High-Performance Pure Aluminum Coatings on Stainless Steels by Cold Spray

Abstract

:1. Introduction

2. Materials and Methods

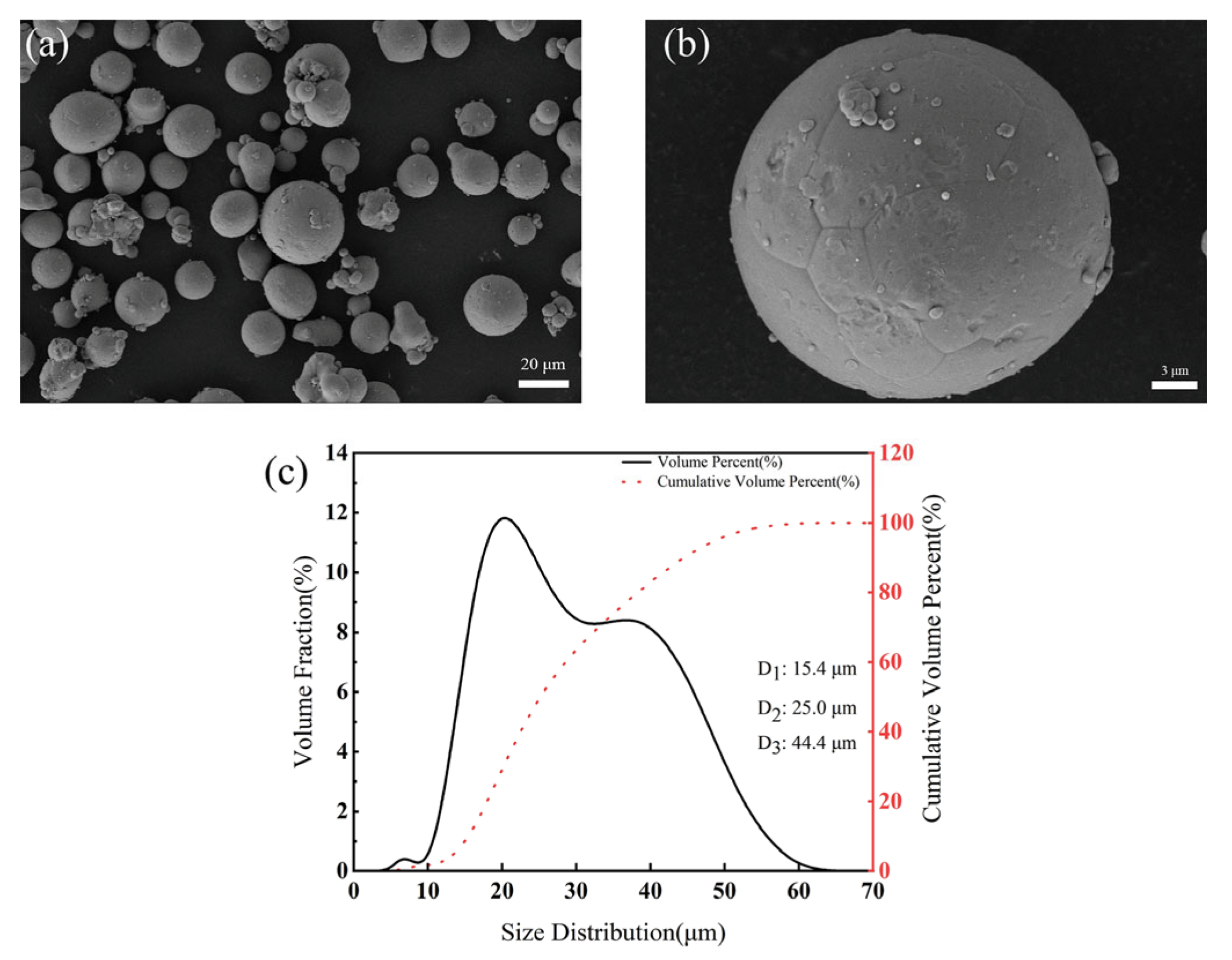

2.1. Experimental Materials

2.2. Coating Preparation

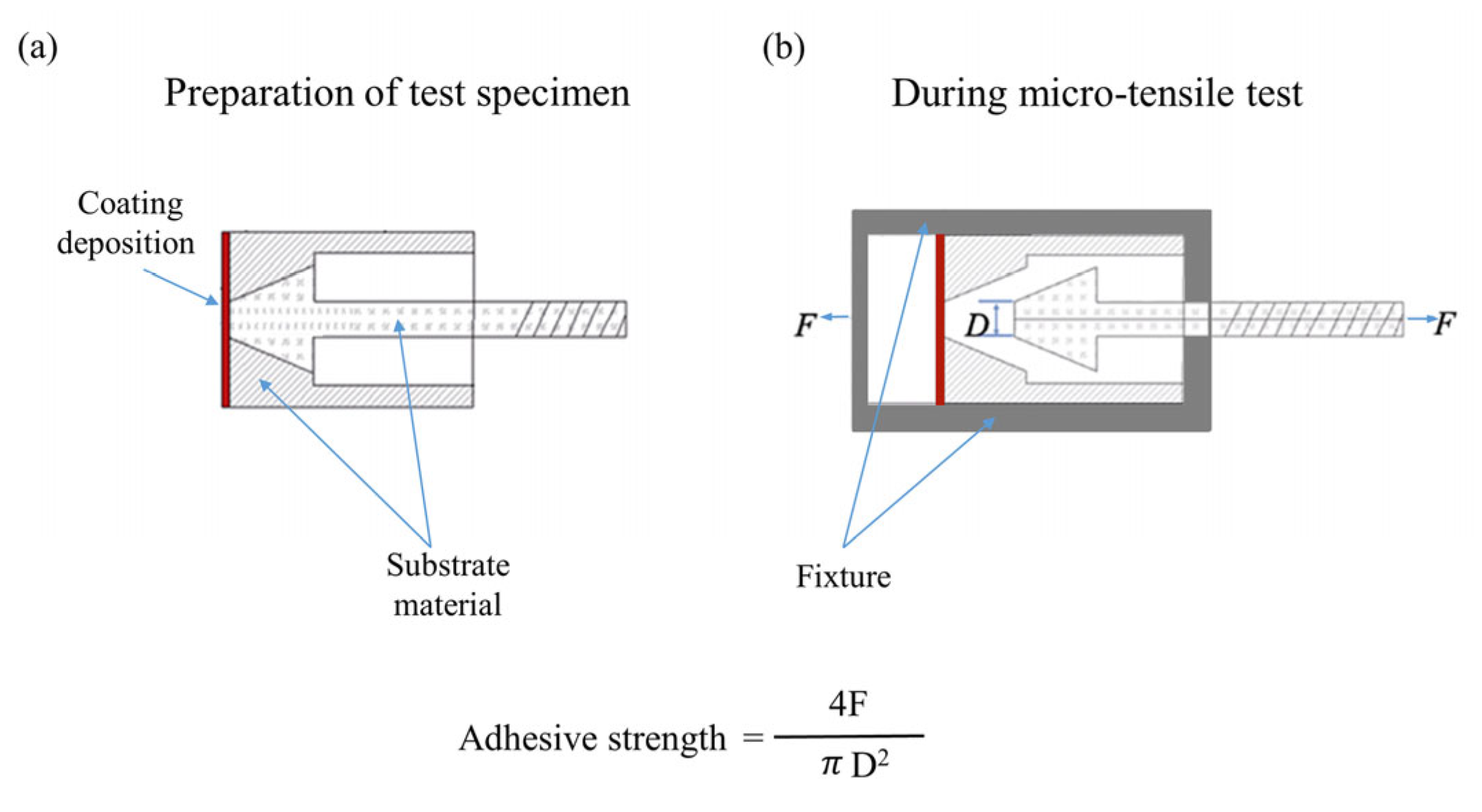

2.3. Sample Characterization

3. Results and Discussion

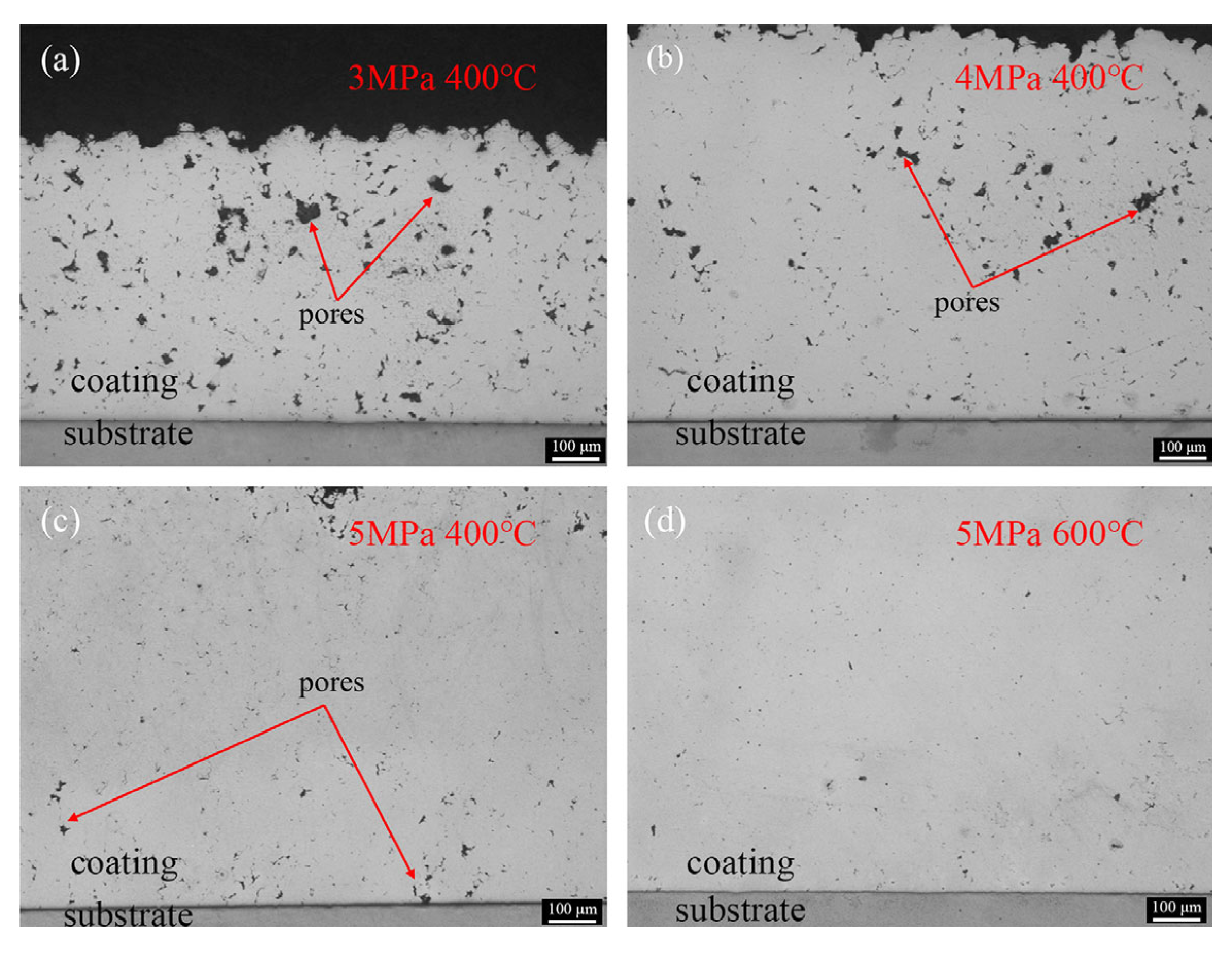

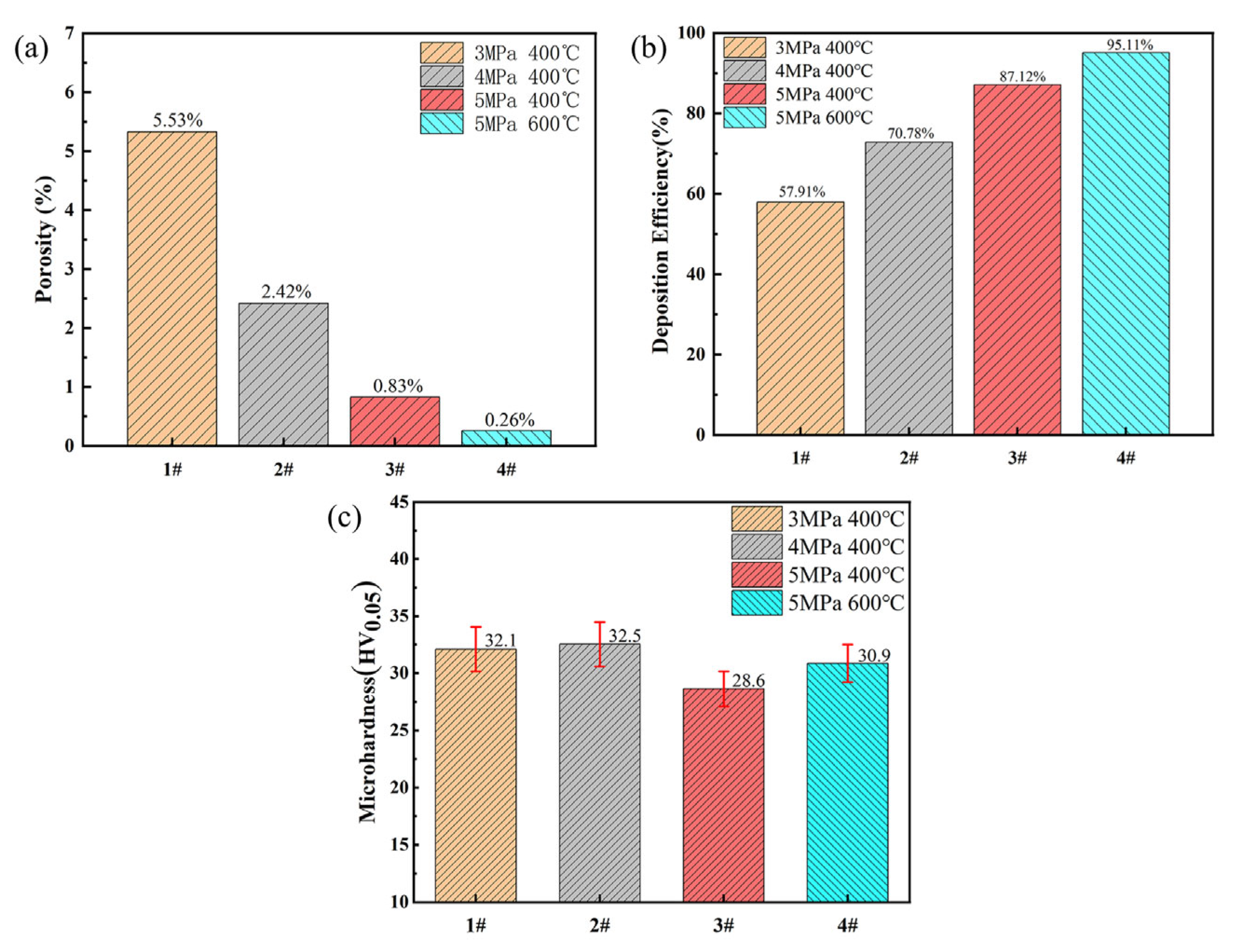

3.1. Microstructure and Microhardness

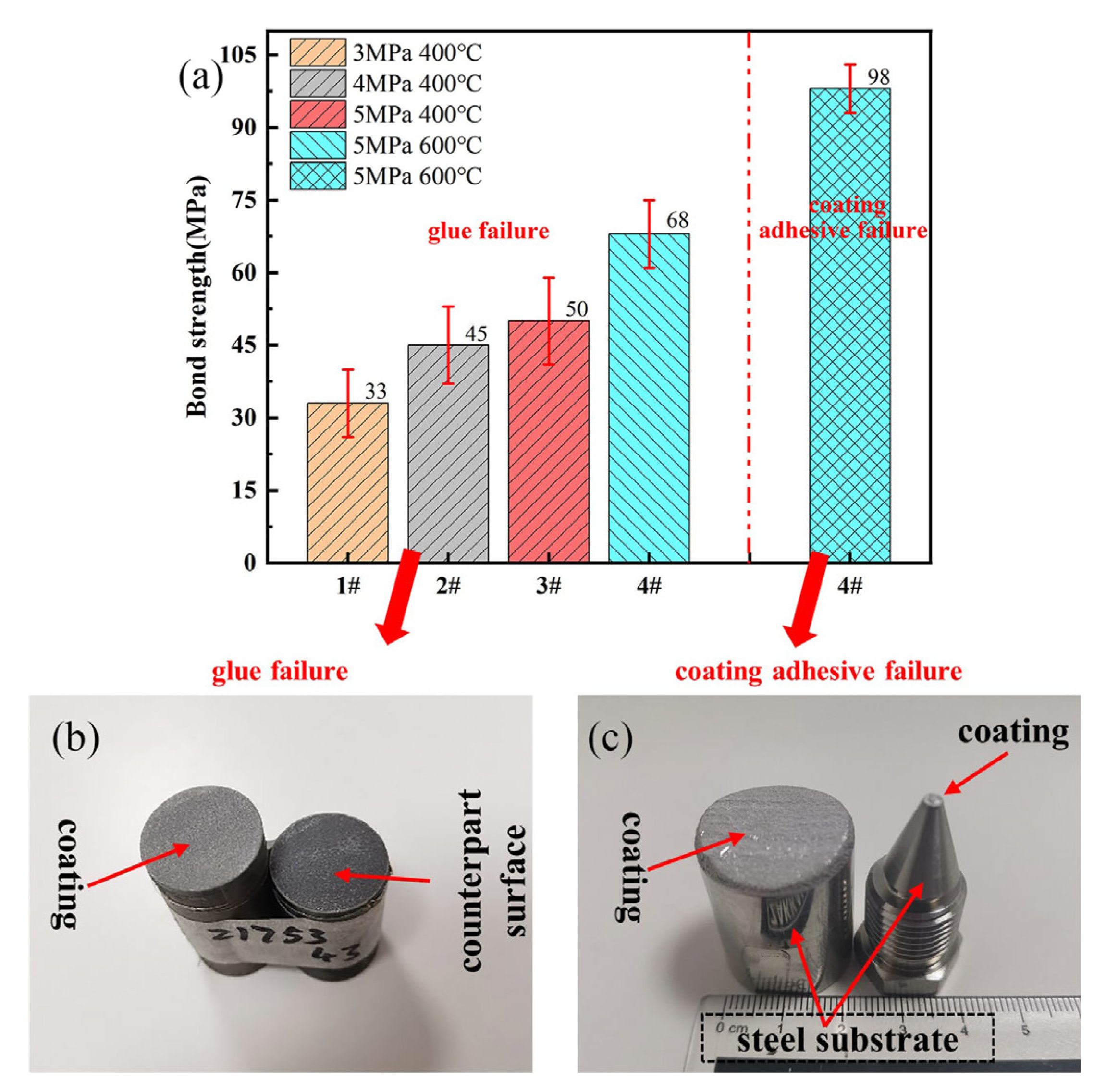

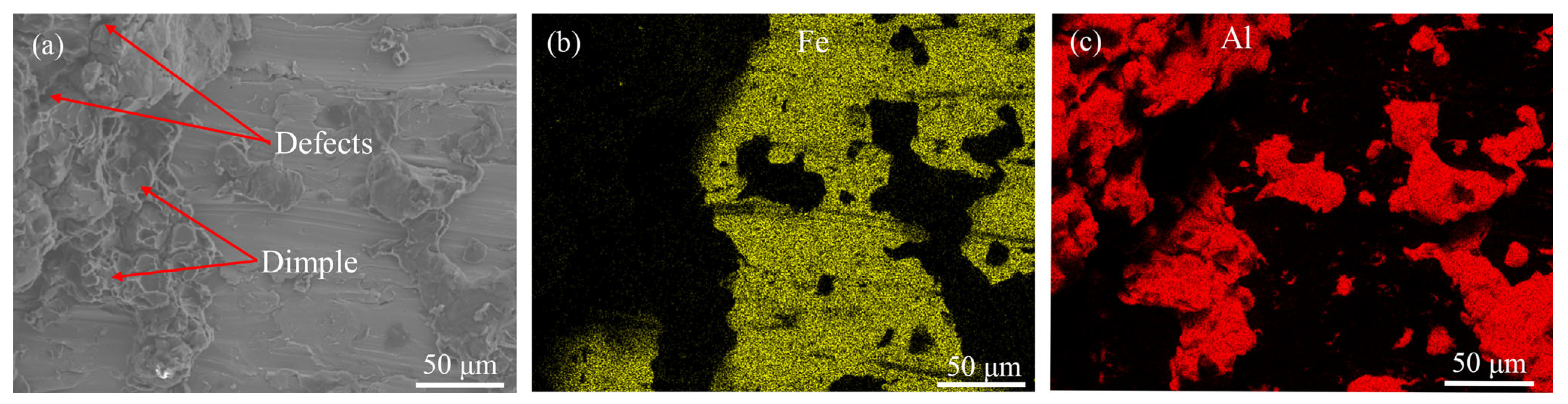

3.2. Bond Strength

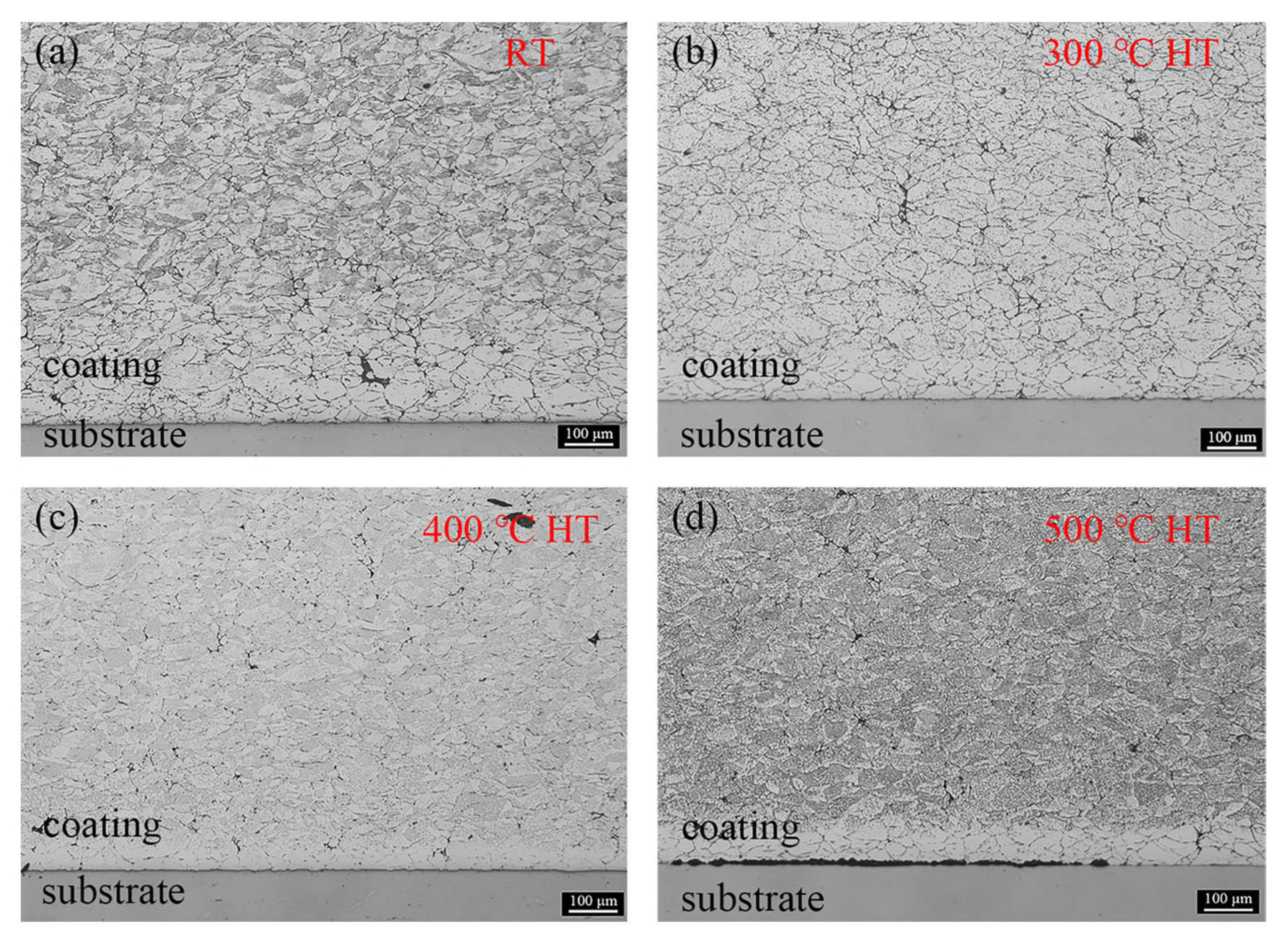

3.3. Heat Treatment

4. Conclusions

- (1)

- Using N2 as the carrier gas, pure aluminum coatings with excellent interfacial bonding were successfully prepared on the 304 stainless steel surface. The coating has good overall performance under the process parameters of 5 MPa 600 °C, the bonding strength is ~98 MPa, the DE is ~95%, and the coating porosity is ~0.3%.

- (2)

- With the increase of heat treatment temperature, the cold-sprayed aluminum coating becomes more homogenous in the microstructure, its microhardness is reduced, and the adhesive strength seems to be slightly reduced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barajas-Valdes, U.; Suárez, O.M. Nanomechanical properties of thin films manufactured via magnetron sputtering from pure aluminum and aluminum-boron targets. Thin Solid Film. 2020, 693, 137670. [Google Scholar] [CrossRef]

- Warren, T.L. The effect of target inertia on the penetration of aluminum targets by rigid ogive-nosed long rods. Int. J. Impact Eng. 2016, 91, 6–13. [Google Scholar] [CrossRef]

- Tang, E.; Zhao, L.; Han, Y.; Chen, C.; Chang, M. Research on the electromagnetic propagating characteristics of hypervelocity impact on the target with aperture and different potential conditions. Aerosp. Sci. Technol. 2020, 107, 106274. [Google Scholar] [CrossRef]

- Rajesh Kumar, B.; Hymavathi, B.; Subba Rao, T. XRD and AFM Studies on Nanostructured Zinc Aluminum Oxide Thin Films Prepared by Multi-Target Magnetron Sputtering. Mater. Today Proc. 2017, 4, 8638–8644. [Google Scholar] [CrossRef]

- Patil, U.S.; Kadam, M.S. Microstructural analysis of SMAW process for joining stainless steel 304 with mild steel 1018 and parametric optimization by using response surface methodology. Mater. Today Proc. 2021, 44, 1811–1815. [Google Scholar] [CrossRef]

- Li, Z.X.; Zhang, L.M.; Ma, A.L.; Hu, J.X.; Zhang, S.; Daniel, E.F.; Zheng, Y.G. Comparative study on the cavitation erosion behavior of two different rolling surfaces on 304 stainless steel. Tribol. Int. 2021, 159, 106994. [Google Scholar] [CrossRef]

- Liao, H.; Zhang, W.; Xie, H.; Li, X.; Zhang, Q.; Wu, X.; Tian, J.; Wang, Z. Effects of welding speed on welding process stability, microstructure and mechanical performance of SUS304 welded by local dry underwater pulsed MIG. J. Manuf. Process. 2023, 88, 84–96. [Google Scholar] [CrossRef]

- Bai, M.; Reddy, L.; Hussain, T. Experimental and thermodynamic investigations on the chlorine-induced corrosion of HVOF thermal sprayed NiAl coatings and 304 stainless steels at 700 °C. Corros. Sci. 2018, 135, 147–157. [Google Scholar] [CrossRef]

- Gorlach, I.A. A new method for thermal spraying of Zn–Al coatings. Thin Solid Film. 2009, 517, 5270–5273. [Google Scholar] [CrossRef]

- Gibbons, G.J.; Hansell, R.G. Thermal-sprayed coatings on aluminium for mould tool protection and upgrade. J. Mater. Process. Technol. 2008, 204, 184–191. [Google Scholar] [CrossRef]

- Sun, B.; Fukanuma, H.; Ohno, N. Study on stainless steel 316L coatings sprayed by a novel high pressure HVOF. Surf. Coat. Technol. 2014, 239, 58–64. [Google Scholar] [CrossRef]

- Han, M.-S.; Woo, Y.-B.; Ko, S.-C.; Jeong, Y.-J.; Jang, S.-K.; Kim, S.-J. Effects of thickness of Al thermal spray coating for STS 304. Trans. Nonferrous Met. Soc. China 2009, 19, 925–929. [Google Scholar] [CrossRef]

- Yin, S.; Suo, X.; Guo, Z.; Liao, H.; Wang, X. Deposition features of cold sprayed copper particles on preheated substrate. Surf. Coat. Technol. 2015, 268, 252–256. [Google Scholar] [CrossRef]

- Srikanth, A.; Mohammed Thalib Basha, G.; Venkateshwarlu, B. A Brief Review on Cold Spray Coating Process. Mater. Today Proc. 2020, 22, 1390–1397. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Fatigue performance of cold spray deposits: Coating, repair and additive manufacturing cases. Int. J. Fatigue 2020, 139, 105744. [Google Scholar] [CrossRef]

- Meng, X.-M.; Zhang, J.-B.; Han, W.; Zhao, J.; Liang, Y.-L. Influence of annealing treatment on the microstructure and mechanical performance of cold sprayed 304 stainless steel coating. Appl. Surf. Sci. 2011, 258, 700–704. [Google Scholar] [CrossRef]

- Coddet, P.; Verdy, C.; Coddet, C.; Debray, F.; Lecouturier, F. Mechanical properties of thick 304L stainless steel deposits processed by He cold spray. Surf. Coat. Technol. 2015, 277, 74–80. [Google Scholar] [CrossRef]

- Meng, X.; Zhang, J.; Zhao, J.; Liang, Y.; Zhang, Y. Influence of Gas Temperature on Microstructure and Properties of Cold Spray 304SS Coating. J. Mater. Sci. Technol. 2011, 27, 809–815. [Google Scholar] [CrossRef]

- Rokni, M.R.; Widener, C.A.; Champagne, V.R. Microstructural stability of ultrafine grained cold sprayed 6061 aluminum alloy. Appl. Surf. Sci. 2014, 290, 482–489. [Google Scholar] [CrossRef]

- Bu, H.; Yandouzi, M.; Lu, C.; Jodoin, B. Post-heat Treatment Effects on Cold-Sprayed Aluminum Coatings on AZ91D Magnesium Substrates. J. Therm. Spray Technol. 2012, 21, 731–739. [Google Scholar] [CrossRef]

- Blochet, Q.; Delloro, F.; N’Guyen, F.; Jeulin, D.; Borit, F.; Jeandin, M. Effect of the Cold-Sprayed Aluminum Coating-Substrate Interface Morphology on Bond Strength for Aircraft Repair Application. J. Therm. Spray Technol. 2017, 26, 671–686. [Google Scholar] [CrossRef]

- Luo, X.-T.; Li, S.-P.; Li, G.-C.; Xie, Y.-C.; Zhang, H.; Huang, R.-Z.; Li, C.-J. Cold spray (CS) deposition of a durable silver coating with high infrared reflectivity for radiation energy saving in the polysilicon CVD reactor. Surf. Coat. Technol. 2021, 409, 126841. [Google Scholar] [CrossRef]

- Levasseur, D.; Yue, S.; Brochu, M. Pressureless sintering of cold sprayed Inconel 718 deposit. Mater. Sci. Eng. A 2012, 556, 343–350. [Google Scholar] [CrossRef]

- Song, X.; Jin, X.-Z.; Zhai, W.; Tan, A.W.-Y.; Sun, W.; Li, F.; Marinescu, I.; Liu, E. Correlation between the macroscopic adhesion strength of cold spray coating and the microscopic single-particle bonding behaviour: Simulation, experiment and prediction. Appl. Surf. Sci. 2021, 547, 149165. [Google Scholar] [CrossRef]

- Xie, Y.; Planche, M.-P.; Raoelison, R.; Hervé, P.; Suo, X.; He, P.; Liao, H. Investigation on the influence of particle preheating temperature on bonding of cold-sprayed nickel coatings. Surf. Coat. Technol. 2017, 318, 99–105. [Google Scholar] [CrossRef]

- Wong, W. Understanding the Effects of Process Parameters on the Properties of Cold Gas Dynamic Sprayed Pure Titanium Coatings; McGill University: Montréal, QC, Canada, 2012. [Google Scholar]

- Wei, Y.-K.; Luo, X.-T.; Chu, X.; Huang, G.-S.; Li, C.-J. Solid-state additive manufacturing high performance aluminum alloy 6061 enabled by an in-situ micro-forging assisted cold spray. Mater. Sci. Eng. A 2020, 776, 139024. [Google Scholar] [CrossRef]

| No. | Carrier Gas | Gas Pressure (MPa) | Gas Temperature (°C) | Spray Distance (mm) |

|---|---|---|---|---|

| 1# | N2 | 3 | 400 | 20 |

| 2# | N2 | 4 | 400 | 20 |

| 3# | N2 | 5 | 400 | 20 |

| 4# | N2 | 5 | 600 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Yun, H.; Zhang, X.; Chang, D.; Chu, X.; Xie, Y.; Huang, G. High-Performance Pure Aluminum Coatings on Stainless Steels by Cold Spray. Coatings 2023, 13, 738. https://doi.org/10.3390/coatings13040738

Fan J, Yun H, Zhang X, Chang D, Chu X, Xie Y, Huang G. High-Performance Pure Aluminum Coatings on Stainless Steels by Cold Spray. Coatings. 2023; 13(4):738. https://doi.org/10.3390/coatings13040738

Chicago/Turabian StyleFan, Jialin, Haitao Yun, Xiaoqiang Zhang, Dongxu Chang, Xin Chu, Yingchun Xie, and Guosheng Huang. 2023. "High-Performance Pure Aluminum Coatings on Stainless Steels by Cold Spray" Coatings 13, no. 4: 738. https://doi.org/10.3390/coatings13040738

APA StyleFan, J., Yun, H., Zhang, X., Chang, D., Chu, X., Xie, Y., & Huang, G. (2023). High-Performance Pure Aluminum Coatings on Stainless Steels by Cold Spray. Coatings, 13(4), 738. https://doi.org/10.3390/coatings13040738