch depth. When the un-notched asphalt mixture specimens and the specimens with shallow notches break, their displacement is discrete. However, as the notch depth increases, the displacement tends to concentrate. The load values at the failure of the three asphalt mixtures are close at different notch depths. Specifically, SMA-13 has the largest load at failure, followed by AC-13 and AC-16 successively.

3.3.2. Flexural Strength Analysis

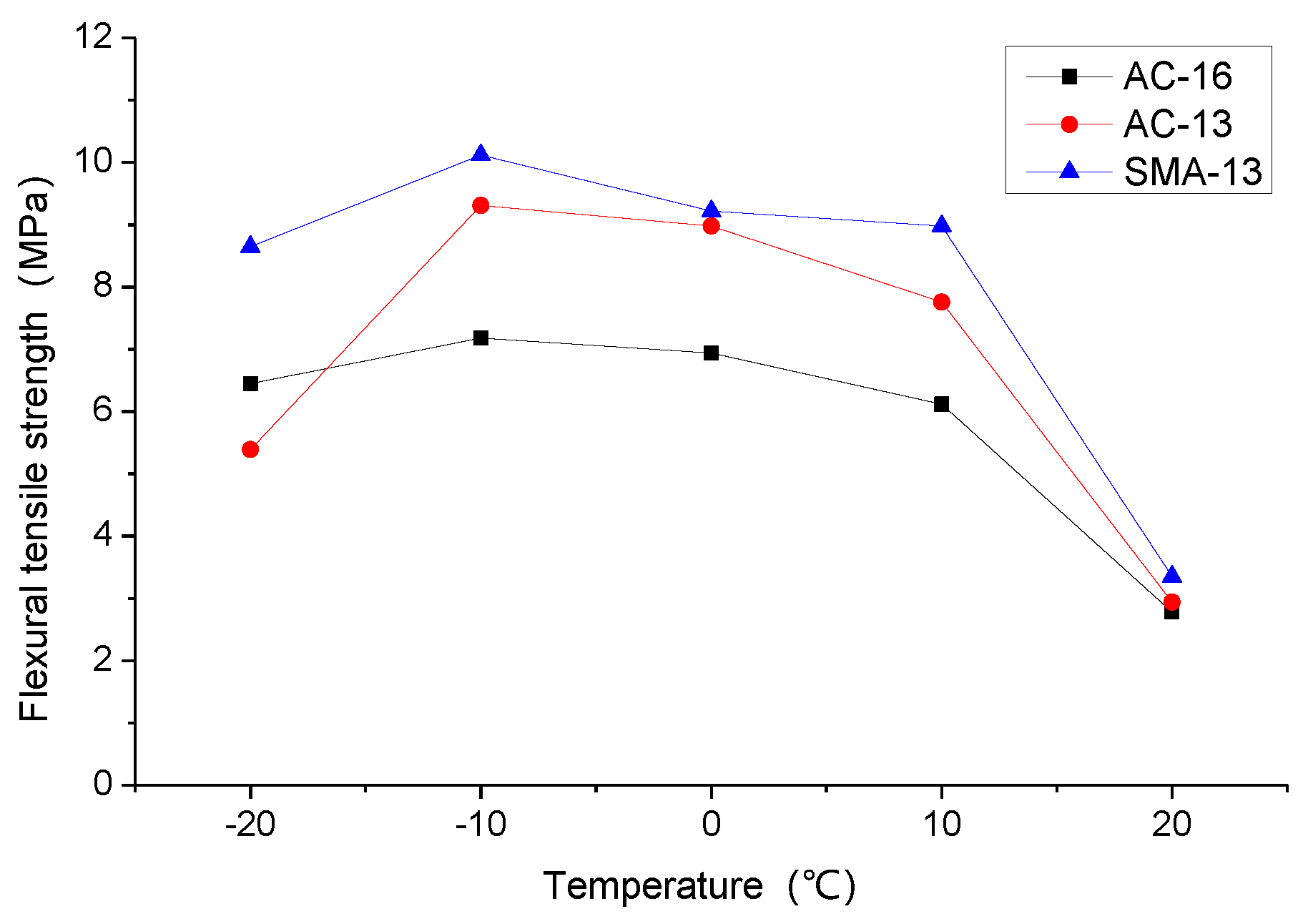

- (1)

- Test results at different temperatures

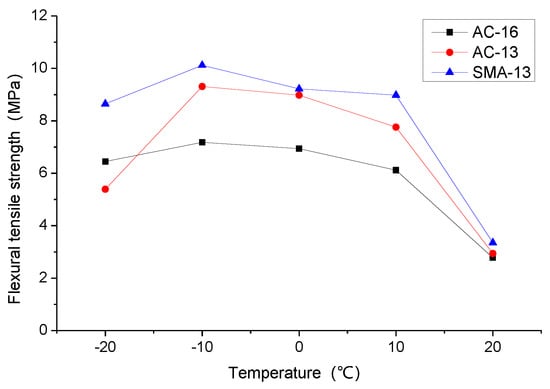

The flexural strength of the three asphalt mixtures with a notch depth of 4 mm at different test temperatures is illustrated in Figure 8.

Figure 8.

Flexural strength of asphalt mixtures at different test temperatures.

According to the above figure, the flexural strength of AC-13, AC-16, and SMA-13 asphalt mixtures has a similar change trend with temperature. Specifically, their flexural strength increases first and then decreases with the reducing temperature. Their flexural strength is ranked as AC-16 < AC-13 < SMA-13. In the range of −20 °C~ −10 °C, the flexural strength increases with the rising temperature. As the temperature climbs from −10 to 10 °C, the flexural strength decreases. When the temperature rises from 10 to 20 °C, the flexural strength decreases at a faster speed. Therefore, it can be considered that 10~20 °C is a sensitive temperature range for flexural tensile strength. At −10 °C, the flexural tensile strength of asphalt mixture reaches the maximum, which can be called embrittlement temperature. When the temperature is higher than the embrittlement temperature, the material shows notable yield failure characteristics. In the crack propagation process, when the flexural strength increases with the dropping temperature, there is a relatively slow subcritical expansion stage. When the temperature is reduced below the embrittlement temperature, the material has remarkable brittle failure features. The subcritical expansion stage lasts for a short time, and the flexural strength decreases as the temperature declines. At a temperature above 10 °C, the asphalt mixture is viscoelastic, with strong rheological properties. The decrease rate of the flexural strength with the increasing temperature above 10 °C is different from that below 10 °C.

- (2)

- Test results at different notch depths

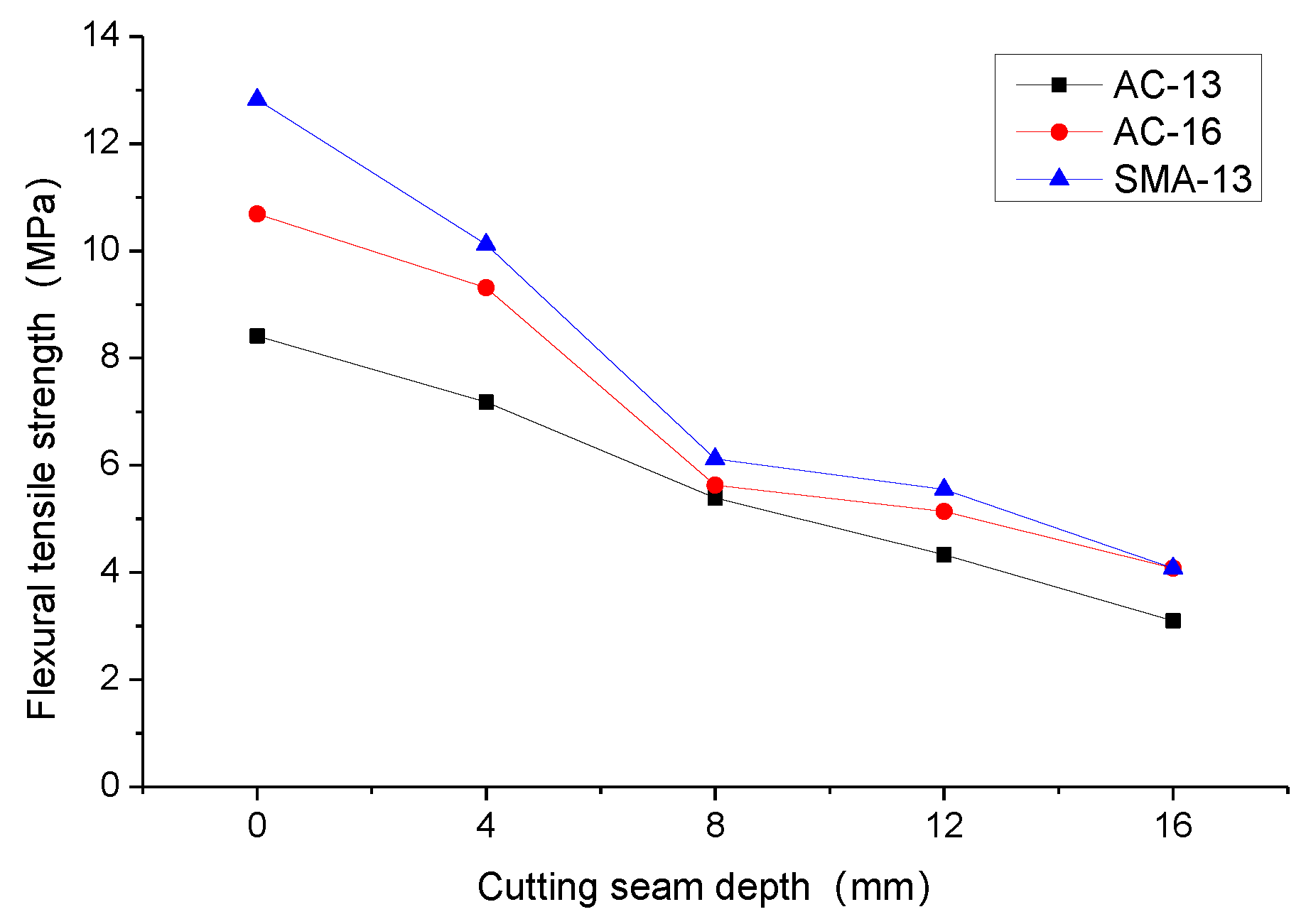

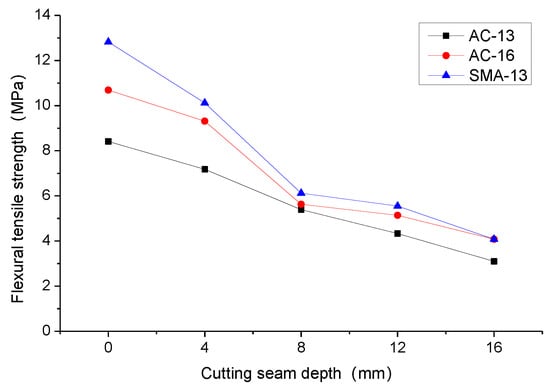

The flexural strength of three asphalt mixtures with different notch depths at the test temperature of −10 °C is shown in Figure 9.

Figure 9.

Flexural strength of asphalt mixtures at different notch depths.

It can be seen from the above figure that the flexural strength of the mixtures decreases with the increasing notch depth, and the difference in flexural strength among the three asphalt mixtures gradually narrows.

3.3.3. Fracture Toughness Analysis

Fracture toughness is defined as the toughness of the material to resist crack propagation fracture. The bending test of the pre-cracked beam specimens was carried out, and the fracture toughness was calculated.

- (1)

- Asphalt mixture fracture toughness at different temperatures

The fracture toughness of three asphalt mixtures with a notch depth of 4 mm at different temperatures is demonstrated in Table 11.

Table 11.

Fracture toughness of asphalt mixtures at different temperatures ().

In the above table, SMA-13 has the largest fracture toughness at different test temperatures, followed by AC-13 and AC-16 successively. This shows that SMA-13 has the best crack resistance, followed by AC-13. AC-16 has the worst crack resistance. Based on the variation in fracture toughness with temperature, the three types of asphalt mixtures have the maximal fracture toughness at the test temperature of −10 °C.

- (2)

- Asphalt mixture fracture toughness at different notch depths

The fracture toughness of three asphalt mixtures with different notch depths at the test temperature of −10 °C is described in Table 12.

Table 12.

Fracture toughness of asphalt mixtures at different notch depths ().

According to the above table, for AC-13 asphalt mixtures, except for the fracture toughness with 8mm notch depth, the fracture toughness with other notch depths is close. The deviation between the maximum and minimum values is 11.95%. For AC-16 asphalt mixtures, the fracture toughness values at different notch depths are close, and the deviation between the maximum and the minimum is 14.00%. For SMA-13 asphalt mixtures, the fracture toughness values at notch depths of 0, 4, and 12 mm are similar, but differ from that at the notch depth of 8 mm. The deviation between the maximum and the minimum is 3.78%. Excluding the influence of test errors, the same type of asphalt mixture has similar fracture toughness at different notch depths. The results show that the initial crack depth has little effect on the fracture toughness of asphalt mixture at low temperature.

4. Conclusions

In this paper, we analyzed the factors influencing the facture characteristics of asphalt mixtures in high altitude and cold regions with large temperature differences, and simulated the conditions in these regions. A variety of asphalt mixtures with different aggregate gradations were manufactured from various asphalt types. Besides, the TSRST and low-temperature bending test were conducted to study the fracture characteristics of asphalt mixtures in high altitude and cold regions with large temperature differences. The main conclusions are as follows:

- (1)

- The low-temperature performance of asphalt mixture evaluated according to the frost-break temperature, flexural strength, and fracture toughness is in good consistency. The low temperature, large temperature differences, cooling rate and mixture raw materials have an important influence on the fracture characteristics of asphalt mixtures.

- (2)

- The weight coefficient of the frost-break temperature obtained by the TSRST test is 56.290%, which can best reflect the crack resistance of the material. Moreover, the frost-break temperature is directly related to the low-temperature cracking of asphalt pavement, and it has a specific physical significance. Therefore, the frost-break temperature is recommended to assess the low-temperature performance of asphalt mixtures.

- (3)

- The asphalt type and mixture type have a significant effect on the fracture characteristics of asphalt mixture. The frost-break temperature of matrix asphalt mixture is 8–10 °C higher than that of modified asphalt mixture, and AC asphalt mixture is 2–4 °C higher than that of SMA asphalt mixture. The excellent asphalt performance has a more important influence on the fracture characteristics of asphalt mixture.

- (4)

- In the low-temperature bending test of notched beams, the flexural strength decreases with the increasing notch depth. SMA-13 has the best low-temperature performance, followed by AC-13 and AC-16 successively. The fracture toughness values of the same asphalt mixture at different notch depths are close, and the deviation between the maximum and the minimum is 3.78%, so the initial crack depth has little effect on the fracture toughness of asphalt mixture at low temperature.

Author Contributions

S.W.: Conceptualization, Methodology, Validation, Investigation, Writing—original draft. H.C.: Conceptualization, Writing—review and editing, Supervision, Project administration, Resources, Funding acquisition. T.C.: Methodology, Writing—review and editing. W.K.: Methodology, Writing—review and editing. W.B.: Writing—review and editing, Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Key R&D Program of China (Grant No. 2021YFB2601200), National Natural Science Foundation of China (No. 52178419), Transportation Industry Key Science and Technology Projects of China (No. 2020-MS1-059) and Youth Science and Technology Innovation Fund project of FHCC (No. YGY2019QC-02).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on reasonable request.

Acknowledgments

Thanks is also to Biao Ding who proposed the idea of the performance test in the current study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Vinson, T.S.; Hicks, R.G.; Janoo, V.C. Low temperature cracking and rutting in asphalt concrete pavements. In Roads and Airfields in Cold Regions; Technical Council on Cold Regions Engineering Monograph; American Society of Civil Engineers: Reston, VA, USA, 1996; pp. 203–248. [Google Scholar]

- Dore, G. Cold Region Pavement. J. Glaciol. Geocryol. 2002, 24, 593–600. [Google Scholar]

- Cao, H.; Chen, T.; Zhu, H.; Ren, H. Influence of Frequent Freeze-Thaw Cycles on Performance of Asphalt Pavement in High-Cold and High-Altitude Areas. Coatings 2022, 12, 752. [Google Scholar] [CrossRef]

- Shahin, M.Y.; McCullough, B.F. Damage Model for Predicting Temperature Cracking in Flexible Pavements; University of Texas: Austin, TX, USA, 1974. [Google Scholar]

- Little, D.N.; Mahboub, K. Engineering properties of first generation plasticized sulfur binders and low temperature fracture evaluation of plasticized sulfur paving mixtures. Transp. Res. Rec. 1985, 1034, 103–111. [Google Scholar]

- Luo, X.; Luo, R.; Lytton, R.L. Characterization of fatigue damage in asphalt mixtures using pseudostrain energy. J. Mater. Civ. Eng. 2012, 25, 208–218. [Google Scholar] [CrossRef]

- Xiao, F.; Zhao, W.; Amirkhanian, S.N. Laboratory investigation of fatigue characteristics of rubberized asphalt mixtures containing warm asphalt additives at a low temperature. J. Test. Eval. 2011, 39, 1. [Google Scholar]

- Eshan, V.D.; Leon, S.; Park, K. Thermal Cracking Prediction Model and Software for Asphalt Pavements. In Proceedings of the Congress of Transportation and Development Institute of the American Society of Civil Engineers 2011, Chicago, IL, USA, 13–16 March 2011; pp. 667–676. [Google Scholar]

- Wei, Y.; Hu, H.; Chu, K. Asphalt mixture’s flexural-tensile strength’s influencing factor in plateau area. West. China Commun. Sci. Technol. 2009, 5, 5–7. [Google Scholar]

- Kliewer, J.E.; Zeng, H.; Vinson, T.S. Aging and low-temperature cracking of asphalt concrete mixture. J. Cold Reg. Eng. 1996, 10, 134–148. [Google Scholar] [CrossRef]

- Guo, B.; Gao, N. Effect of component factors of asphalt mixture on pavement performance in areas with big temperature difference. Road Mach. Constr. Mech. 2017, 34, 81–85. [Google Scholar]

- Li, D.; Meng, Q.; Fang, J. Test and Research on performance of Frost Thawing Resistance of Asphalt Mixture. Highway 2007, 12, 145–147. [Google Scholar]

- Hao, P.; Zhang, D. Research on Evaluation Target for the Cracking Resistance Property of Bituminous Mixture in Low Temperature. Highway 2000, 45, 63–67. [Google Scholar]

- Lu, S.; Tian, X.; Zheng, J. Simulation Research on Thermal Fatigue Damage to Bituminous Mixture. Highway 2005, 2, 116–118. [Google Scholar]

- Guo, W.; Zhang, Z. Influence of ray aging on low temperature performance of asphalt mixture in plateau-cold region. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2012, 31, 51–53. [Google Scholar]

- Zhang, Y. Study on Low Temperature Crack Resistance and Mix Design Method of Asphalt Mixture in Permafrost Regions; Chang’an University: Xi’an, China, 2004. [Google Scholar]

- Fu, Q. Analysis of temperature fatigue expansion life of asphalt pavement cracks. In Proceedings of the 10th China Association for Science and Technology Annual Conference of China Association for Science and Technology and Henan Provincial People’s Government, Zhengzhou, China, 1 September 2008; pp. 9–11. [Google Scholar]

- Krcmarik, M.; Varma, S.; Kutay, M.E.; Jamrah, A. Development of Predictive Models for Low-Temperature Indirect Tensile Strength of Asphalt Mixtures. J. Mater. Civ. Eng. 2016, 28, 04016139. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Evaluation of engineering, economic and environmental suitability of waste filler incorporated asphalt mixes and pavements. Road Mater. Pavement Des. 2021, 22, S624–S640. [Google Scholar] [CrossRef]

- Wen, H. Use of fracture work density obtained from indirect tensile testing for the mix design and development of a fatigue model. Int. J. Pavement Eng. 2013, 14, 561–568. [Google Scholar] [CrossRef]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. Ministry of Communications: Beijing, China, 2004.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transportation: Beijing, China, 2011.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).