Effect of Salt Bath Nitriding and Reoxidation Composite Texture on Frictional Properties of Valve Steel 4Cr10Si2Mo

Abstract

1. Introduction

2. Materials and Experiments

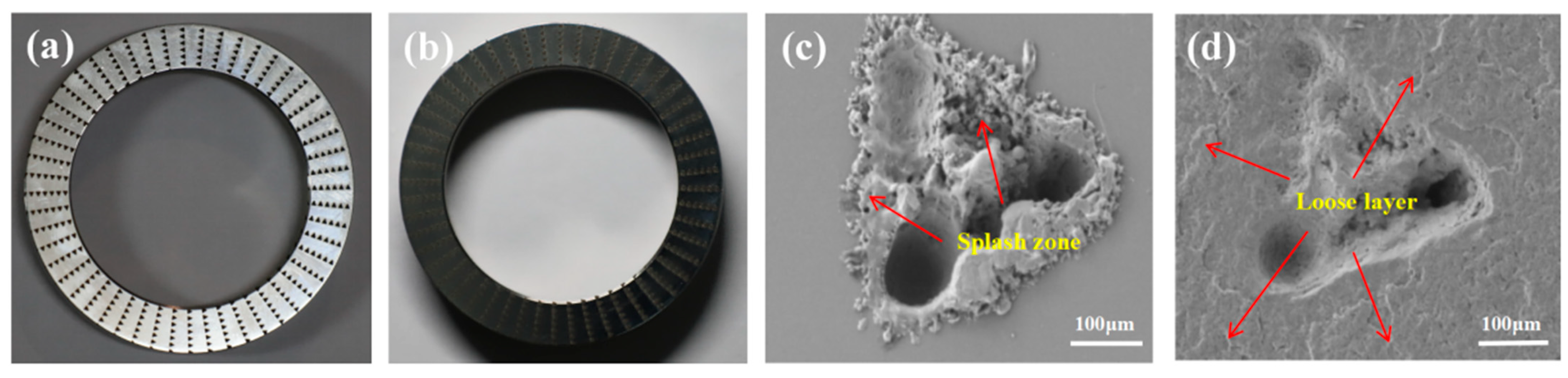

2.1. Material Preparation

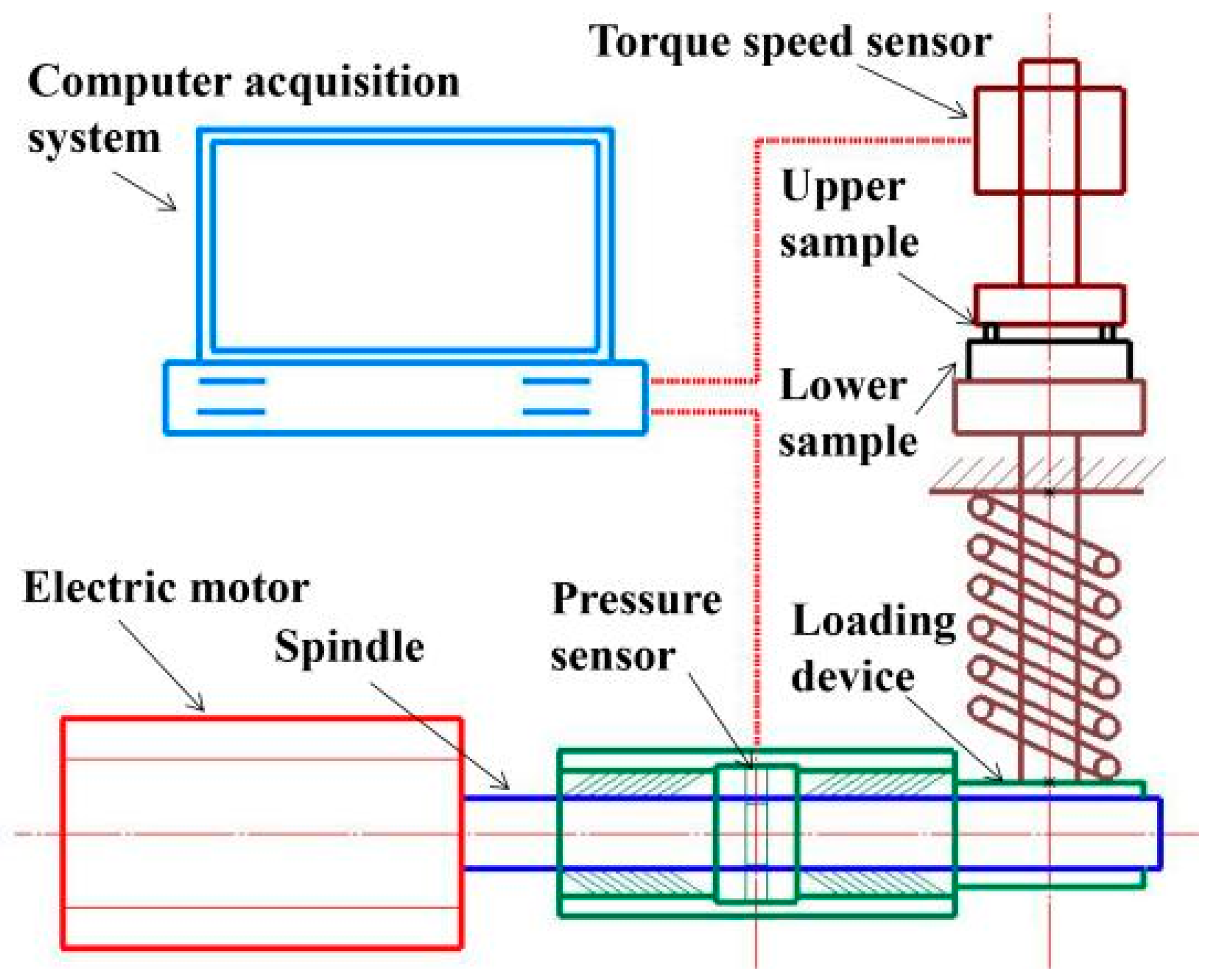

2.2. Friction and Wear Experiments

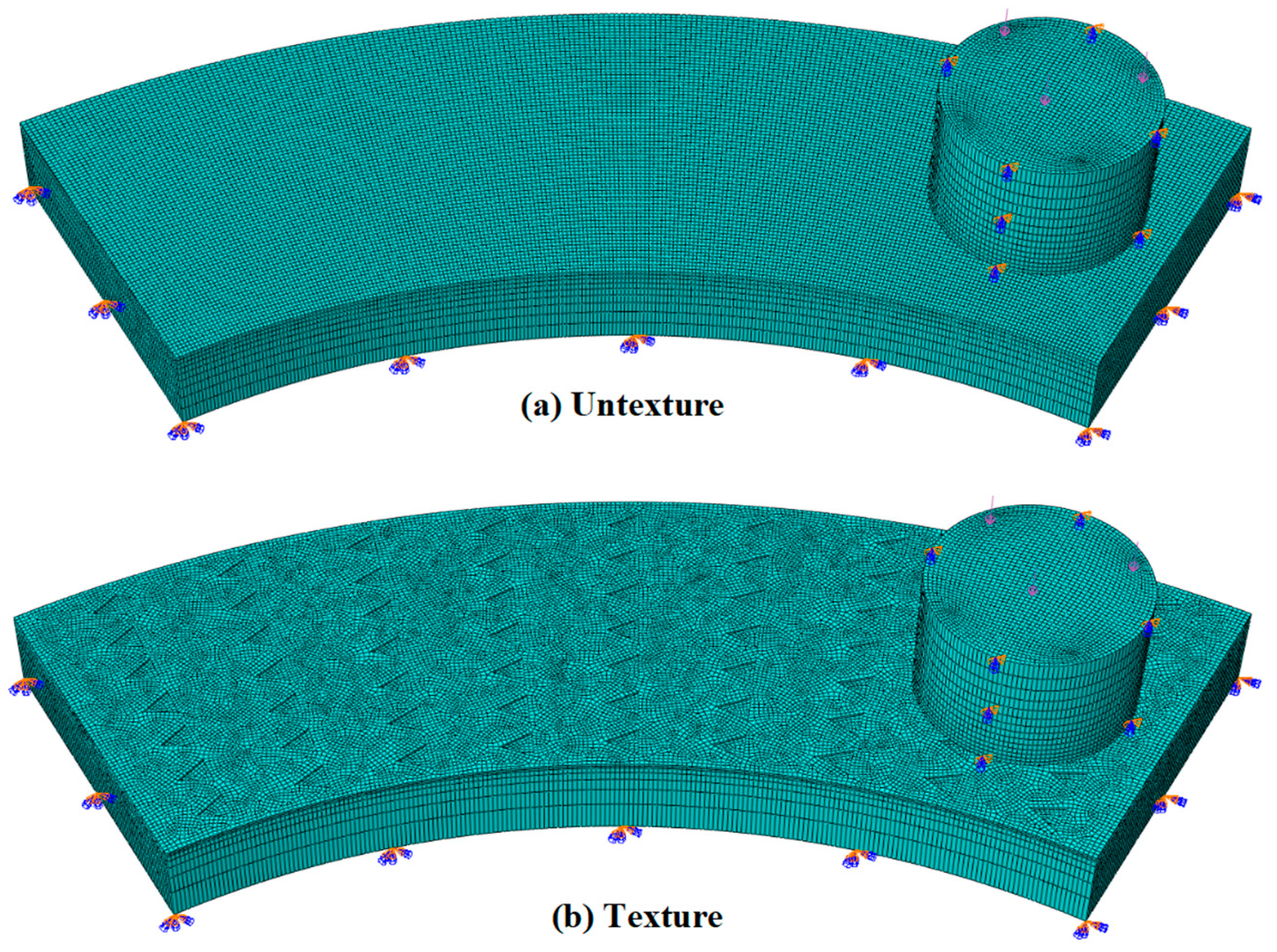

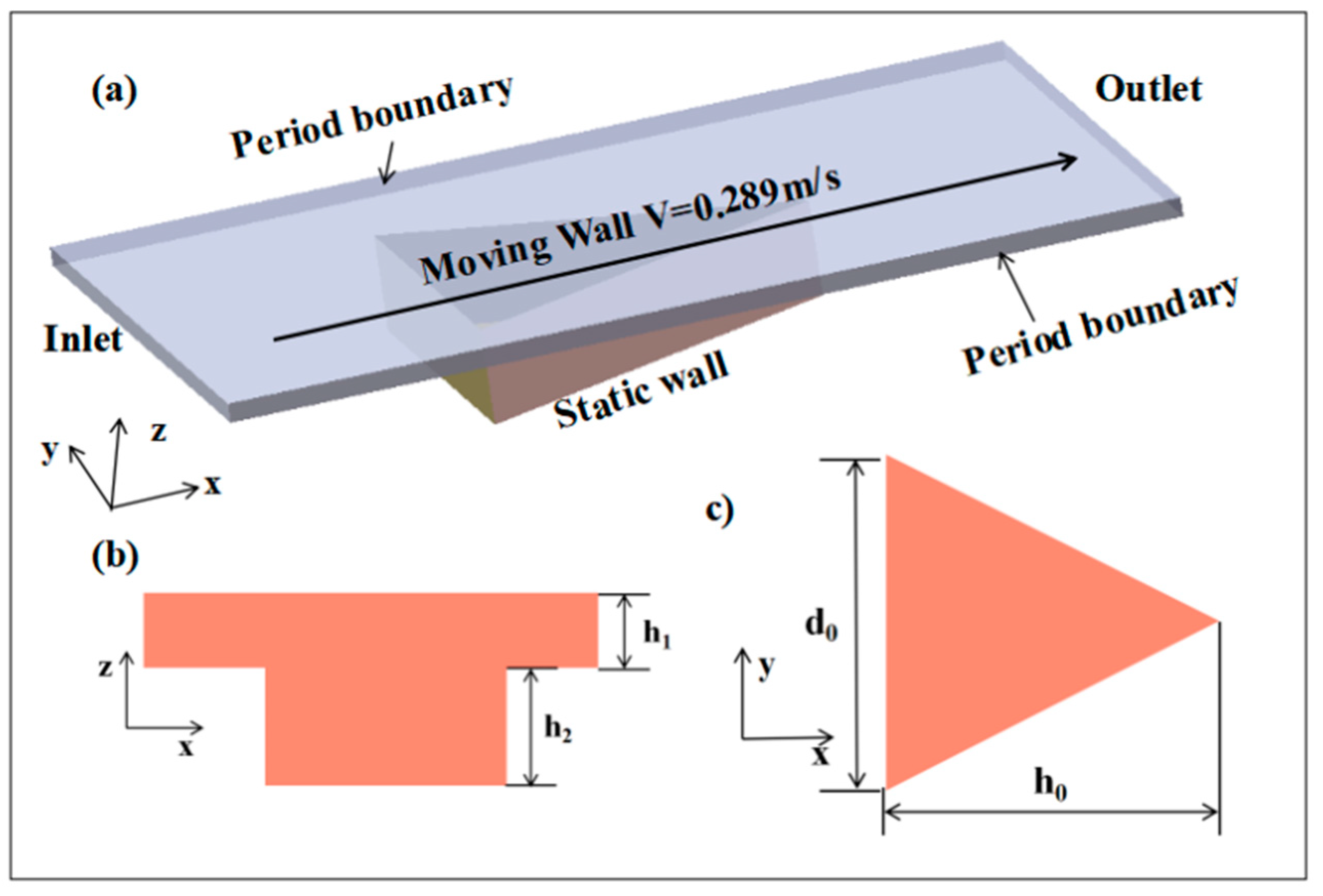

2.3. Simulation

3. Experimental Results and Discussion

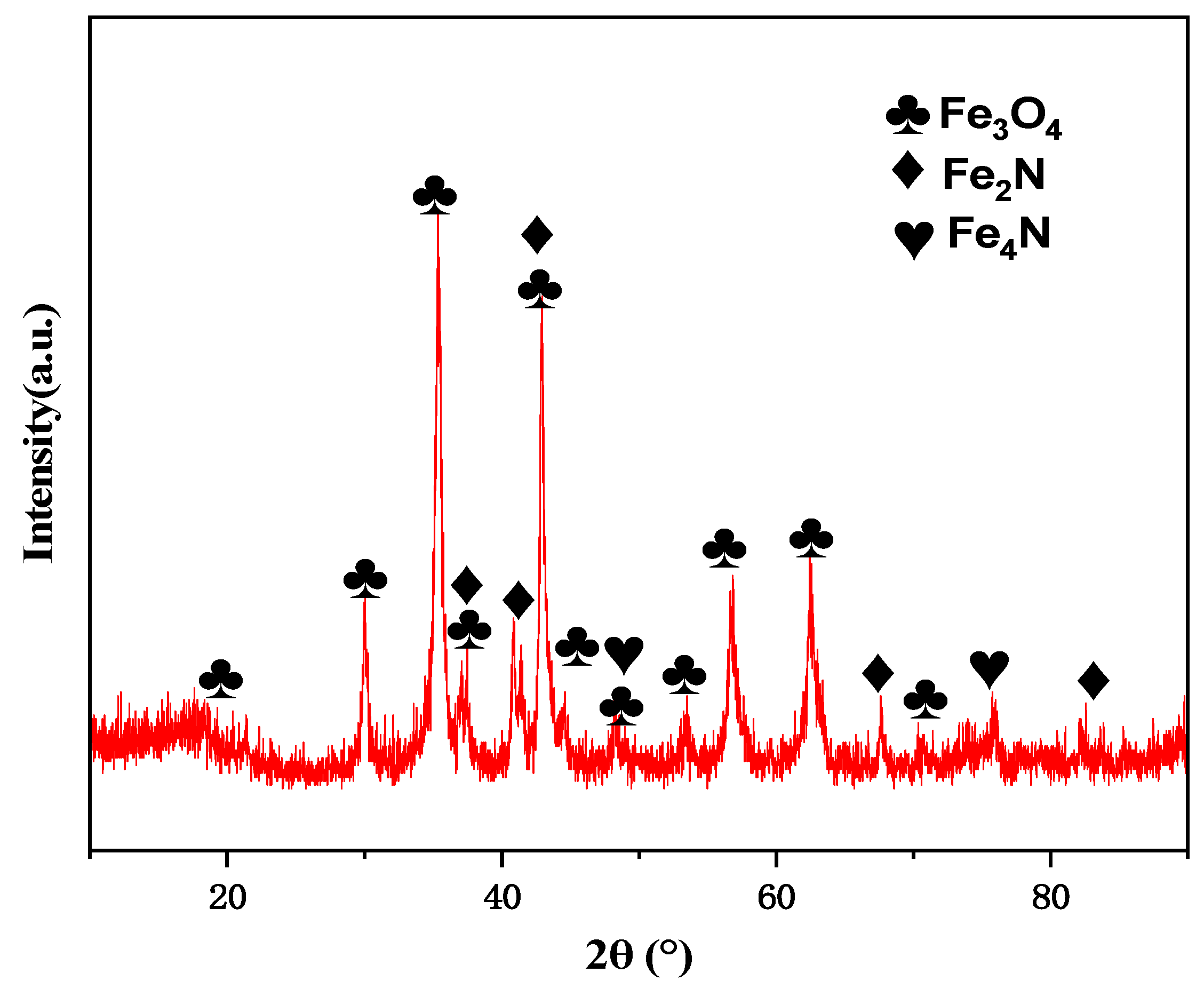

3.1. Phase Analysis of Sample before and after Nitriding

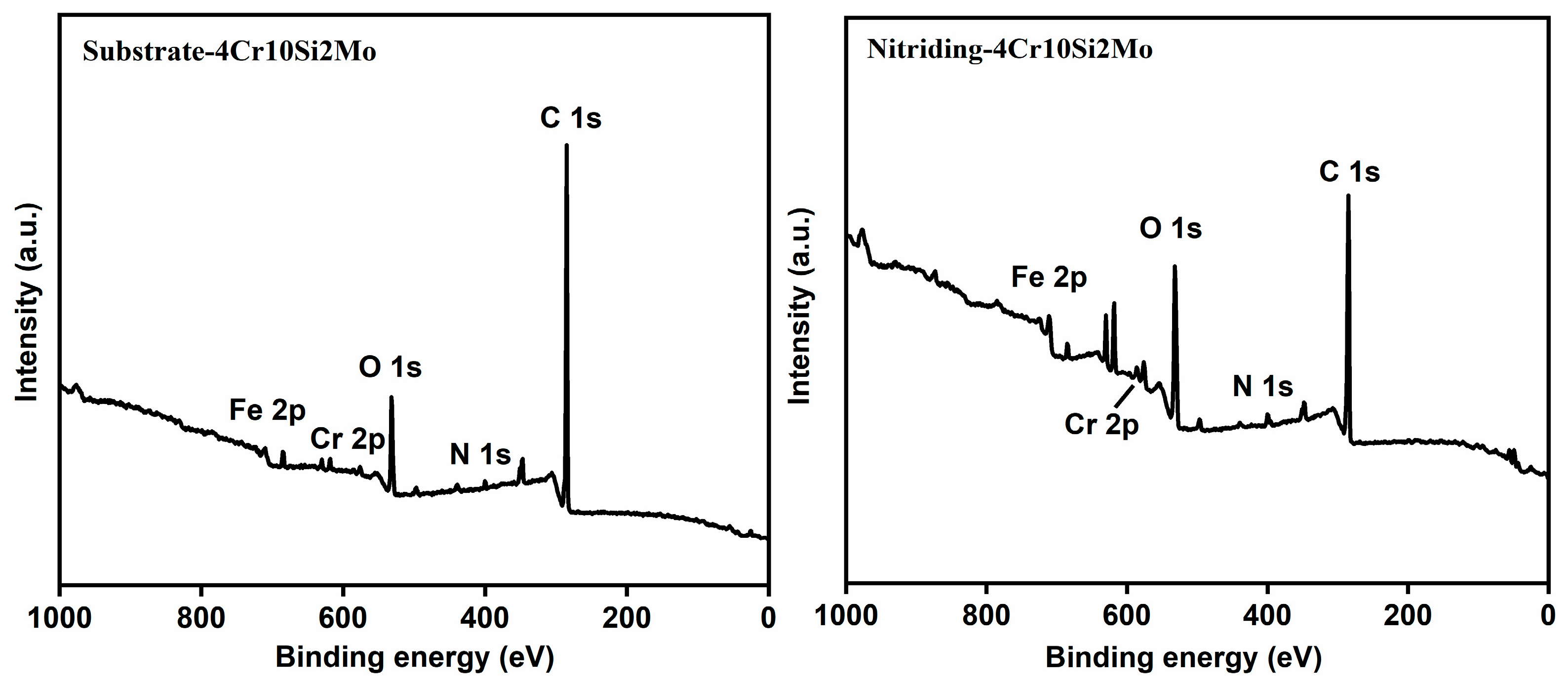

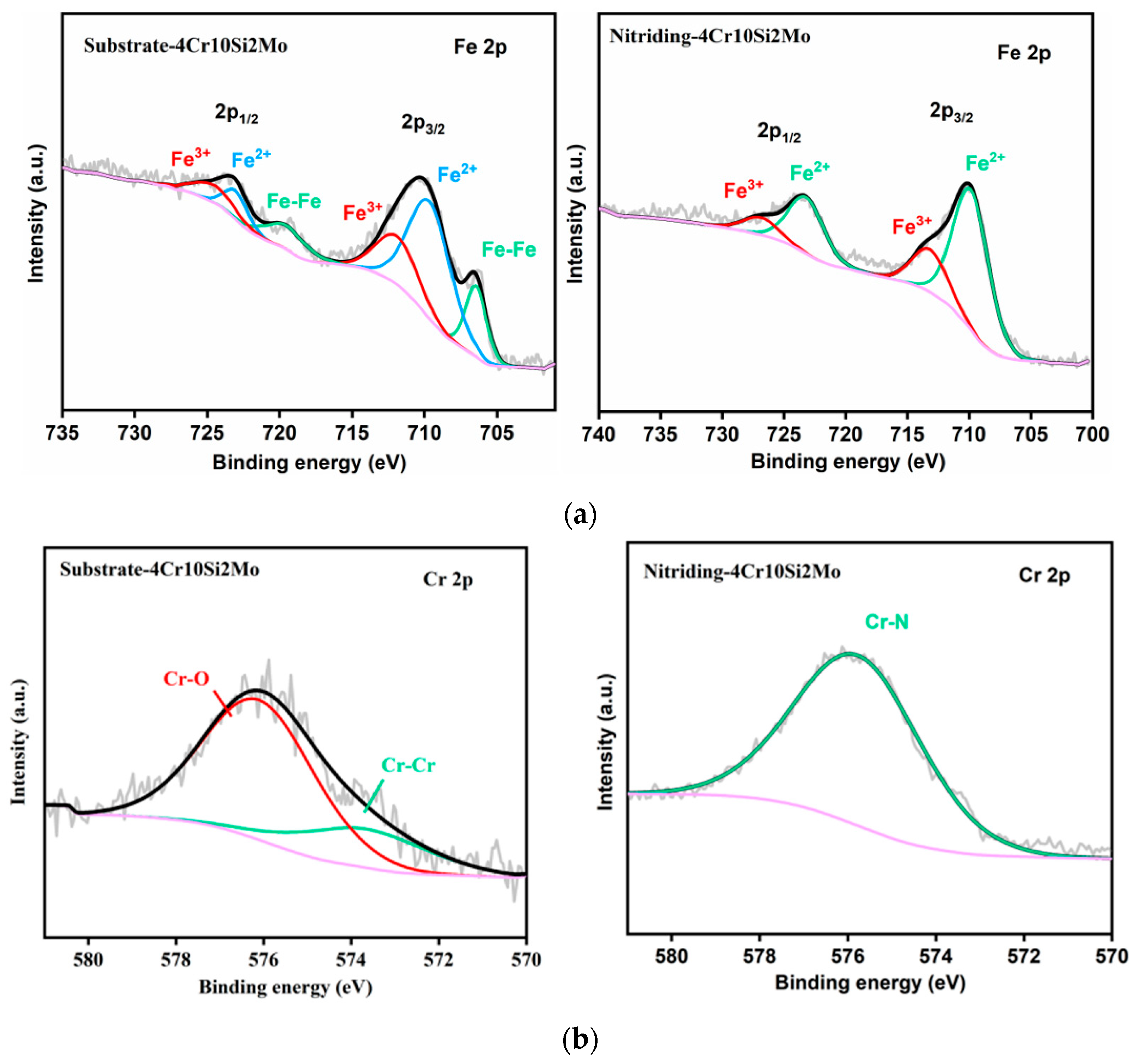

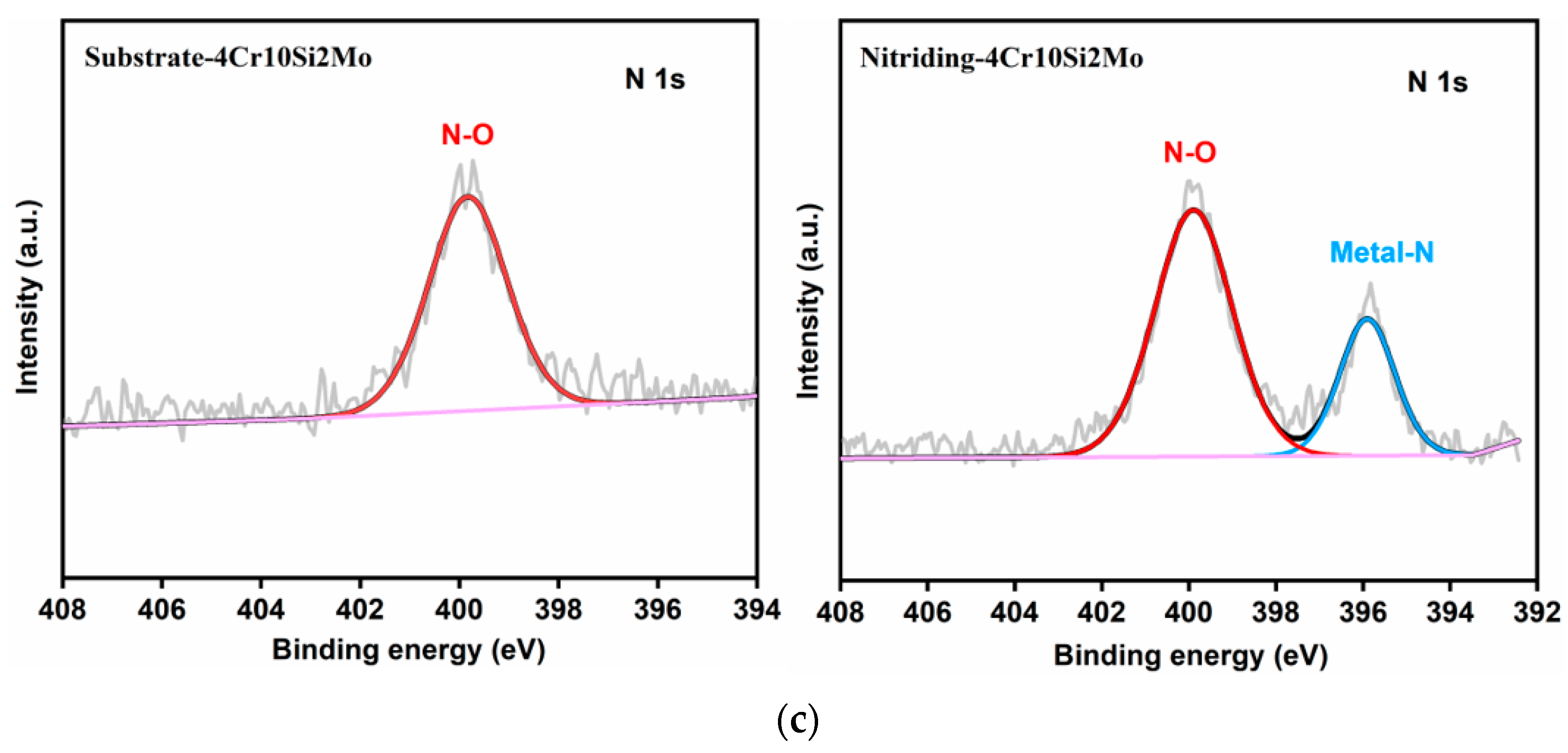

3.2. Elemental Valence Analysis before and after Nitriding

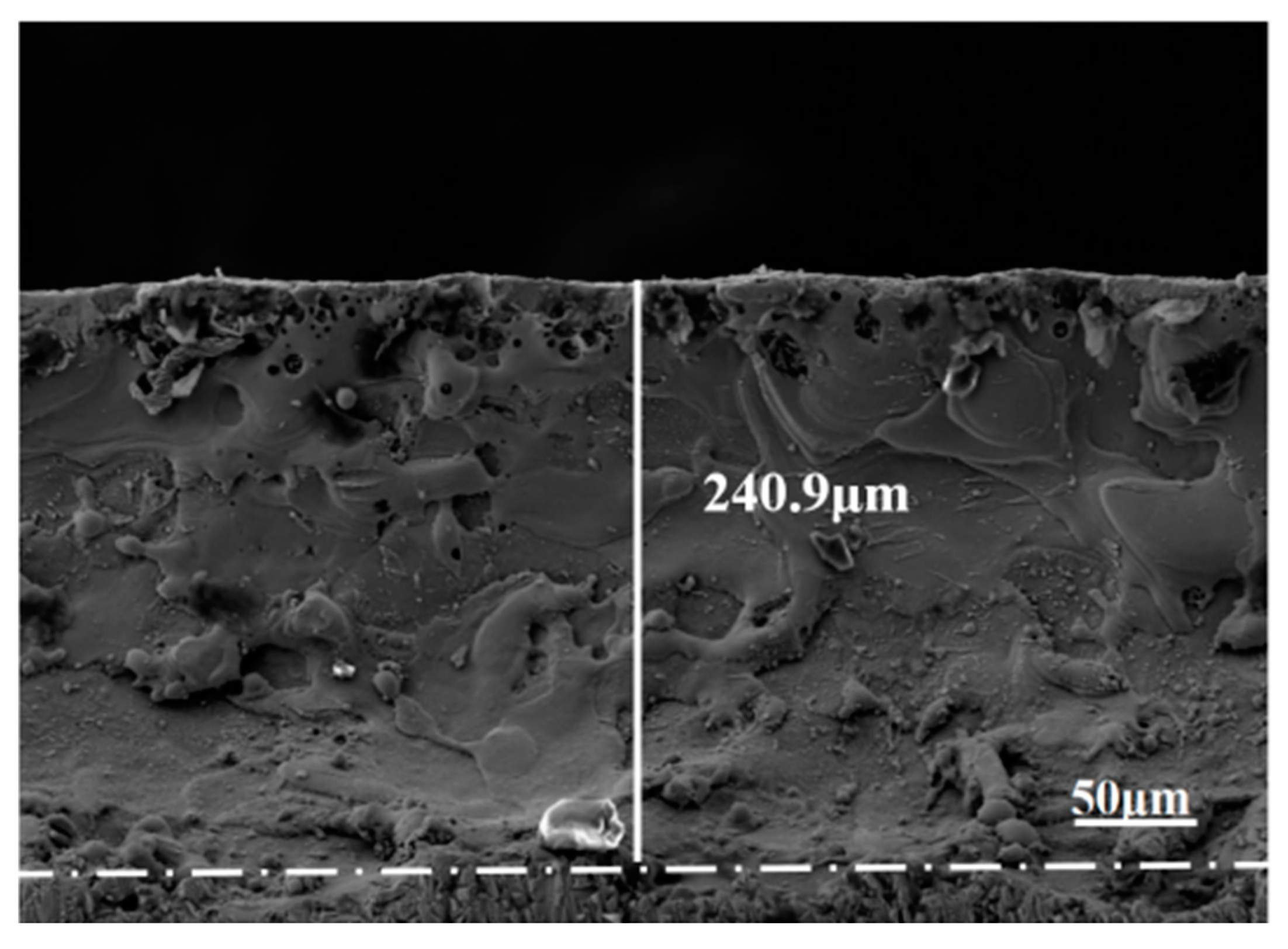

3.3. Surface Hardness and Thickness of Nitriding Layer of Nitriding Sample

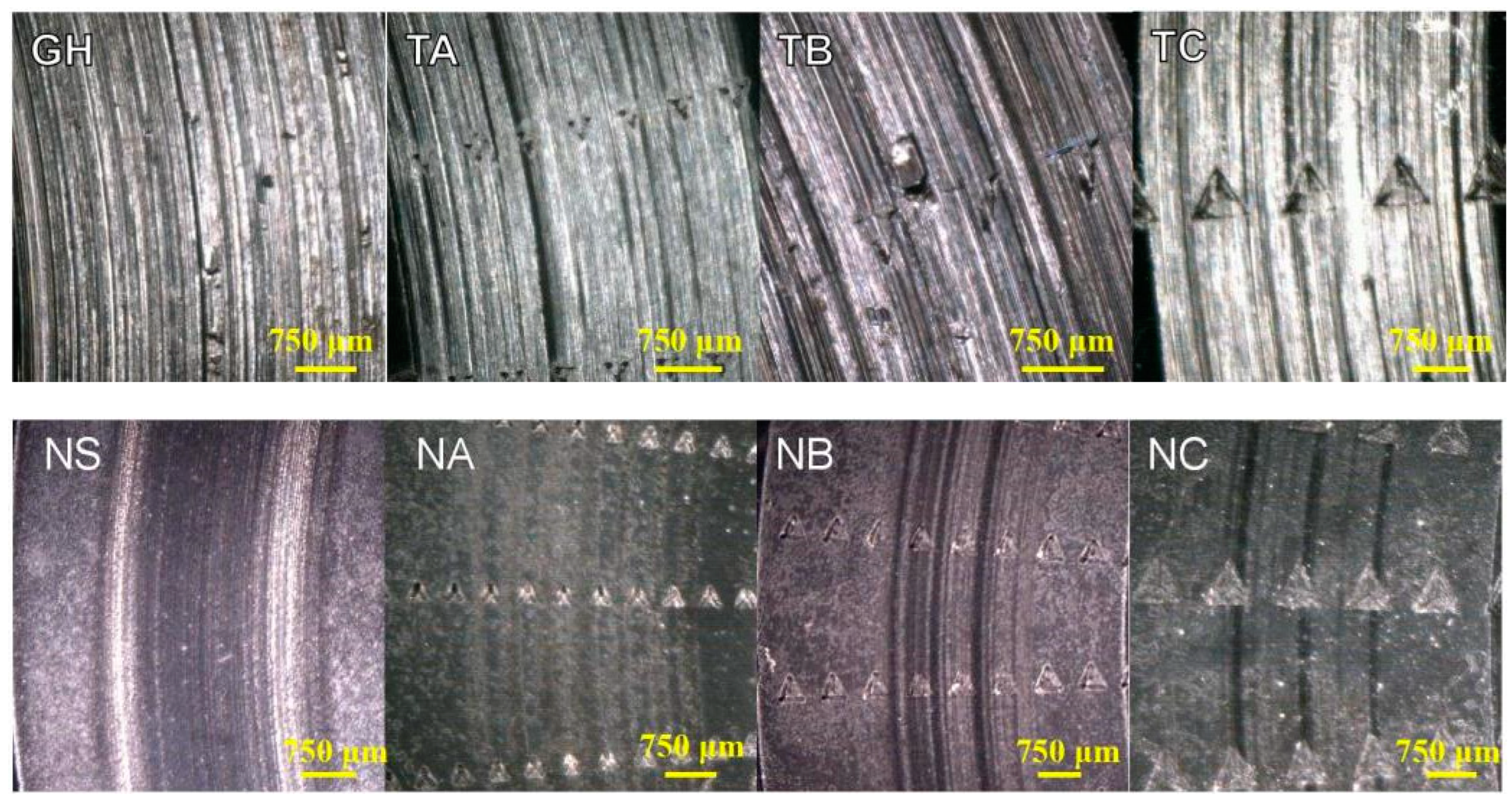

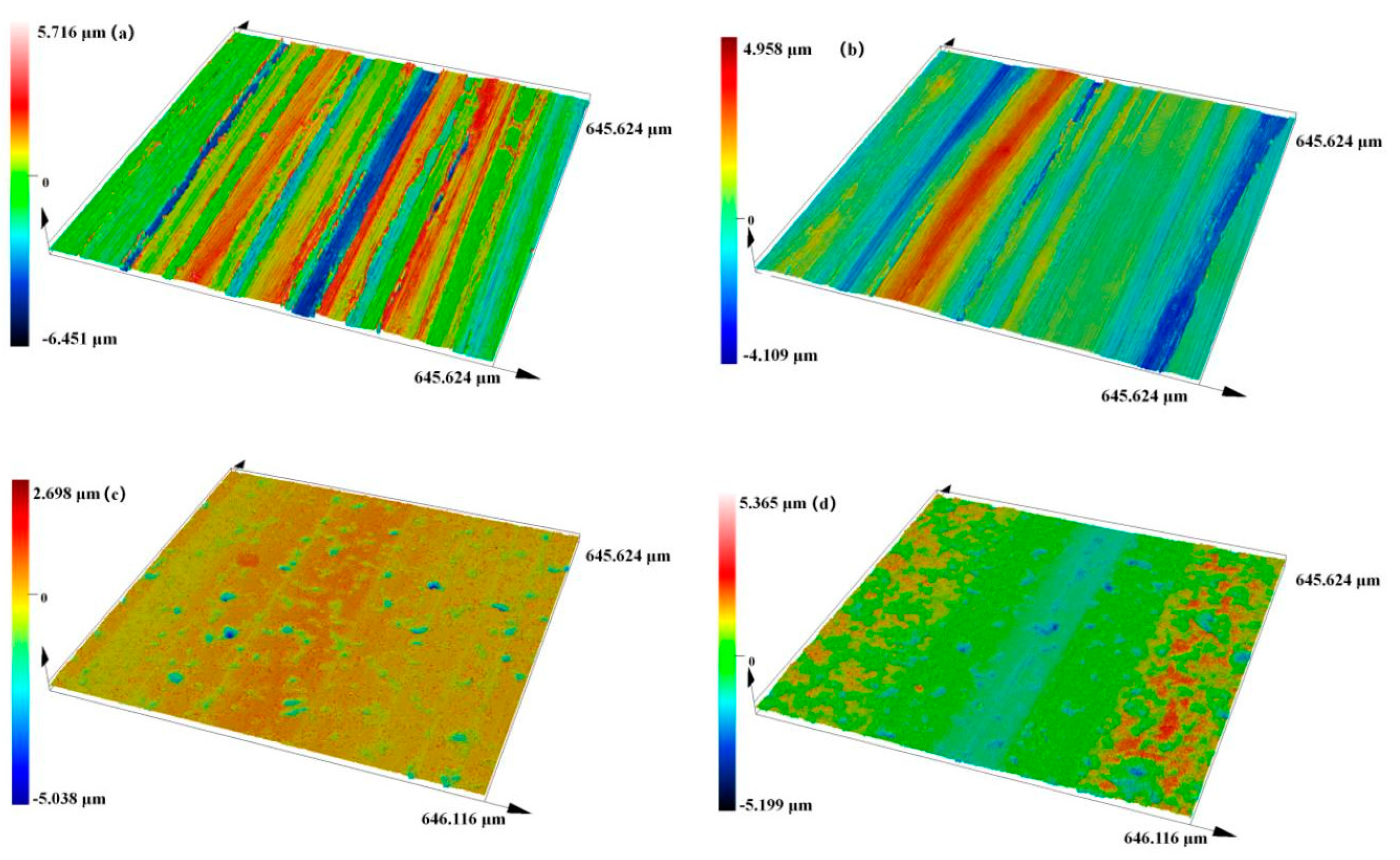

3.4. Analysis of Surface Texture Samples before and after Nitriding

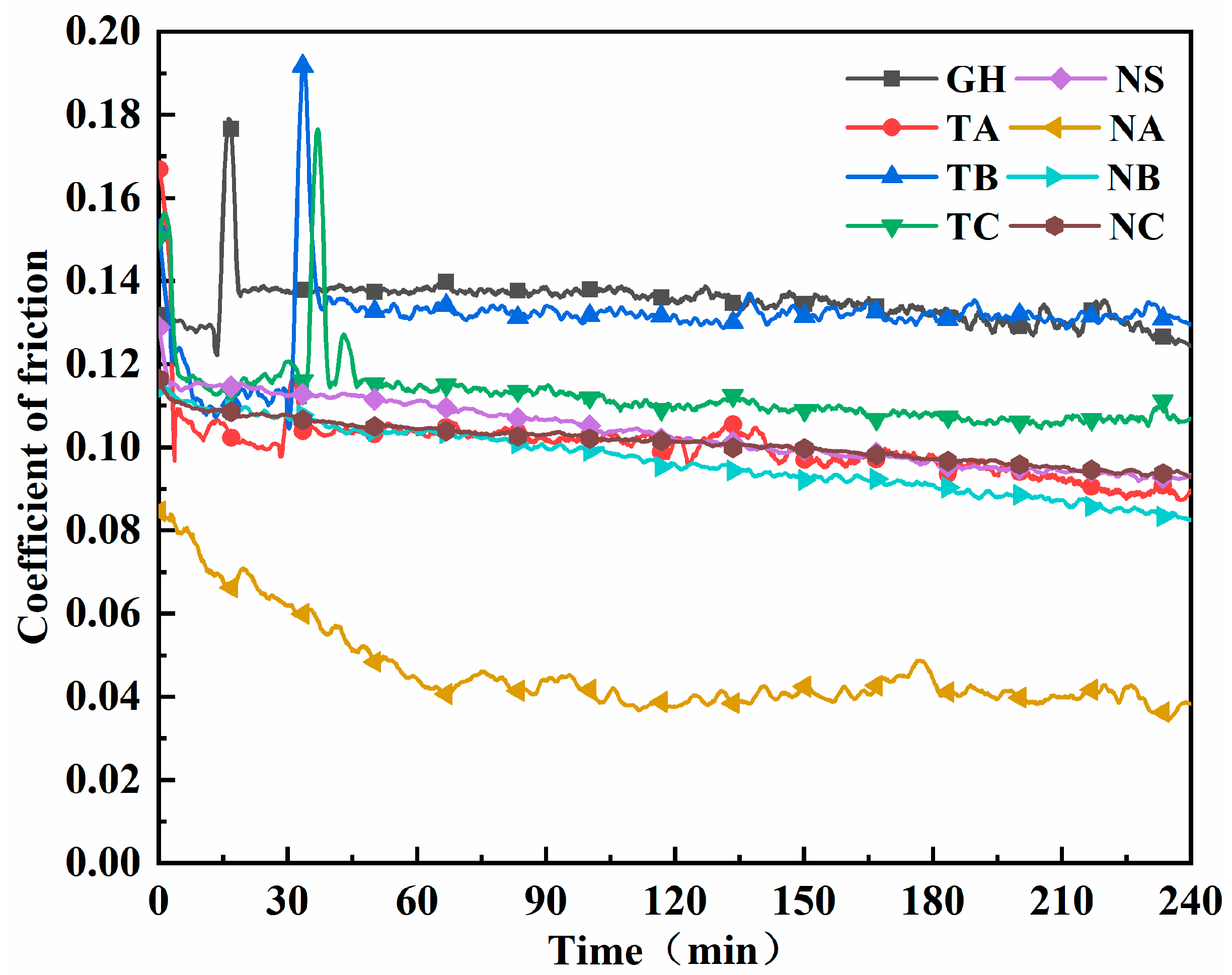

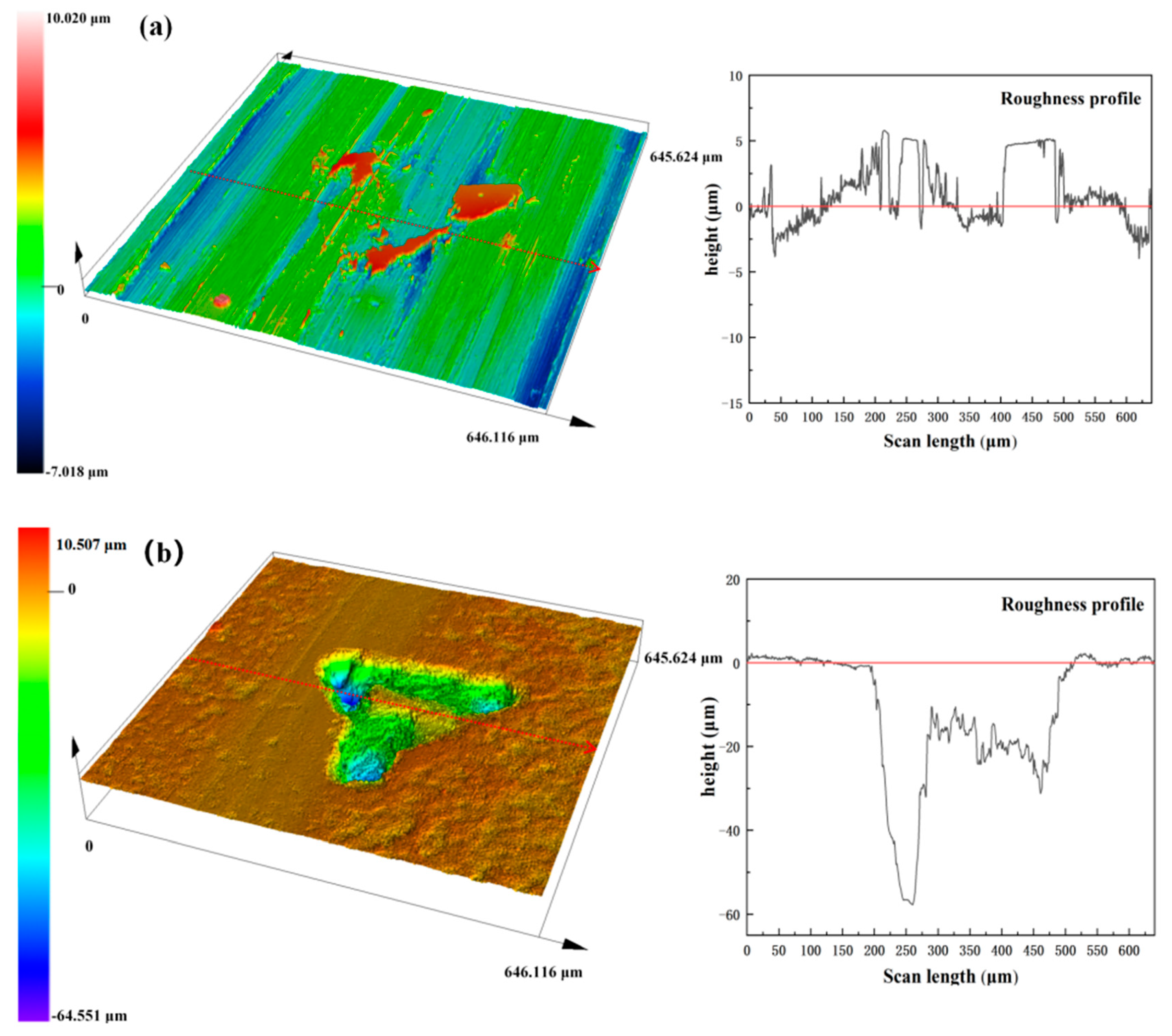

3.5. Analysis of Frictional Wear Mechanism

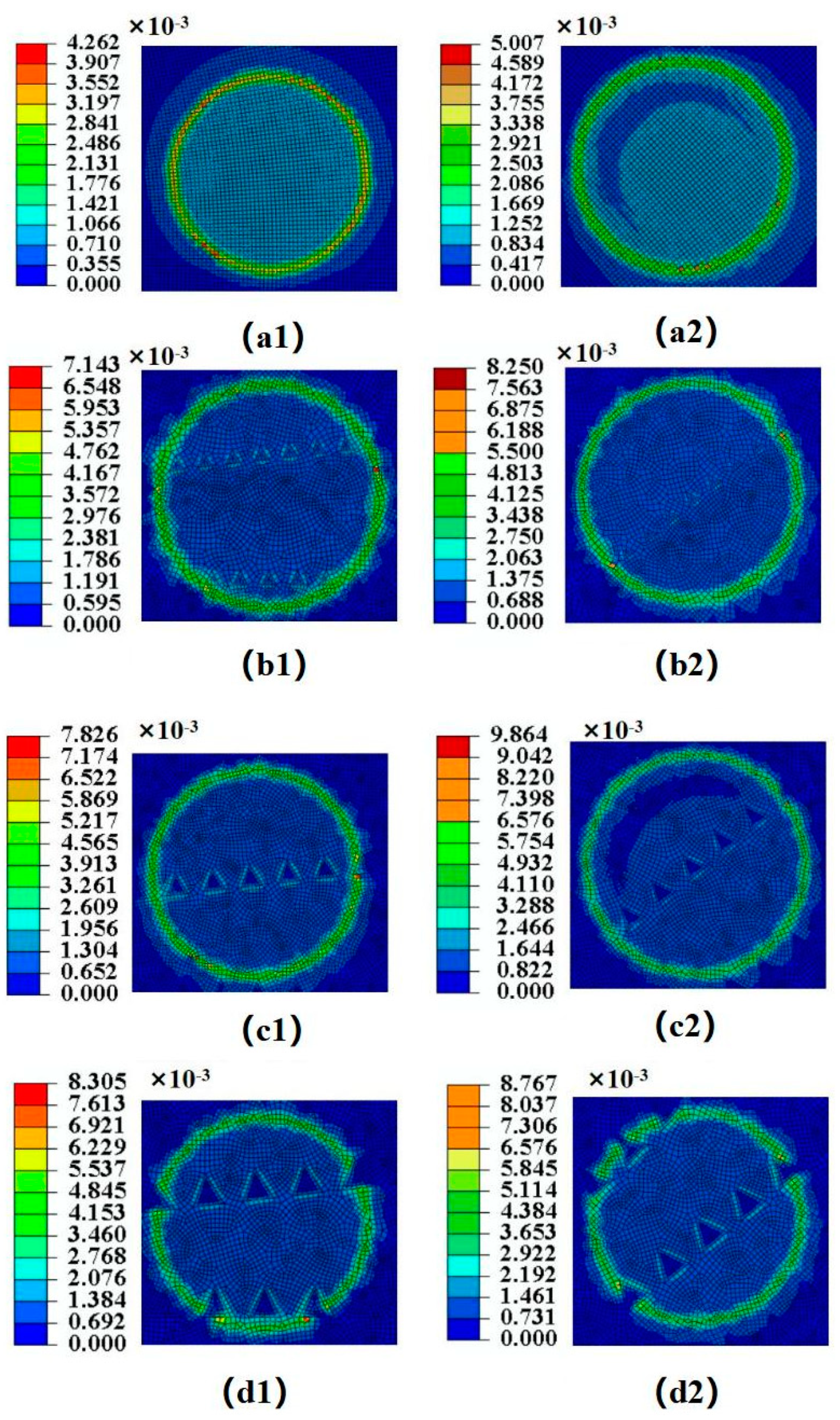

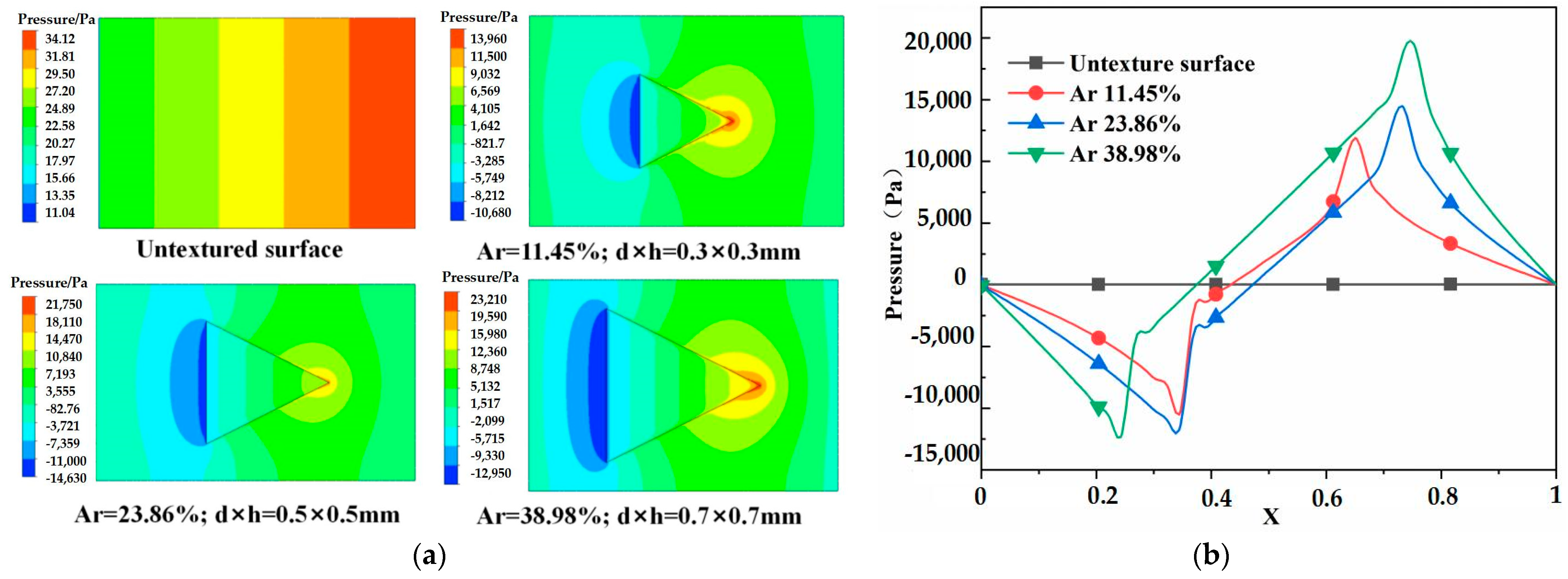

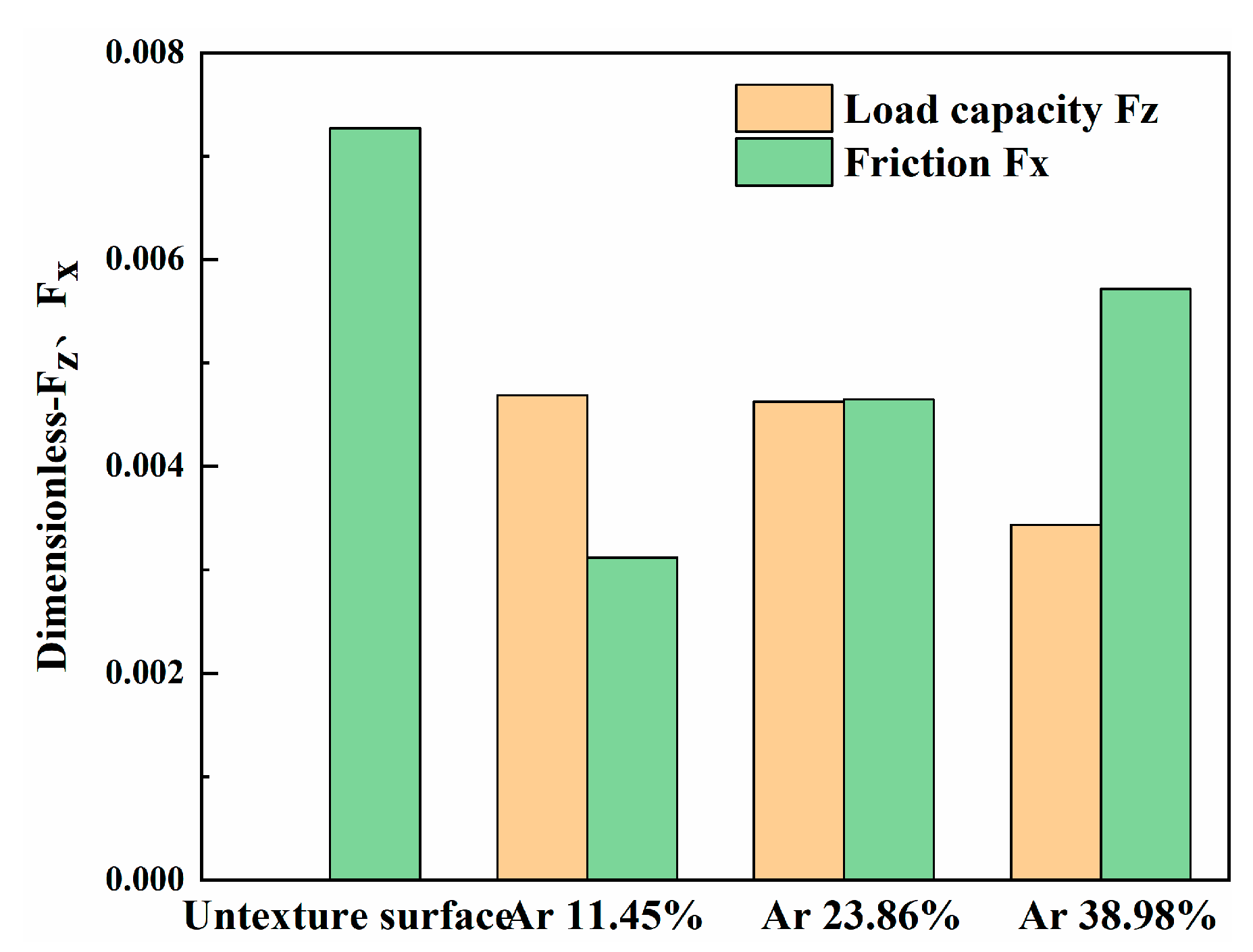

4. Discussion of Simulation Results

5. Conclusions

- After nitriding and oxidation in the salt bath, the surface hardness of the sample was significantly enhanced, the surface hardness could reach 710 HV0.5, and the hardness was doubled. The upper surface of the nitriding sample was mainly Fe4O3 and Fe2N, and Cr-N was also detected on the surface. However, the magnetite phase (Fe3O4) and Fe2N seem to play a more important role in the wear process. Fe3O4 can reduce the friction coefficient and reduce oxidation wear. Fe2N can increase surface hardness.

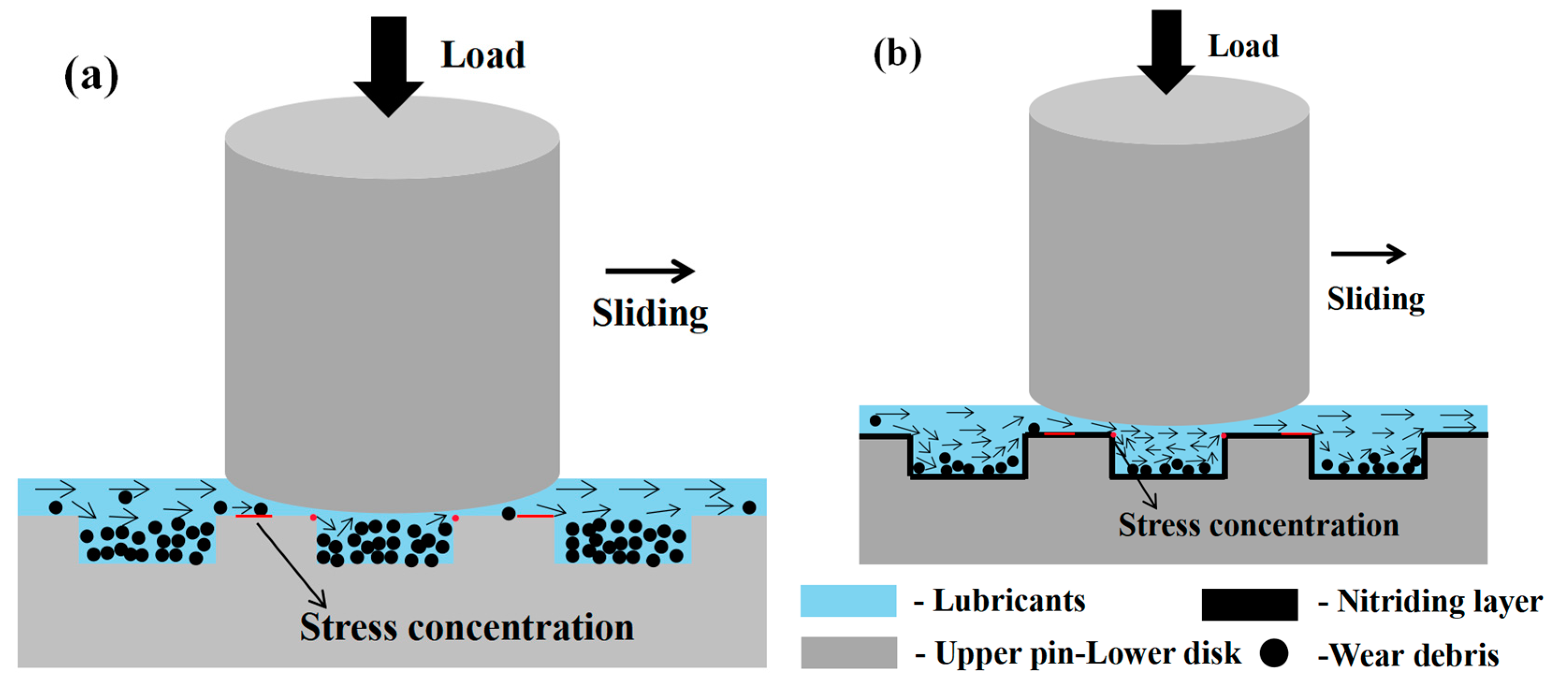

- A textured surface can reduce the coefficient of friction. However, the material surface wear was high in the absence of nitriding and high load conditions. Adding texture to the surface increased the average stress on the contact surface, especially the stress concentration near the texture. This can also explain the severe wear near the textured area of the non-nitrided sample in the experiment. Among the different area occupancies, the textured surface with an area density of 11.45% experienced less stress. The triangular texture produced a wedge effect in the fluid lubrication, and the pressure difference was generated in the texture’s inner cavity to improve the oil film’s bearing capacity. The dimensionless oil film had the most significant bearing capacity and the most minor dimensionless friction resistance when the area density was 11.45%. Through various characterization methods, it can be proved that 4Cr10Si2Mo has a pronounced anti-friction effect under the texture composite nitriding treatment. Among them, the triangular texture with an area density of 11.45% (d × h = 0.3 × 0.3) had the best friction reduction effect, and the friction coefficient decreased by 65%.

- The collection of abrasive particles by triangular texture can significantly reduce abrasive wear damage to the contact surface. However, due to some uncollected abrasive particles on the textured surface, the local contact stress is too large, resulting in deeper wear scars on the non-textured areas of the textured surface. When the stress on the textured surface exceeds its elastic limit, the material will fail under repeated stress cycles. At the same time, the texture function will gradually weaken or even be destroyed. Therefore, in this work, the surface hardness was increased by salt bath nitriding and oxidation, and the role of texture could be better utilized. This composite modification increases the tribological properties of the 4Cr10Si2Mo valve steel, benefiting the engineering applications of valve steel and even auto parts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Qiwen, W.; Zhang, Z.; Yucan, F.U.; Jiuhua, X.U. Surface micro-texture on sapphire fabricated by laser ablation trajectory regulation. Chin. J. Aeronaut. 2022, 35, 525–536. [Google Scholar] [CrossRef]

- Sani, E.; Sciti, D.; Silvestroni, L.; Bellucci, A.; Orlando, S.; Trucchi, D.M. Tailoring optical properties of surfaces in wide spectral ranges by multi-scale femtosecond-laser texturing: A case-study for TaB2 ceramics. Opt. Mater. 2020, 109, 110347. [Google Scholar] [CrossRef]

- Iglesias, P.; Bermudez, M.D.; Moscoso, W.; Rao, B.C.; Shankar, M.R.; Chandrasekar, S. Friction and wear of nanostructured metals created by large strain extrusion machining. Wear 2007, 263, 636–642. [Google Scholar] [CrossRef]

- Wang, H.; Sun, A.; Qi, X.; Dong, Y.; Fan, B. Wear properties of textured lubricant films filled with graphite and polytetrafluoroethylene (PTFE) via laser surface texturing (LST). Tribol. Int. 2022, 167, 107414. [Google Scholar] [CrossRef]

- Behera, R.R.; Das, A.; Hasan, A.; Pamu, D.; Pandey, L.M.; Sankar, M.R. Deposition of biphasic calcium phosphate film on laser surface textured Ti–6Al–4V and its effect on different biological properties for orthopedic applications. J. Alloys Compd. 2020, 842, 155683. [Google Scholar] [CrossRef]

- Guo, H.; Smith, T.W.; Iglesias, P. The study of hexanoate-based protic ionic liquids used as lubricants in steel-steel contact. J. Mol. Liq. 2020, 299, 112208. [Google Scholar] [CrossRef]

- Sasaki, S. Environmentally friendly tribology (Eco-tribology). J. Mech. Sci. Technol. 2010, 24, 67–71. [Google Scholar] [CrossRef]

- Cao, W.; Hu, T.; Fan, H.; Hu, L. Laser surface texturing and tribological behaviour under solid lubrication on titanium and titanium alloy surfaces. Int. J. Surf. Sci. Eng. 2021, 15, 50–66. [Google Scholar] [CrossRef]

- Hu, D.; Guo, Z.; Xie, X.; Yuan, C. Effect of spherical-convex surface texture on tribological performance of water-lubricated bearing. Tribol. Int. 2019, 134, 341–351. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Some innovative surface texturing techniques for tribological purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 429–448. [Google Scholar] [CrossRef]

- Uddin, M.S.; Ibatan, T.; Shankar, S. Influence of surface texture shape, geometry and orientation on hydrodynamic lubrication performance of plane-to-plane slider surfaces. Lubr. Sci. 2017, 29, 153–181. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G.Z.; Zhang, D.Y.; Chen, W.J.; Dong, G.N. Optimization of texture shape based on genetic algorithm under unidirectional sliding. Tribol. Int. 2017, 115, 222–232. [Google Scholar] [CrossRef]

- Maldonado-Cortés, D.; Peña-Parás, L.; Martínez, N.R.; Leal, M.P.; Correa, D.I.Q. Tribological characterization of different geometries generated with laser surface texturing for tooling applications. Wear 2021, 477, 203856. [Google Scholar] [CrossRef]

- Chen, J.; Zeng, L.; Wu, Z.; Chen, K. Experimental investigation of disc partial surface texture on the generation of hydrodynamic lubricating performance under conformal contact condition. AIP Adv. 2018, 8, 125205. [Google Scholar] [CrossRef]

- Wang, C.; Hong, J.; Cui, M.; Huang, H.; Zhang, L.; Yan, J. The effects of simultaneous laser nitriding and texturing on surface hardness and tribological properties of Ti6Al4V. Surf. Coat. Tech. 2022, 437, 128358. [Google Scholar] [CrossRef]

- Zong, X.; Wang, H.; Li, J.; Cheng, X.; Li, Z.; Tang, H. Microstructure characterization and evolution mechanism of titanium during laser surface nitriding. Mater. Charact. 2022, 190, 112029. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, Y.; Wu, G.; Li, L.; Yao, J.; Zhang, Q. The microstructure and cavitation erosion resistance of Ti6Al4V alloy treated by laser gas nitriding with scanning galvanometer. Opt. Laser Technol. 2022, 153, 108270. [Google Scholar] [CrossRef]

- Uzun, Y. Tribocorrosion properties of plasma nitrided, Ti-DLC coated and duplex surface treated AISI 316L stainless steel. Surf. Coat. Tech. 2022, 441, 128587. [Google Scholar] [CrossRef]

- Michla JR, J.; Rajini, N.; Ismail, S.O.; Prabhu, T.R.; Mohammad, F.; Siengchin, S.; Devi, M.I. Effects of nitriding on salt spray corrosion resistance of additively manufactured 17-4 PH steels. Mater. Lett. 2022, 330, 133258. [Google Scholar] [CrossRef]

- Du, C.; Zhang, J.; Lian, Y.; Ding, X. Effect of Cr–N precipitations on thermal fatigue behaviour of GX-8 steel nitrided layer. J. Mater. Res. Technol. 2022, 20, 3333–3343. [Google Scholar] [CrossRef]

- Gandhi, M.M.; Bain, A.; Prasanna, G.L.; Vamshi, M.; Saranya, J.; Dhruthi, N.; Sateesh, N.; Subbiah, R. Examination on dry sliding wear behavior of AISI 304 stainless steel treated with salt bath nitriding process. Mater. Today Proc. 2021, 44, 1412–1417. [Google Scholar]

- Wong-Ángel, W.D.; Martínez-Trinidad, J.; Campos-Silva, I.; Hernandez-Hernandez, V.; Silva-Rivera, U.S.; García-León, R.A. Wear-Corrosion Synergy on Din-16MnCr5 Steel Under Nitriding and Post-Oxidizing Treatments. J. Bio-Tribo-Corros. 2021, 7, 83. [Google Scholar] [CrossRef]

- Chen, X.; Feng, S.; Wang, L.; Zhang, F.; Shi, Z.; Ming, S.; Li, Y.; Liu, B.; Cai, Z.B. Effect of salt bath temperature on microstructure and fretting wear of nitrided 2.25 Cr–1Mo steel in liquid sodium. Appl. Surf. Sci. 2022, 606, 154988. [Google Scholar] [CrossRef]

- Hegadekatte, V.; Hilgert, J.; Kraft, O.; Huber, N. Multi time scale simulations for wear prediction in micro-gears. Wear 2010, 268, 316–324. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Feng, X.; Yu, S. Effect of laser surface texturing on Si3N4/TiC ceramic sliding against steel under dry friction. Mater. Des. 2013, 52, 234–245. [Google Scholar] [CrossRef]

- Yan, X.; Wang, W.; Liu, X.; Xu, J.; Zhu, L.; Yang, B. Using FEM to study the frictional instability induced by third-body particles confined in frictional interface. Ind. Lubr. Tribol. 2020, 72, 1239–1244. [Google Scholar] [CrossRef]

- Li, D.; Yang, X.; Wu, Y.; Wang, S.; Wan, Z.; Liu, W.; Xia, G. Theoretical analysis and experimental research of surface texture hydrodynamic lubrication. Chin. J. Mech. Eng.-En. 2022, 35, 30. [Google Scholar] [CrossRef]

- Somers MA, J.; Mittemeijer, E.J. Layer-growth kinetics on gaseous nitriding of pure iron: Evaluation of diffusion coefficients for nitrogen in iron nitrides. Metall. Mater. Trans. A 1995, 26, 57–74. [Google Scholar] [CrossRef]

- Somers MA, J.; Mittemeijer, E.J. Phase transformations and stress relaxation in γ′-Fe4N1-x surface layers during oxidation. Metall. Mater. Trans. A 1990, 21, 901–912. [Google Scholar] [CrossRef]

- Matauschek, J.; Trenkler, H. Neue Erkenntnisse über den Aufbau und die Porigkeit der beim Badnitrieren erzeugten Verbindungsschicht. HTM-J. Heat. Treat. Mat. 1977, 32, 177–181. [Google Scholar] [CrossRef]

- Podgornik, B.; Hogmark, S.; Pezdirnik, J. Comparison between different test methods for evaluation of galling properties of surface engineered tool surfaces. Wear 2004, 257, 843–851. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Kelly, G.; Rolfe, B.F.; Pereira, M.P. The effect of temperature on sliding wear of steel-tool steel pairs. Wear 2012, 282, 22–30. [Google Scholar] [CrossRef]

- Etsion, I. Improving tribological performance of mechanical components by laser surface texturing. Tribol. Lett. 2004, 17, 733–737. [Google Scholar] [CrossRef]

- Yin, B.; Xu, B.; Jia, H.; Zhou, H.; Fu, Y.; Hua, X. Effects of the array modes of laser-textured micro-dimples on the tribological performance of cylinder liner–piston ring. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 871–881. [Google Scholar] [CrossRef]

- Andersson, P.; Koskinen, J.; Varjus, S.; Gerbig, Y.; Haefke, H.; Georgiou, S.; Zhmud, B.; Buss, W. Microlubrication effect by laser-textured steel surfaces. Wear 2007, 262, 369–379. [Google Scholar] [CrossRef]

- Novotný, P.; Jonák, M.; Vacula, J. Evolutionary optimisation of the thrust bearing considering multiple operating conditions in turbomachinery. Int. J. Mech. Sci. 2021, 195, 106240. [Google Scholar] [CrossRef]

- Shi, L.; Wei, W.; Wang, T.; Zhang, Y.; Zhu, W.; Wang, X. Experimental investigation of the effect of typical surface texture patterns on mechanical seal performance. J. Braz. Soc. Mech. Sci. 2020, 42, 227. [Google Scholar] [CrossRef]

- Dan, L.; Xuefeng, Y.; Chongyang, L.; Jian, C.; Shouren, W.; Yanjun, W. Tribological characteristics of a cemented carbide friction surface with chevron pattern micro-texture based on different texture density. Tribol. Int. 2020, 142, 106016. [Google Scholar] [CrossRef]

- Wakuda, M.; Yamauchi, Y.; Kanzaki, S.; Yasuda, Y. Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 2003, 254, 356–363. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, H.; Chen, S.; Tang, H. Study on the influence of micro-textures on wear mechanism of cemented carbide tools. Int. J. Adv. Manuf. Technol. 2020, 108, 1701–1712. [Google Scholar] [CrossRef]

- Hou, Q.; Yang, X.; Cheng, J.; Wang, S.; Duan, D.; Xiao, J.; Li, W. Optimization of performance parameters and mechanism of bionic texture on friction surface. Coatings 2020, 10, 171. [Google Scholar] [CrossRef]

- Lianmin, Y.; Shengguan, Q.; Fuqiang, L.; Xiao, Z.; Li, X. High temperature properties of 21-4N valve steel. J. Mater. Sci. Eng. 2020, 38, 409–413, 517. [Google Scholar] [CrossRef]

- Corengia, P.; Walther, F.; Ybarra, G.; Sommadossi, S.; Corbari, R.; Broitman, E. Friction and rolling–sliding wear of DC-pulsed plasma nitrided AISI 410 martensitic stainless steel. Wear 2006, 260, 479–485. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, D.Y.; Hua, M.; Dong, G.N.; Chin, K.S. A study on the tribological behavior of surface texturing on babbitt alloy under mixed or starved lubrication. Tribol. Lett. 2014, 56, 305–315. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G. A laser surface textured hydrostatic mechanical seal. Tribol. Trans. 2002, 45, 430–434. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G.; Zhang, D.Y.; Chin, K.S. A mixed lubrication model for studying tribological behaviors of surface texturing. Tribol. Int. 2016, 93, 583–592. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.; Zhu, H.; Yang, H. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Hu, C.Y.; Wan, X.L.; Wu, K.M.; Xu, D.M.; Li, G.Q.; Xu, G.; Misra, R.D.K. On the impacts of grain refinement and strain-induced deformation on three-body abrasive wear responses of 18Cr–8Ni austenitic stainless steel. Wear 2020, 446, 203181. [Google Scholar] [CrossRef]

| Chemical Composition | C | Si | Mn | P | Cr | Ni | Mo | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 4Cr10Si2Mo | 0.39 | 2.24 | 0.45 | 0.022 | 9.90 | 0.30 | 0.75 | 0.006 | Bal |

| HT 200 | >3.0 | >1.4 | >0.6 | >0.15 | - | - | - | >0.12 | Bal |

| Non-Nitrided Group | Nitriding Group | Texture Parameters d × h (mm) | Texture Area Density (Ar) |

|---|---|---|---|

| TA | NA | Nitriding 0.3 × 0.3 | 11.45% |

| TB | NB | Nitriding 0.5 × 0.5 | 23.86% |

| TC | NC | Nitriding 0.7 × 0.7 | 38.98% |

| GH | NS | Untextured surface | 0 |

| Points | 1 | 2 | 3 | 4 | 5 | 6 | Averages |

|---|---|---|---|---|---|---|---|

| Substrate | 327.6 | 326.0 | 339.4 | 349.9 | 358.8 | 363.3 | 344.2 |

| Nitriding | 701.1 | 712.9 | 695.0 | 685.1 | 722.8 | 748.8 | 710.5 |

| Group | GH Group | TA Group Unstructured Area | NS Group | NA Group Unstructured Area |

|---|---|---|---|---|

| Sa, μm | 1.332 | 0.87 | 0.308 | 0.733 |

| Sq, μm | 1.66 | 1.136 | 0.45 | 0.907 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Tan, Z.; Chen, W.; Li, D.; Zhang, J.; Wang, Z.; Mao, Y.; Wang, Y.; Guo, W. Effect of Salt Bath Nitriding and Reoxidation Composite Texture on Frictional Properties of Valve Steel 4Cr10Si2Mo. Coatings 2023, 13, 776. https://doi.org/10.3390/coatings13040776

Dai Y, Tan Z, Chen W, Li D, Zhang J, Wang Z, Mao Y, Wang Y, Guo W. Effect of Salt Bath Nitriding and Reoxidation Composite Texture on Frictional Properties of Valve Steel 4Cr10Si2Mo. Coatings. 2023; 13(4):776. https://doi.org/10.3390/coatings13040776

Chicago/Turabian StyleDai, Yifan, Zefei Tan, Wengang Chen, Dongyang Li, Jubang Zhang, Zexiao Wang, Yukun Mao, Yuhao Wang, and Wenxuan Guo. 2023. "Effect of Salt Bath Nitriding and Reoxidation Composite Texture on Frictional Properties of Valve Steel 4Cr10Si2Mo" Coatings 13, no. 4: 776. https://doi.org/10.3390/coatings13040776

APA StyleDai, Y., Tan, Z., Chen, W., Li, D., Zhang, J., Wang, Z., Mao, Y., Wang, Y., & Guo, W. (2023). Effect of Salt Bath Nitriding and Reoxidation Composite Texture on Frictional Properties of Valve Steel 4Cr10Si2Mo. Coatings, 13(4), 776. https://doi.org/10.3390/coatings13040776