Effect of Pre-Soaking Treatment Method of Plant-Based Aggregate on the Properties of Lightweight Concrete—Preliminary Study

Abstract

:1. Introduction

2. Materials and Methods

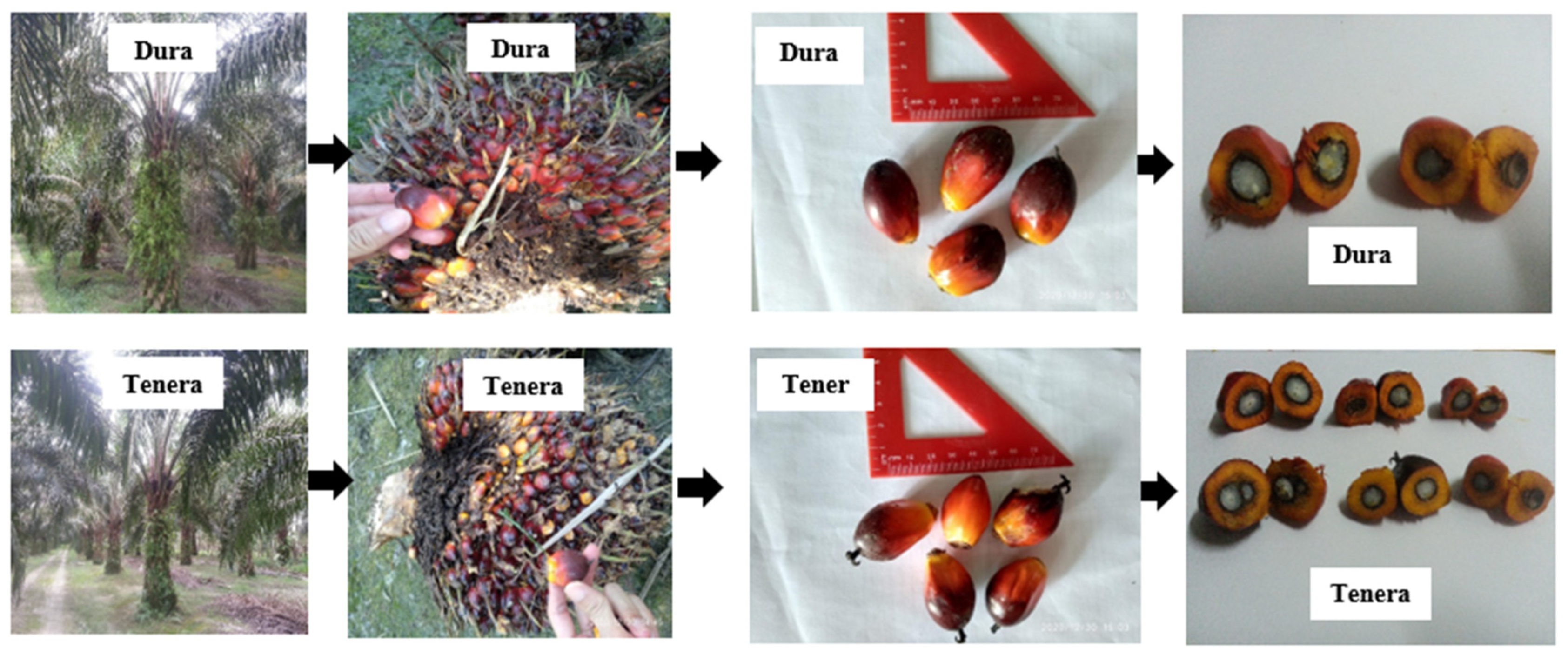

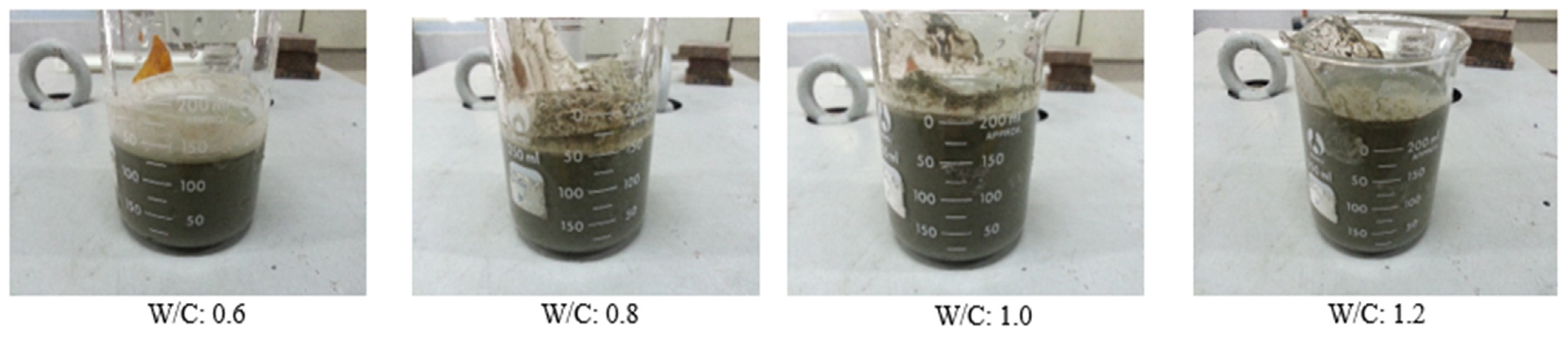

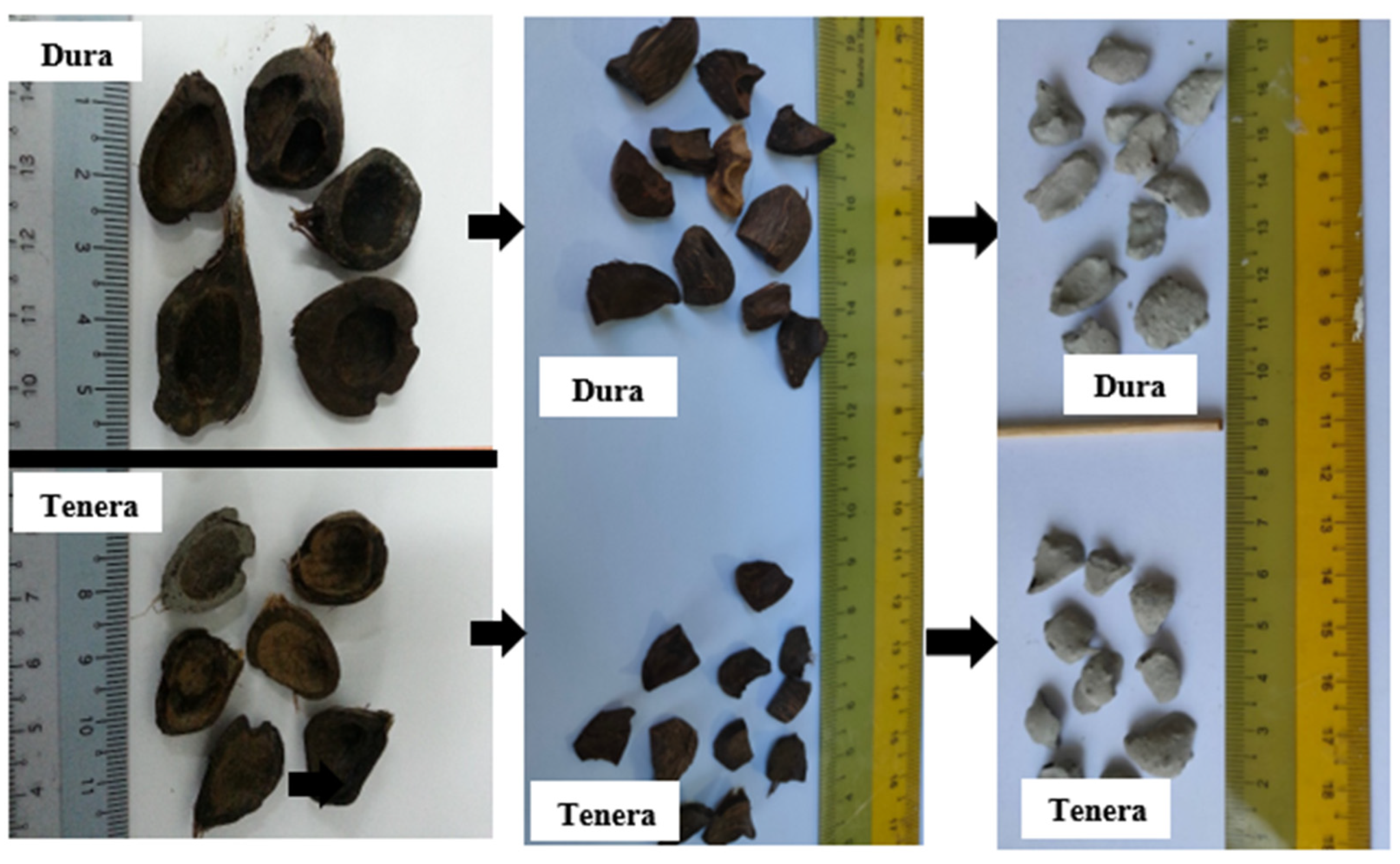

2.1. Materials

2.2. Concrete Sample Preparation and Methods of Testing

3. Results and Discussion

3.1. Fresh Properties and Densities

3.2. Densities (Demoulded, Air-Dry and Oven-Dry)

3.3. Mechanical Properties of Concrete

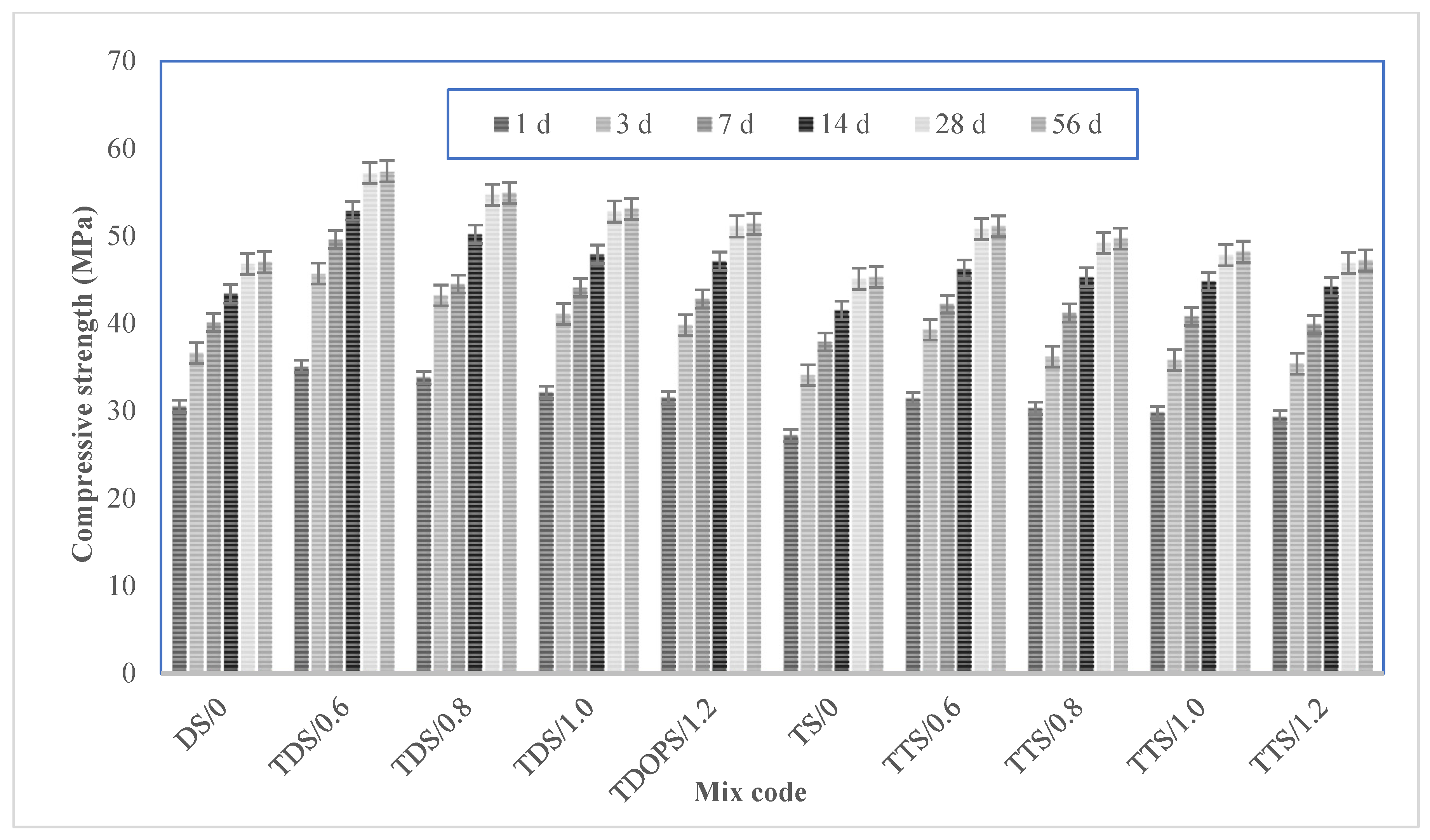

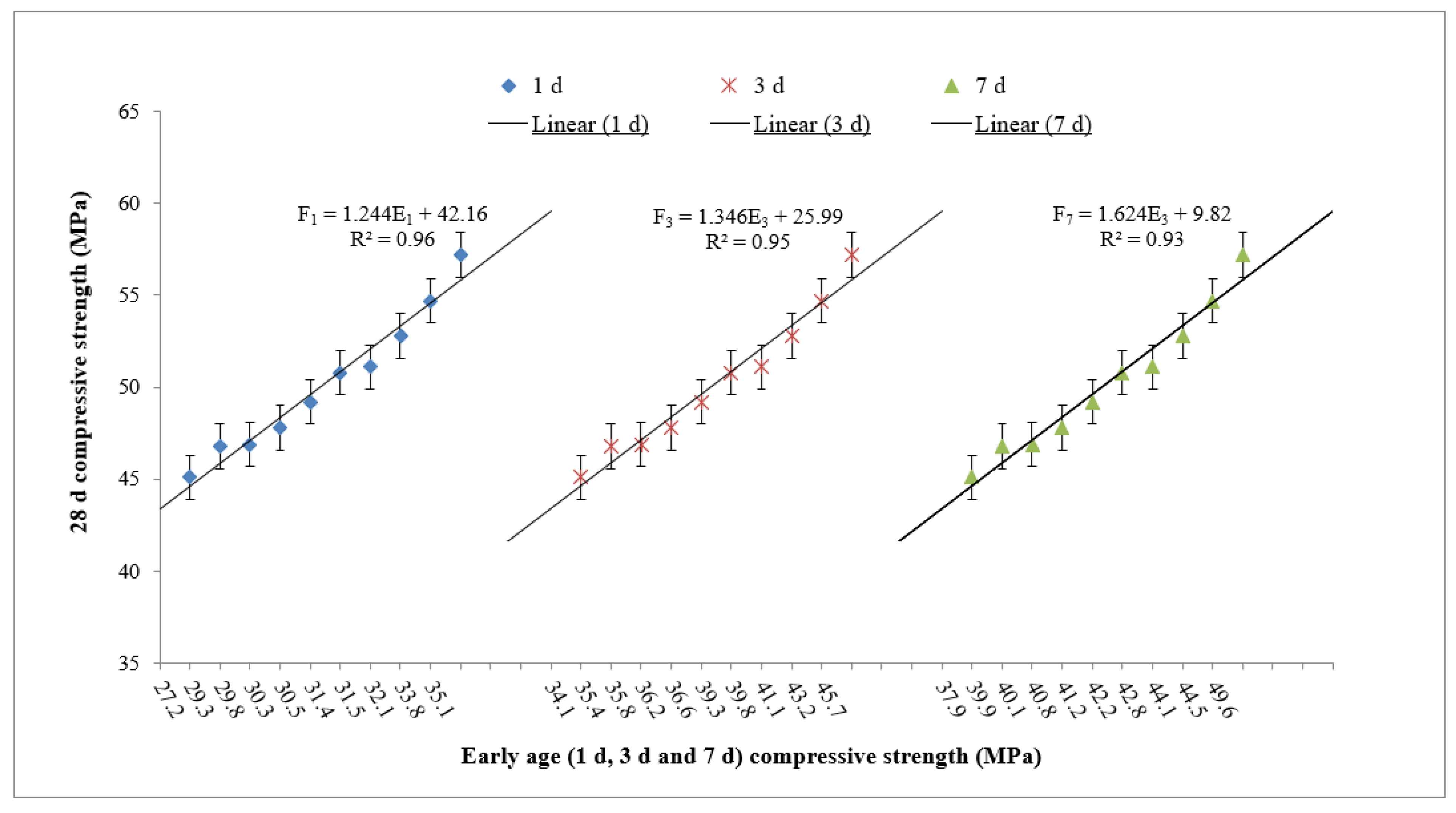

Compressive Strength Test

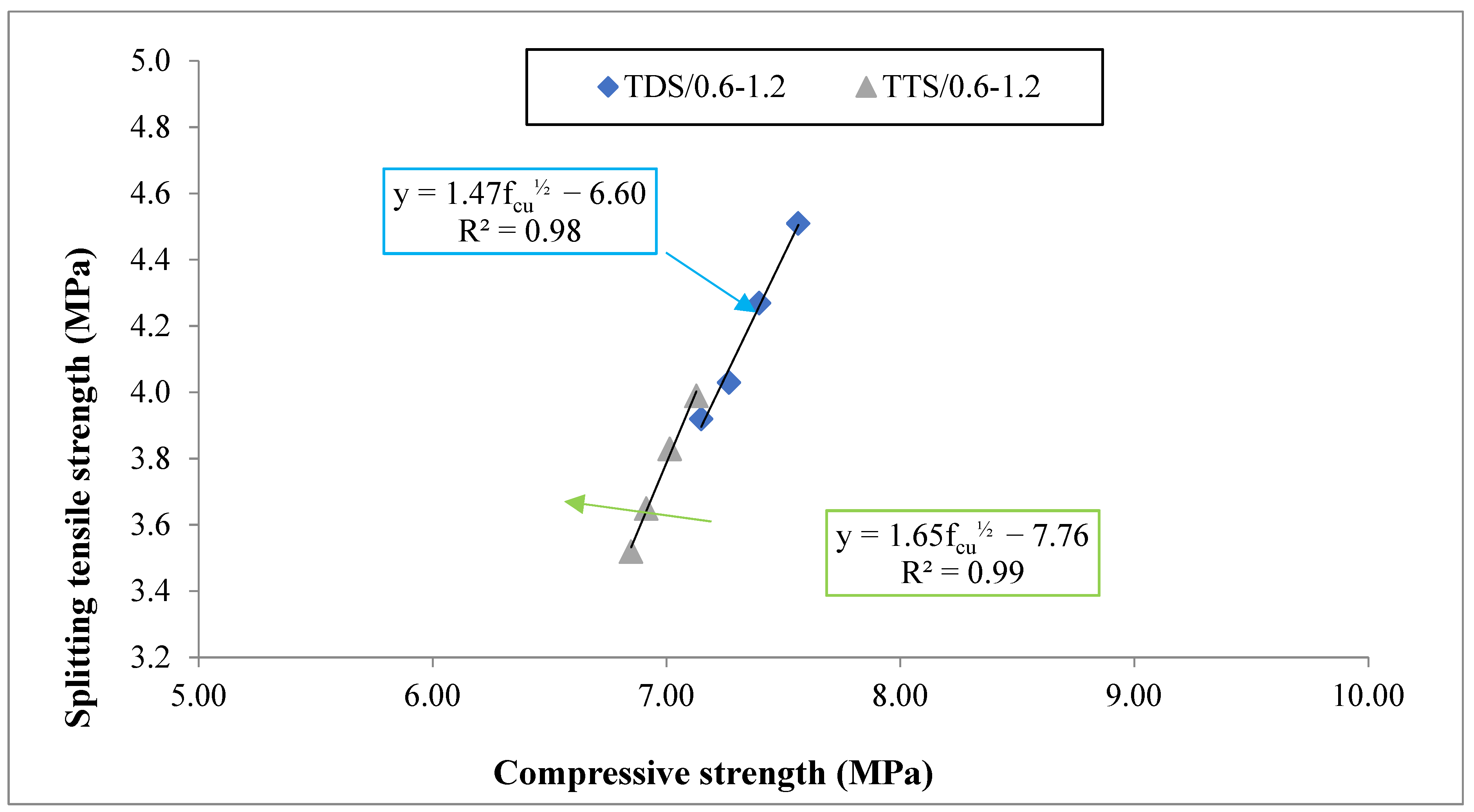

3.4. Split Tensile Strength Test

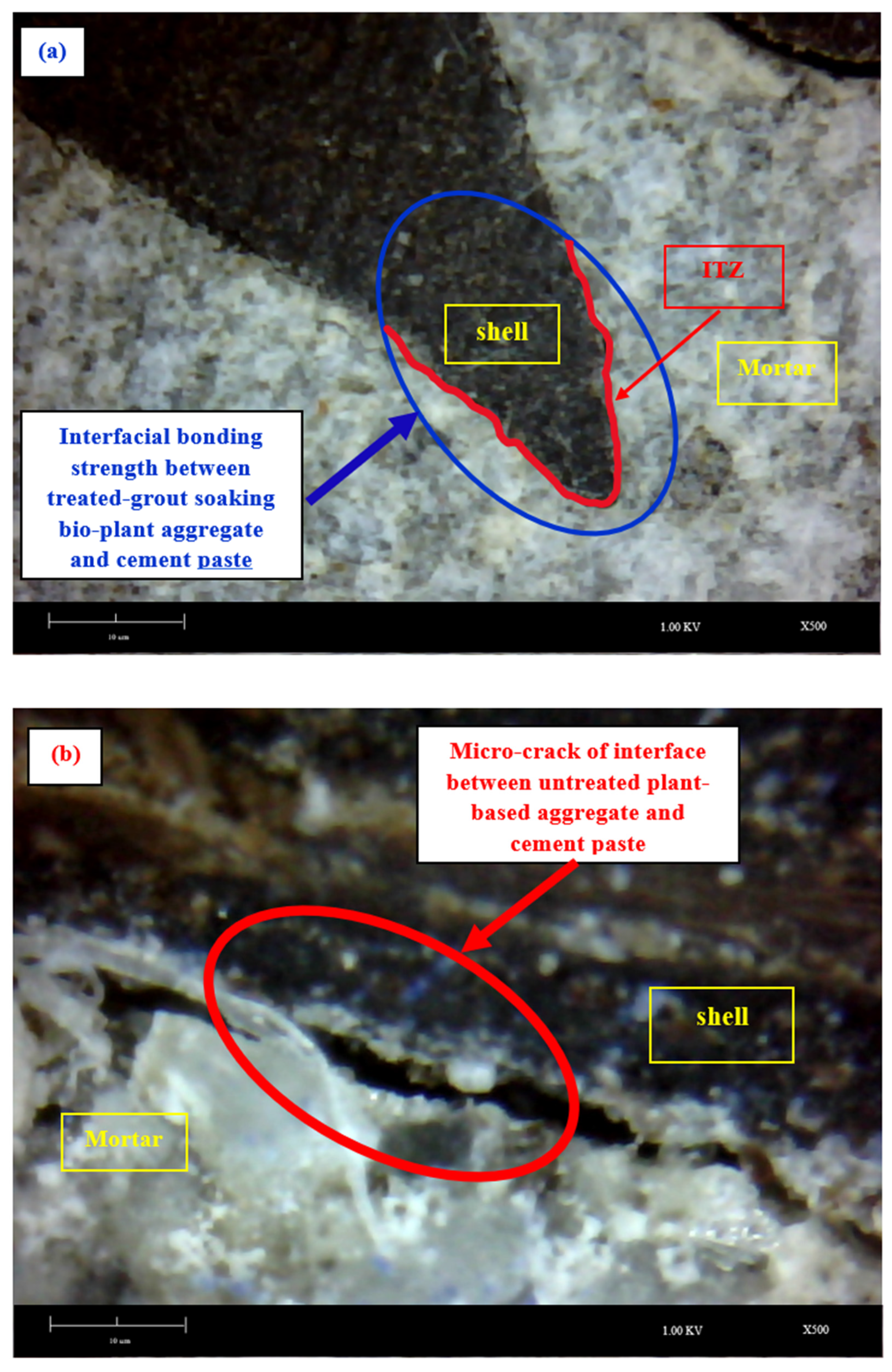

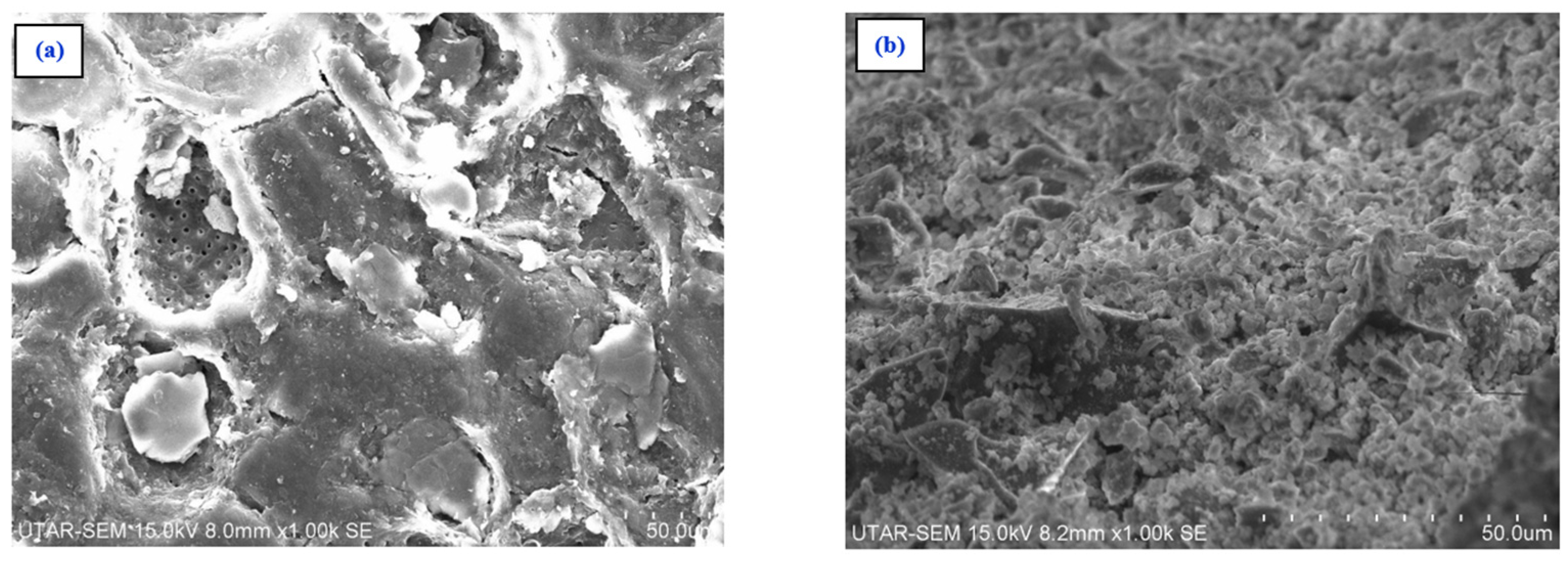

3.5. Strength Relationship

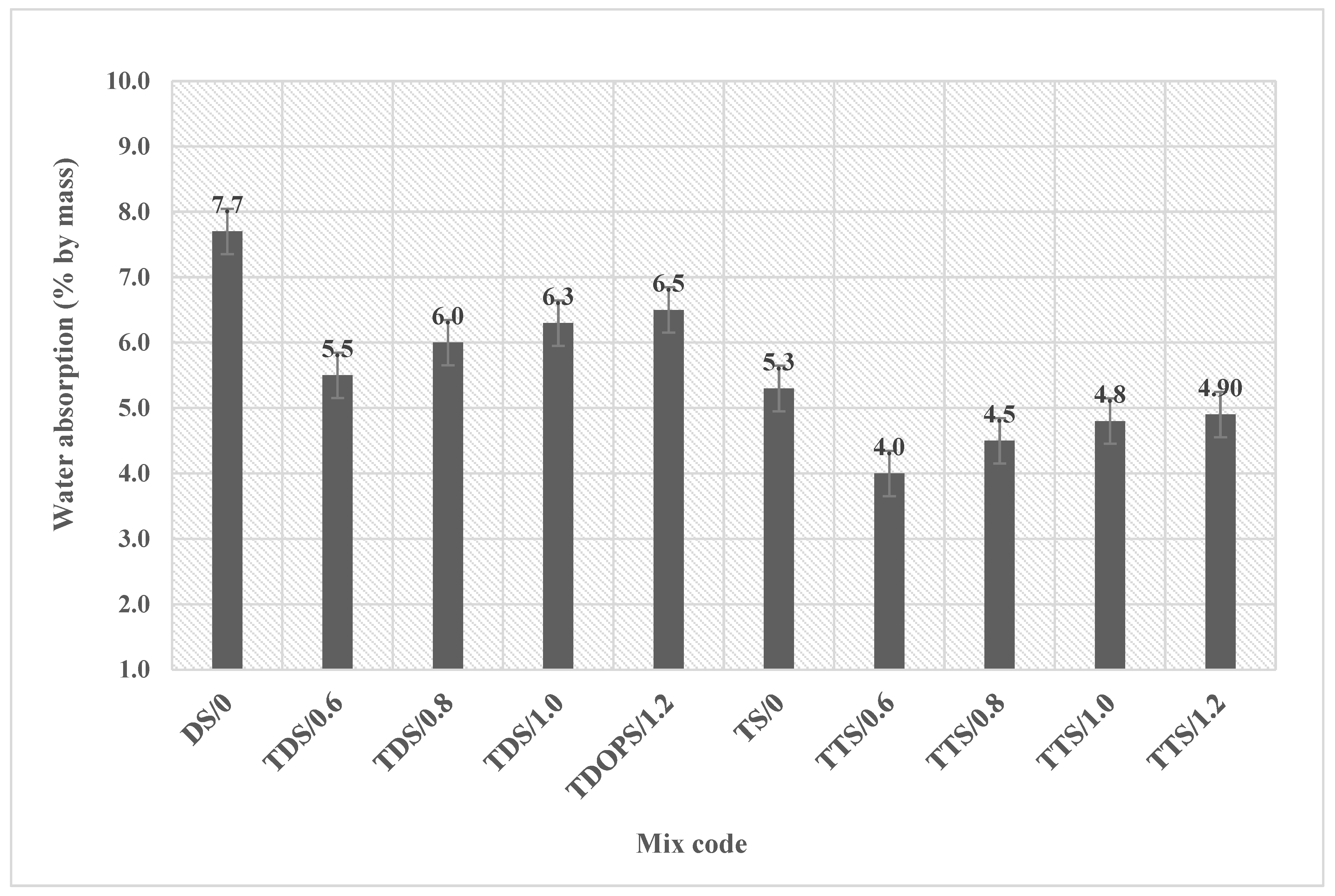

3.6. Water Absorption

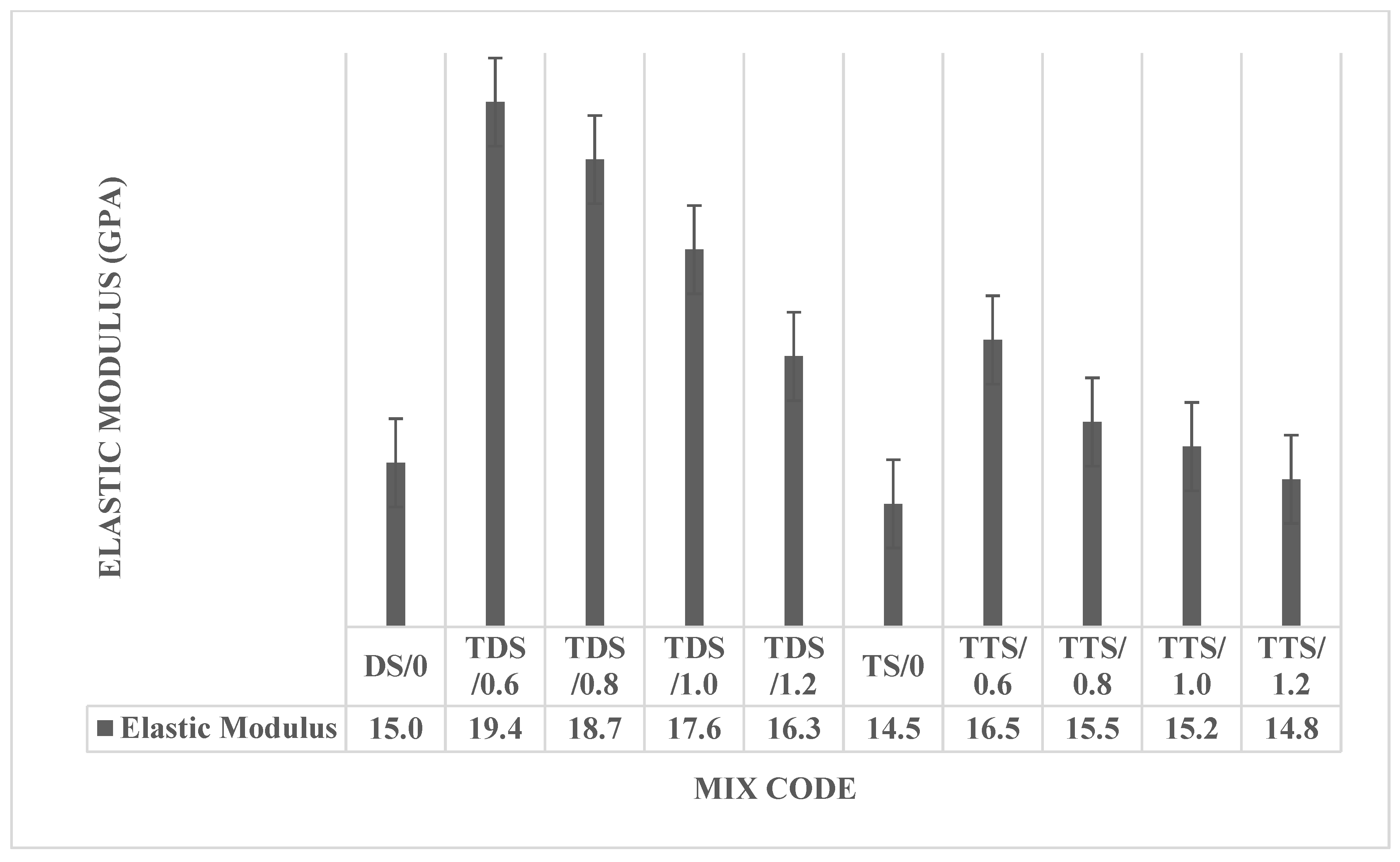

3.7. Elastic Modulus

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kanojia, A.; Jain, S.K. Performance of coconut shell as coarse aggregate in concrete. Constr. Build. Mater. 2017, 140, 150–156. [Google Scholar] [CrossRef]

- Mehta, K.P. Reducing the environmental impact of concrete. Concr. Int. 2001, 23, 61–66. [Google Scholar]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Zhang, T.; Ghaffarianhoseini, A.; Tookey, J. A critical comparison of green building rating systems. Build. Environ. 2017, 123, 243–260. [Google Scholar] [CrossRef]

- Alwan, Z.; Jones, P.; Holgate, P. Strategic sustainable development in the UK construction industry, through the framework for strategic sustainable development, using Building Information Modelling. J. Clean. Prod. 2017, 140, 349–358. [Google Scholar] [CrossRef]

- Hwang, B.G.; Zhu, L.; Tan, J.S.H. Green business park project management: Barriers and solutions for sustainable development. J. Clean. Prod. 2017, 153, 209–219. [Google Scholar] [CrossRef]

- Traore, Y.B.; Messan, A.; Hannawi, K.; Gerard, J.; Prince, W.; Tsobnang, F. Effect of oil palm shell treatment on the physical and mechanical properties of lightweight concrete. Constr. Build. Mater. 2018, 161, 452–460. [Google Scholar] [CrossRef]

- Yew, M.K.; Yew, M.C.; Beh, J.H.; Saw, L.H.; Lim, S.K. Effects of pre-treated on dura shell and tenera shell for high strength lightweight concrete. J. Buil. Eng. 2021, 42, 102493. [Google Scholar] [CrossRef]

- Yap, S.P.; Alengaram, U.J.; Mo, K.H.; Jumaat, M.Z. Ductility behaviours of oil palm shell steel fibre-reinforced concrete beams under flexural loading. Europ. J. Env. Civ. Eng. 2019, 237, 13. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hasaniyah, M.W.; Zeyad, A.M.; Yusuf , M.O. Properties of concrete containing recycled seashells as cement partial replacement: A review. J. Clean. Prod. 2019, 237, 13. [Google Scholar] [CrossRef]

- Abang, A.; Abang, A.; Abdus Salam, S.; Abang, A.R. Basic strength properties of lightweight concrete using agricultural wastes as aggregates. In Proceedings of the International Conference on Low Cost Housing for Developing Countries, Roorkee, India, 12–17 November 1984; pp. 143–146. [Google Scholar]

- Uysal, T.; Duman, G.; Onal, Y.; Yasa, I.; Yanik, J. Production of activated carbon and fungicidal oil from peach stone by two-stage process. J. Anal. Appl. Pyrol. 2014, 108, 47–55. [Google Scholar] [CrossRef]

- Promraksa, A.; Rakmak, N. Biochar production from palm oil mill residues and application of the biochar to adsorb carbon dioxide. Heliyon 2020, 6, e04019. [Google Scholar] [CrossRef]

- Kaynak, B.; Topal, H.; Atimtay, A.T. Peach and apricot stone combustion in a bubbling fluidized bed. Fuel Process. Technol. 2005, 86, 1175–1193. [Google Scholar] [CrossRef]

- Hosseini, P.; Booshehrian, A.; Delkash, M.; Ghavami, S.; Zanjani, M.K. Use of nano- SiO2 to improve microstructure and compressive strength of recycled aggregate concretes. In Nanotechnology in Construction (NICOM3); Springer: Berlin/Heidelberg, Germany, 2009; pp. 215–222. [Google Scholar]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Utilization of ground granulated blast furnace slag as partial cement replacement in lightweight oil palm shell concrete. Mater. Struct. 2015, 48, 2545–2556. [Google Scholar] [CrossRef]

- Wu, F.; Liu, C.; Sun, W.; Ma, Y.; Zhang, L. Effect of peach shell as lightweight aggregate on mechanics and creep properties of concrete. Eur. J. Environ. Civ. Eng. 2020, 24, 2534–2552. [Google Scholar] [CrossRef]

- Maldonado, E.A.; Olivares, F.H. Study of Fine Mortar Powder from Different Waste Sources for Recycled Concrete Production. In Sustainable Development and Renovation in Architecture, Urbanism and Engineering; Springer: Cham, Switzerland, 2017; pp. 253–262. [Google Scholar]

- Wang, J.Y.; Zhao, G.J.; Takato, N. Change of brightness, chromatism and infra-red spectra of compressed China fir wood during heat treatment. J. Beijing For. Univ. 2001, 23, 59–64. [Google Scholar]

- Wang, Y.; Zhang, Z.; Fan, H.; Wang, J. Wood carbonization as a protective treatment on resistance to wood destroying fungi. Int. Biodeterior. Biodegrad. 2018, 129, 42–49. [Google Scholar] [CrossRef]

- Wu, F.; Liu, C.; Sun, W.; Zhang, L.; Ma, Y. Mechanical and creep properties of concrete containing Apricot shell lightweight aggregate. KSCE J. Civ. Eng. 2019, 23, 2948–2957. [Google Scholar] [CrossRef]

- Mannan, M.A.; Alexander, J.; Ganapathy, C.; Teo, D.C.L. Quality improvement of oil palm shell (OPS) as coarse aggregate in lightweight concrete. Build. Environ. 2006, 41, 1239–1242. [Google Scholar] [CrossRef]

- Yew, M.K.; Mahmud, H.B.; Ang, B.C.; Yew, M.C. Effects of heat treatment on oil palm shell coarse aggregates for high strength lightweight concrete. Mater. Des. 2014, 54, 702–707. [Google Scholar] [CrossRef]

- Yew, M.K.; Beh, J.H.; Yew, M.C.; Lee, F.W.; Saw, L.H.; Lim, S.K. Performance of surface modification on bio-based aggregate for high strength lightweight concrete. Case Stud. Constr. 2022, 16, e00910. [Google Scholar] [CrossRef]

- “MPOC Expects Palm Oil Production to Dip to 19.5 Million Tonnes in 2020,” MPOC Expects Palm Oil Production to Dip to 19.5 Million Tonnes in 2020 | The Edge Markets. MPOC Expects Palm Oil Production to Dip to 19.5 Million Tonnes in 2020 | The Edge Markets. Available online: https://www.theedgemarkets.com/article/mpoc-expects-palm-oil-production-dip-195-million-tonnes-2020 (accessed on 7 April 2023).

- Serina, R. Malaysian Independent Oil Palm Smallholders and their struggle to Survive 2020; ISEAS-Yusuf Ishak Institute: Singapore, 2020; p. 144. [Google Scholar]

- Yew, M.K.; Mahmud, H.B.; Ang, B.C.; Yew, M.C. Effects of oil palm shell coarse aggregate species on high strength lightweight concrete. Sci. World. J. 2014, 2014, 387647. [Google Scholar] [CrossRef]

- Albert, K.; Barbara, K.; Matt, P. Oil Palm Expansion in Peninsular Malaysia is Guided by Non-Transparency. Chain Reaction Research. 2021. Available online: https://chainreactionresearch.com/wp-content/uploads/2021/05/Oil-Palm-Expansion-in (accessed on 1 May 2021).

- Kupaei, R.H.; Alengaram, U.J.; Jumaat, M.Z. The effect of different parameters on the development of compressive strength of oil palm shell geopolymer concrete. Sci. World J. 2014, 2014, 898536. [Google Scholar] [CrossRef]

- Chin, C.O.; Yang, X.; Kong, S.Y.; Paul, S.C.; Wong, L.S. Mechanical and thermal properties of lightweight concrete incorporated with activated carbon as coarse aggregate. J. Build. Eng. 2020, 31, 101347. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Megat Johari, M.A.; Bassam, A. Tayeh and Abdalla Saba. Ultrafine palm oil fuel ash: From an agro-industry by-product into a highly efficient mineral admixture for high strength green concrete. J. Eng. Appl. Sci. 2017, 12, 8187–8196. [Google Scholar]

- Alexandre Bogas, J.; de Brito, J.; Figueiredo, J.M. Mechanical characterization of concrete produced with recycled lightweight expanded clay aggregate concrete. J. Clean. Prod. 2015, 89, 187–195. [Google Scholar] [CrossRef]

- Zhao, H.; Ding, J.; Li, S.; Wang, P.; Chen, Y.; Liu, Y.; Tian, Q. Effects of porous shale waste brick lightweight aggregate on mechanical properties and autogenous deformation of early-age concrete. Constr. Build. Mater. 2020, 261, 120450. [Google Scholar] [CrossRef]

- Hasan, M.; Saidi, T.; Afifuddin, M. Mechanical properties and absorption of lightweight concrete using lightweight aggregate from diatomaceous earth. Constr. Build. Mater. 2021, 277, 122324. [Google Scholar] [CrossRef]

- Loh, L.T.; Yew, M.K.; Yew, M.C.; Beh, J.H.; Lee, F.W.; Lim, S.K.; Kwong, K.Z. Mechanical and Thermal Properties of Synthetic Polypropylene Fiber–Reinforced Renewable Oil Palm Shell Lightweight Concrete. Material 2021, 14, 2337. [Google Scholar] [CrossRef] [PubMed]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Oil palm shell as a lightweight aggregate for production high strength lightweight concrete. Constr. Build. Mater. 2011, 25, 1848–1853. [Google Scholar] [CrossRef]

- BS EN 12390; Part 3 Testing Hardened Concrete–Compressive Strength of Test Specimens. British Standard Institution: Milton Keynes, UK, 2009.

- BS EN 12390; Part 6 Testing Hardened Concrete–Splitting Tensile Strength of Test Specimens. British Standard Institution: Milton Keynes, UK, 2009.

- BS EN 12390; Part 13 Testing Hardened Concrete–Modulus of Elasticity of Test Specimens. British Standard Institution: Milton Keynes, UK, 2013.

- Wu, F.; Yu, Q.; Liu, C. Durability of thermal insulating bio-based lightweight concrete: Understanding of heat treatment on bio-aggregates. Constr. Build. Mater. 2021, 269, 121800. [Google Scholar] [CrossRef]

- Ryu, H.S.; Kim, D.M.; Shin, S.H.; Lim, S.M.; Park, W.J. Evaluation on the Surface Modification of Recycled Fine Aggregates in Aqueous H2SiF6 Solution. Int. J. Concr. Struct. Mater. 2018, 12, 19. [Google Scholar] [CrossRef]

- Martirena, F.; Castaño, T.; Alujas, A.; Orozco-Morales, R.; Martinez, L.; Linsel, S. Improving quality of coarse recycled aggregates through cement coating. J. Sustain. Cem.-Based Mater. 2017, 6, 69–84. [Google Scholar] [CrossRef]

- Frost, J. Introduction to Statistics: An Intuitive Guide. 2019, p. 104. Available online: https://statisticsbyjim.com/basics/introduction-statistics-intuitive-guide/ (accessed on 2 March 2020).

- Neville, A.M. Properties of Concrete, 14th ed.; CTP-VVP: Kuala Lumpur, Malaysia, 2008. [Google Scholar]

- Babu, K.G.; Babu, D.S. Behaviour of lightweight expanded polystyrene concrete containing silica fume. Cem. Concr. Res. 2003, 33, 755–762. [Google Scholar] [CrossRef]

- Mazaheripour, M.; Ghanbarpour, S.; Mirmoradi, S.H.; Hosseinpour, I. The effect of polypropylene fibres on the properties of fresh and hardened lightweight self- compacting concrete. Constr. Build. Mater. 2011, 25, 351–358. [Google Scholar] [CrossRef]

- Swamy, R.N.; Lambert, G.H. Mix design and properties of concrete made from PFA coarse aggregates and sand. Int. J. Cem. Compos. Lightweight Concr. 1983, 5, 263–275. [Google Scholar] [CrossRef]

| Chemical Analysis | (%) | Physical Properties | Unit | |

|---|---|---|---|---|

| SiO2 | 21.5 | Specify gravity | g/cm3 | 3.14 |

| Al2O2 | 5.9 | Specific surface area | cm2/g | 3510 |

| Fe2O2 | 3.4 | Compressive strength | MPa | |

| CaO | 59.8 | 3 days | - | 23.3 |

| SO3 | 4.3 | 28 days | - | 46.2 |

| MgO | 2.9 | Flexural strength | MPa | |

| Loss on ignition | 0.6 | 3 days | - | 4.2 |

| 28 days | - | 7.3 | ||

| Initial setting time | min | 230 |

| Physical Property | Unit | Fine Aggregate | Coarse Aggregate | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (River Sand) | DS/0 | TDS/0.6 | TDS/0.8 | TDS/1.0 | TDS/1.2 | TS/0 | TTS/0.6 | TTS/0.8 | TTS/1.0 | TTS/1.2 | ||

| Specific gravity | g/cm2 | 2.67 | 1.23 | 1.47 | 1.45 | 1.40 | 1.38 | 1.12 | 1.33 | 1.31 | 1.28 | 1.26 |

| Bulk density | kg/m2 | 1568 | 623 | 656 | 654 | 647 | 646 | 618 | 641 | 647 | 637 | 635 |

| Fineness modulus | 2.71 | 5.0 | 5.7 | 5.5 | 5.4 | 5.3 | 2.4 | 5.2 | 5.1 | 4.6 | 4.2 | |

| Water absorption (20 min) | % | - | 7.0 | 3.52 | 3.55 | 3.68 | 3.70 | 6.8 | 3.37 | 3.35 | 3.45 | 3.40 |

| Water absorption (24 h) | % | 1.2 | 17.0 | 14.6 | 14.9 | 15.2 | 15.4 | 15.2 | 12.3 | 12.5 | 13.0 | 13.5 |

| Aggregate impact value | % | - | 2.38 | 3.56 | 3.52 | 3.50 | 3.48 | 2.27 | 3.55 | 3.53 | 3.50 | 3.40 |

| LA abrasion value | % | - | 7 | 18 | 16 | 13 | 12 | 5 | 14 | 12 | 10 | 8 |

| Flakiness index | % | - | 35 | 21 | 23 | 27 | 29 | 31 | 22 | 24 | 26 | 28 |

| Surface texture | - | Rough | Rough | Rough | Rough | Rough | Rough | Rough | Rough | Rough | Rough | Rough |

| Sieve Size (mm) | Cumulative % by Weight Passing Sieve Size | |||

|---|---|---|---|---|

| DS (12.5 mm) | TS (12.5 mm) | TDS (9.5 mm) | TTS (9.5 mm) | |

| 20 | 100 | 100 | 100 | 100 |

| 12.5 | 100 | 100 | 100 | 100 |

| 9.5 | 84.15 | 84.50 | 100 | 100 |

| 8 | 59.60 | 59.90 | 93.35 | 94.75 |

| 4.75 | 24.50 | 22.70 | 26.20 | 25.80 |

| 2.36 | 3.50 | 4.60 | 4.85 | 4.90 |

| Mix Code | Cement | Silica Fume | Water | W/C | Sand | SP | OPS | Temperature (°C) | Heating Time (h) | Grout Coating (W/C) |

|---|---|---|---|---|---|---|---|---|---|---|

| DS/0 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 355 | Room temperature | 0 | 0 |

| TDS/0.6 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 425 | 75 | 0.5 | 0.6 |

| TDS/0.8 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 410 | 75 | 0.5 | 0.8 |

| TDS/1.0 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 395 | 75 | 0.5 | 1.0 |

| TDS/1.2 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 380 | 75 | 0.5 | 1.2 |

| TS/0 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 345 | Room temperature | 0 | 0 |

| TTS/0.6 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 420 | 75 | 0.5 | 0.6 |

| TTS/0.8 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 405 | 75 | 0.5 | 0.8 |

| TTS/1.0 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 390 | 75 | 0.5 | 1.0 |

| TTS/1.2 | 490 | 25 | 154 | 0.3 | 908 | 6.2 | 375 | 75 | 0.5 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yew, M.K.; Yew, M.C.; Beh, J.H.; Lee, F.W.; Lim, S.K.; Lee, Y.L.; Lim, J.H.; Kabeer, K.I.S.A. Effect of Pre-Soaking Treatment Method of Plant-Based Aggregate on the Properties of Lightweight Concrete—Preliminary Study. Coatings 2023, 13, 864. https://doi.org/10.3390/coatings13050864

Yew MK, Yew MC, Beh JH, Lee FW, Lim SK, Lee YL, Lim JH, Kabeer KISA. Effect of Pre-Soaking Treatment Method of Plant-Based Aggregate on the Properties of Lightweight Concrete—Preliminary Study. Coatings. 2023; 13(5):864. https://doi.org/10.3390/coatings13050864

Chicago/Turabian StyleYew, Ming Kun, Ming Chian Yew, Jing Han Beh, Foo Wei Lee, Siong Kang Lim, Yee Ling Lee, Jee Hock Lim, and K. I. Syed Ahmed Kabeer. 2023. "Effect of Pre-Soaking Treatment Method of Plant-Based Aggregate on the Properties of Lightweight Concrete—Preliminary Study" Coatings 13, no. 5: 864. https://doi.org/10.3390/coatings13050864

APA StyleYew, M. K., Yew, M. C., Beh, J. H., Lee, F. W., Lim, S. K., Lee, Y. L., Lim, J. H., & Kabeer, K. I. S. A. (2023). Effect of Pre-Soaking Treatment Method of Plant-Based Aggregate on the Properties of Lightweight Concrete—Preliminary Study. Coatings, 13(5), 864. https://doi.org/10.3390/coatings13050864