An Experimental Study on Biochar/Polypyrrole Coating for Blade Anti-Icing of Wind Turbines

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Materials and Preparation

2.2. Characterization Method and Equipment

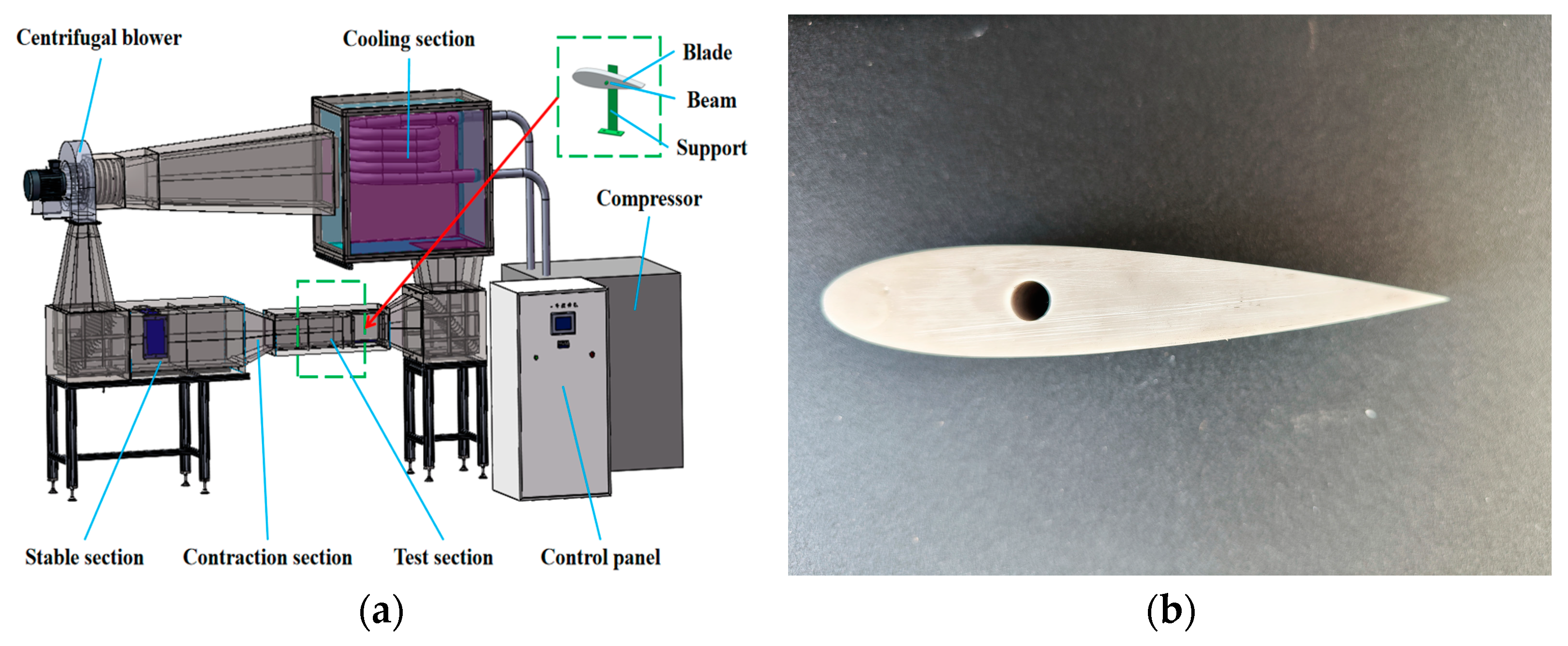

2.3. Anti-Icing Test System and Method

2.4. Adhesion Test of Ice

2.5. Stability Test

3. Results

3.1. Main Physical Property Test of Coating

3.1.1. Fourier Transform Infrared Spectroscopy (FT-IR)

3.1.2. Morphology and Surface Analysis

3.1.3. Static Contact Angle and Sliding Angle Analysis

3.1.4. Blade Icing Bond Strength Test

3.1.5. Stability Test

3.2. Anti-Icing Test of Coating

3.2.1. Icing Distribution

3.2.2. Icing Area

3.2.3. Maximum Icing Thickness of Leading Edge

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, T.; Jiaqiang, E.; Yang, W.M.; Deng, Y.; An, H.; Zhang, Z.; Pham, M. Investigation on the applicability for adjusting reaction rates of the optimized biodiesel skeletal mechanism. Energy 2018, 150, 1031–1038. [Google Scholar] [CrossRef]

- Tong, G.; Li, Y.; Tagawa, K.; Feng, F. Effects of blade airfoil chord length and rotor diameter on aerodynamic performance of straight-bladed vertical axis wind turbines by numerical simulation. Energy 2023, 265, 126325. [Google Scholar] [CrossRef]

- Mu, Z.; Li, Y.; Guo, W.; Shen, H.; Tagawa, K. An Experimental Study on Adhesion Strength of Offshore Atmospheric Icing on a Wind Turbine Blade Airfoil. Coatings 2023, 13, 164. [Google Scholar] [CrossRef]

- Li, Y.; Shen, H.; Guo, W. Simulation and experimental study on the ultrasonic micro-vibration de-icing method for wind turbine blades. Energies 2021, 14, 8246. [Google Scholar] [CrossRef]

- Guo, W.; Shen, H.; Li, Y.; Feng, F.; Tagawa, K. Wind tunnel tests of the rime icing characteristics of a straight-bladed vertical axis wind turbine. Renew. Energy 2021, 179, 116–132. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, Y.; Xu, X.; Meng, X.; Qu, J.; Wang, Z.; Liu, C.; Qu, B. Preparation, characterization and application of activated carbon from corn cob by KOH activation for removal of Hg(II) from aqueous solution. Bioresour. Technol. 2020, 306, 123154. [Google Scholar] [CrossRef]

- Li, Y.; Tagawa, K.; Feng, F.; Li, Q.; He, Q. A wind tunnel experimental study of icing on wind turbine blade airfoil. Energy Convers. Manag. 2014, 85, 591–595. [Google Scholar] [CrossRef]

- Cao, Y.; Lu, Y.; Liu, N.; Li, Y.; Wang, P.; Dai, C.; Wei, Y. Multi-applicable, durable superhydrophobic anti-icing coating through template-method and chemical vapor deposition. Surf. Interfaces 2022, 32, 102100. [Google Scholar] [CrossRef]

- Boinovich, L.B.; Emelyanenko, A.M.; Emelyanenko, K.A.; Modin, E.B. Modus Operandi of Protective and Anti-icing Mechanisms Underlying the Design of Longstanding Outdoor Icephobic Coatings. ACS Nano 2019, 13, 4335–4346. [Google Scholar] [CrossRef] [PubMed]

- Xiang, H.; Xia, H.; Chen, Y.; Wu, Y.; Chen, H.; Yan, M. Pavement anti-icing coating based on a functional composite of NaCl microcapsules. Constr. Build. Mater. 2021, 307, 125010. [Google Scholar] [CrossRef]

- Kulinich, S.A.; Farzaneh, M. Ice adhesion on super-hydrophobic surfaces. Appl. Surf. Sci. 2009, 255, 8153–8157. [Google Scholar] [CrossRef]

- Xu, K.; Hu, J.; Jiang, X.; Meng, W.; Lan, B.; Shu, L. Anti-Icing Performance of Hydrophobic Silicone–Acrylate Resin Coatings on Wind Blades. Coatings 2018, 8, 151. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Shi, F.; Yu, X.; Liu, H.; Fu, Y.; Wang, Z.; Jiang, L.; Li, X. Polyelectrolyte Multilayer as Matrix forElectrochemical Deposition of Gold Clusters: Toward Super-hydrophobic Surface. J. Am. Chem. Soc. 2004, 126, 3064–3065. [Google Scholar] [CrossRef] [PubMed]

- Antonini, C.; Innocenti, M.; Horn, T.; Marengo, M.; Amirfazli, A. Understanding the effect ofsuperhydrophobic coatings on energy reduction in anti-icing systems. Cold Reg. Sci. Technol. 2011, 67, 58–67. [Google Scholar] [CrossRef]

- Diedkova, K.; Pogrebnjak, A.D.; Kyrylenko, S.; Smyrnova, K.; Buranich, V.V.; Horodek, P.; Zukowski, P.; Koltunowicz, T.N.; Galaszkiewicz, P.; Makashina, K.; et al. Polycaprolactone-MXene Nanofibrous Scaffolds for Tissue Engineering. ACS Appl. Mater. Interfaces 2023, 15, 14033–14047. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; He, M.; Chen, J.; Wang, J.; Song, Y.; Jiang, L. Anti-Icing Surfaces Based on Enhanced Self-Propelled Jumping of Condensed Water Microdroplets. Chem. Commun. 2013, 49, 4516–4518. [Google Scholar] [CrossRef]

- Shi, L.; Feng, F.; Guo, W.; Li, Y. Research and Development of a Small-Scale Icing Wind Tunnel Test System for Blade Airfoil Icing Characteristics. Int. J. Rotating Mach. 2021, 2021, 5598859. [Google Scholar] [CrossRef]

- Liu, Z.; Feng, F.; Li, Y.; Sun, Y.; Tagawa, K. A corncob biochar-based superhydrophobic photothermal coating with micro-nano-porous rough-structure for ice-phobic properties. Surf. Coat. Technol. 2023, 457, 129299. [Google Scholar] [CrossRef]

- Vrancken, R.J.; Kusumaatmaja, H.; Hermans, K.; Prenen, A.M.; Pierre-Louis, O.; Bastiaansen, C.W.; Broer, D.J. Fully reversible transition from wenzel to Cassie−Baxter states on corrugated superhydrophobic surfaces. Langmuir 2010, 26, 3335–3341. [Google Scholar] [CrossRef]

- Khoobi, M.; Motevalizadeh, S.F.; Asadgol, Z.; Forootanfar, H.; Shafiee, A.; Faramarzi, M.A. Polyethyleneimine-modified superparamagnetic Fe3O4 nanoparticles for lipase immobilization: Characterization and 17 application. Mater. Chem. Phys. 2015, 149–150, 77–86. [Google Scholar] [CrossRef]

- Nateghi, M.R.; Dehghan, S.; Shateri-Khalilabad, M. A Facile Route for Fabrication of Conductive Hydrophobic Textile Materials Using N-octyl/N-perfluorohexyl Substituted Polypyrrole. Int. J. Polym. Mater. Polym. Biomater. 2013, 62, 648–652. [Google Scholar] [CrossRef]

- Dubal, D.P.; Lee, S.H.; Kim, J.G.; Kim, W.B.; Lokhande, C.D. Porous polypyrrole clusters prepared by electropolymerization for a high performance supercapacitor. J. Mater. Chem. 2012, 22, 3044–3052. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Removal of pharmaceuticals and personal care products (PPCPs) from wastewater: A review. J. Environ. Manag. 2016, 182, 620–640. [Google Scholar] [CrossRef]

- Ensikat, H.J.; Ditsche-Kuru, P.; Neinhuis, C.; Barthlott, W. Superhydrophobicity in perfection: The outstanding properties of the lotus leaf. Beilstein J. Nanotechnol. 2011, 2, 152–161. [Google Scholar] [CrossRef] [Green Version]

- Gao, X.; Su, L.; Jiang, G.; Pang, J.; Lin, L. Dimensional Stability of Lotus Leaf-like Nanostructure Superhydrophobic Bamboo by Modification Using Xylan. Bioresources 2020, 15, 3443–3457. [Google Scholar] [CrossRef]

- Wang, Y.R.; Chen, Y.J.; Zhu, C.L. Electromagnetic wave absorption property of polypyrrole nanowires/graphene composite (in Chinese). Sci. Sin. Phys. Mech. Astron. 2017, 47, 127201. [Google Scholar] [CrossRef] [Green Version]

- Torun, I.; Ruzi, M.; Er, F.; Onses, M.S. Superhydrophobic coatings made from biocompatible polydimethylsiloxane and natural wax. Prog. Org. Coat. 2019, 136, 105279. [Google Scholar] [CrossRef]

- Wang, X.; Peng, X.; Wang, B. Contact Angle Hysteresis and Hysteresis Tension on Rough Solid Surface. Chineae J. Chen. Eng. 2004, 12, 615–621. [Google Scholar]

- Luo, B.H.; Shum, P.W.; Zhou, Z.F.; Li, K.Y. Surface geometrical model modification and contact angle prediction for the laser patterned steel surface. Surf. Coat. Technol. 2010, 205, 2597–2604. [Google Scholar] [CrossRef]

- Zhang, X.X.; Min, C. Icephobicity of Functionalized Graphene Surfaces. J. Nanomater. 2016, 2016, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Valentini, L.; Bon, S.B.; Pugno, N.M.; Santana, M.H.; López-Manchado, M.A.; Giorgi, G. Synergistic icephobic behaviour of swollen nitrile butadiene rubber graphene and/or carbon nanotube composites. Composites 2018, 166, 352–360. [Google Scholar] [CrossRef]

- Rezazad, H.; Vahdati-Khajeh, S.; Eftekhari-Sis, B. Egg yolk biomass derived carbon material as a highly efficient and reusable hydrophobic oil-absorbent. J. Porous. Mater. 2020, 27, 1439–1446. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, X.; Jia, H.; Zhou, Y.; Ma, J.; Liu, X.; Jiang, L.; Chen, S. Superhydrophobic Polytetrafluoroethylene/Heat-Shrinkable Polyvinyl Chloride Composite Film with Super Anti-Icing Property. Polymers 2019, 11, 805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Imtiaz, S.; Zhang, J.; Zafar, Z.A.; Ji, S.; Huang, T.; Anderson, J.A.; Zhang, Z.; Huang, Y. Biomass-derived nanostructured porous carbons for lithium-sulfur batteries. Sci. China Mater. 2016, 59, 389–407. [Google Scholar] [CrossRef] [Green Version]

- Feng, F.; Shen, H.; Zhao, H.; Qu, B.; Li, Y. Research on Anti-icing Characteristics of Super-hydrophobic MoS_2Nano-coated Blade. J. Eng. Thermophys. 2021, 42, 1168–1175. [Google Scholar]

- Rajalakshmi, N. Carbon Nanotubes and Graphene for Photonic Applications. Graphene 2013, 1, 142–143. [Google Scholar] [CrossRef]

- Bharathidasan, T.; Kumar, S.V.; Bobji, M.S.; Chakradhar, R.P.; Basu, B.J. Effect of wettability and surface roughness on ice-adhesion strength of hydrophilic, hydrophobic and superhydrophobic surfaces. Appl. Surf. Sci. 2014, 314, 241–250. [Google Scholar] [CrossRef]

- Ruan, M.; Li, W.; Wang, B.; Deng, B.; Ma, F.; Yu, Z. Preparation and anti-icing behavior of superhydrophobic surfaces on aluminum alloy substrates. Langmuir 2013, 29, 8482–8491. [Google Scholar] [CrossRef]

- Latthe, S.S.; Sutar, R.S.; Bhosale, A.K.; Nagappan, S.; Ha, C.S.; Sadasivuni, K.K.; Liu, S.; Xing, R. Recent developments in air-trapped superhydrophobic and liquid-infused slippery surfaces for anti-icing application. Prog. Org. Coat. Int. Rev. J. 2019, 137, 105373. [Google Scholar] [CrossRef]

| Drug Name | Manufacturer |

|---|---|

| Hydrochloric acid (HCl) | Harbin Chemical Reagent Factory, Harbin, China |

| Pyrrole monomer | Shanghai Jingchun Reagent Co., Ltd., Shanghai, China |

| Thioacetamide | Shanghai Ziyi Reagent Factory, Shanghai, China |

| Cetyltrimethylammonium bromide | Shanghai Ziyi Reagent Factory, Shanghai, China |

| Ammonium persulfate | Tianjin Bodi Chemical Co., Ltd., Tianjin, China |

| Anhydrous ethanol | Tianjin Fuyu Fine Chemical Co., Ltd., Tianjin, China |

| Polydimethylsiloxane (PDMS) | Dow Corning Corporation, Auburn, MI, USA |

| N-Hexane | Tianjin Fuyu Fine Chemical Co., Ltd., Tianjin, China |

| Cow dung | Harbin Rear Xujiatun Cattle Farm, Harbin, China |

| Instrument Name | Model | Manufacturer |

|---|---|---|

| Fourier infrared spectrometer | LPHA-T | Bruker, Ettlingen, Germany |

| Field emission scanning electron microscope | SU8010 | Hitachi, Tokyo, Japan |

| Specific surface area and porosity analyzer | ASAP2460 | Mack Corporation, Arlington, VT, USA |

| Contact angle measuring instrument | JCD2000D3M | Shanghai Zhongchen Digital Technic Apparatus CO, Ltd., Shanghai, China |

| Digital display push-pull gauge | HP-300 | Edberg Instrument Co, Ltd., Beijing, China |

| Angel of Attack (Degree) | Wind Speed (m/s) | Temperature (°C) | Icing Time (min) |

|---|---|---|---|

| 0 | 5 | −5 | 0–3 |

| 0 | 5 | −10 | 0–3 |

| 0 | 5 | −15 | 0–3 |

| 0 | 10 | −5 | 0–3 |

| 0 | 10 | −10 | 0–3 |

| 0 | 10 | −15 | 0–3 |

| 0 | 15 | −5 | 0–3 |

| 0 | 15 | −15 | 0–3 |

| 0 | 15 | −15 | 0–3 |

| Sample | Number of Times | Wind Speed (m/s) | Temperature (°C) | Ice Coverage Area (mm2) |

|---|---|---|---|---|

| biochar/ polypyrrole | 1 | 10 | −10 | 60.58 |

| 2 | 10 | −10 | 59.23 | |

| 3 | 10 | −10 | 61.34 | |

| 4 | 10 | −10 | 60.85 | |

| 5 | 10 | −10 | 61.88 | |

| 6 | 10 | −10 | 62.54 | |

| 7 | 10 | −10 | 64.36 | |

| 8 | 10 | −10 | 63.78 | |

| 9 | 10 | −10 | 64.66 | |

| 10 | 10 | −10 | 63.96 |

| Sample | Number of Times | Icing Bond Strength (KPa) |

|---|---|---|

| biochar/ polypyrrole | 1 | 65.32 |

| 2 | 64.89 | |

| 3 | 65.98 | |

| 4 | 63.78 | |

| 5 | 66.23 | |

| 6 | 66.85 | |

| 7 | 67.83 | |

| 8 | 68.21 | |

| 9 | 69.14 | |

| 10 | 71.31 |

| Sample | Wind Speed (m/s) | Temperature (°C) | Maximum Ice Coverage Area (mm2) |

|---|---|---|---|

| uncoated | 5 | −5 | 51.65 |

| 15 | −5 | 112.52 | |

| 15 | −10 | 141.86 | |

| biochar | 5 | −5 | 45.64 |

| 15 | −5 | 101.52 | |

| 15 | −10 | 100.16 | |

| biochar/ polypyrrole | 5 | −5 | 40.88 |

| 15 | −5 | 90.92 | |

| 15 | −10 | 88.60 |

| Sample | Wind Speed (m/s) | Temperature (°C) | Maximum Ice Thickness (mm) |

|---|---|---|---|

| uncoated | 15 | −5 | 6.66 |

| 15 | −10 | 7.40 | |

| 15 | −15 | 6.03 | |

| biochar | 15 | −5 | 3.72 |

| 15 | −10 | 5.21 | |

| 15 | −15 | 4.92 | |

| biochar/ polypyrrole | 15 | −5 | 2.47 |

| 15 | −10 | 4.95 | |

| 15 | −15 | 4.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Li, X.; Mu, Z.; Li, Y.; Feng, F. An Experimental Study on Biochar/Polypyrrole Coating for Blade Anti-Icing of Wind Turbines. Coatings 2023, 13, 759. https://doi.org/10.3390/coatings13040759

Li X, Li X, Mu Z, Li Y, Feng F. An Experimental Study on Biochar/Polypyrrole Coating for Blade Anti-Icing of Wind Turbines. Coatings. 2023; 13(4):759. https://doi.org/10.3390/coatings13040759

Chicago/Turabian StyleLi, Xiaoheng, Xiaojuan Li, Zhongqiu Mu, Yan Li, and Fang Feng. 2023. "An Experimental Study on Biochar/Polypyrrole Coating for Blade Anti-Icing of Wind Turbines" Coatings 13, no. 4: 759. https://doi.org/10.3390/coatings13040759

APA StyleLi, X., Li, X., Mu, Z., Li, Y., & Feng, F. (2023). An Experimental Study on Biochar/Polypyrrole Coating for Blade Anti-Icing of Wind Turbines. Coatings, 13(4), 759. https://doi.org/10.3390/coatings13040759